Patents

Literature

33results about How to "Reduced demolition workload" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

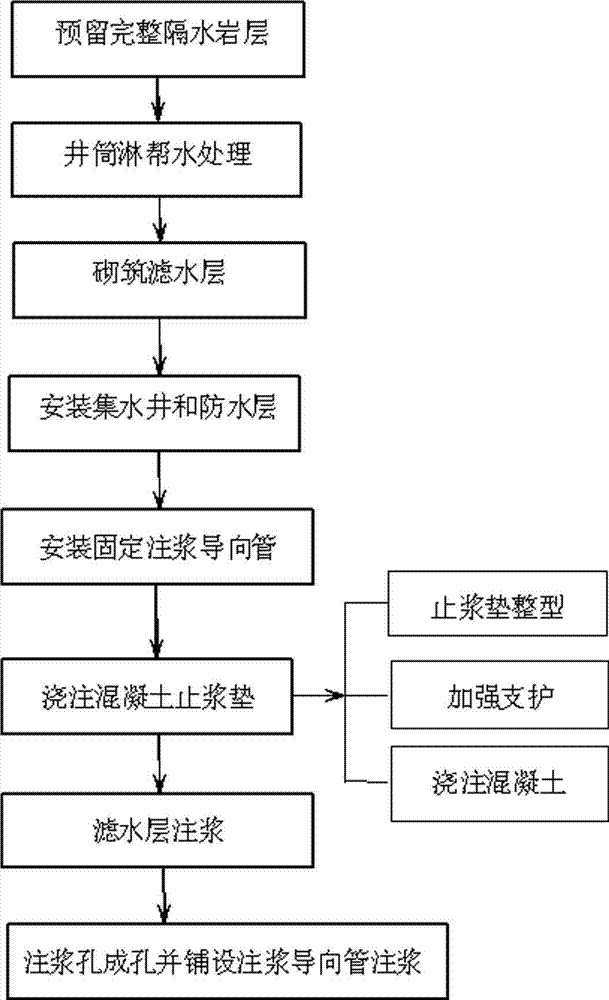

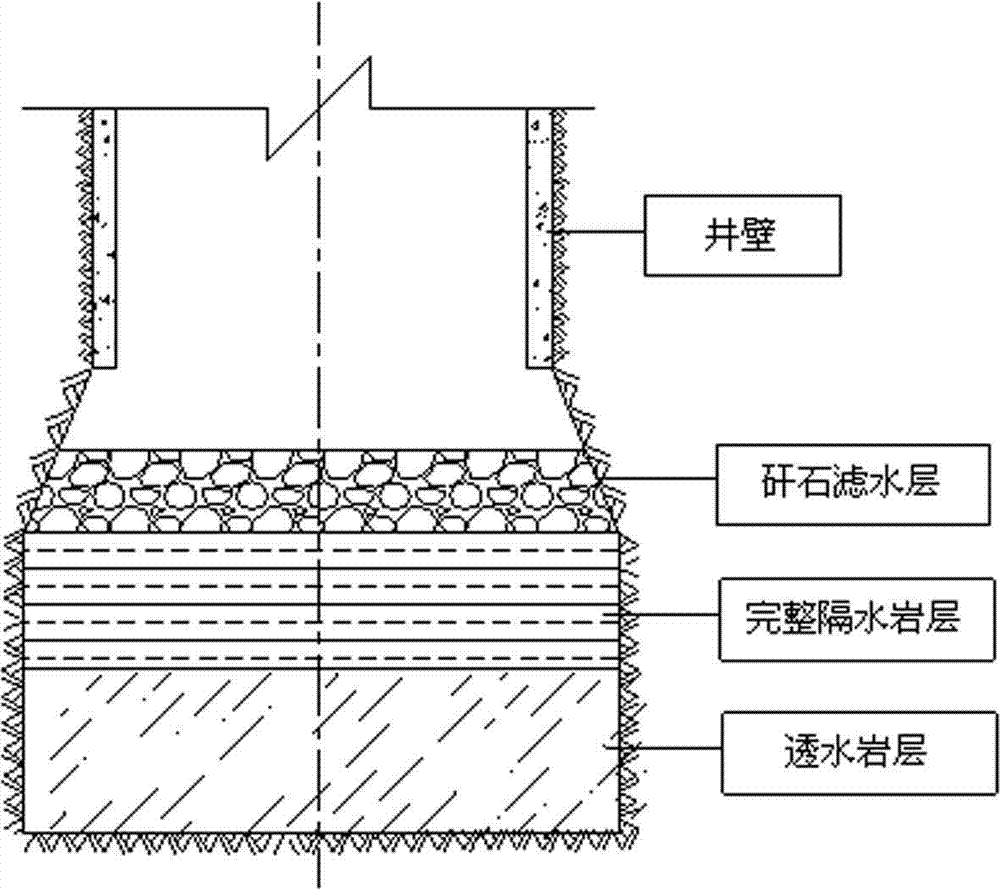

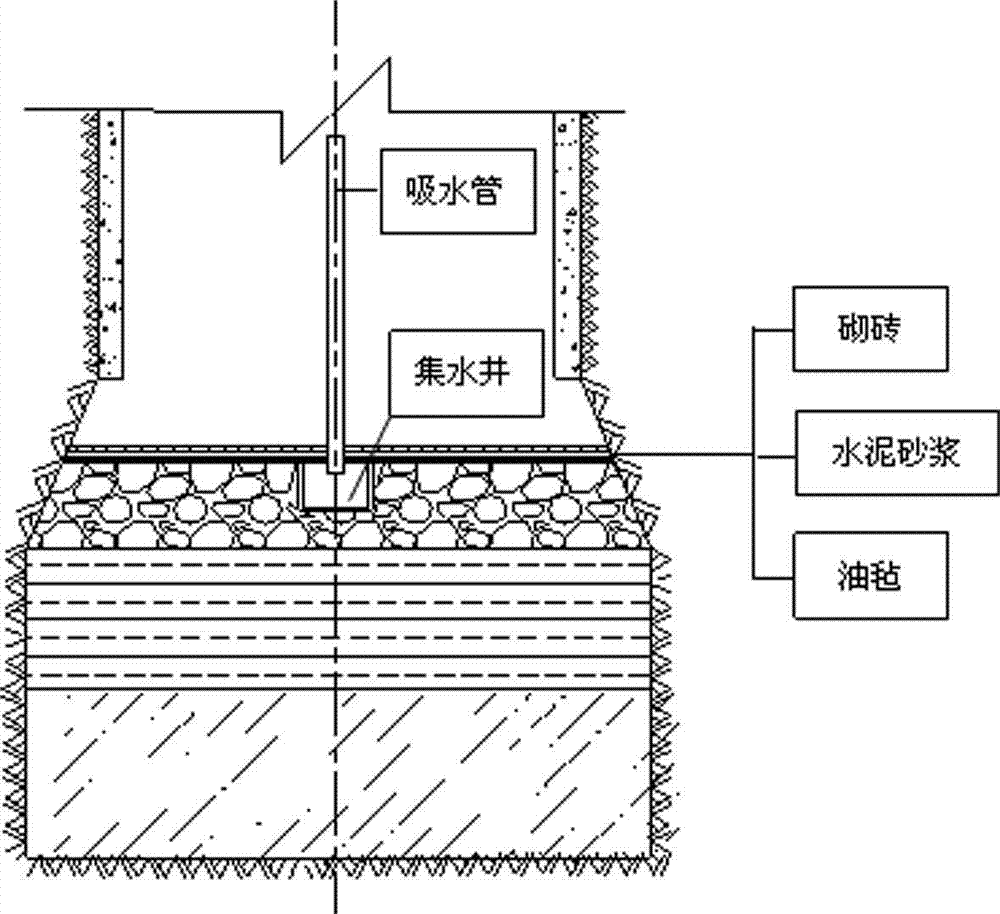

Pre-grouting and water plugging method for permeable layer in vertical shaft

A pre-grouting and water plugging method for a permeable layer in a vertical shaft includes the steps of reserving complete waterproof rock strata, performing spraying water treatment for a shaft body, building a water filtering layer, mounting a drainage sump and a waterproof layer, mounting and fixing a grouting guide pipe, pouring concrete grouting pad, performing water filtering layer grouting and performing grouting hole formation and laying the grouting guide pipe for grouting. The pre-grouting and water plugging method has the advantages that high grouting pressure meeting design requirements can be borne, grouting and water plugging effects under high water pressure and high grouting pressure during construction of the vertical shaft are guaranteed, the thickness of the grouting pad can be decreased to the greatest extent, and grouting pad construction and detachment workload is reduced, so that grouting effect is guaranteed, shaft body advancement speed is increased, and more obvious effect is achieved particularly as for a large-thickness permeable layer. Therefore, the pre-grouting and water plugging method can be effectively applied to pre-grouting and water plugging of the permeable layer in the vertical shaft and has good effect on experimental verification.

Owner:WUHAN SURVEYING GEOTECHN RES INST OF MCC

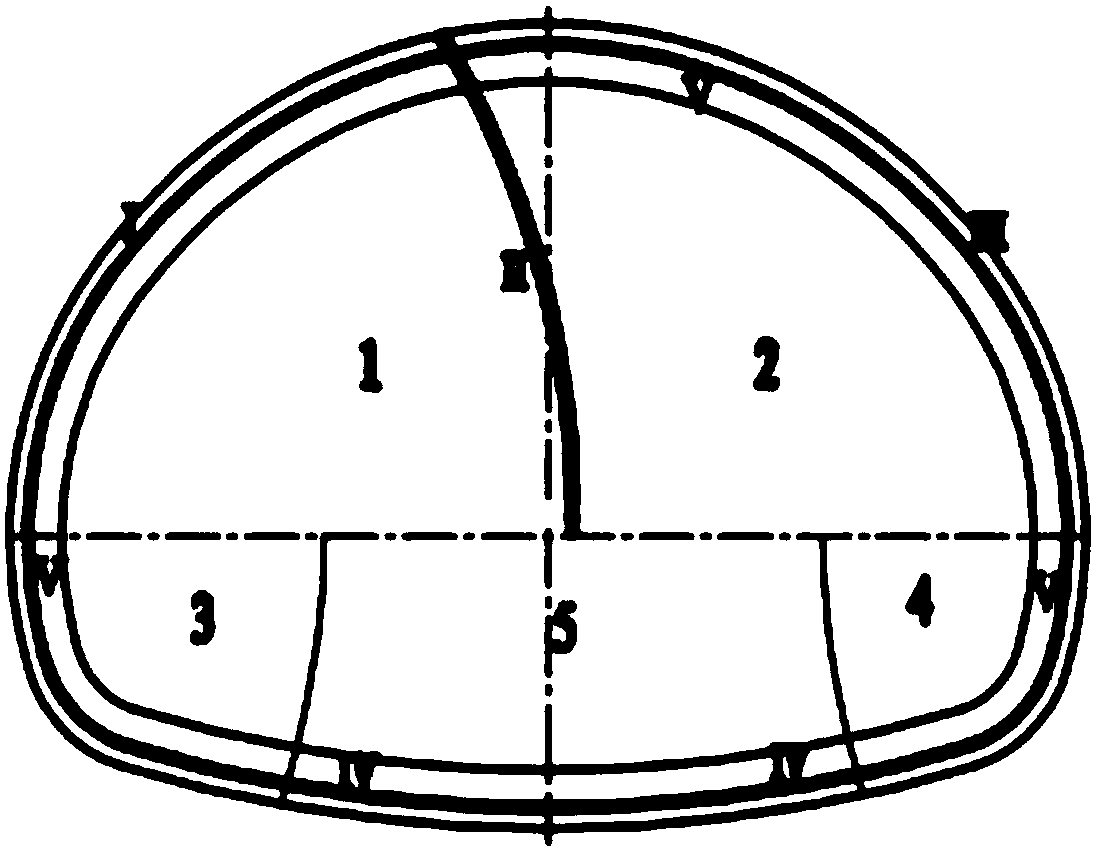

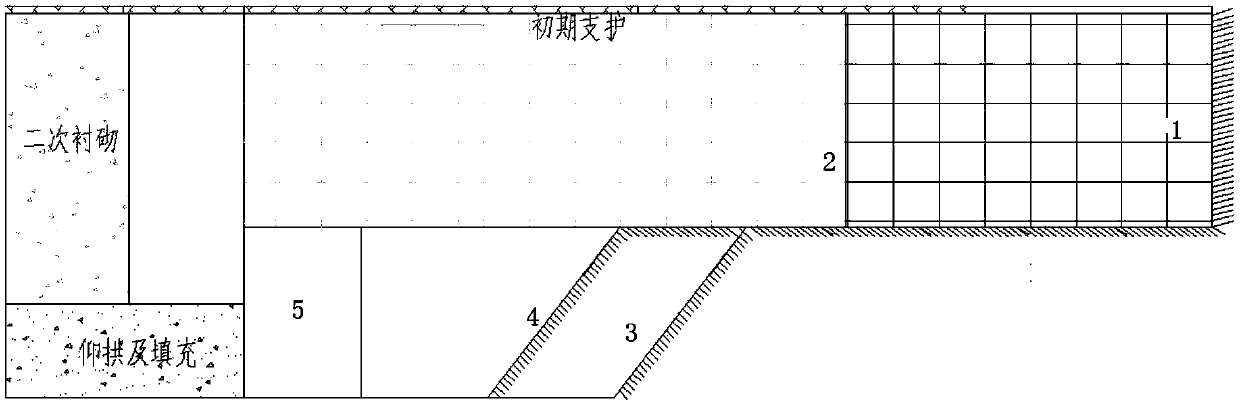

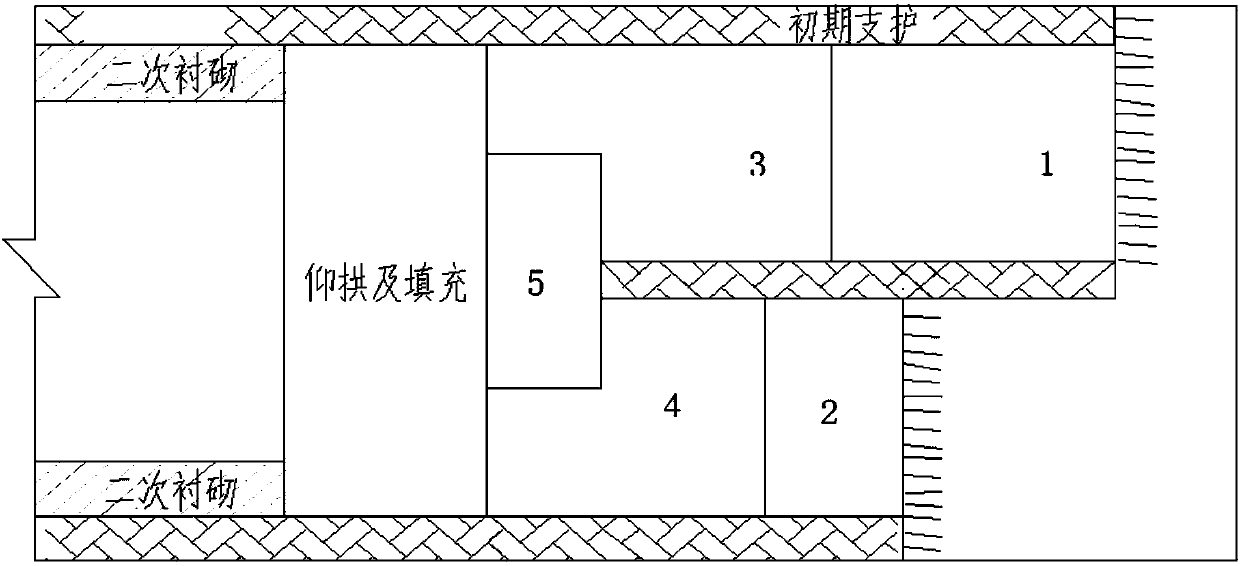

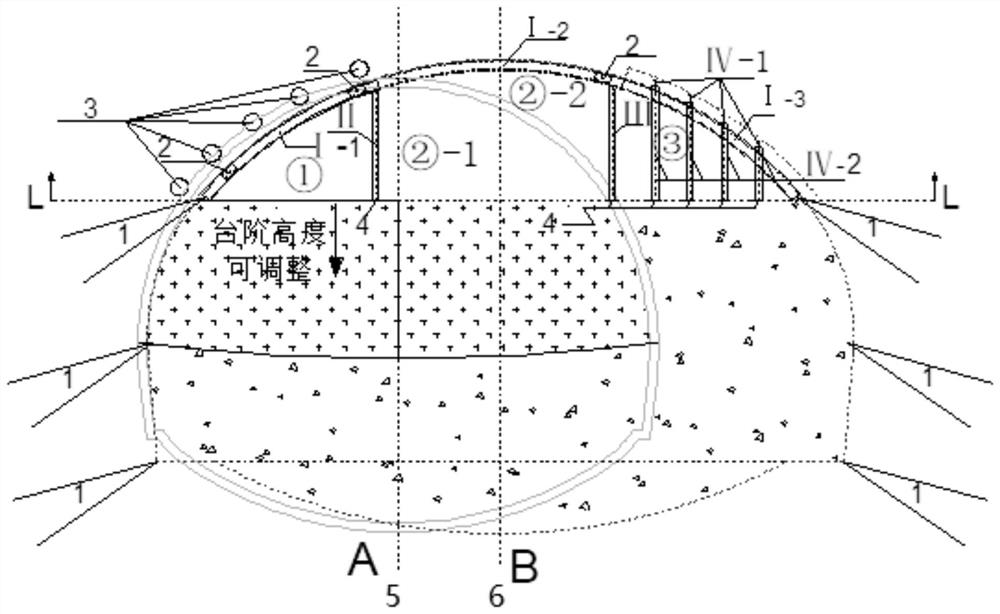

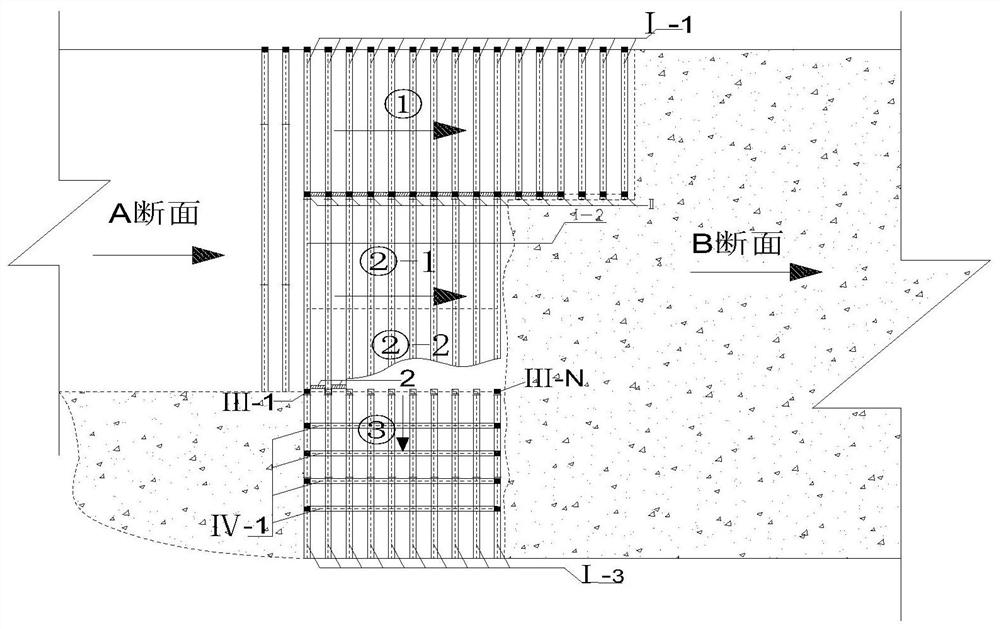

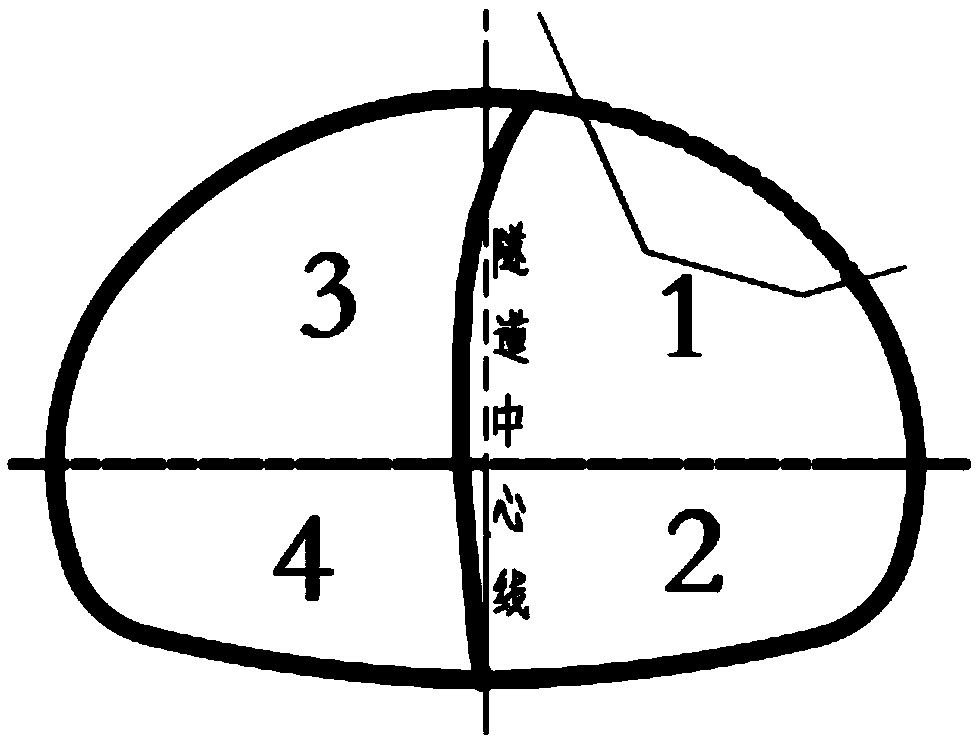

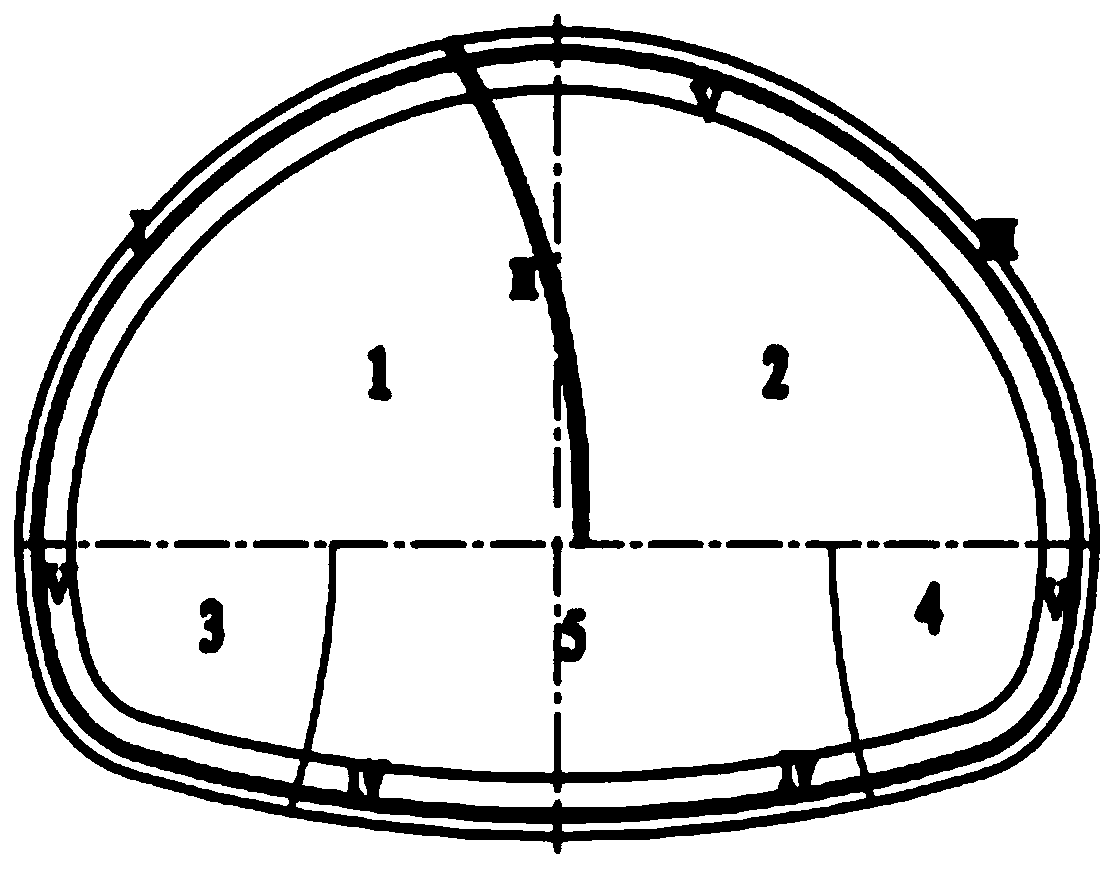

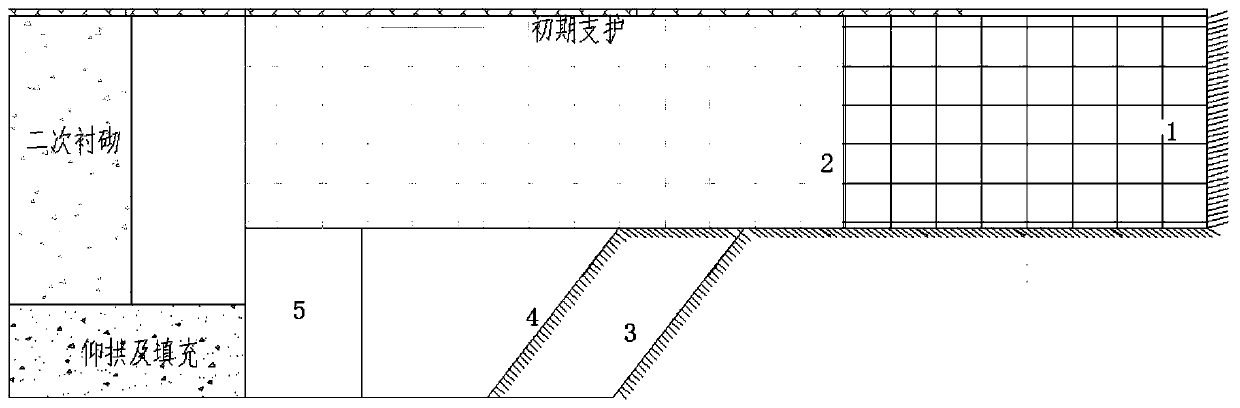

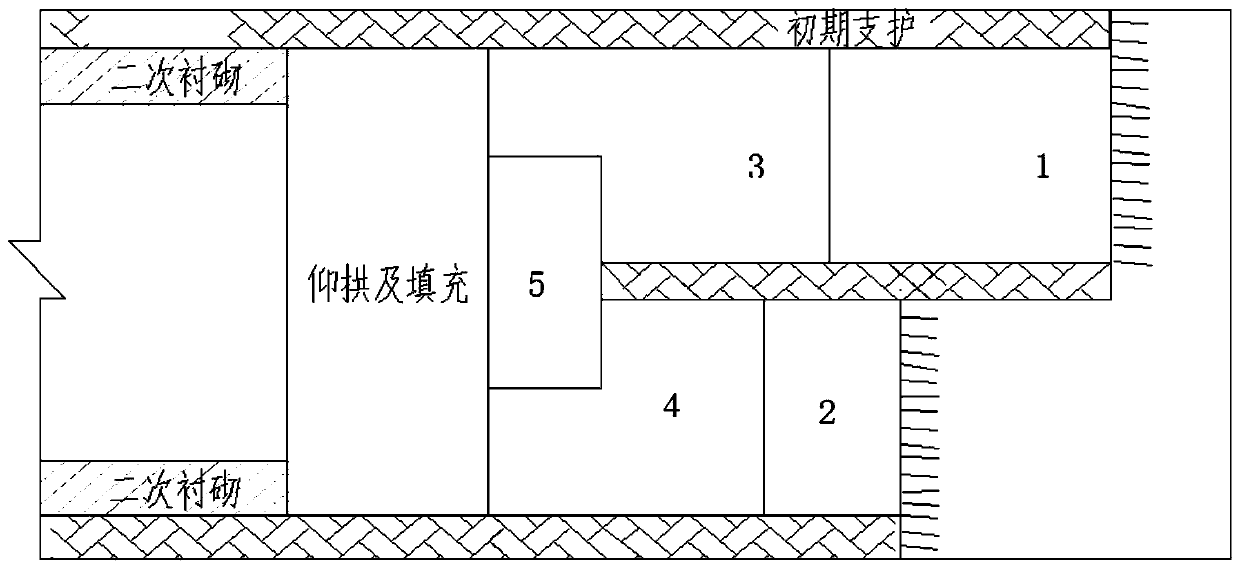

Method for excavating combined vertical erection branch part of super-large rocky section tunnel steel frame rock wall

ActiveCN108035733AEnsure safetyEnsure stabilityUnderground chambersTunnel liningEconomic benefitsSteel frame

