Multi-stage slurry separation method for construction of slurry shield machine in fine particle stratum

A technology of multi-stage separation and shield machine, applied in multi-stage treatment of water/sewage, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve problems such as environmental pollution, increased construction costs, and difficulty in sedimentation. To achieve the effect of eliminating environmental pollution and saving construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] specific implementation

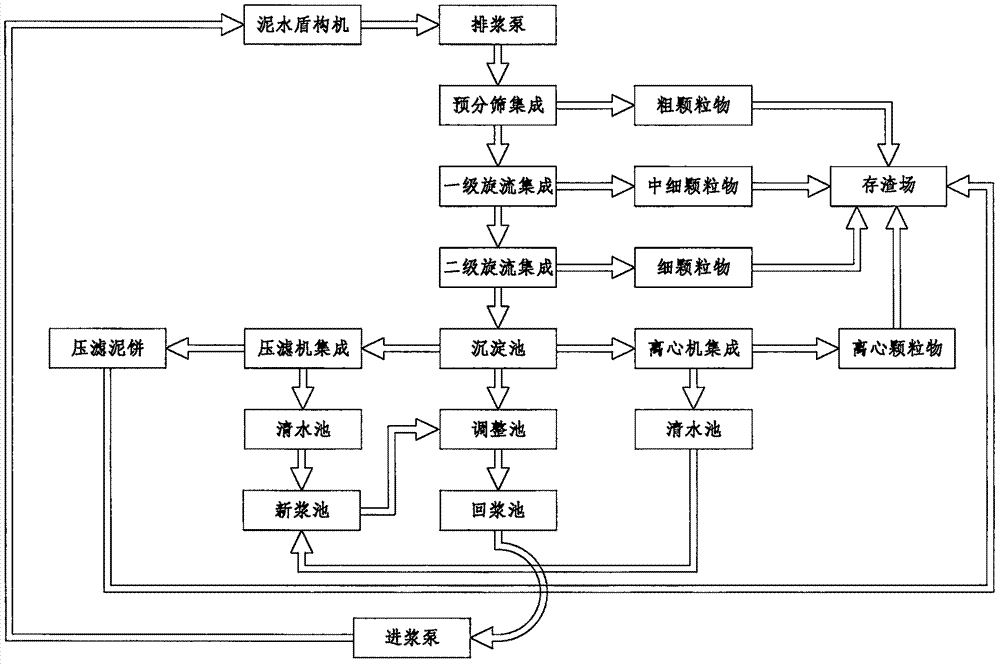

[0023] The invention relates to a mud multistage separation method for construction of a mud-water shield machine in a fine-grained stratum, and is especially suitable for mud-water separation in urban central areas or narrow construction sites.

[0024] The mud multi-stage separation method of the present invention uses a set of independent muddy water treatment system, said muddy water treatment system includes pre-sieving integration, first-level swirl integration, second-level swirl integration, slag storage yard, two sets of mud pool integration , centrifuge integration and filter press integration.

[0025] combine figure 1 , each set of mud tank integration includes a new slurry tank, a clear water tank, three sedimentation tanks, a slurry return tank, and an adjustment tank. The new slurry tank and the adjustment tank are equipped with a full range of agitators that move in place without dead ends , the three sedimentation tanks are a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com