Patents

Literature

68results about How to "Reduce the amount of grout" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

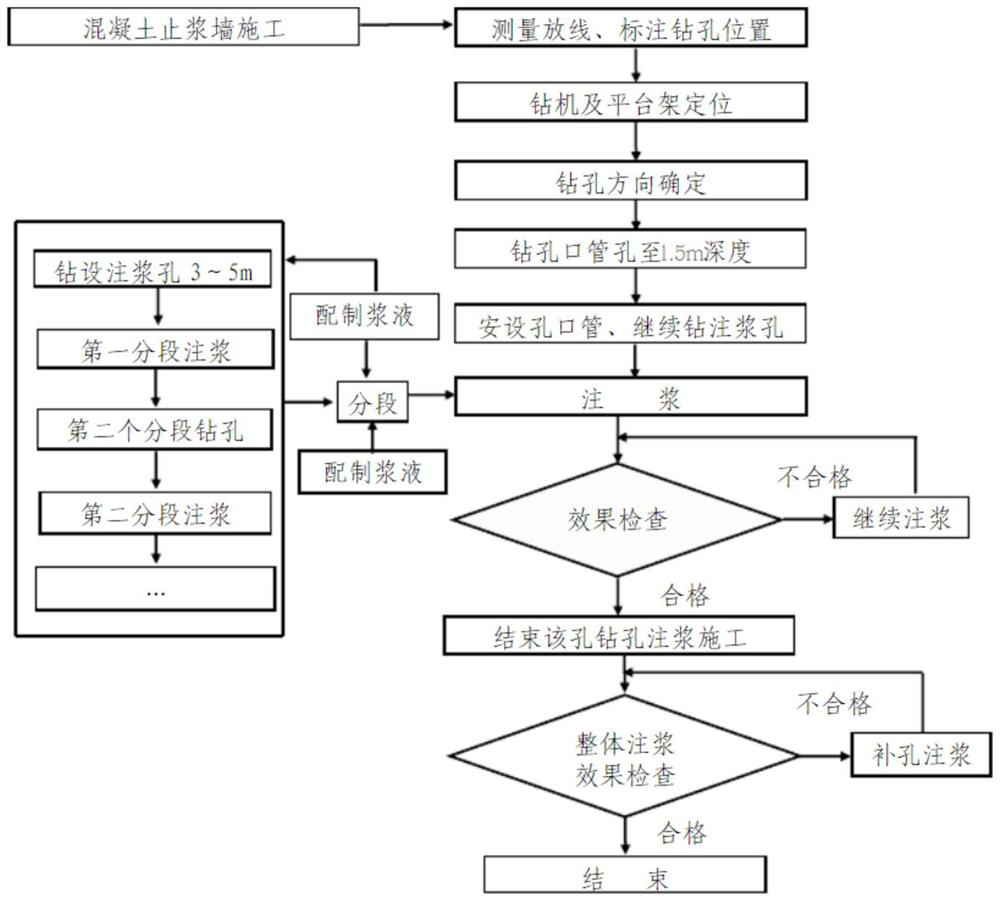

Tunnel information tracing accurate grouting method

ActiveCN101832142AOptimizing the Number of Grouting HolesReduce the amount of waterUnderground chambersTunnel liningGlass fiberGeomorphology

