Method for excavating combined vertical erection branch part of super-large rocky section tunnel steel frame rock wall

A super-large cross-section and partial excavation technology, which is applied to tunnels, tunnel linings, shaft equipment, etc., can solve the problems of slow dismantling of support systems, instability of surrounding rocks, and high cost, so as to reduce the workload of construction and dismantling, and speed up construction. The effect of construction speed and reduction of construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

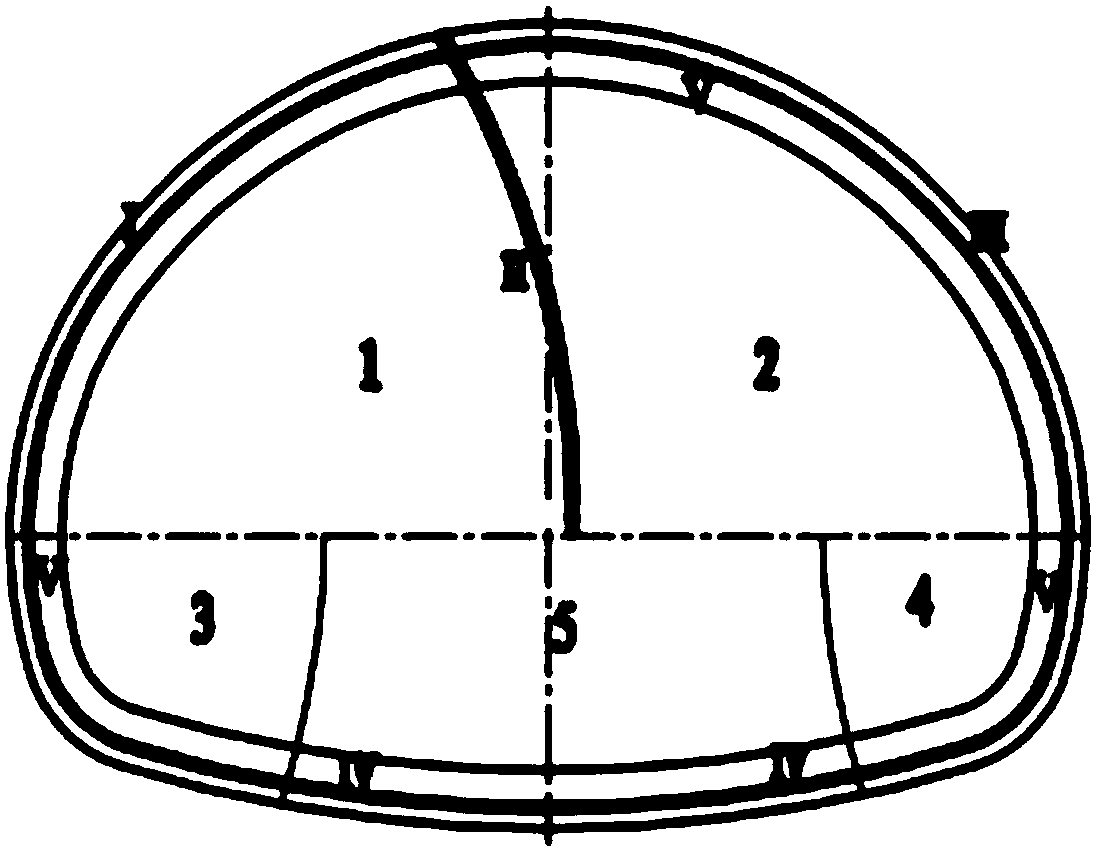

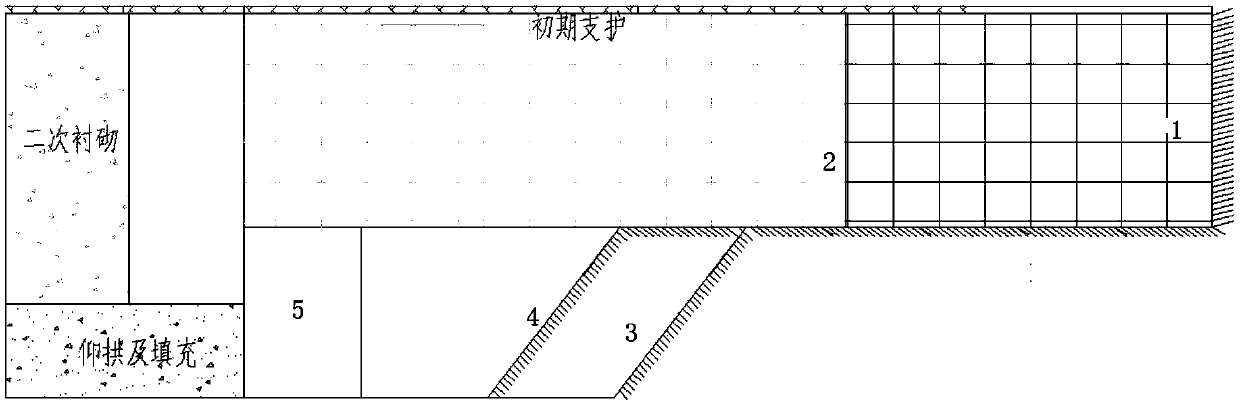

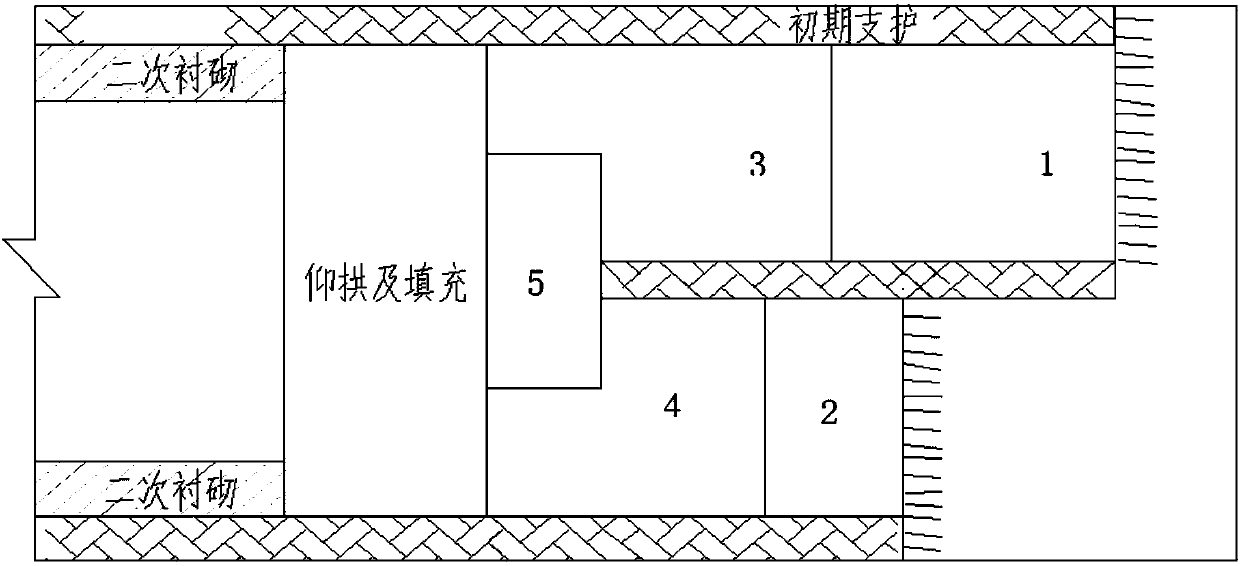

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. The present invention is used in tunnels and underground structures with rock super-large sections (area greater than 170m2) 2 ), the section is divided into 5 parts according to the sequence of excavation, the upper half section is divided into two parts, the steel frame is used as the middle partition support in the middle to reduce the span of the section, and the lower half section is divided into three parts. Part, the middle part and the partition wall of the upper half section together form a vertical support, which will be dismantled after the deformation of the initial support is stable.

[0033] The specific method is:

[0034] 1) if figure 1 As shown, the section of the tunnel is divided into 5 parts, which are respectively described as Part 1—the upper left pilot tunnel (the first excavation part), Part 2—the upper right p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com