The invention provides a method for excavating a combined vertical erection branch part of a super-large rocky section tunnel steel frame rock wall. The method includes the specific steps that an excavation section of a tunnel is set, wherein an upper left pilot tunnel is a first excavation part, an upper right pilot tunnel is a second excavation part, the upper left pilot tunnel and the upper right pilot tunnel constitute an upper excavation section, a lower left pilot tunnel is a third excavation part, a lower right pilot tunnel is a fourth excavation part, a rock wall body is a fifth excavation part, the lower left pilot tunnel, the lower right pilot tunnel and the rock wall constitute a lower excavation part, and besides, a first supporting and protecting part, a second supporting andprotecting part, a third supporting and protecting part, a fourth supporting and protecting part and a fifth supporting and protecting part are included; the various excavation parts are excavated inturn, and primary support and protection is conducted on the corresponding supporting and protecting parts; in the entire excavation process, the second excavation part is kept lagging behind the first excavation part, the third excavation part lags behind the second excavation part, and the fourth excavation part lags behind the third excavation part. According to the method, large-scale machinery is convenient to work in the case of a super-large section tunnel, the excavation speed is fast, and the economic benefit is obvious.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD +1

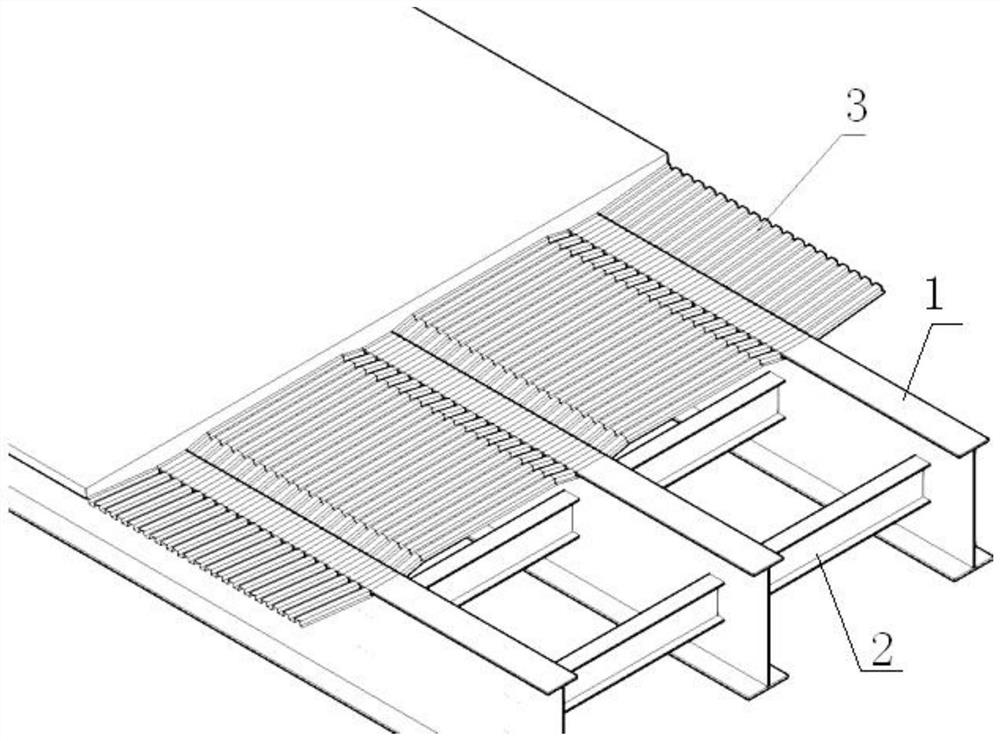

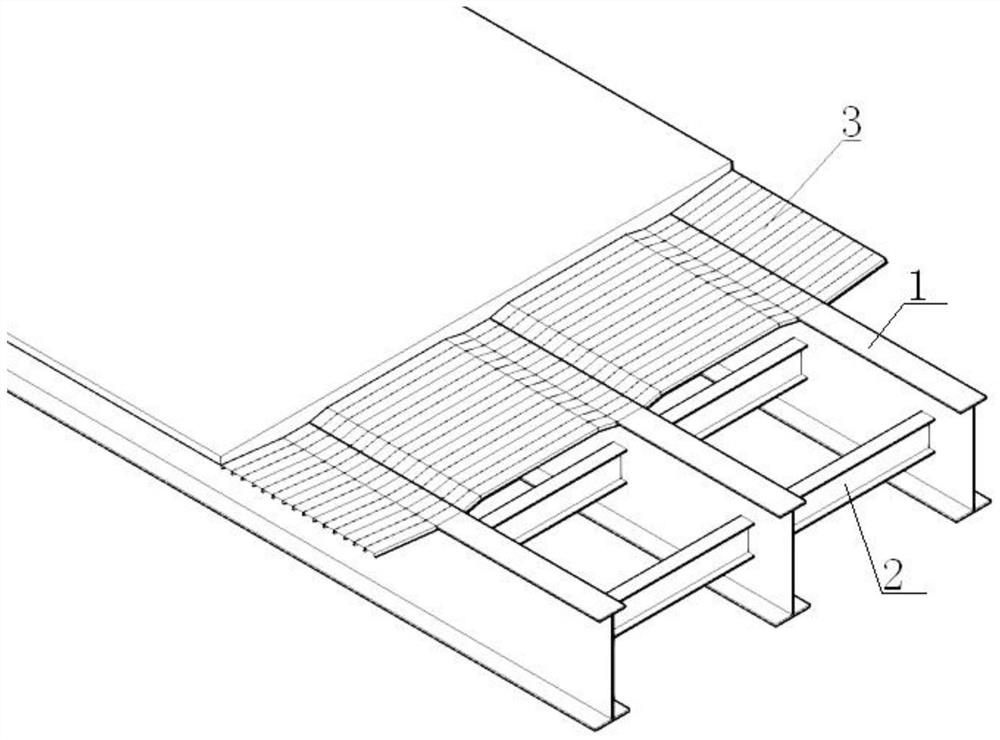

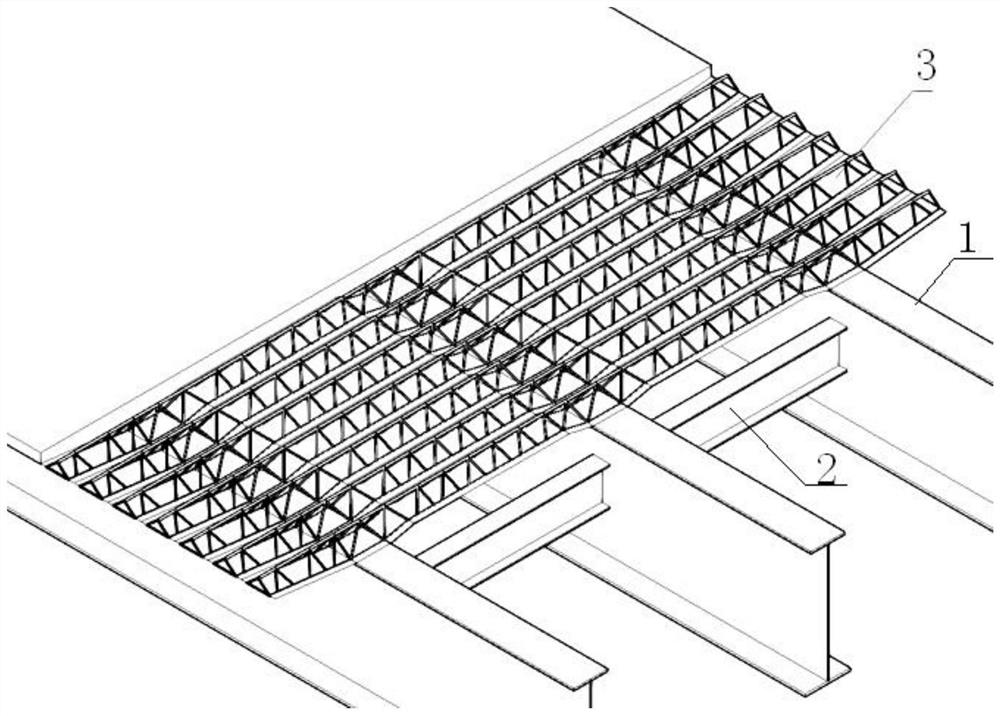

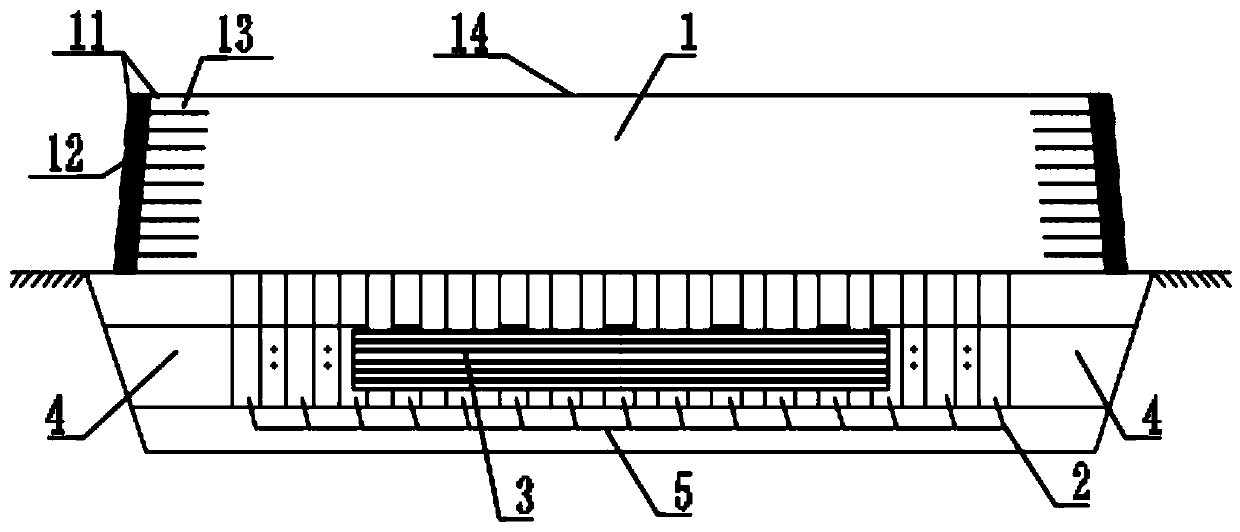

Support-free construction method of steel-concrete concrete composite beam concrete cast-in-place bridge deck

PendingCN111622112AReduced demolition workloadHigh security riskBridge structural detailsBridge erection/assemblySteel platesRebar

The invention belongs to the technical field of bridge construction, and particularly provides a support-free construction method of a steel-concrete composite beam concrete cast-in-place bridge deck.The method comprises the following steps of installing steel main beams and steel cross beams according to drawing requirements, and machining needed profiled steel plates or steel plates according to a transverse line type of a bottom surface of a bridge deck; laying processed profiled steel plates on an upper flange plate of the steel main beams section by section in a bridge direction; installing reinforcing steel bars in the bridge deck on the laid profiled steel plates; installing side molds on the two sides of the bridge deck; and pouring concrete on the profiled steel plates and on inner sides of side molds in the step 3) and curing. Problems that in the prior art, supports and formworks need to be disassembled after bridge deck construction is completed in support construction, and a disassembling workload is large are solved; and support-free construction is adopted, dismounting operation is not needed, high-altitude operation is not needed, a safety risk is reduced, a dismounting operation platform does not need to be built, construction cost is reduced, and construction efficiency is improved.

Owner:CCCC SHEC SECOND ENG

Method for rapidly positioning penetrating screw rod holes of generator motor stator

ActiveCN104393720ARapid positioningPrecise positioningManufacturing stator/rotor bodiesPunchingEqualization

The invention discloses a method for rapidly positioning penetrating screw rod holes of a generator motor stator. The method comprises the steps: mounting big equalization positioning ribs; stacking up stator punching plates; adjusting the uniformity of the stator punching plates and checking notch grinding situations of the stator punching plates; assembling a penetrating screw rod sample plate, making mark points and punching holes. In the method, the stator punching plates are stacked up in a half overlapping method; the stacked stator punching plates are positioned with a positioning bolt and used as a penetrating screw rod hole sample plate; the penetrating screw rod hole sample plate is assembled for positioning the stator; the penetrating screw rod hole sample plate is dismounted and then the stator is punched; and the penetrating screw rod hole sample plate can be repeatedly used to position the stator. The method for rapidly positioning the penetrating screw rod holes of the generator motor stator has the advantages of small amount of positioning work, high positioning efficiency and accurate positioning; the secondary washing and the secondary storage of the stator punching plates can be avoided.

Owner:STATE GRID CORP OF CHINA +2

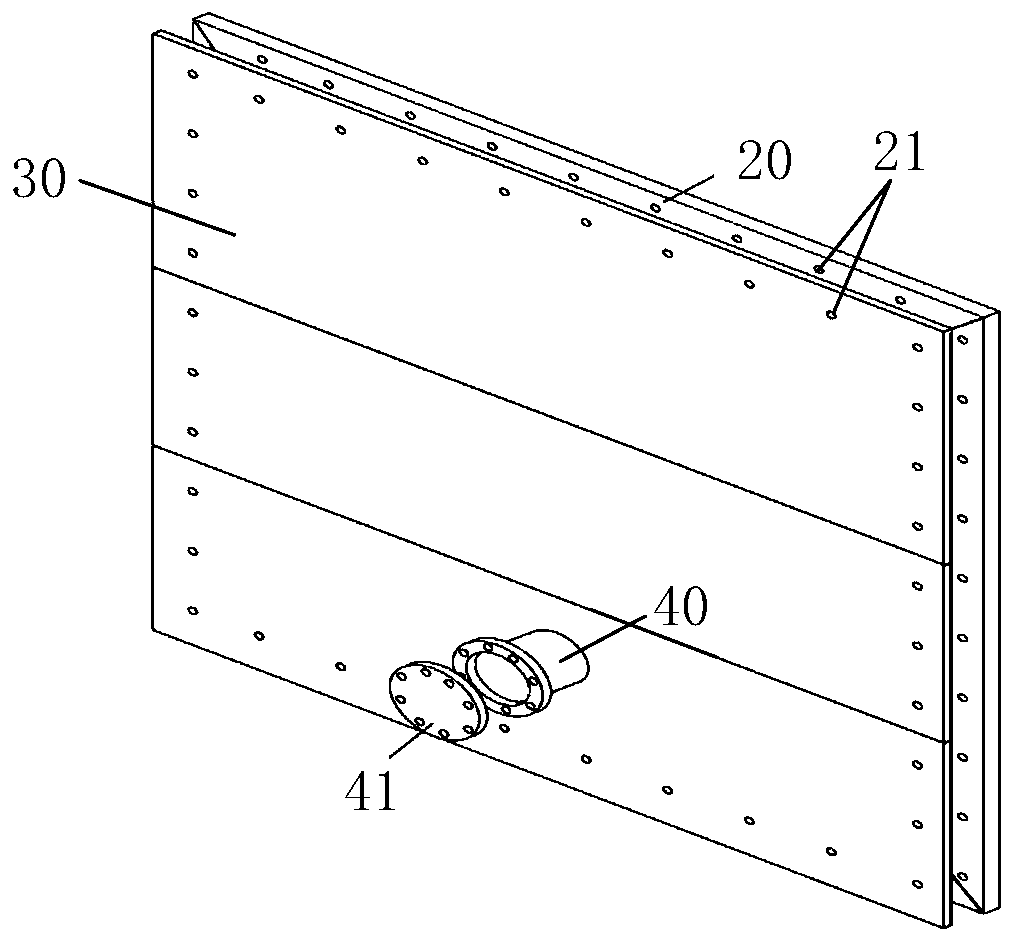

Sewage pipeline blocking device and construction method thereof

PendingCN110185118AEnsure construction safetyImprove the blocking effectSewer pipelinesPipeflowArchitectural engineering

The invention relates to a sewage pipeline blocking device and a construction method thereof. The sewage pipeline blocking device is arranged on the wall of a working well and is used for sealing a pipeline. The sewage pipeline blocking device comprises a rubber plate, a water retaining steel plate and a reserved hole pipe which are arranged in sequence, wherein the rubber plate is attached to thewell wall; first preserved holes which are corresponding in positions are respectively formed in the water retaining steel plate and the rubber plate; and the reserved hole pipe communicates with thefirst preserved holes. According to the sewage pipeline blocking device, the water retaining steel plate is used for main blocking, performs sealing water stop in combination with the rubber plate, has a relatively good blocking effect, and can ensure the construction safety in an operation area; the reserved hole pipe can realize the continuous sewage transportation, and the transportation of intake sewage of sewage treatment plants does not need to be completely stopped; the dismantling workload in later period is small; the workload of underwater frogmen is effectively reduced; and the operating risk is reduced.

Owner:SHANGHAI MUNICIPAL CONSTR

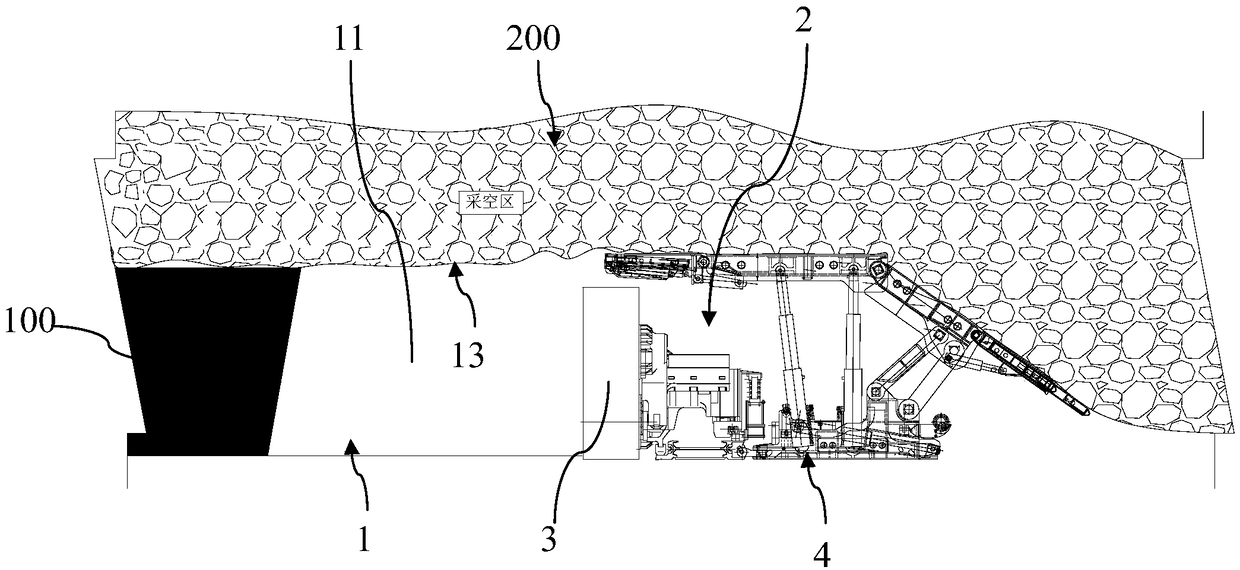

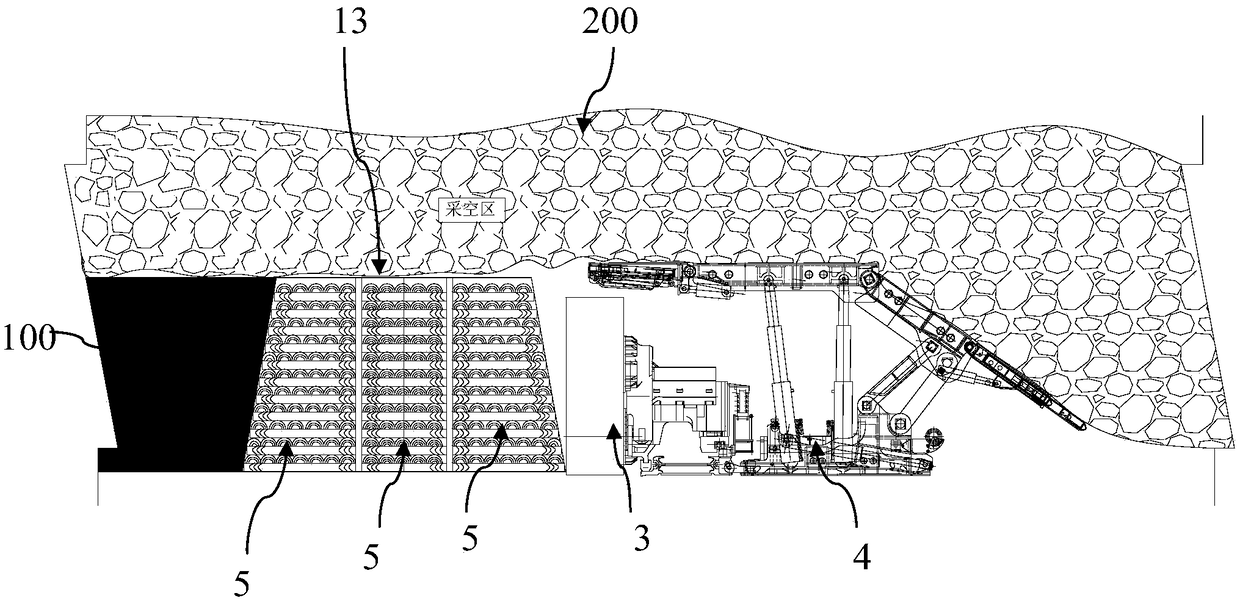

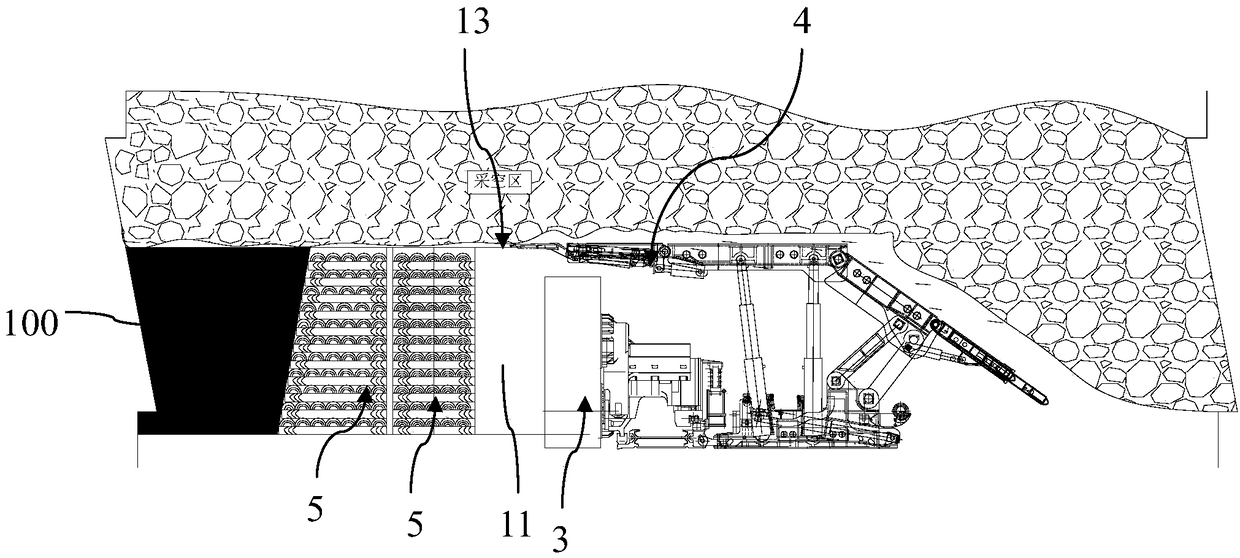

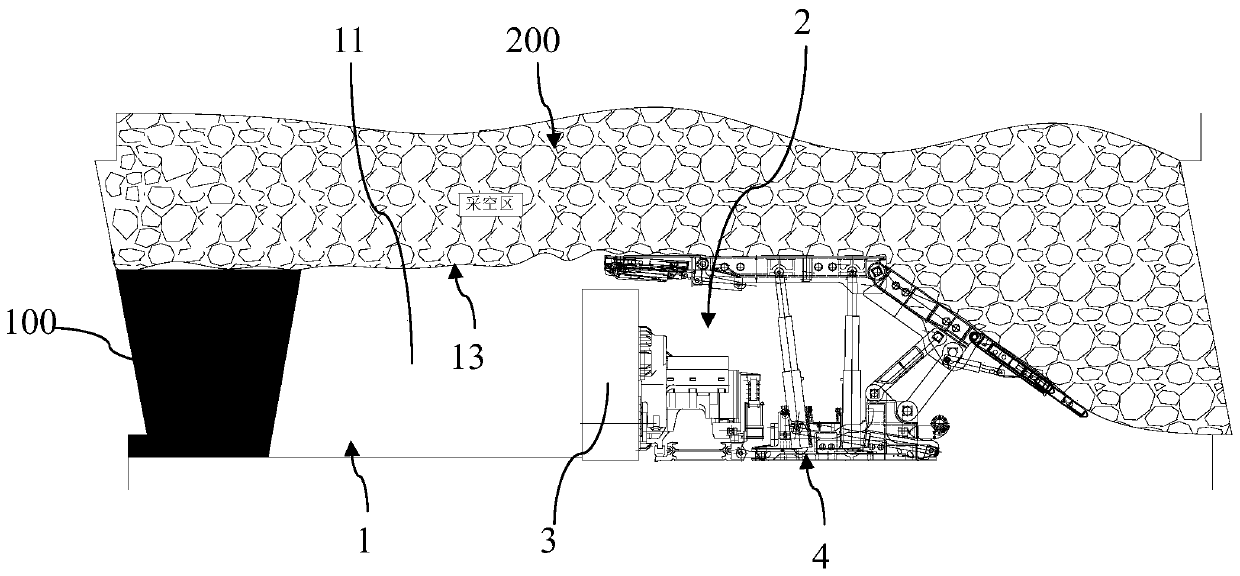

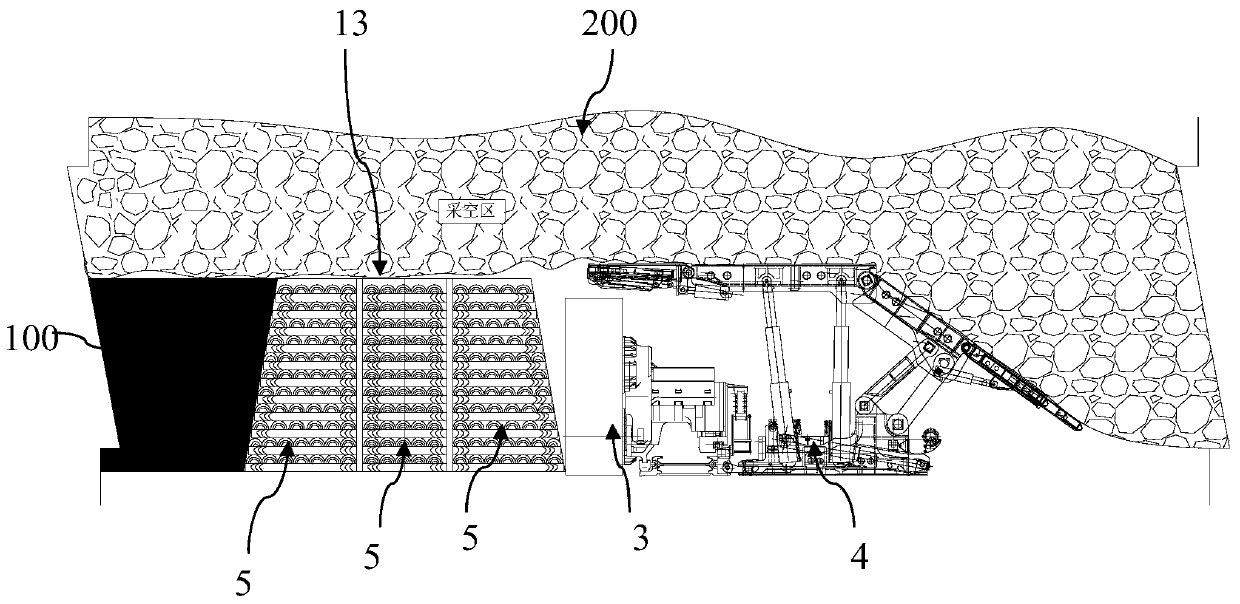

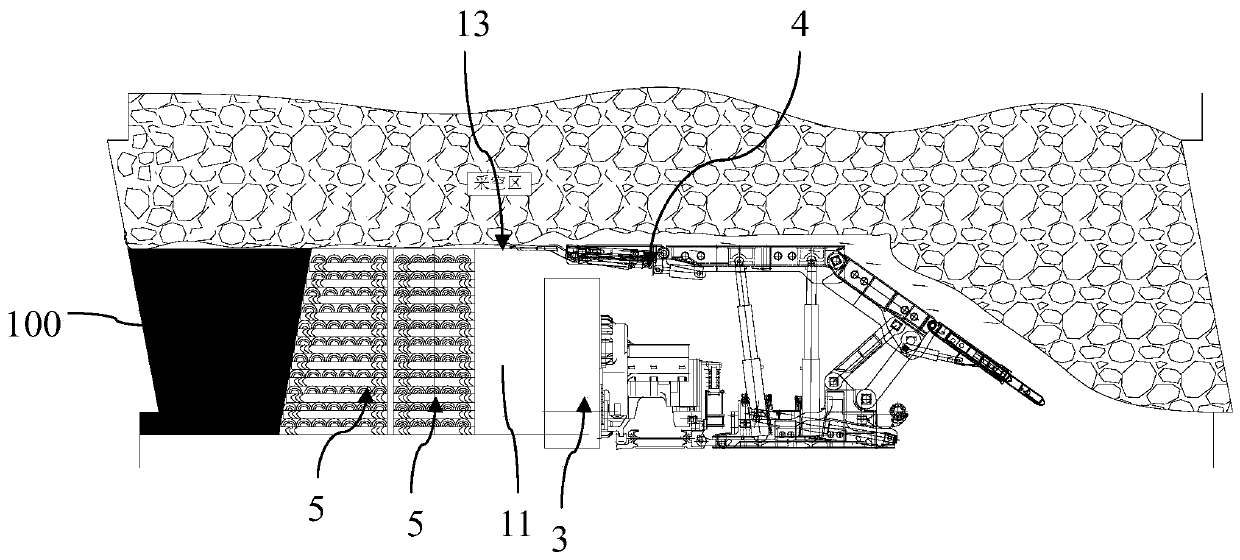

Method for passing through abandoned roadway

ActiveCN109098713AReduced demolition workloadReduce labor intensityUnderground miningSurface miningComputer scienceCoal

