Patents

Literature

140results about How to "Guaranteed grouting effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

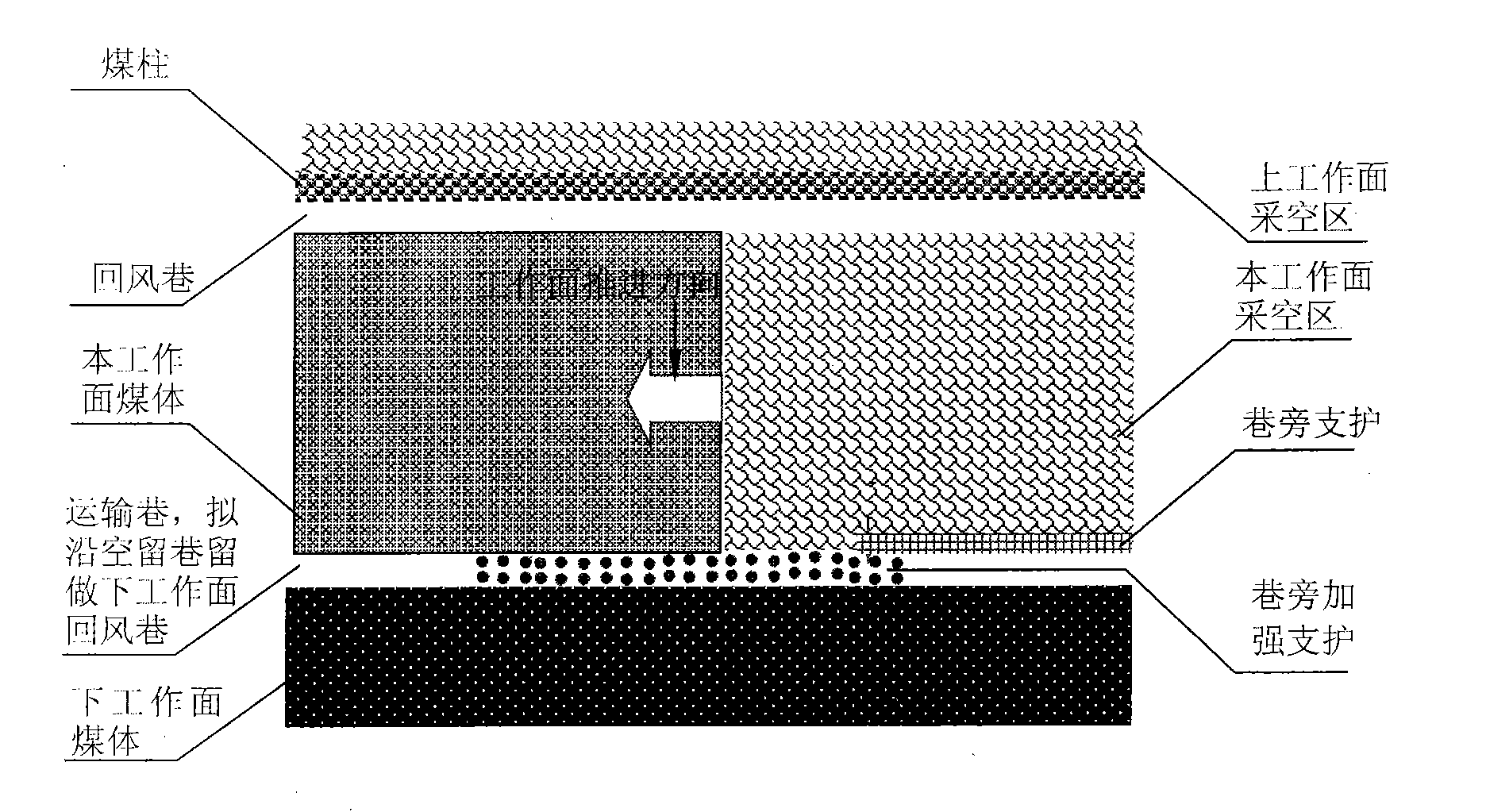

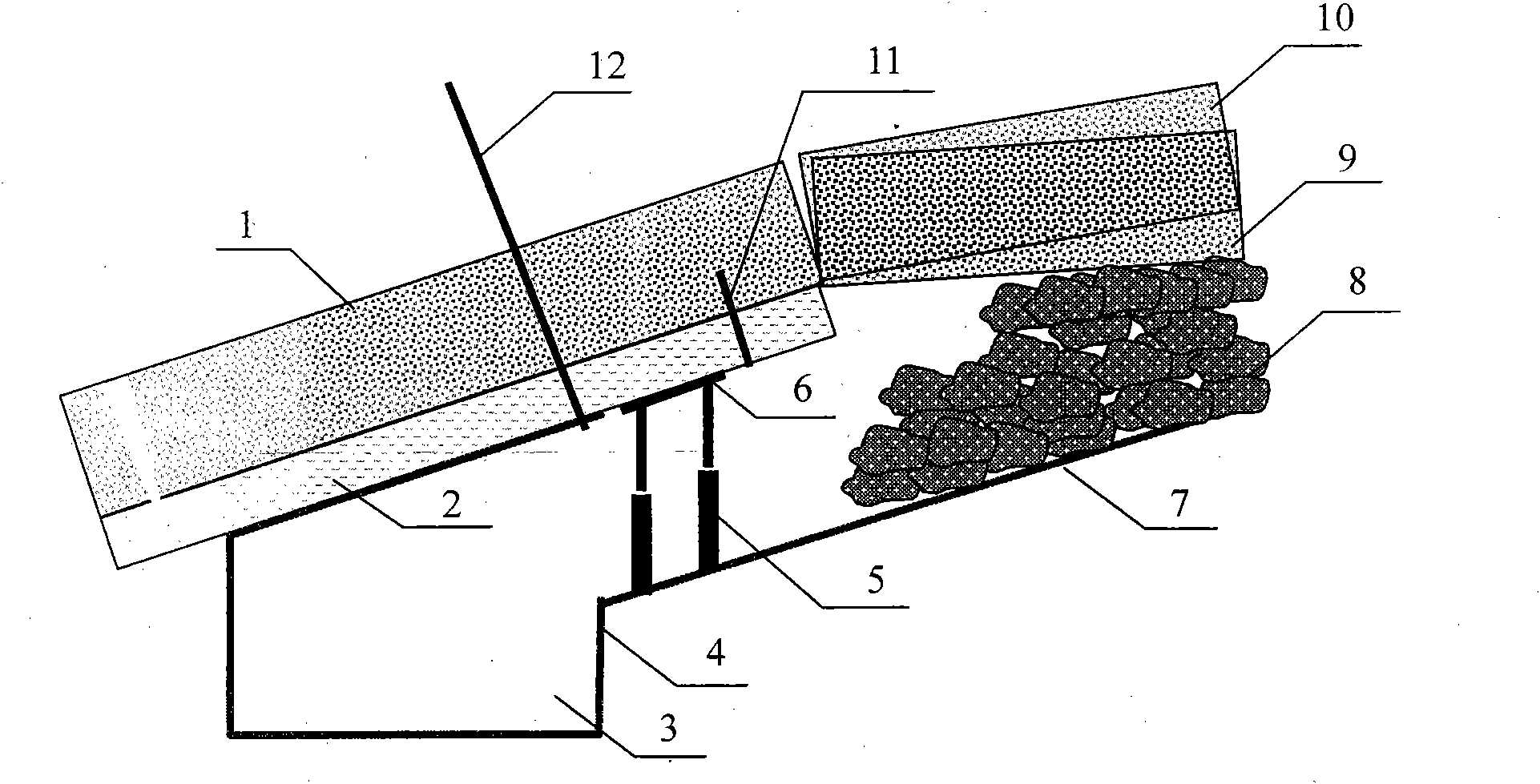

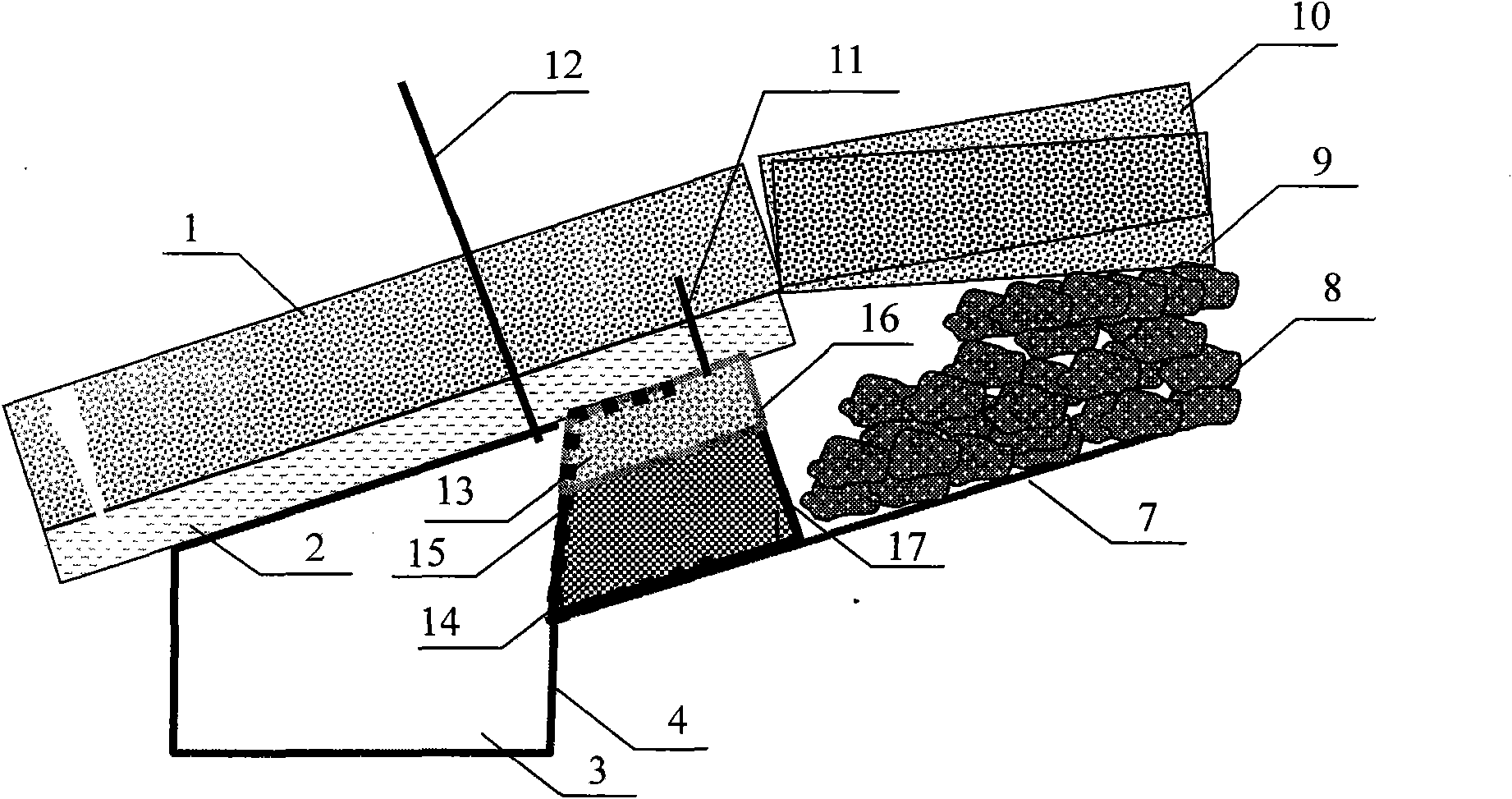

Coal mine gob-side entry retaining roadside segment bearing unequal strength support principle and application

InactiveCN101922292AGuaranteed grouting effectUnderground miningTunnel/mines ventillationEngineeringLarge deformation

The invention discloses a support principle which is suitable for coal mine gob-side entry retaining segment bearing roadside support and an application method. After a working surface begins to be exploited, a transport road adopts gob-side entry retaining which is completely preserved to be used as a return airway for the next working surface. According to characteristics of stratum movement, the segment bearing principle is put forward to carry out the roadside unequal strength support. The roadside unequal strength support is that bearing-deformation of a roadside support material carries out support of different strengths according to the segment movement intensity of the stratum in order to adapt to movement characteristics in different phases, namely different stratum movement phases, and correspondingly, the roadside support material has different mechanical properties and bearing-deformation parameters. Roadway support of the transport road is combined support by upper-layer padding and lower-layer padding. The whole padding combination body has not only large deformation amount but also high bearing strength, thus achieving double effects of support and sealing. The coal mine gob-side entry retaining roadside segment bearing unequal strength support principle and the application method are suitable for coal mine underground gob-side entry retaining roadside support.

Owner:成云海 +1

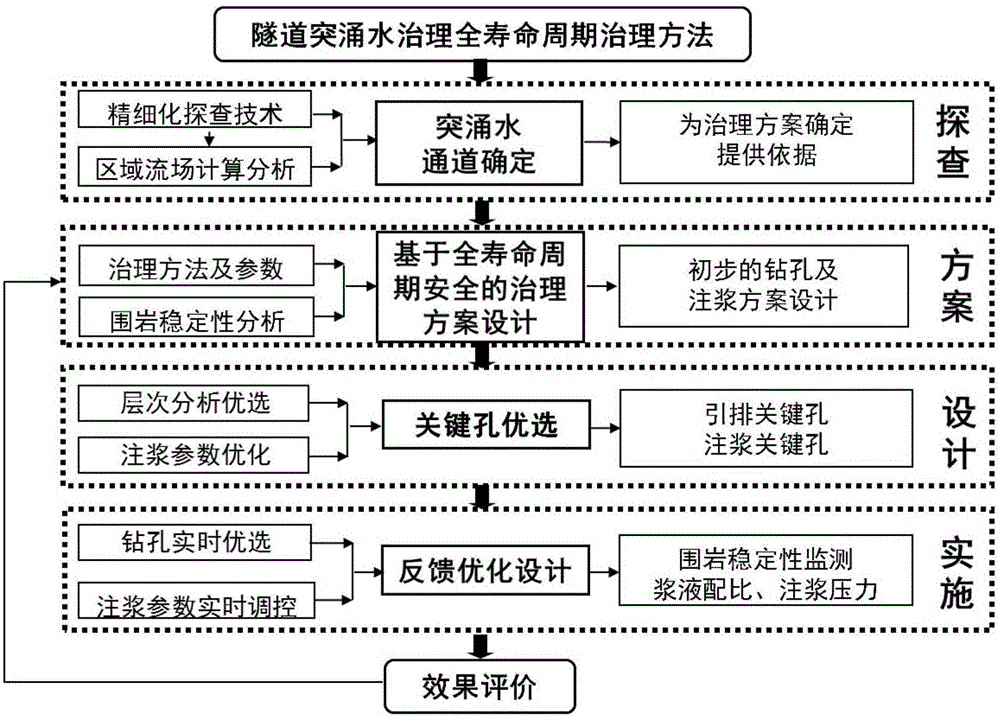

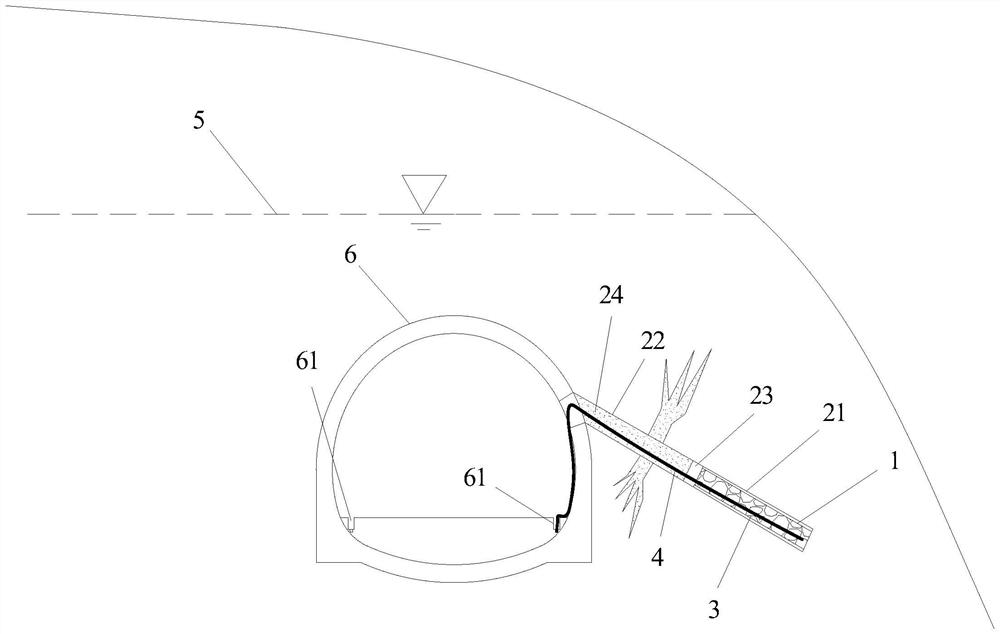

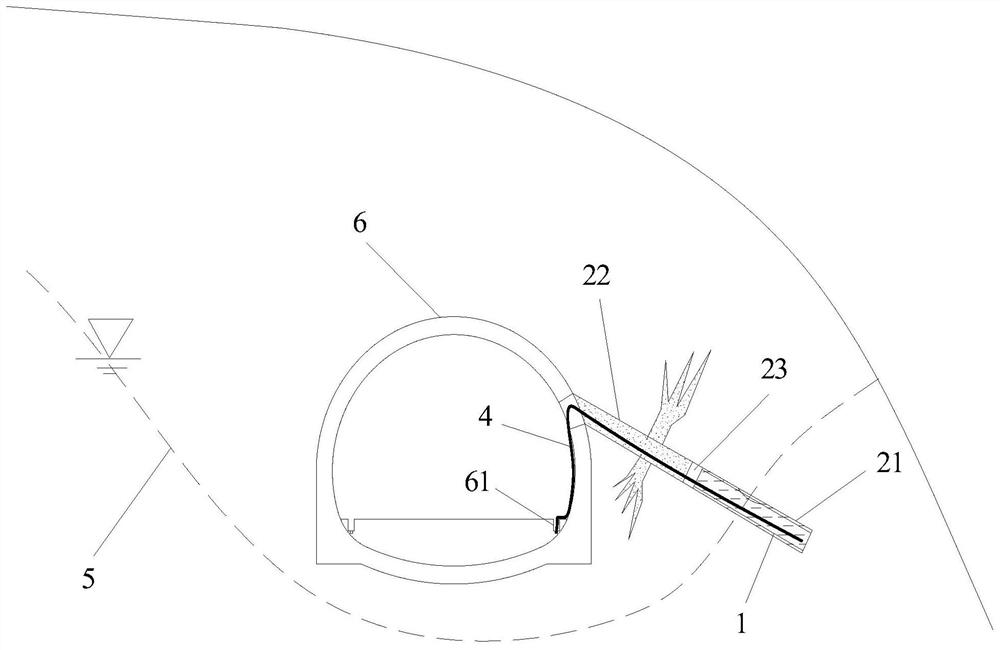

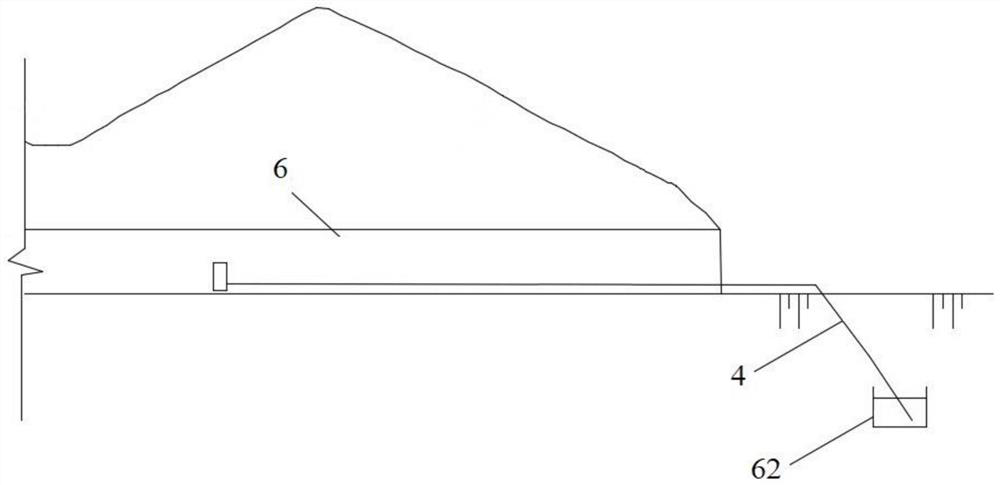

Life-cycle treatment method of water inrush in tunnel

ActiveCN105041345AImprove targetingImprove effectivenessUnderground chambersTunnel liningWall rockTunnel construction

The invention discloses a life-cycle treatment method of water inrush in a tunnel. The method comprises the steps that three-dimensional morphologic features of a water conductive structure of a water inrush zone in the tunnel are obtained by combining geological data, excavation data, detection results of comprehensive geophysical detection and numerical calculation results; grouting sealing water inrush is taken into account, surrounding rock physical mechanical parameters are improved simultaneously, design of a treatment scheme is conducted on the water inrush zone in the tunnel, and design of a keyhole and a drainage keyhole is conducted according to a water inrush main controlling structure; the stability of the tunnel in the construction period and the safety in the operation period are guaranteed by conducting numerical simulation on the tunnel section which is reinforced according to the design scheme; grouting construction is conducted according to the design scheme, a monitoring device is buried during the construction process, and feedback optimal design is implemented; inspection is conducted on the treatment effect of the grouting reinforcement section in the tunnel, and the excavation time is determined. According to the life-cycle treatment method of the water inrush in the tunnel, it is guaranteed that the surrounding rock in the tunnel construction period is stale and water inrush of the tunnel does not occur in the operation period, the chronic problem that nine of the ten tunnels leak is completely eradicated, and the effective treatment of the water inrush in the tunnel and the environmental protection are achieved.

