Shallow-burying exposure construction method applicable to hard rock tunnel with extra large fracture surface

A technology with super large section and construction method, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve problems such as poor applicability, environmental damage, and large excavation volume, and achieve the goal of reducing construction costs, reducing pollution, and speeding up construction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

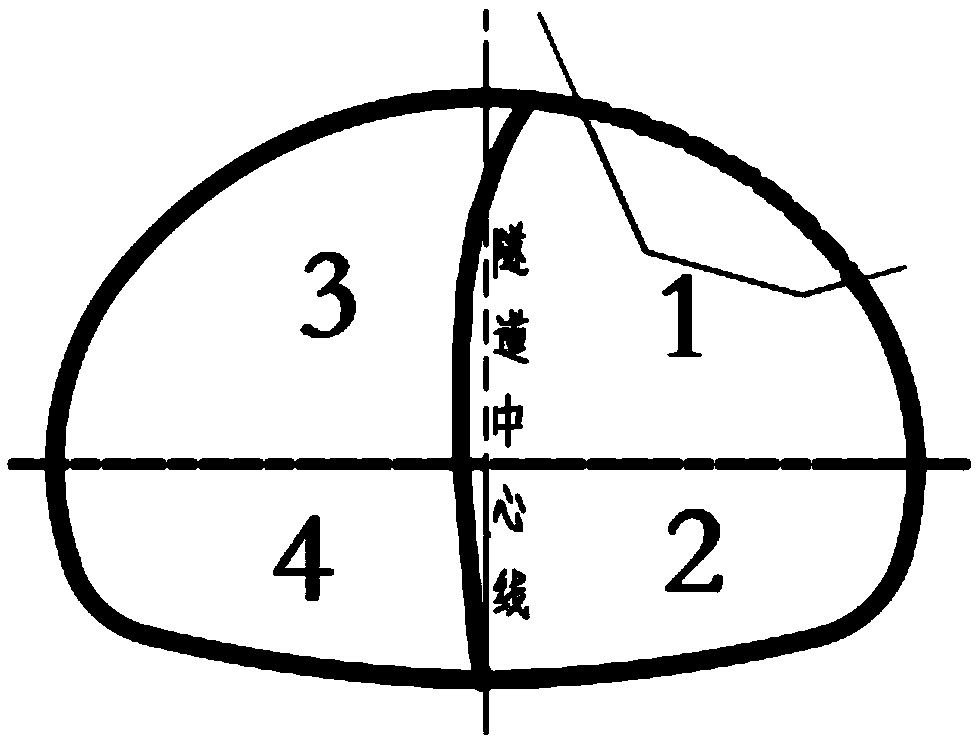

[0027] Example 1: if figure 1 As shown, the CD method is used for construction.