The invention discloses a method for passing through an abandoned roadway. The method for passing through the abandoned roadway comprises a method for allowing a coal face to pass through the abandoned roadway. The method for allowing the coal face to pass through the abandoned roadway comprises the following steps: S01: marking a first intersection area intersected with the coal face in the abandoned roadway in advance; S02: sequentially distributing at least two mutually-independent first support timber cribs along the advancing direction of the coal face in the first intersection area to support a first false roof; S03: allowing a coal cutter in the coal face to advance in a sectional way in the first intersection area to cut the first support timber cribs; and S04: allowing the coal cutter to sequentially advance according to the way in the step S03 until the coal cutter passes through the first intersection area. According to the method for passing through the abandoned roadway, the workload for dismounting the timber cribs is reduced by adopting the mutually-independent support timber cribs, the labor intensity of staff is alleviated, the workload is reduced, and the assuredprocessibility factor of the staff is improved.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

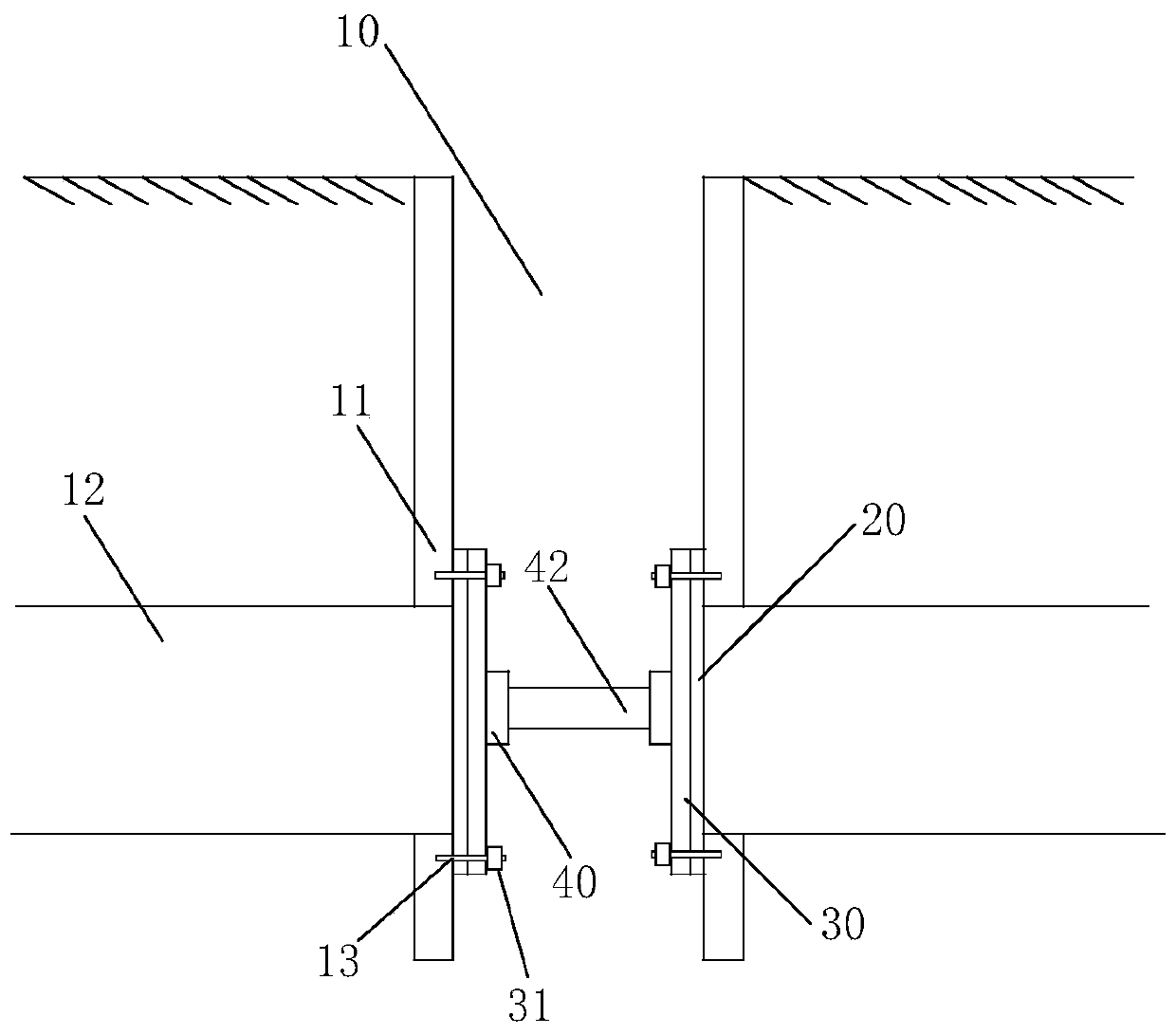

Sliding type folding wallboard

PendingCN109537731AHigh strengthReduced demolition workloadBuilding constructionsEngineeringSteel frame

The invention discloses a sliding type folding wallboard. The wallboard comprises a sliding type guide rail and at least two vertical unit plates, wherein the sliding type guide rail comprises at least two hollow connecting pipes which sequentially sleeve each other; the hollow connecting pipes are transversely arranged, and the head parts of the hollow connecting pipes are arranged in the tail parts of the adjacent hollow connecting pipes; vertical connecting shafts are disposed on the tail parts of the hollow connecting pipes, the unit plates are in one-to-one correspondence with the connecting shafts, and the unit plates are rotationally connected with the connecting shafts. The sliding type guide rail in the structure can provide relatively high strength, the unit plates can provide shielding, a steel frame structure does not need to be built again, plates or cloth does not need to be laid, and a large number of connecting pieces do not need to be installed on the site; when the structure serves as a large-scale wallboard of a large temporary building so that the workload, time consumption, labor cost and the like for dismantling the large temporary building can be reduced.