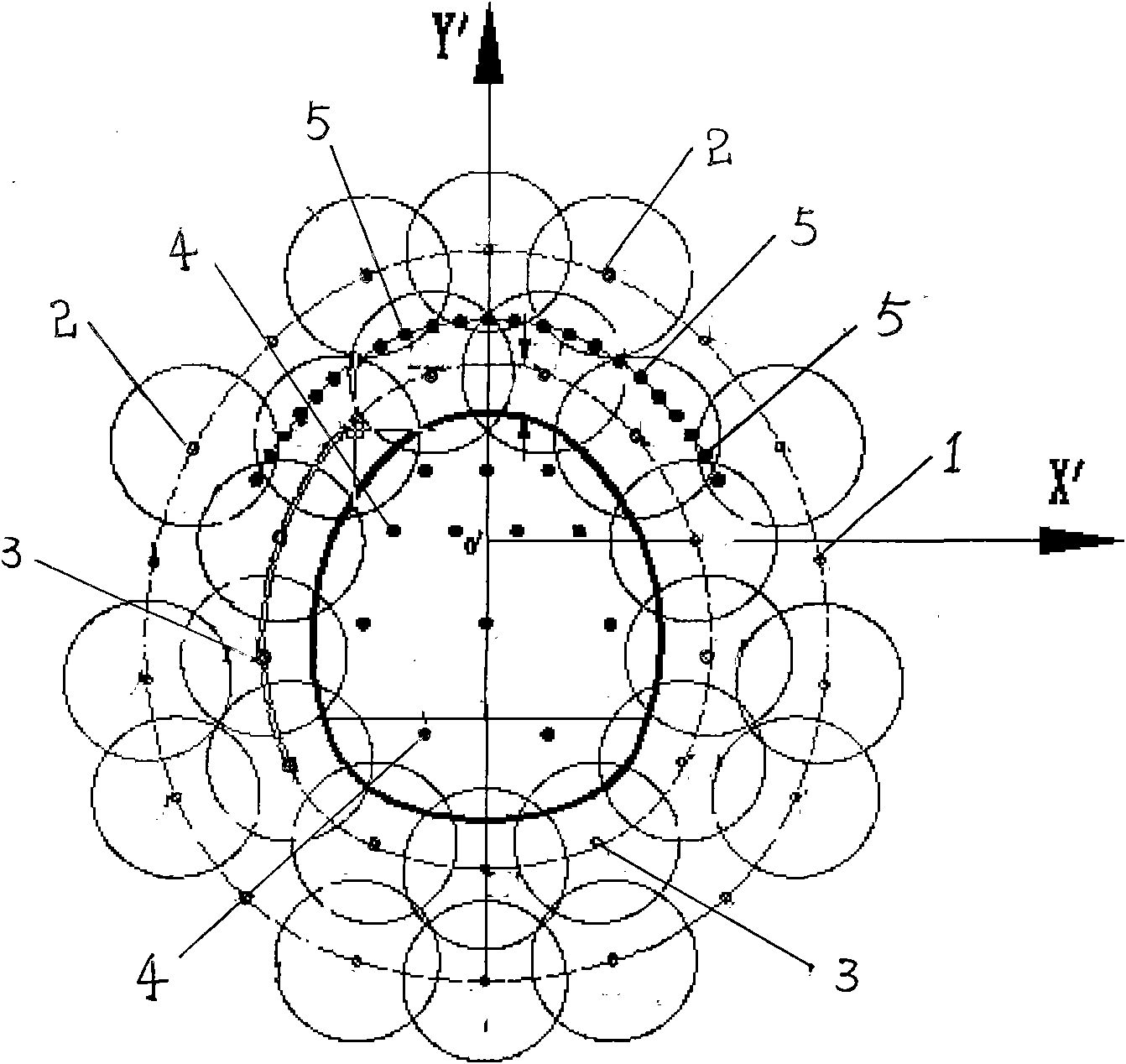

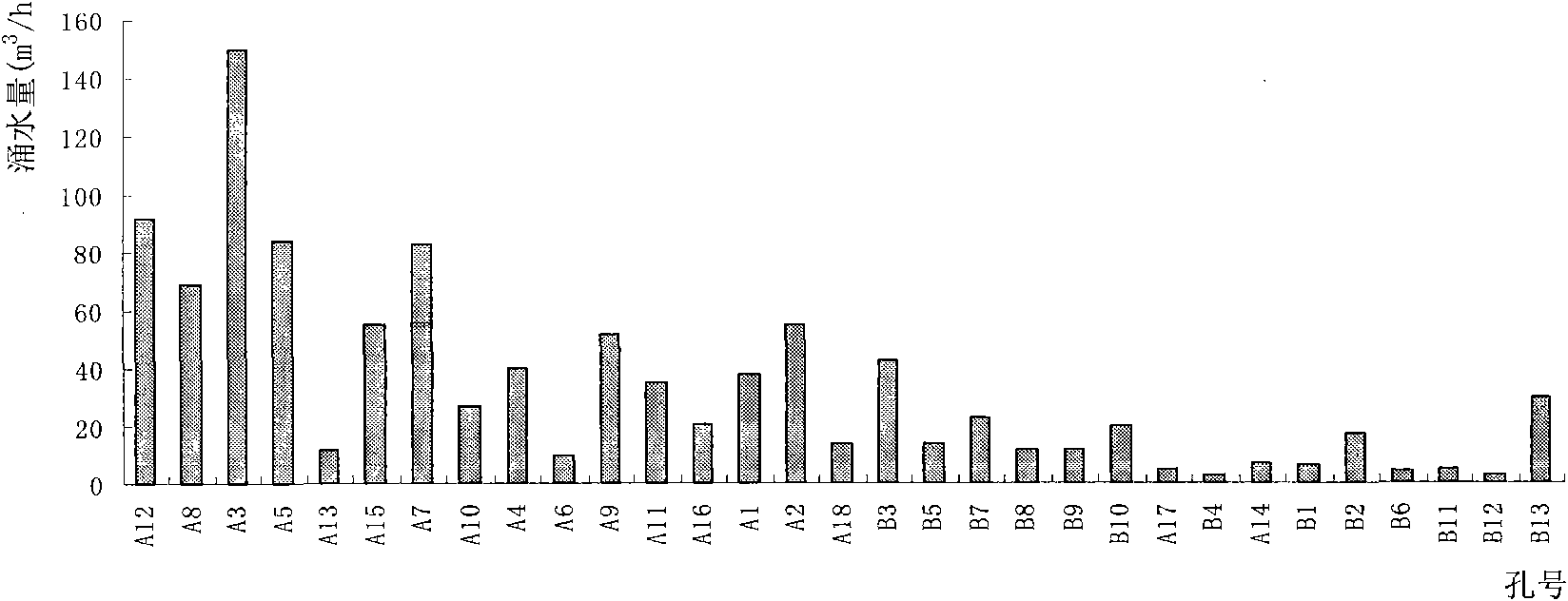

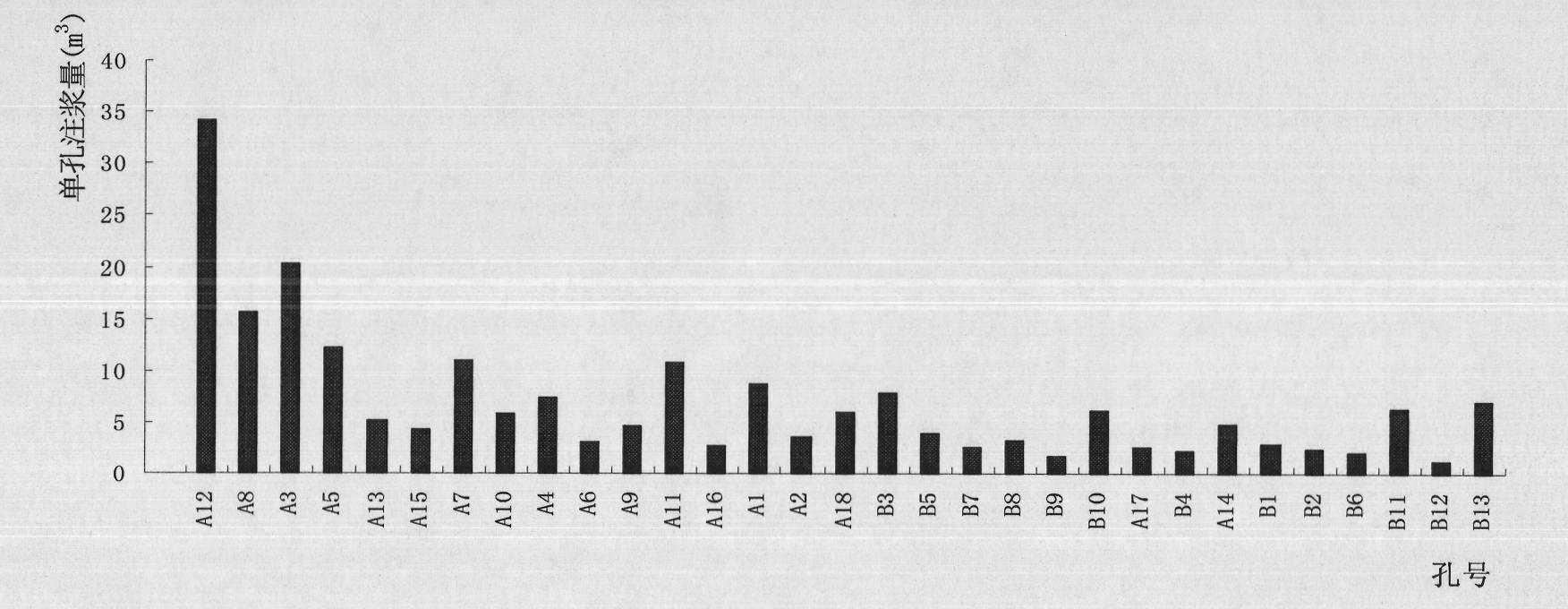

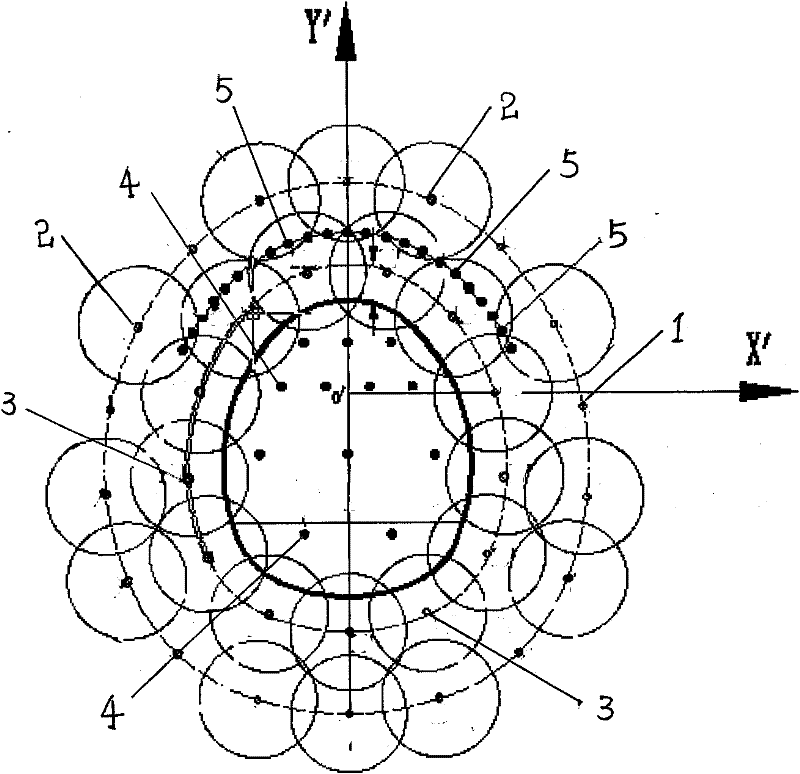

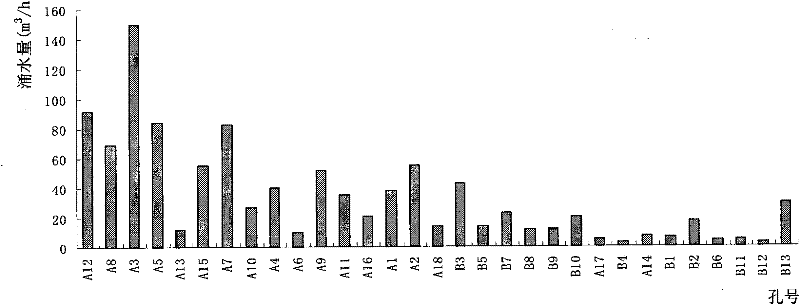

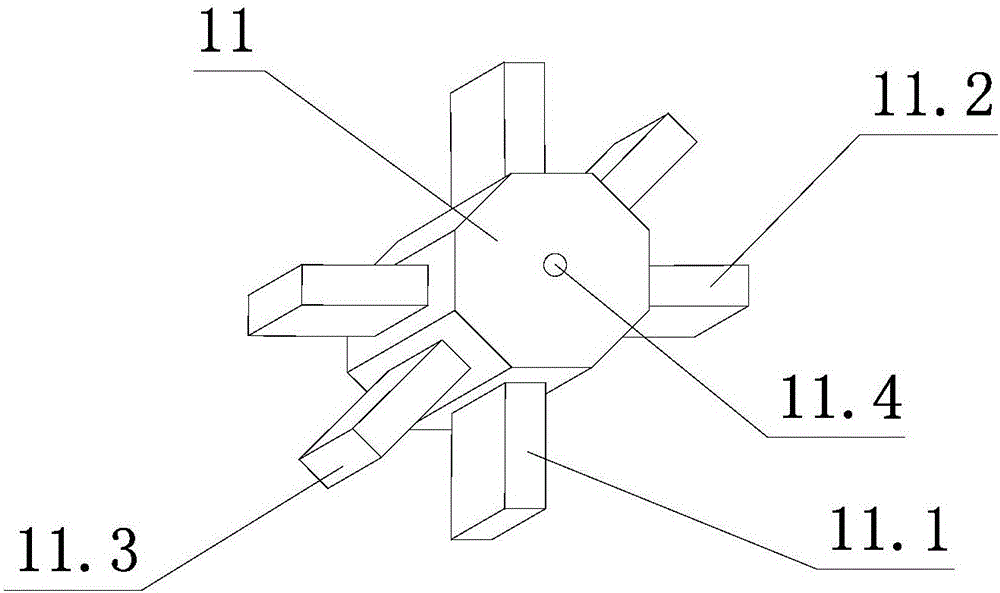

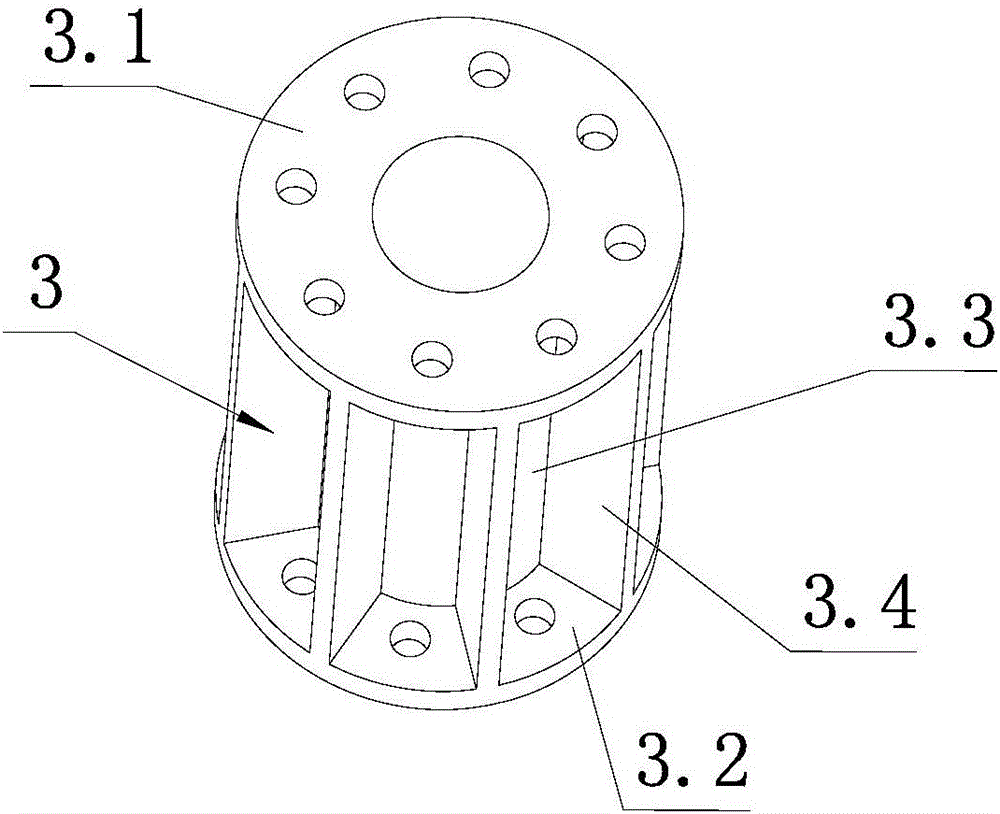

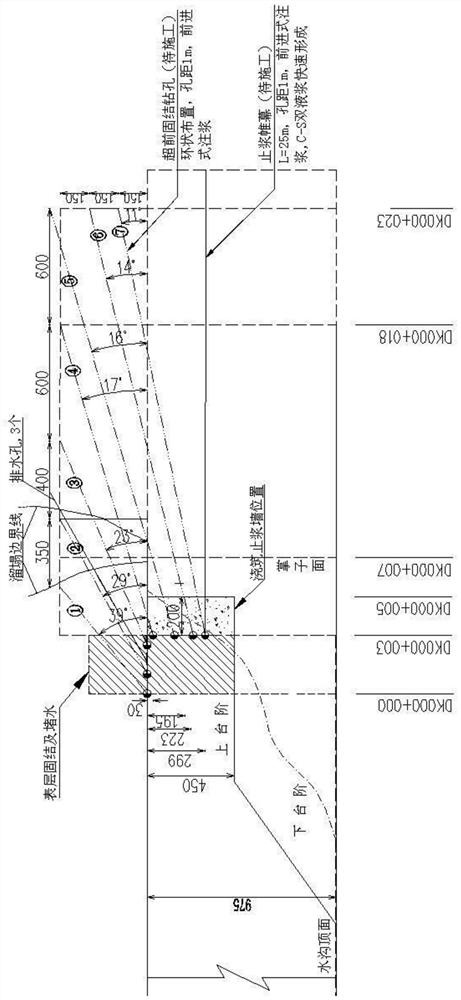

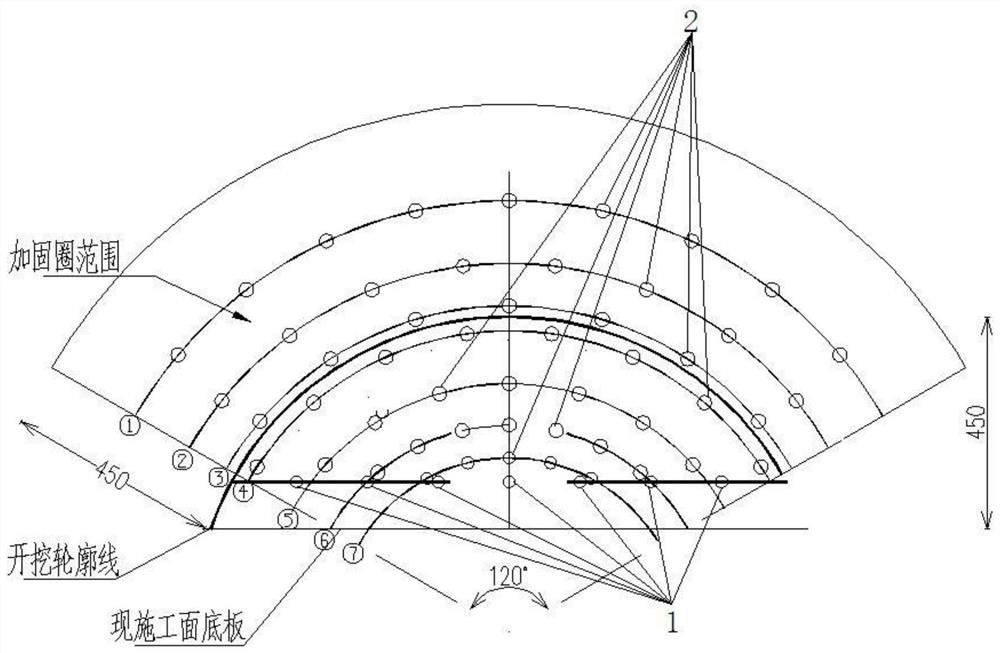

The invention relates to the field of tunnel grouting, in particular to a tunnel information tracing accurate grouting method, which solves the problems of thick reinforcing ring, large number of drilled holes, long construction period and the like of the traditional curtain grouting method adopted in current tunnel grouting. The method comprises the processes of grout stopping wall building, arrangement of orifice tubes and grouting tubes, measurement of the water burst of a drill hole, packer test, hole arrangement, drilling operation and grouting, wherein the hole arrangement and the grouting are performed according to the sequence from an advance geological drill hole to other outer ring holes to an inner ring hole to a working surface stabilizing hole to an access hole to a pipe-shed hole; and steps such as advance big pipe-shed construction of a working chamber and working surface stabilization by using a glass fiber anchor rod are saved. In the invention, a break through is made in the conventional construction philosophy, grouting design and geological change are tightly combined together, a grouting mechanism of 'crack blocking, water reduction, surrounding rock fixation and stratum stabilization' is adopted, the grouting holes are reduced by 30 to 40 percent, grouting quality is improved, the safe and quick construction is guaranteed, major water burst and mud burst accidents are eliminated, and the environment is protected maximally.

Owner:CHINA RAILWAY 12TH BUREAU GRP

Rapid construction method of high-pressure water-rich fault zone of tunnel

ActiveCN101798930AReduce water pressure in tunnelReduce water and mud inrushUnderground chambersTunnel liningWorld classTunnel construction

The invention relates to the field of tunnel construction, in particular to a rapid construction method of a high-pressure water-rich fault zone of a tunnel, which solves a plurality of problems in the construction method of high-pressure water-rich fault zone tunnels under the guide of the traditional knowledge. A draining branch tunnel is additionally arranged between a main tunnel and a parallel heading, the water flow pressure of the hanging wall of a fault interface is reduced progressively, and a large amount of water is discharged from the main tunnel by adopting a guiding and non-clogging mode; when the water pressure of the main tunnel is reduced to 0.3-0.5MPa, an informationized tracking and accurate grouting method is used for grouting and reinforcing the main tunnel; and rapidly excavating and sealing technology is used for excavating the main tunnel and the parallel heading. The invention adopts the technology combining the water distribution and pressure reduction mode, the informationized tracking and accurate grouting method and the rapidly excavating and sealing technology for high-pressure water-rich shattered fault zones for the first time, breaks through the traditional concept that the water distribution and pressure reduction mode is opposite to the grouting and reinforcing construction method, solves the world-class problem of construction of the high-pressure water-rich fault zone of the tunnel, improves the construction progress and the construction efficiency, and ensures safe and rapid perforation of the tunnel.

Owner:CHINA RAILWAY 12TH BUREAU GRP

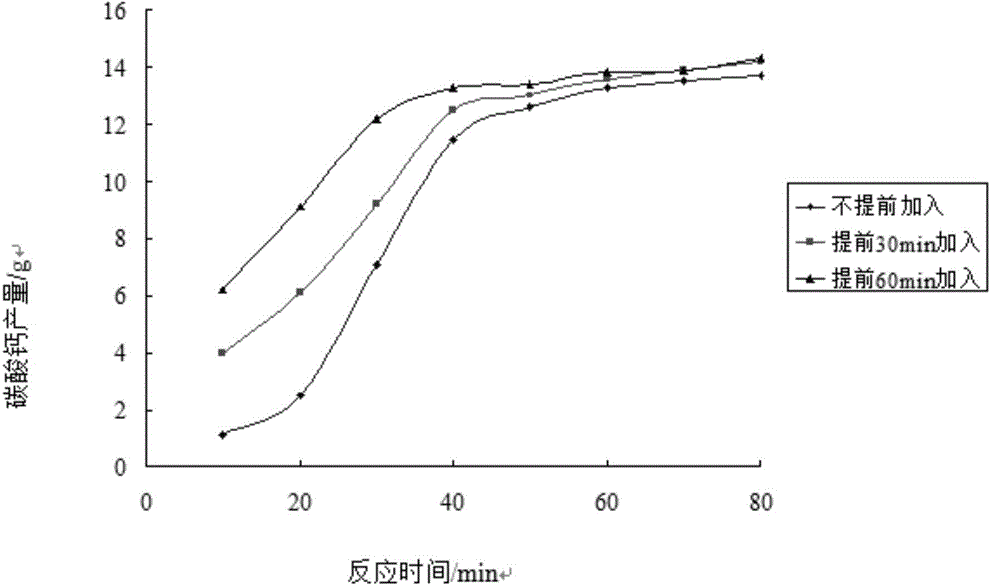

Microorganism grouting method capable of improving early-stage calcium carbonate deposit volume

ActiveCN104818719AIncrease early depositionIncrease depositionArtificial islandsUnderwater structuresMicroorganismCalcium carbonate precipitation

The invention discloses a microorganism grouting method capable of improving an early-stage calcium carbonate deposit volume, which comprises the following steps: (1) a nutritive salt solution is added into a microorganism bacterium liquid to obtain a mixed liquid of bacterium liquid and nutritive salt, and standing is carried out for 0.5-1h; and (2) during grouting, the mixed liquid of bacterium liquid and nutritive salt is blended with a calcium salt solution according to a predetermined proportion. Due to the adoption of a microorganism grouting material, not only is the total output of calcium carbonate sediment effectively improved, but also the early-stage output of the sediment is can be effectively improved, so that important significance is provided for blocking concrete cracks by utilizing a grouting method. Only a lot of calcium carbonate sediment is generated in relatively short time, the concrete cracks can be blocked in relatively short time, and thus grouting amount and times can be reduced.

Owner:SHANDONG JIANZHU UNIV

Compound colloid for treating coal bed fire

InactiveCN1931397AImprove stabilityDisappear quicklyFire rescueFire extinguisherSuspending AgentsSlurry

The compound colloid for treating coal bed fire consists of water, aggregate and gel forming agent. The aggregate is fly ash, loess, sand soil or rock powder; and the gel forming agent is sodium polyacrylate. When the compound colloid is used, water and the aggregate are first mixed to form slurry, and sodium polyacrylate is then added. Into the compound colloid, aluminum sulfate and ammonium bicarbonate may be added to foam the gel and to decrease the slurry consumption, and some suspending agent may be added to avoid settling of the aggregate during pipelining. The fire extinguishing colloid for coal bed has low cost, simple operation and low consumption.

Owner:西安森兰科贸有限责任公司

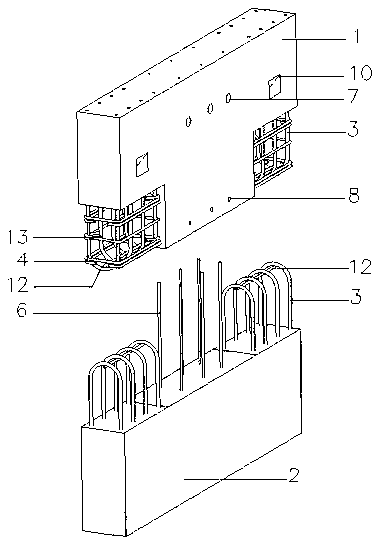

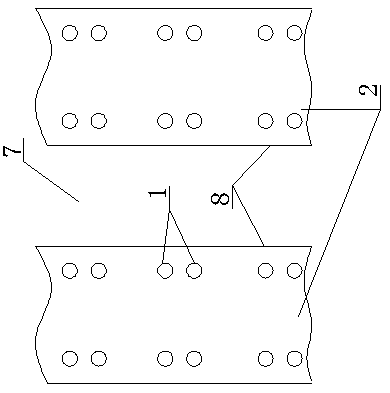

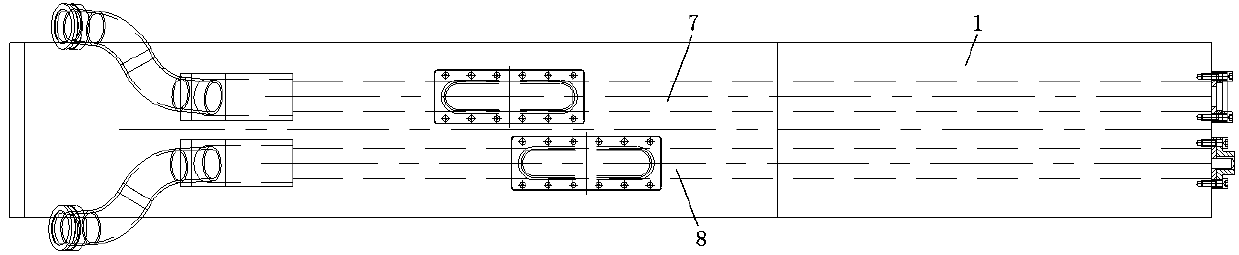

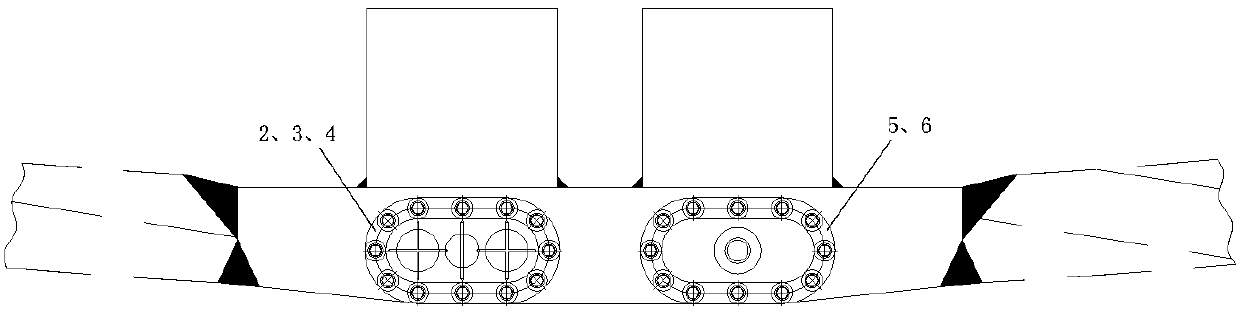

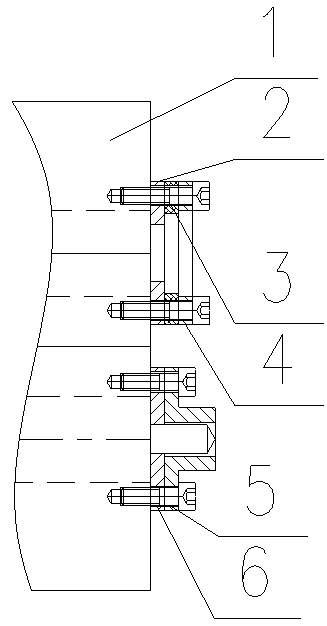

Precast concrete member connected by straight thread and pier head lock anchor grouting sleeve, and method for assembling same

The invention relates to a precast concrete member connected by a straight thread and a pier head lock anchor grouting sleeve, and a method for assembling the precast concrete member, belonging to the technical field of constructional engineering assembly concrete structures. The method of connecting by the straight thread and the pier head lock anchor grouting sleeve is adopted; one end of a reinforcing steel bar is processed into the straight thread (6), and the other end of the reinforcing steel bar is processed into a pier head (5); the inner wall of the end with smaller diameter of a connecting sleeve is processed into a thread (9) which is connected with the reinforcing steel by the straight thread (6) and is used for transmitting force; the inner wall of the end with larger diameter of the connecting sleeve is processed into a thread (16) which is connected with a matched plug ring (10) by an external thread (17); after grouting is carried out through a grouting hole, the original way that the tensile force of the reinforcing steel bar of a prefabricated part connected by grouting is transmitted mainly by bonding is changed by the reinforcing steel bar through lock anchor extrusion and bonding force transmission among the pier head of the reinforcing steel bar, the plug ring, grouting material and the sleeve. The safety and economical efficiency of the connection of the novel precast concrete member are improved.

Owner:CHINA CONSTR ENG DESIGN GROUP +1

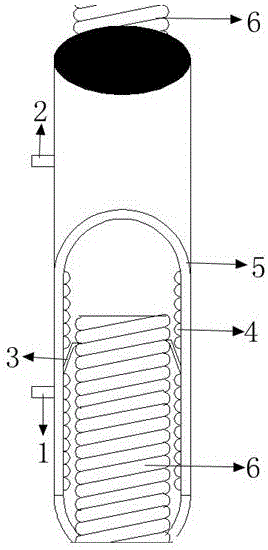

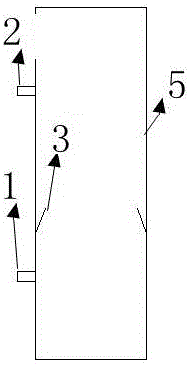

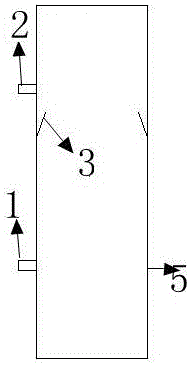

Self-tightening half grouting sleeve connecting piece

The invention relates to a self-tightening half grouting sleeve connecting piece mainly applied to connecting of vertical reinforcing steel bars, including connecting of shear walls, frame columns and hanging board lamps. The self-tightening half grouting sleeve connecting piece is composed of a grouting opening (1), a thick liquid discharging opening (2), poking pieces (3), threads (4), a sleeve (5) and reinforcing steel bars (6). The diameter of the sleeve (5) is larger than the diameter of each reinforcing steel bar (6). The threads (4) are arranged on the inner wall of the sleeve (5). The grouting opening (1) is formed in the lower portion of the sleeve (5), the thick liquid discharging opening (2) is formed in the upper portion of the sleeve (5), and the poking pieces (3) are arranged in the position, between the grouting opening (1) and the thick liquid discharging opening (2), of the inner wall of the sleeve (5). The self-tightening half grouting sleeve connecting piece has the effects and advantages that the self gravity of the structure is utilized to conduct structure connecting, so that the structure is firmer; the diameter is increased slightly, so that the error-tolerant rate is increased; and meanwhile, connecting force is increased due to existing of the poking pieces, so that the length of the connecting piece can be reduced properly.

