Construction method of below-sensitive-building water-enriched rock stratum full-section grouting shield

A construction method and building technology, applied in underground chambers, earthwork drilling, wellbore lining, etc., can solve problems such as difficult to meet expected quality requirements and progress goals, shield tunneling cannot be normally excavated, and soil pressure is difficult to control, etc., to achieve Control surface subsidence, reduce groundwater loss, and facilitate excavation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

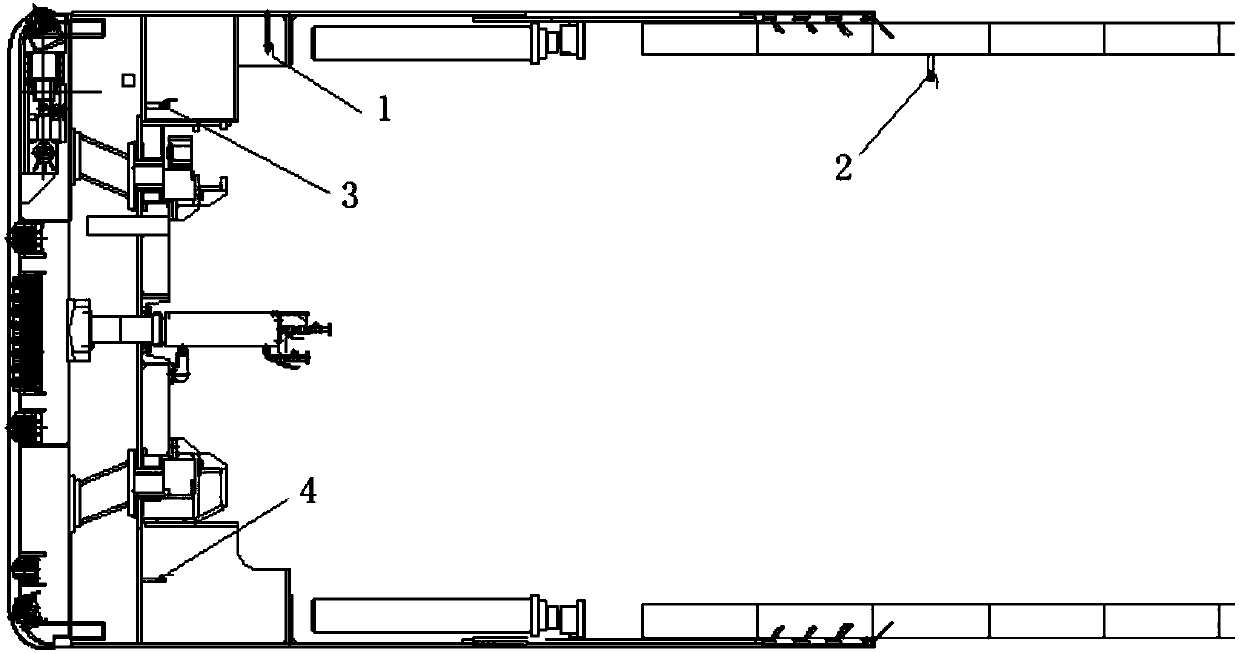

[0027] The present invention will be further described below in conjunction with specific embodiments and drawings.

[0028] An intercity rail project in Nanhai District, Foshan City, Guangdong Province. A section of the shield tunnel in the project has a buried depth of 47.5 meters and withstands a head height of 35-39m. The tunnel body is tertiary gravel sandstone with well-developed rock mass joints and fissures , The tunnel face fissure water is relatively large, and the bedrock fissure water of the tunnel body section has certain connectivity with the pore water of the Quaternary overburden. The surface of this section of the tunnel is a textile city, and some buildings are more sensitive to groundwater loss, and some settlement and cracking have occurred before the shield tunnel passes. In view of the above situation, the full-face grouting shield construction method of the water-rich rock layer under the sensitive building of the present invention is adopted for constructi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com