Owner:FOSHAN UNIVERSITY

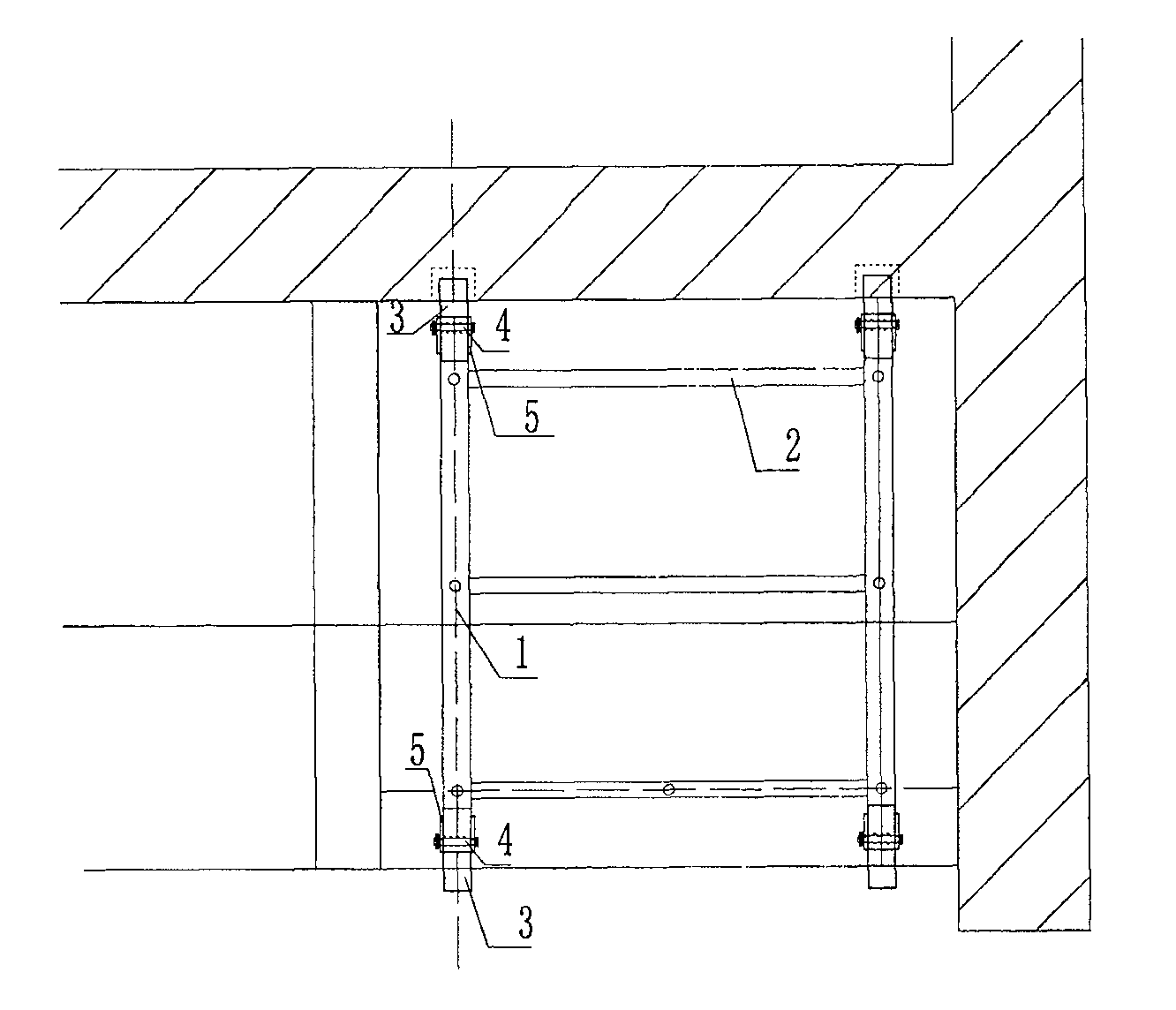

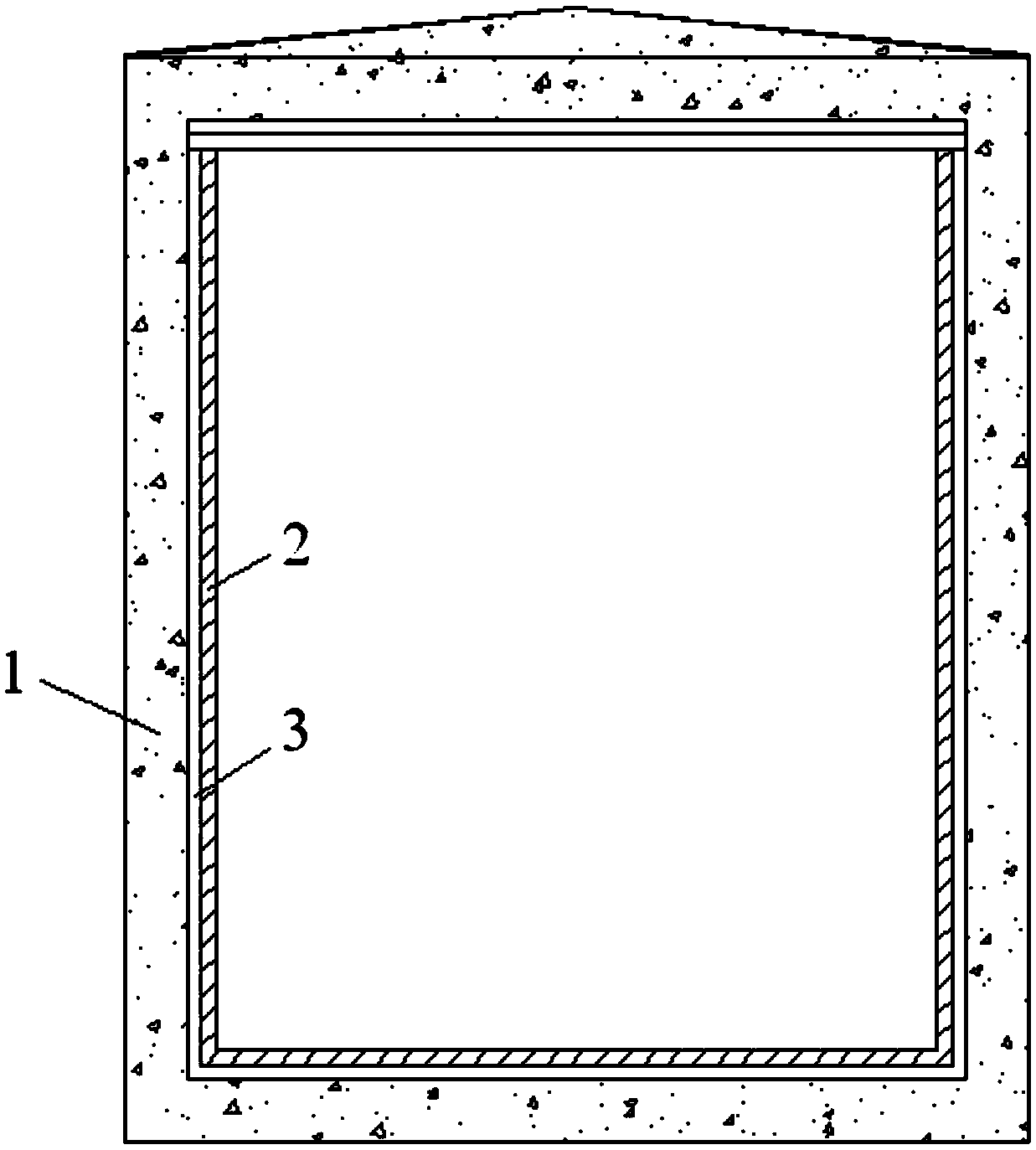

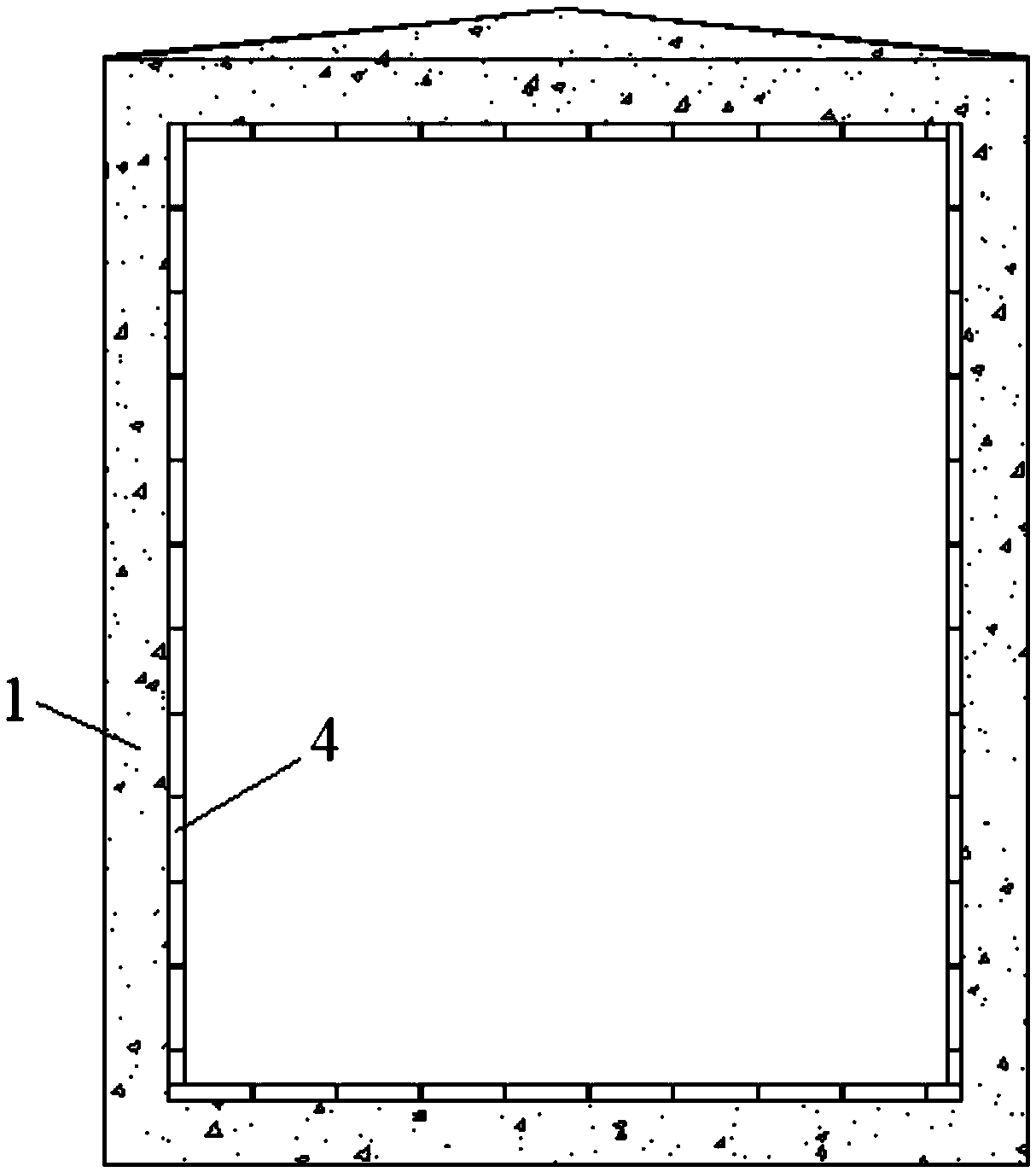

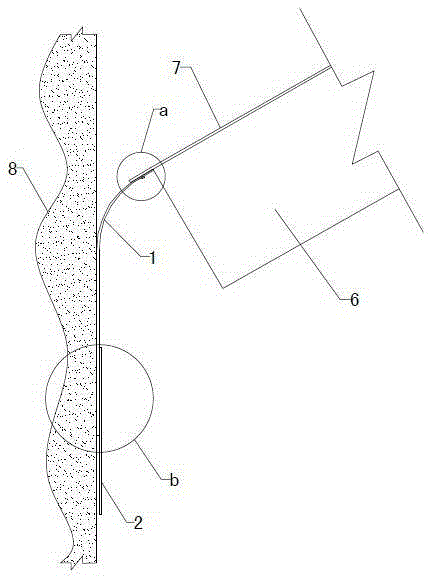

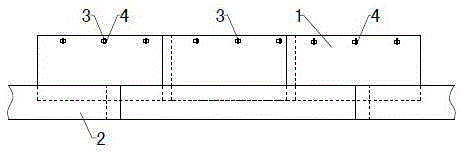

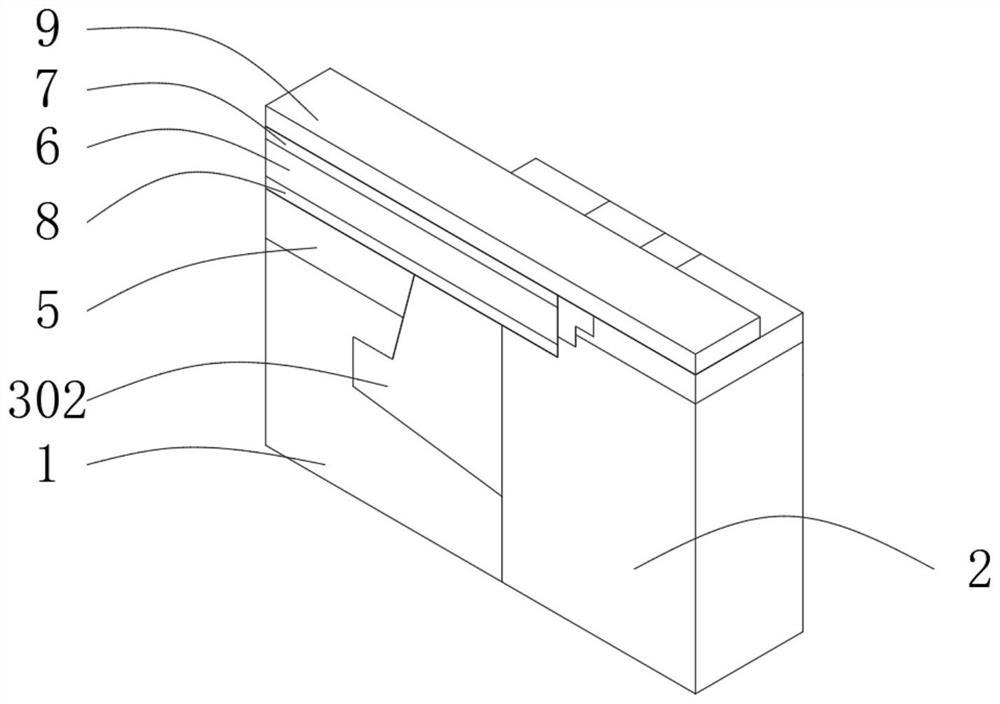

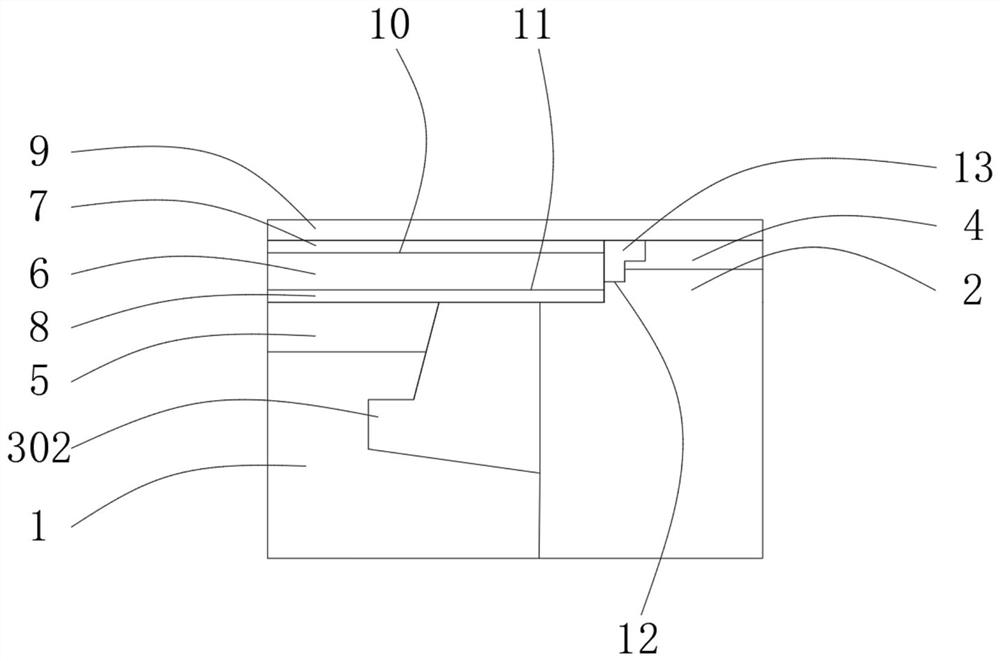

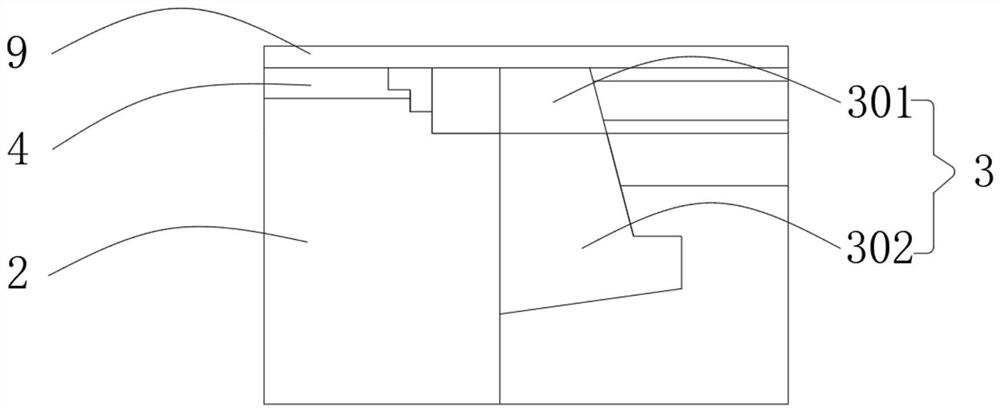

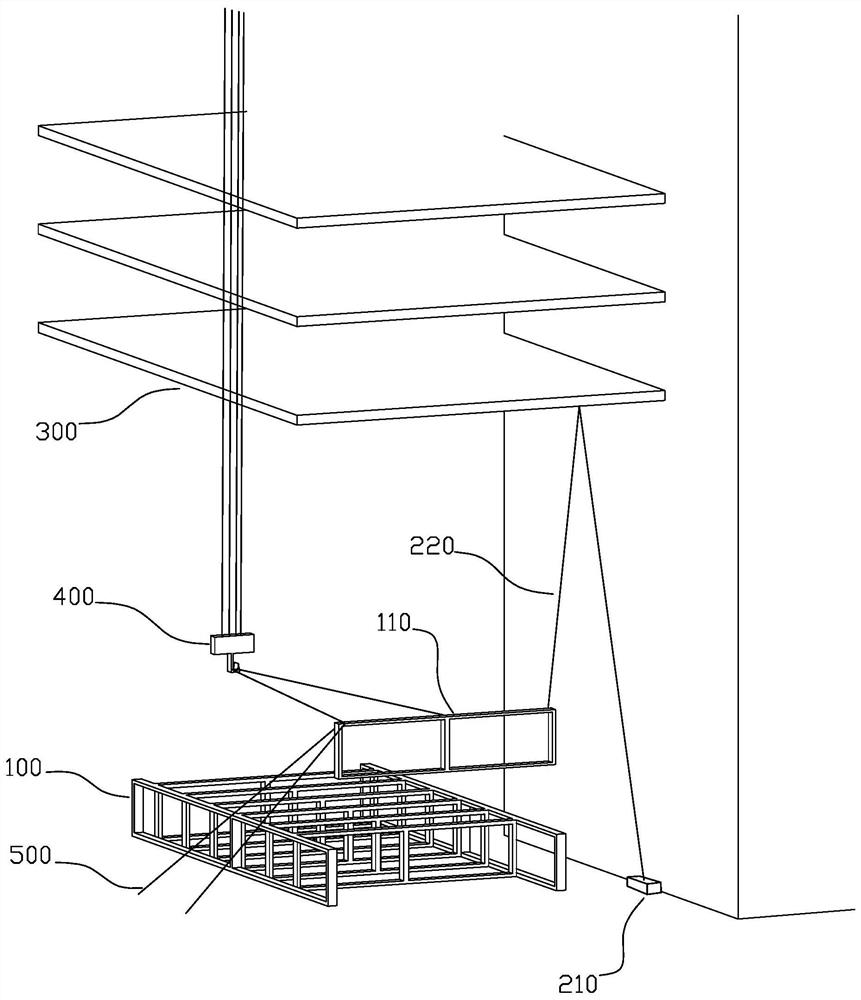

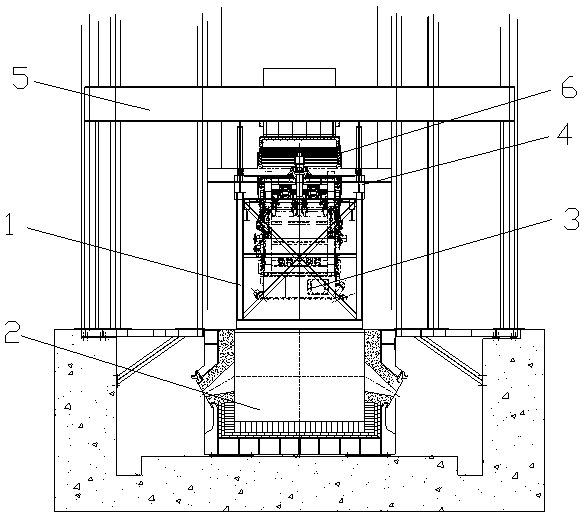

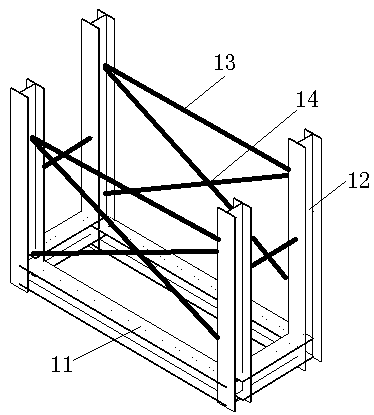

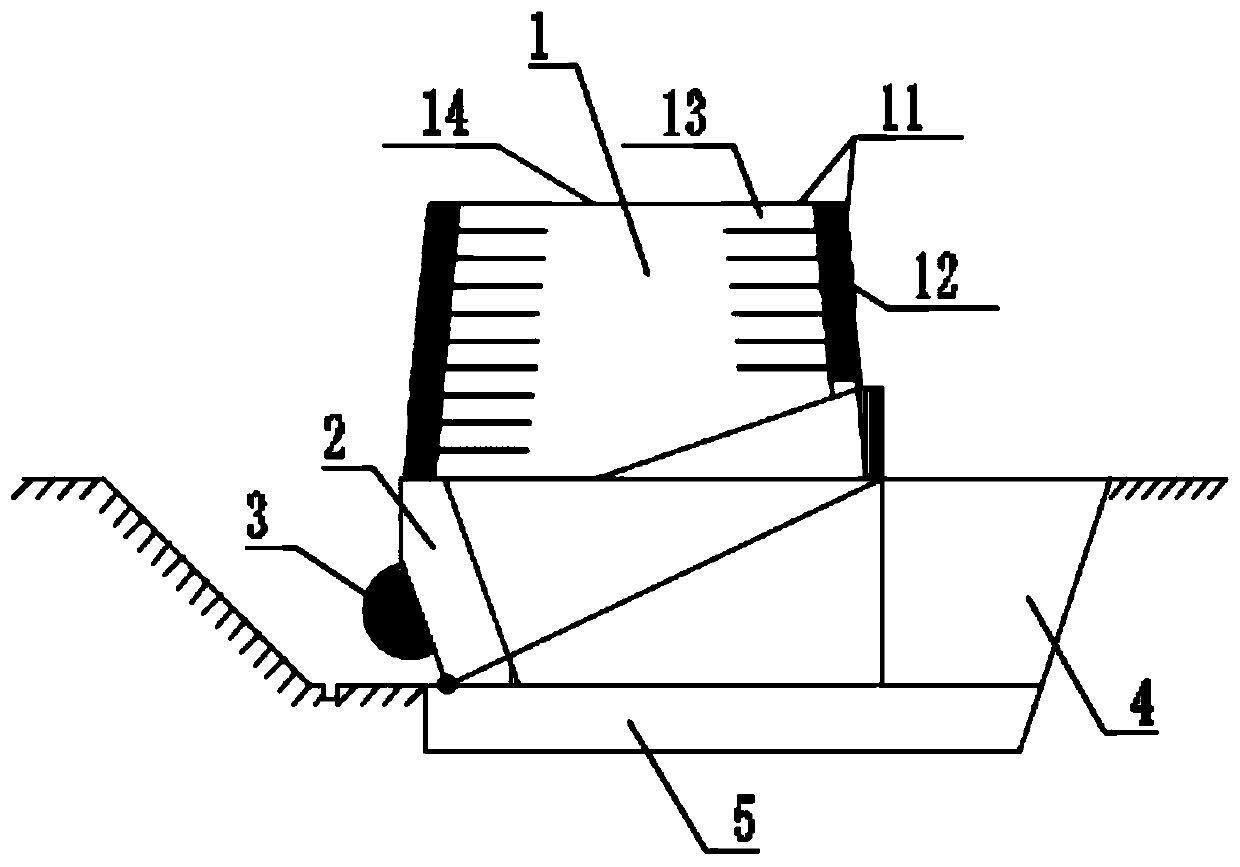

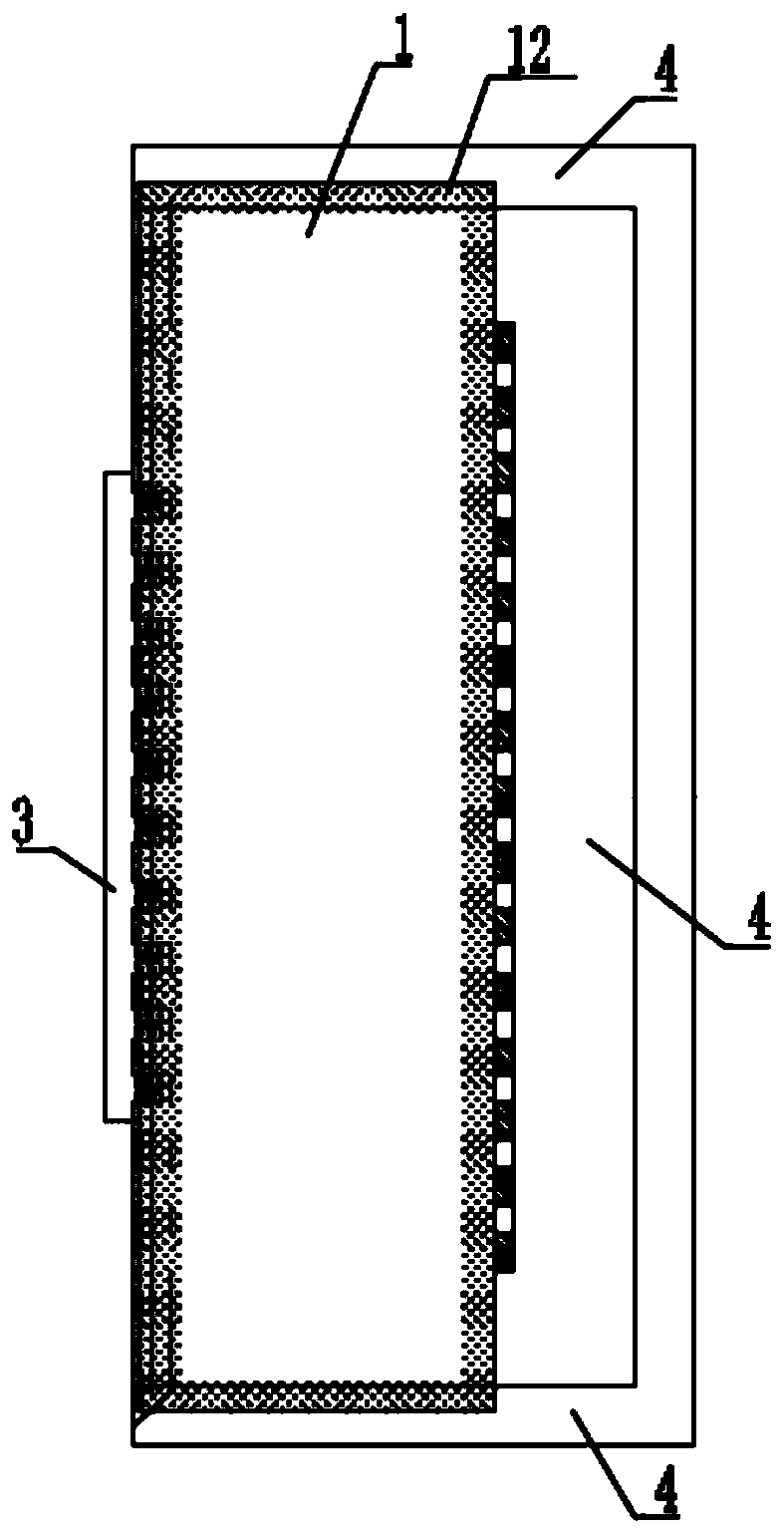

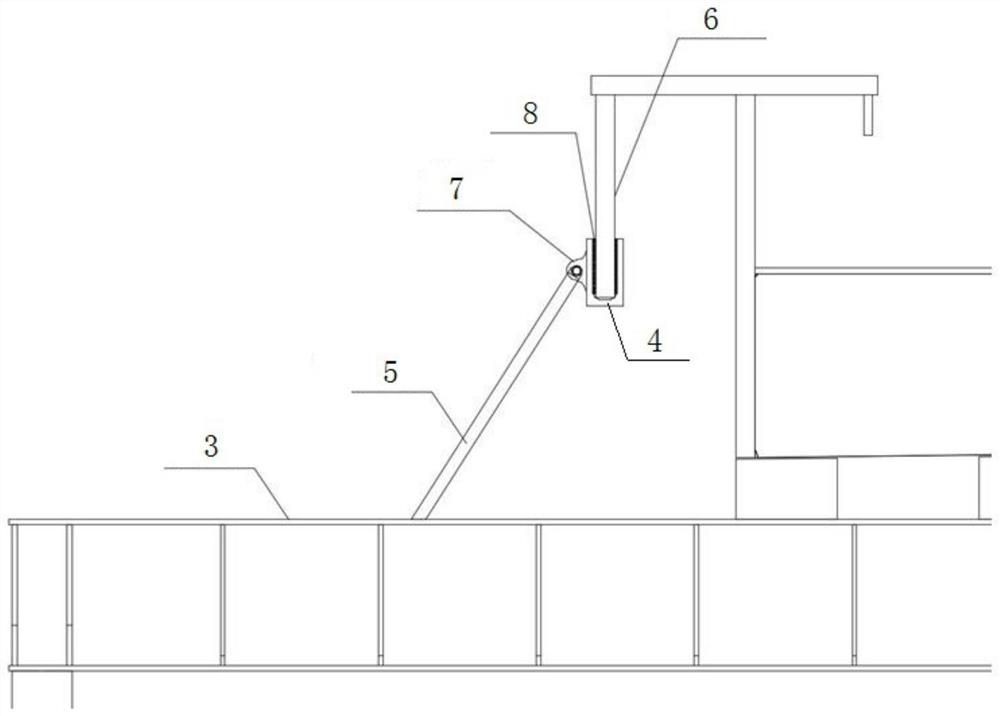

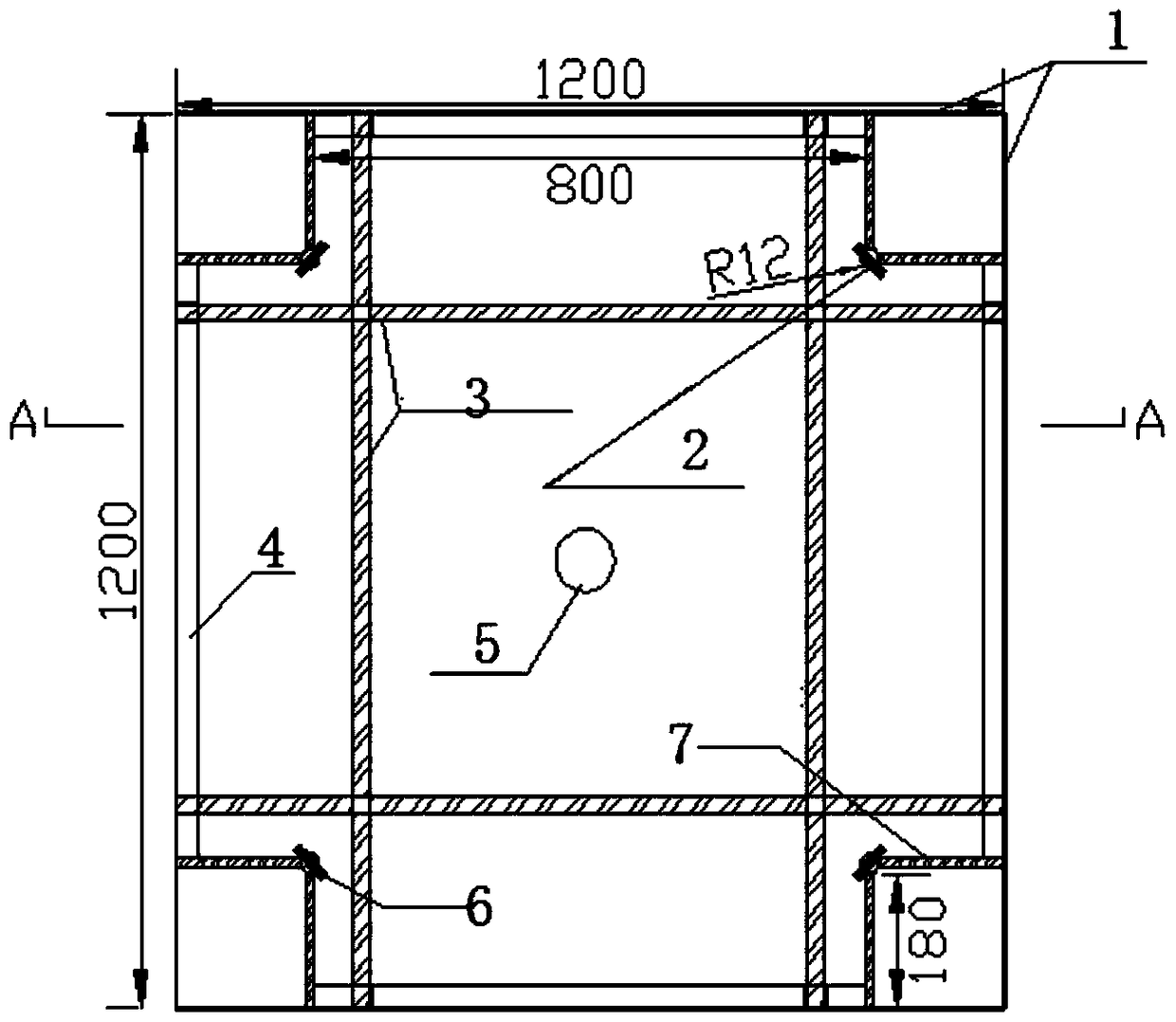

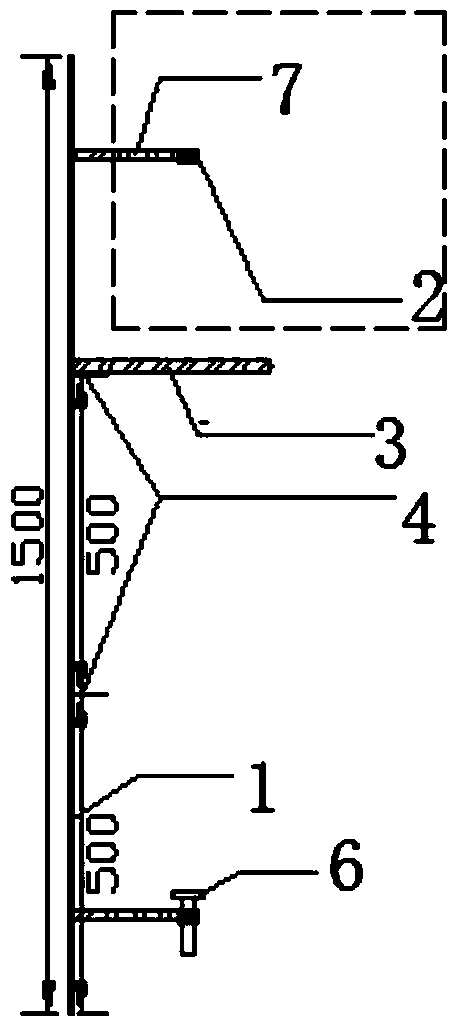

Tool type scaffold for elevator well

The invention discloses an elevator shaft scaffolding tool, which comprises a main beam (1), a steel I-beam (2), and is characterized by also comprising crab claws (3), pin shafts (4) and crab claw supports (5), wherein the main beam (1) and the steel I-beam (2) form a floor of the elevator shaft scaffolding tool. The crab claws supports (5) are welded at two ends of the main beam (1) and are connected with the crab claws (3). The structure can effectively reduce workload of and racks used in building and detaching the scaffolding tool in an elevator shaft as well as construction cost.

Owner:中建三局集团(深圳)有限公司 +1

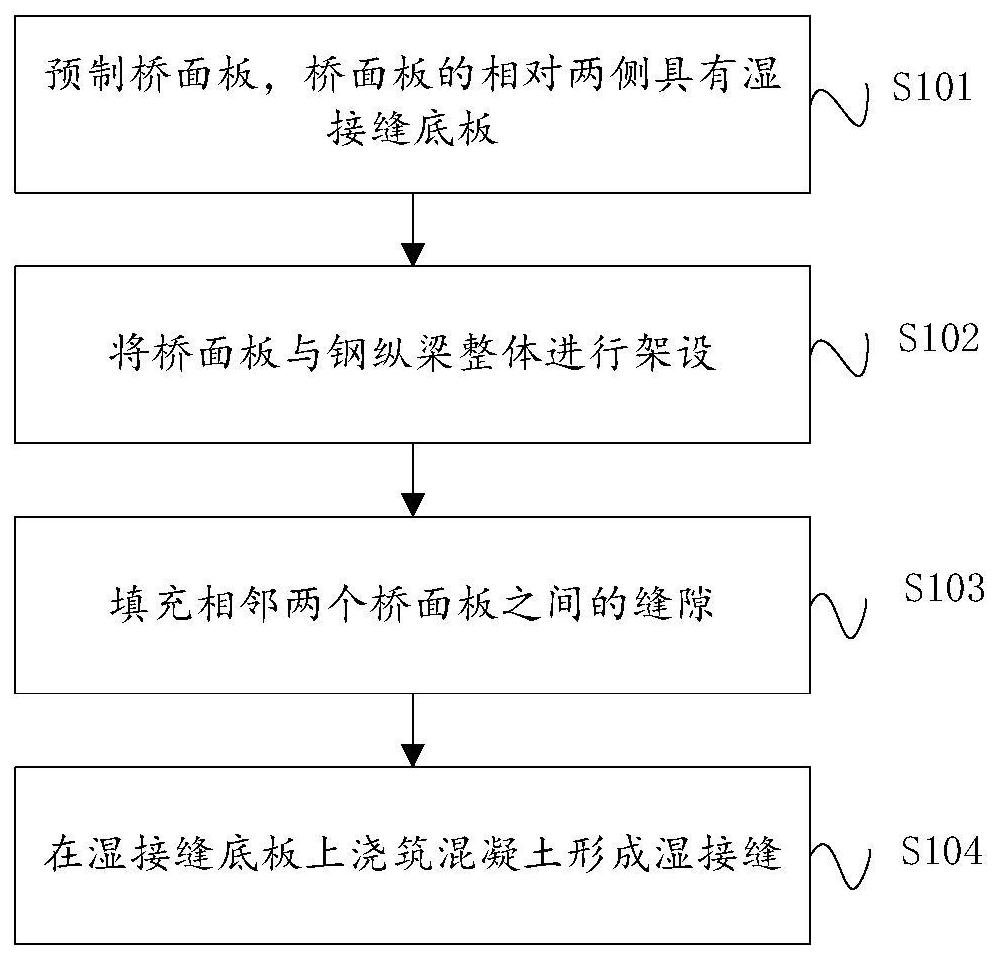

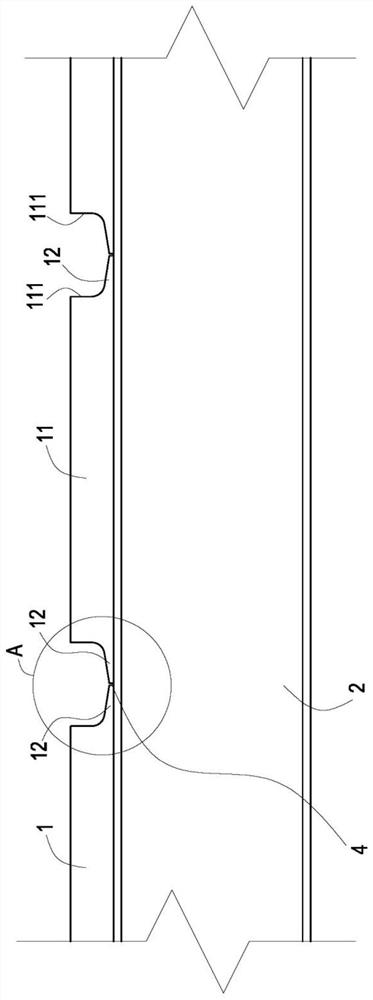

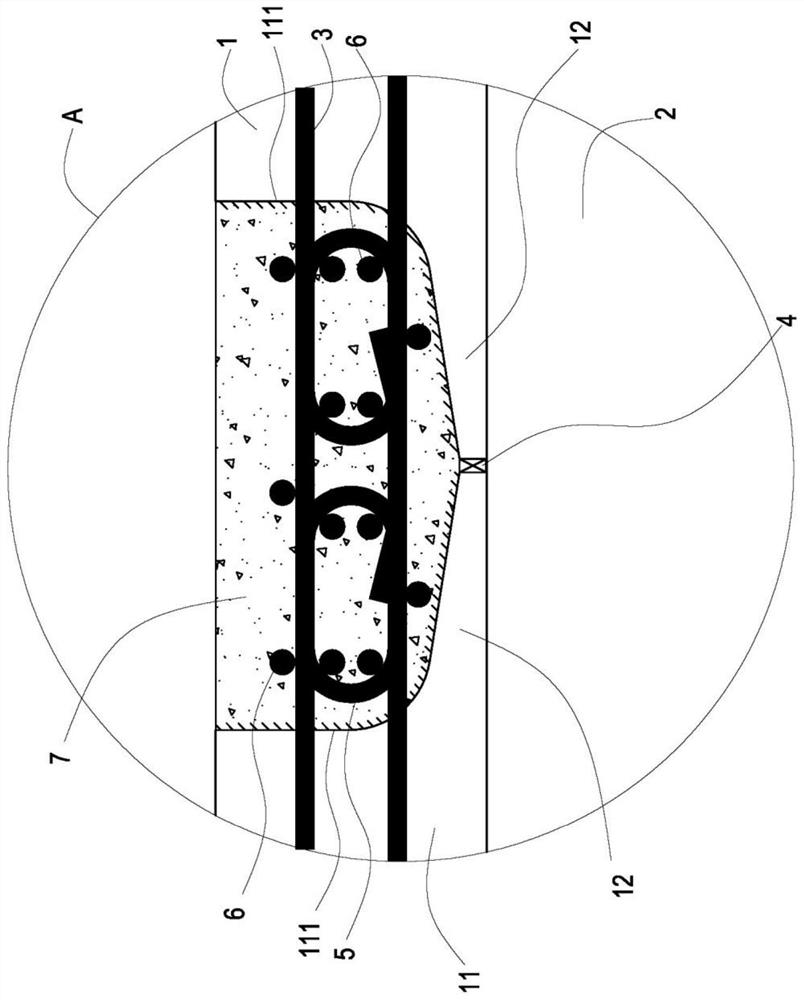

Cast-in-place wet joint construction method and bridge structure

PendingCN112323635AReduced installation effortReduced demolition workloadBridge structural detailsBridge erection/assemblyArchitectural engineeringBridge deck

The invention relates to a cast-in-place wet joint construction method and a bridge structure. The cast-in-place wet joint construction method comprises the following steps that bridge decks are prefabricated, and wet joint bottom plates are arranged on the two opposite sides of each bridge deck; the bridge decks and steel longitudinal beams are erected as a whole; a gap between every two adjacentbridge decks is filled; and concrete is poured on the wet joint bottom plates to form wet joints. According to the cast-in-place wet joint construction method and the bridge structure, the wet jointbottom plates prepared in advance can serve as the bottom dies of the cast-in-place wet joints, the workload of mounting and dismounting of the wet joint concrete bottom dies is reduced, and thereforeconstruction is convenient, and the workload is small.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD

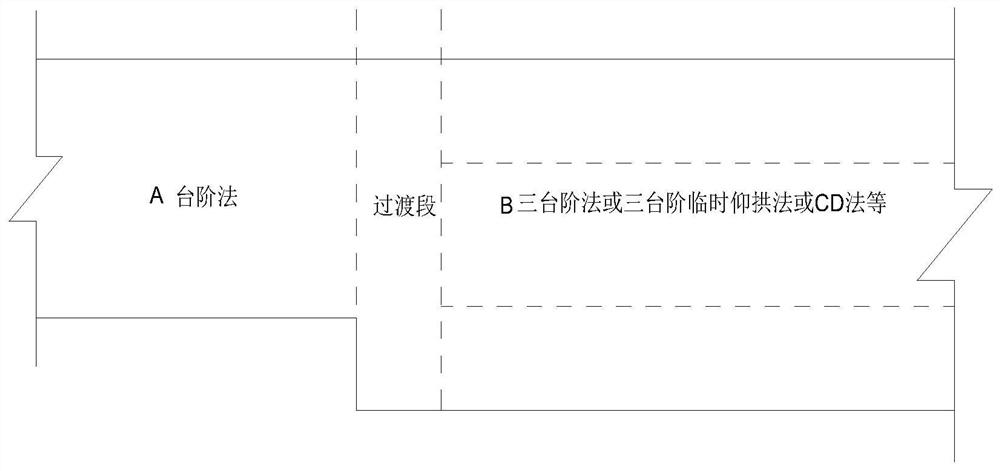

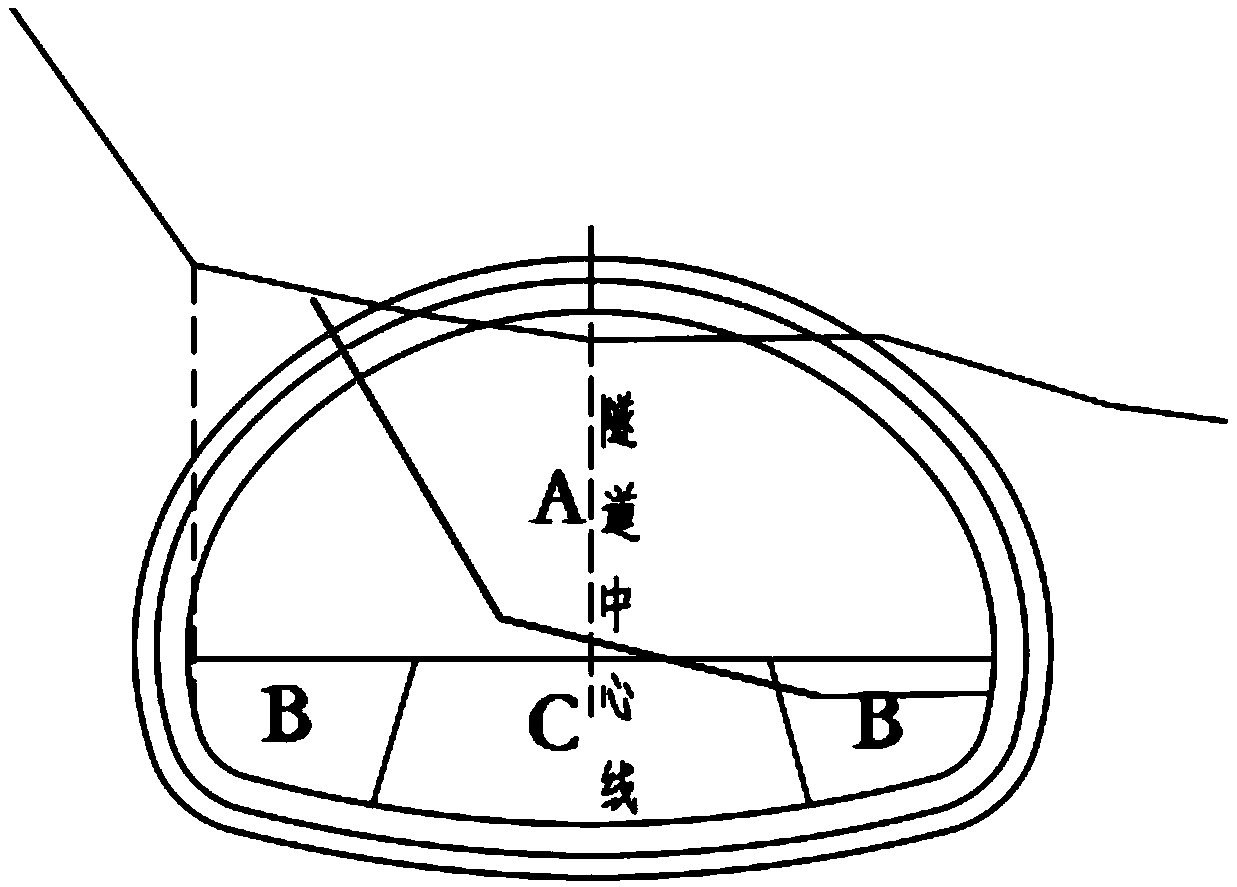

Construction method for transverse expanding excavation conversion when tunnel section suddenly changes to large-span section

PendingCN112814686AStress structure is stableReduced demolition workloadUnderground chambersTunnel liningArchitectural engineeringEngineering

The invention belongs to the field of tunnel engineering, and particularly relates to a construction method for transverse expanding excavation conversion when a tunnel section suddenly changes to a large-span section. According to the construction method, when the tunnel section enters the transition section of the suddenly-changed large-span section, firstly a preceding pilot tunnel is excavated, and then excavation expands towards the arch part of the suddenly-changed large-span section while excavating a following pilot tunnel; then 90-degree straight turning pilot tunnel expanding excavation is conducted in the side wall direction, during expanding excavation, a portal support is added to serve as temporary protection, and a portal cross beam is installed outside the large-span section contour line in the line direction; and after excavation is conducted to the position of a side wall arch foot of the large-span section, an annular arch frame of the large-span section is erected on the lower side of a portal cross beam at a time. According to the construction method, the portal support is large in operation space, high in safety and convenient to construct, meanwhile, the portal cross beam is arranged on the outer side of a main tunnel primary support arch frame, extension or erection of the main tunnel annular arch frame is not affected, the portal cross beam and upright end wall portal vertical supports at the junction of the two sections can serve as permanent primary supports, and the dismantling workload of the temporary portal is reduced.

Owner:CHINA RAILWAY 20 BUREAU GRP

Core formwork used for pouring top air passage of subway rail and construction method

ActiveCN110630019AEasy to removeReduced demolition workloadForms/shuttering/falseworksRear quarterWrinkle skin

The invention relates to a core formwork used for pouring a top air passage of a subway rail. The core formwork comprises a lower formwork plate, two side formwork plates separately hinged to the twoends of the upper side of the lower formwork plate, a supporting plate located over the lower formwork plate, and an inflatable airbag. Each side formwork plate comprises a side plate part hinged to the lower formwork plate and a corner part integrally formed on the upper edge of the side plate part, wherein one edge of the corner part is connected with the side plate part, and the other edge of the corner part upwards extends towards the supporting plate and abuts against the supporting plate. The inflatable airbag comprises an outer lining. The outer lining comprises slot-shaped first liningskin and second lining skin, wherein the first lining skin is fixed between the lower formwork plate and the two side formwork plates, and only the upper side of the first lining skin is opened; thesecond lining skin is fixed to the lower side of the supporting plate, and the two edges of the second lining skin stretch out of the supporting plate; and the edge of the second lining skin is fixedly connected with the open edge of the first lining skin, so that a wrinkle which is concave towards the interior of the outer lining is formed on the outer lining and corresponds to the contact position of the supporting plate and the lower formwork plate. The core formwork has the effects of being convenient to dismantle, small in dismantling work, and capable of saving time and labor.

