Pre-grouting and water plugging method for permeable layer in vertical shaft

A technology of permeable layer and pre-grouting, which is applied in shaft equipment, earthwork drilling, wellbore lining, etc. It can solve problems such as difficulty in guaranteeing grouting effect, threat of mine excavation, and poor grouting effect, so as to reduce construction and demolition work quantity, increase the speed of wellbore excavation, and ensure the effect of grouting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

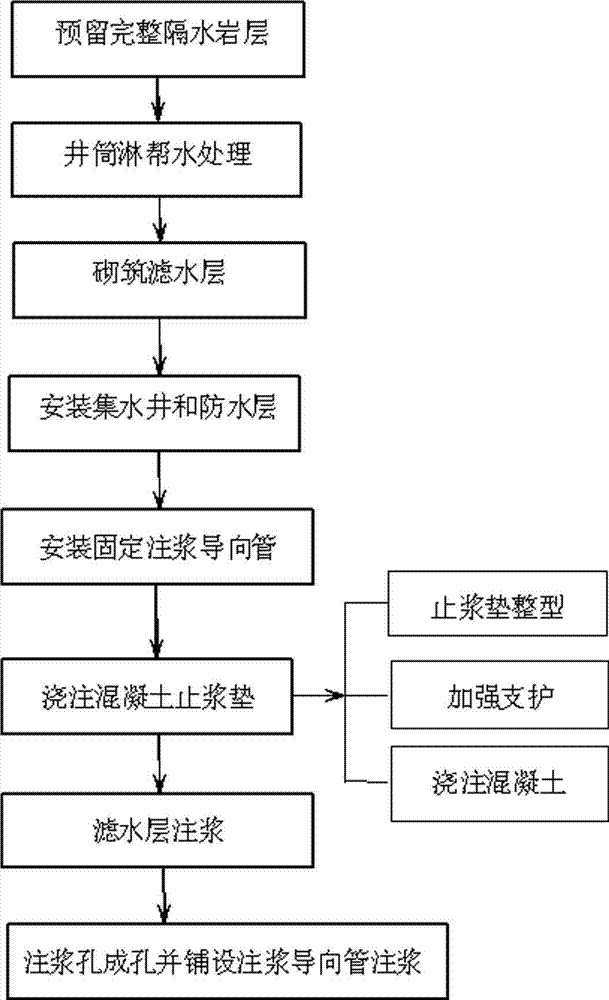

[0017] The method for pre-grouting water plugging of the permeable layer in the vertical shaft according to the present invention has the following steps:

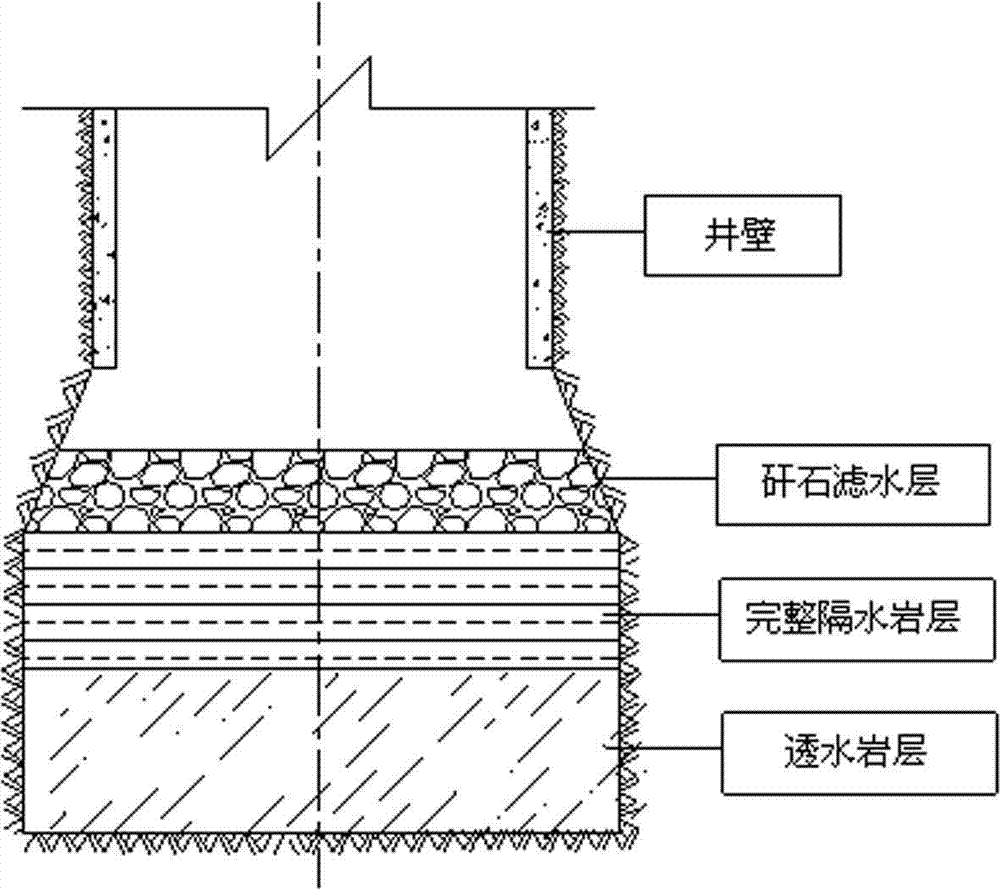

[0018] The specific operation content of the step (1) is: consult the geological survey data, and reserve a complete water-resisting rock layer of a certain thickness on the upper part before the shaft is excavated to the water-permeable rock layer.

[0019] The specific operation content of the step (2) is: use the method of grouting behind the well wall to block the shower water in the wellbore. Water does not enter the working face to ensure the pouring quality of concrete;

[0020] The specific operation content of the step (3) is: after the shaft is excavated to the position where the grout stop pad is built, the broken gangue on the working face is leveled according to the designed thickness;

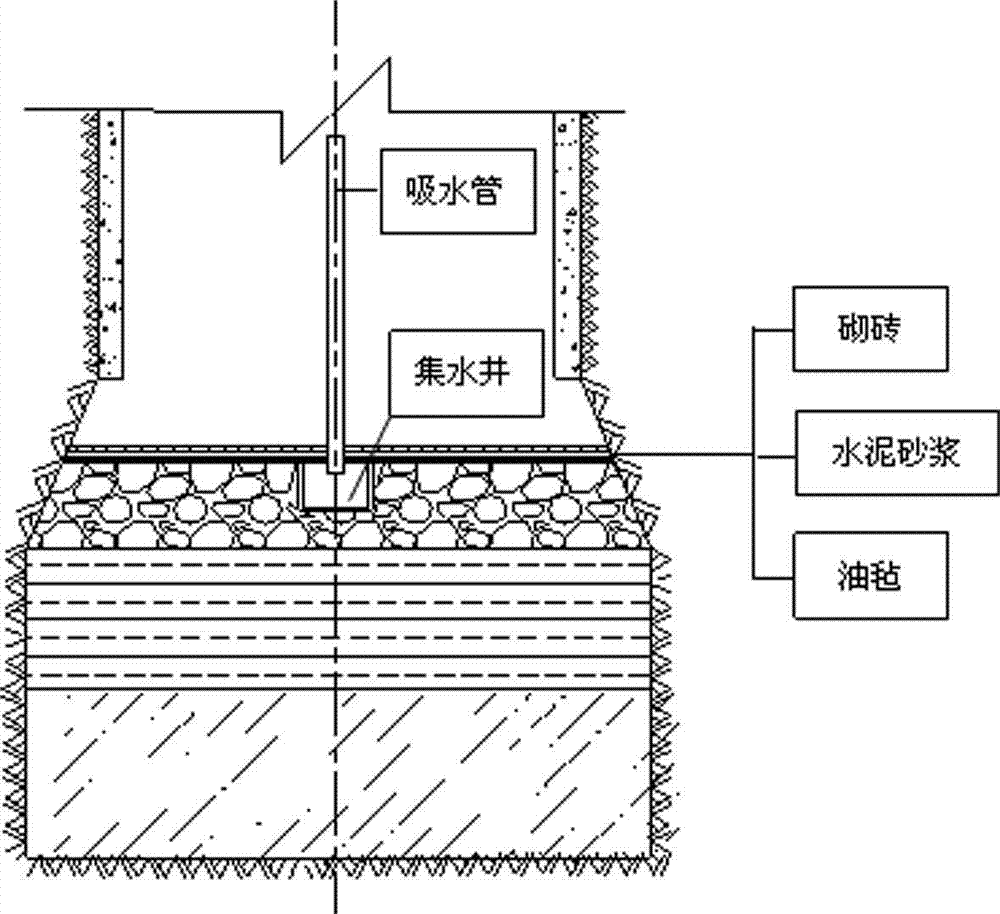

[0021] The specific operation content of the step (4) is: excavate a water collection well with a specification of 0.6×0.6×...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com