Owner:安徽博泰装饰材料有限公司

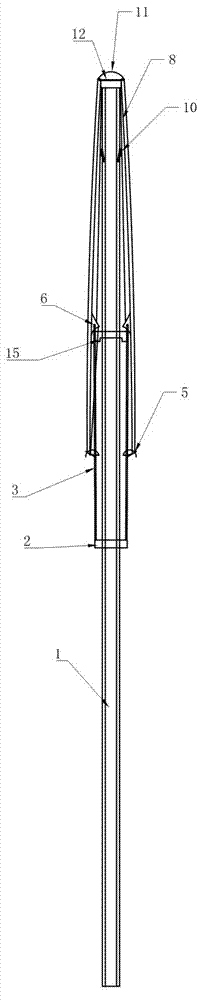

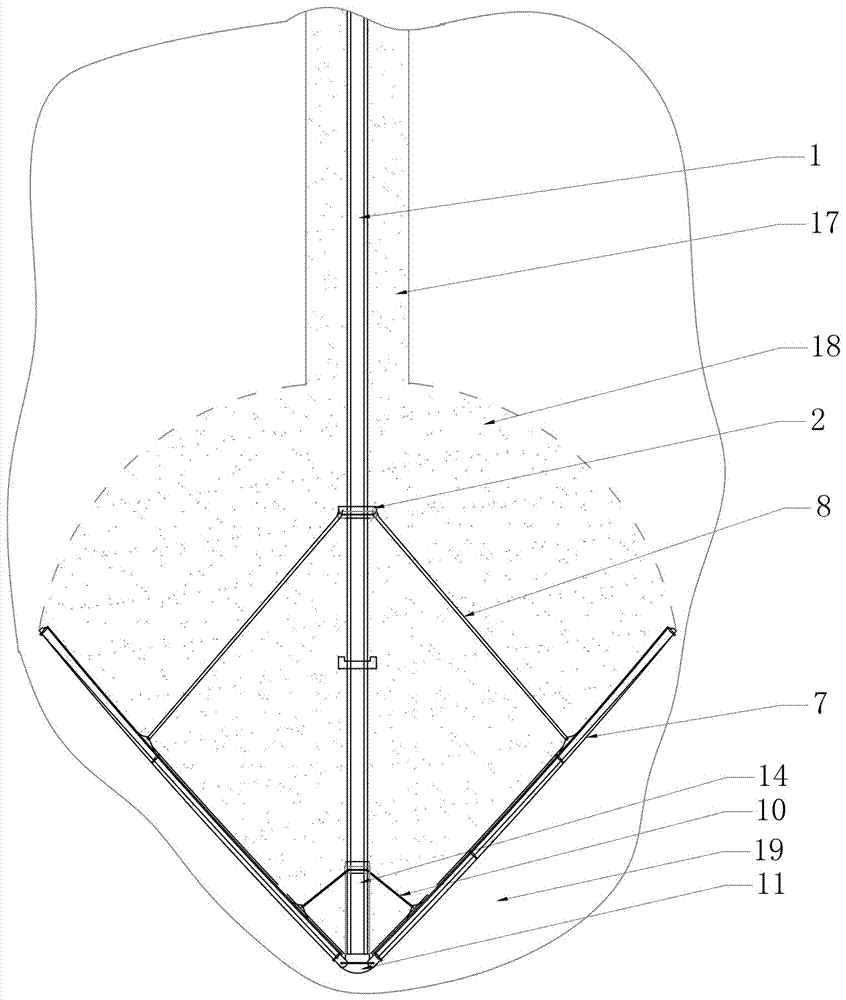

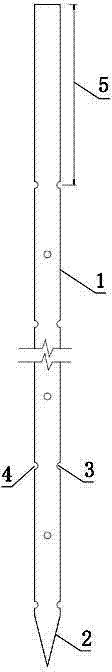

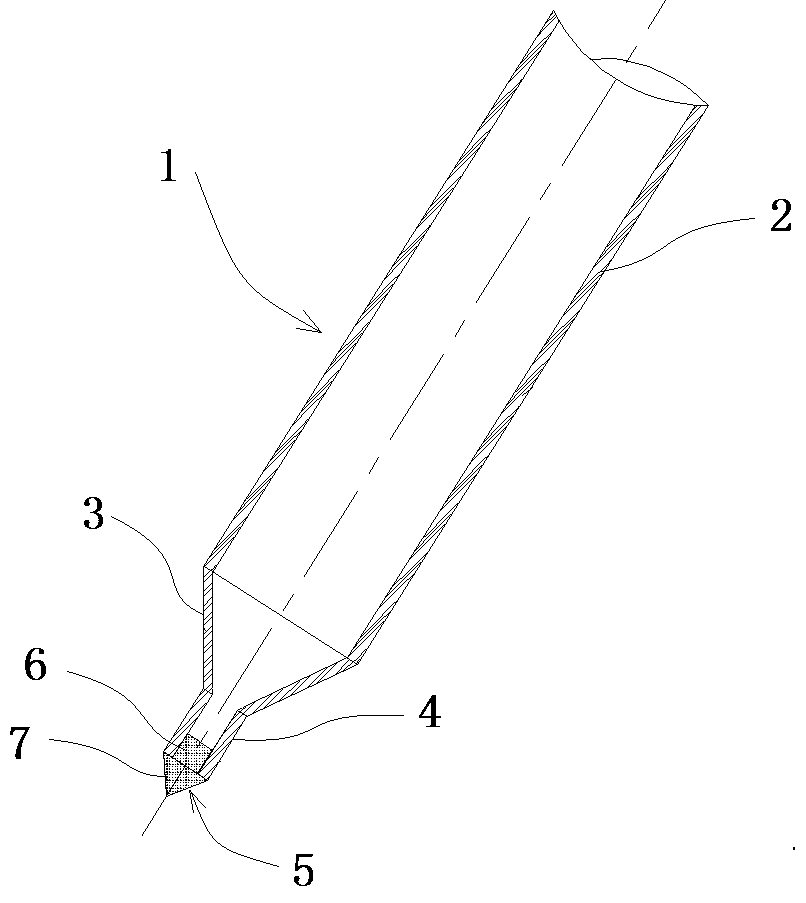

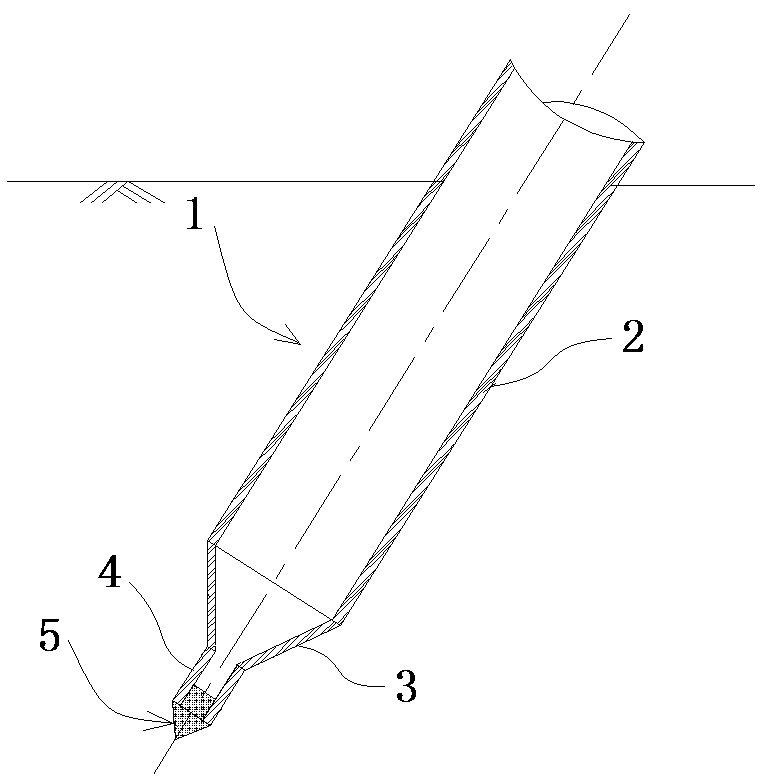

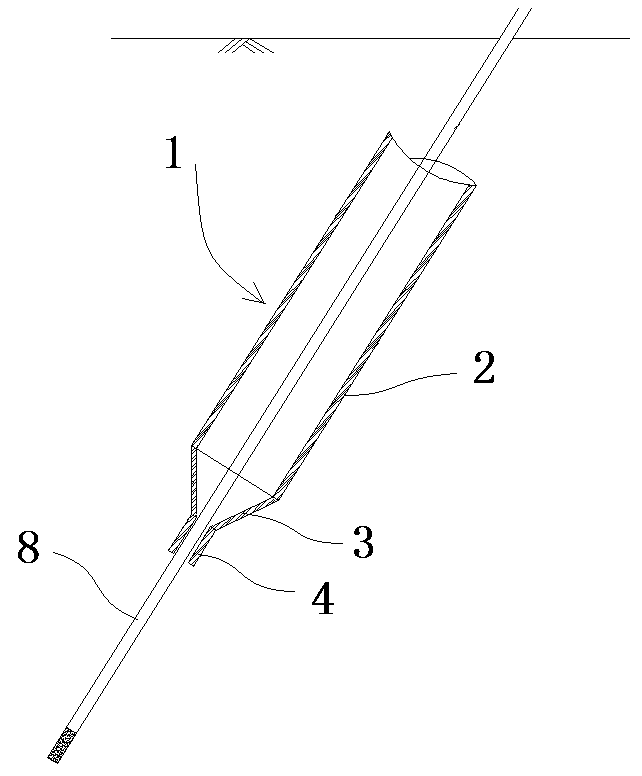

Anchor stock structure with expanded head

PendingCN107989037AIncrease frictionImprove bearing capacityProtective foundationBulkheads/pilesGroutSurface shape

The invention discloses an anchor stock structure with an expanded head. The anchor stock structure is characterized in that an end socket of an anchor stock is provided with a shrinkage-strutting device which consists of an umbrella surface, umbrella ribs, a lower brace rod, an upper brace rod, a slide block and a sleeve pipe and is of an umbrella structure; the lower brace rod is connected withthe umbrella ribs and the slide block in a hinging manner; the upper brace rod is formed by hinging two rod elements, and further, is connected with the umbrella ribs and the sleeve pipe in the hinging manner; when the anchor stock is placed, the shrunk umbrella surface and the umbrella ribs are pushed to the bottom of an anchor hole together with the anchor stock; the slide block is pushed to a limiting retainer ring to be fixed; after the umbrella surface is strutted in a cambered surface shape, grout is injected to fill a compact hole to form an anchor stock pile of an expanded head structure. Compared with the prior art, the anchor stock structure has a small grout injection amount and high bearing capacity, is used for effectively solving a problem that anchoring force is insufficient, has a simple structure, is conveniently constructed, and is particularly applicable to anchor stock pile foundation projects of easy-to-collapse soil layers, including a pebble, muddy soil and the like, of a soft soil stratum.