Owner:CRPCEC SHENZHEN ENG

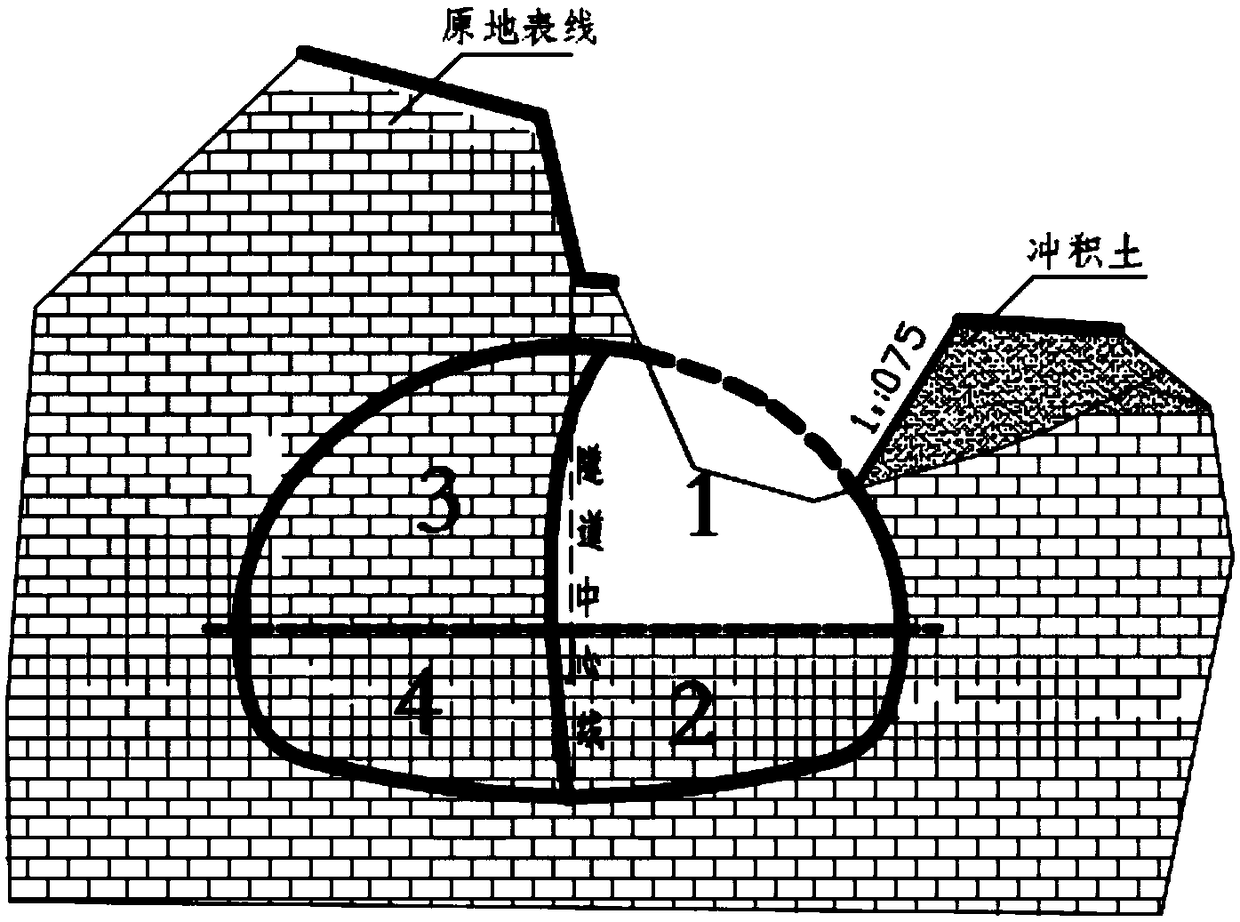

Shallow-burying exposure construction method applicable to hard rock tunnel with extra large fracture surface

ActiveCN108708739AFast constructionReduce construction costsUnderground chambersTunnel liningRock tunnelSoil science

The invention provides a shallow-burying exposure construction method applicable to a hard rock tunnel with an extra large fracture surface. The excavated volume of soft soil exposed on the earth surface is compared with that of a first excavation part formed by means of a CD method, cover arch construction is conducted if the excavated volume of the soft soil is higher than that of the first excavation part, a benching tunneling method is adopted for excavation, and if the excavated volume of the soft soil is not higher than that of the first excavation part, the CD method is adopted for excavation; according to the CD method, the whole process is divided into four steps for excavation, correspondingly there are four parts to be supported, and backfill of the ground needs to be conductedin time after a second excavation part is completed; according to the benching tunneling method, the whole process is divided into three steps for excavation, and backfill of the earth surface is conducted after excavation of an upper bench is finished; side slopes of excavated soft soil are supported in time through bolt mesh spraying. The open excavation amount and grouting amount of the groundare decreased under the situation that the fracture surface of the tunnel is extra large, the adaptability is high, environmental pollution is small, the excavation speed is high, and economic benefits are remarkable.

Owner:CHINA TIESIJU CIVIL ENG GROUP +1

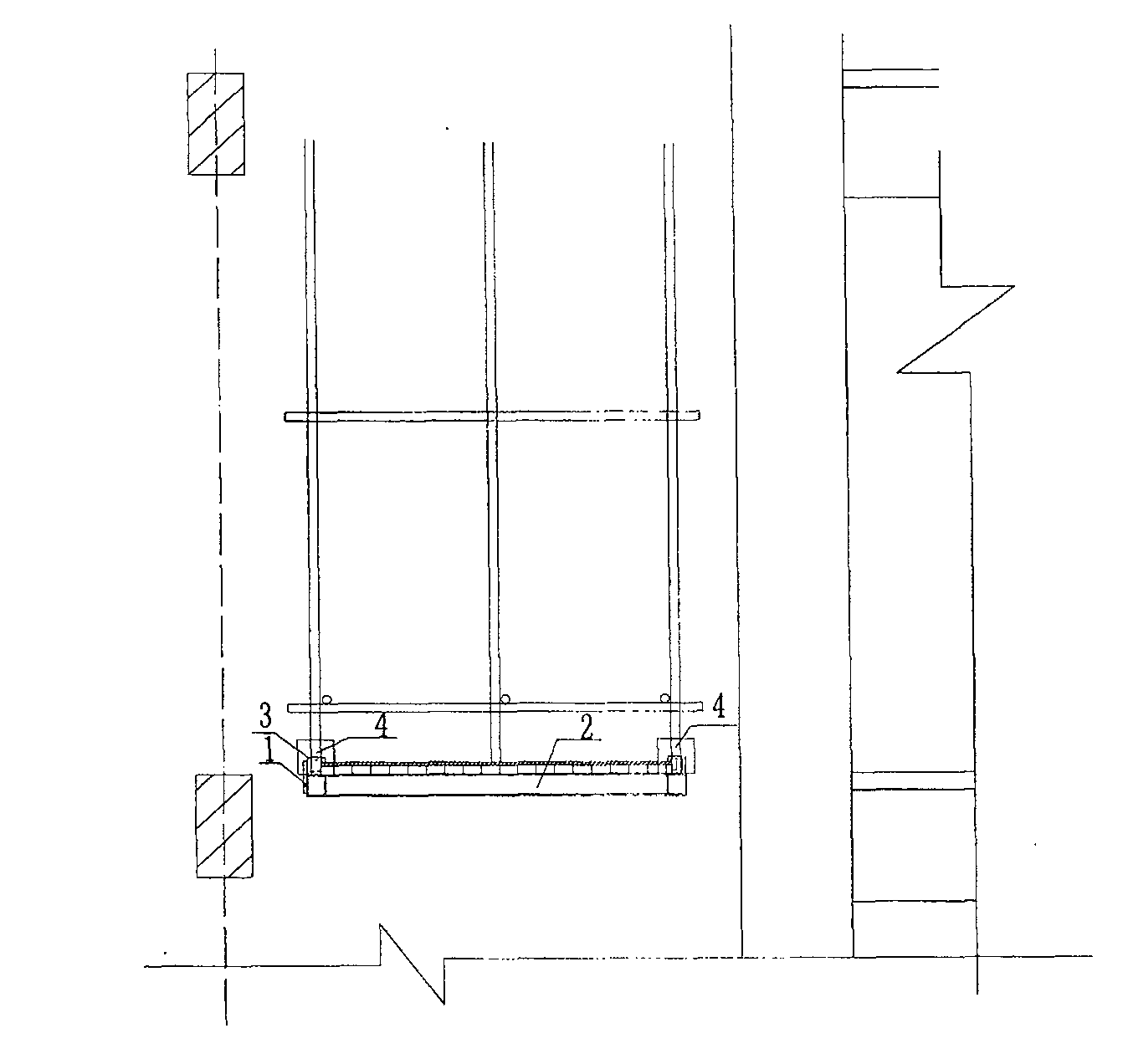

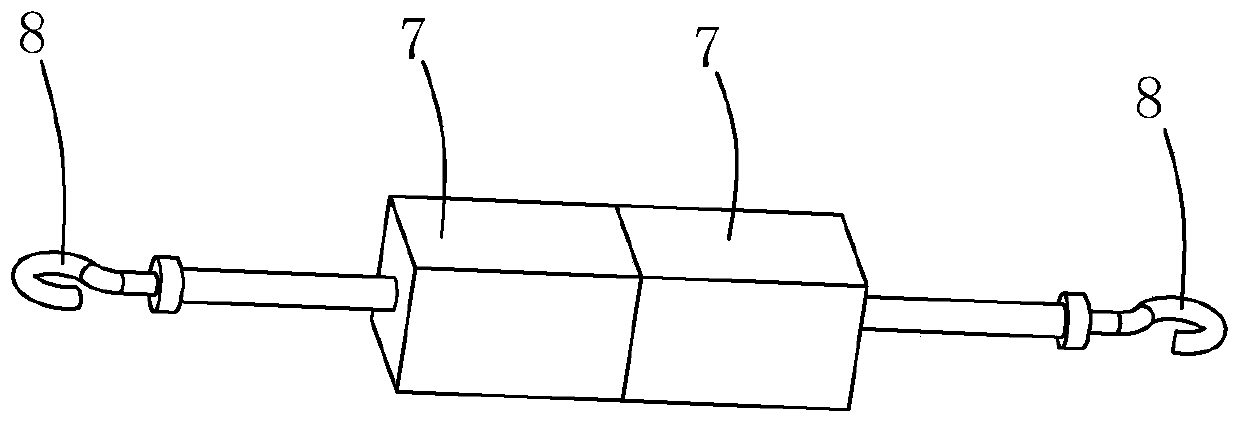

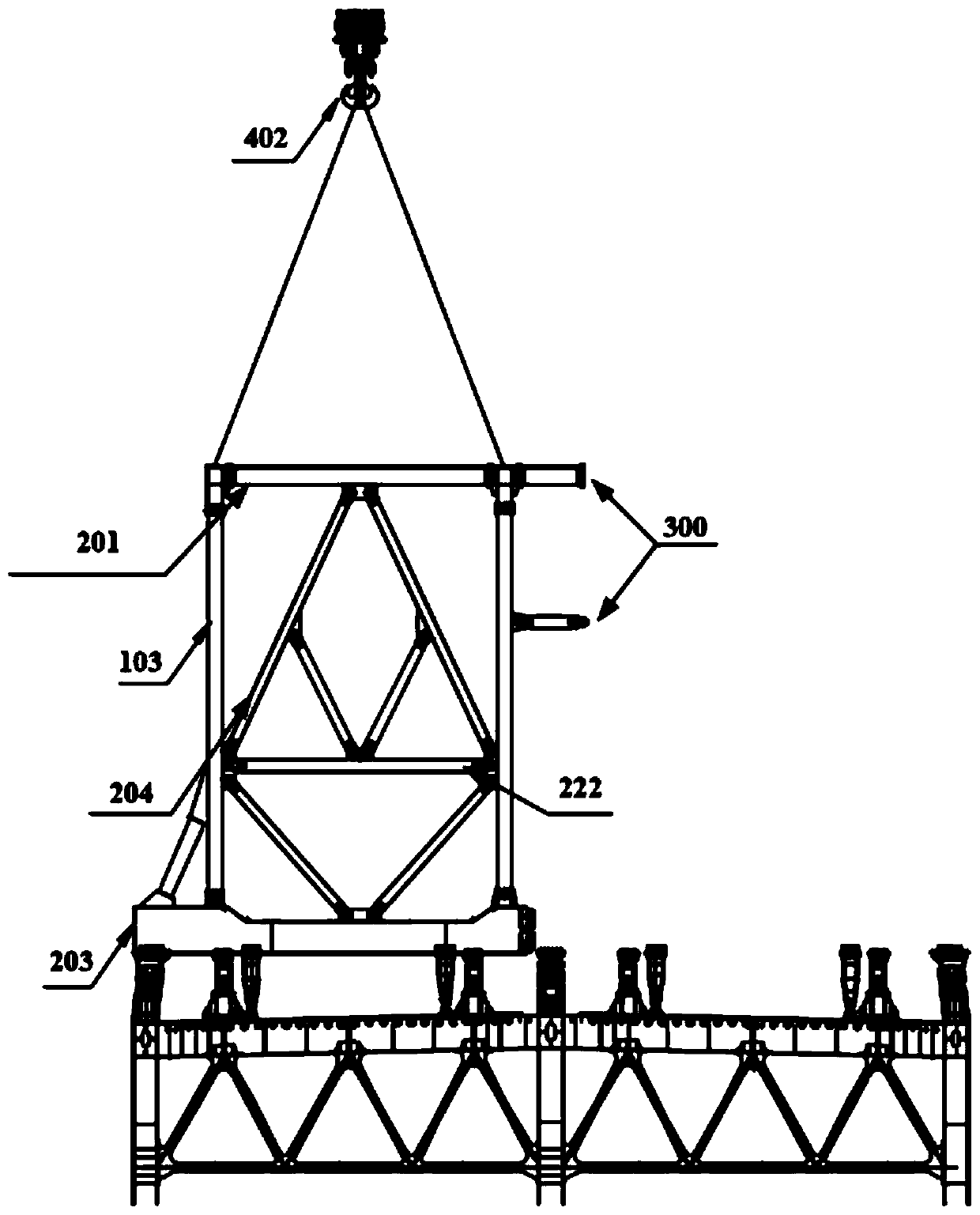

Fining twisted steel-based lifting appliance and lifting method thereof

InactiveCN101898739AReduce productionReduce installationLifting devicesReciprocating motionArchitectural engineering

The invention discloses a fining twisted steel-based lifting appliance and a lifting method thereof. The lifting appliance comprises a first fixed beam; fining twisted steel passes through the two ends of the first fixed beam through an anchor; the middle of the fining twisted steel passes through a second fixed beam through an anchor; a hydraulic jack is arranged above the second fixed beam; the top of the hydraulic jack is provided with a movable beam; and the fining twisted steel passes through the two ends of the movable beam through an anchor. The lifting method comprises the following steps of: welding the first fixed beam on a lifted object, and welding the second fixed beam on a fixed reference object; fastening the anchor on the movable beam and the anchor on the first fixed beam, and lifting the hydraulic jack; loosening the anchor on the movable beam, fastening the anchor on the second fixed beam, and retracting the hydraulic jack; and reciprocating the movable beam until the lifted object is in position. The fining twisted steel and the anchors are adopted to serve as the lifting appliances for the first time so as to lift equipment in a small space and avoid frequent replacement of stress groups.

Owner:TIANJIN 20 CONSTR

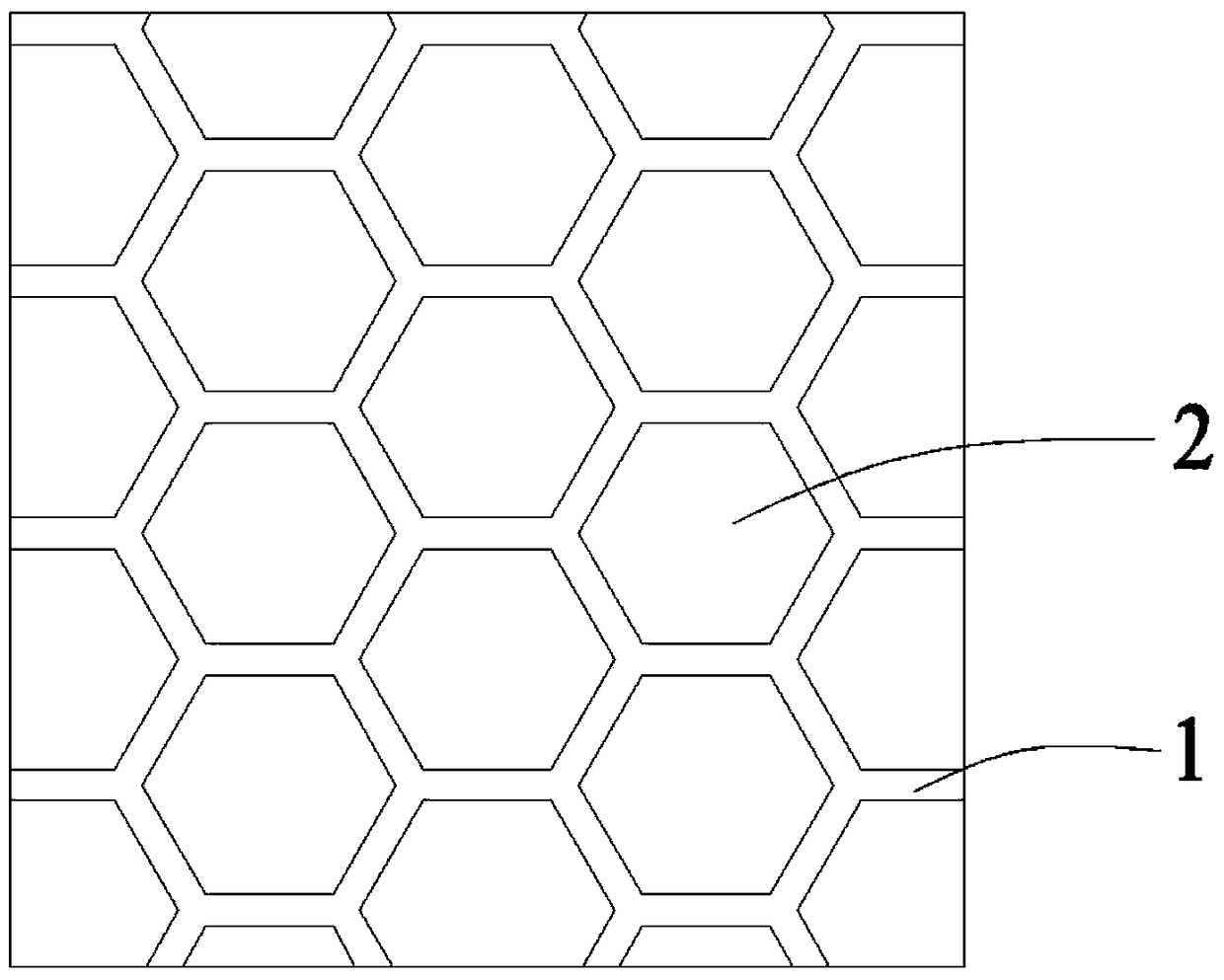

Water-stopping form board

PendingCN109267543ALess investmentImprove pouring qualityArtificial islandsProtective foundationBoard structureBuilding construction

The invention relates to the technical field of building construction structures, in particular to a water-stopping form board. The water-stopping form board comprises a flaky framework and is characterized in that a plurality of through holes are evenly distributed in the framework, first filling structures which can expand after water absorption are filled into the through holes, the first filling structures filled into the through holes and the framework form a planar form board structure without pores in the surface, and a waterproof structure with time effectiveness wraps the outer side of the form board formed by the framework and the first filling structures. The water-stopping form board is simple in structure, convenient in mounting and pouring, capable of greatly increasing concrete pouring efficiency, capable of increasing the water stopping effect at concrete gaps and worthy of popularization and does not need an additional new water-stopping structure.

Owner:HUBEI PROVINCIAL WATER RESOURCES & HYDROPOWER PLANNING SURVEY & DESIGN INST

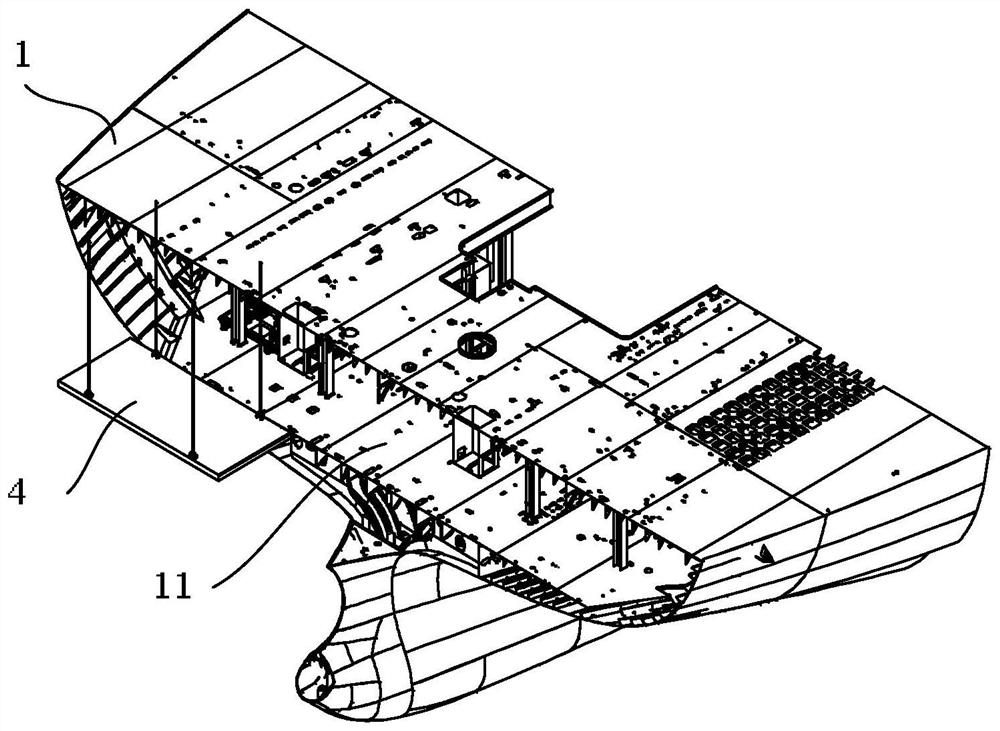

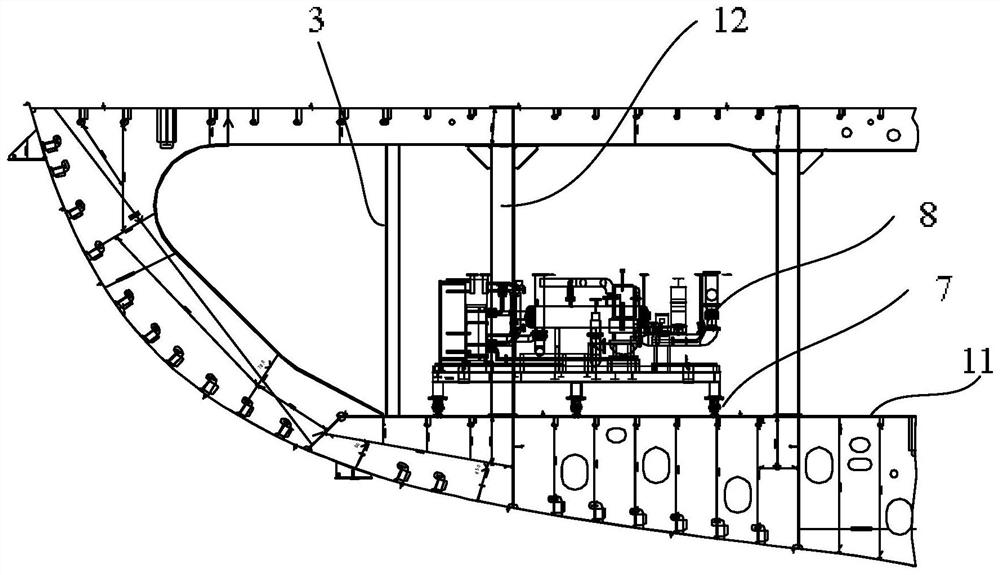

Cabin sealing installation method of a water glycol unit for dual-fuel bulk cargo shi

The invention relates to the technical field of ships, in particular to a cabin sealing installation method of a water glycol unit for a dual-fuel bulk cargo ship, which comprises the following steps of: determining an obstacle strut on an entering path of to-be-installed equipment in an opening end of a three-deck block; supporting and reinforcing components are installed on the side portions of the obstacle supporting columns and the lower portion of a lower plate of the three-deck block; dismantling the obstacle supporting columns and other obstacles; laying a first rail on the bearing component, and laying a second rail on the lower plate; installing the walking wheels on the to-be-installed equipment, and then hoisting the to-be-installed equipment to the bearing component; hoisting the bearing component to the position flush with the edge of the lower plate, and fixing the bearing component; applying external force, so that the to-be-installed equipment sequentially moves to a preset position along the first track and the second track; and subsequently repairing and welding the supporting columns, and dismounting the second rail and the supporting reinforcing member. Before the tail block is carried, the equipment to be installed is pulled in from the tail, the workload of dismantling the structure and an outfitting piece is minimum, the construction is most convenient, and the influence of cabin sealing is avoided.

Owner:SHANGHAI WAIGAOQIAO SHIP BUILDING CO LTD

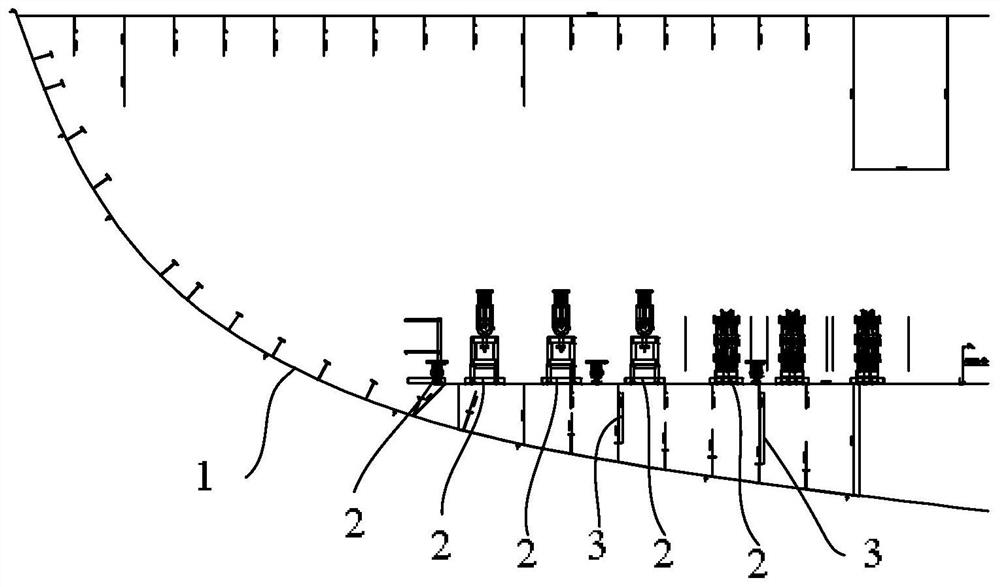

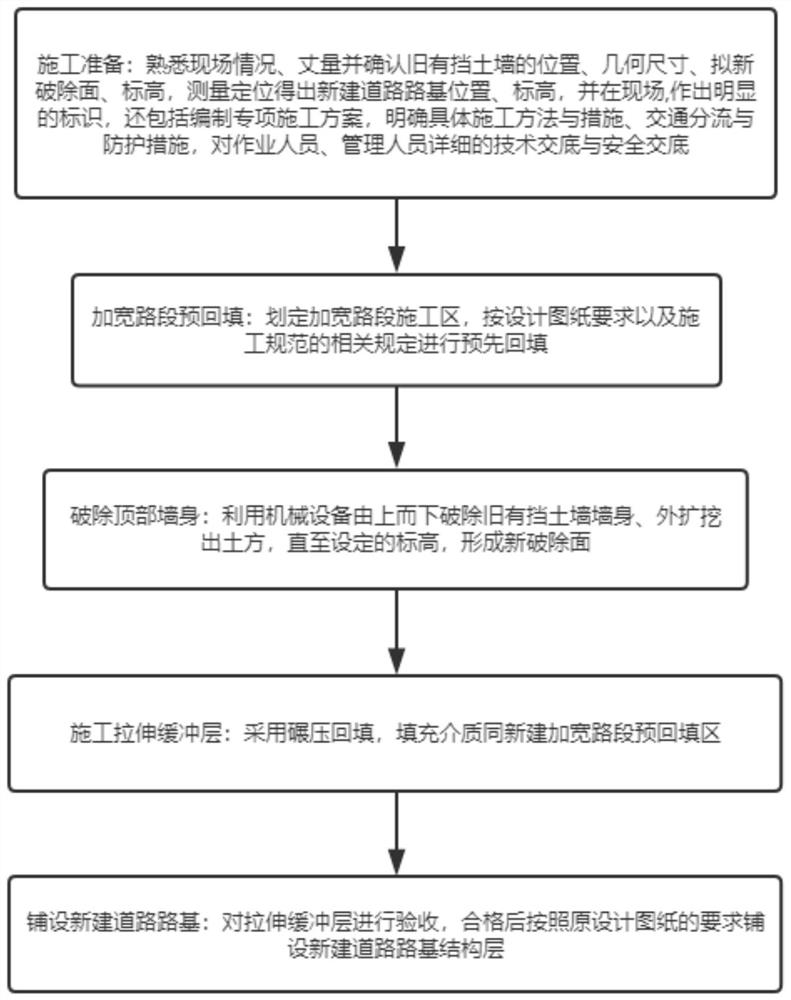

Construction method for treating old retaining wall by arranging stretching buffer layer

PendingCN112878124AAvoid destructionImprove integrityArtificial islandsRoadwaysTraffic diversionArchitectural engineering

The invention discloses a construction method for treating an old retaining wall by arranging a stretching buffer layer, and relates to the technical field of civil engineering. The problems that the construction period is prolonged, and the safety protection risk of operation points is increased are solved. The construction method specifically comprises the following steps: construction preparation: being familiar with site conditions, measuring and confirming the position and geometric dimension of an old retaining wall, simulating a new broken surface and elevation, measuring and positioning to obtain the position and elevation of a new road roadbed, making an obvious mark on site, compiling a special construction scheme, and determining specific construction methods and measures, traffic diversion and protection measures and detailed technical disclosure and safety disclosure for operating personnel and management personnel; widening road section pre-backfilling: delimiting a widening road section construction area, and performing pre-backfilling according to design drawing requirements and related regulations of construction specifications. According to the method, unnecessary work content is greatly reduced, the production efficiency is improved by reducing the workload, and the construction period is shortened.