Owner:SHANDONG UNIV

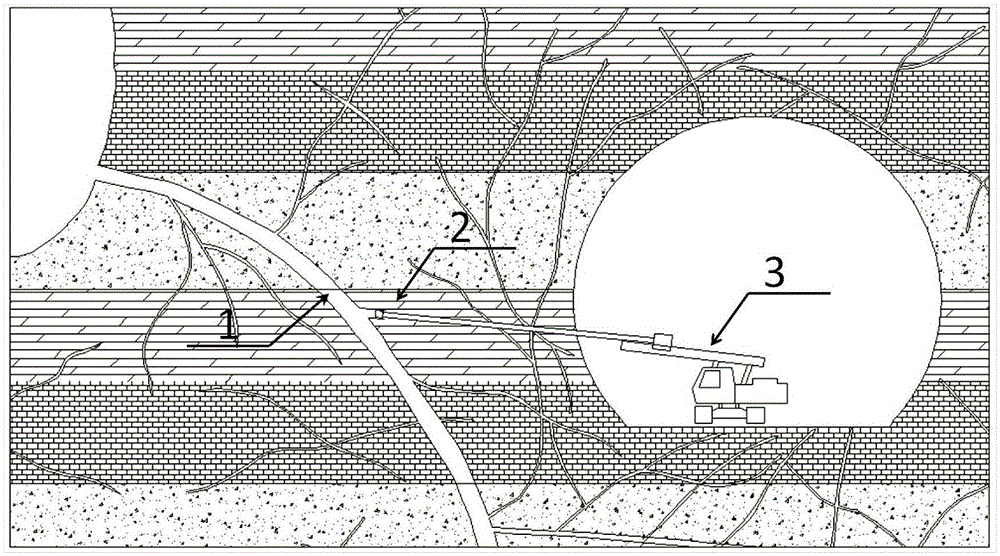

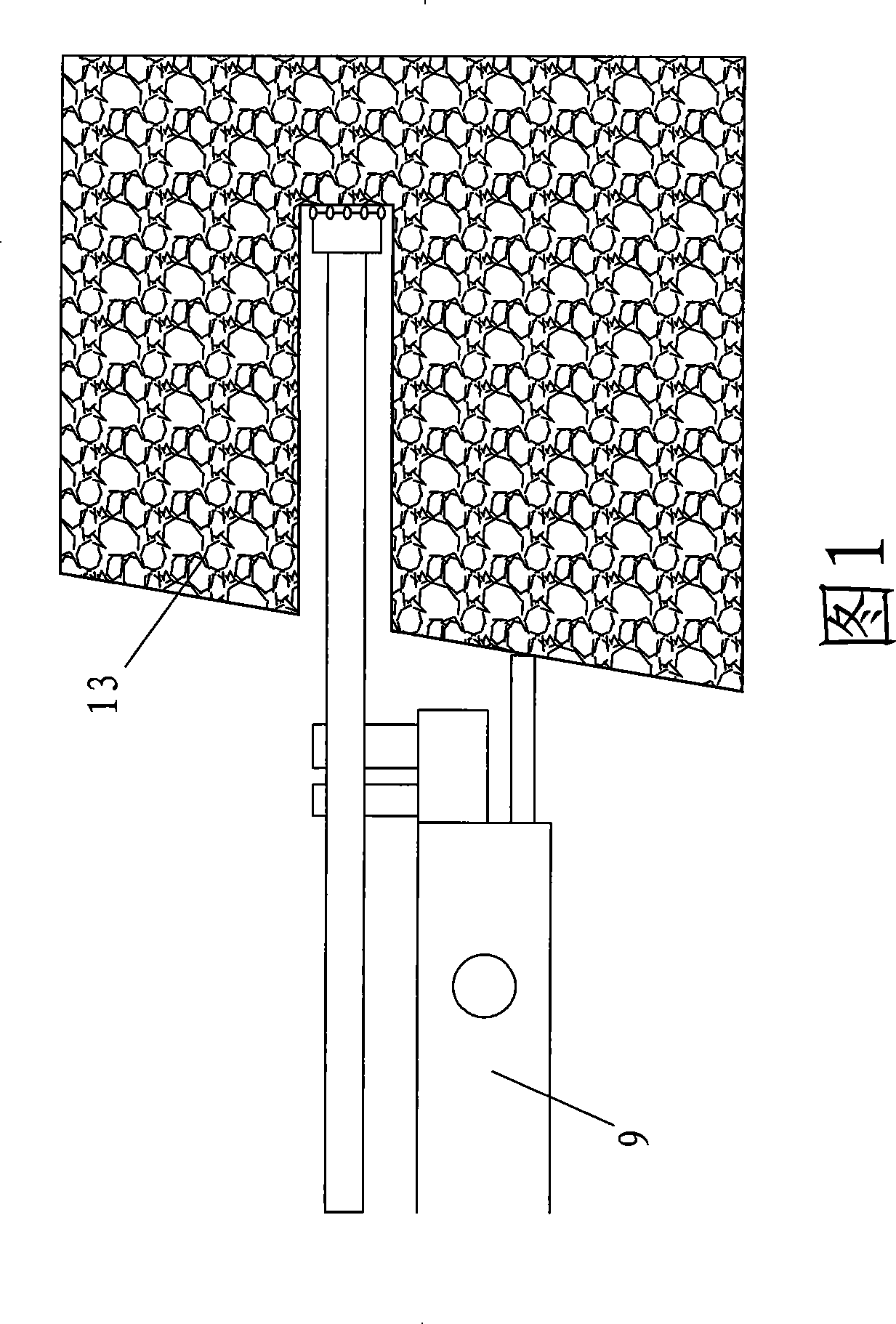

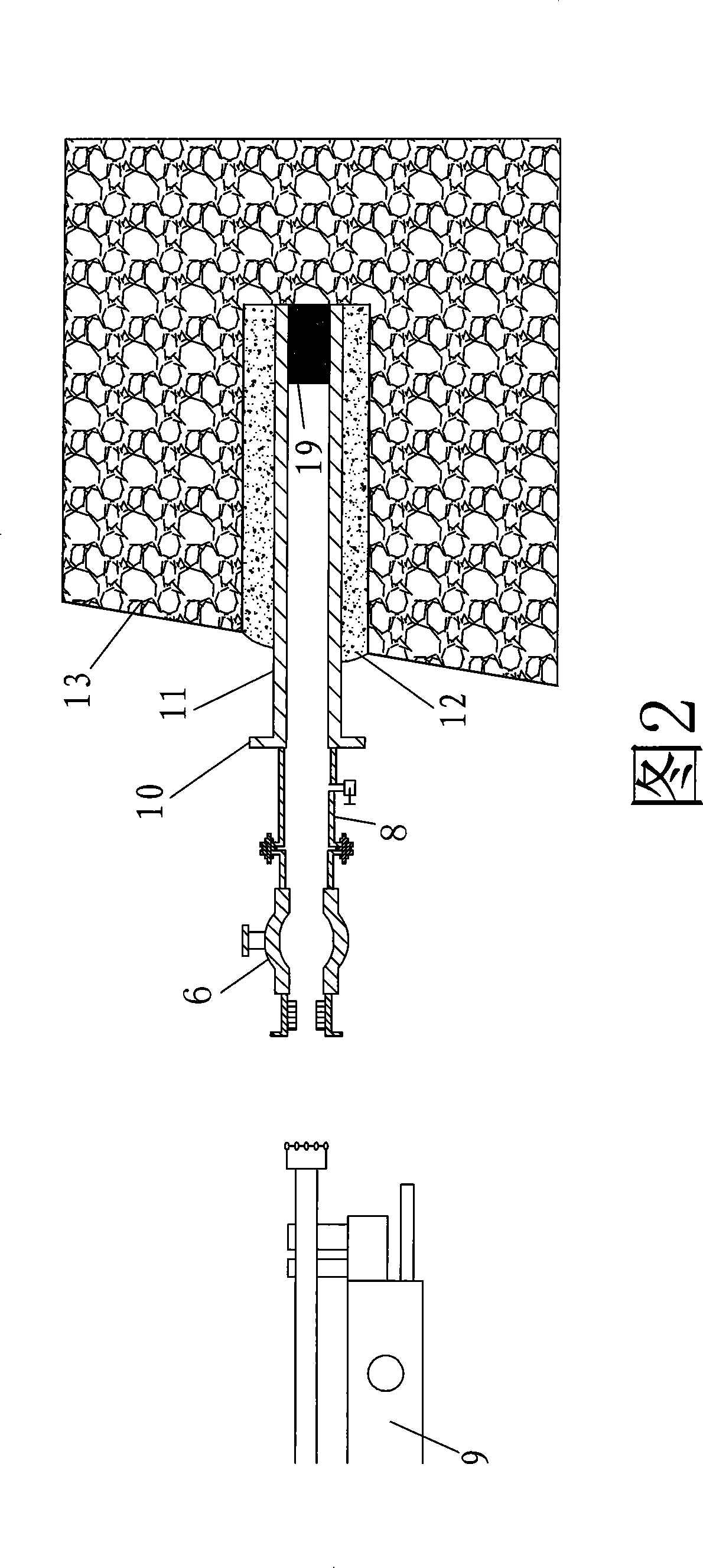

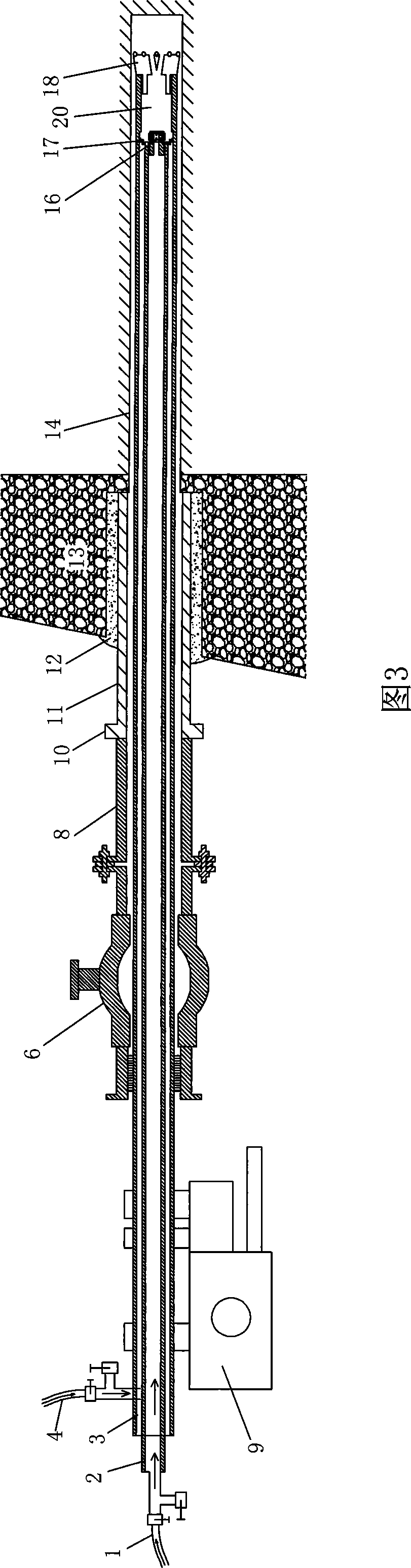

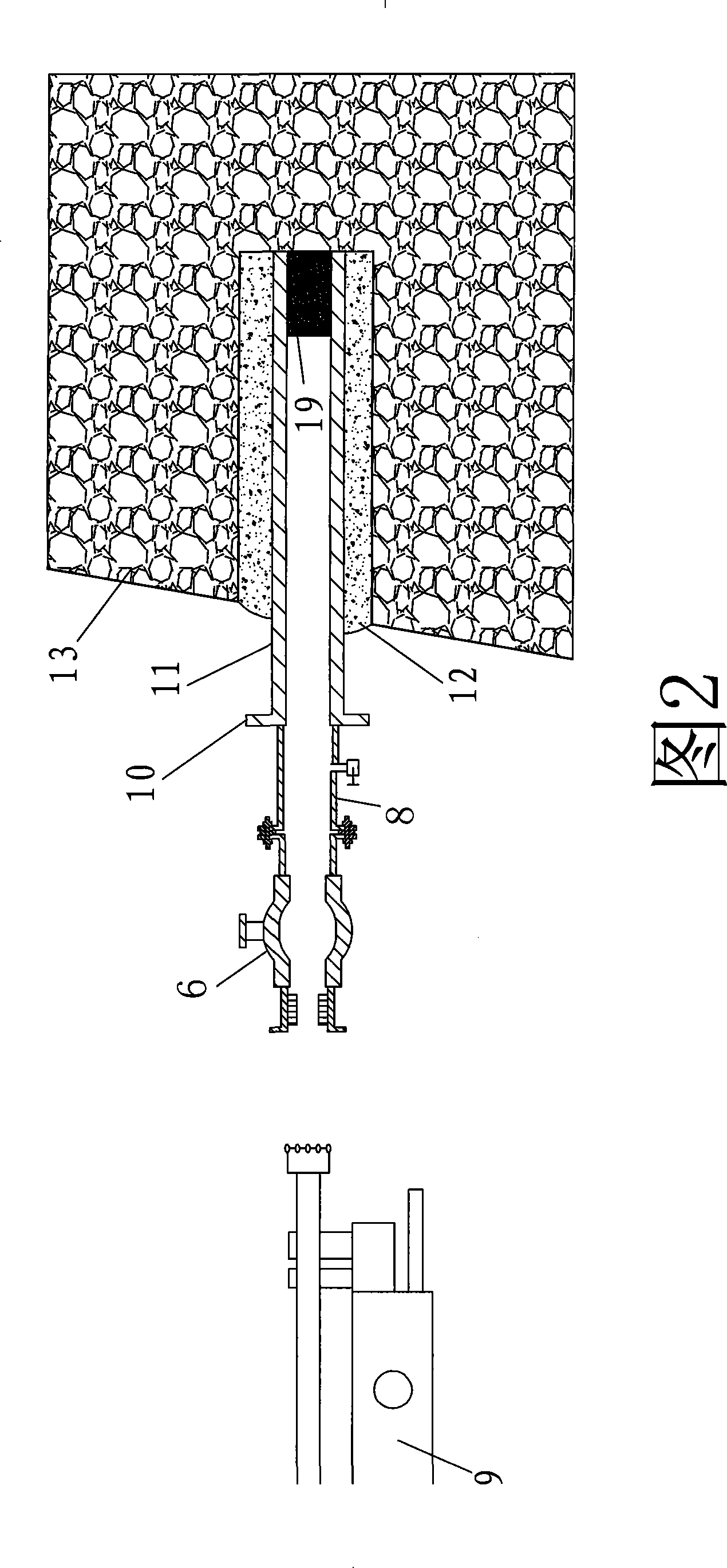

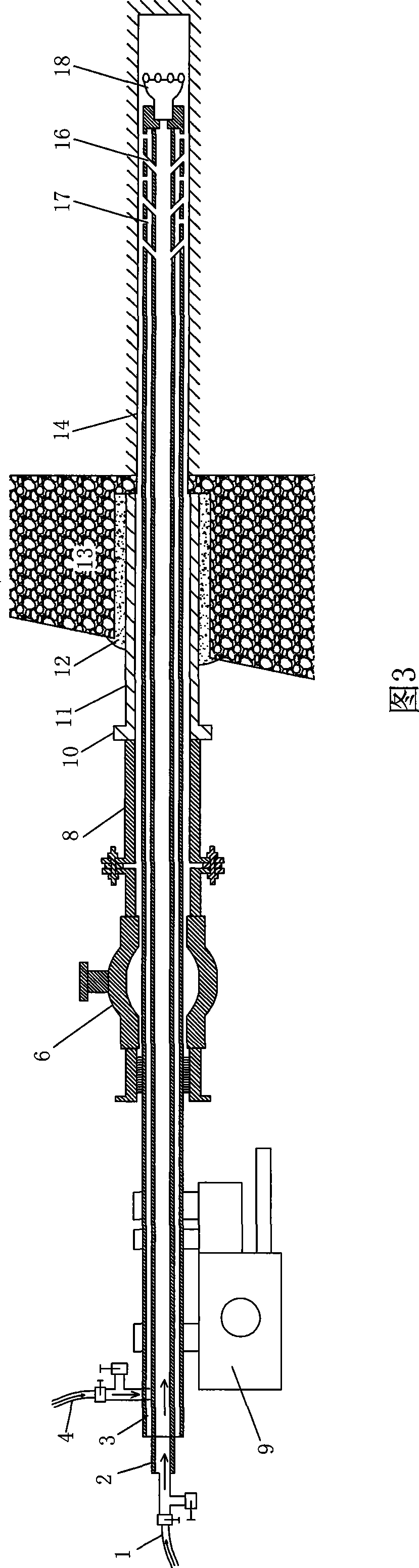

Subsection retrusive slip-casting method for porthole slurry-stop mixed double-pipe within tube

ActiveCN101251019AGuaranteed mixing effectGuaranteed pressureUnderground chambersTunnel liningDouble tubeEngineering

The invention provides a sectional retreating grouting method for a mixed duplex pipe inside an orifice stop-grouting pipe, comprising the following technological steps that: a shallow hole is drilled on a grouting wall (13) by utilization of a drilling machine at first; a drill rod is retreated; an orifice pipe (11) is arranged and then fixed on the orifice wall by utilization of anchor agents (12); the drill rod with a single drill bit and the structure of an inner sleeve and an outer sleeve is adopted for drilling; one end of the orifice pipe positioned on the outside of the drill hole is connected with a drainage (8) and a water inrush resistant device (6) during the drilling process; tail ends of both an inner pipe (2) and an outer pipe (3) of the drill rod are connected with water supply pipes; drilling is performed through the water inrush resistant device, the drainage and the orifice pipe until the designed drilling depth is reached; the water inrush resistant device is disassembled; a hollow pressure plate (5) and a stop-grouting plug (7) are sleeved on the drill rod; the water supply pipes on tail ends of the inner pipe and the outer pipe are respectively connected with a cement slurry supply pipe and a water glass slurry supply pipe; grouting is performed and cement slurry and water glass slurry are mixed in a hybrid chamber (20) and then ejected from the front of the drill bit; when the designed grouting quantity is reached, the drill rod is released by the stop-grouting plug; after the drill rod is retreated for a section of distance, the stop-grouting plug is sealed again, and a gap between the drainage and the outer pipe is grouted continuously; in such manner, a section is grouted and retreated and then another section is grouted until grouting of the hole is finished.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD

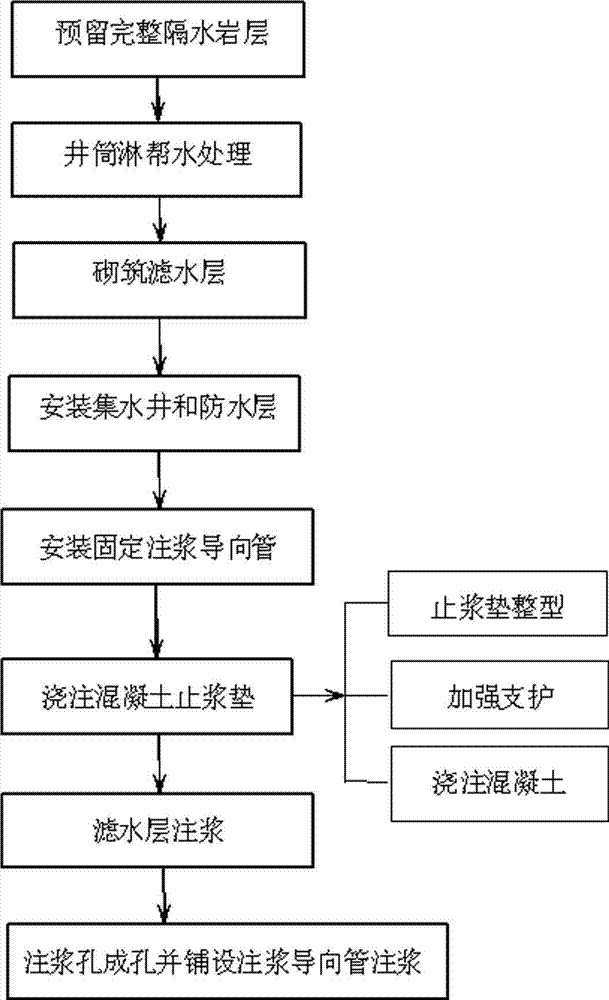

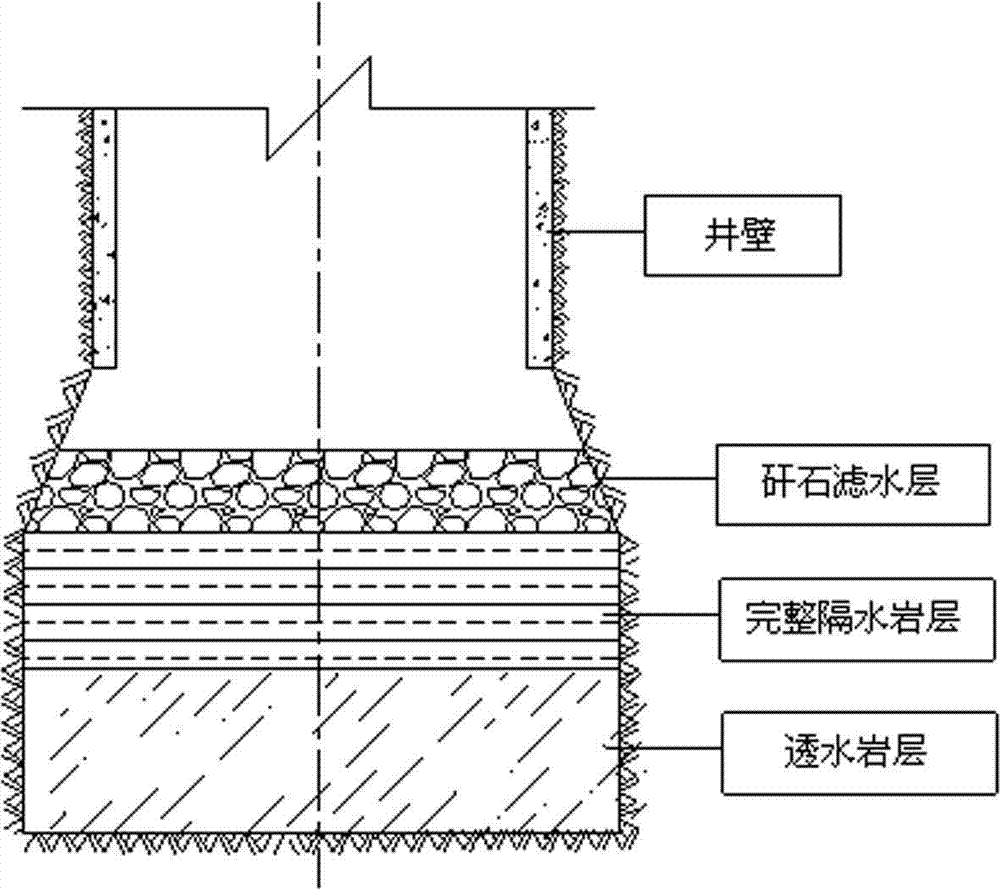

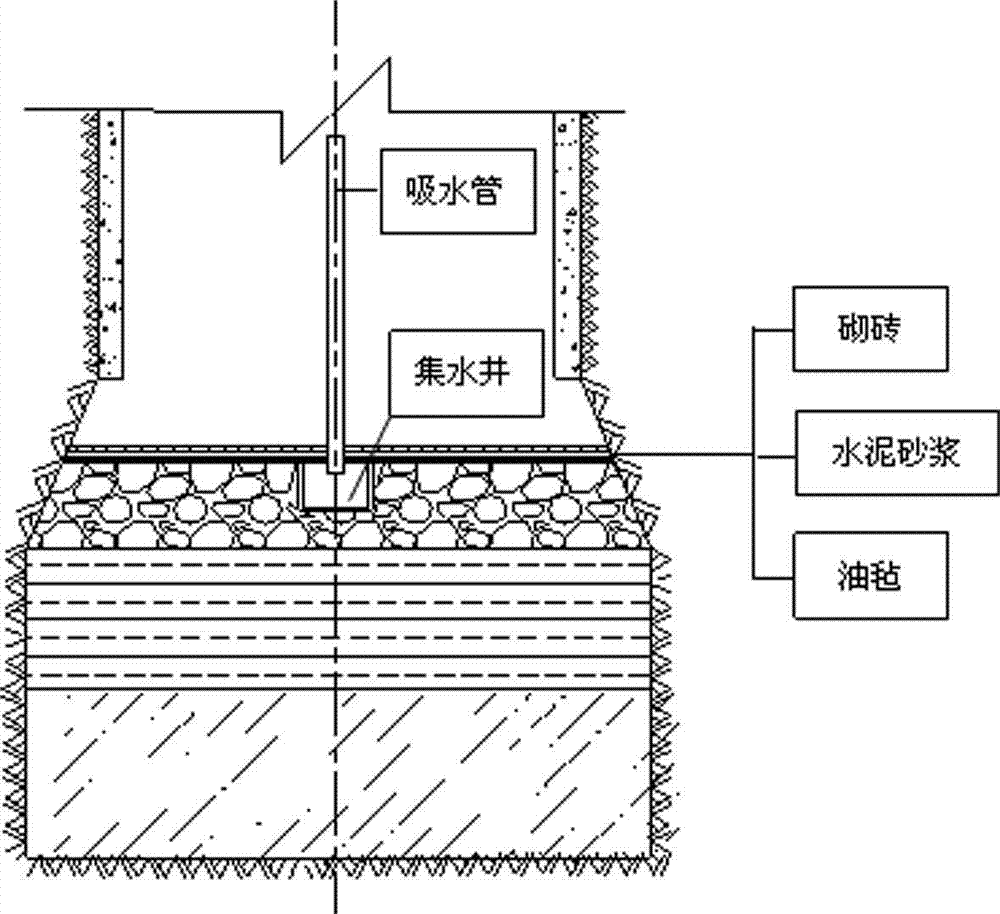

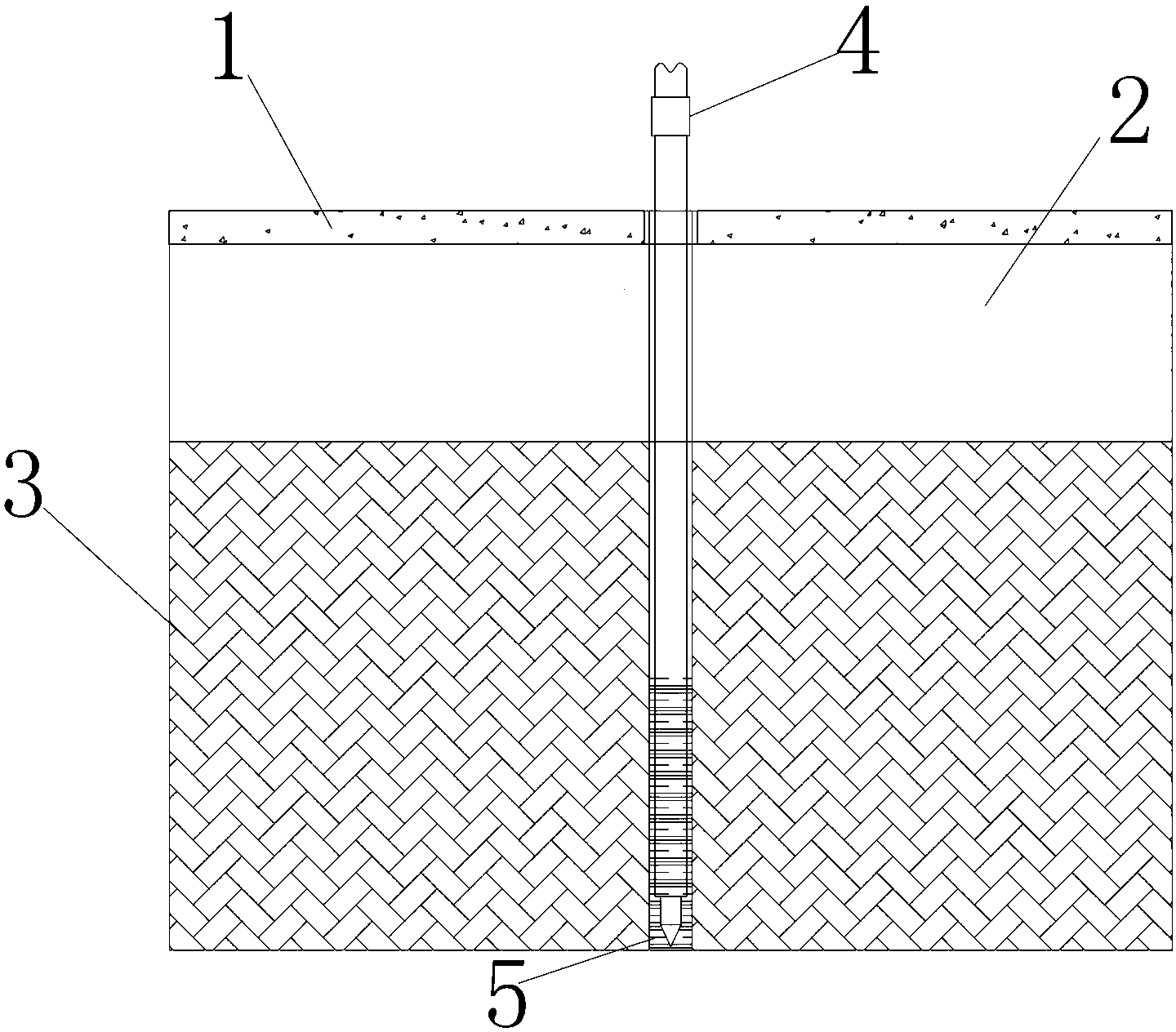

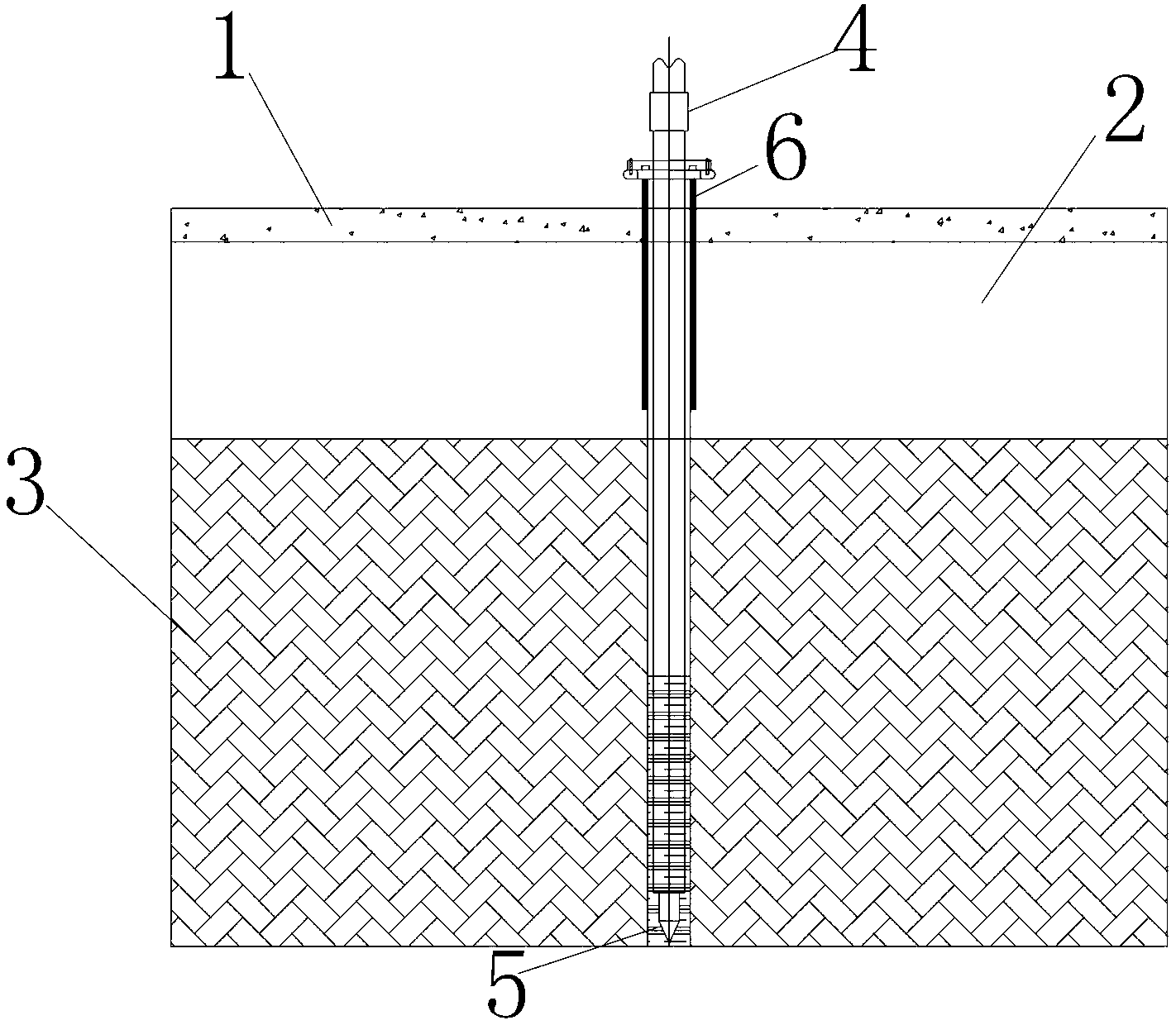

Pre-grouting and water plugging method for permeable layer in vertical shaft

A pre-grouting and water plugging method for a permeable layer in a vertical shaft includes the steps of reserving complete waterproof rock strata, performing spraying water treatment for a shaft body, building a water filtering layer, mounting a drainage sump and a waterproof layer, mounting and fixing a grouting guide pipe, pouring concrete grouting pad, performing water filtering layer grouting and performing grouting hole formation and laying the grouting guide pipe for grouting. The pre-grouting and water plugging method has the advantages that high grouting pressure meeting design requirements can be borne, grouting and water plugging effects under high water pressure and high grouting pressure during construction of the vertical shaft are guaranteed, the thickness of the grouting pad can be decreased to the greatest extent, and grouting pad construction and detachment workload is reduced, so that grouting effect is guaranteed, shaft body advancement speed is increased, and more obvious effect is achieved particularly as for a large-thickness permeable layer. Therefore, the pre-grouting and water plugging method can be effectively applied to pre-grouting and water plugging of the permeable layer in the vertical shaft and has good effect on experimental verification.