Owner:SHANGHAI ZHIPING FOUNDATION ENG CO LTD

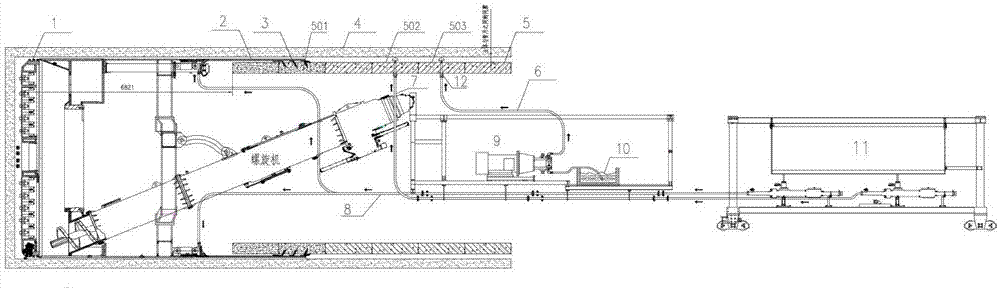

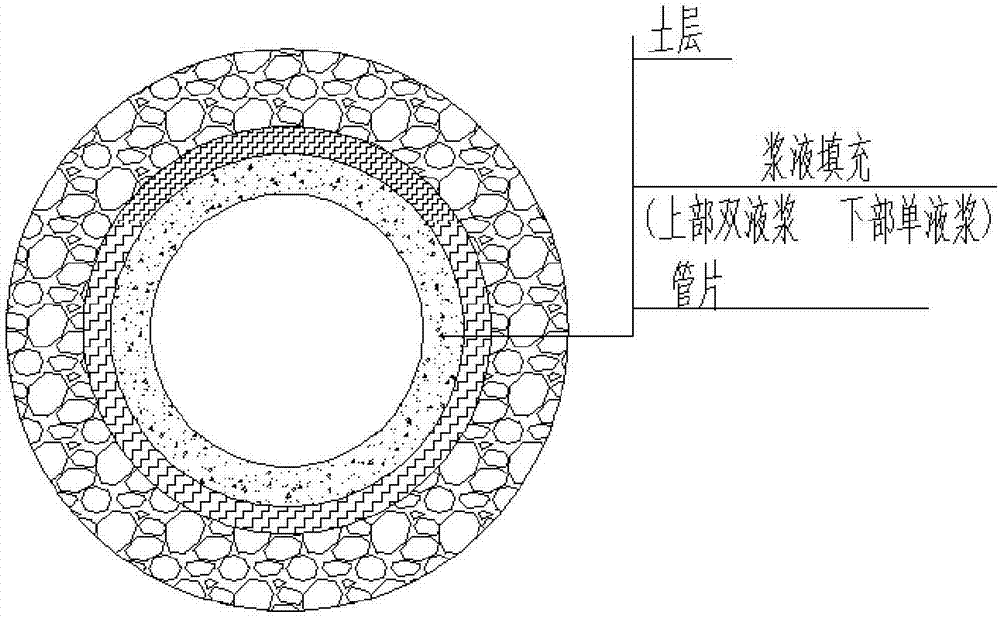

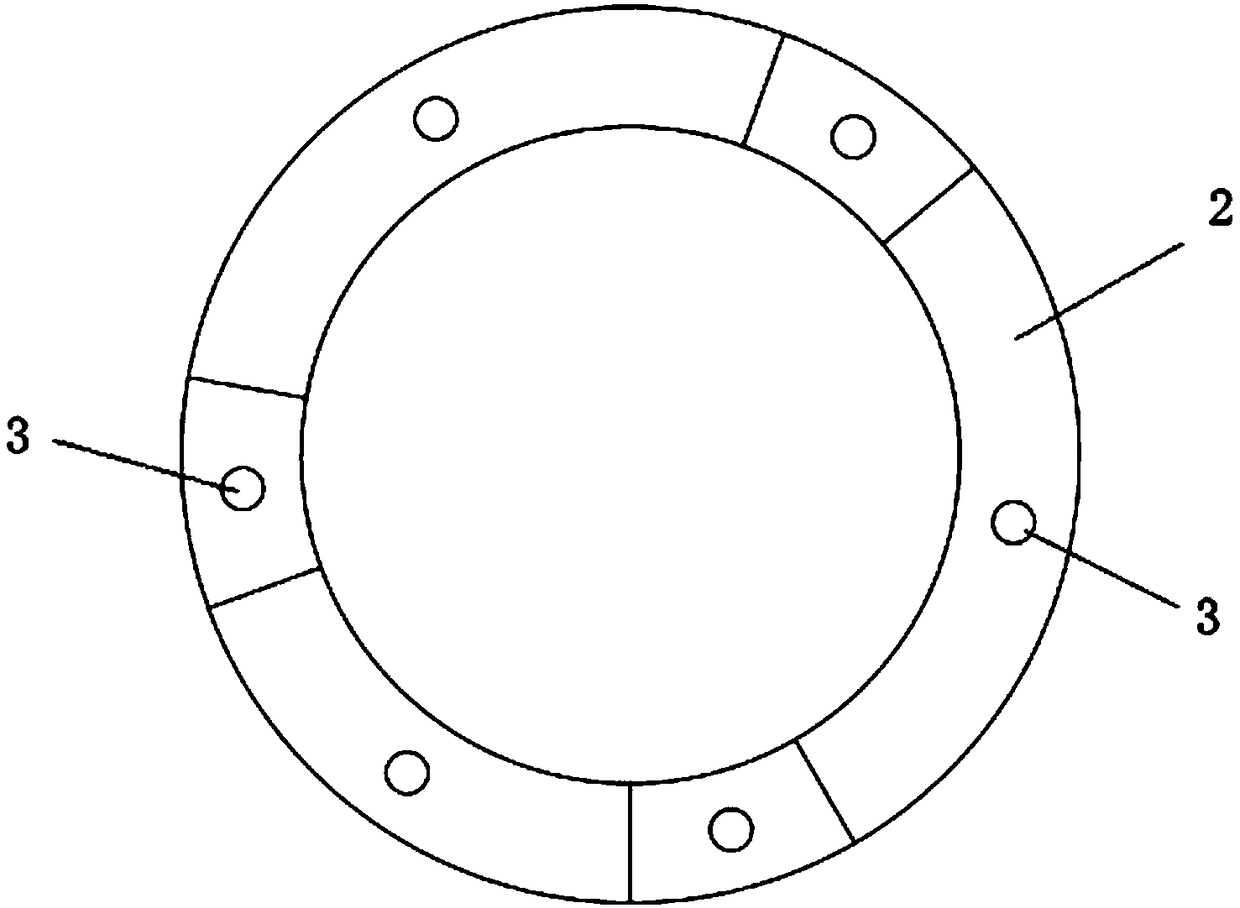

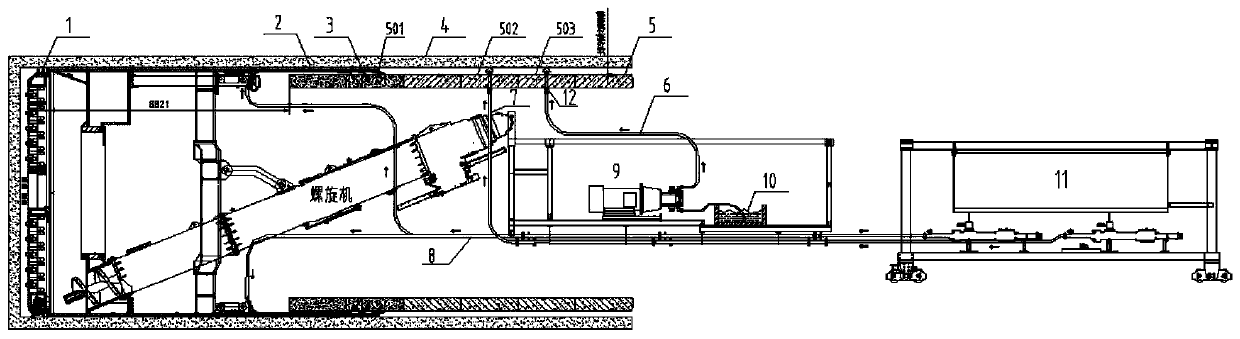

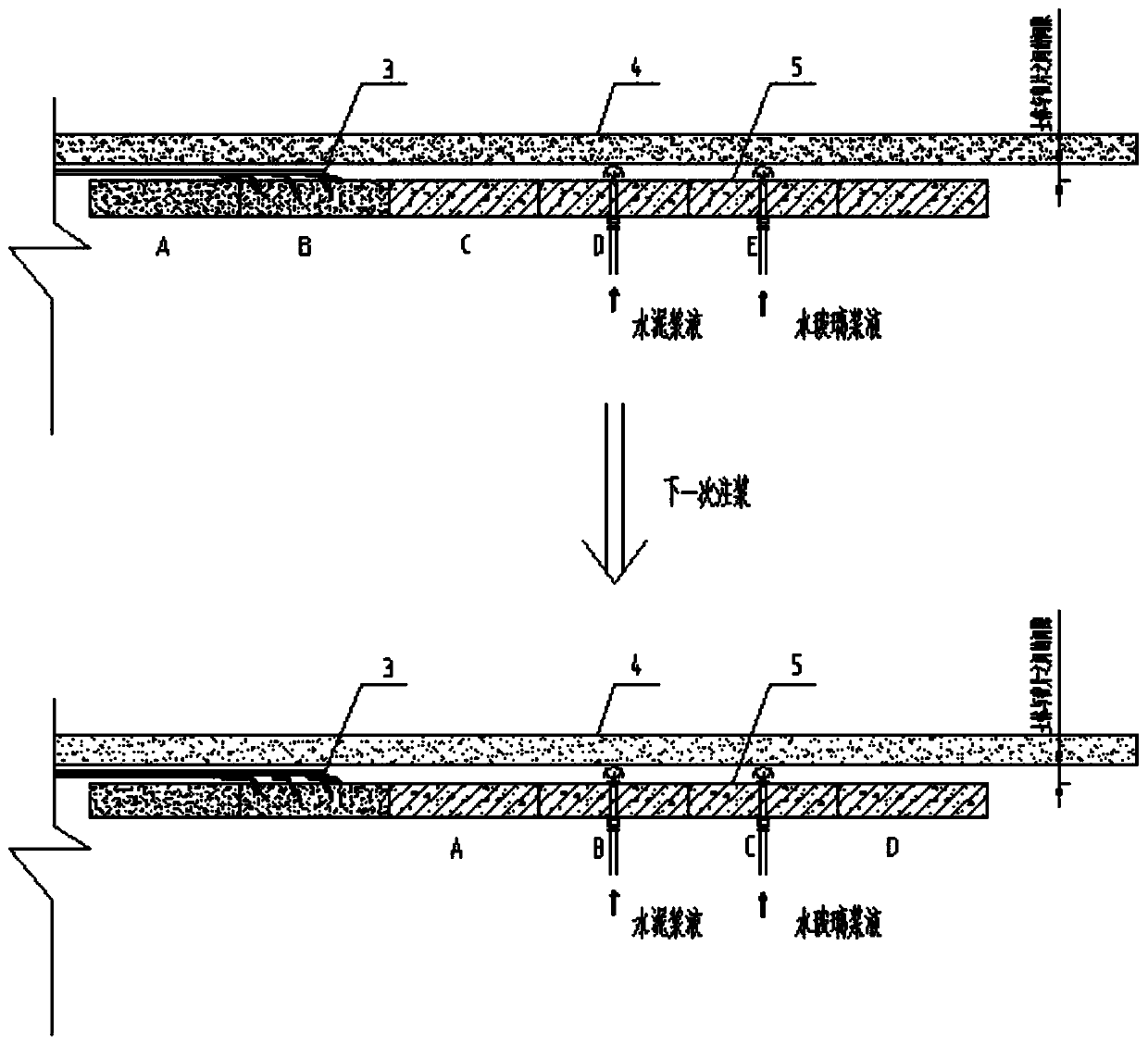

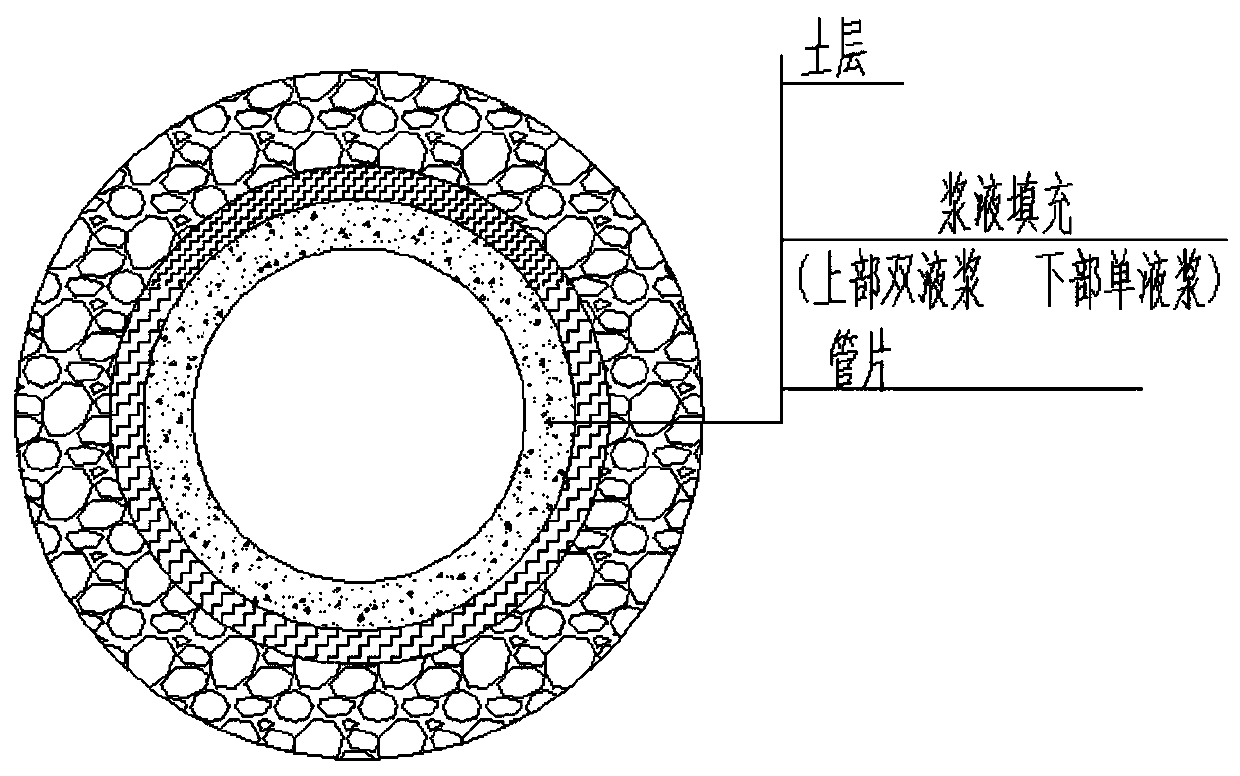

Anti-subsidence control method by supplying grouting in real time in shield construction

ActiveCN107120121AImprove timelinessImprove effectivenessUnderground chambersTunnel liningMaterial resourcesSlurry

The invention discloses an anti-subsidence control method by supplying grouting in real time in shield construction. According to the anti-subsidence control method, a shield machine cutter, a shield shell, a shield tail brush, around soil layers, segments, a first annular segment, a second annular segment, a third annular segment, a water glass grout grouting pipe, an auxiliary synchronous grouting pipe, a main synchronous grouting pipe, a water glass grout grouting pump, a water glass grout preparation barrel, a shield machine cement grout synchronous grouting box and a ball valve are included. Synchronous grouting and secondary grout supplying are effectively integrated, cement injection and water glass injection are organically combined, therefore the timeliness and the effectiveness of filling of gap in the backs of the segments are strengthened, disturbances caused by intersection construction of a traditional secondary grouting and normal tunneling of the shield machine are eliminated, compared with the traditional secondary grouting method, cement grout does not need to be prepared separately, the grouting amount is greatly decreased by separately pumping the water glass grout, the construction schedule is speeded up, the automation level is improved by taking full use of self equipment of the shield machine, and the manpower and material resources are saved.

Owner:CCTEB INFRASTRUCTURE CONSTR CO LTD +1

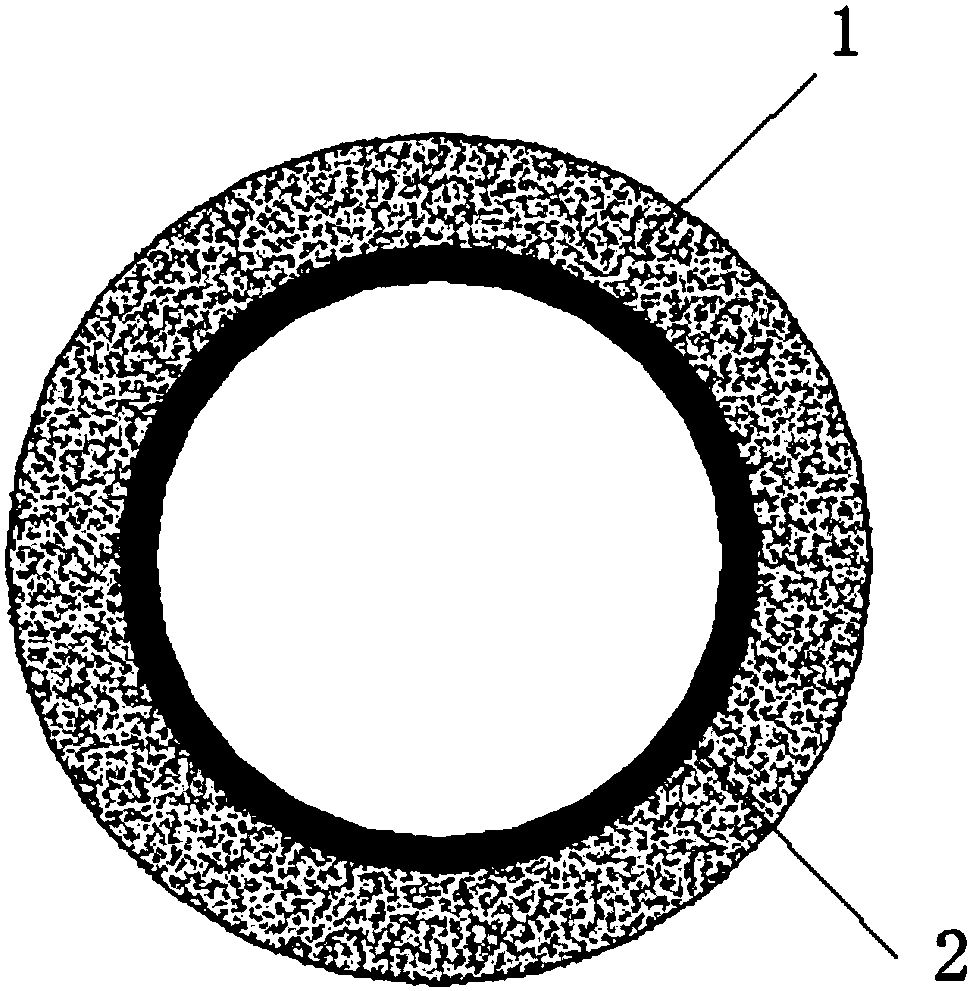

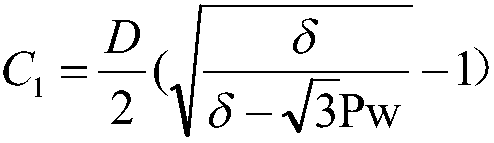

Construction method for grouting reinforced region applied to water-rich sand layer shield tunnel

ActiveCN108166994ALow priceReduce the amount of groutUnderground chambersTunnel liningTunnel constructionControl mode

The invention belongs to the field of tunnel construction, and particularly relates to a construction method for a grouting reinforced region applied to a water-rich sand layer shield tunnel. According to the technical scheme, the construction method comprises the following steps that 1, parameters of the grouting reinforced region and a grouting control mode are determined; 2, a grouting pump islaid to open reserved grouting holes on a segment; 3, grout is transported to a grout storing tank at the tail portion of a shield; 4, the grout is grouted synchronously through the reserved groutingholes on the segment to form the grouting reinforced region; and 5, the effect of the grouting reinforced region is monitored. According to the construction method for the grouting reinforced region applied to the water-rich sand layer shield tunnel, the grouting reinforced region formed for a sand layer can play a good role in strengthening and stopping water, the price of the grout is low, the amount of grouting is low, no secondary grouting is needed, and the construction process is easy to operate.

Owner:NORTHEASTERN UNIV

Grouting reinforcement construction process capable of realizing draining and plugging combined effect for underground water in vertical shaft

InactiveCN103089301AAvoid the tendency to diffuse penetrationPrevent sinkingFoundation engineeringDrainagePhosphoric acidSlurry

The invention relates to a grouting reinforcement construction process capable of realizing a draining and plugging combined effect for underground water in a vertical shaft. The grouting reinforcement construction process includes steps of (1), temporarily sealing the bottom of the vertical shaft, arranging grouting pipes on inner and outer sides of the vertical shaft, arranging drain pipes matched with the grouting pipes on the vertical shaft and locally pumping the water by a vacuum pump; (2), diluting sodium silicate of raw grout 39Be' by water to obtain grout 28Be', mixing TGRM grouting materials with cement according to a proportion of 1:3 to obtain second grout, mixing the grout 28Be' with the second grout according to a proportion of 1:1 to obtain liquid A, diluting sodium silicate of raw grout 39Be' by water to obtain grout 30Be', diluting strong phosphoric acid by water according to a proportion of 1:6 to obtain diluted phosphoric acid, and mixing the grout 30Be' with the diluted phosphoric acid according to a proportion of 1:1 to obtain liquid B; (3), alternately filling the liquid A and the liquid B into reinforcement soil layers of the vertical shaft via the grouting pipes and completing grouting for the periphery of the vertical shaft; and (4), feeding small pipes within a 1.5m range of the periphery of the vertical shaft by the aid of high-pressure blast, and alternately filling the liquid A and the liquid B into the periphery of the vertical shaft via the small pipes. The grouting reinforcement construction process has the advantages that 'draining' and 'plugging' are combined and work along both lines in the grouting construction process for the vertical shaft, so that water layers are prevented from diffusing and permeating towards feeble grouted positions, the vertical shaft construction difficulty is lowered, and the construction safety degree is increased.

Owner:BEIJING MUNICIPAL CONSTR

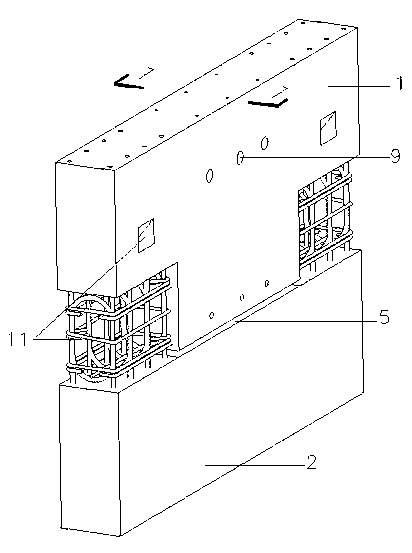

Precast concrete members connected by locking and anchoring pier heads and grouting variable diameter sleeve, prefabricated concrete member and manufacturing method of prefabricated concrete member

InactiveCN104264909AReduce the overall heightReduce the overall diameterWallsBuilding reinforcementsRebarPrecast concrete

The invention provides precast concrete members connected by locking and anchoring pier heads and grouting a variable diameter sleeve, a prefabricated concrete member and a manufacturing method of the prefabricated concrete member, belonging to the technical field of prefabricated concrete structures in architectural engineering. A sleeve connection method for transferring forces based on extrusion and bonding is adopted, a pier head (5) and a pier head (6) are processed at the two ends of rebars, one end of a connecting sleeve (7) adopts the sleeve inner diameter smaller than the outer diameter of the rebar pier head (6) at the corresponding end, a plugging ring (10) with an inner diameter smaller than the outer diameter of the rebar pier head (5) at the corresponding end is adopted at the other end of the connecting sleeve, and the rebars transfer forces by utilizing locking and anchoring extrusion and bonding among the pier heads, the plugging ring, the grouting materials and the sleeve through sleeve grouting, thus changing the previous mode that the pull of the rebars of the precast concrete members connected through grouting is mainly transferred through bonding. The safety and economy of connection of the novel precast concrete members are improved to some extent.

Owner:CHINA CONSTR ENG DESIGN GROUP +1

Prefabricated concrete member, assembled concrete member and fabricating method through straight thread and nut locking anchor grouting sleeve connection

The invention discloses a prefabricated concrete member, an assembled concrete member and a fabricating method through straight thread and nut locking anchor grouting sleeve connection and belongs to the technical field of assembled concrete structures of constructional engineering. A method of straight thread and nut locking anchor grouting sleeve connection is applied, one end of a reinforcing steel bar is machined to form a straight thread (6), a nut (5) is connected with the other end of the reinforcing steel bar, the inner wall of a small-diameter end of a connecting sleeve is machined to form a screw thread (9) so as to be connected with the reinforcing steel bar through the straight thread (6) to transmit force, the inner wall of a large-diameter end of the connecting sleeve is machined to form a screw thread (16) so as to be connected with a matched blocking ring (10) through an external thread (17), after grouting through a grouting hole (8), the pulling force of the reinforcing steel bar is transmitted through locking anchor extruding and cementation among the reinforcing steel bar nut, the blocking ring, a grouting material and the sleeve, and traditional methods that pulling forces of reinforcing steel bars of prefabricated members through grouting connection are mainly transmitted through cementation are changed. According to the prefabricated concrete member, the assembled concrete member and the fabricating method through straight thread and nut locking anchor grouting sleeve connection, the connection of the novel prefabricated concrete member is improved in terms of safety and economical efficiency.

