Roadway drivage advanced telescopic cantilever support device and construction method thereof

A support device and telescopic arm technology, which is applied in the direction of earthwork drilling, bolt installation, mine roof support, etc., can solve the problems of roof support and excavation interference, large safety hazards, no roof support, etc., and achieve temporary support Larger range, higher tunneling speed, and higher construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings.

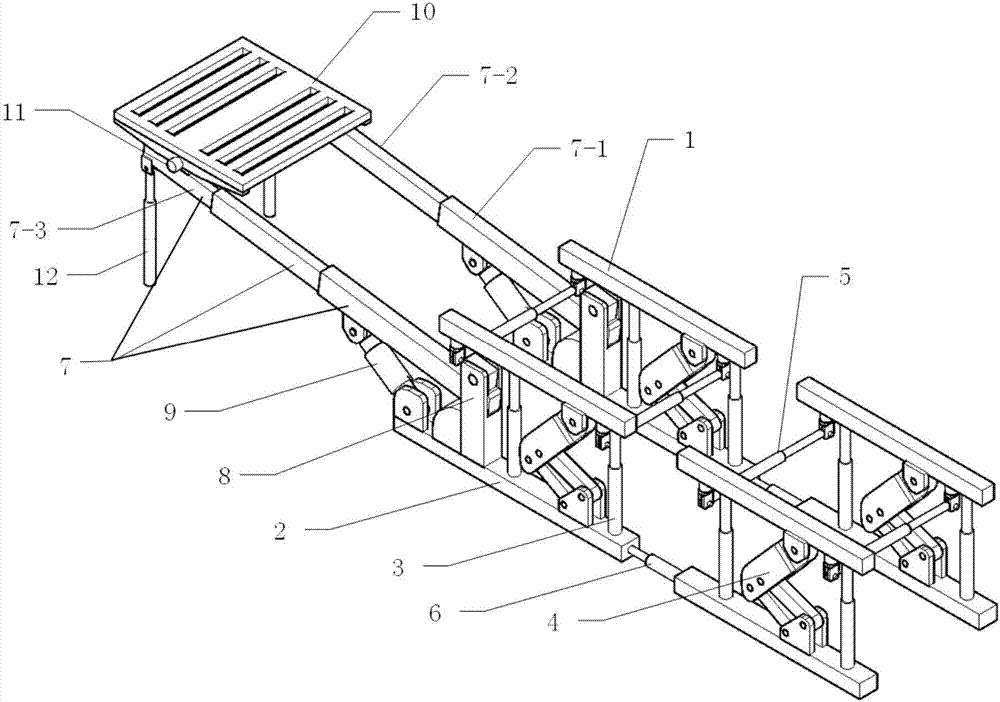

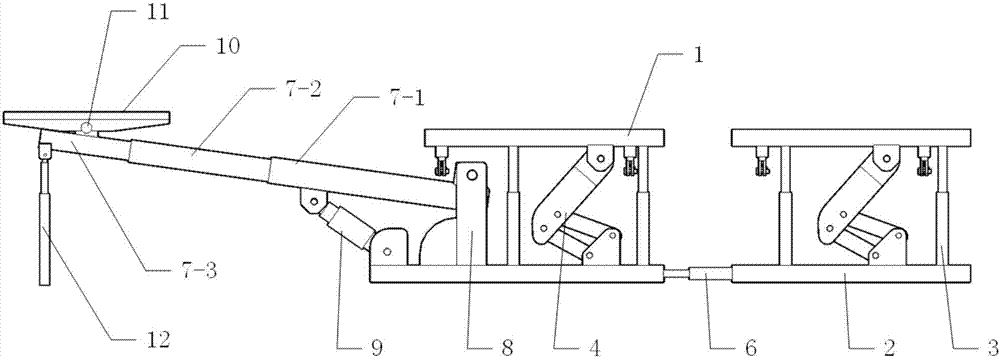

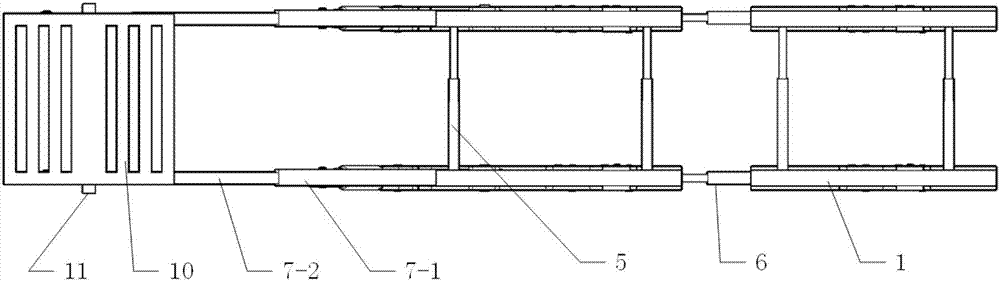

[0035] Such as Figure 1 to Figure 4 As shown, the advance telescopic cantilever support device for roadway excavation provided by the present invention includes an electro-hydraulic control system, a pump station, a trough support, a telescopic arm 7 and a roof grid 10 .

[0036] The trough support is composed of two rows and two columns with a total of four support units connected by a horizontal cylinder 5 and a vertical cylinder 6. The top beam 1 of the two rows of support units is connected by a horizontal cylinder 5. The horizontal cylinder 5 is used to connect the two rows of support units. It is integrated to prevent tipping. The bases 2 of the two rows of support units are connected by the longitudinal cylinder 6. The longitudinal cylinder 6 is used to pull forward and push back to move the whole device. The base 2 consists of two uprights 3 and one four-link...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com