Owner:WUHAN SURVEYING GEOTECHN RES INST OF MCC

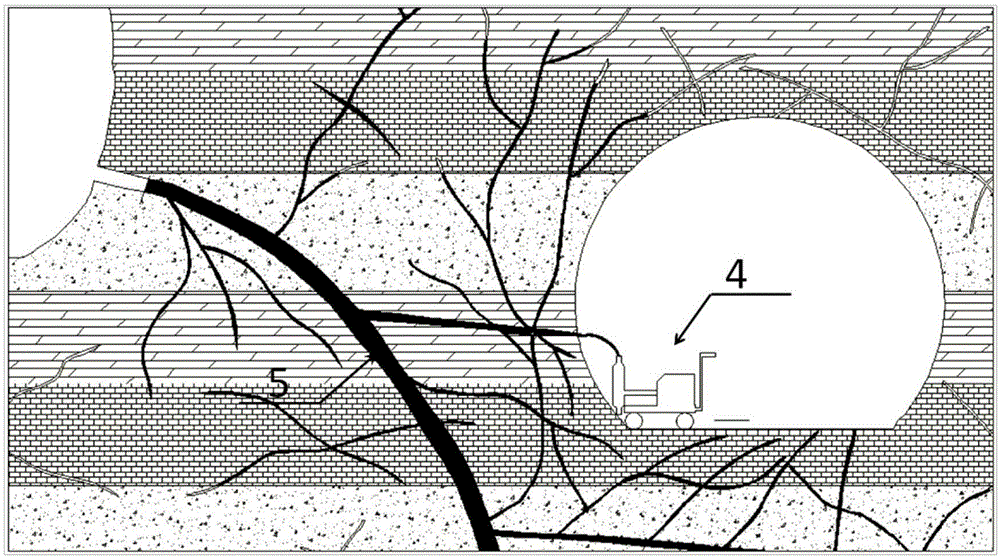

Subsection retrusive slip-casting method for porthole slurry-stop mixed double-pipe

ActiveCN101251018AWell mixedGuarantee the quality of groutingUnderground chambersTunnel liningDouble tubeEngineering

The invention provides a sectional retreating grouting method for a mixed duplex pipe on the outside of an orifice stop-grouting pipe, comprising the following technological steps that: a shallow hole is drilled on a grouting wall (13) by utilization of a drilling machine at first; a drill rod is retreated; an orifice pipe (11) is arranged and then fixed on the orifice wall by utilization of anchor agents (12); the drill rod with a single drill bit and the structure of an inner sleeve and an outer sleeve is adopted for drilling; one end of the orifice pipe positioned on the outside of the drill hole is connected with a drainage (8) and a water inrush resistant device (6) during the drilling process; tail ends of both an inner pipe (2) and an outer pipe (3) of the drill rod are connected with water supply pipes; drilling is performed through the water inrush resistant device, the drainage and the orifice pipe until the designed drilling depth is reached; the water inrush resistant device is disassembled; a hollow pressure plate (5) and a stop-grouting plug (7) are sleeved on the drill rod; the water supply pipes on tail ends of the inner pipe and the outer pipe are respectively connected with a cement slurry supply pipe and a water glass slurry supply pipe; grouting is performed and cement slurry is driven to be ejected from the front of the drill bit along the inner pipe, and simultaneously the cement slurry and water glass slurry are ejected respectively from a water and slurry outlet hole (16) and a water and slurry outlet hole (17) on the front section of the inner pipe and the outer pipe, mixed on the outside of the pipes and then enter into the stratum; when the designed grouting quantity is reached, the drill rod is released by the stop-grouting plug; after the drill rod is retreated for a section of distance, the stop-grouting plug is sealed again, and a gap between the drainage and the outer pipe is grouted continuously; in such manner.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD

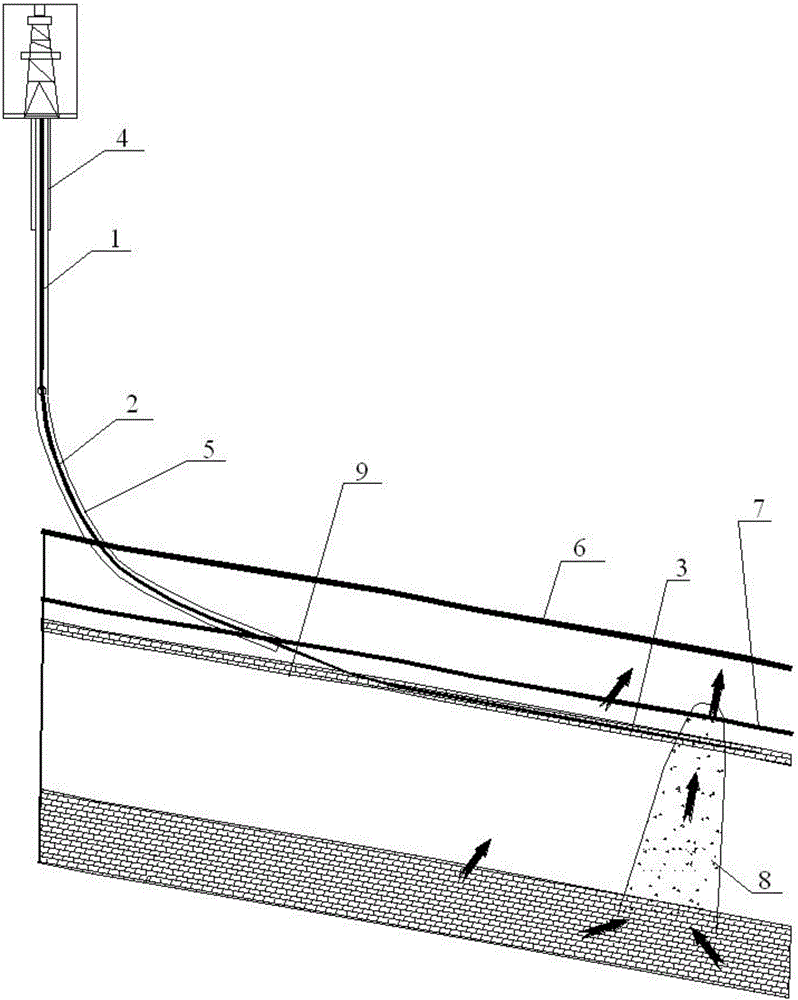

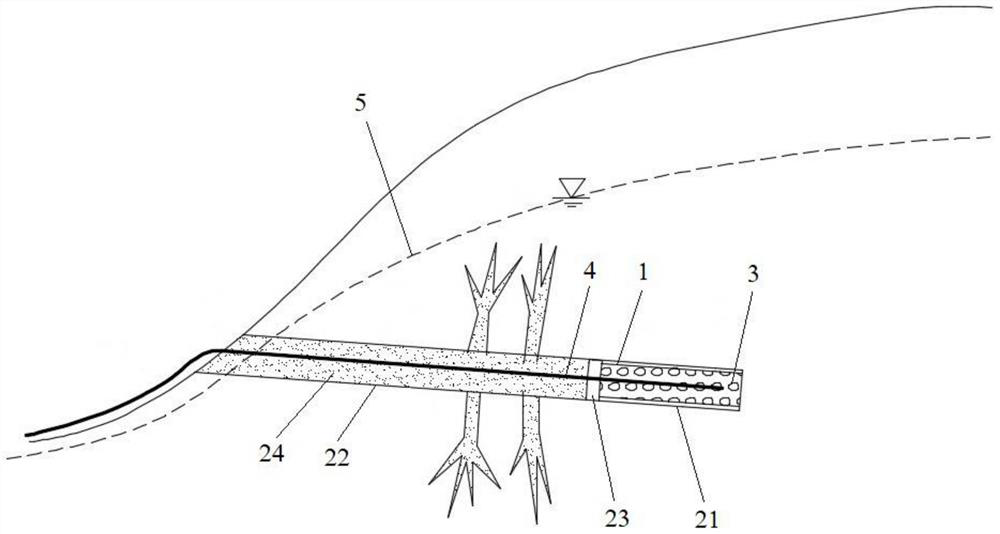

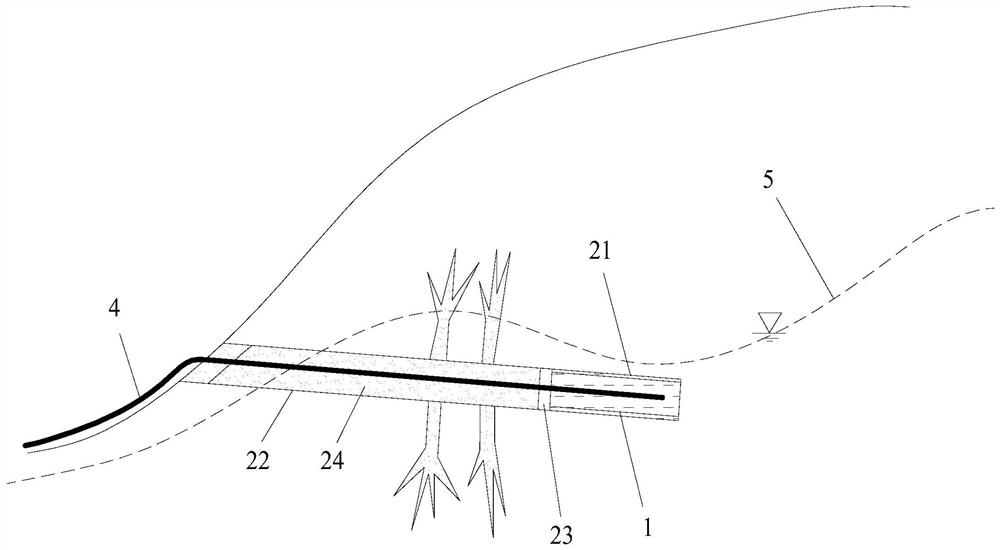

Method using surface orientation bedding drilling grouting to reinforce laminar limestone

InactiveCN106703692AIncrease the grouting pressureReinforcement and reconstruction area is wideDirectional drillingSealing/packingGeomorphologyWater source

The invention discloses a method using surface orientation bedding drilling grouting to reinforce laminar limestone. The method includes: performing surface drilling until a suspected water outlet point is reached, performing drilling grouting, wherein drilled holes include a main hole and branch holes, the main hole is provided with a straight hole section and an oriented bedding section, an oriented slanting-guide section is further arranged between the straight hole section and the oriented bedding section, and the branch holes include primary branch holes and secondary branch holes; a water-bearing stratum is modified through the drilling grouting, grouting pressure is 1.5-3.5 times of the hydrostatic pressure of a to-be-grouted point, grouting termination pressure is 3.5-4 times of the hydrostatic pressure, and the lime-cement-flyash water-bearing stratum is transformed into a water-resisting layer to resist lime, cement and flyash and water of the water-bearing stratum below the lime, cement and flyash. By the method, hidden water guide channels are blocked, a base Ordovician limestone karst powerful water source is blocked, and safety of deep exploitation is guaranteed.

Owner:HUAIBEI MINING IND +1

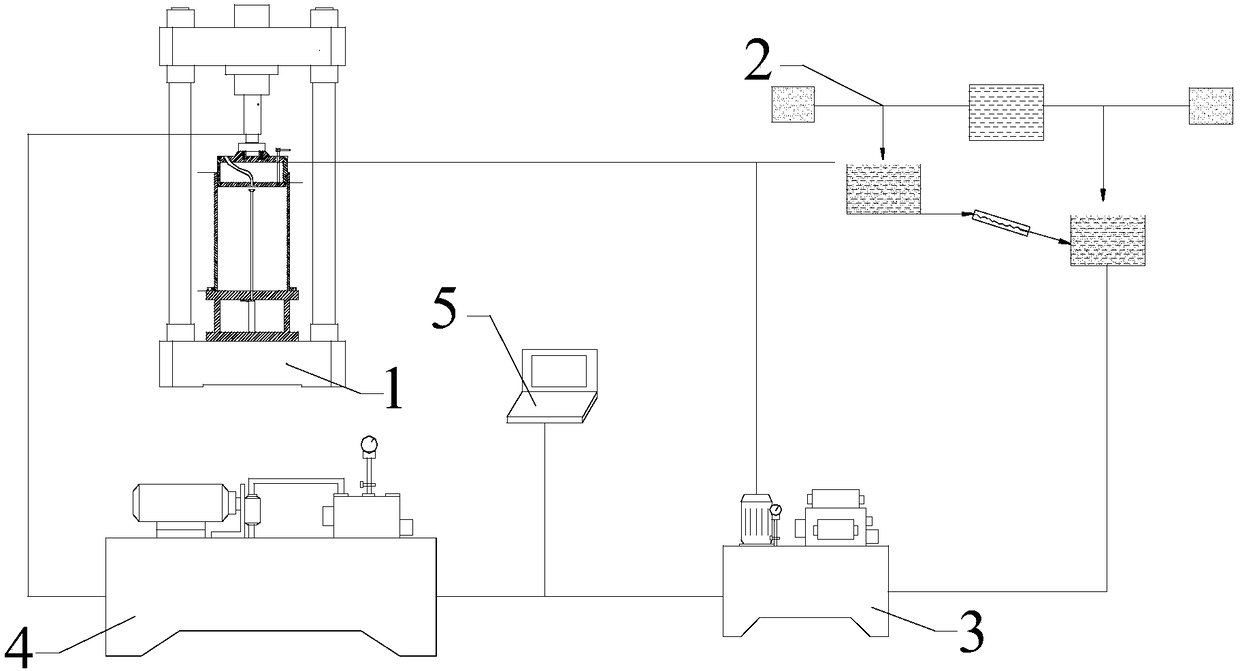

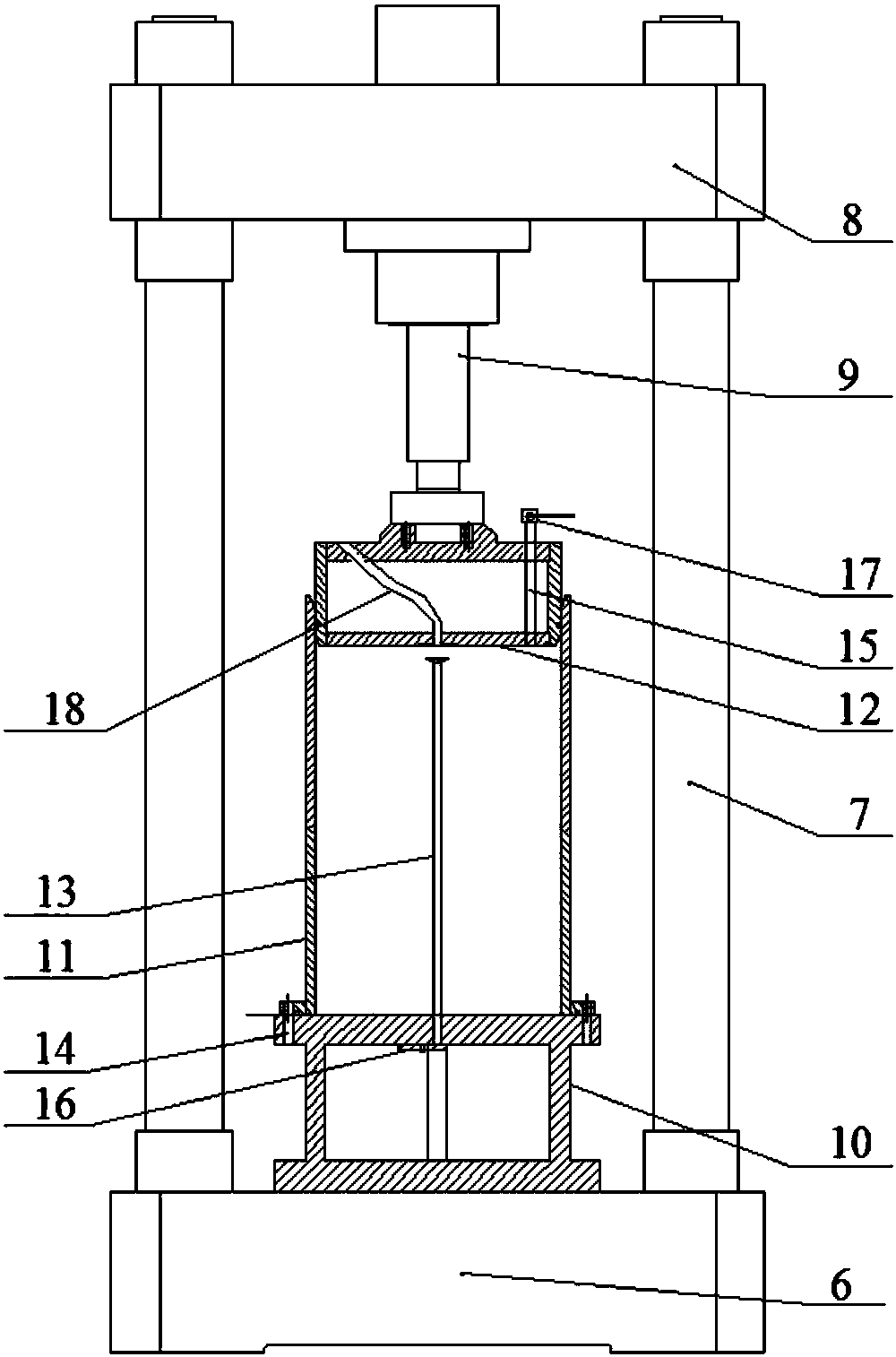

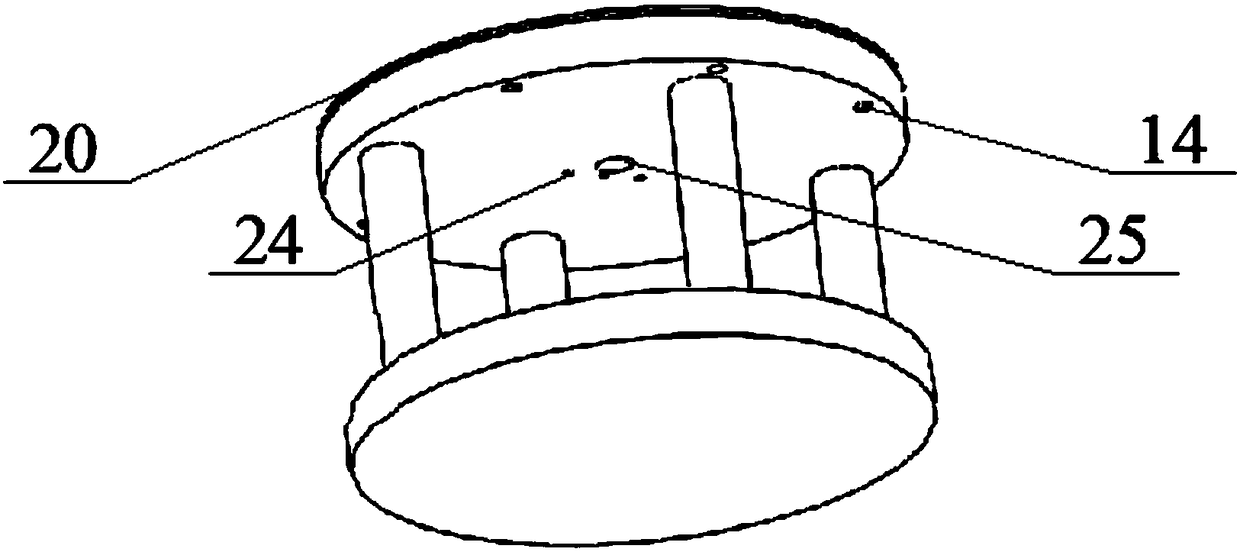

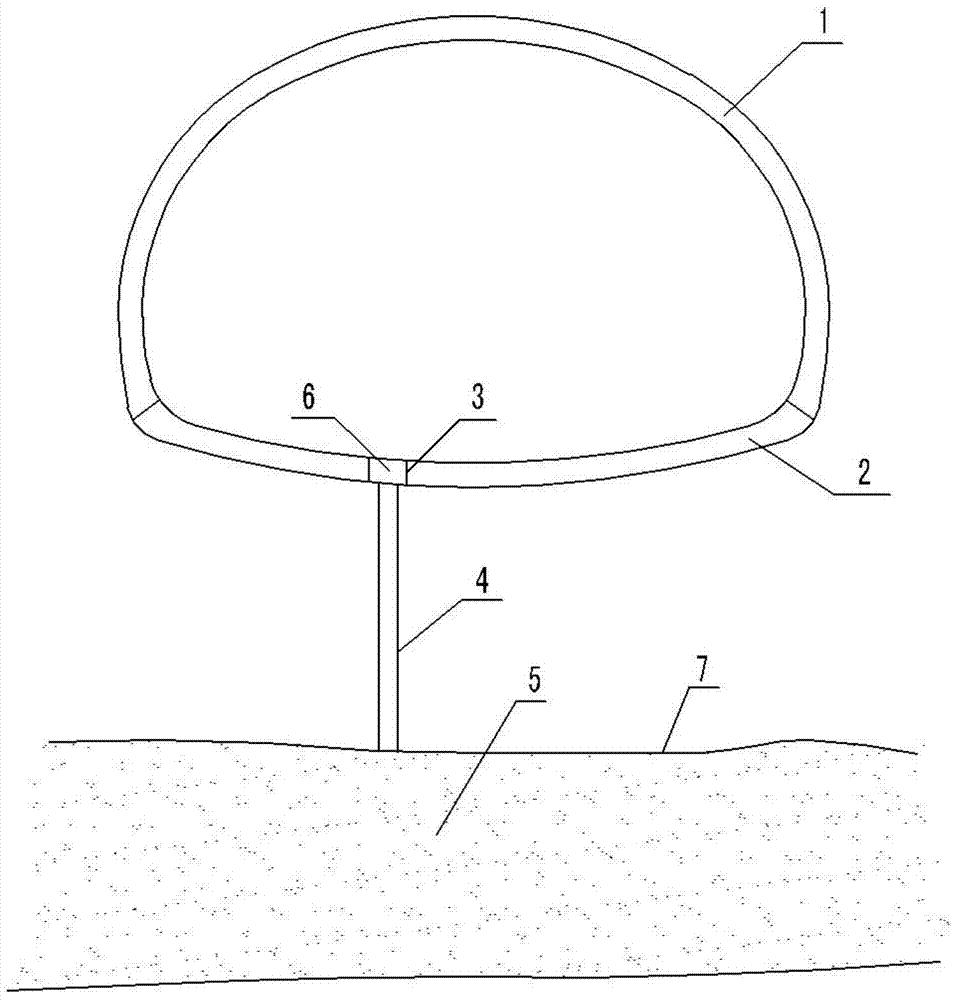

Experiment system for simulating grouting effect of old goaf

InactiveCN108362859AEasy to chooseEasy to optimizeMaterial strength using tensile/compressive forcesEarth material testingConfined spaceEngineering

The invention discloses an experiment system for simulating the grouting effect of an old goaf and relates to the technical field of coal mines. The experiment system comprises a main experiment bodydevice, a slurrying device, a grouting volume-grouting pressure double control servo device, a displacement-pressure double control servo device and a control center, wherein the main experiment bodydevice comprises a base, an experiment module, a grouting steel pipe, a cross beam and other parts, and a loading oil cylinder is arranged in the middle of the cross beam and connected with a loadingpress head and controls the loading press head to move vertically; the experiment module is formed by a semi-circular member I and a semi-circular member II through buckling, when moving vertically downwards, the loading press head is completely attached to the inner wall of the experiment module, and a confined space is formed between the loading press head and the experiment module. With adoption of the system, indoor analog simulation for the grouting condition of the old goaf can be performed in advance, and strength of grouting solids after the experiment is detected, so that the groutingreinforcement effect is predicted.