Owner:广西建工第五建筑工程集团有限公司

Flue modification method and flue anticorrosive structure

InactiveCN109631065AWithout changing the load-bearing structureReduce loadChimneysBrickInsulation layer

The invention discloses a flue modification method and a flue anticorrosive structure. The flue modification method comprises: removing the original heat insulation layer and the inner liner layer ofa flue shell, and performing sandblasting, grinding and partial repairing on the inner wall of the flue shell; and then coating the inner wall of the flue shell with a primer layer, and after the primer layer is completely cured, adhering a glass brick to the primer layer with an adhesive to form a heat-insulating anti-corrosion layer. The flue anticorrosive structure comprises a flue shell, and is characterized in that the inner wall surface of the flue shell is covered with a heat-insulating anti-corrosion layer, and the heat-insulating anti-corrosion layer comprises a primer layer coveringthe inner wall surface of the flue shell and a glass brick attached to the primer layer with an adhesive. The invention utilizes the original concrete (brick) flue shell structure, and uses the superior anti-corrosion characteristics of the primer, the adhesive and the glass brick, thereby achieving the dual purpose of anti-corrosion and heat preservation in the wet flue gas environment, and provides a cost-effective flue modification structure with simple structure and an effective anti-corrosion layer.

Owner:上海辰鸣电力工程有限公司

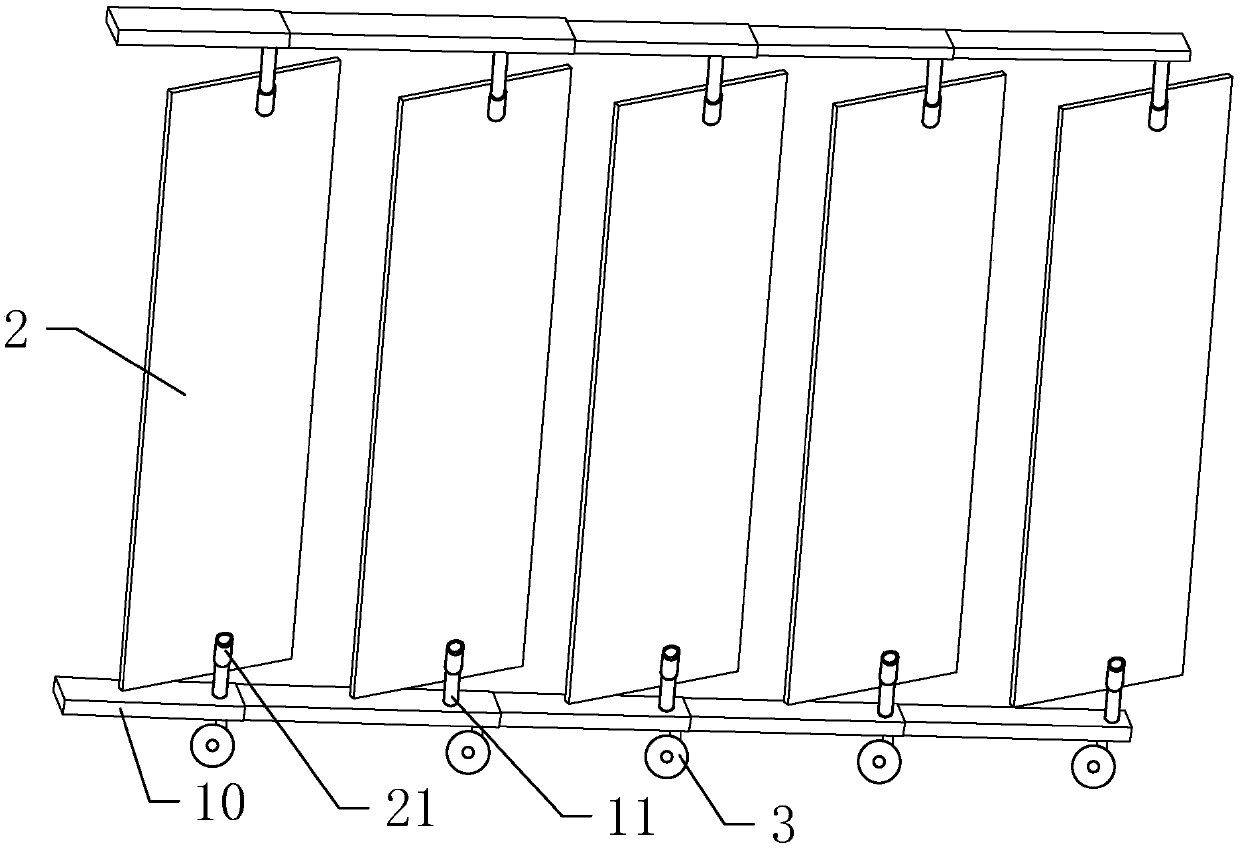

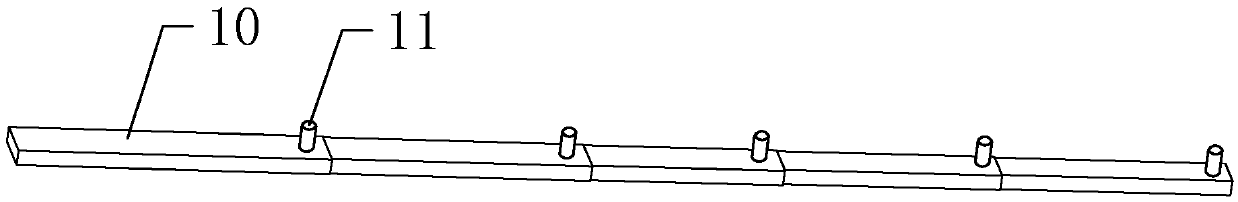

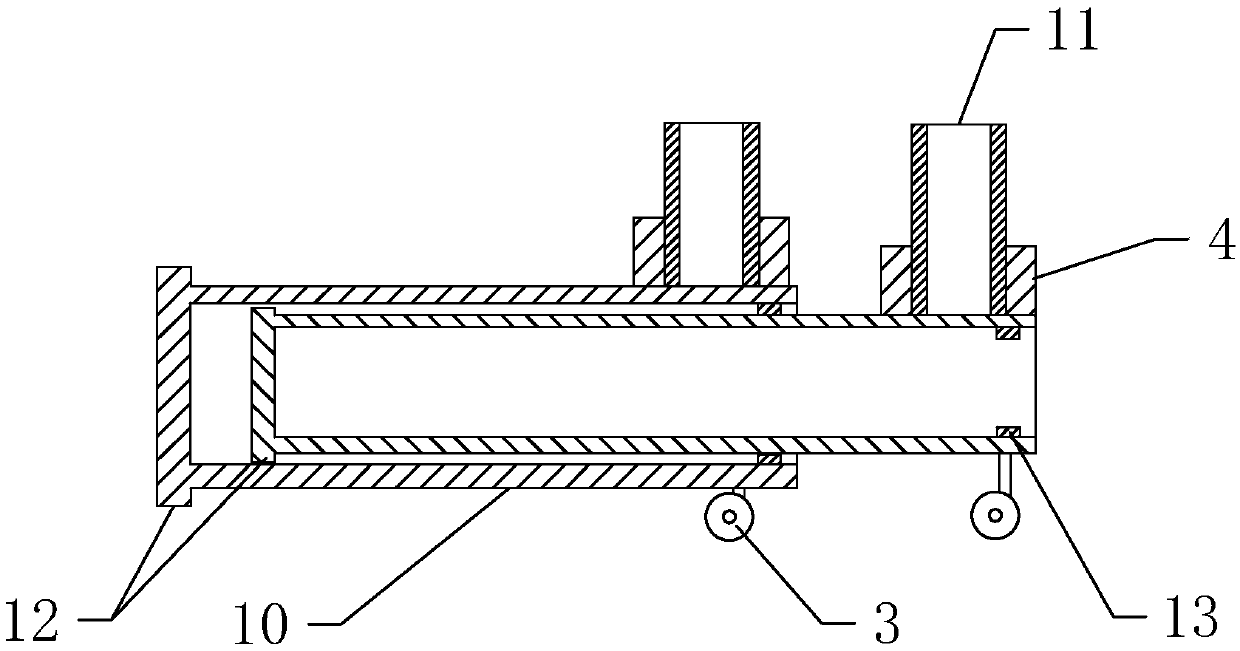

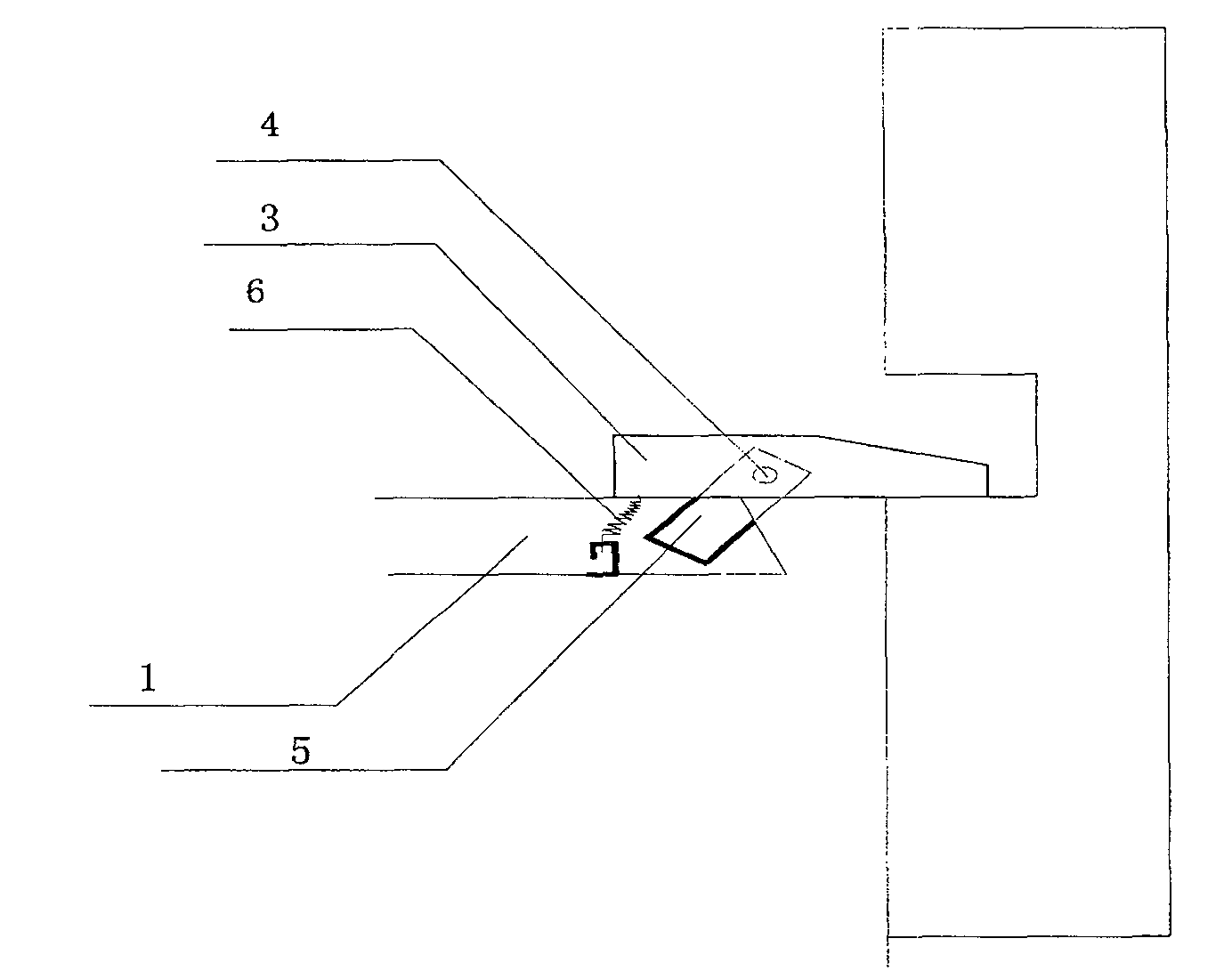

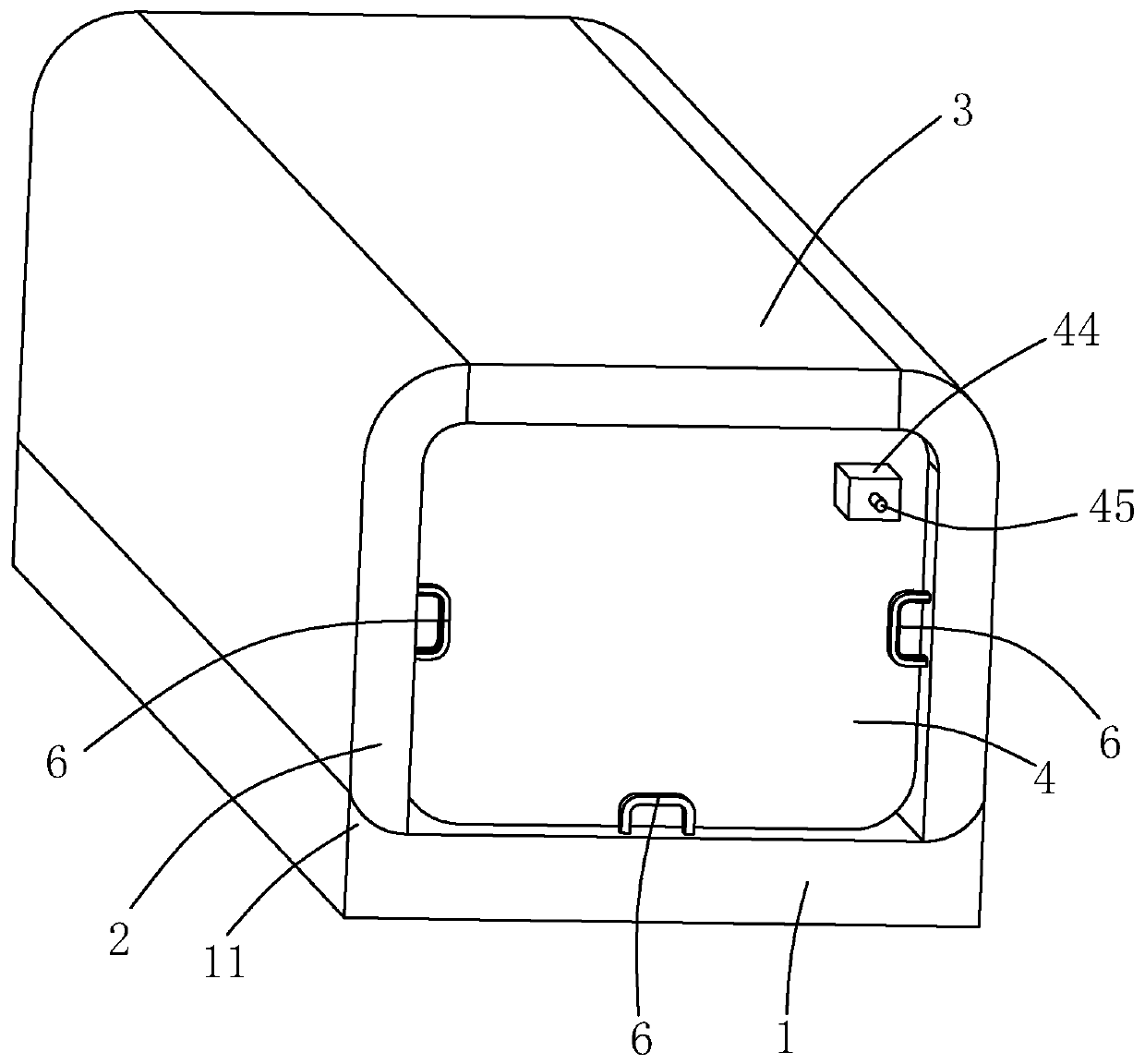

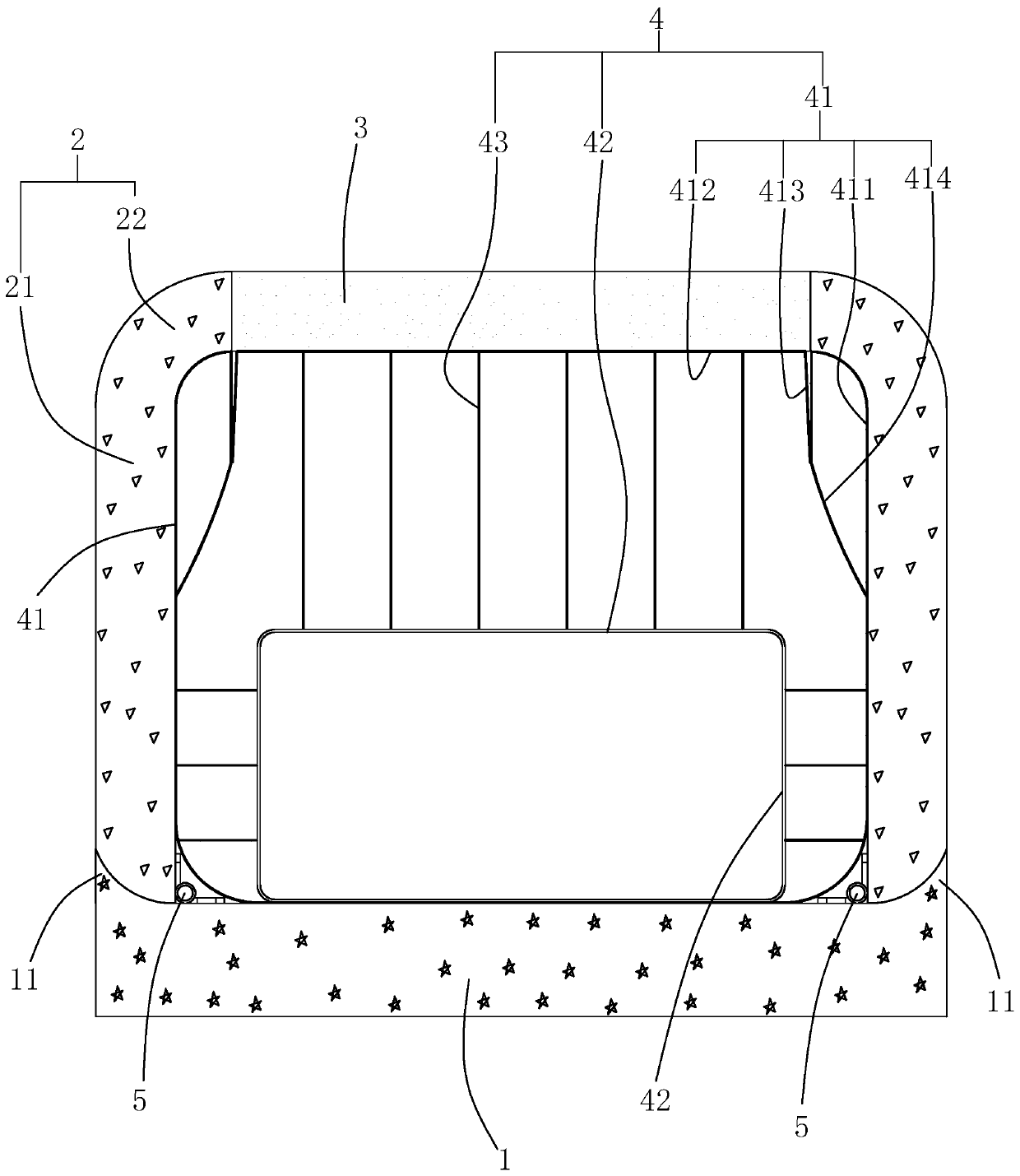

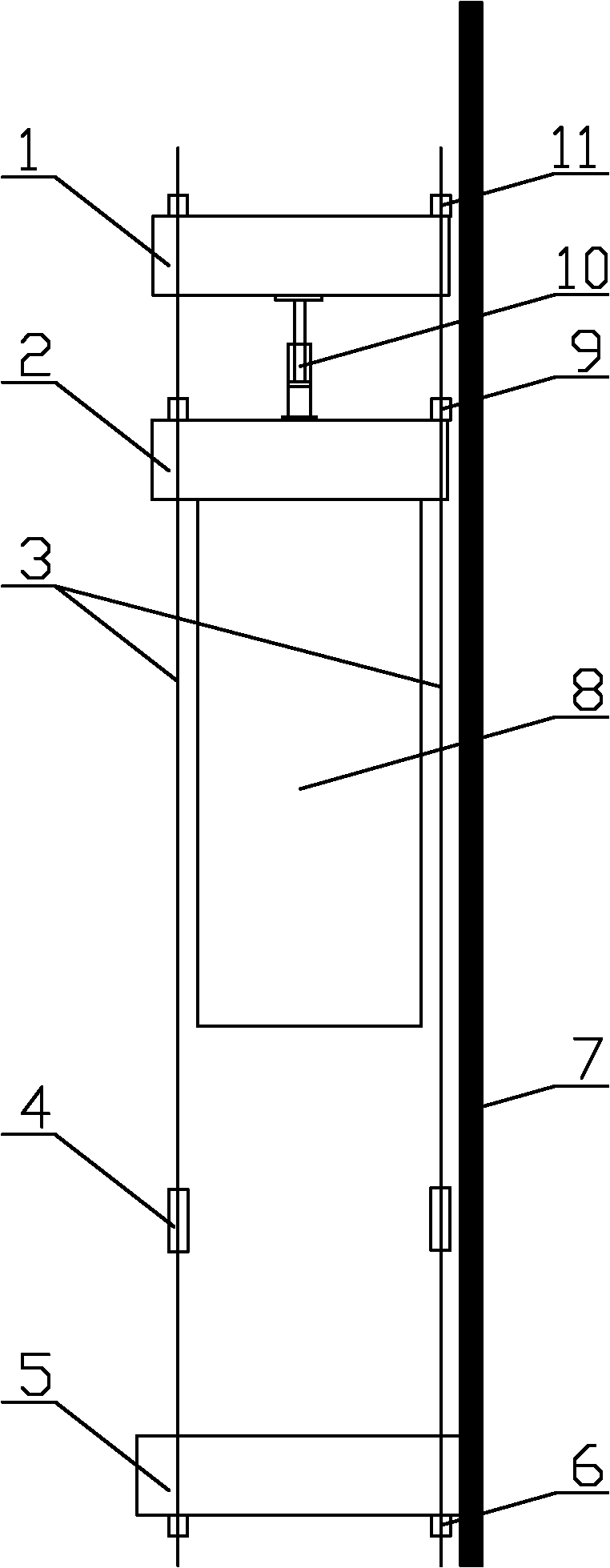

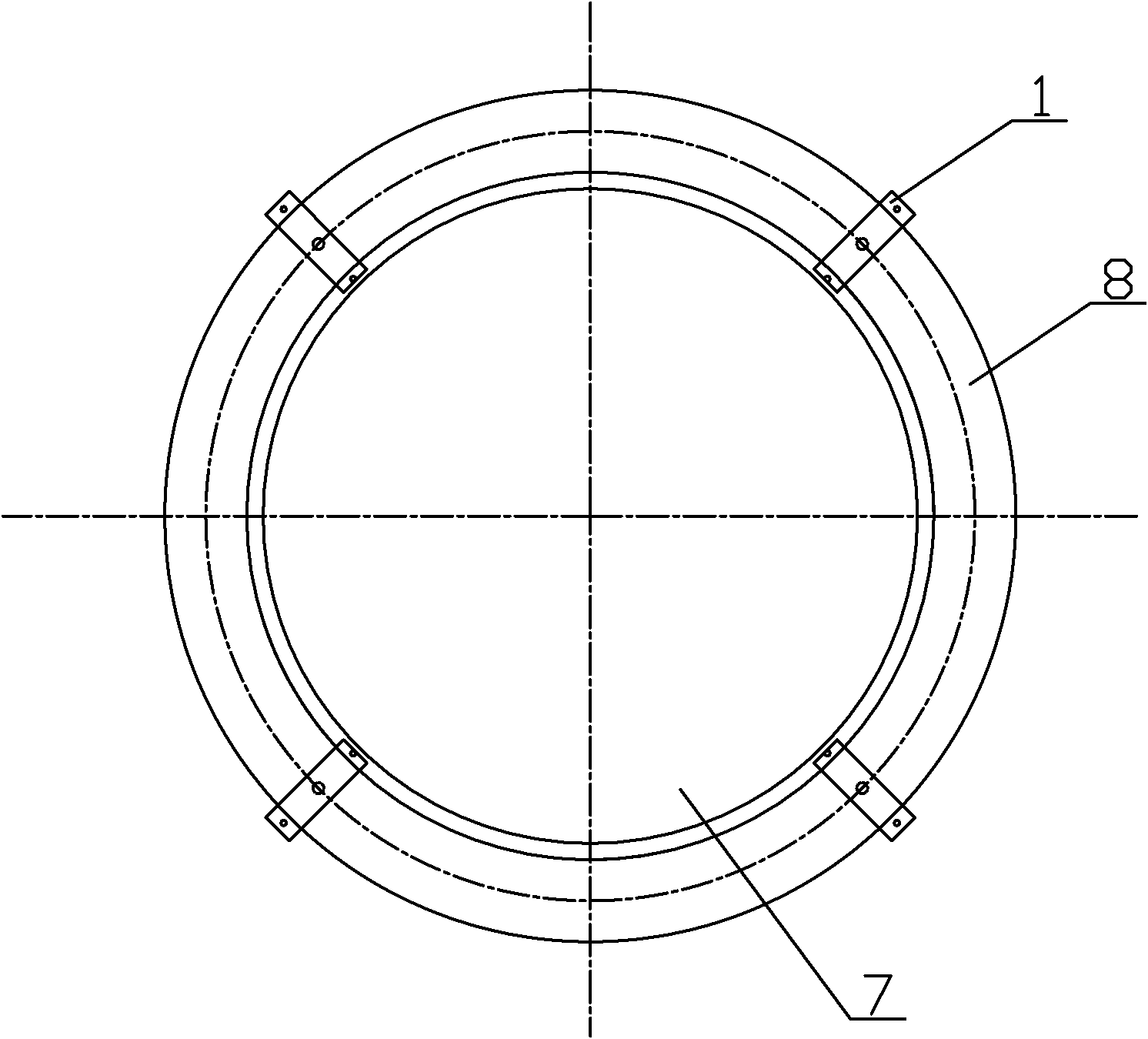

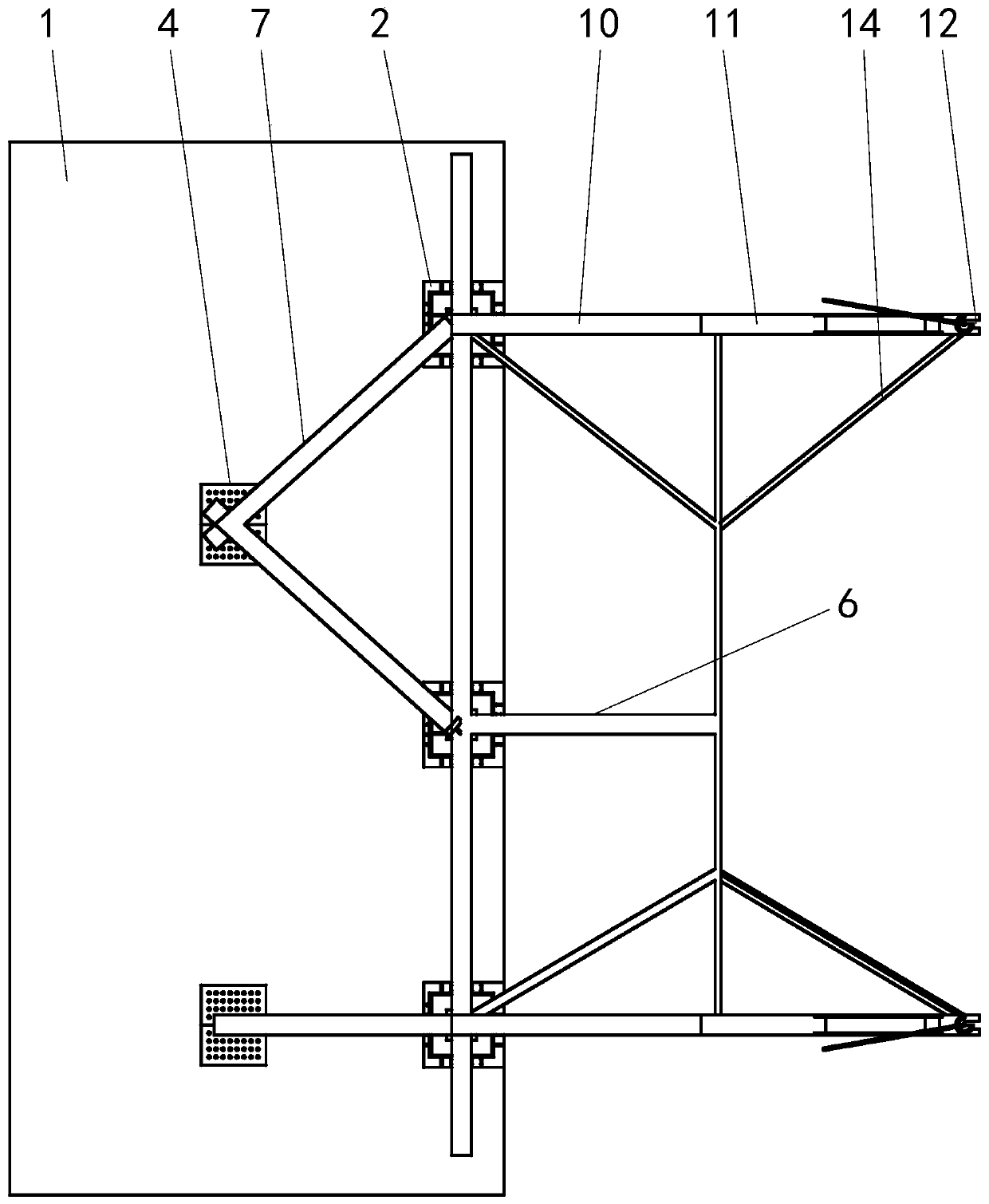

Sealing equipment and construction technology of lng full-contained tank vault air blowing jacking process