Owner:CHINA CONSTR ENG DESIGN GROUP +1

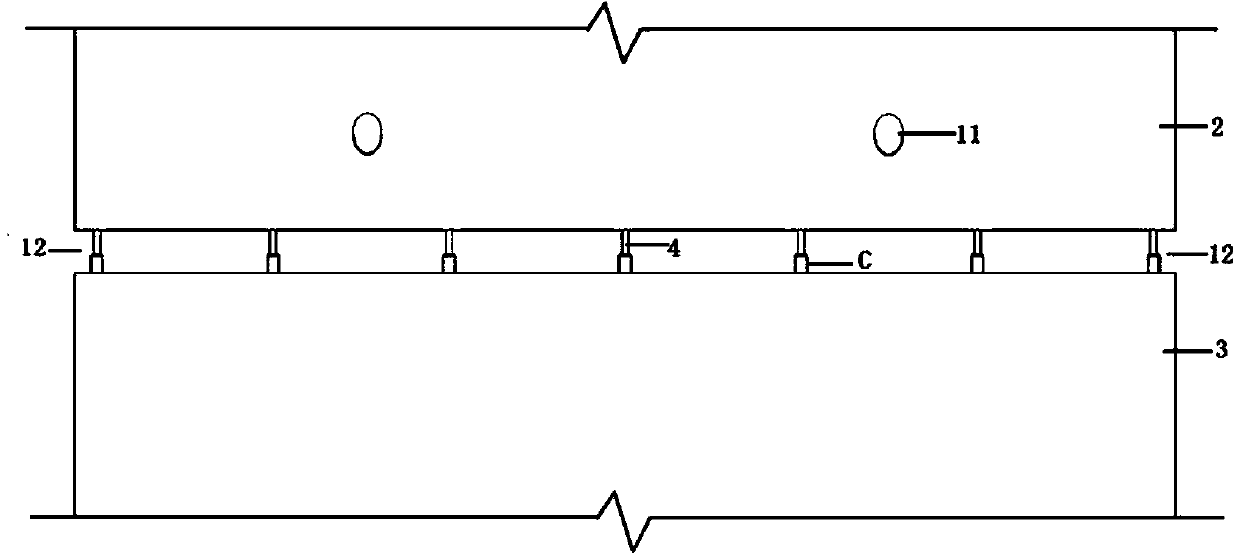

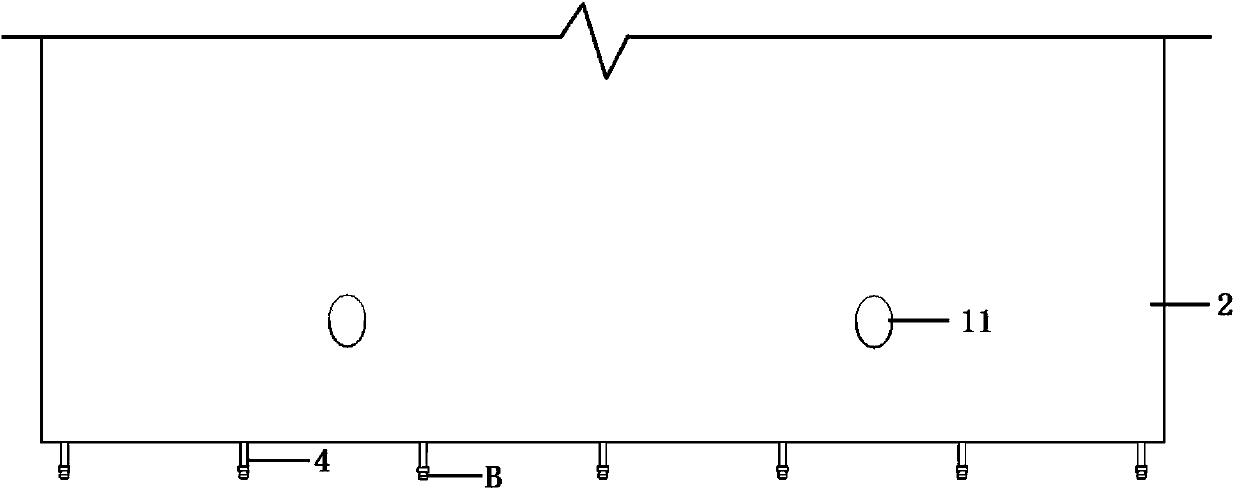

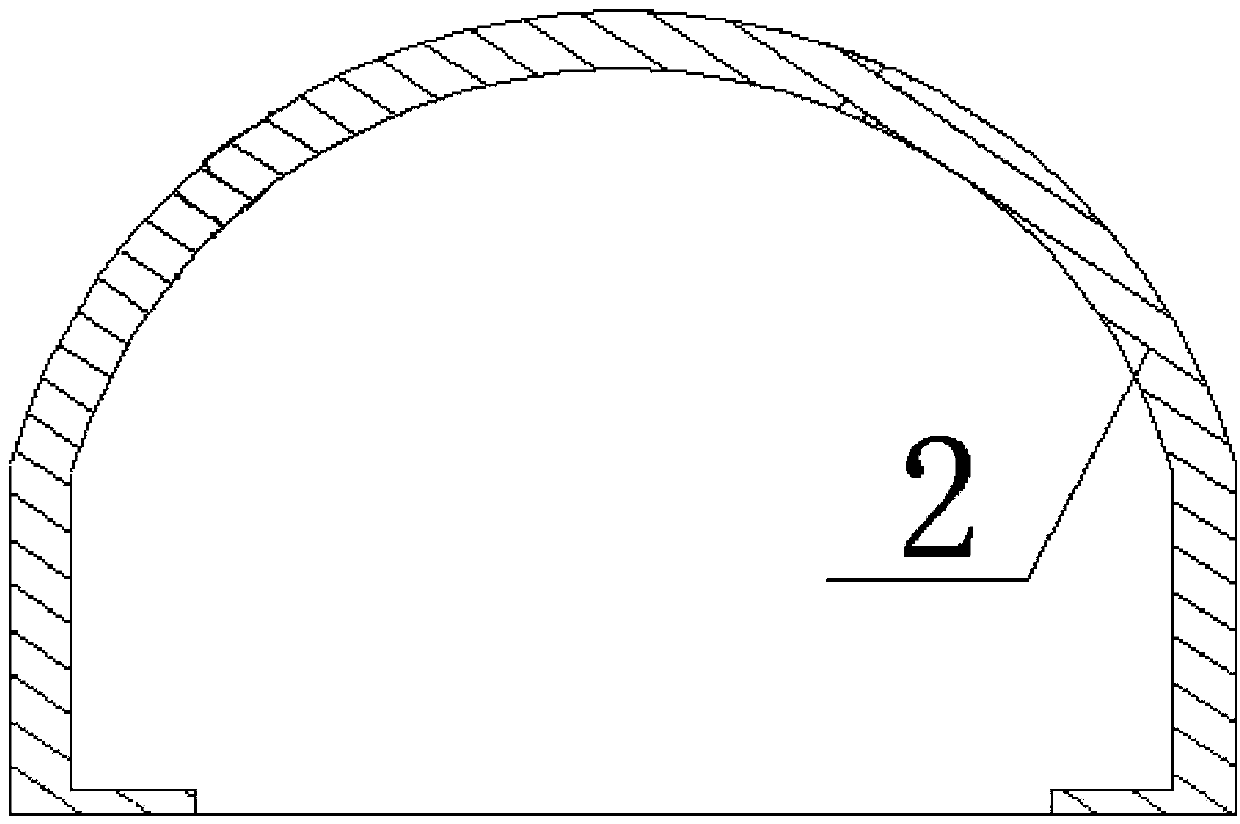

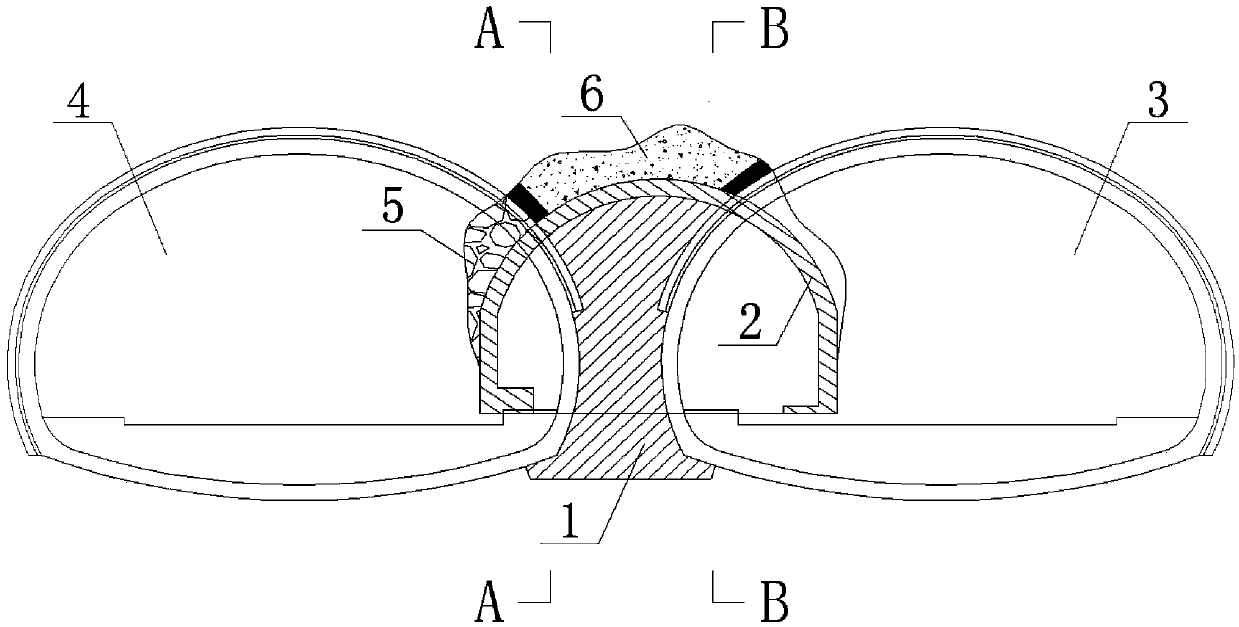

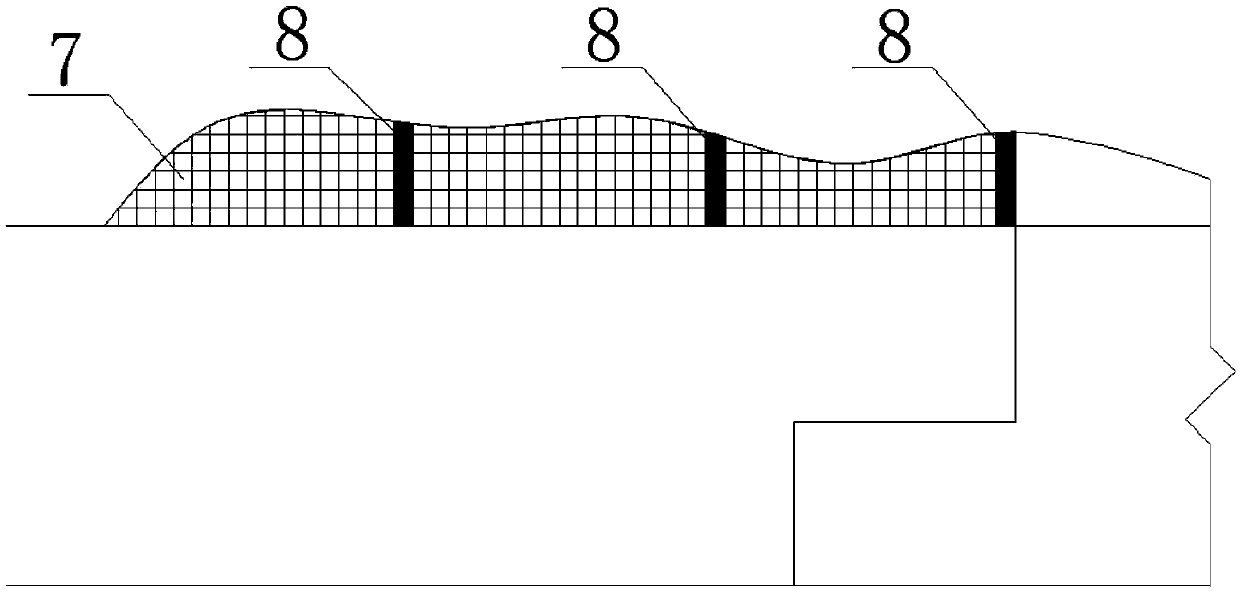

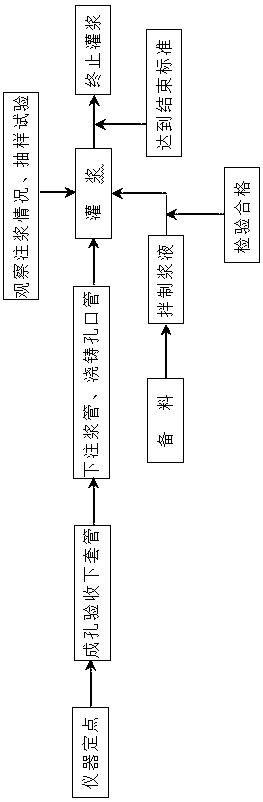

Middle separation wall top original lining cavity backfilling construction method when single-hole tunnel is changed into multiple arches

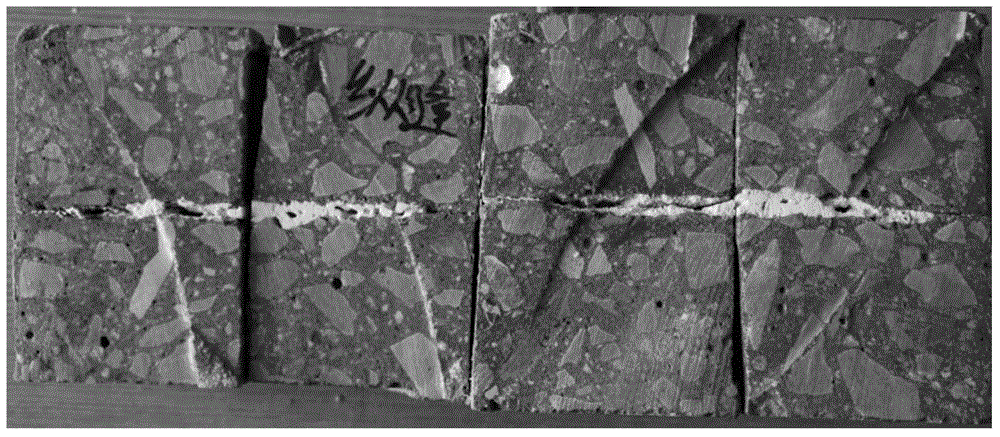

InactiveCN103953366AReduce the amount of groutLow costUnderground chambersTunnel liningRebarShotcrete

The invention discloses a middle separation wall top original lining cavity backfilling construction method when a single-hole tunnel is changed into multiple arches. The method sequentially comprises the following steps that a, a middle separation wall is cast; b, an anterior hole is constructed; c, hole slag dug from the anterior hole is used for filling back a cavity arranged at one side of a posterior hole to the digging outline part of the posterior hole; d, a steel bar net is paved on the top of the backfilled hole slag, and then, concrete is sprayed on the surface of the steel bar net; e, an end template is arranged along a tunnel longitudinal frame, in addition, the end template, the surrounding rock and the original lining are fixedly built through lining by using anchor bolts; f, a side template is erected at the digging outline part of the anterior hole; g, concrete is filled and is compactly vibrated and smashed; h, the posterior hole is constructed; i, the original lining of the existing tunnel in the anterior hole and the posterior hole is dismounted. The construction method has the advantages that the original tunnel top cavity backfilling problem is effectively solved, so the pressure of the surrounding rock is uniformly transmitted onto a support protection structure, the stress uniformity and the structure completeness of the lining can be ensured, and the loading capability and the durability are improved.