Owner:SHANDONG UNIV OF SCI & TECH

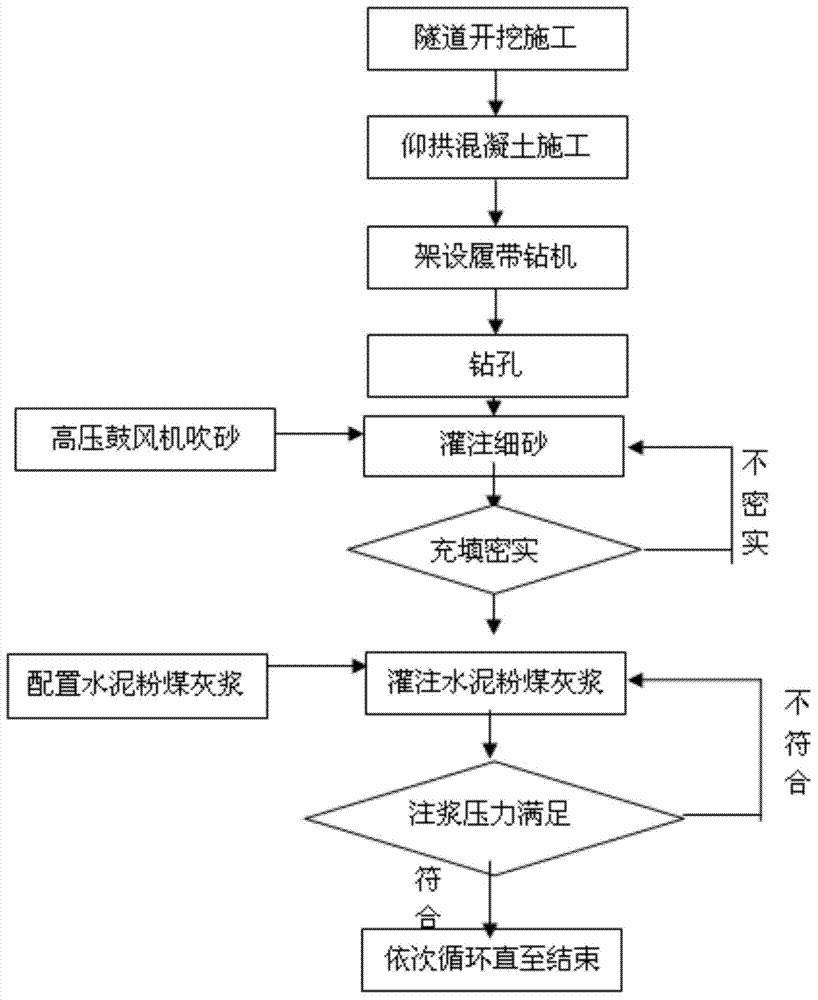

Filling and construction method for goaf below tunnel

Owner:中铁二十四局集团安徽工程有限公司 +1

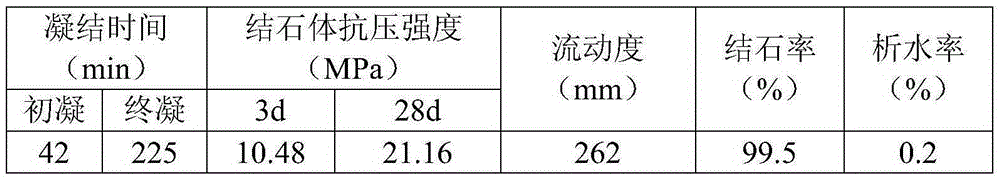

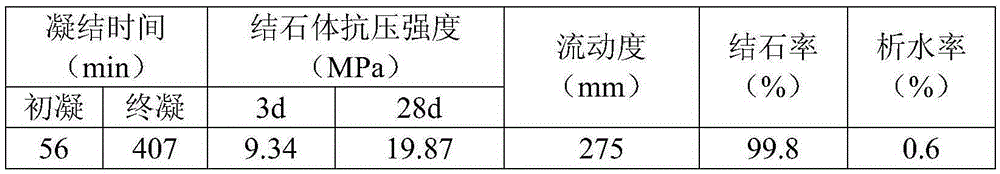

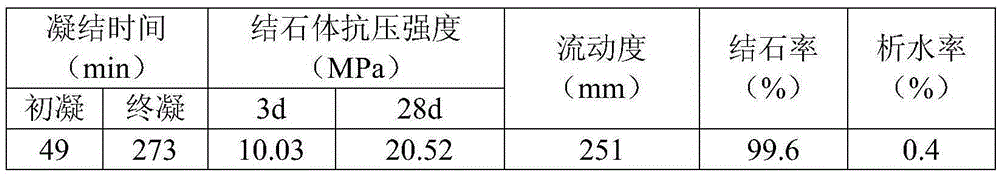

Geopolymer composite grouting material, and preparation method and use method thereof

The invention discloses a geopolymer composite grouting material, and a preparation method and a use method thereof. The preparation method comprises the following steps: uniformly mixing cement clinker, metakaolin, silica fume, blast furnace slag, fly ash, metal mine tailing, quicklime, a water reducer and dispersible latex powder according to a certain ratio, and grinding to prepare fine powder until the sieving residue ratio of a square hole sieve with the fineness of 45[mu]m is not greater than 30%. Solid wastes comprising the blast furnace slag, the fly ash and the metal mine tailings are adopted in the invention, so the cost of the material is reduced, the fluidity of the material is improved, and the compressive strength of the geopolymer composite grouting material is also improved without increasing the cost.

Owner:SHANDONG UNIV OF SCI & TECH

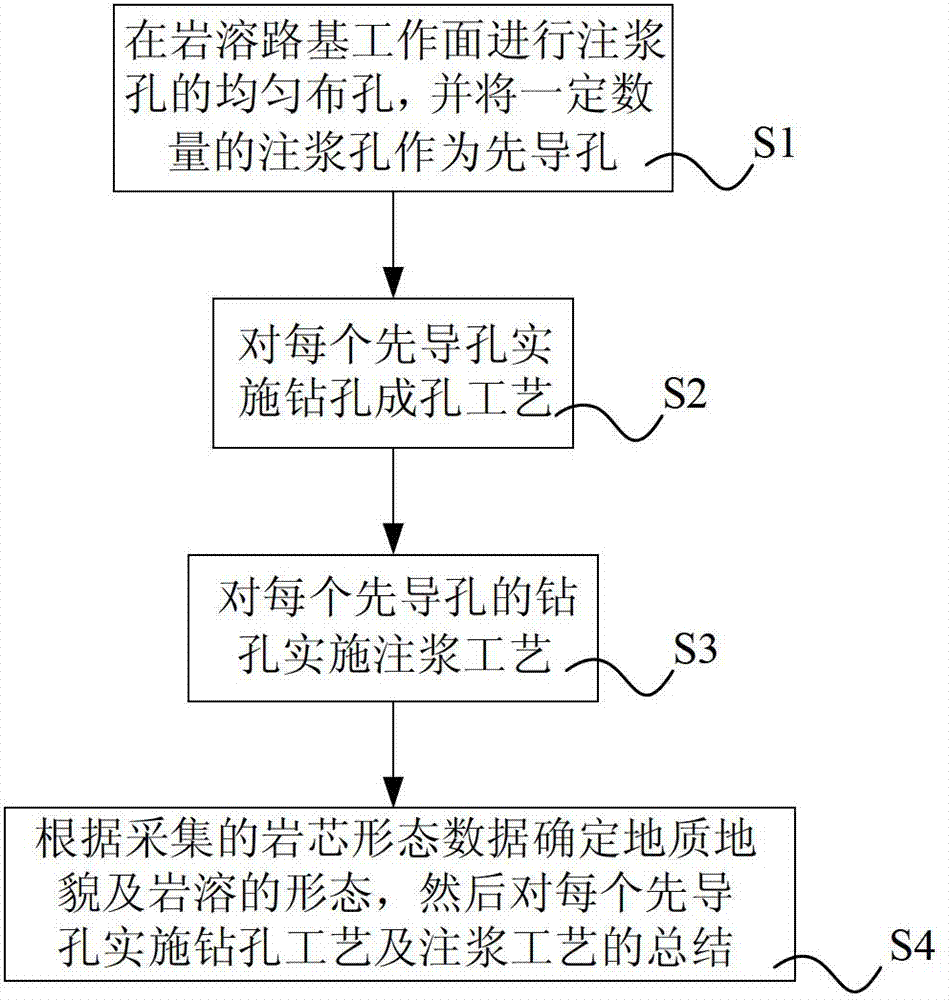

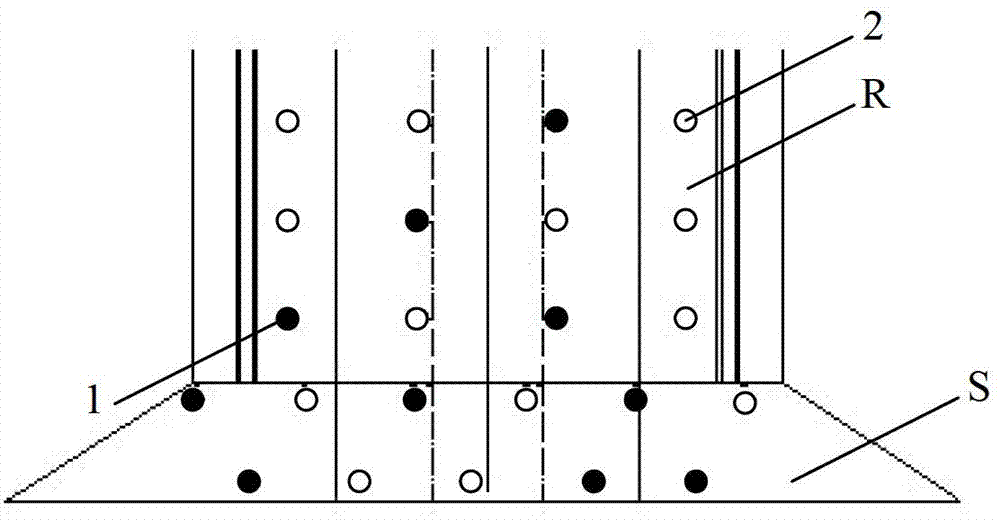

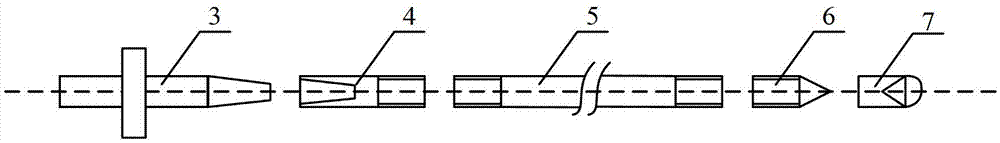

Karst roadbed grouting process

The invention discloses a karst roadbed grouting process, belonging to the technical field of grouting processes. According to the karst roadbed grouting process, a certain number of grouting holes are selected as pilot holes; rock core morphology data are obtained while the holes are drilled so as to confirm the morphology of rock cores, thereby determining a grouting scheme of the grouting holes, for example, for large karst caves, sand can be grouted firstly and grout can be filled secondly, and for small karst caves, the grout can be filled directly, so that the grouting quantity can be controlled well, and the grouting effect is ensured; the hole drilling and grouting of later grouting holes can be instructed by using the geological condition and construction processes summarized from the pilot holes; the grouting can be carried out on a large number of normal holes, thereby being beneficial for construction of large area; by adopting a CS (Cement-Sodium Silicate) double liquid grouting mode, the time in initial set and final set is greatly shortened, the rigidity and strength of the grout after being solidified are ensured, and the instant construction after the grouting is realized.

Owner:CHINA RAILWAY 19 BUREAU GRP CO LTD

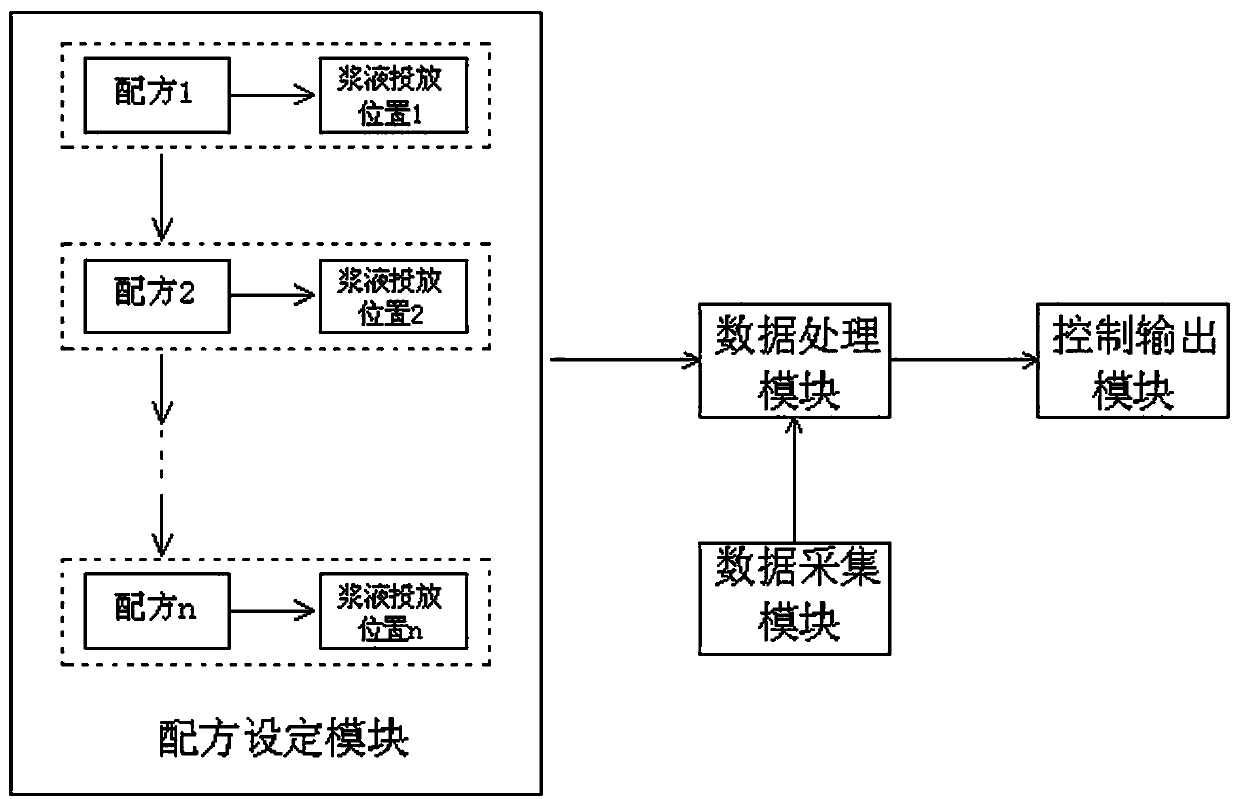

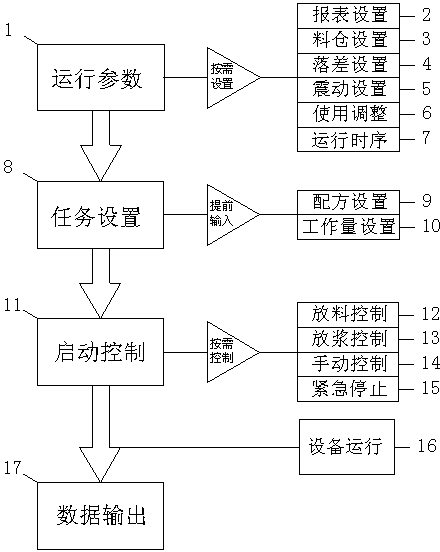

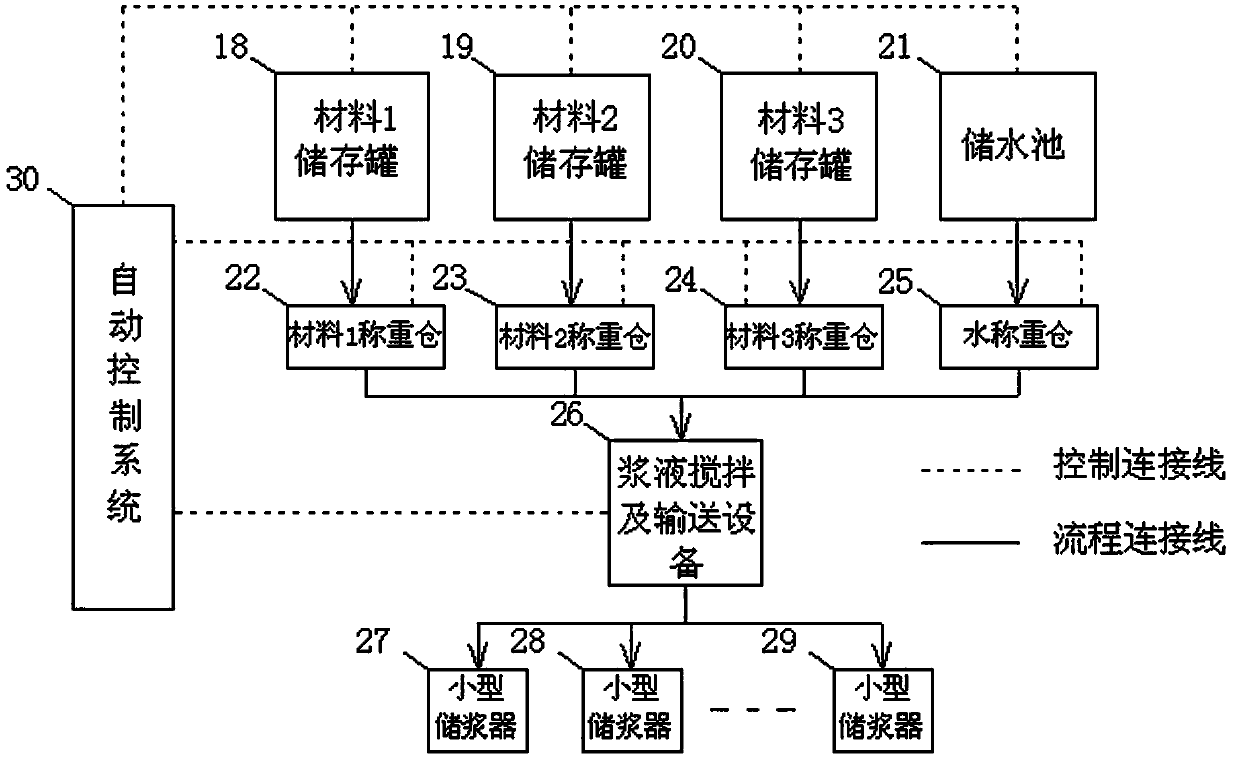

On-site automatic preparation system for mixed injection slurry

ActiveCN103806447APrecise ratioRealize ready-to-useFoundation engineeringSocial benefitsAutomatic control

The invention provides an on-site automatic preparation system for mixed injection slurry, and relates to the technical field of mine curtain slurry injection or water conservancy anti-seepage slurry injection. External hardware equipment comprises weighing and adding equipment, slurry stirring equipment and slurry conveying equipment, wherein the slurry stirring equipment structurally comprises a stirring tank, and a pumping and jet flow water pump is connected with an inner cavity of the stirring tank through a slurry inlet pipe and a slurry outlet pipe. The external hardware equipment is in communication connection with central control equipment, power distribution control enables signals to be transmitted accurately and achieves accurate control over the equipment, and a single worker can independently finish continuous preparation of the slurry. A computer of the central automatic control equipment sends control instruction signals to the external hardware equipment according to the needed preparation proportion of the slurry and a corresponding slurry storage device. The on-site automatic preparation system for the mixed injection slurry achieves the purpose that the slurry is used once being prepared, avoids waste of the slurry, is easy and convenient to operate, can be operated only by one worker, saves manpower and material resources, guarantees the quality of the slurry, and largely improves economic and social benefits.

Owner:NORTH CHINA ENG INVESTIGATION INST

Hole sealing grout stop material and grouting hole sealing process

The invention discloses a hole sealing grout stop material, which is a hole sealing grout stop material for guaranteeing grouting pressurization under the condition of loose permeable rock-soil body, high underground level or confined water. The hole sealing grout stop material is mainly prepared from clay primary grout, cement and sodium metaaluminate, wherein every 2 L of clay primary grout is mixed with 700-900 g of cement and 12.5-17.5 g of sodium metaaluminate. A grouting hole sealing process comprises hole sealing operation and grouting operation, wherein the hole sealing operation specifically comprises the following steps of: after forming a hole, dropping a grouting pipe to the bottom of the hole and mounting a orifice closer; opening the orifice closer and injecting the hole sealing grout stop material; closing the orifice closer and flushing the grouting pipe by using stable grout; and opening the orifice closer, performing grouting operation after solidifying the hole sealing grout stop material, and guaranteeing reliable hole sealing grouting through continuous lift grouting. The grouting hole sealing process has the advantages of simple steps, less equipment investment, high applicability, capabilities of guaranteeing the reliability of the hole sealing grout and increasing the grouting efficiency and the like.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