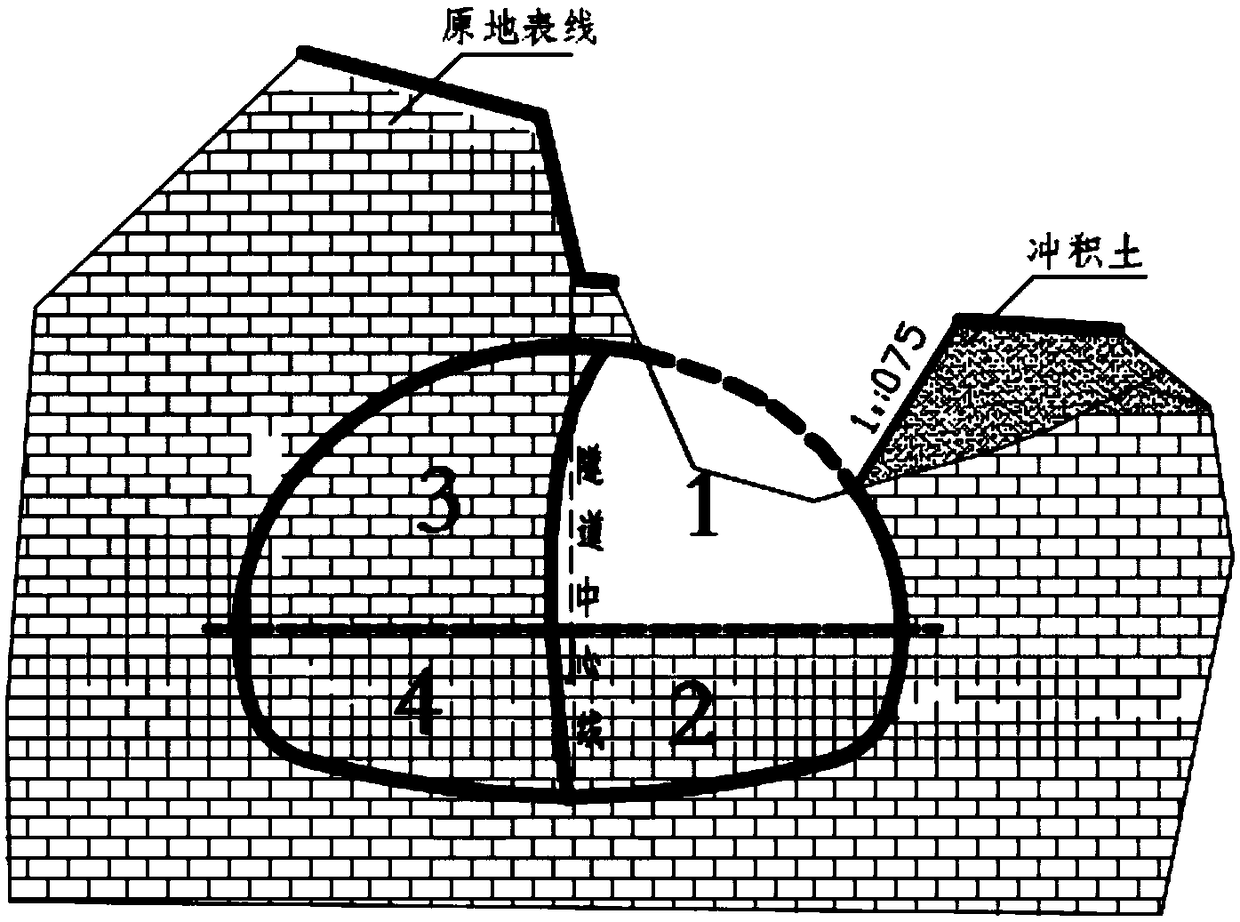

[0028] The section of the tunnel is divided into 4 parts, which are respectively described as upper right part - upper right pilot tunnel (first excavation part), lower right part - lower right pilot tunnel (second excavation part), upper left part - upper left pilot tunnel (third excavation part). excavation part), lower left part-lower left pilot tunnel (fourth excavation part), excavation shall be carried out in sequence according to the numerical sequence, see Figure 3 ~ Figure 8 .

[0029] First, remove the weak soil within the influence range of the exposed surface, and protect the slope of the weak soil with anchor net spraying;

[0030] Excavate the first excavation part, then support the first support part; excavate the second excavation part, and then support the second support part; backfill the tunnel arch with soil pressure Excavate the third excavation part, then support the thi...

