Stability control construction method of water-enriched soft rock tunnel passing through fault crushed zone

A technology of stability control and construction method, applied in tunnels, tunnel linings, drainage, etc., can solve problems such as large-area encroachment of surrounding rock, restriction of construction period, subsidence arch distortion and deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

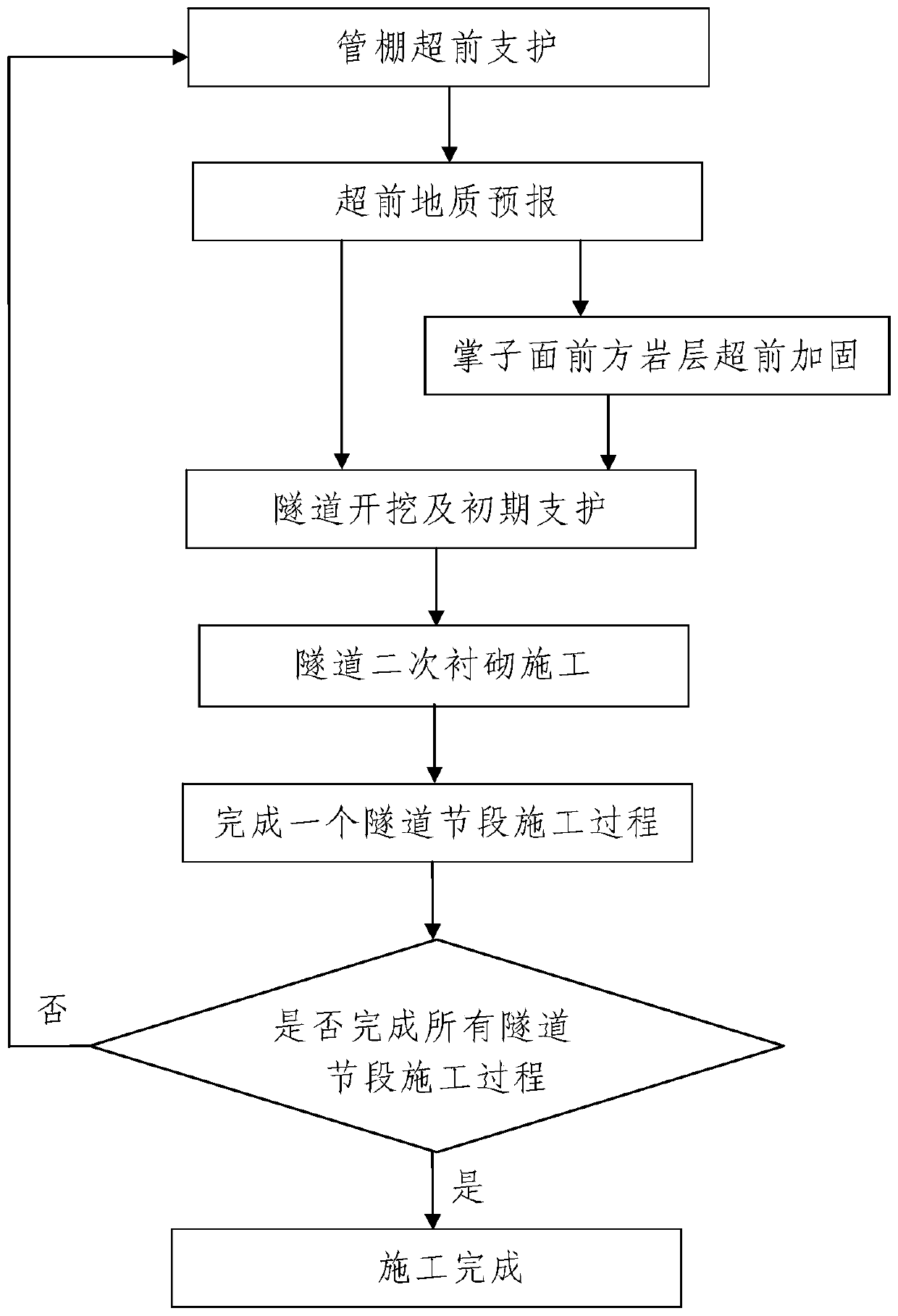

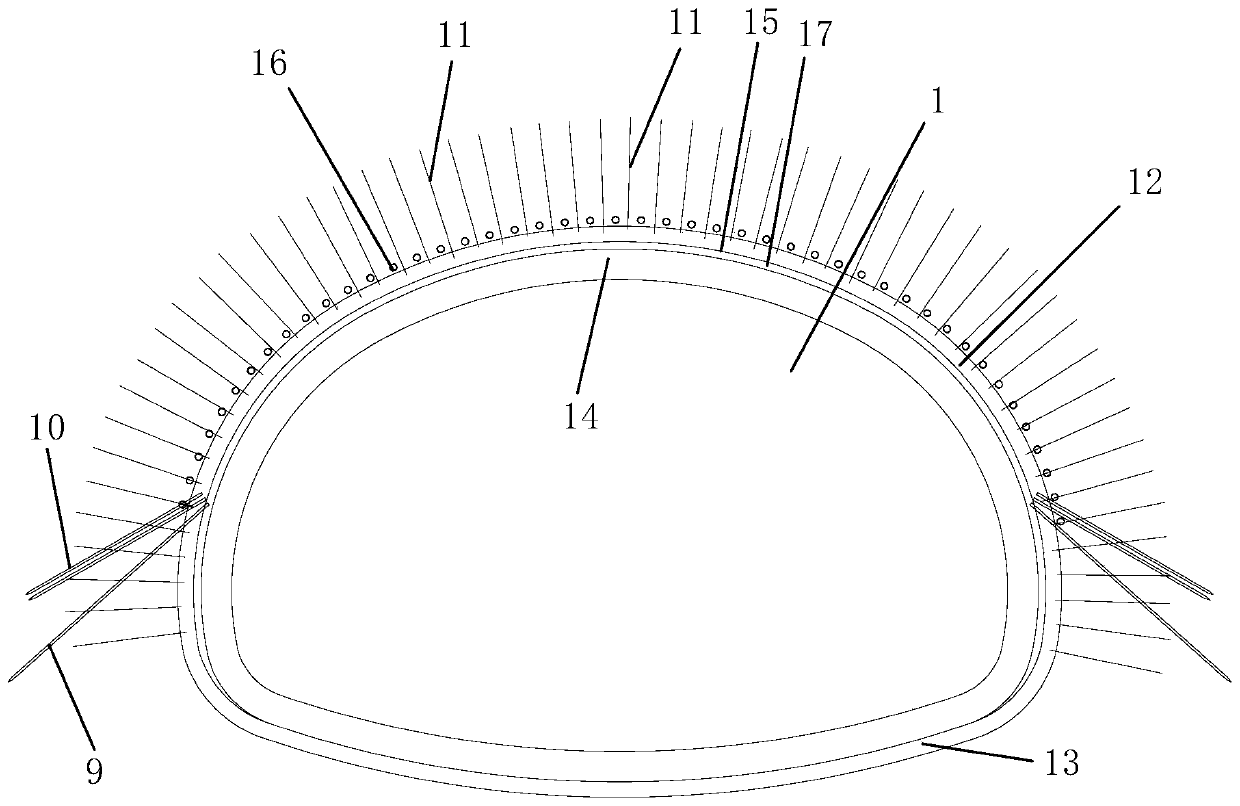

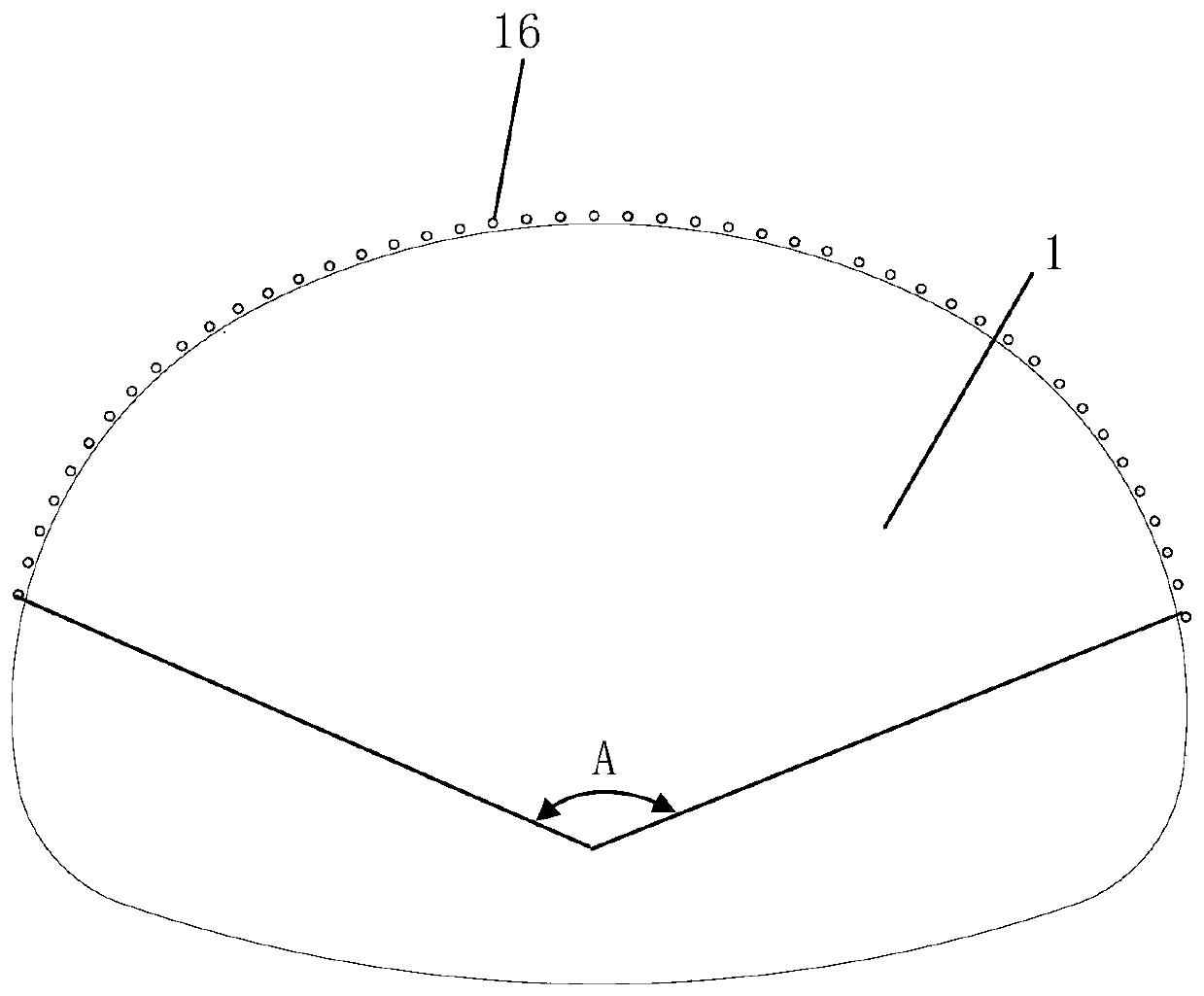

[0120] Such as figure 1 Shown is a construction method for stability control of a water-rich soft rock tunnel passing through the fault fracture zone. The cross-sectional area of the tunnel 1 is greater than 100m 2 ; combine figure 2 , image 3 and Figure 15 , the tunnel hole is divided into an upper hole body 1-5 and a lower hole body 1-6 located directly below the upper hole body 1-5; the excavation height of the tunnel hole is greater than 10m, and the opening of the upper hole body 1 The excavation height is 6.5m-8m, and the excavation height of the lower cave body 1-6 is 3.5m-4.5m; the surrounding rock grade of the tunnel hole is grade V;

[0121] The constructed tunnel 1 is divided into a plurality of tunnel segments 18 from back to front along the longitudinal extension direction of the tunnel, and the length of each tunnel segment 18 is 28m to 32m;

[0122] When constructing the constructed tunnel 1, construct the plurality of tunnel segments 18 in the construc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com