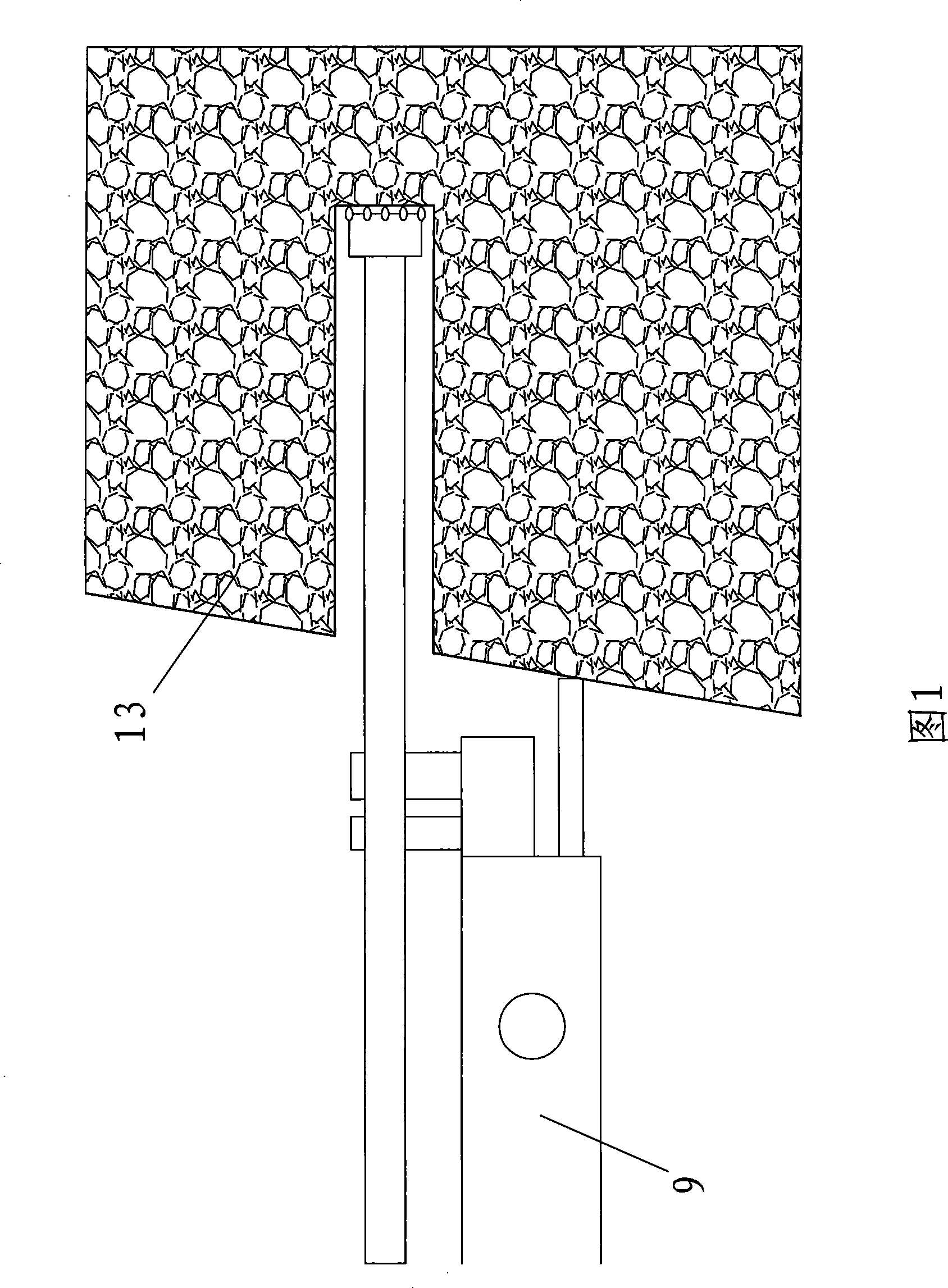

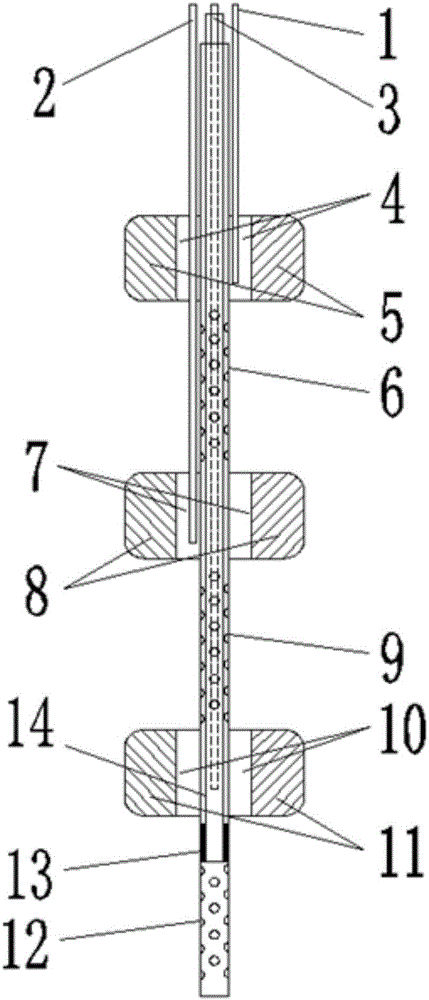

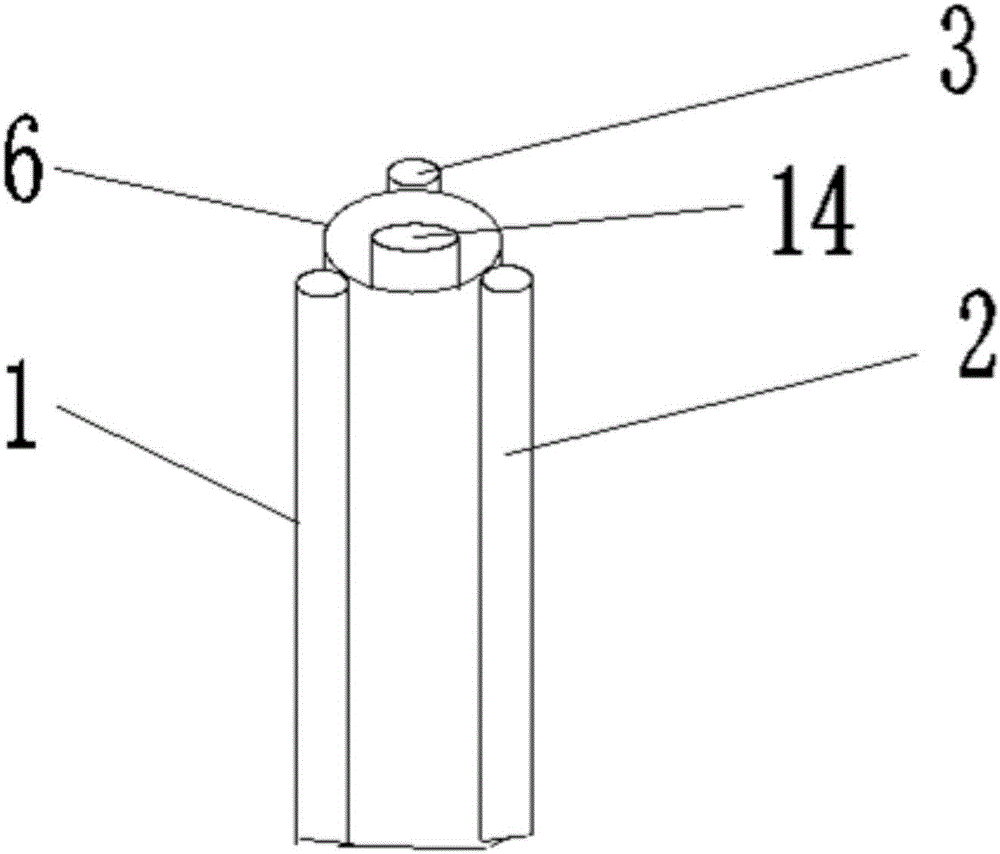

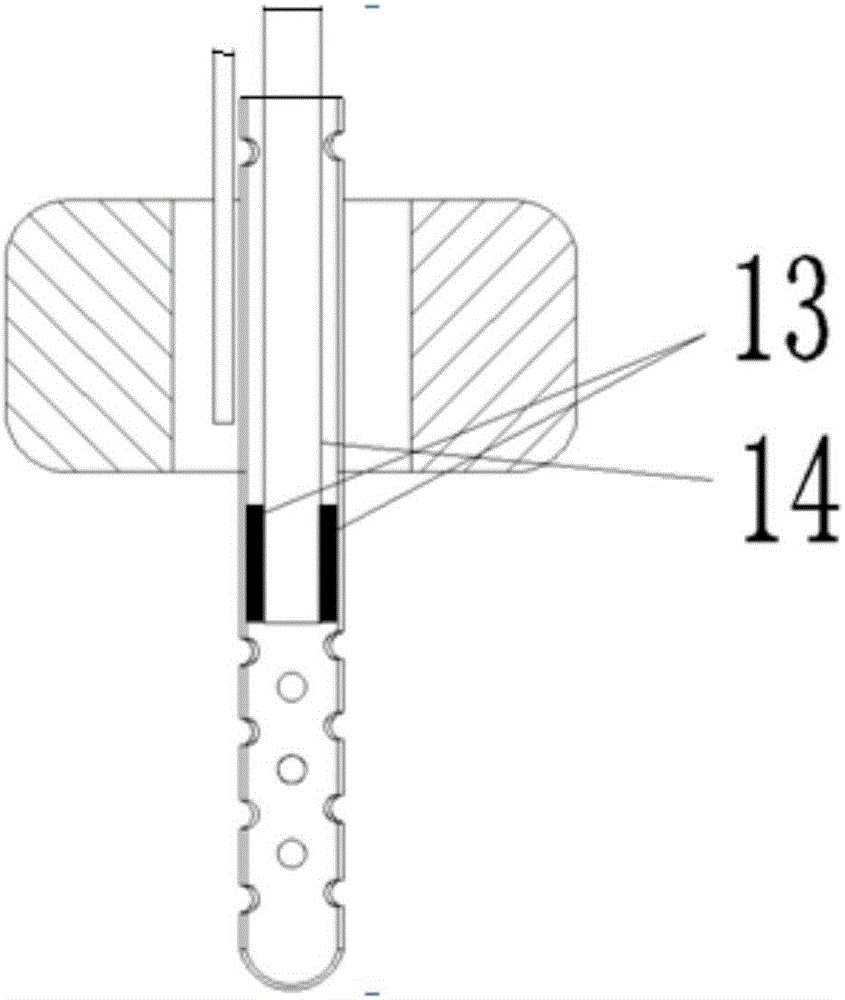

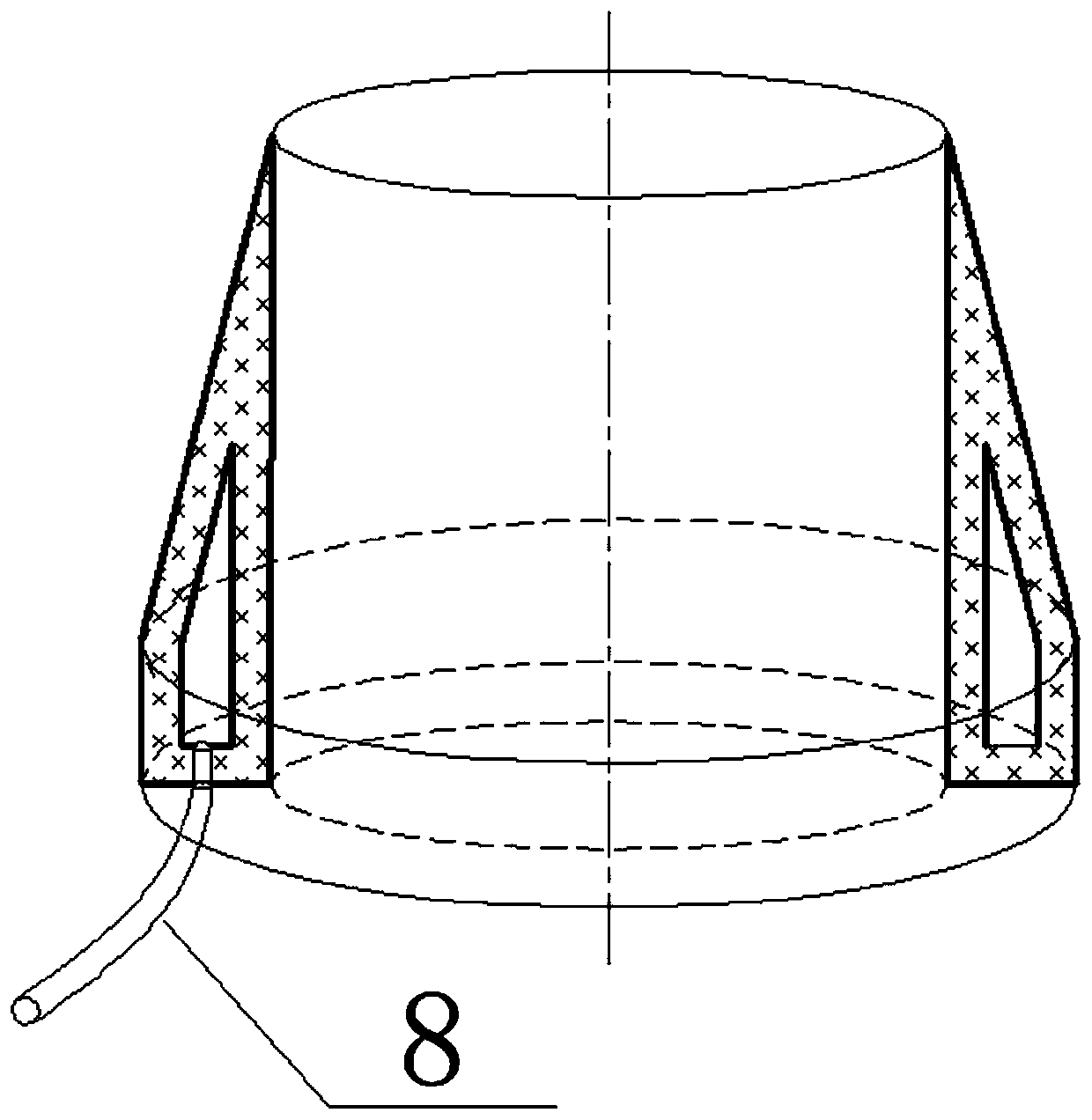

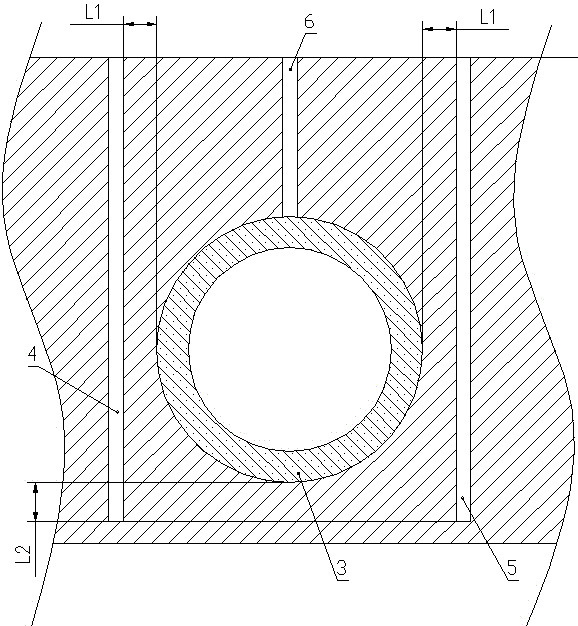

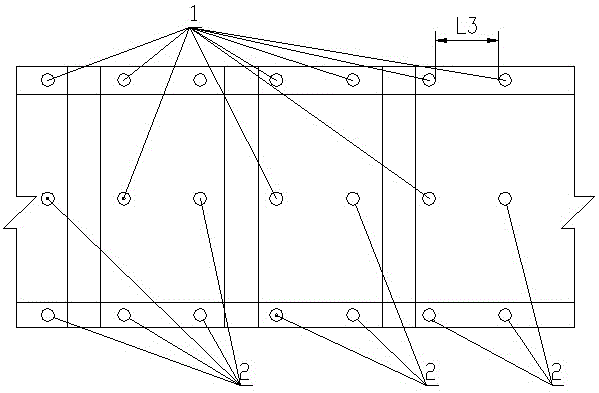

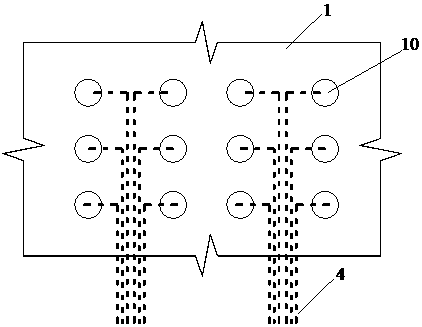

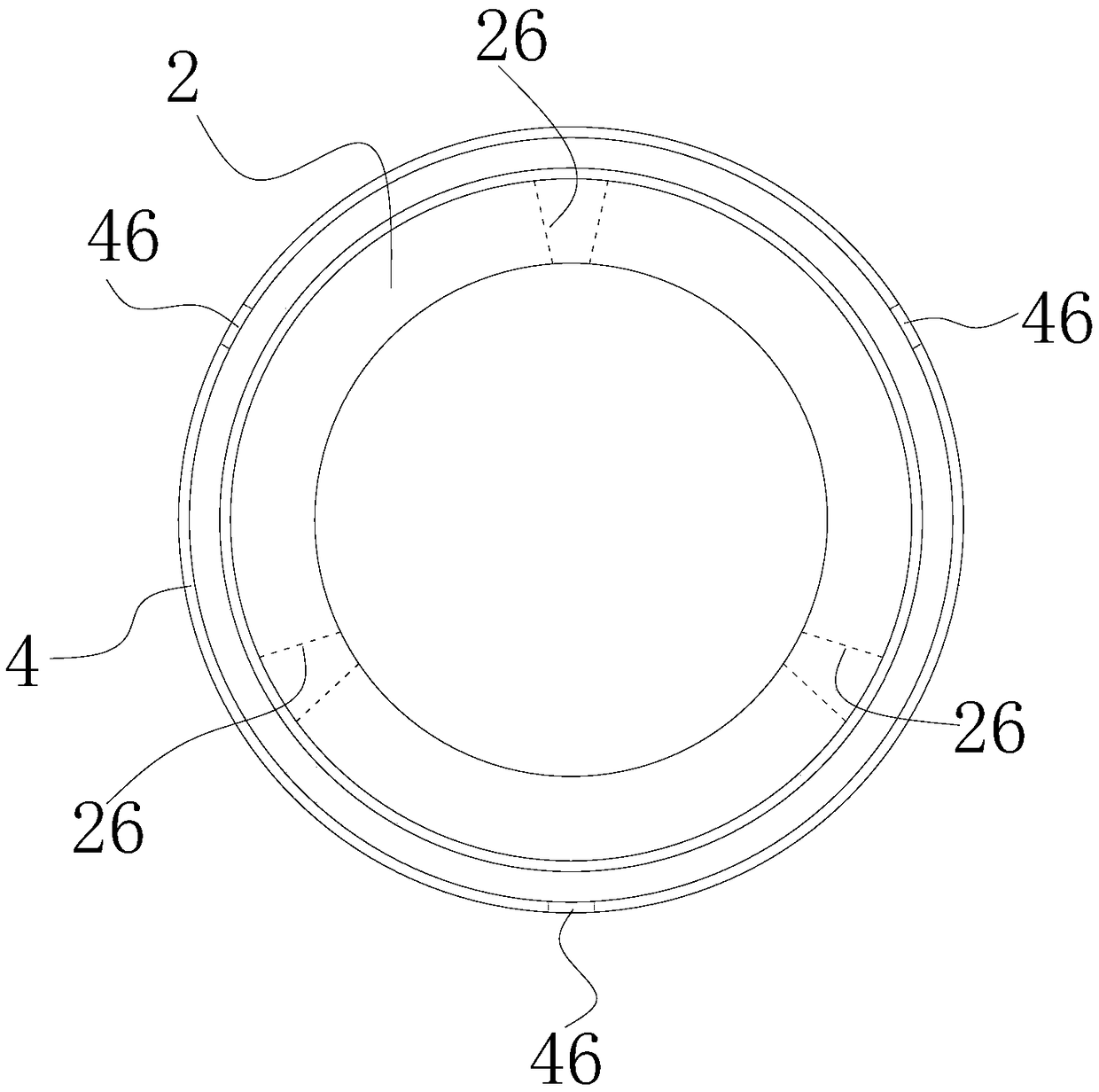

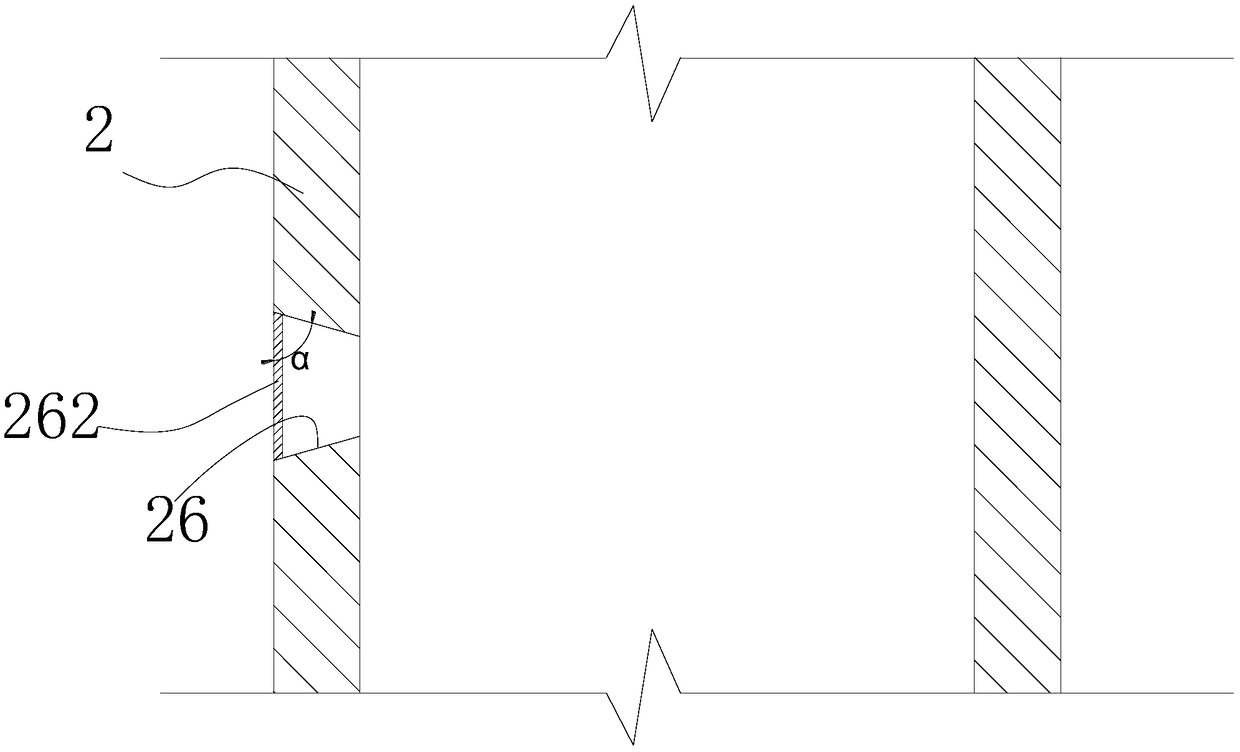

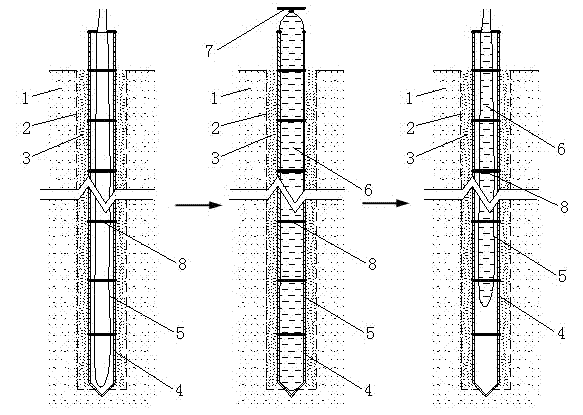

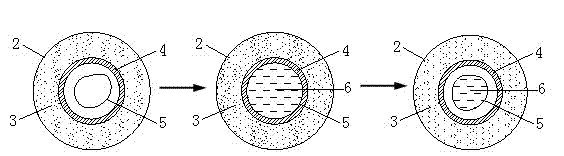

Series mold bag retrusive type subsection slip casting device and slip casting method

InactiveCN106677160AGuaranteed grouting effectDiffusion limitationSoil preservationSteel tubeGalvanization

The invention relates to a series mold bag retrusive type subsection slip casting device and slip casting method. The series mold bag retrusive type subsection slip casting device comprises a series mold bag device, a retrusive type slip casting pipe and the like; the series mold bag device is composed of three different-length mold bag slip casting steel pipes outside galvanized steel sleeves, an upper mold bag, a middle mold bag and a lower mold bag; slurry outlet holes are distributed in non-mold-bag zones of the galvanized steel sleeves, the mold bag slip casting steel pipes are bundled to the galvanized steel sleeves through iron wires, each slip casting steel pipe corresponds to one corresponding mold bag, the mold bags include the upper mold bag, the middle mold bag and the lower mold bag, and the mold bags are bundled to the galvanized steel sleeves through iron wires; and the retrusive type slip casting pipe is composed of a slip casting pipe, a slurry stopping plug and the like. The invention further discloses a using method of the device. According to the characteristics of retrusive type subsection slip casting, after the mold bags are supported through slip casting, a stratum is naturally divided into three slip casting sections, and conditions are provided for retrusive type subsection slip casting slurry diffusion; and meanwhile, the stratum is extruded in the mold bag supporting process, and subsection slip casting is facilitated.

Owner:SHANDONG UNIV

Vented anchoring and grouting device for common anchor rod and using method thereof

ActiveCN110230511ADoes not affect the support effectGood support effectAnchoring boltsEngineeringBuilding construction

The invention discloses a vented anchoring and grouting device for a common anchor rod and a using method thereof. The vented anchoring and grouting device includes an anchor rod, fastening nuts, a sealing washer, a venting grouting composite end socket, a tray, a venting grouting integrated pipe, an inflatable elastic grouting-stop plug, a guide protection cover, a sealing dustproof film, and ananchoring agent. According to the vented anchoring and grouting device for the common anchor rod, a venting passage and a grouting passage are separately arranged, and the venting grouting composite end socket is fixed in a borehole through the inflatable elastic grouting-stop plug; and according to the vented anchoring and grouting device for the common anchor rod and the using method thereof, inthe process of mounting the common anchor rod, by adding the device, a mounting hole can be directly used as a grouting hole for grouting without affecting normal pre-tightening force reinforcement of the common anchor rod, while a rock mass is reinforced, a common end socket anchoring anchor rod is changed to full length anchoring, the vented anchoring and grouting device solves the problems ofventing and plugging in the processes of anchoring and grouting support and grouting, the grouting effect is improved, and construction workload and the support cost of anchoring and grouting are reduced.

Owner:ANHUI UNIV OF SCI & TECH

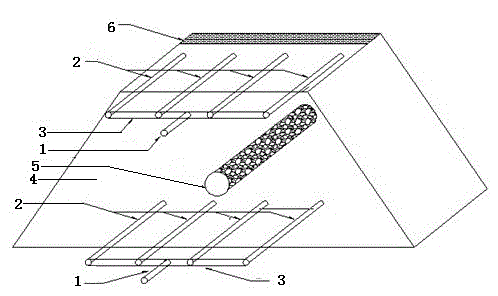

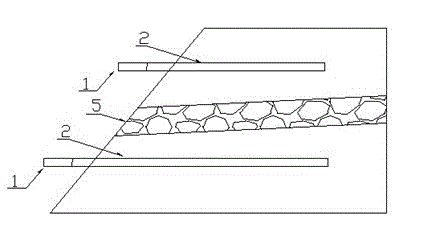

Roadbed subsidence grouting treatment structure and construction method thereof

ActiveCN103334371AGuaranteed StrengthGuaranteed grouting pressureGround-workRoads maintainenceStructural engineeringGeotechnical engineering

The invention discloses a roadbed subsidence grouting treatment structure and a construction method thereof. The roadbed subsidence grouting treatment structure comprises a plurality of rows of grouting pipe groups which are arranged on both sides of a central division strip of a roadbed and inserted at the interior of the roadbed horizontally from the outer side of the roadbed, wherein each row of grouting pipe groups comprise a plurality of grouting pipes; a plurality of grouting pipes in the same row are exposed at one end of the outer side of the roadbed and are communicated with one side of a same connecting pipe; the other side of the connecting pipe is communicated with a grouting main pipe; and drainage sewers in the same direction as the grouting pipes are arranged between two adjacent rows of grouting pipe groups. The grouting effect of a plurality of grouting pipes can be ensured, and accumulated water in the roadbed is drained in time; and moreover, the construction technology is simple, and the manufacturing cost is low.

Owner:CENT SOUTH UNIV

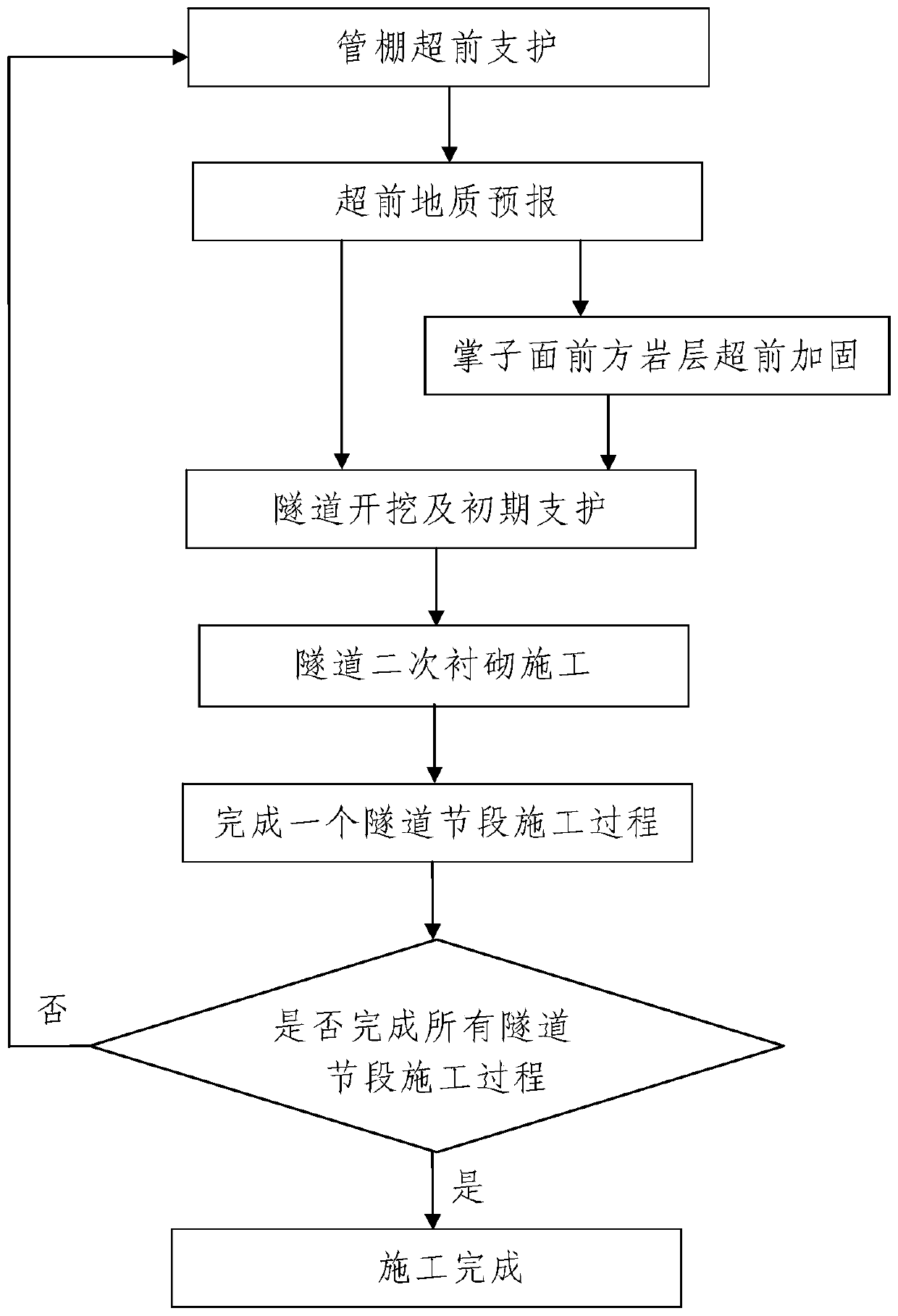

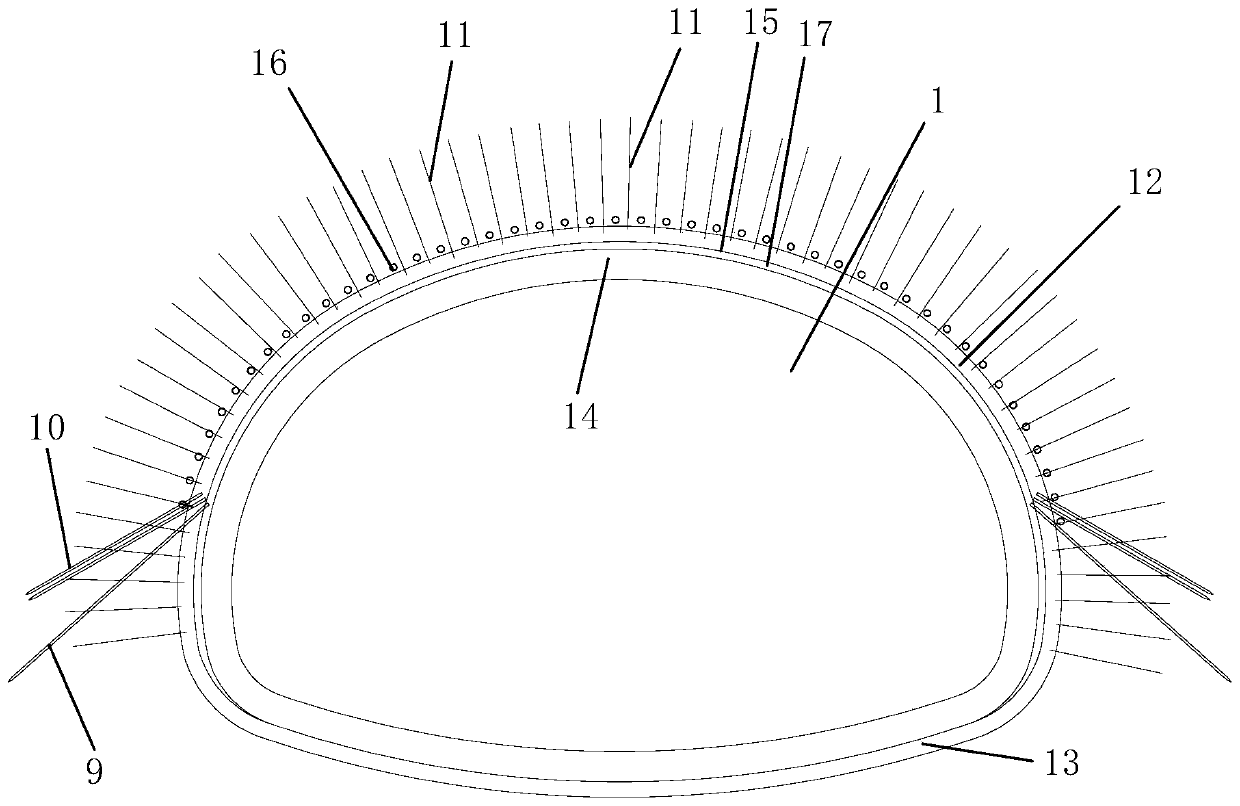

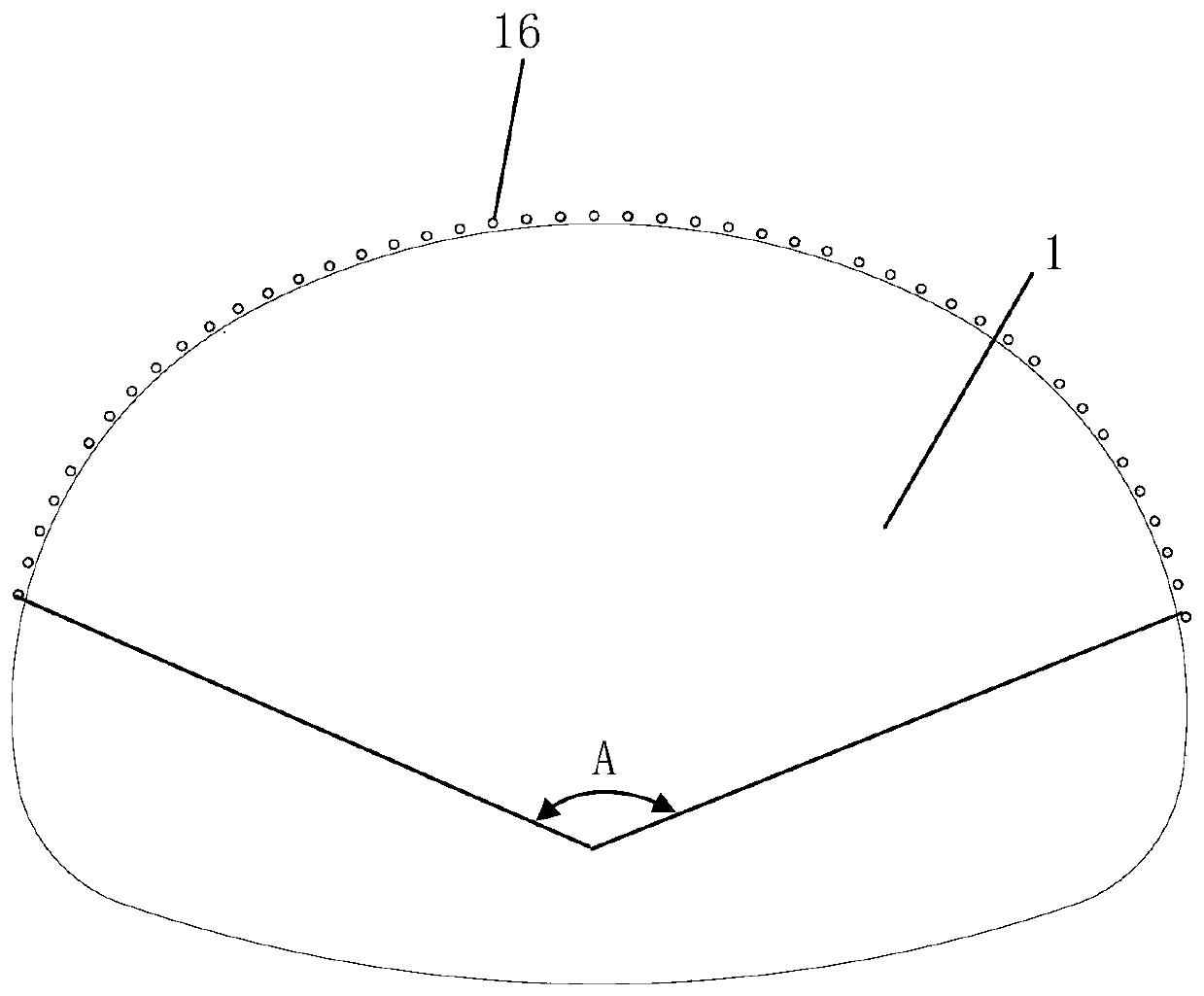

Stability control construction method of water-enriched soft rock tunnel passing through fault crushed zone