Owner:CHANGAN UNIV +1

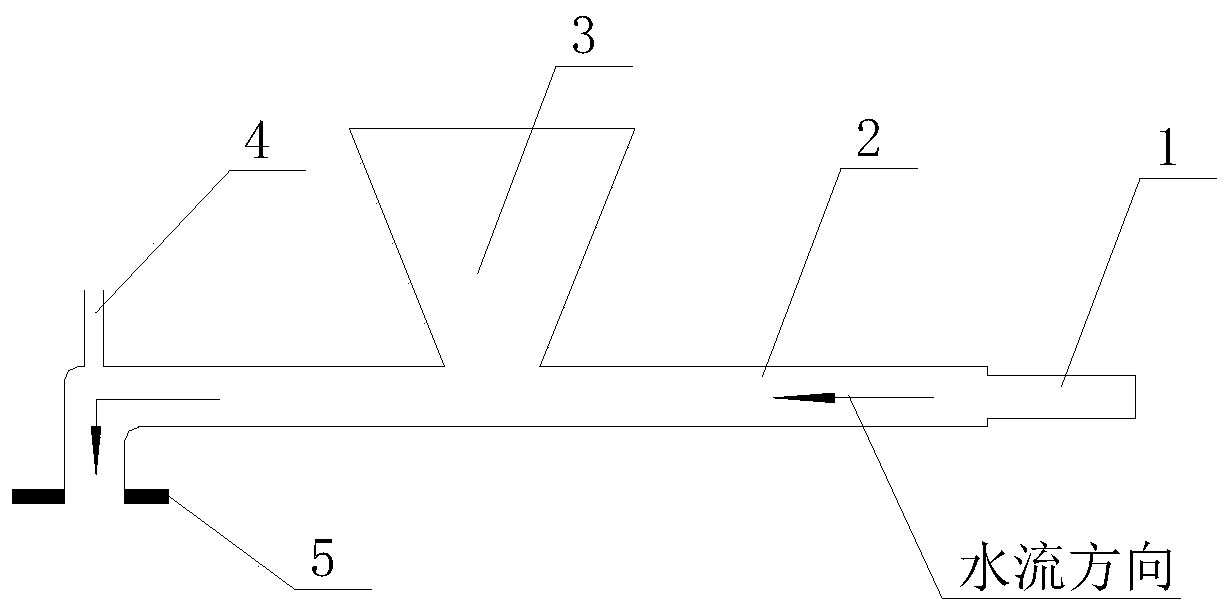

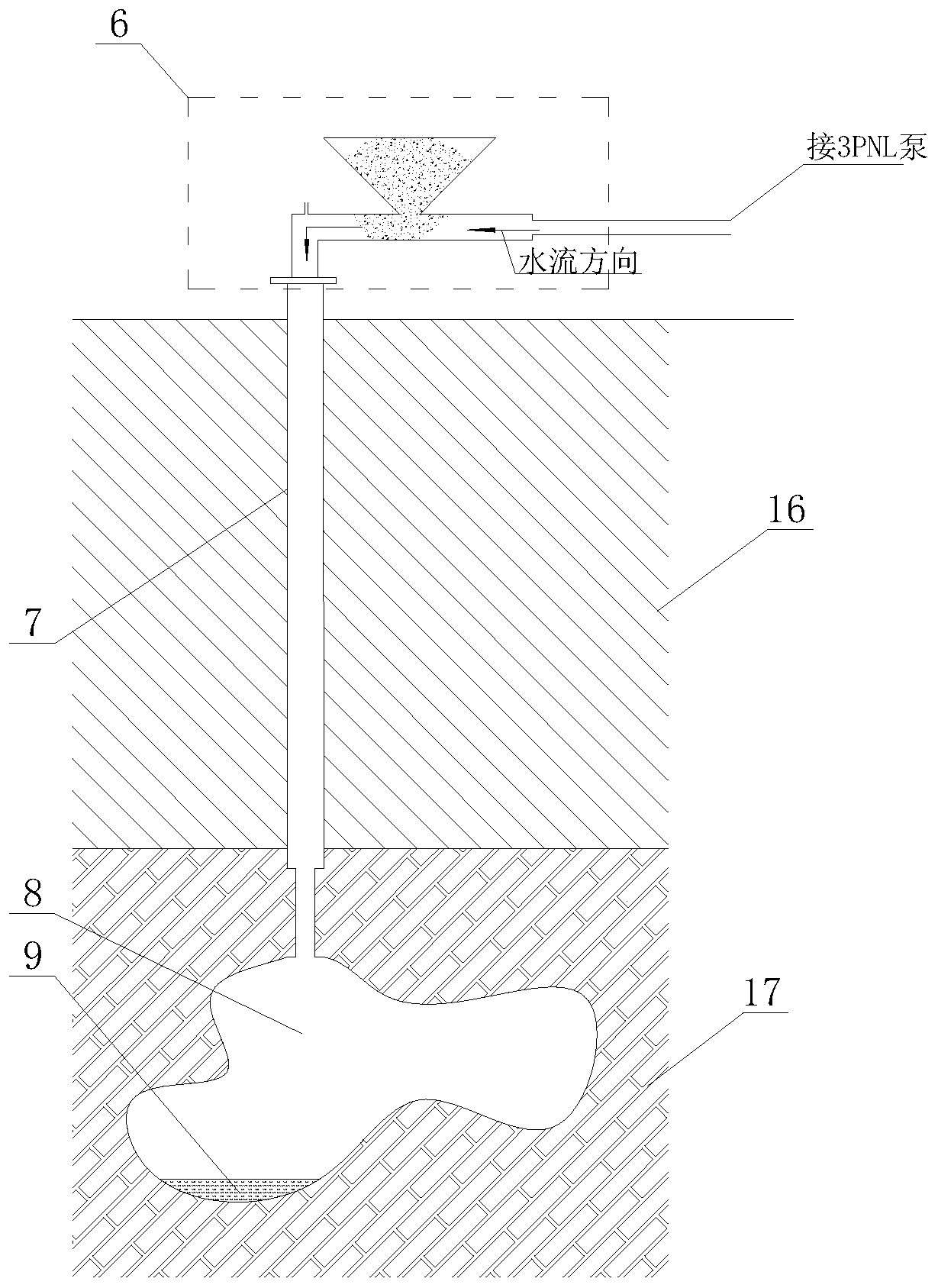

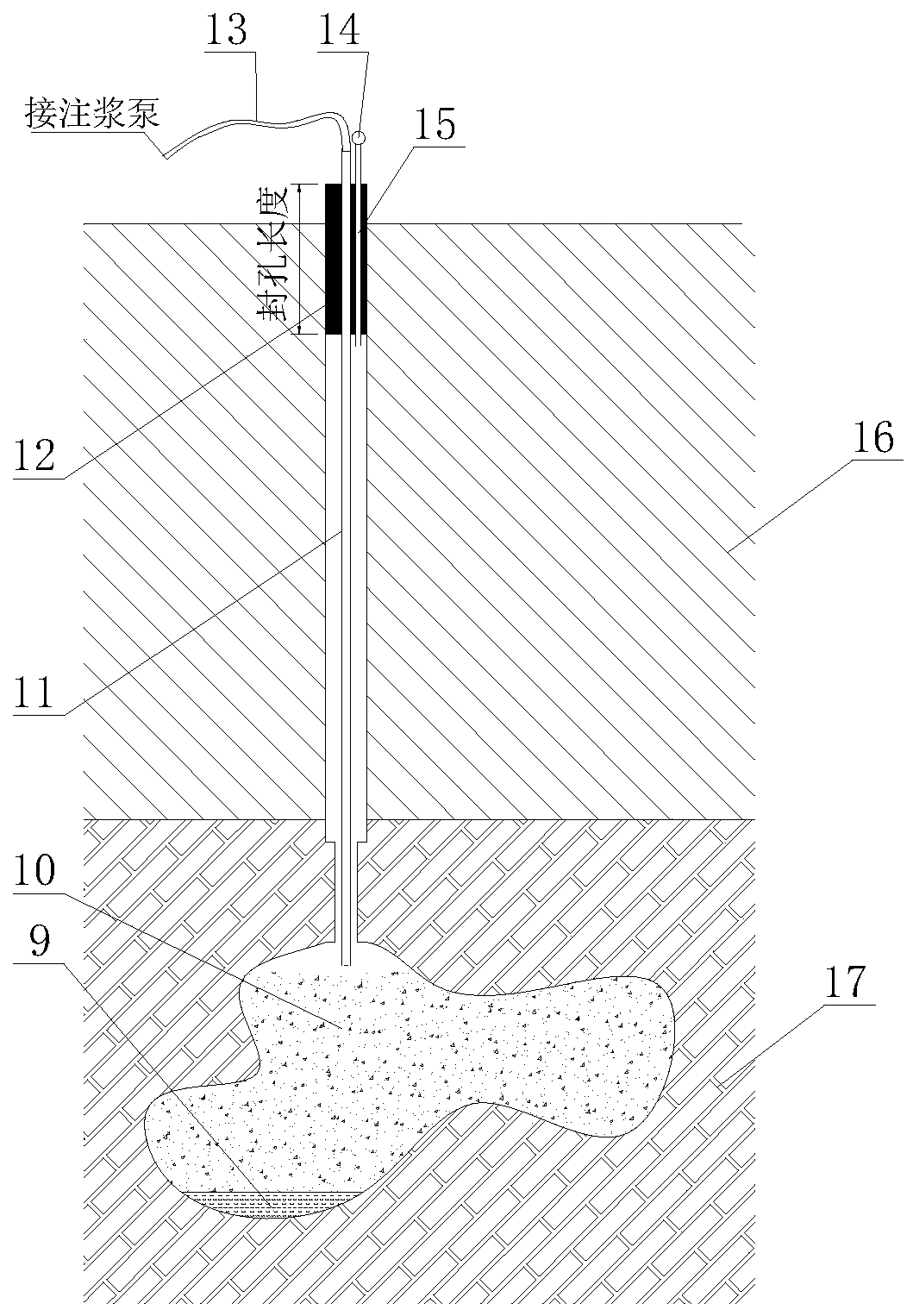

Method for filling underground cavity of bedrock stratum through filler grouting and hydraulic filling device

InactiveCN111535297AReduce the amount of groutReduce processing costsUnderground chambersTunnel liningSoil scienceBedrock

The invention relates to the technical field of karst cave filling, provides a method for filling an underground cavity of a bedrock stratum through filler grouting, and particularly relates to a filling method of a deep-covering type (burial depth is larger than 30.0 meters) large-space karst cave and a roadway. The method comprises the steps of determining a drilling position, drilling a covering soil layer, arranging a conveying casing pipe, drilling a bedrock section, filling by a hydraulic filling method and grouting. According to the method, the underground cavity is filled with the gravel material through the hydraulic filling method, then grouting is conducted, the filled gravel material is solidified, and the integrity of the filling material is improved; and the filled gravel materials can occupy the space in the underground cavity, the grouting amount is greatly reduced, the treatment cost is reduced, a connecting channel between the cavity and the outside of the cavity canbe blocked or reduced, the filling treatment effect of the underground cavity is improved, and the filling treatment problem of the deep covering type large-space karst cave and the roadway is solved.The invention further provides a hydraulic filling device, the hydraulic filling device is used for filling the underground cavity with gravel materials, the filling speed is high, and the filling effect is good.

Owner:HEBEI CONSTR & INVESTIGATION RES INST

Reinforcing and lifting method for strip-shaped or box-shaped foundation building

ActiveCN112081155AGuaranteed stabilityEnsure stabilitySoil preservationPressure groutingStructural engineering

The invention relates to a reinforcing and lifting method for a strip-shaped or box-shaped foundation building. The reinforcing and lifting method comprises the following steps that the lifting side of the building is determined according to the elevations of measuring points; a plurality of reinforcing grouting holes inclining downwards are formed in the side surface of a strip-shaped foundationor a box-shaped foundation partition wall at intervals, and a reinforcing body is formed below the strip-shaped foundation or the partition wall by adopting pressure grouting in the reinforcing grouting holes; lifting holes inclining downwards are formed in the two ends close to the lifting side of the building; and the lifting holes go deep into the bottom of the reinforcing body, pressure grouting is carried out in the lifting holes at the same time, the reinforcing body is used as a buffer strip, the lifting side of the building is lifted, the lifting speed is controlled, the elevations oftwo corners are finally lifted to the same elevations as the elevations of corners corresponding to the non-lifting side of the building at the same time, then a reinforcing pile foundation is formedbelow the reinforcing body, and the reinforcing pile foundation and the reinforcing body jointly support the strip-shaped foundation. The reinforcing and lifting method has the advantages of being good in overall stability, controllable in lifting speed and height, small in damage to the building and capable of preventing secondary sedimentation.

Owner:BEIJING HENGXIANG HONGYE FOUND REINFORCEMENT TECH CO LTD

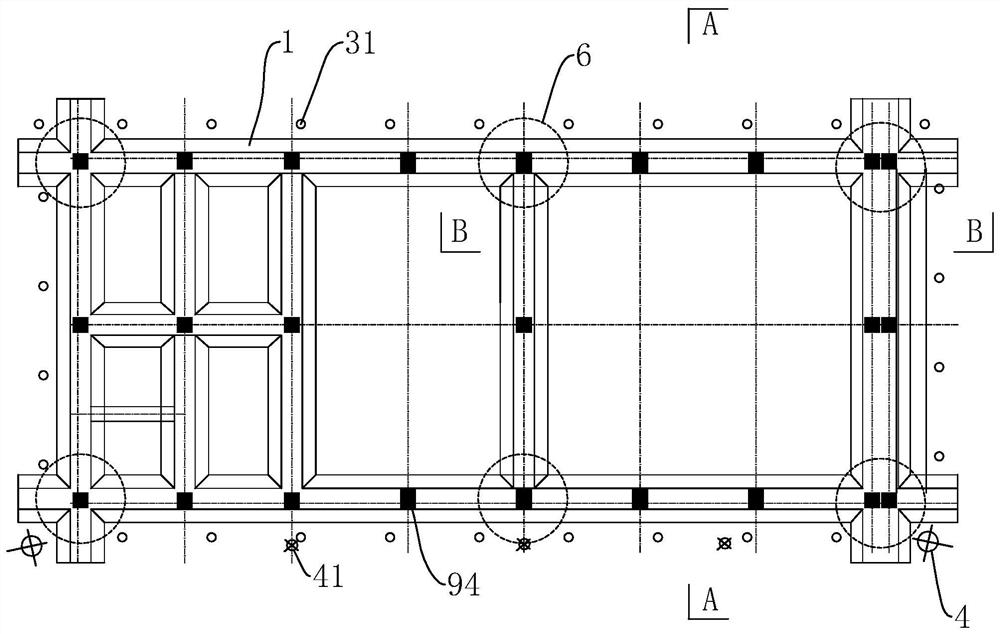

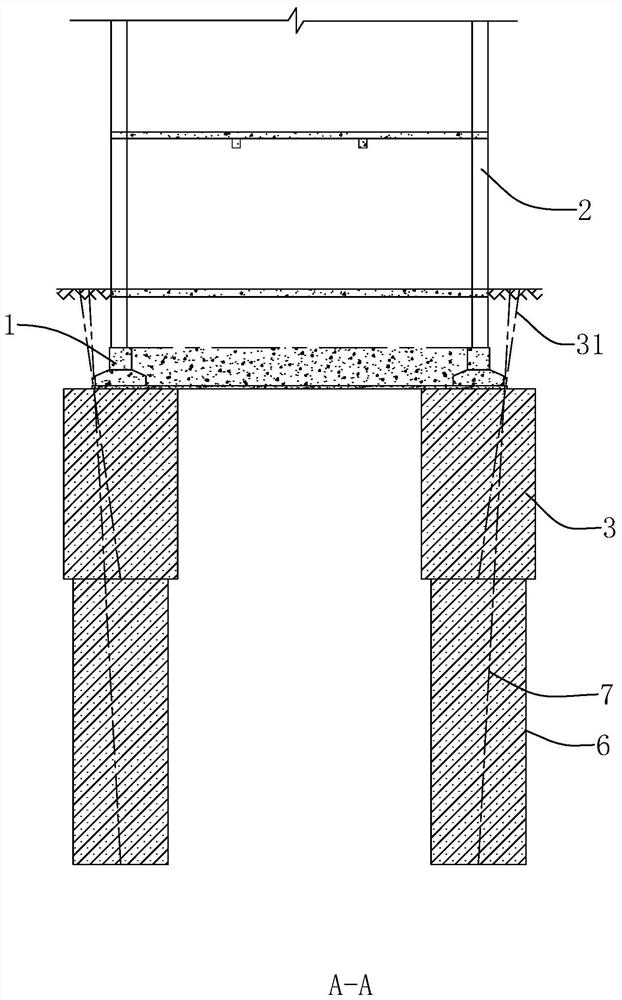

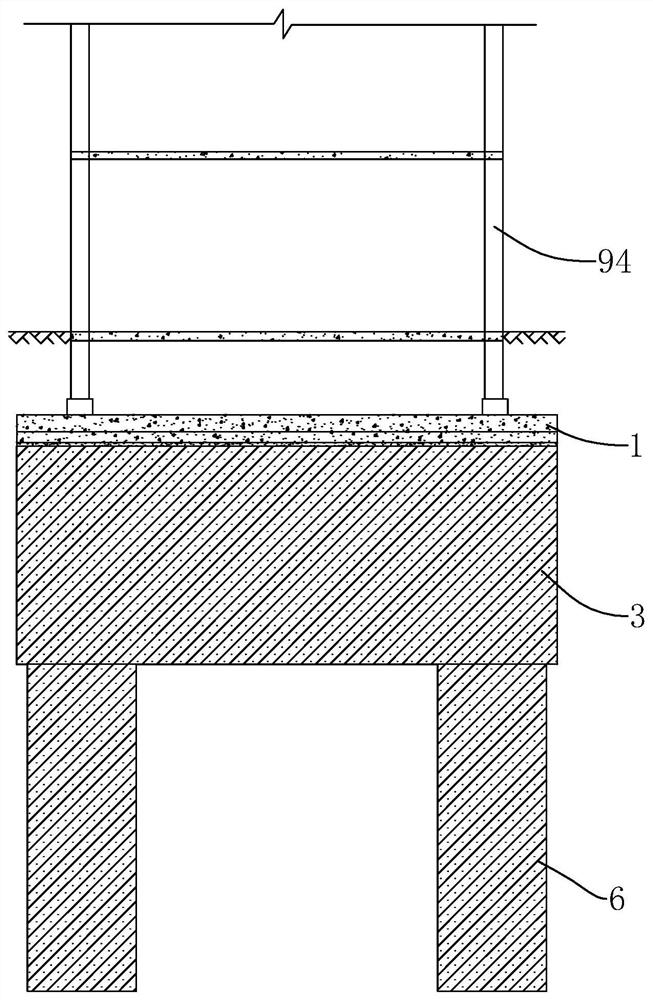

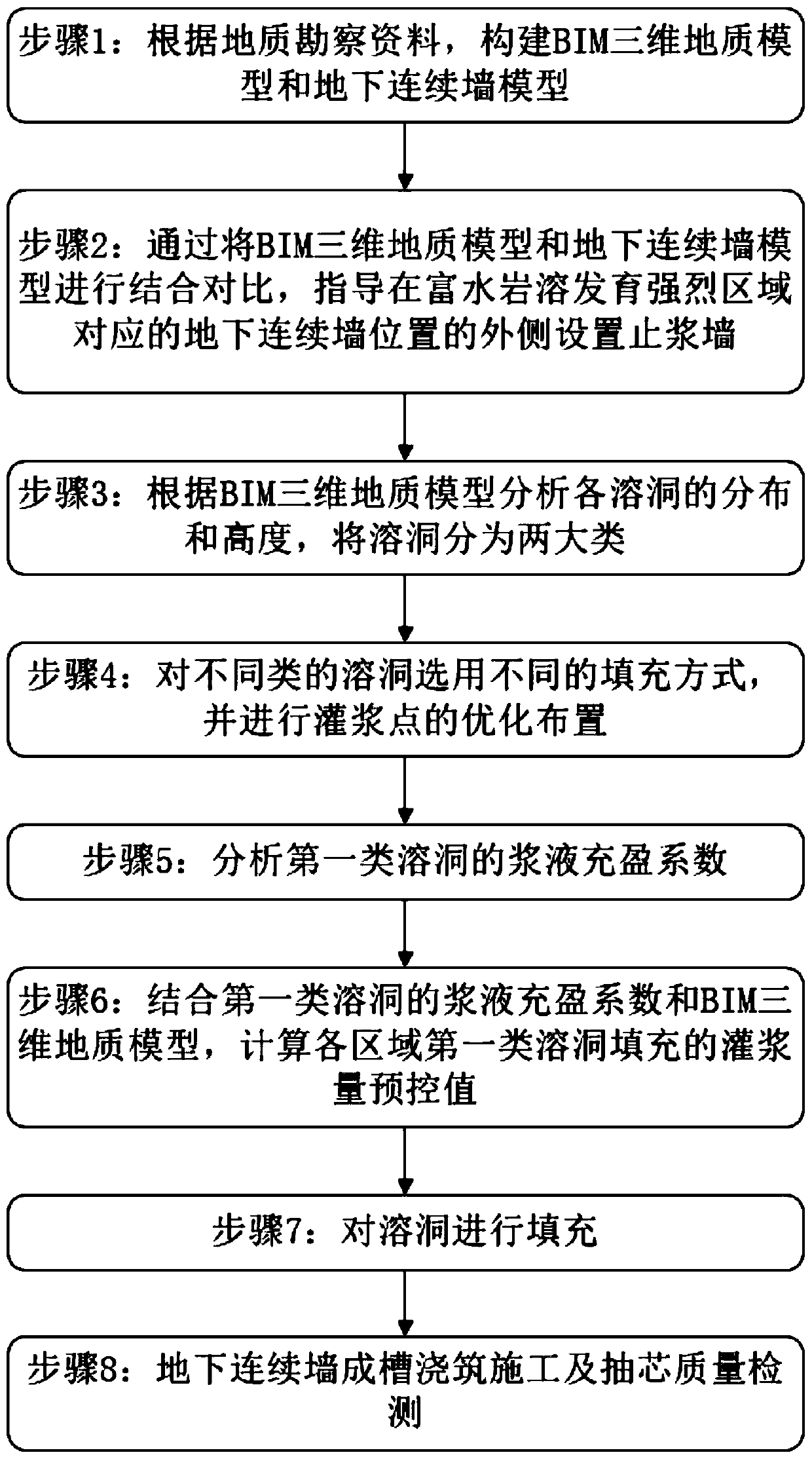

Construction method of underground continuous wall with water-rich karst development geology and grouting wall structure

PendingCN110904951ARealize construction pre-controlAvoid churnExcavationsBulkheads/pilesSlurry wallSoil science

The invention discloses a construction method of an underground continuous wall with water-rich karst development geology and a grouting wall structure. By constructing a BIM 3D geological model for reflecting the underground karst condition, the direction, distribution and size of a karst cave can be directly displayed, and a grouting wall is arranged on the outer side of the underground continuous wall of the water-rich karst high-development area under the guidance of the BIM 3D geological model to prevent the slurry filled in the karst cave from losing; and the geological model is used toclassify the karst cave, different filling methods are adopted, the layout of grouting points is optimized according to the different filling methods, a basis is provided for the analysis of filling coefficient and the statistics of slurry volume of the karst cave, and the construction pre-control of filling treatment of the karst cave is better achieved.

Owner:广州珠江建设发展有限公司

Precast concrete component and assembly concrete component connected with pier head locking anchor grouting straight sleeve and production method thereof

InactiveCN104264788AReduce the overall heightReduce the overall diameterBuilding reinforcementsPull forceRebar

The invention provides a precast concrete component and an assembly concrete component connected with a pier head locking anchor grouting straight sleeve and a production method thereof and belongs to the technical field of construction engineering assembly concrete structures. A method of sleeve connection based on extrusion and binding force transfer is adopted and a pier head (5) and a pier head (6) are machined at two ends of steel bars respectively; the sleeve inner diameter of one end of a connecting sleeve (7) is smaller than the outer diameter of the corresponding end of steel bar pier head (6); the inner diameter of the other end of the connecting sleeve is large and the other end of the connecting sleeve is provided with threads; a blocking ring (10) is connected with the connecting sleeve, wherein the inner diameter of the blocking ring (10) is smaller than the outer diameter of the corresponding end of steel bar pier head (5); the locking anchor extrusion and binding force transfer among the steel bar pier heads, the blocking ring, the sleeve and grouting materials is utilized through the steel bars due to the sleeve grouting and accordingly the mode that the steel bar tension of the previous grouting connection precast component is mainly transferred through bonding is changed. According to the production method, the safety and the economy of the connection of the novel precast concrete component are improved.