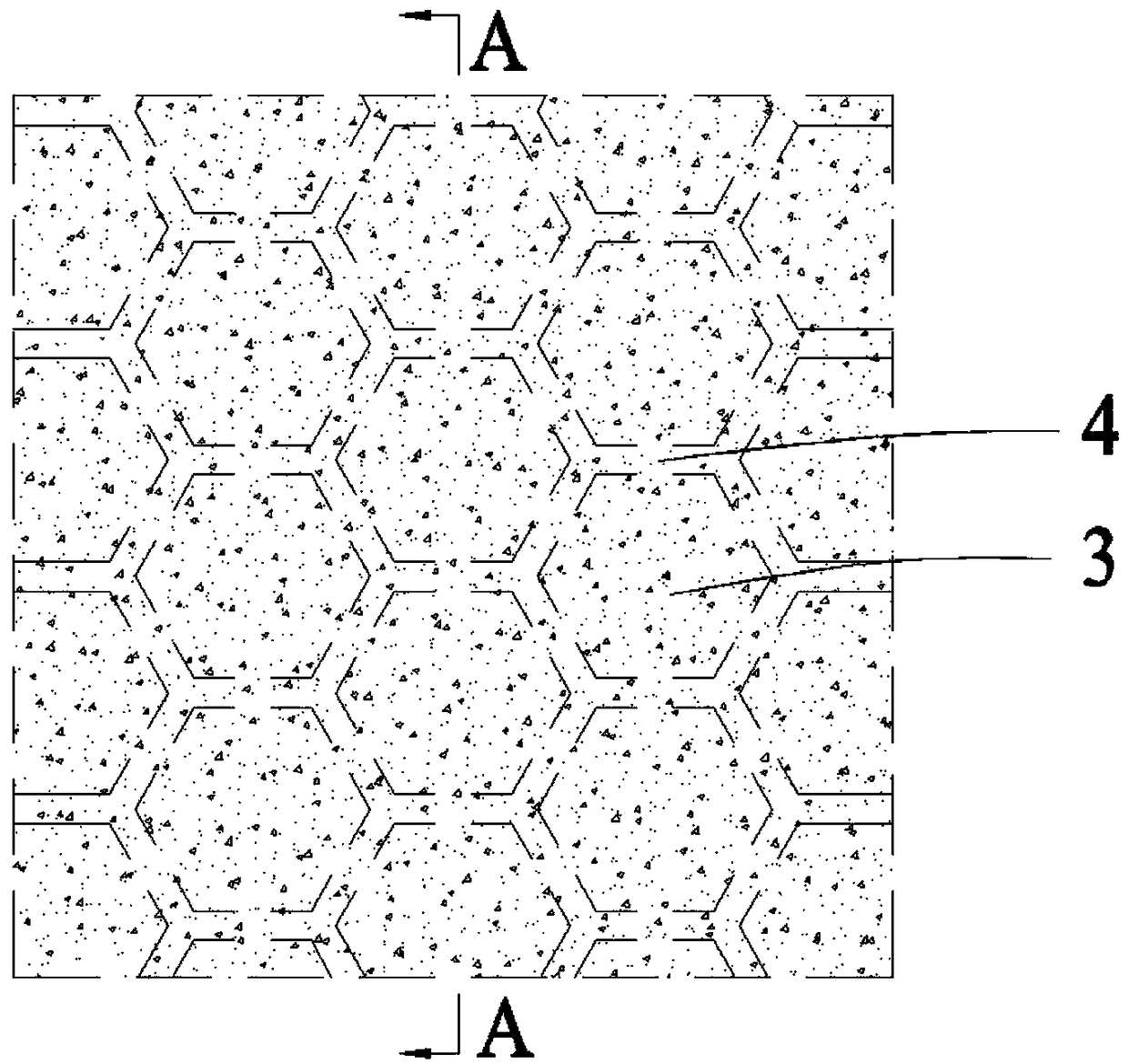

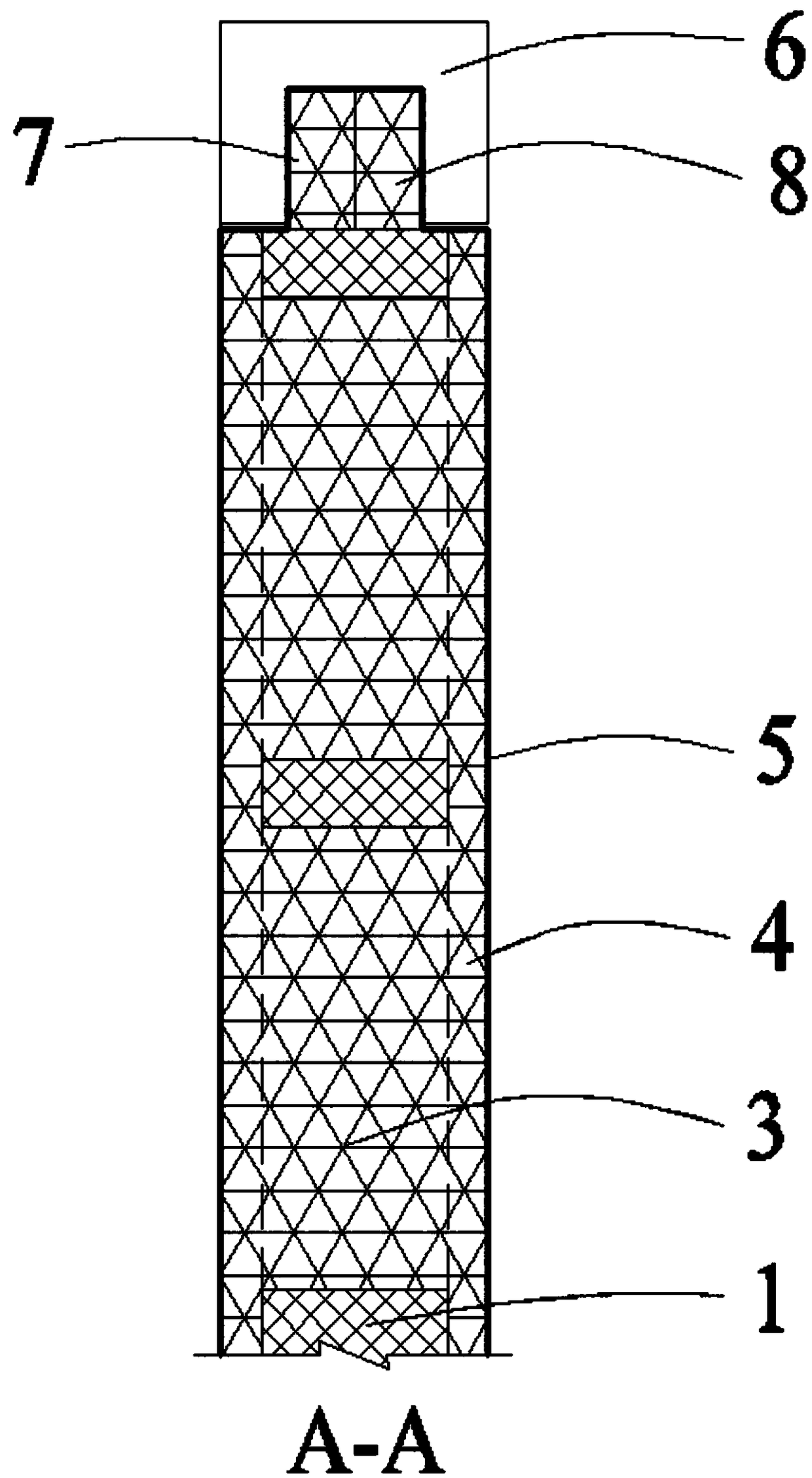

ActiveCN103899756BReduced demolition workloadFit tightlyEngine sealsPressure vesselsEngineeringClerestory

The invention relates to a set of sealing equipment and construction technology in the LNG full containment tank vault air-blowing jacking process and belongs to the technical field of LNG full containment tank equipment. The equipment comprises a main seal and an auxiliary seal. The main seal comprises a plurality of main sealing plates (1) which are connected end to end in an overlapped mode, and the upper edges of the main sealing plates (1) are fixed to the lower surface of a tank top covering plate (7). The auxiliary seal comprises auxiliary sealing soft plates (2) connected to the lower portions of the main sealing plates (1) in an overlapped mode. According to the construction technology, after the main sealing plates (1) and the auxiliary sealing soft plates (2) are cut according to specific specifications, the main sealing plates (1) are fixed to the lower surface of the tank top covering plate (7) through a batter board (3) and wedges (4), the auxiliary sealing soft plates (2) are bonded to the lower edges of the main sealing plates (1), after sealing is qualified, enough air is introduced in, and then vault air-blowing jacking is completed. Through the sealing equipment and the construction technology in the LNG full containment tank vault air-blowing jacking process, the problems that a sealing system in the LNG full containment tank vault air-blowing jacking process is difficult to install, poor in sealing effect and high in requirement for a concrete outer tank wall are solved.

Owner:SINOPEC TENTH CONSTR

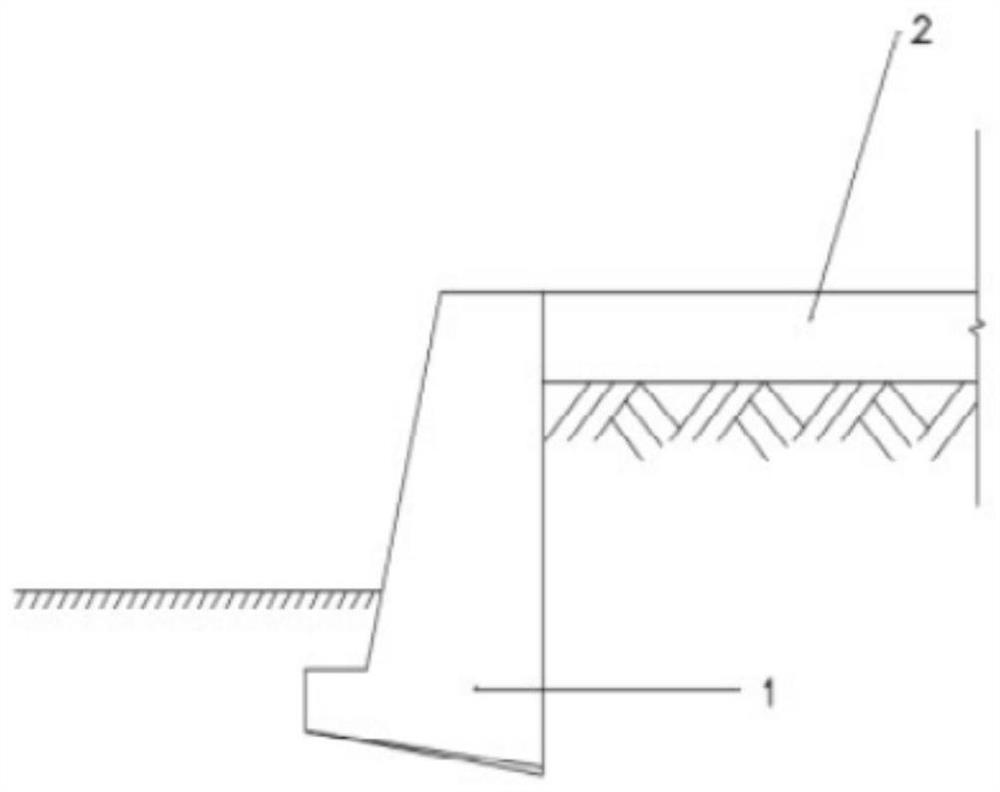

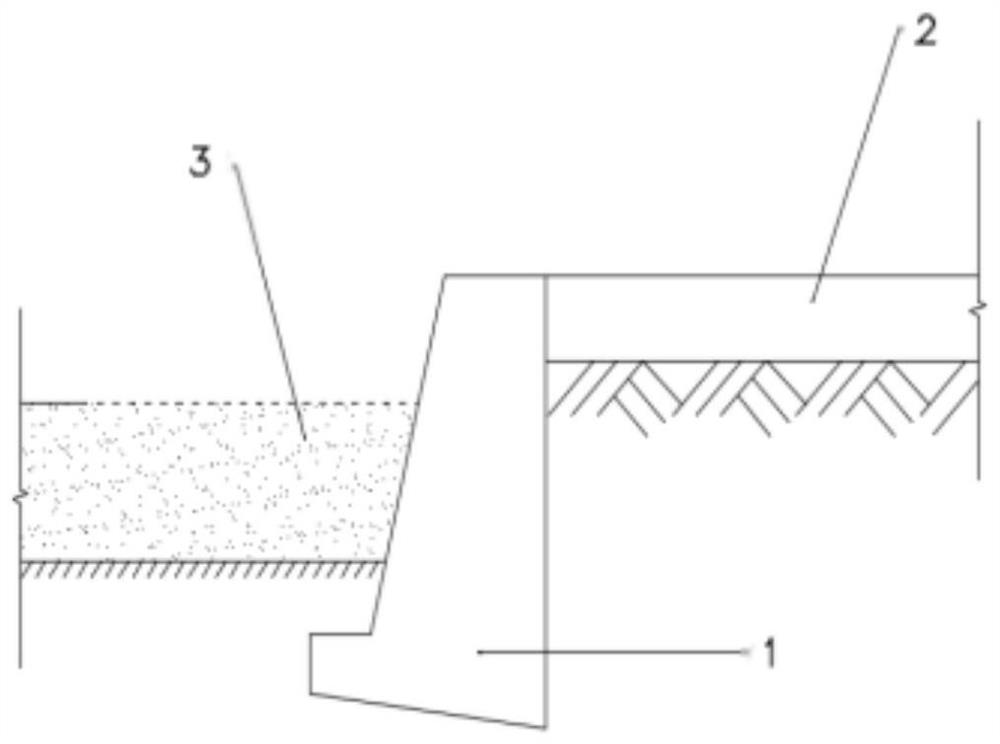

Old retaining wall treated by arranging stretching buffer layer

PendingCN112796343AImprove integrityImprove adaptabilityArtificial islandsProtective foundationArchitectural engineeringRoad surface

The invention provides an old retaining wall provided with a stretching buffer layer for treatment, and belongs to the technical field of pavement infrastructure engineering. The old retaining wall provided with the stretching buffer layer for treatment comprises a left underground layer, a right underground layer is fixedly connected to one side face of the left underground layer, and an existing retaining wall is fixedly connected to the inner wall of the left underground layer. The tensile buffer layer is arranged, the elasticity and the bearing capacity of a soil body are utilized, the pavement load is released, the situation that a newly-built road is damaged by the counter-acting force of an old retaining wall on the lower layer is avoided, meanwhile, the two-way double-layer reinforcing band is arranged, and the integrity and the adaptability of the tensile buffer layer can be improved. Internal stress and differential settlement caused by non-uniform materials of an old retaining wall on the lower layer, an original road bed and a surrounding backfill soil layer are effectively reduced, so that the strength of a newly-built pavement is better enhanced, and long-term use is facilitated.

Owner:广西建工第五建筑工程集团有限公司

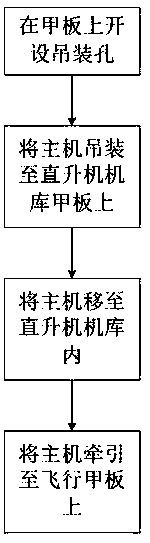

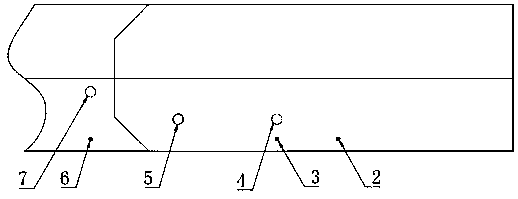

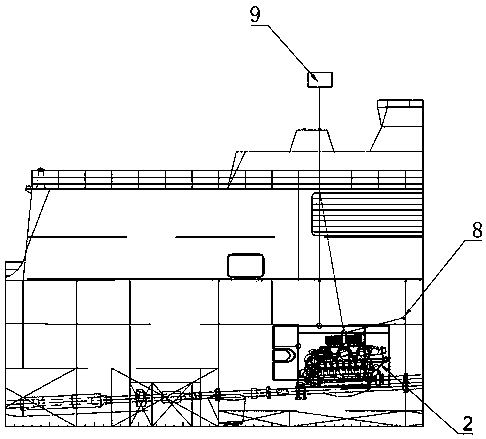

A method for getting out of the cabin for the overhaul of the ship's main engine

The invention discloses an out-of-cabin method for overhauling of a ship main engine and belongs to the technical field of ship construction. The out-of-cabin method comprises the following steps thatfirstly, a first set of hoisting holes, a second set of hoisting holes and a third set of hoisting holes are formed in a hull; secondly, the main engine is hoisted from the interior of a main enginecabin to a deck of a helicopter hanger through a first crane; thirdly, through alternate hoisting of the first crane and a floating crane, the main engine is moved into the helicopter hanger; and fourthly, through a winch, a channel steel rail and a carrying trolley, the main engine is moved to a flight deck. The out-of-cabin method is easy to grasp, the time and labor are saved, the workload of out-of-cabin operation of the main engine is reduced, and the defect that the main engine is prone to being damaged due to the fact that other methods are used in the out-of-cabin process can be avoided; and the out-of-cabin method has the characteristics of being easy to operate, safe and reliable, can be applied to overhauling out-of-cabin operation of the 3000 T ship main engine and can also beused for reference for civil ships.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

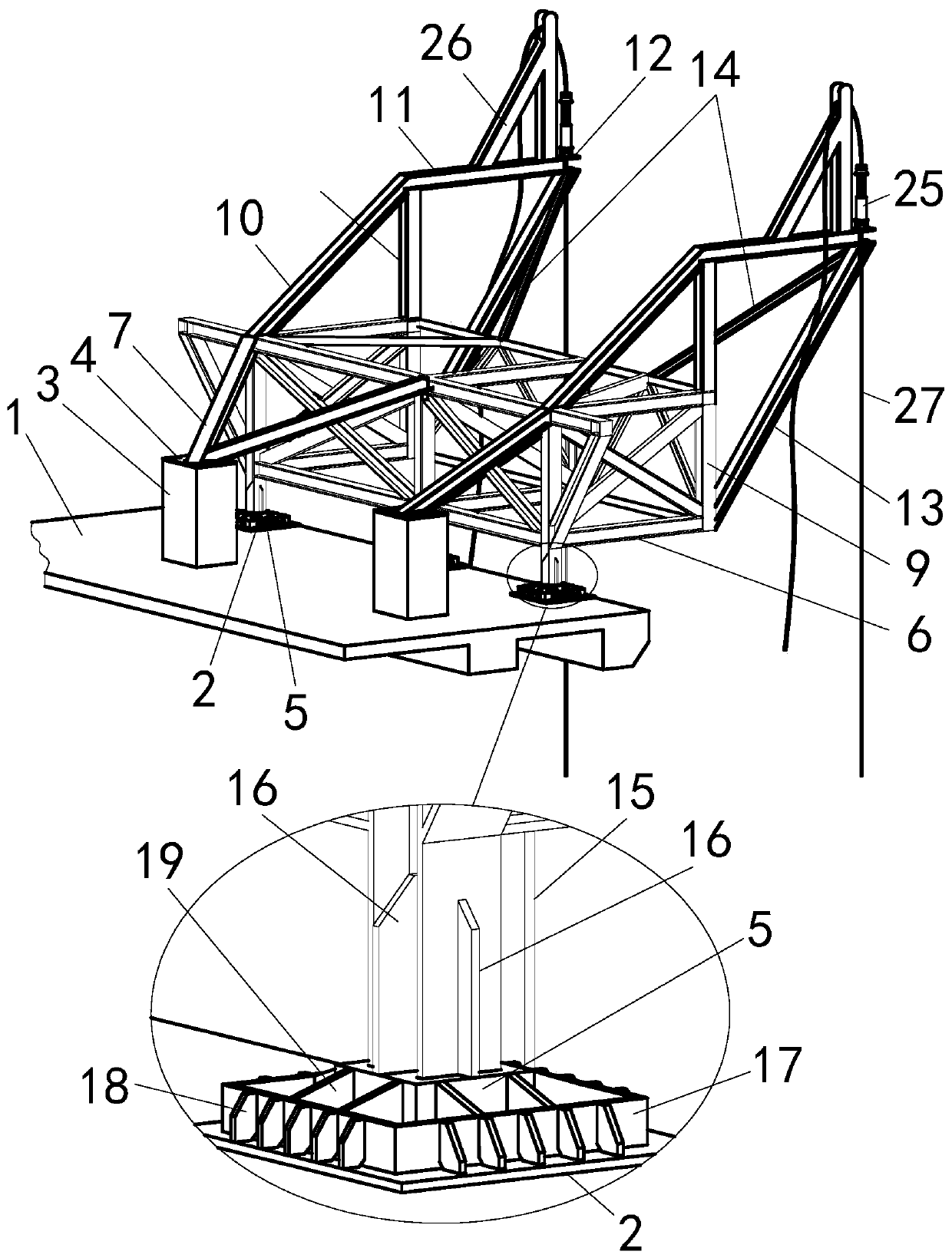

Lifting platform for lifting large-span high-altitude corridor truss

PendingCN109707172AImprove stabilityEasy dockingBuilding material handlingReinforced concreteEngineering

The invention discloses a lifting platform for lifting a large-span high-altitude corridor truss. The lifting platform comprises supporting steel plates, a reinforced concrete pier is arranged at thetop surface of a building, and a ground anchor steel plate is embedded in the reinforced concrete pier. Seismic isolation supports are arranged on the supporting steel plates, and an end truss is located on the seismic isolation supports. A cross beam at the rear end of the end truss is connected with the ground anchor steel plate through a ground anchor tie rod. Hoisting platforms are separatelyinstalled on both sides of the top of the end truss. The hoisting platforms include support columns, and the bottom ends of the support columns and stand columns on both sides of the front end of theend truss are connected in a welded mode. The rear sides of the top ends of the support columns are connected with the cross beam at the rear end of the end truss in a welded mode through diagonal tierods. Horizontal suspension beams are welded to the front sides of the top ends of the support columns, and the bottoms of the horizontal suspension beams are connected with the bottoms of stand columns on the front side of the end truss in a welded mode through support rods. The inner sides of the horizontal suspension beams are connected with the middle part of a cross beam at the top of the end truss in a welded mode through diagonal ligaments. The lifting platform has good stability, can reduce the total weight of lifting, reduces the difficulty of lifting, and facilitates the butt jointafter lifting. The lifting platform is convenient to erect and dismantle, and is beneficial to controlling the construction cost.

Owner:CHINA CONSTR FOURTH ENG DIV +1

Truss structure dismantling method

PendingCN113479774AAvoid safety accidentsLeave stablePortable liftingLoad-engaging elementsPull forceArchitectural engineering

The invention discloses a truss structure dismantling method, and belongs to the technical field of building construction. The method comprises the following steps: a truss structure is dismantled into a plurality of sub-trusses; a tower crane is connected with one ends of the sub-trusses and is used for providing oblique upward pulling force deviating to one sides of the sub-trusses; an auxiliary hoisting device is arranged in a projection area, and the auxiliary hoisting device is connected with the other ends of the sub-trusses and used for providing oblique upward pulling force deviating to the other sides of the sub-trusses; the projection area is an area where an overhanging outer frame is projected on the ground; the tower crane and the auxiliary hoisting device synchronously hoist the sub-trusses to enable the sub-trusses to leave the projection area; and after the sub-trusses leave the projection area, the auxiliary hoisting device stops hoisting, and the tower crane hoists the sub-trusses to the ground. According to the truss structure dismantling method, the hoisting performance of the tower crane can be fully utilized, the dismantling workload is reduced, and the operation efficiency can be improved.

Owner:CHINA CONSTR SCI & IND CORP LTD

Removal method of furnace nose of hot-dip galvanizing unit

ActiveCN109081241BImprove construction efficiencyReduced demolition workloadLoad-engaging elementsMetallurgyMetal expansion joint

The invention discloses a dismantling method for a hot galvanizing unit furnace nose. The method comprises the following steps that: a hot galvanizing unit halts, a zinc pot is dismantled, various types of media which enter the furnace nose stop being transferred, and are closed, the pipelines of various types of media are dismantled and marked, and the furnace nose is positioned on a halting position; a temporary bracket is manufactured and is assembled below the furnace nose; the temporary bracket is connected with a steel structure for hanging the furnace nose, stand columns are independently supported on a steel cross beam below a swinging mechanism and the pull rod cross beam of the furnace nose; a travelling crane and a steel beam are hoisted on the big cross beam of the furnace nose, the big cross beam is cut and dismantled and is hoisted to a storage area; a metal expansion joint is dismounted, and the expansion and contraction quantity of the metal expansion joint is fixed; and a hoisting steel wire rope is adopted to bind the furnace nose and the steel structure, connection between the steel structure and a foundation is cut off, and the travelling crane is connected withthe hoisting steel wire rope to integrally hoist the furnace nose, the steel structure and the temporary bracket out of the storage area to finish dismantling the furnace nose. By use of the method,construction efficiency is improved, workload is reduced, potential safety hazards are avoided, the intact furnace nose component is guaranteed, and the accuracy of the secondary installation of the furnace nose is improved.