ActiveCN110905530AThe method steps are simpleReasonable designUnderground chambersDrainageSupporting systemArchitectural engineering

The invention discloses a stability control construction method of a water-enriched soft rock tunnel passing through a fault crushed zone. A plurality of tunnel segments in a construction tunnel are constructed respectively from back to front. During construction of any one of the tunnel segments, the method comprises the following steps: 1, performing pipe shed forepoling; 2, performing tunnel excavation and preliminary bracing: performing upper peripheral side cavity excavation and preliminary bracing, performing a reserved core soil area cavity excavation and preliminary bracing, excavatingthe cavity which is excavated firstly and performing preliminary bracing as well as excavating the cavity which is excavated secondly and performing preliminary bracing; and 3, performing tunnel secondary lining construction. The method is reasonable in design, simple and convenient in construction and good in use effect; before excavation, the upper cavity is subjected to forepoling by a self-drilling pipe shed and is excavated by a two-step method, so that the excavation efficiency is effectively improved; and meanwhile, an integral supporting system with a stable structure, which is formedby connecting a surrounding rock integral reinforced structure outside the cavity and a tunnel preliminary bracing structure and tunnel secondary lining, can effectively improve the stability of thetunnel structure and guarantee the later safety of the tunnel structure.

Owner:中铁二十局集团第二工程有限公司

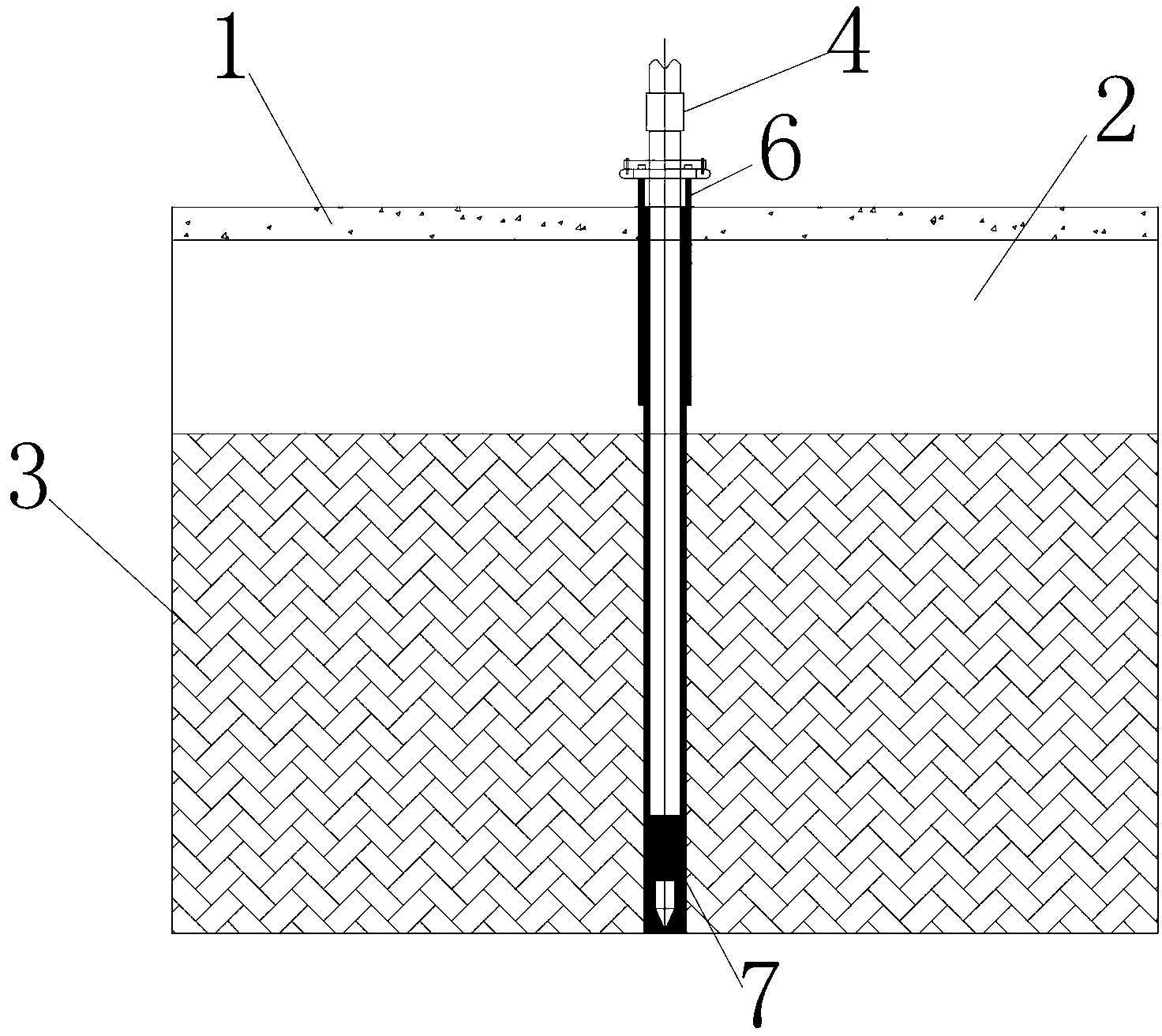

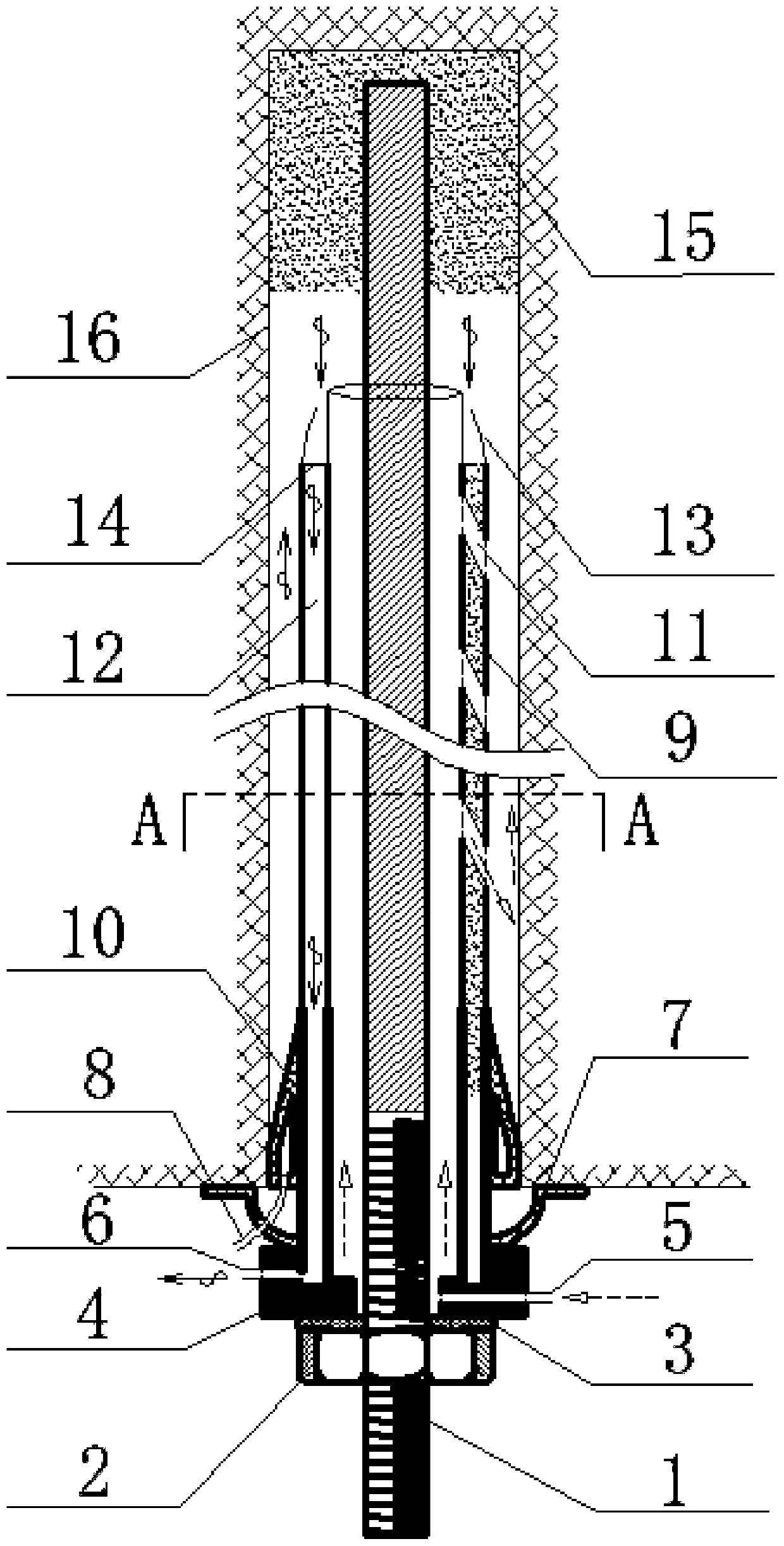

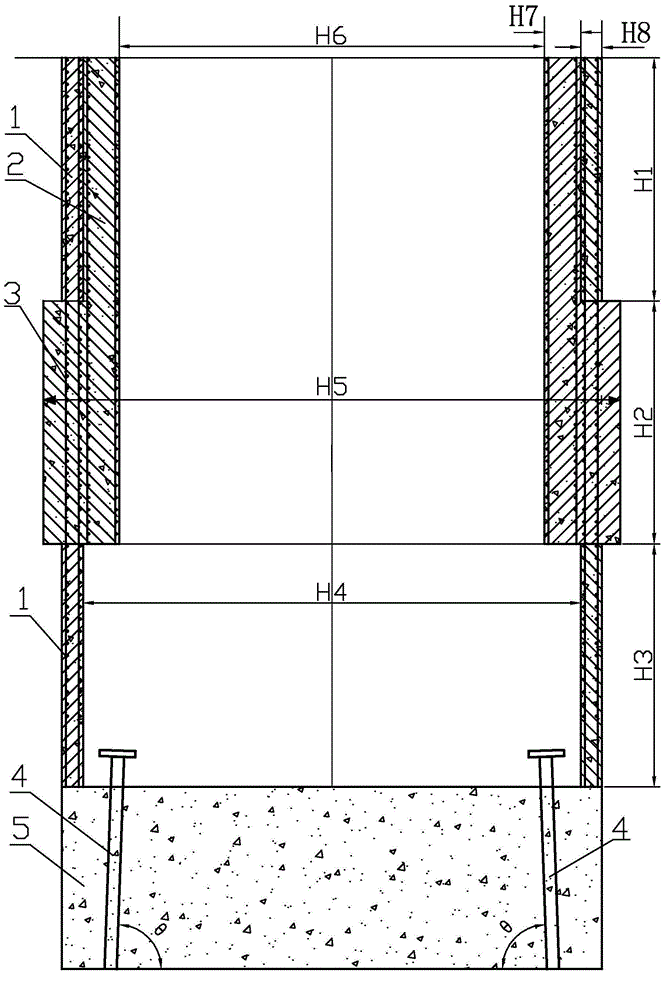

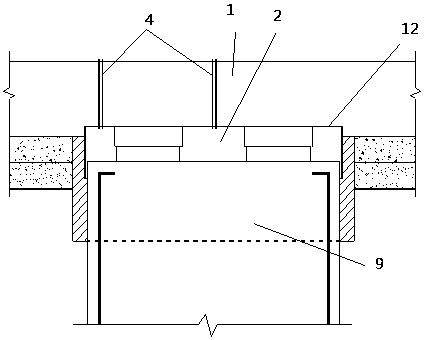

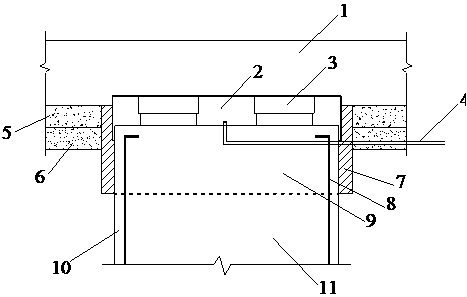

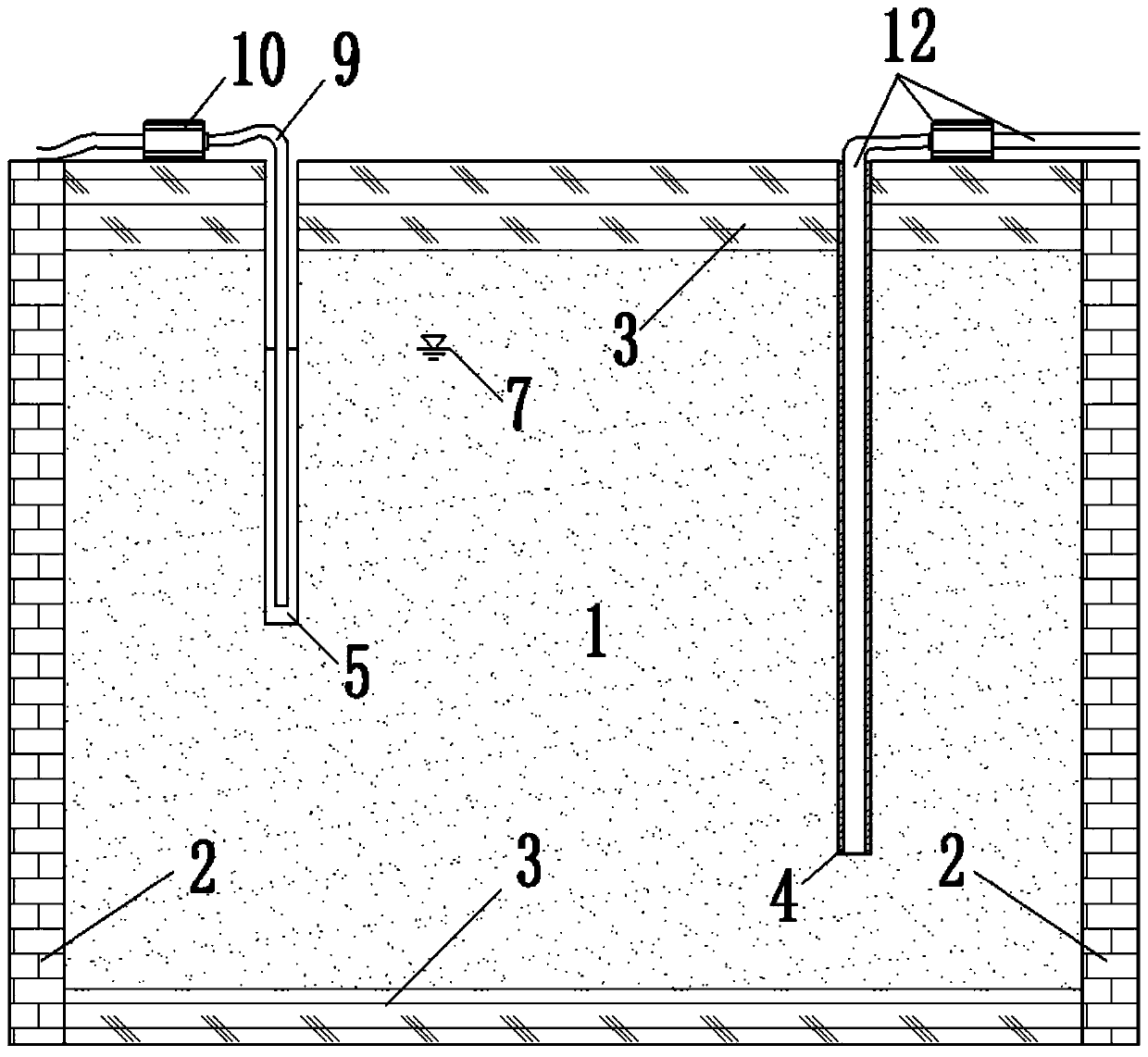

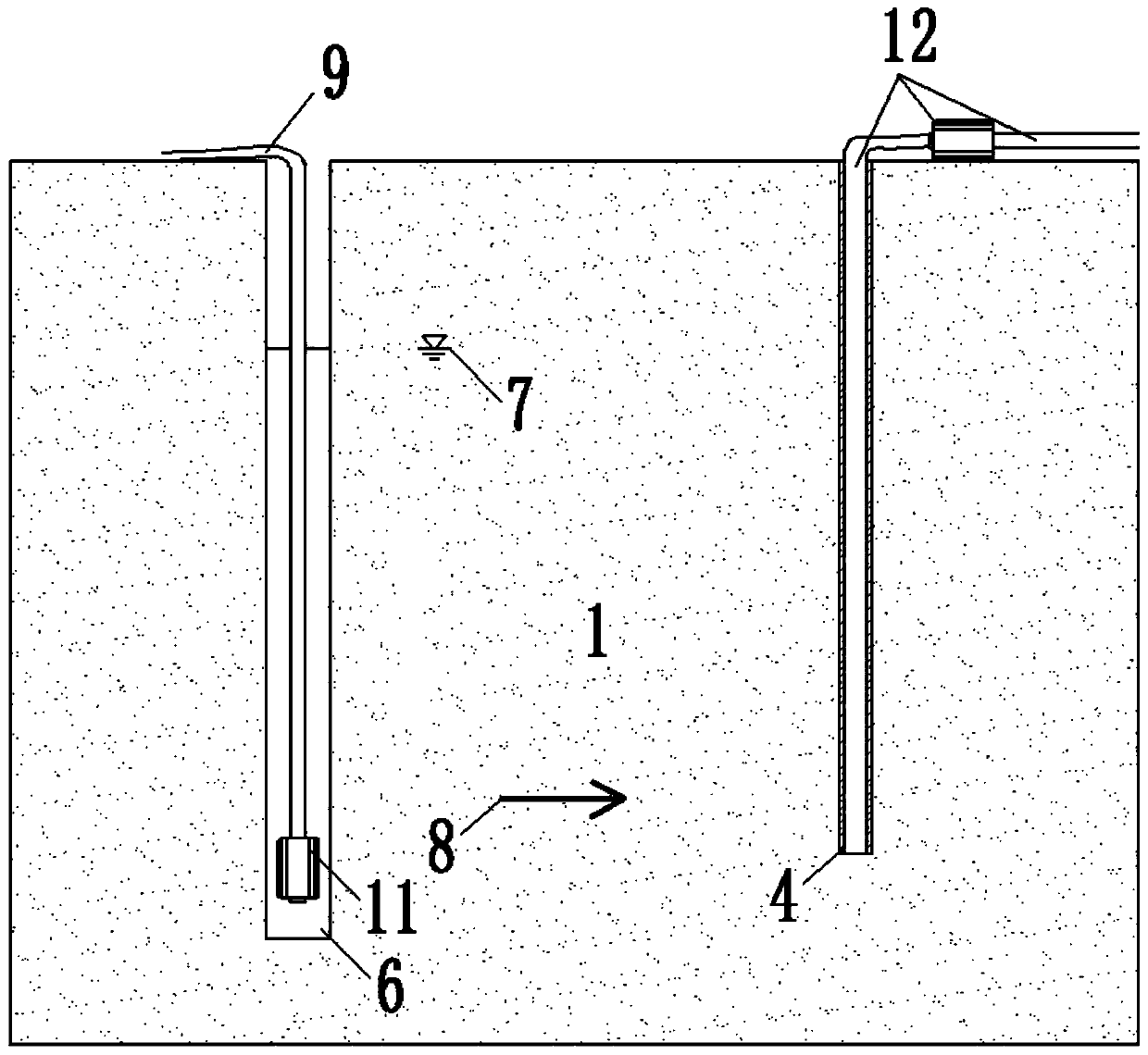

Vertical shaft overall pouring section walling crib and vertical shaft overall pouring section walling crib construction method

InactiveCN104533425AIncrease the height of the grouting sectionGuaranteed grouting effectShaft liningDrilling machinesDrill hole

The invention provides a vertical shaft overall pouring section walling crib and a vertical shaft overall pouring section walling crib construction method. The problems that a water detection drilling machine only can be arranged on the inner side of the inner wall of a shaft in the prior art, under the condition of certain drilling angle inclination, the position of a last hole can hardly exceed the range of the diameter of a pierced pipe, the radius of a formed heavy curtain is small, and the grouting effect is poor are solved. The vertical shaft overall pouring section walling crib comprises an outer shaft wall, an inner shaft wall, a shaft walling crib body, two water detection hole pipes and a grout stop pad. The two water detection hole pipes are embedded in the grout stop pad. The shaft walling crib body is connected with the outer shaft wall. The bottom end face of the shaft walling crib body is flush with the bottom end face of the inner shaft wall. The inner shaft wall is connected with the outer shaft wall. The upper end face of the inner shaft wall is flush with the upper end face of the outer shaft wall. The invention further relates to the vertical shaft overall pouring section walling crib construction method. The vertical shaft overall pouring section walling crib and the vertical shaft overall pouring section walling crib construction method are used for vertical shaft construction.

Owner:CHINA COAL ENERGY HEILONGJIANG COAL CHEM

Water proofing and leak repairing construction method for sewage pipe network below underground water level

The invention discloses a water proofing and leak repairing construction method for a sewage pipe network below the underground water level. The method is performed through the following steps that 1, sewage removal is performed on a pipeline; 2, leak points are found and marked; 3, a precipitation well is drilled, and precipitation processing is performed on a construction well point; 4, leaking stoppage is performed on the interior of the pipeline; 5, a grouting hole is drilled, and cement paste is backfilled and grouted. According to the method, a lining pipe does not need to be used, the construction cost is saved by 50% compared with the method that water proofing and leak repairing are performed on the sewage pipe network in a lining pipe mode, and the high application and popularization value is achieved; the actual available pipe diameter of the sewage pipeline cannot be reduced, and the phenomenon that the drainage capacity of the sewage pipeline is reduced due to water proofing and leak repairing cannot occur; by grouting on the exterior of the pipeline to form a grouting layer at the periphery of the sewage pipeline, the strata at the periphery of the sewage pipeline is reinforced, and effective protection on the sewage pipeline is formed to prevent formation stress from destroying the sewage pipeline.