Owner:CHINA CONSTR ENG DESIGN GROUP +1

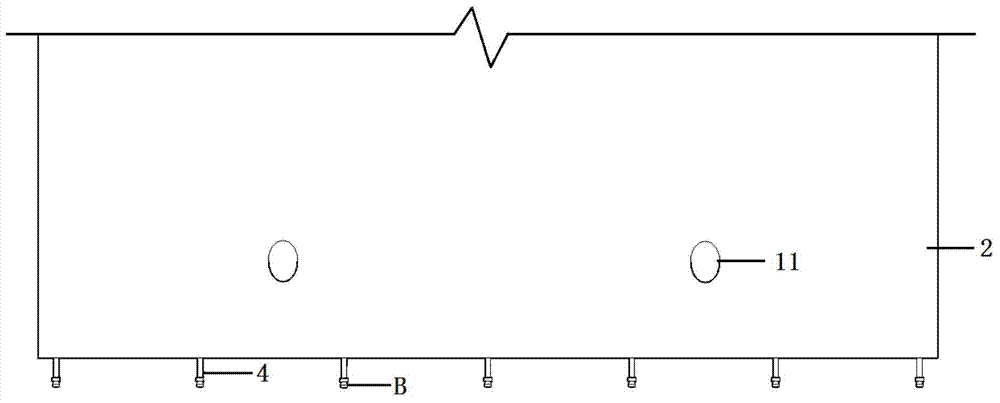

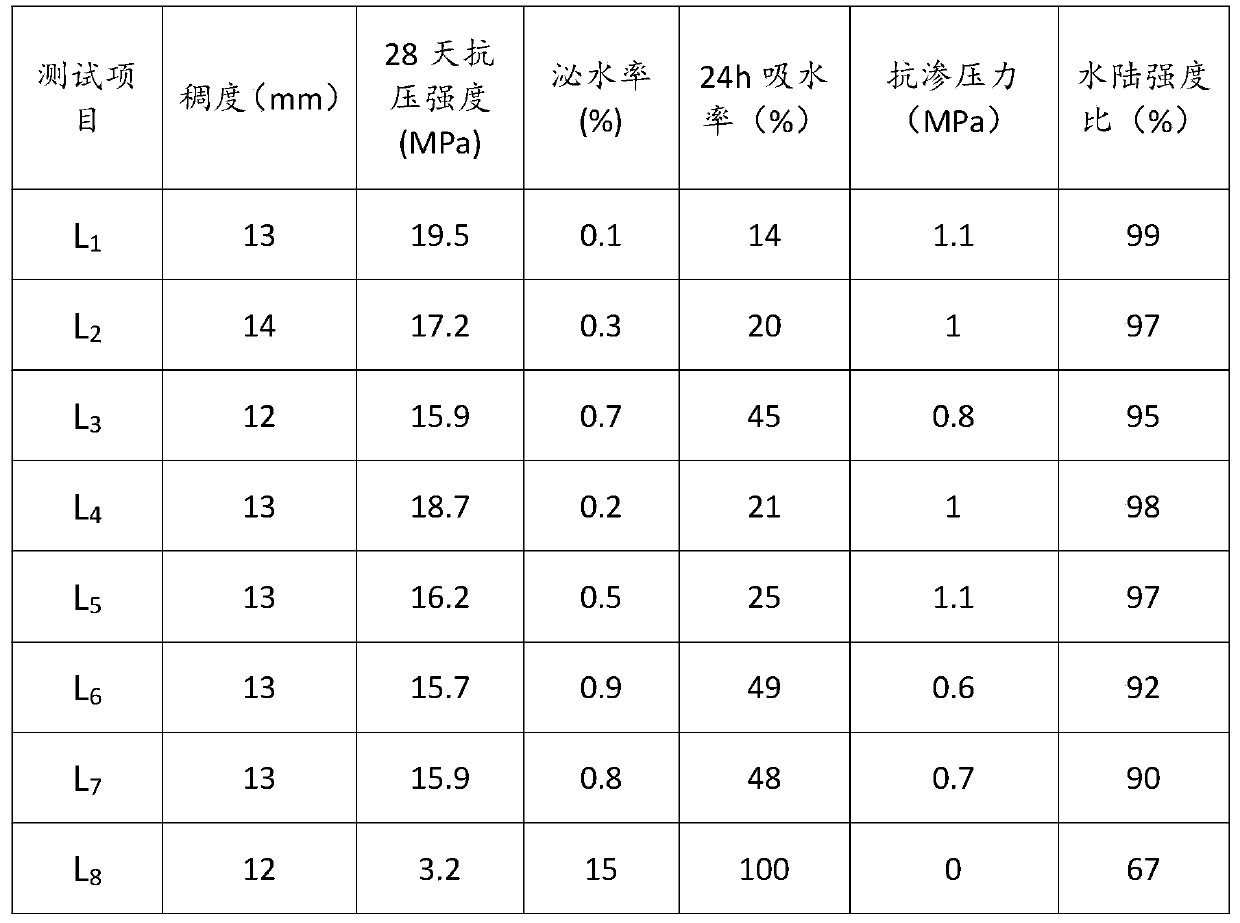

Coral micropowder-based waterproof grouting material suitable for offshore island water-enriched stratum

InactiveCN109970415AReduce the amount of groutImprove water retentionPulverized fuel ashAbsorption rate

The invention discloses a coral micropowder-based waterproof grouting material suitable for an offshore island water-enriched stratum. The coral micropowder-based waterproof grouting material suitablefor the water-enriched stratum is prepared from, by mass, 30-60% of coral micropowder, 15-25% of common Portland cement, 13-30% of pulverized fuel ash, 2-6% of silicon micropowder, 2-5% of a water-resistance dispersing agent, 0.05-0.1% of a silane impregnant, 1-4% of a corrosion-prevention rust-resistance agent and the balance high-performance water-reducing agents. The coral micropowder-based waterproof grouting material has the advantages of being good in fluidity and water resistance and dispersibility, low in water absorption rate and bleeding rate and good in seepage resistance; the coral micropowder-based waterproof grouting material can resist corrosion and dispersion on the water-enriched stratum when used for grouting construction of the offshore island water-enriched stratum, and can be quickly coagulated, and construction operation is facilitated.

Owner:CHINA ACAD OF BUILDING RES +3

Construction method of hand-dug piles

The invention discloses a construction method of hand-dug piles. The method comprises the following steps: firstly, making preparation of construction, and making injection tubes and modifying a pneumatic pick; mounting a pneumatic pick head to the pneumatic pick, driving downward an annular injection tube annularly and radially along the base of an opening protective ring, and putting a cement mortar delivery hose at the rear end of the injection tube and fixing; making an injection liquid (i.e. cement mortar) composed of cement and water at a ratio of 1:0.75, adding a quick-setting agent into the injection liquid to reduce the time of osmosis; stopping injection when the injection amount of each injection tube reaches the design amount, and driving the exposed parts of the injection tubes into the soil by using the pneumatic pick; excavating the next segment, and connecting the concrete support wall with the top of the injection tubes; performing injection segment support wall construction; and after the excavation of each injection reinforcement segment is completed, repeating the previous steps till the loose gravel formation segment is passed through. The construction method has the advantages of simple construction, low investment, multi-segmental and circulating reinforcement and small injection amount, and can effectively prevent the loss of injection liquids, solidify the gravel formation, increase the friction force between the pile and the formation and improve the load-carrying capability of the friction piles.