Owner:CHINA MCC20 GRP CORP

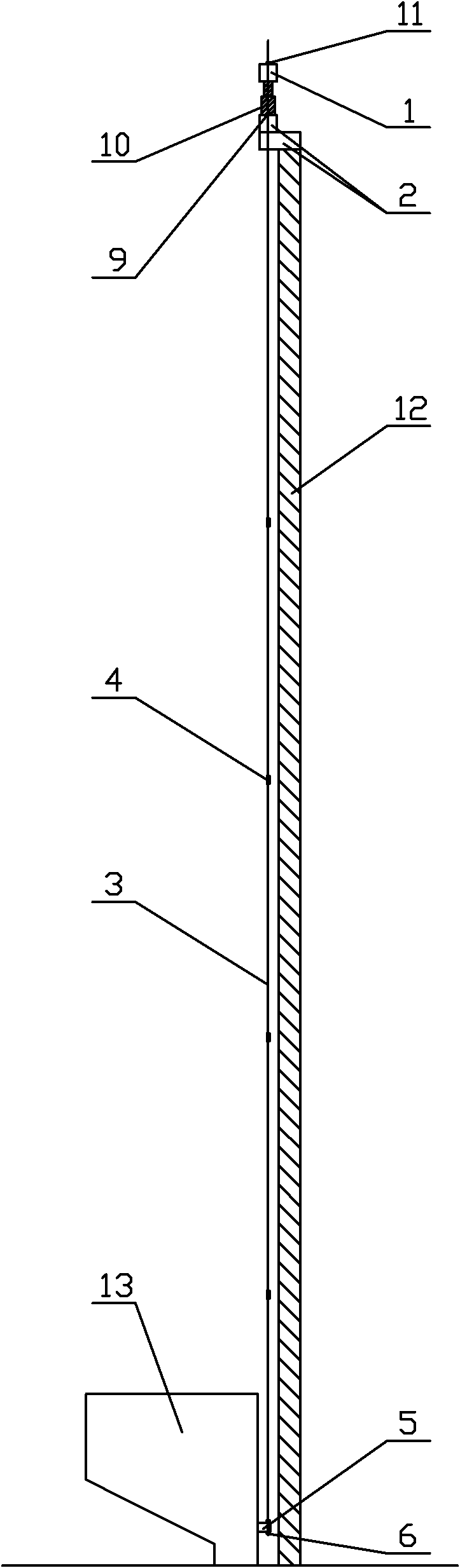

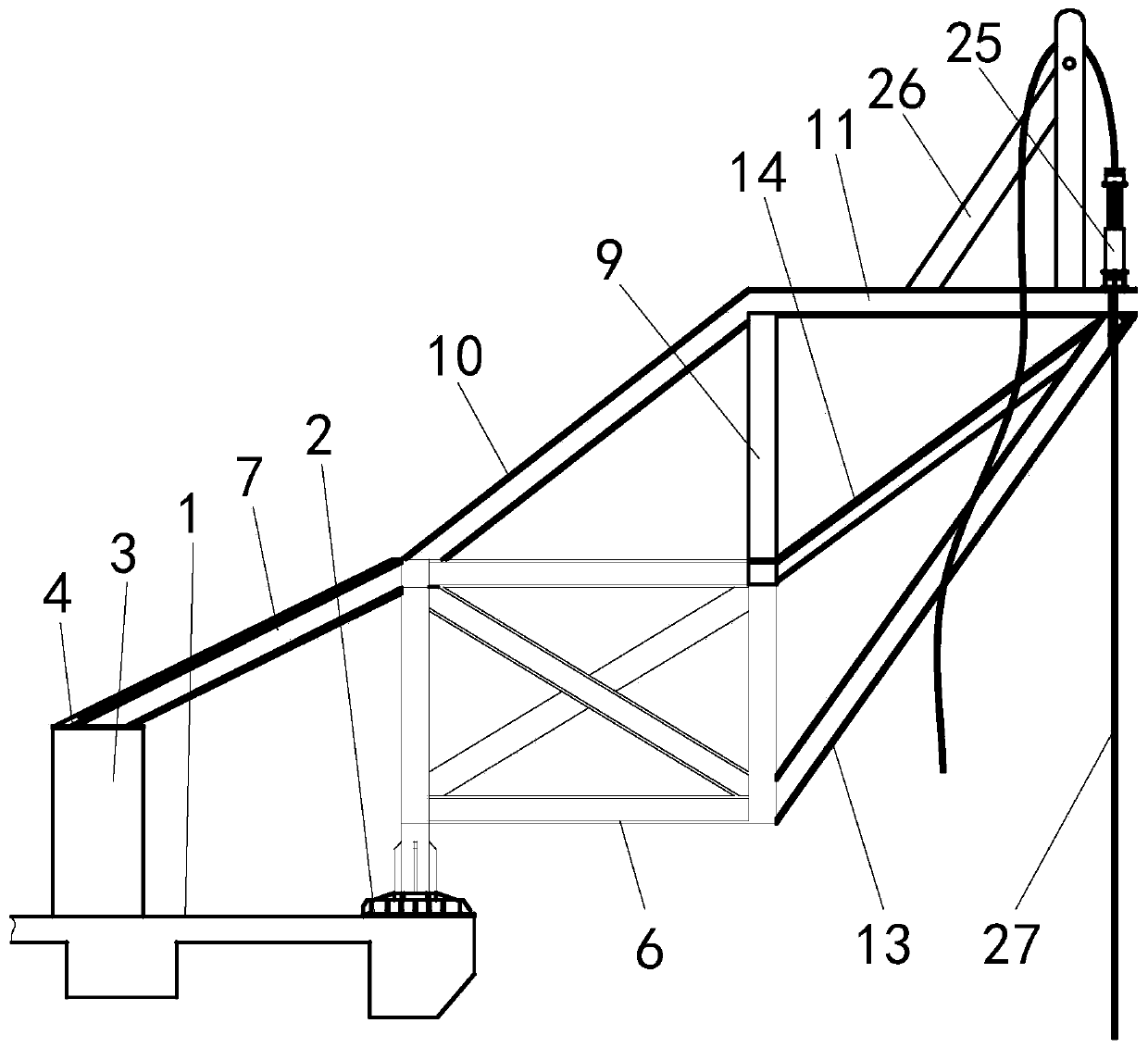

Ground anchor structure of cable-stayed buckling and hanging cable hoisting system and construction method

PendingCN110820740AReduced demolition workloadFirm edgesRopes and cables for vehicles/pulleyCable carsGeogridEarth anchor

The invention discloses a ground anchor structure of a cable-stayed buckling and hanging cable hoisting system and a construction method. The ground anchor structure of the cable-stayed buckling and hanging cable hoisting system comprises a lower weight and an upper weight arranged at the top of the lower weight, wherein the upper weight comprises a plurality of weight layers which are verticallystacked together; each weight layer comprises a fence arranged on the periphery of the weight layer and a soil body filled in the fence; the fence is formed by piling ecological bagged soil; a geogridis further arranged on the edge of each weight layer; and the geogrids are folded on the upper surfaces of the weight layers after wrapping the fences from the lower surfaces of the weight layers. According to the ground anchor structure, the soil body upper weight is adopted, the effect of the ground anchor structure is the same as that of a traditional concrete upper weight, earthwork excavatedby a foundation pit is reused to replace concrete for weight, a large amount of materials are saved, the construction cost is low, and the workload of later ground anchor disassembly and the influence on the surrounding environment can be reduced.

Owner:GUANGXI ROAD & BRIDGE ENG GRP CO LTD

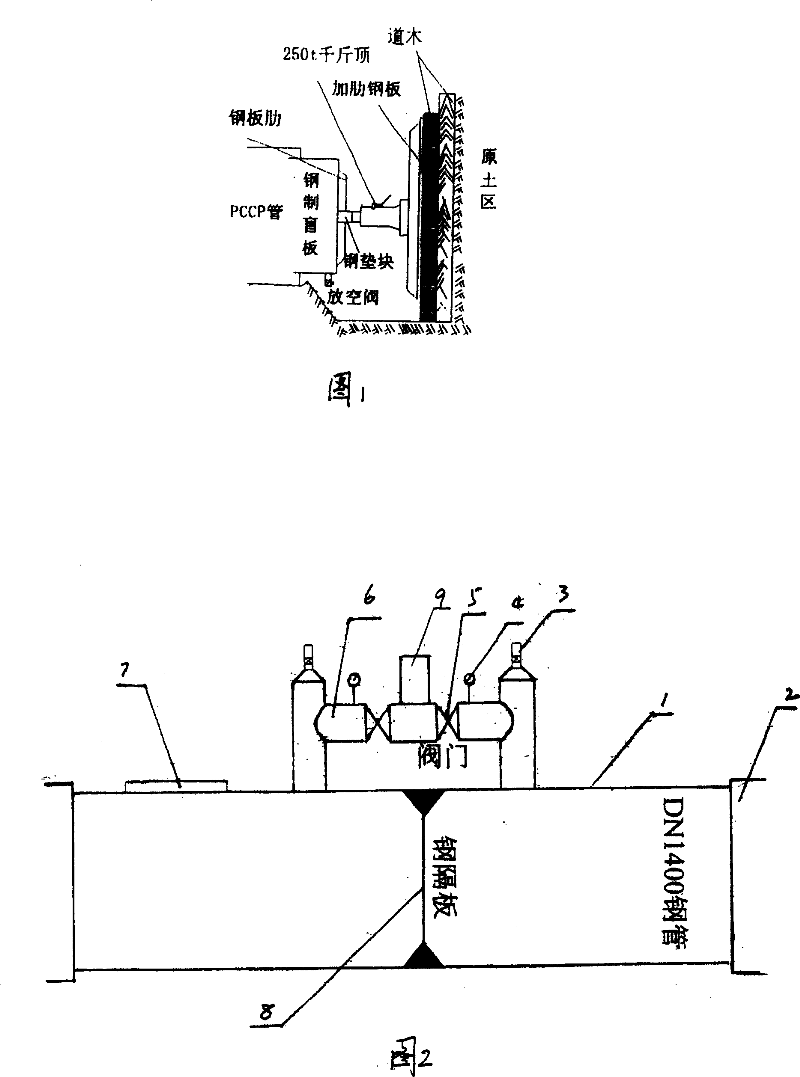

Middle pressure test technology and device for widebore pipeline construction

InactiveCN100357721CReduce meeting workloadReduced installation effortHydraulic/pneumatic force measurementFluid-tightness measurement using fluid/vacuumExhaust valveArchitectural engineering

The present invention is the intermediate pressure test technology and apparatus for large caliber pipeline construction. The pressure test apparatus consists of one steel pipe, steel partition board welded inside the steel pipe, H-shaped by-pass pipe, water injecting pipe mounted onto the by-pass pipe, by-pass valve, exhaust valve pressure gauge. The pressure test apparatus is connected via union with the pipeline to be pressure tested, the pipeline is injected with water to test leakage, and after test, water is exhausted and the steel partition board, by-pass pipe, etc. are eliminated. The present invention needs no interruption of the construction during pressure test and can speed engineering construction.

Owner:XUZHOU INST OF ARCHITECTURAL TECH

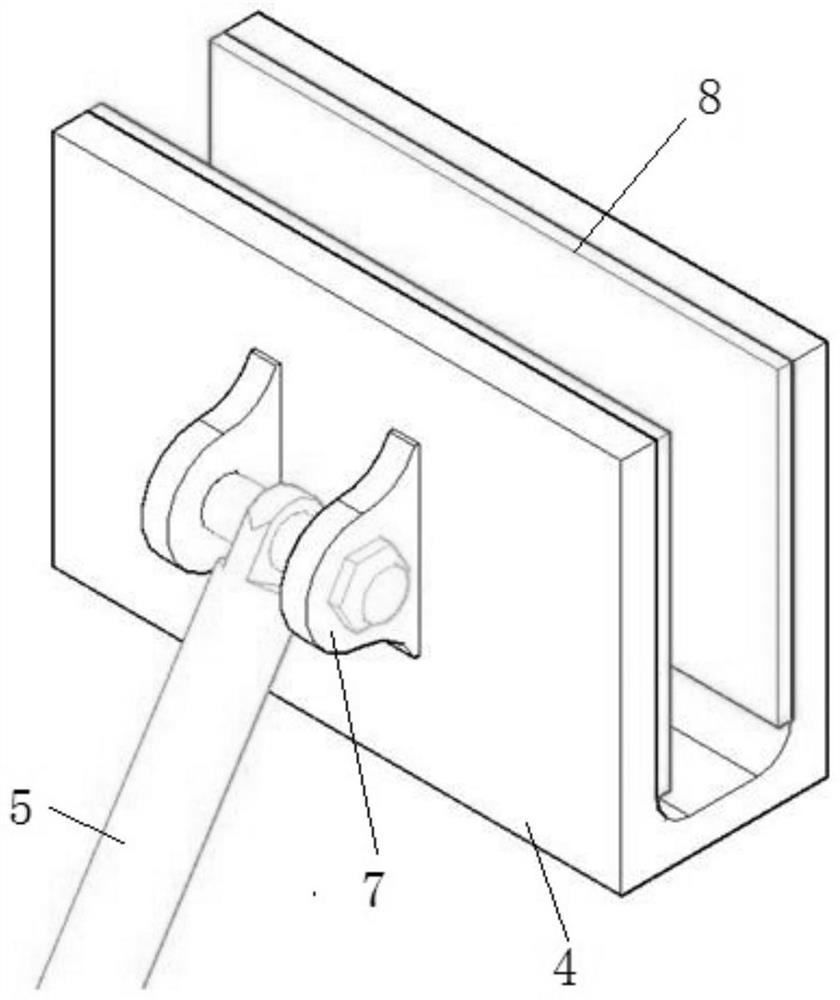

Segmented transportation method and supporting device for hatch coaming

PendingCN114180001AReduced demolition workloadEnsure Structural IntegrityWaterborne vesselsPortal frameStructural integrity

The invention discloses a segmented transportation method for a hatch coaming. The segmented transportation method comprises the following steps that two gantries are placed on the ground in parallel; hoisting equipment is used for hoisting and placing the hatch coaming section by section on the portal frame; the flat car is moved to the bottoms of the two gantries, and the gantries are shored through a shoring mechanism of the flat car; a supporting device is arranged on each portal frame to support the corresponding hatch coaming subsection; and the hatch coaming is transported to a designated position in a segmented mode through a flat car. When the hatch coaming sections are transported, the supporting device is used for supporting the hatch coaming sections, the supporting effect can be achieved, the supporting device does not need to be welded to the hatch coaming sections, the workload of cutting, grinding and the like during follow-up dismounting of the supporting device is reduced, and the working efficiency is improved. And meanwhile, the structure of the hatch coaming section cannot be damaged during dismantling, and the structural integrity of the hatch coaming section is guaranteed.

Owner:SHANGHAI JIANGNAN CHANGXING SHIPBUILDING

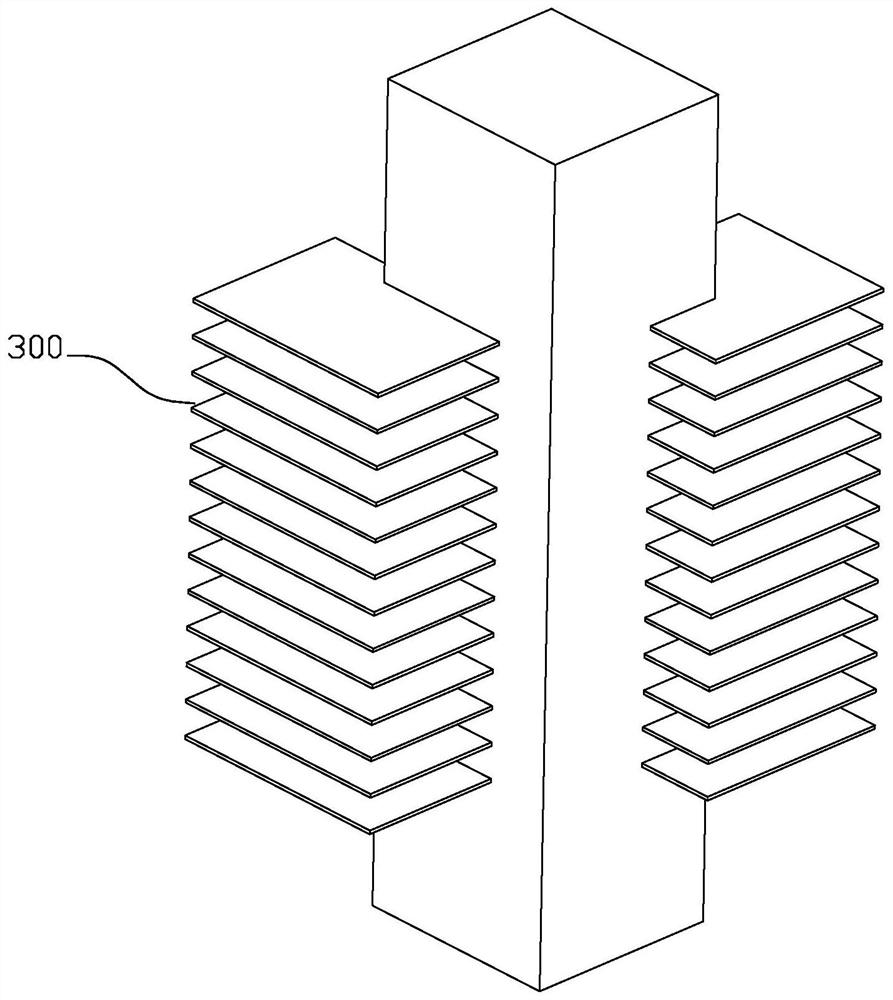

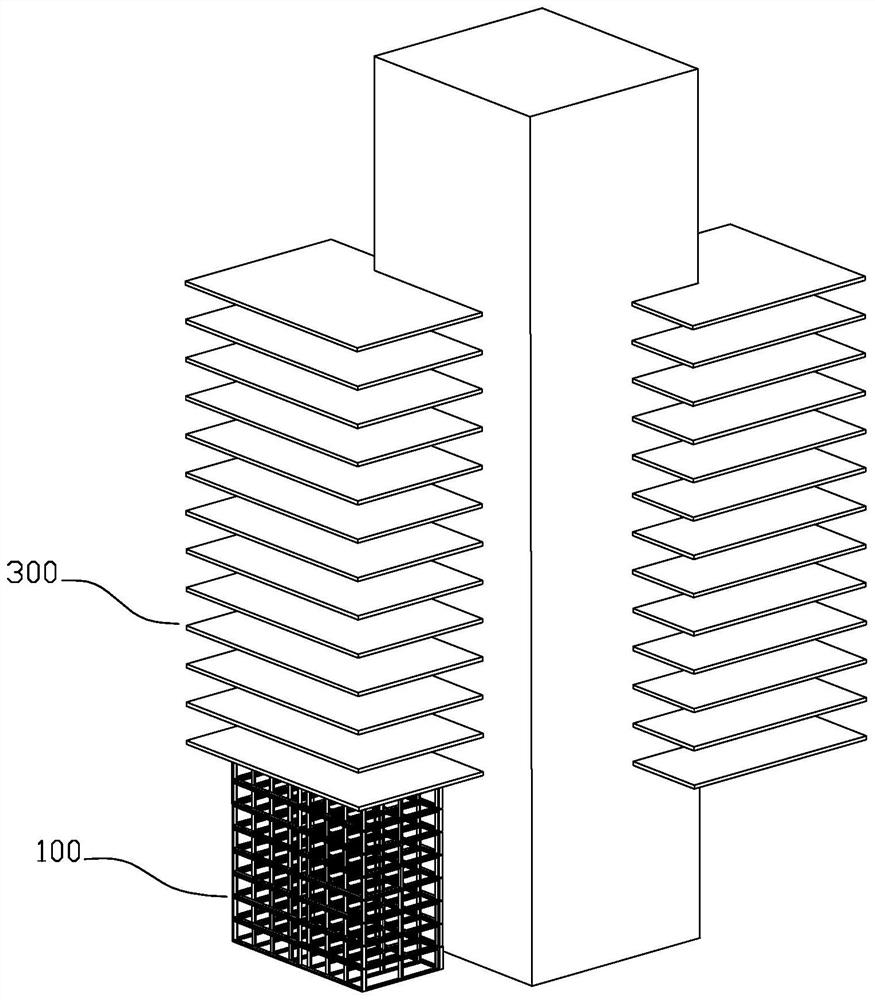

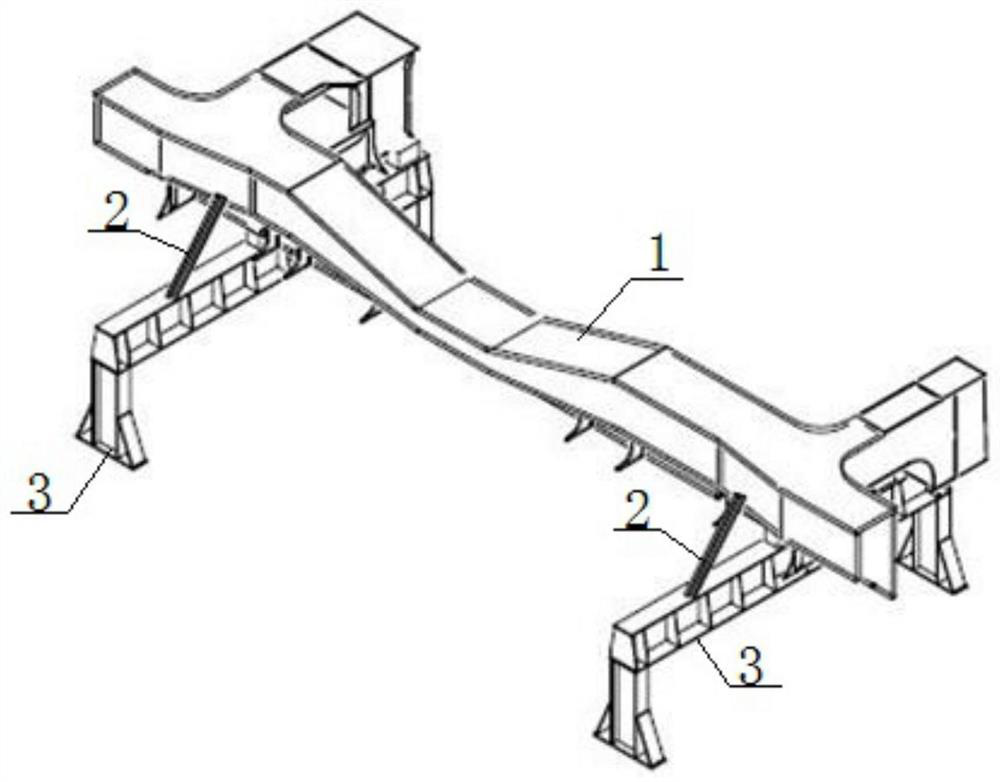

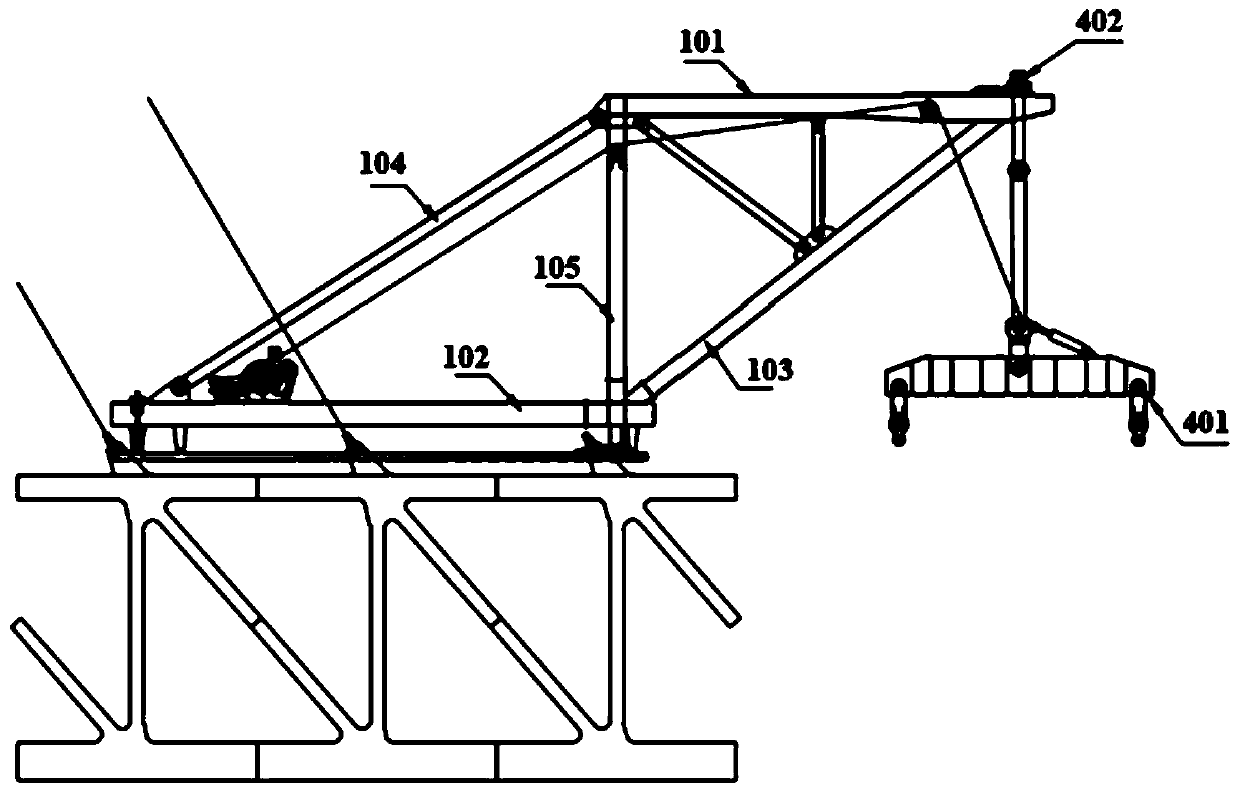

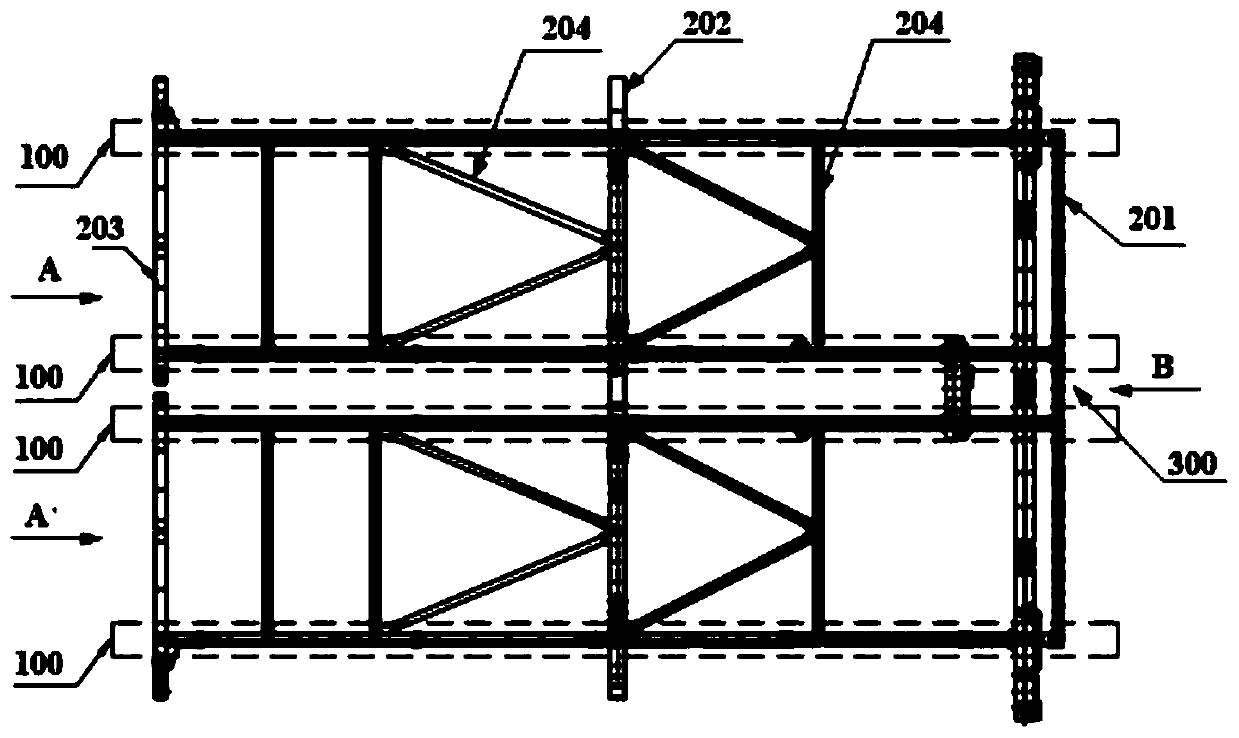

Assembly type large-tonnage girder erection hoister and girder erection method

PendingCN111532998ARapid Modular AssemblyShorten the construction periodBridge erection/assemblyCranesBridge engineeringArchitectural engineering

The invention discloses an assembly type large-tonnage girder erection hoister and a girder erection method and relates to the technical field of bridge engineering construction equipment. The assembly type large-tonnage girder erection hoister comprises a first preassembled rack A, a second preassembled rack A', an intermediate connecting assembly B, a lifting tool 401 and a hoisting assembly 402, wherein the lifting tool 401 and the hoisting assembly 402 are connected with the first preassembled rack A and the second preassembled rack A'; the first preassembled rack A and the second preassembled rack A' each comprise two girder plates 100, a cross beam 201, a middle cross beam 202 and a rear cross beam 203, and the cross beam 201, the middle cross beam 202 and the rear cross beam 203 areconnected between the two girder plates 100; and the intermediate connecting assembly B is connected between the first preassembled rack A and the second preassembled rack A'. The assembly type large-tonnage girder erection hoister provided by the invention can be modularly assembled or disassembled, is easy to assemble or disassemble, convenient to install and dismantle and capable of shorteningthe construction period.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD

A Partial Excavation Method of Steel Frame and Rock Wall Combination Vertical Brace for Rock Super-large Section Tunnel

ActiveCN108035733BEnsure safetyEnsure stabilityUnderground chambersTunnel liningEconomic benefitsSteel frame

The invention provides a method for excavating a combined vertical erection branch part of a super-large rocky section tunnel steel frame rock wall. The method includes the specific steps that an excavation section of a tunnel is set, wherein an upper left pilot tunnel is a first excavation part, an upper right pilot tunnel is a second excavation part, the upper left pilot tunnel and the upper right pilot tunnel constitute an upper excavation section, a lower left pilot tunnel is a third excavation part, a lower right pilot tunnel is a fourth excavation part, a rock wall body is a fifth excavation part, the lower left pilot tunnel, the lower right pilot tunnel and the rock wall constitute a lower excavation part, and besides, a first supporting and protecting part, a second supporting andprotecting part, a third supporting and protecting part, a fourth supporting and protecting part and a fifth supporting and protecting part are included; the various excavation parts are excavated inturn, and primary support and protection is conducted on the corresponding supporting and protecting parts; in the entire excavation process, the second excavation part is kept lagging behind the first excavation part, the third excavation part lags behind the second excavation part, and the fourth excavation part lags behind the third excavation part. According to the method, large-scale machinery is convenient to work in the case of a super-large section tunnel, the excavation speed is fast, and the economic benefit is obvious.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD +1

Installation and protection device for inclinometer pipe used in filling soil, its processing method and use method

The present invention adopts the technical problem to be solved by the present invention through the following technical solutions. The present invention is a protection device for installing an inclinometer pipe in a filled soil body. The protection device consists of a steel protection plate and an angle steel support frame. , connecting ring, threaded steel mandrel and connecting pin. Specifically: an outer frame composed of protective plates, with angle steel at the upper and lower corners of the outer frame. The angle steel is composed of steel bars with staggered heights. The steel bars that make up the angle steel are connected. Angle steel support frames corresponding to the angle steel are arranged at the upper and lower ends of each protection plate. Rebar steel ejector rods are fixed on the opposite angle steel support frames, and an inclinometer tube is arranged at the center of the outer frame. The invention also provides a processing method and using method of the protective device.

Owner:长江空间信息技术工程有限公司(武汉)

a way through the empty alley

ActiveCN109098713BReduced demolition workloadReduce labor intensityUnderground miningSurface miningMechanical engineeringCoal

The invention discloses a method for passing through an abandoned roadway. The method for passing through the abandoned roadway comprises a method for allowing a coal face to pass through the abandoned roadway. The method for allowing the coal face to pass through the abandoned roadway comprises the following steps: S01: marking a first intersection area intersected with the coal face in the abandoned roadway in advance; S02: sequentially distributing at least two mutually-independent first support timber cribs along the advancing direction of the coal face in the first intersection area to support a first false roof; S03: allowing a coal cutter in the coal face to advance in a sectional way in the first intersection area to cut the first support timber cribs; and S04: allowing the coal cutter to sequentially advance according to the way in the step S03 until the coal cutter passes through the first intersection area. According to the method for passing through the abandoned roadway, the workload for dismounting the timber cribs is reduced by adopting the mutually-independent support timber cribs, the labor intensity of staff is alleviated, the workload is reduced, and the assuredprocessibility factor of the staff is improved.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com