Owner:XUCHANG WATER CONSERVANCY CONSTR ENG CO LTD

Construction device for sealing and filling headspace cavity of foundation pile of composite pile

The invention discloses a construction device for sealing and filling the headspace cavity of the foundation pile of a composite pile. When secondary pouring is carried out on the pile top, a novel grouting bottom pipe is firmly welded with a main reinforcement and is poured in a secondary pile top, and the pipe orifice is inserted in the cavity of the pile top; the novel grouting bottom pipe at the external part of the foundation pile is embedded in foundation soil shallow stratum and is led to the ground from the side face of a raft plate. Compared with the traditional grouting method, the construction device can economically and reasonably realize the grouting and sealing operation on the cavity of the pile top, ensures that the integrality of the raft plate is not destroyed and that rebar binding operation is smoothly carried out, reduces the engineering cost and improves the working efficiency.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

Grouting structure capable of filling soluble crystal and construction method

ActiveCN111794238AReduce crackingImprove negative pressure effectExcavationsBulkheads/pilesSoil scienceOutfall

The invention discloses a grouting structure capable of filling a soluble crystal and a construction method. The structure comprises a water permeating section and a grouting section, wherein a water-stop component is arranged between the water permeating section and the grouting section; a water permeating tube is arranged in the water permeating section; the solid-state soluble crystal is filledin the water permeating section; a water inlet of a water drainage tube is arranged in the water permeating section; and elevation of the water inlet of the water drainage tube is greater than that of the water outlet of the water drainage tube. The grouting structure is beneficial for increasing grouting pressure, reduces cracks of the grouting section, and improves sealing effect, so that negative-pressure effect of the water permeating section is improved; during grouting, the water-stop component can be effectively supported, and slurry is prevented from entering the water permeating section to disturb formation of a negative-pressure environment, so that blockage of the water permeating tube is avoided, the water-stop component is prevented from greater displacement as a result of extrusion, and continuous water drainage effect of a slope deep layer is favorably guaranteed, and therefore, the grouting structure is of great significance on solving the water drainage and control problem of a large slope.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

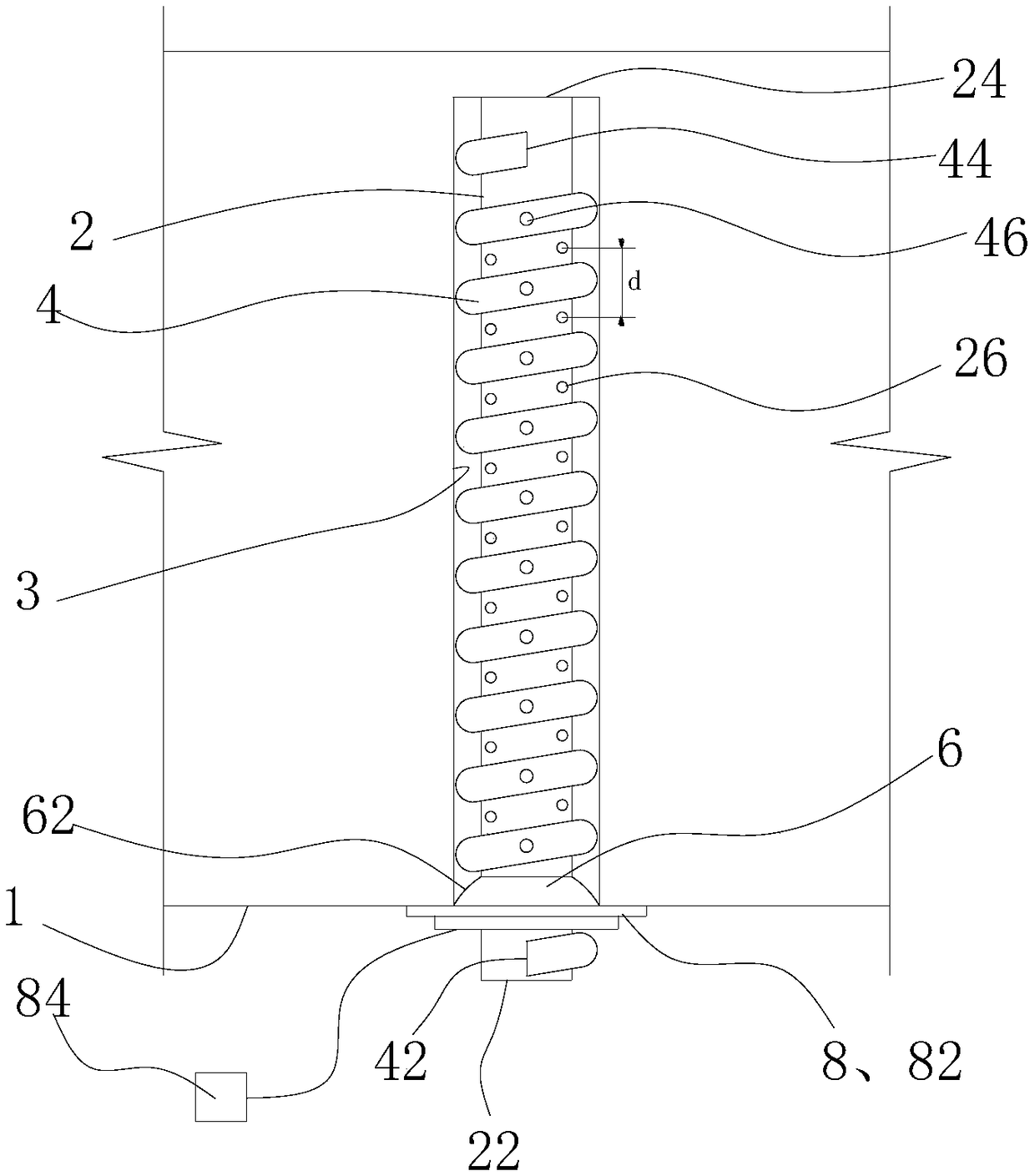

Grouting pipe with improved grouting effect and grouting process

ActiveCN109026023APrevent slurry lossGuaranteed grouting effectUnderground chambersTunnel liningEngineeringCement accelerator

The invention discloses a grouting pipe with an improved grouting effect. The grouting pipe comprises a hollow tubular body, a plurality of first spouting ports disposed on the side portion of the body and capable of spouting slurry outwards, and a branch pipe spirally surrounding the outer side of the body and provided with a plurality of second spouting ports capable of spouting the slurry outwards. Therefore, the grouting pipe has two passages including the body and the branch pipe through which mortar and a cement accelerator can be poured simultaneously and respectively. The combination of the body and the branch pipe has a better rock formation reinforcement effect, especially for water-rich rock formations. A tunnel grouting process, by using the grouting pipe of the present invention, can easily and simultaneously pour the mortar and the cement accelerator, is simple in process and has a better rock formation reinforcement effect.

Owner:江苏华设远州交通科技有限公司 +1

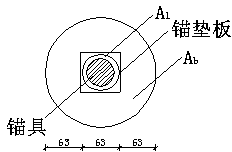

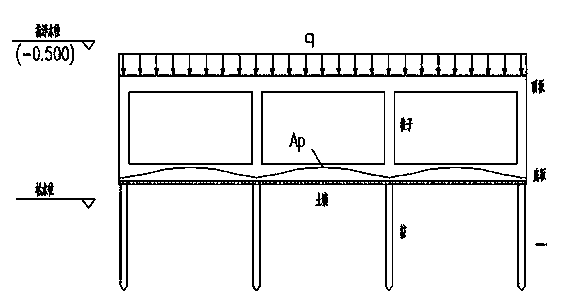

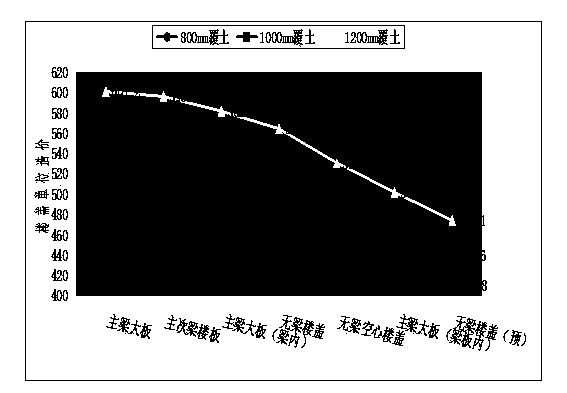

Method for designing and constructing waterproof plate for underground garage by post-tensioning bonded prestressed construction process

ActiveCN104314103ALower the altitudeLow costArtificial islandsProtective foundationPre stressArchitectural engineering

The invention relates to a method for designing and constructing a waterproof plate for an underground garage by a post-tensioning bonded prestressed construction process. The method is characterized in that the waterproof plate adopts a beamless structure comprising a bottom plate and a top plate, and is subjected to post-tensioning bonded prestressed construction; the method mainly comprises the steps of arranging bars, pouring, tensioning, grouting, and performing cutting and anchor sealing; before construction, the bar preparation scheme is determined through the lateral restraint analysis of the underground garage, and the occurrence of post-pouring belt cracks is avoided through staged tensioning and set temperature shrinkage; the tensioning end of a prestressed bar is arranged in the center of the bottom plate or a post-pouring belt region, so that the periphery can be subjected to soil covering and waterproof construction in time, and the construction period is shortened; the prestressed bar runs through the bottom of the pier cap of the pier of the bottom plate during arrangement, and a reinforcing bar does not need to be added to the pier cap, so that the cost is reduced.

Owner:江苏开来预应力工程有限公司

Tunnel water seepage and harmful gas discharge structure and semi-closed ice-filled drilling construction method

ActiveCN111810234AEfficient dischargePrevent escapeMining devicesUnderground chambersOutfallDrainage tubes

The invention discloses a tunnel water seepage and harmful gas discharge structure and a semi-closed ice-filled drilling construction method. The structure includes a permeable pipe arranged in a permeable section of a drilling hole. The drilling hole includes the permeable section and a grouting section, the drilling hole is drilled from the side wall of a tunnel, a water stop member is arrangedbetween the permeable section and the grouting section, the permeable pipe is filled with ice, and the permeable section is internally provided with an water inlet of a drainage pipe; and the elevation of the water inlet of the drainage pipe is higher than the elevation of a water outlet of the drainage pipe, and the lift of the drainage pipe is less than the height of a water column correspondingto the atmospheric pressure. According to the tunnel water seepage and harmful gas discharge structure, harmful gases in the surrounding rock in the drainage link can be effectively discharged, the situation that the harmful gas escapes or is greatly accumulated in the surrounding rock is reduced, the safety risk is reduced, and the water-stop member can be effectively supported during grouting,the structure is beneficial to increase the grouting pressure, the negative pressure effect of the permeable section improved, and the tunnel water seepage and harmful gas discharge structure is conducive to ensuring continuous drainage and exhaust effects and is of great significance to solving the problem of tunnel water seepage and gas leakage.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

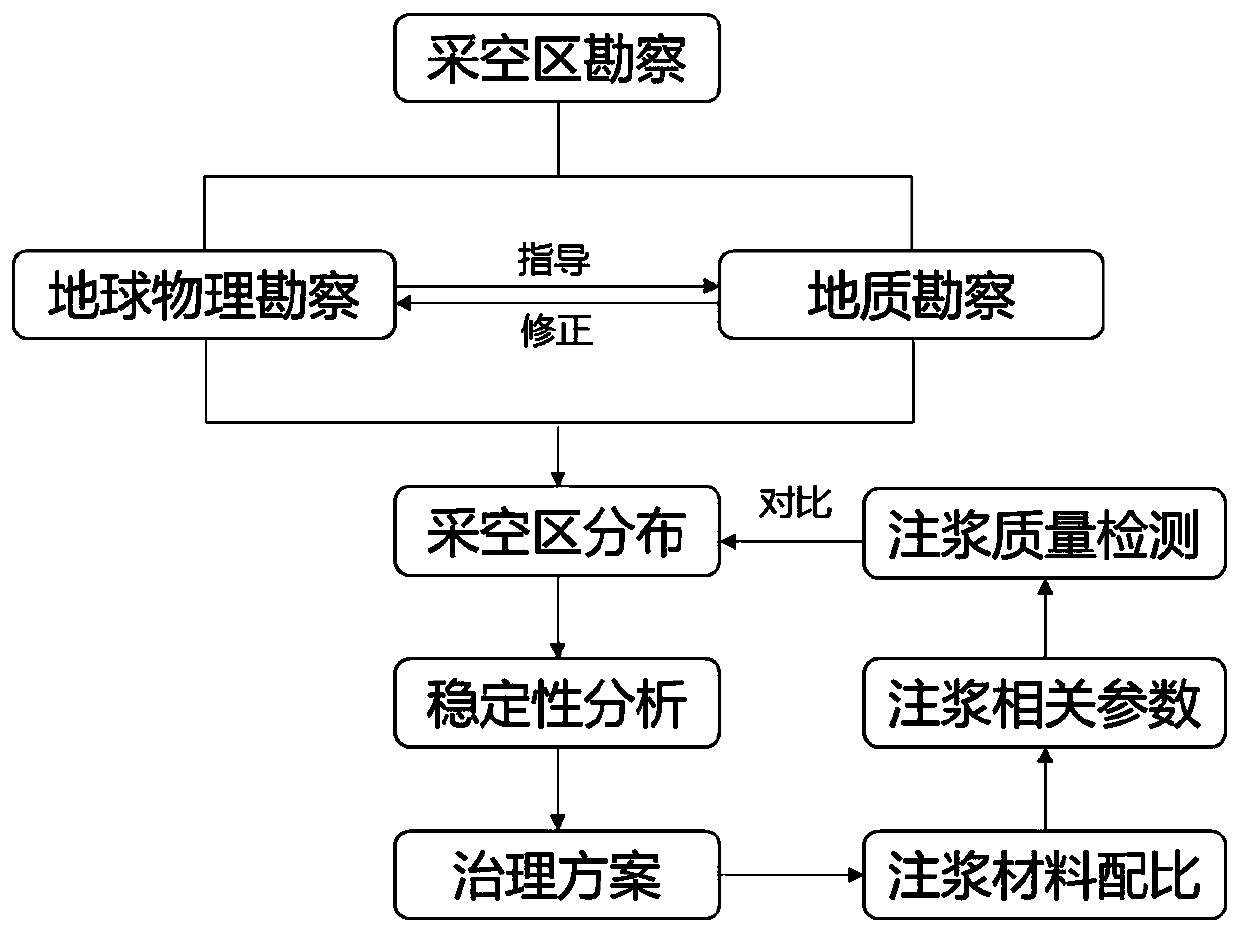

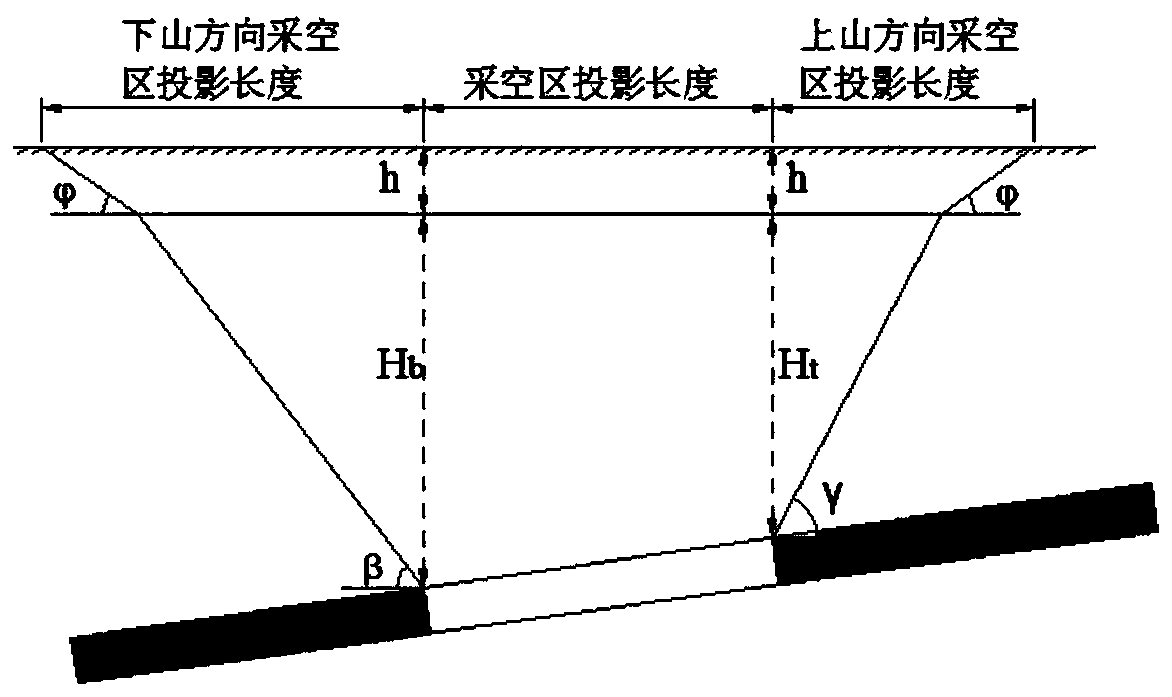

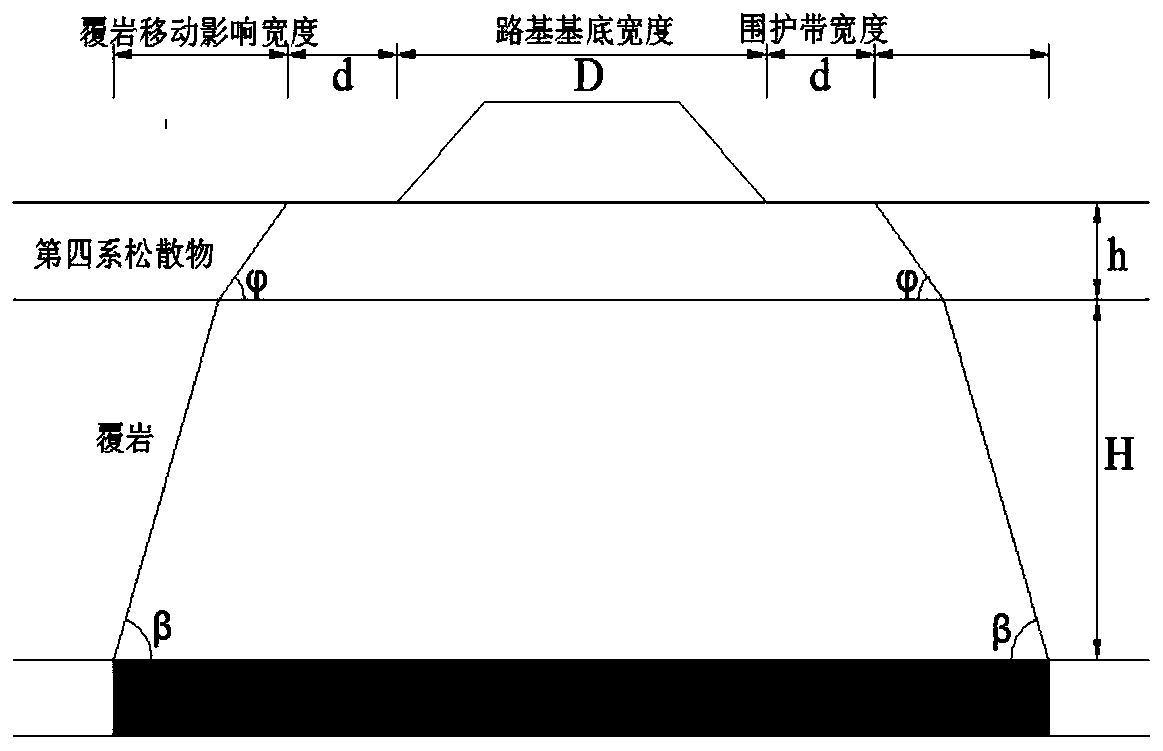

Expressway underlie warehouse type inclined coal seam goaf comprehensive-treatment method

InactiveCN111396056ACalculation Governance ScopeAccurate evaluationUnderground miningSurface miningHigh densityMining engineering

The invention discloses an expressway underlie warehouse type inclined coal seam goaf comprehensive-treatment method, and provides a comprehensive and systematic comprehensive treatment method by comprehensively considering and improving multiple aspects such as goaf reconnaissance, stability analysis, a treatment technology and grouting quality detection. Through the joint connection of geophysical prospecting and geological work, the distribution situations of a goaf, various coal mining situations and coal seam essential characteristics are accurately obtained. By comprehensively considering cavity distribution, buried depth, overlying rock performances, roadbed types (excavation and embankment) and other factors, and referring to current domestic implemented projects and relevant regulations, a treatment range of the goaf is accurately calculated. According to the expressway underlie warehouse type inclined coal seam goaf comprehensive-treatment method provided by the invention, the grouting quality is detected through four detection methods, namely, drilling, acoustic detection, a high-density electrical method and ground deformation detection, and detection results obtained by the different methods can be verified mutually and can be compared with exploration results, so that a treatment effect of the goaf can be intuitively and accurately evaluated.