example 2

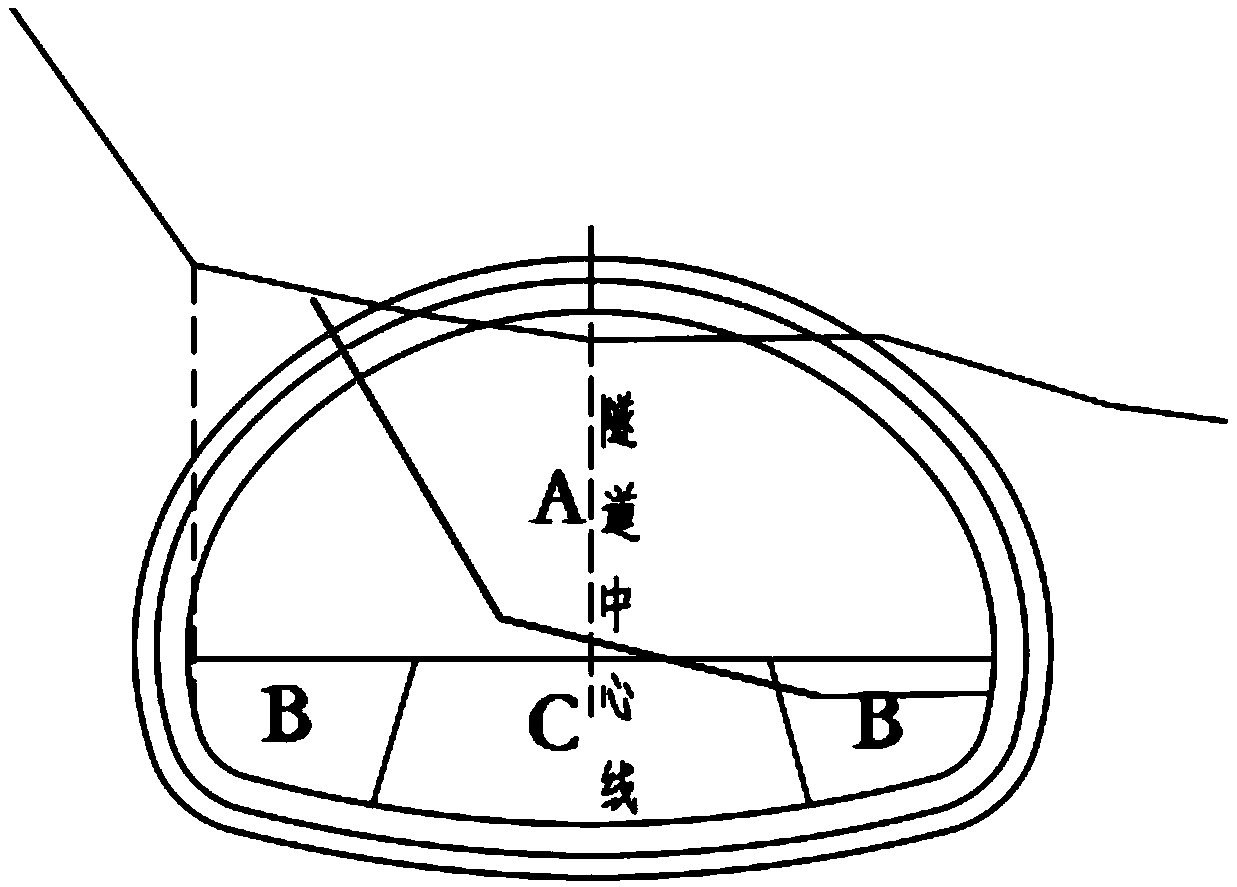

[0032] Example 2: if figure 2 As shown, the step method is used for construction.

[0033] The section of the tunnel is divided into three parts, which are described as upper part-upper step (excavation part A), left and right parts-lower step left and right pilot tunnels (excavation part B), middle part-lower step core soil (excavation part C). Excavation Department), excavation shall be carried out sequentially according to the numerical sequence, see the specific excavation Figure 9 ~ Figure 14 .

[0034] First, remove the weak soil within the influence range of the exposed surface, and protect the slope of the weak soil with anchor net spraying;

[0035] First carry out backfilling; excavate the A-th excavation part, and then support the A-th support part; excavate the B-th excavation part, and then support the B-th support part; The excavation part C is excavated, and then the support part C is supported; during the whole excavation process, the excavation part B lag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com