Owner:CHANGAN UNIV

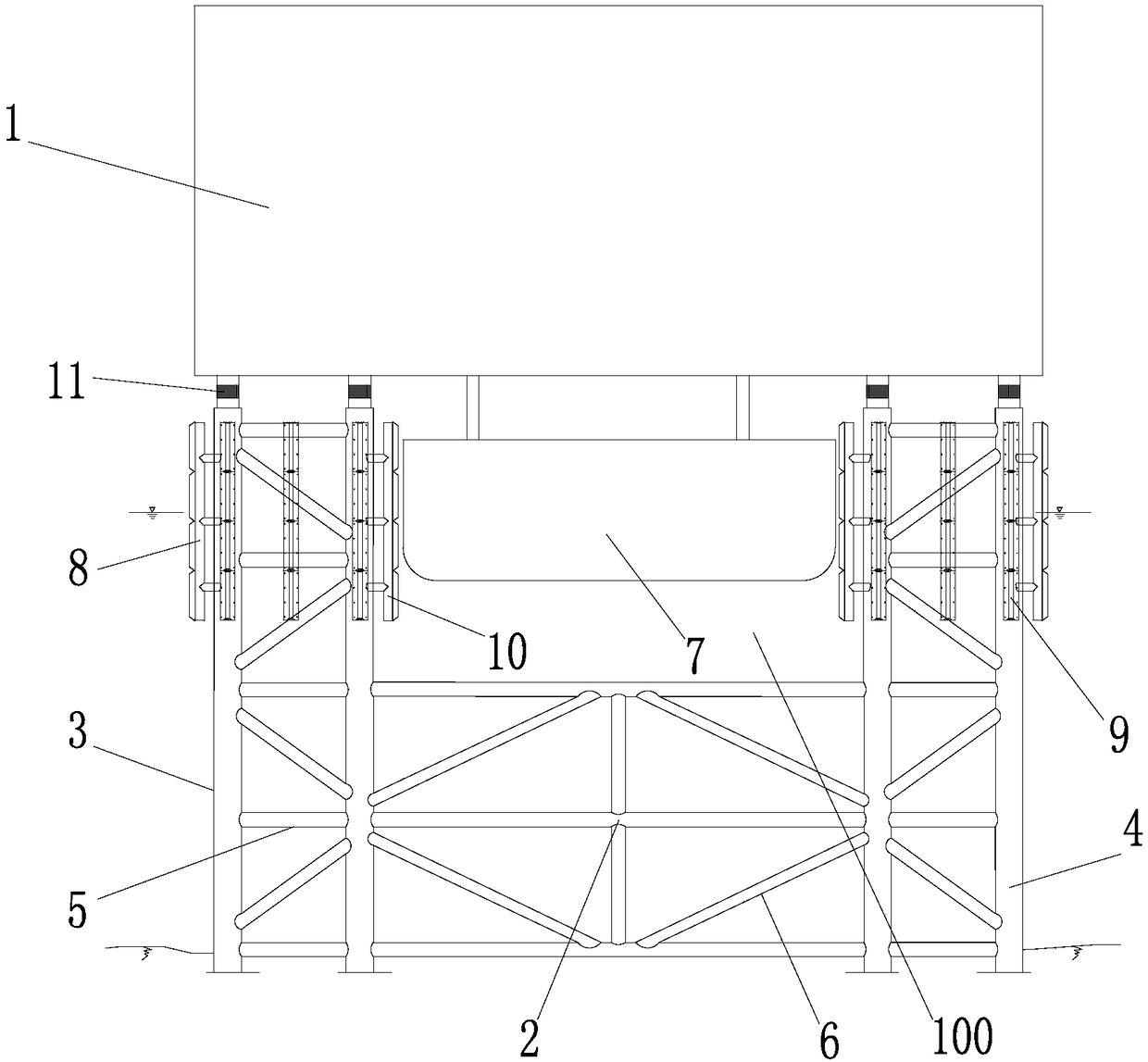

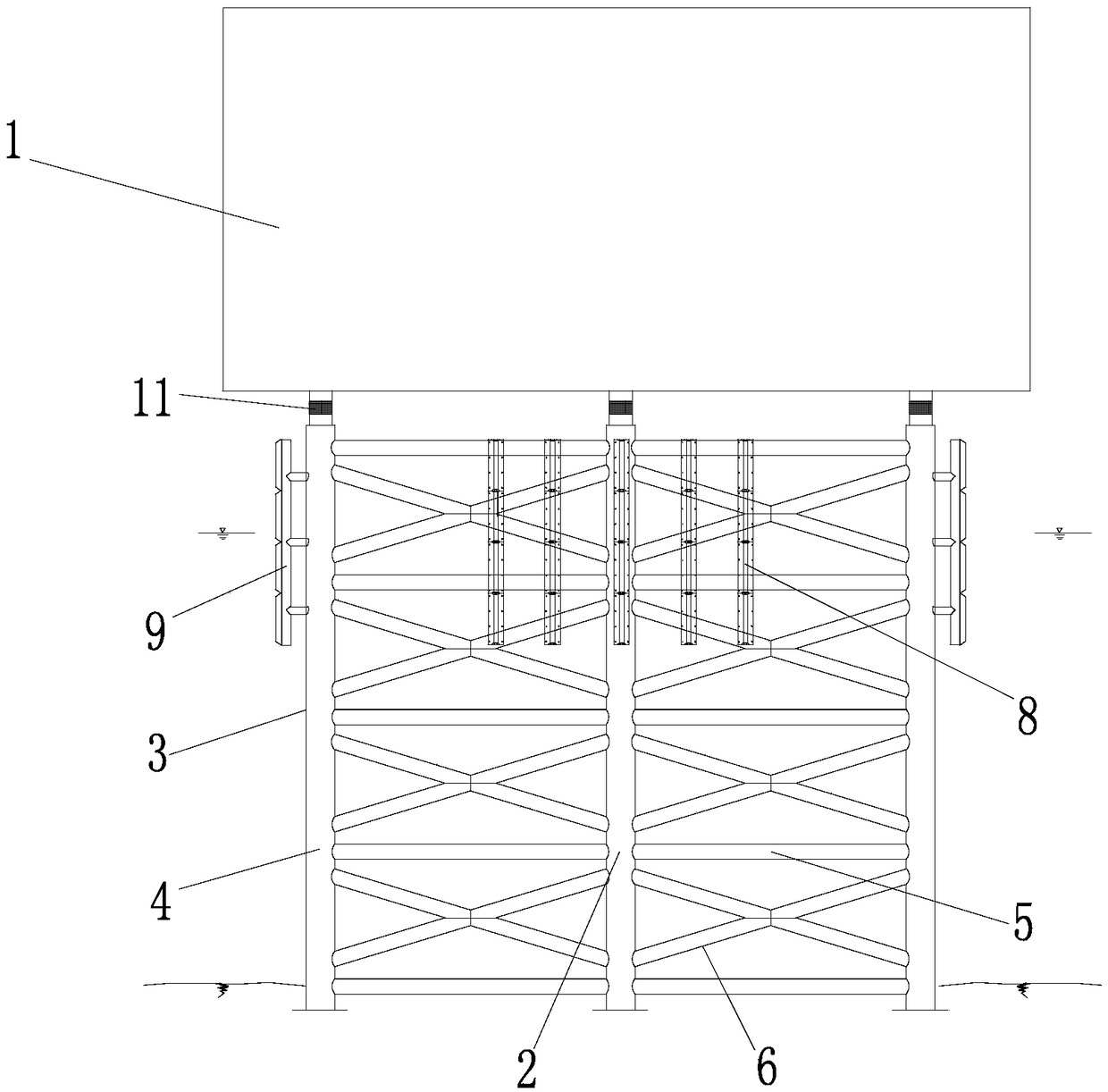

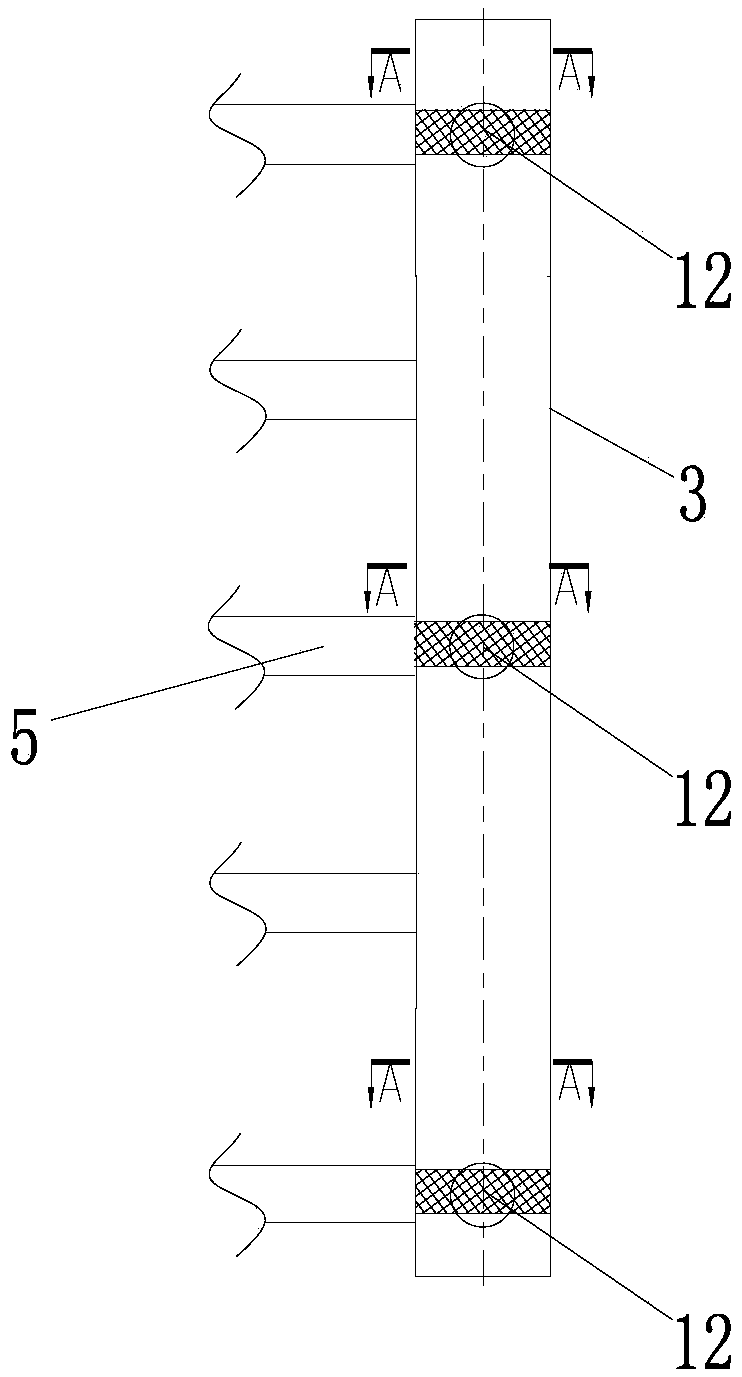

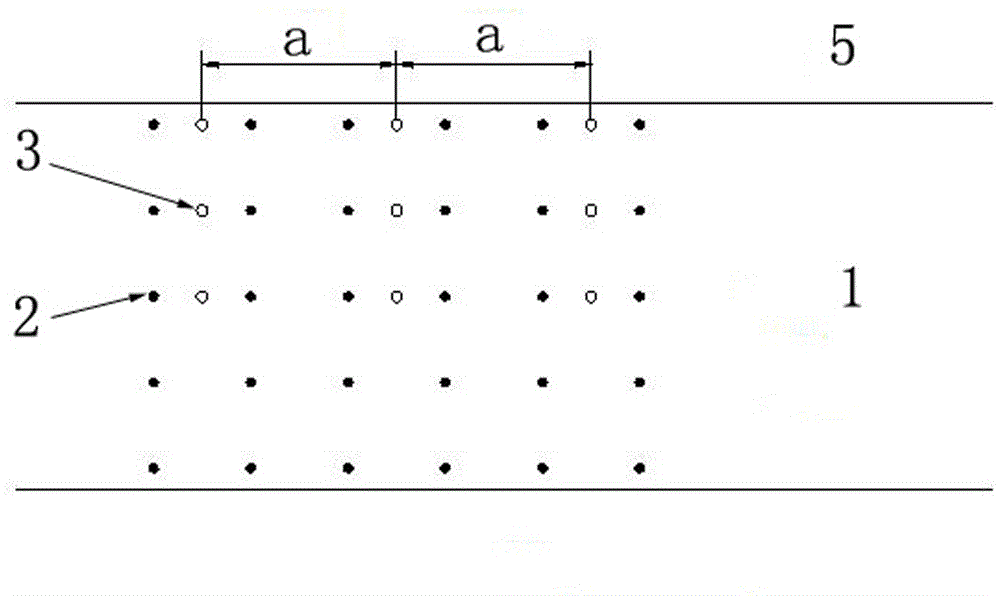

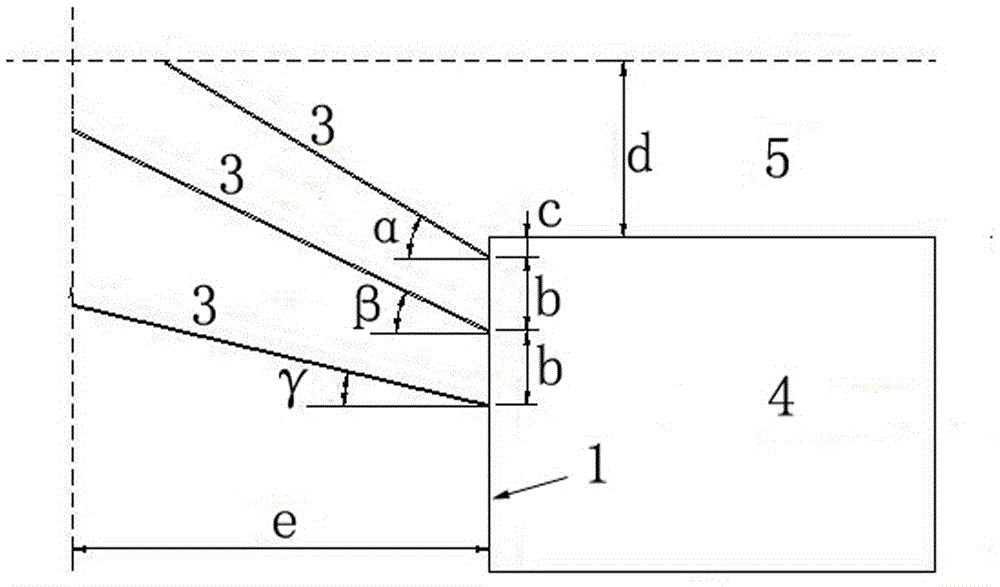

Large-scale offshore platform integral type conduit frame structure suitable for installation in deep water sea area by floating and supporting method and installation method thereof

PendingCN109267555ASafe and reliable structureEasy constructionArtificial islandsUnderwater structuresHorizontal forceStructural integrity

The invention provides a large-scale offshore platform integral type conduit frame structure suitable for installation in a deep sea area by a floating and supporting method and an installation methodthereof. The integral type conduit frame structure is formed by connecting a main conduit, a steel pipe pile, a cross brace and an inclined brace into a whole. The upper part of the integral type conduit frame is a floating and supporting method ship inlet area, and the lower part of the integral type conduit frame is a conduit frame communication area. The main conduits of the integral conduit frame are arranged on the two wings in the longitudinal direction of the platform, and a certain hollow area is reserved in the middle of the main conduit at the inner side so as to ensure the entry and exit of the barge when the floating and supporting method is used for installation. The lower communication area is a multi-layer truss structure, and the main conduits at the two sides are connected into a whole through the truss structure. The large-scale offshore platform integral type conduit frame structure suitable for installation in deep water sea area by floating and supporting method and the installation method thereof are not only suitable for installing the offshore platform by the floating and supporting method in the deep water area, but also meet the structural integrity requirement of the conduit frame in the deep water area, and can bear the vertical force transmitted by an upper electric platform and the horizontal force caused by the environmental load. The integral type conduit frame structure and the installation method thereof are also suitable for large-scale ocean platform structures arranged in other deep water sea areas.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

Working face tailgate crushed coal grouting reinforcing method

ActiveCN106761841AEarly strengthHigh terminal strengthUnderground chambersDrilling compositionElevation angleResidual strength

The invention provides a working face tailgate crushed coal grouting reinforcing method. The method solves the problem that tailgate surrounding rock is difficult to maintain due to expansion, loosening, crushing and the like. According to the method, a plurality of rows of grouting holes are formed in a coal cutting side, each row of grouting holes includes three grouting holes different in elevation angle, and grouting is conducted by means of special quick-solidified materials. By means of grouting reinforcing, the structure and properties of the surrounding rock are improved, the roadway surrounding rock bearing capacity is improved, and the crushed surrounding rock maintenance condition is effectively improved. Meanwhile, stable and reliable strength points are provided for anchor rod supporting, and the anchoring force of anchor rods in the crushed surrounding rock is improved. Besides, the brand new grouting materials are used in the method, the grouting materials are high in solidification speed, and slurry forming the high-water materials solidifies within 20-40 min, is high in early strength, quick in increase, high in residual strength, free of toxins and harm and little in corrosion.

Owner:CHINA MINING & CIVIL NEW MATERIAL SCI & TECH LTD

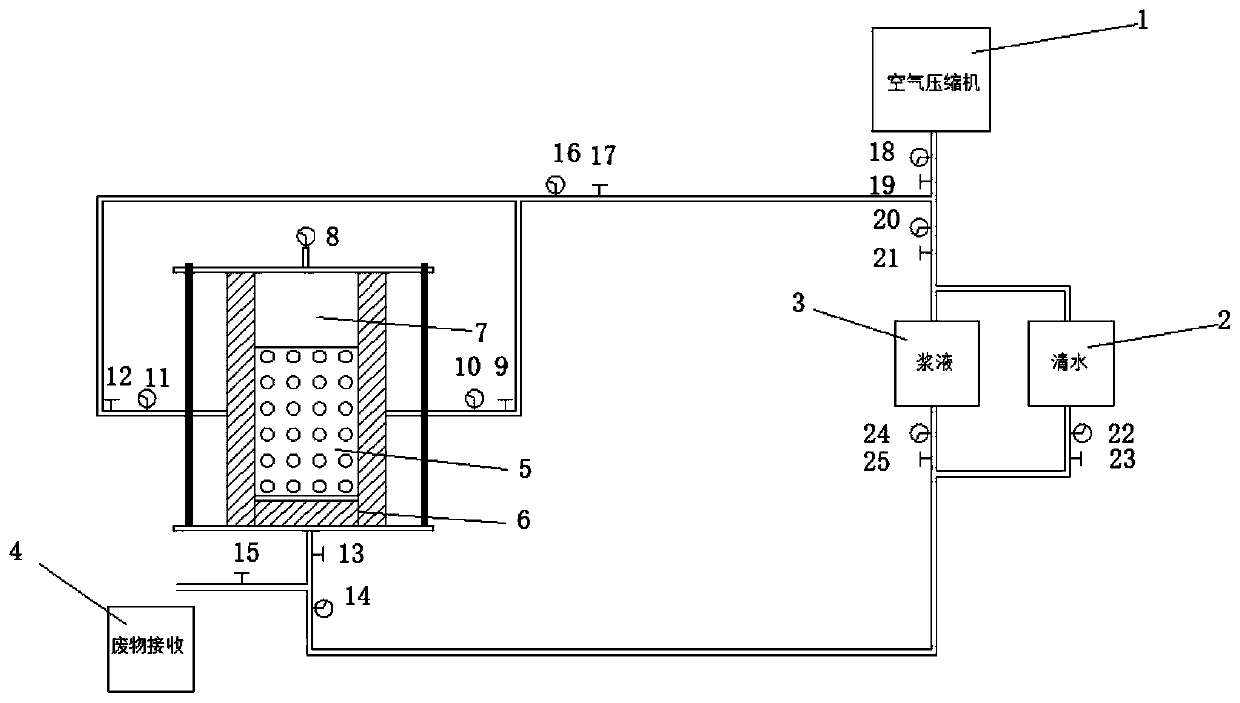

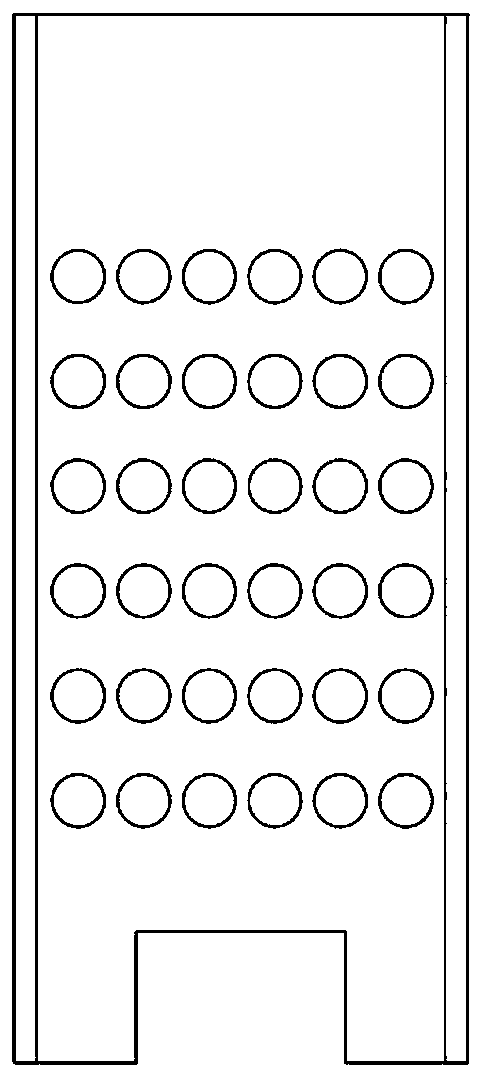

Experimental testing device for reinforcing fractured rock sample through high-pressure permeation grouting and grouting method

PendingCN111006952AGood effectRealize all-round groutingSurface/boundary effectMaterial strength using tensile/compressive forcesMicrofine cementAir compressor

The invention discloses an experimental testing device for reinforcing a fractured rock sample through high-pressure permeation grouting and a grouting method. The experimental testing device comprises a grouting sample loading area, a grouting device and a cleaning device, wherein the grouting device comprises an air compressor and a slurry barrel. High-pressure air drives superfine cement slurryin the slurry barrel to enter the bottom of the grouting sample loading area; the high-pressure air passes through a plurality of valves and then enters the two sides in the grouting area; the grouting sample loading area is of a sealed structure and comprises a slurry loading area, a grouting area and a metal hollow cylinder clamp; during grouting, a fractured rock sample is placed in a center hole of the clamp; high-pressure slurry flowing out of the slurry barrel permeates from the bottom end of a slurry filling area at the lower portion of the clamp and the periphery of the clamp and fills the rock sample at the same time; and clear water is pumped out by the high-pressure air to clean residual slurry in the pipeline into a waste receiving barrel. The rock sample grouting effect is observed through low-position grouting and high-position slurry turning, cleaning is conducted in time while grouting is completed to avoid slurry deposition, operation is convenient, grouting control is accurate, and the grouting effect is good.

Owner:HOHAI UNIV

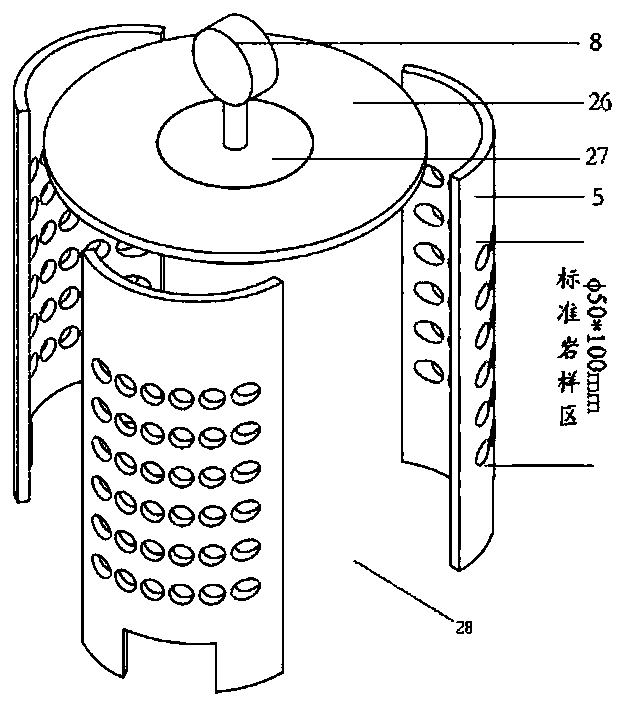

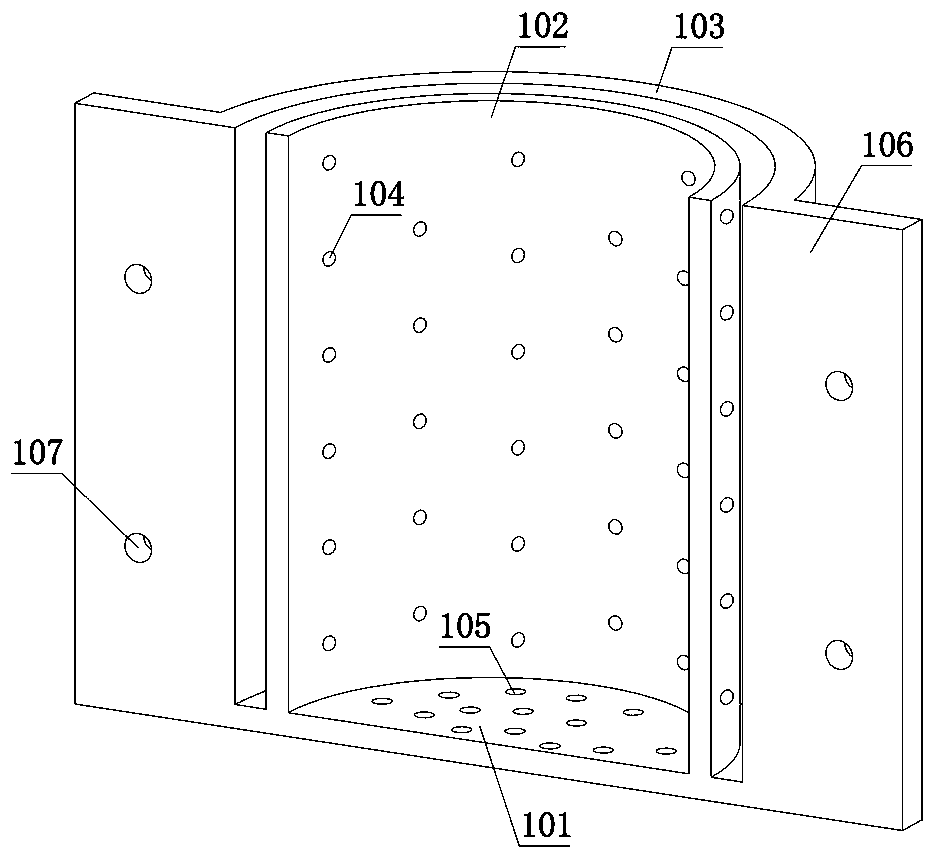

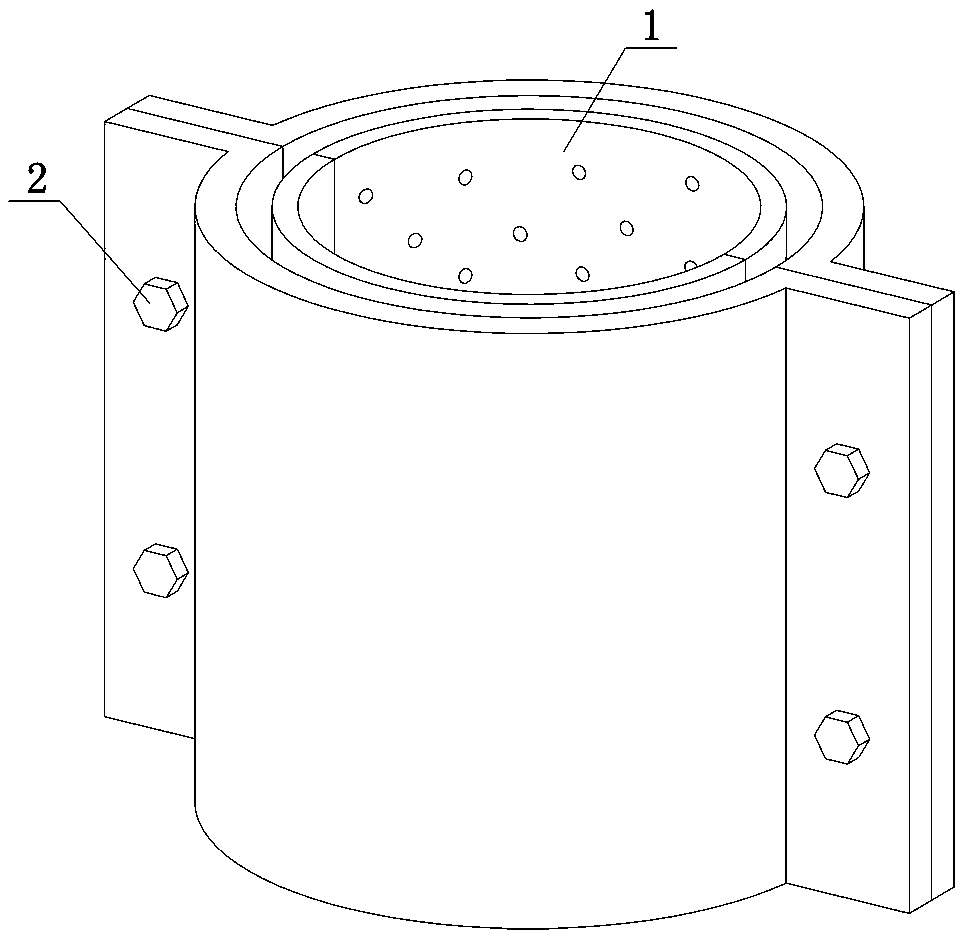

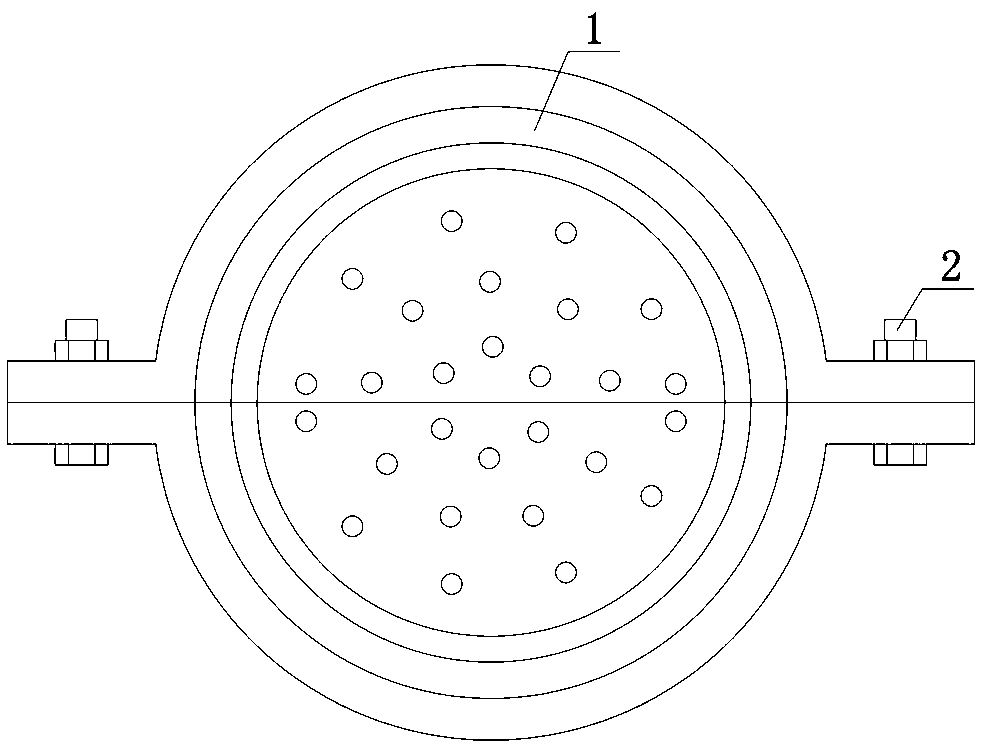

Mold and method for preparing silt soil sample based on microbial grouting

PendingCN110160851ASolve the uniformity of groutingGuaranteed grouting effectPreparing sample for investigationMicroorganismNutrient solution

The present invention relates to a mold for preparing a silt soil sample based on microbial grouting. The mold comprises two templates that are in detachable connection; wherein each template comprises a bottom plate, an inner curved plate and an outer curved plate, a plurality of first circular holes are arranged on sidewall of the inner curved plate, and a plurality of second circular holes arearranged in the bottom plate, and a steel wire mesh is arranged on inner surface of the inner curved plate; a filter unit is disposed in an enclosed space on the inner curved plate above the bottom plate. The invention also provides a method for preparing the silt soil sample based on microbial grouting, the method comprises following steps: selecting a mold; culturing microorganism; measuring urease activity; putting the soil into the mold; and injecting microbial liquid and a nutrient solution along the periphery. The mold and method can be applied to silt soil with small permeability coefficient, passes the microbial liquid through the plurality of first circular holes as grouting channels to realize multi-dimensional and multipoint filling inside the soil, can effectively solve grouting uniformity without disturbing the soil, and ensure grouting effect and improving efficiency.

Owner:HENAN UNIVERSITY

Inner geotextile bag sleeve valve pipe grouting construction method

InactiveCN103898913AAvoid pulping problemsSerum blocking effectFoundation engineeringSlurryMechanical engineering

The invention discloses an inner geotextile bag sleeve valve pipe grouting construction method. On the basis of a conventional sleeve valve pipe grouting technology, a geotextile bag which can be filled with water and made by sewing impermeable geotextile is applied. After a sleeve valve pipe is inserted or first-time grouting is ended, the geotextile bag slightly longer than the sleeve valve pipe is guided to the bottom of the sleeve valve pipe through a cavity in the sleeve valve pipe, and clean water is poured into the geotextile bag till the whole cavity of the sleeve valve pipe is filled with clean water; when first-time grouting on holes to be injected with slurry starts or before repeated second-time grouting on the holes to be injected with slurry starts, the geotextile bag is taken out, and the remaining steps are the same as a conventional sleeve valve pipe grouting construction method. With the method, not only are the advantages of the conventional sleeve valve pipe grouting kept, but also the problem that slurry enters the sleeve valve pipe because of slurry mixing in the grouting process and the problem that the sleeve valve pipe is blocked because of deformation are solved, and meanwhile remaining slurry in the sleeve valve pipe can be removed effectively. The applied geotextile bag is easy to manufacture, low in cost, convenient to construct and capable of being repeatedly used and thus has very good application prospects.

Owner:HOHAI UNIV

Induced-type grouting construction method

InactiveCN110206018ASimple and fast operationSolve the problem of insufficient injectionSoil preservationWater tableEnvironmental geology

The invention discloses an induced-type grouting construction method. The induced-type grouting construction method is suitable for closed strata and comprises the following steps that A, a grouting hole is designed on a soil body to be grouted and reinforced, a pumping hole or a pumping well is arranged outside the grouting diffusion range of the grouting hole, and the pumping hole or the pumpingwell is formed by construction; B, pumping equipment is arranged, and the pumping port in the pumping hole or the pumping well is lower than the groundwater level; C, the grouting hole is formed by construction, and grouting equipment is arranged; D, the pumping equipment is started to pump water by the pumping hole or the pumping well, meanwhile the grouting equipment is started to grout by thegrouting hole, until the design final grouting standard is reached, and grouting of the grouting hole is completed; and E, the steps A to D are repeated until all the grouting holes in the expected grouting area are grouted. The construction method is simple and convenient in operation, high in economic efficiency and high in grouting efficiency, and it is guaranteed that the grouting effect meetsthe expected requirements.

Owner:GUANGXI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com