Owner:THE THIRD ENG CO LTD OF CHINA RAILWAY SEVENTH GRP

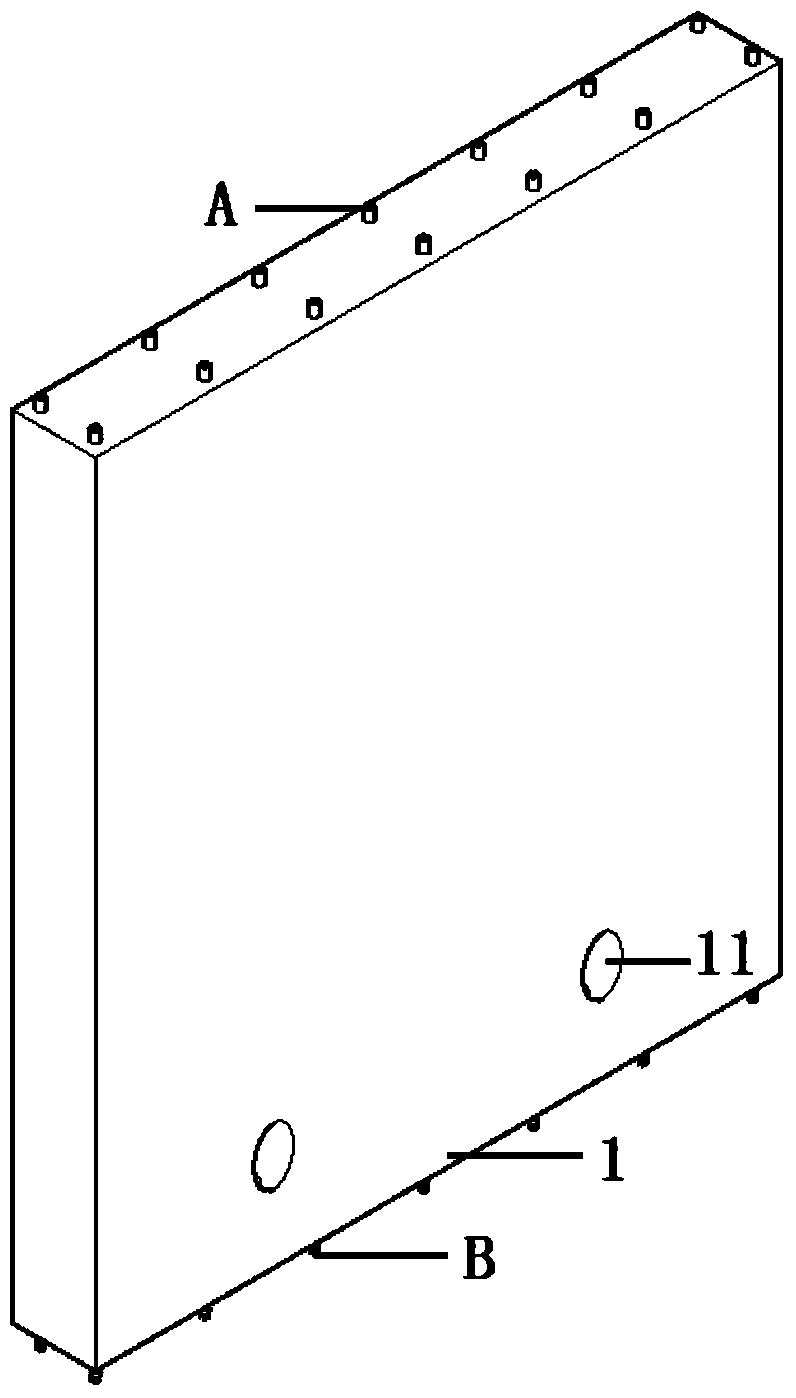

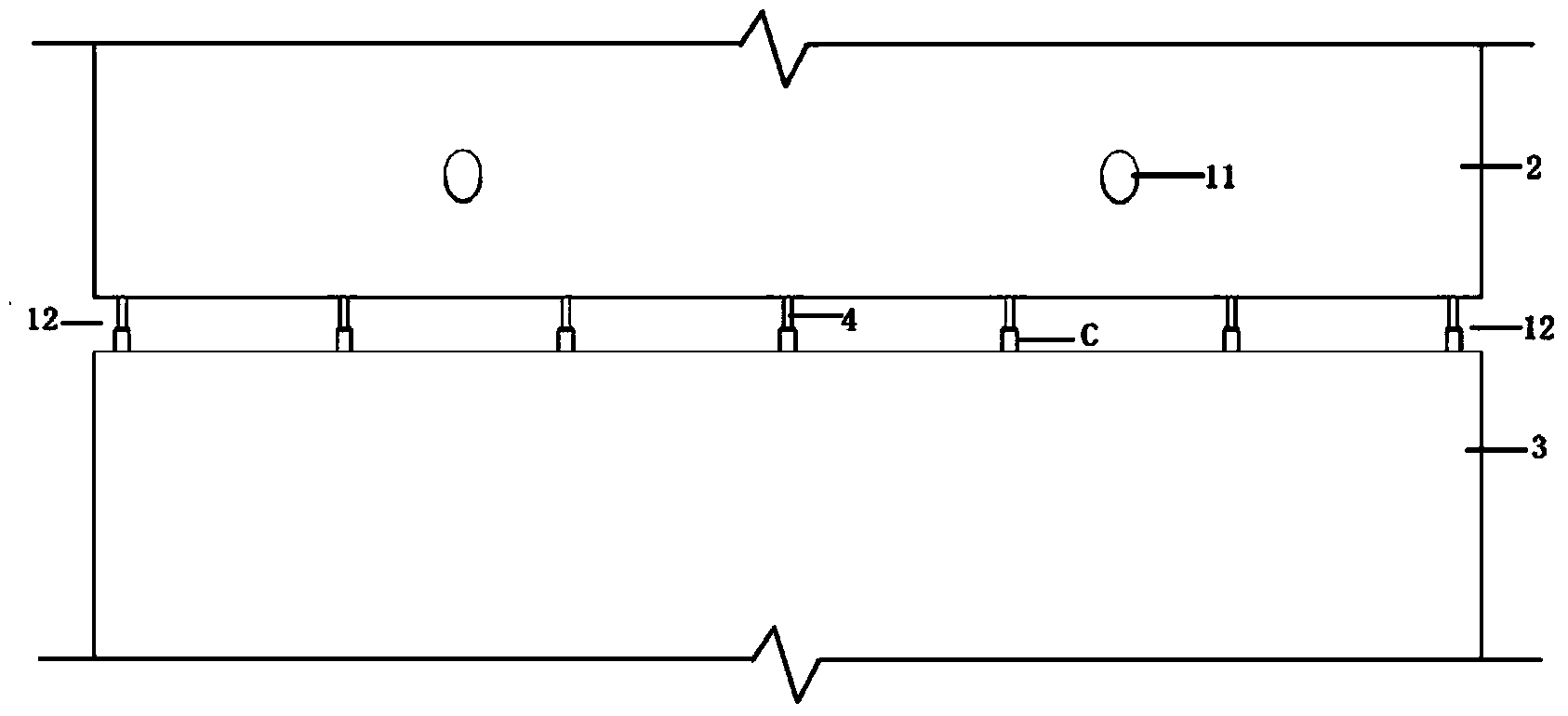

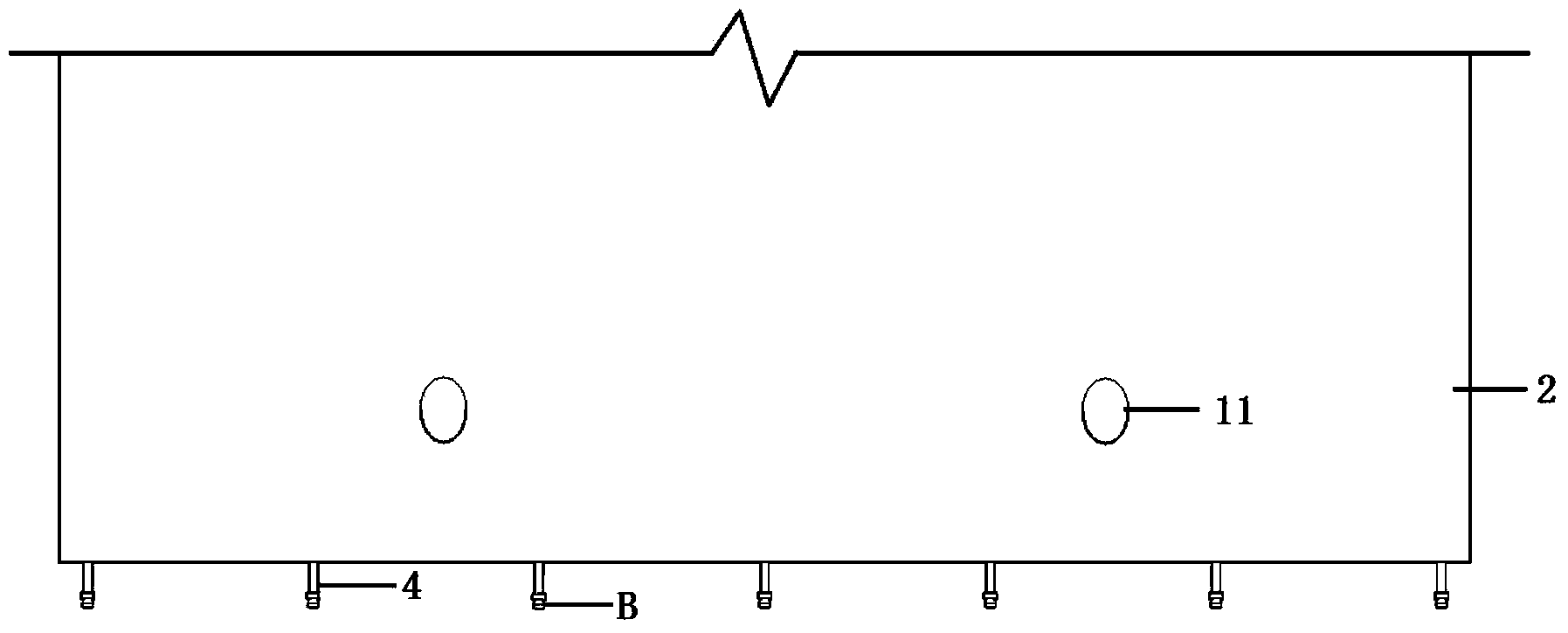

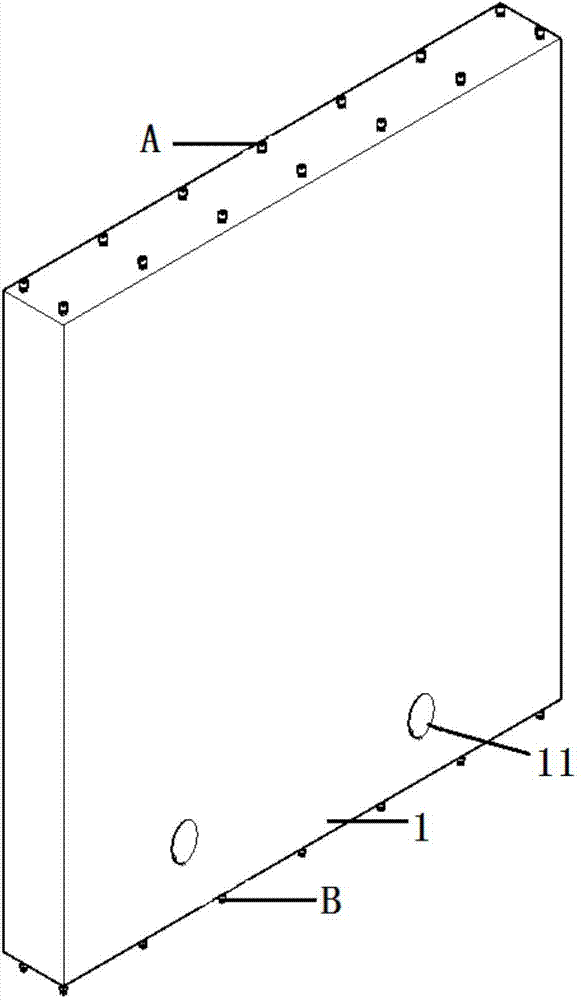

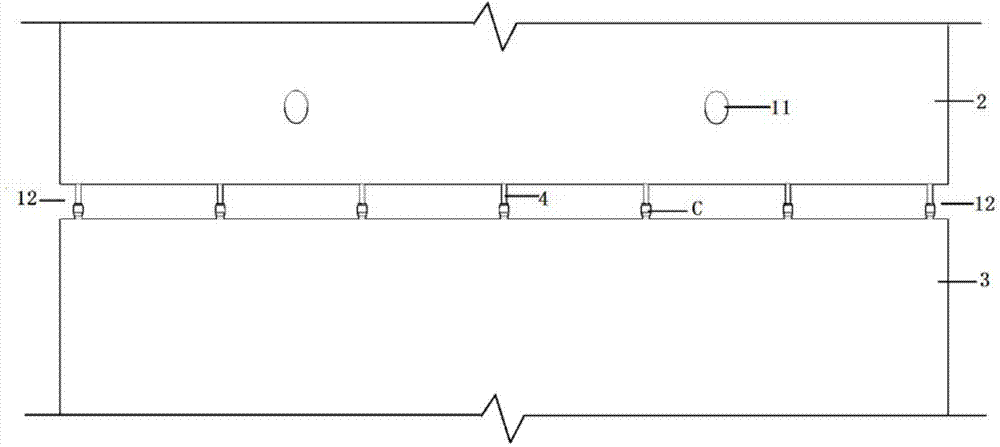

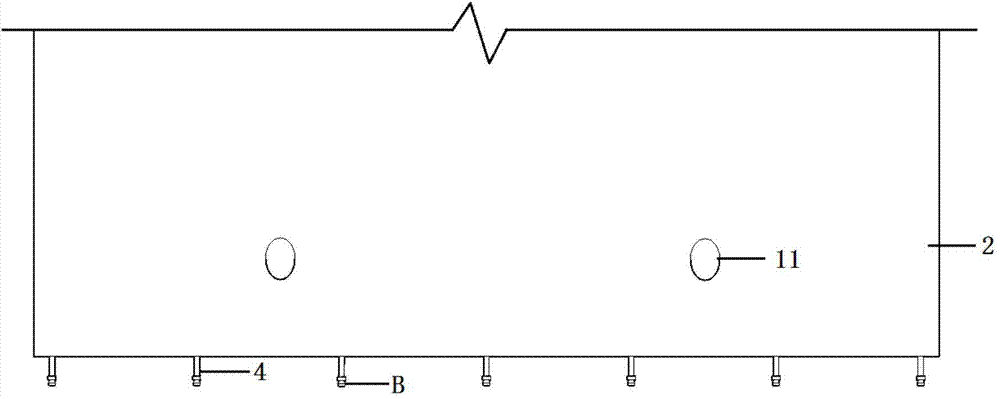

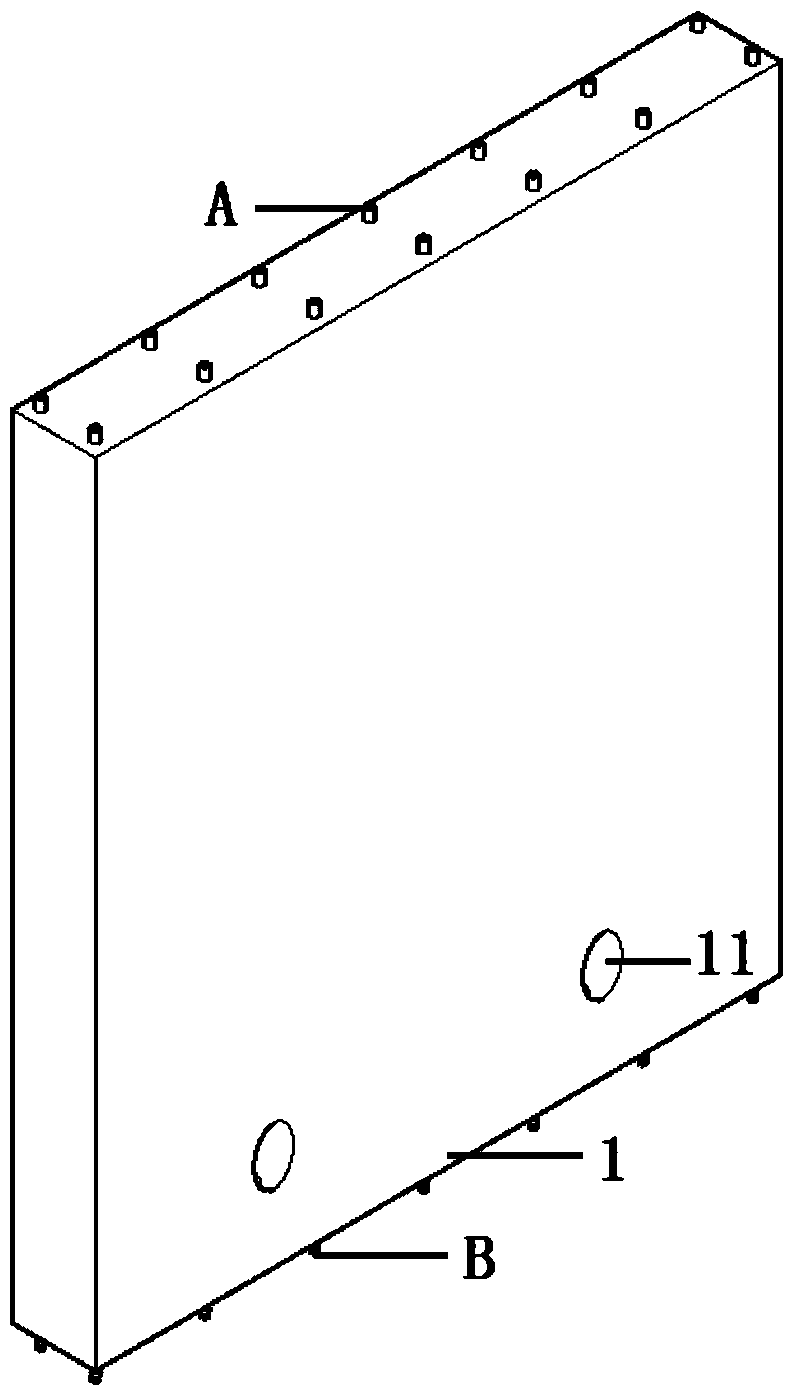

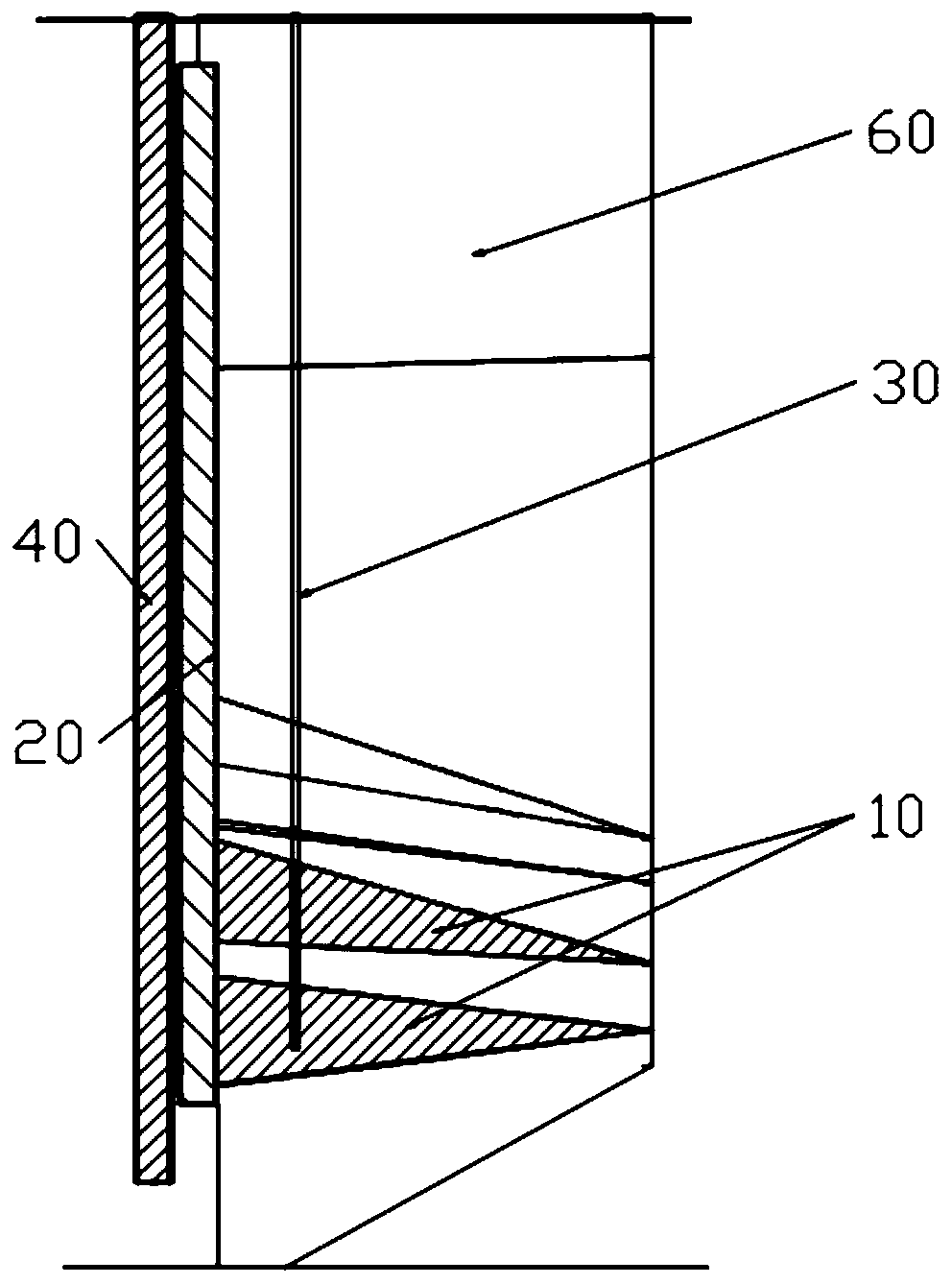

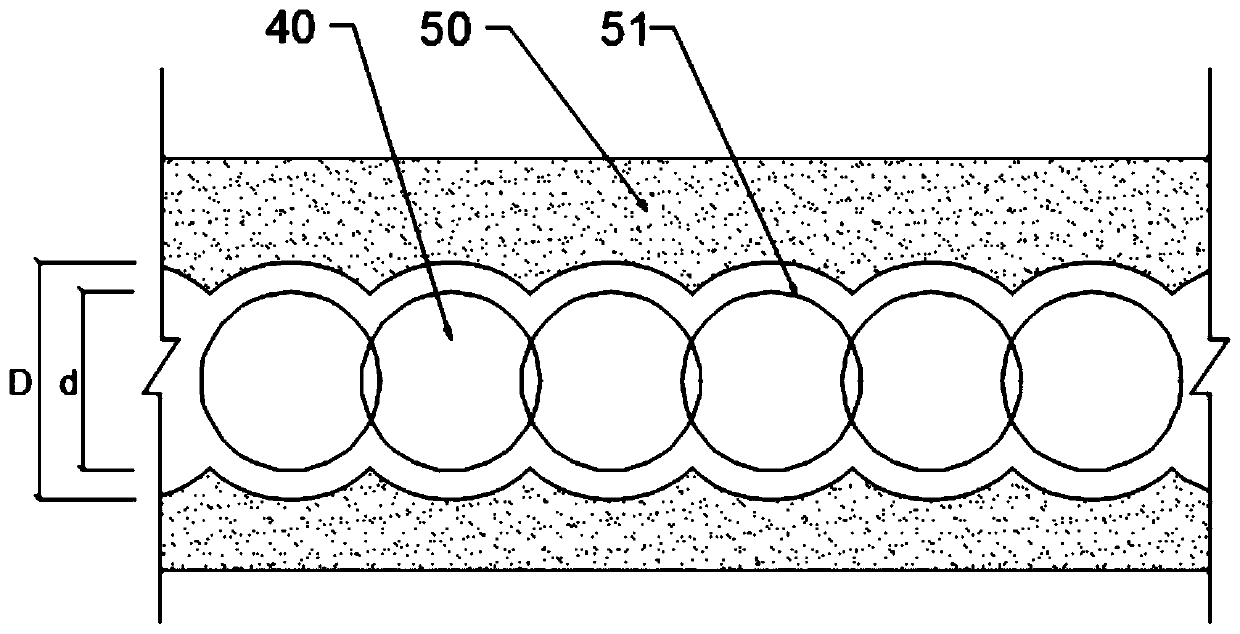

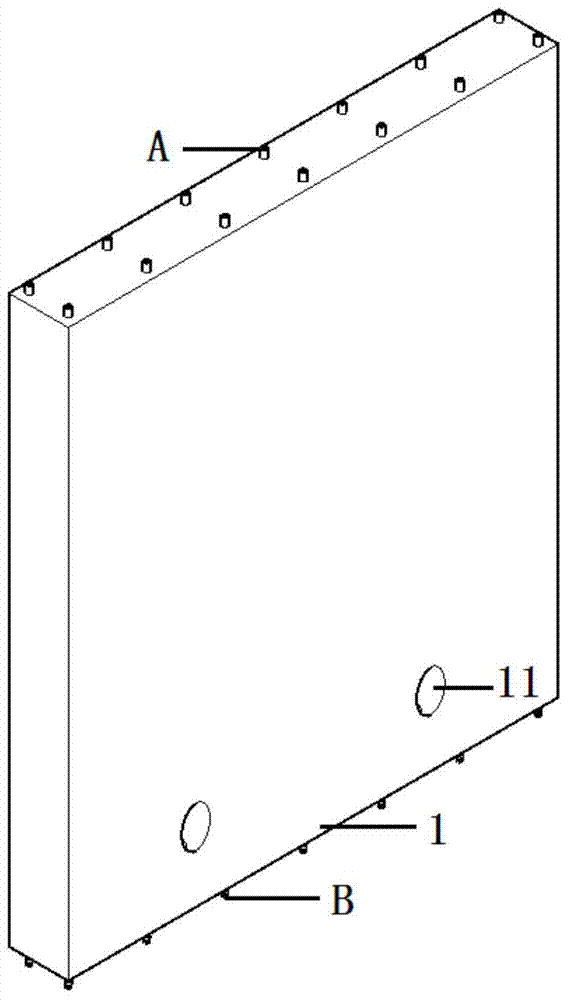

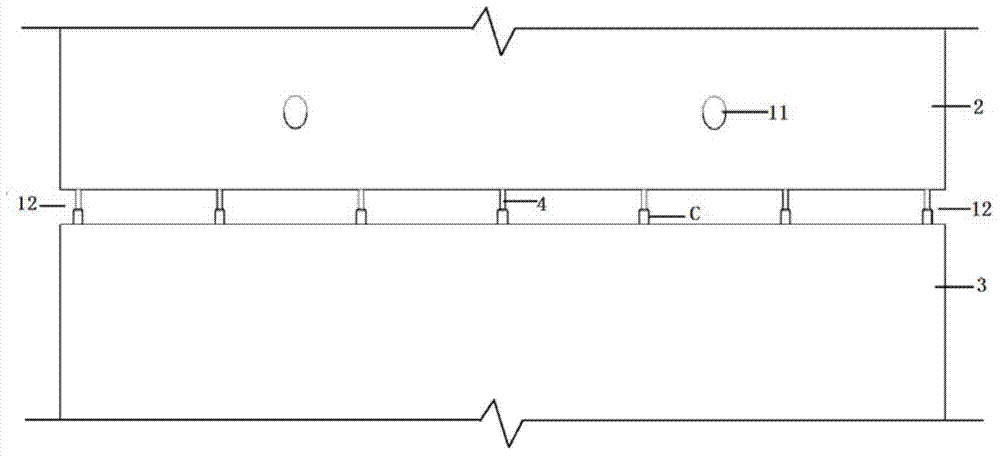

Vertical mixed connection structure and method of prefabricated internal wallboards for assembling shear wall structure

The invention discloses a vertical mixed connection structure and method of prefabricated internal wallboards for assembling a shear wall structure. On the structure, edge components of upper-layer and lower-layer prefabricated internal wallboard structures are overlapped through vertical steel bars and U-shaped ribs, and horizontal reinforcing ribs and local cast-in-place concrete are arranged in a closed ring so as to realize the edge components equivalent to the cast-in-place concrete, the vertically distributed steel bars at the middle part of the components are connected in a manner of indirect overlapping by use of mortar anchor steel bars of a retention metal mortar anchor pipe so as to form an entire shear wall. By utilizing the local cast-in-place concrete moist joint at the edge component part formed by the mixed connection and the dry joint of bedding and grouting at the part of the vertically distributed steel bars, the shear strength and rigidity of the horizontal jointing part of the prefabricated internal wallboards are improved; casting holes reserved at the bottom of the edge components can be used for solving the problem of casting the local cast-in-place concrete; and the vertically distributed steel bars are connected in a manner of indirect overlapping by use of the mortar anchor, which facilitates the installation and temporary fixation of the wallboards on a concrete floor. The mixed connection structure of the prefabricated internal wallboards, provided by the invention, ensures the overall performance of the shear wall; and construction is convenient.

Owner:SOUTHEAST UNIV

Rapid construction method of high-pressure water-rich fault zone of tunnel

ActiveCN101798930BSolve world-class problemsGood effect of water separation and pressure reductionUnderground chambersTunnel liningWater flowEngineering

The invention relates to the field of tunnel construction, in particular to a rapid construction method of a high-pressure water-rich fault zone of a tunnel, which solves a plurality of problems in the construction method of high-pressure water-rich fault zone tunnels under the guide of the traditional knowledge. A draining branch tunnel is additionally arranged between a main tunnel and a parallel heading, the water flow pressure of the hanging wall of a fault interface is reduced progressively, and a large amount of water is discharged from the main tunnel by adopting a guiding and non-clogging mode; when the water pressure of the main tunnel is reduced to 0.3-0.5MPa, an informationized tracking and accurate grouting method is used for grouting and reinforcing the main tunnel; and rapidly excavating and sealing technology is used for excavating the main tunnel and the parallel heading. The invention adopts the technology combining the water distribution and pressure reduction mode, the informationized tracking and accurate grouting method and the rapidly excavating and sealing technology for high-pressure water-rich shattered fault zones for the first time, breaks through the traditional concept that the water distribution and pressure reduction mode is opposite to the grouting and reinforcing construction method, solves the world-class problem of construction of the high-pressure water-rich fault zone of the tunnel, improves the construction progress and the construction efficiency, and ensures safe and rapid perforation of the tunnel.

Owner:CHINA RAILWAY 12TH BUREAU GRP

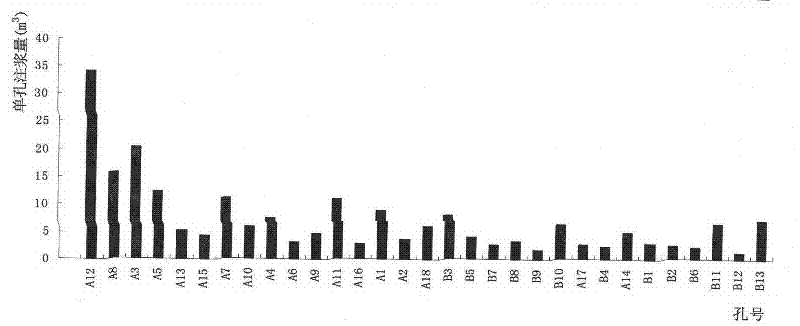

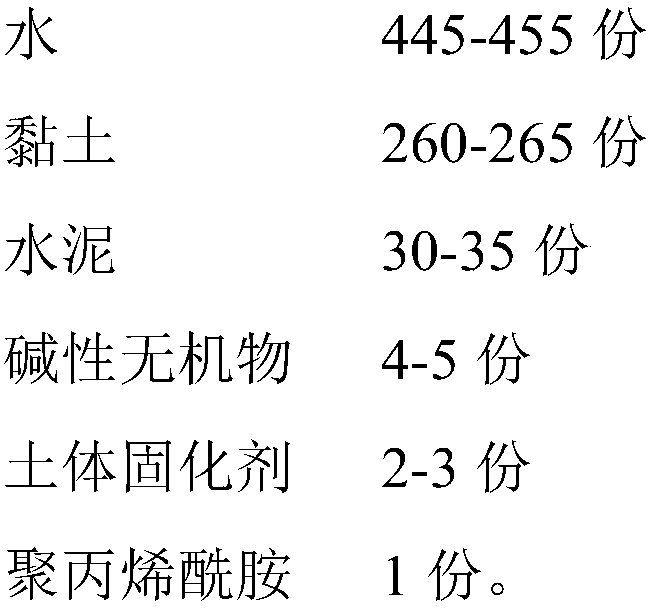

Backfilling slurry as well as preparation method and application thereof

The invention discloses backfilling slurry as well as a preparation method and application thereof. The backfilling slurry is prepared from the following ingredients in parts by mass: 445 to 455 partsof water, 260 to 265 parts of clay, 30 to 35 parts of cement, 4 to 5 parts of basic inorganic matters, 2 to 3 parts of soil curing agents and 1 part of polyacrylamide. The backfilling slurry has theadvantages of high stability, support protection performance, diffusion prevention performance and excellent durability, and can be used for pipe jacking and withdrawal projects.

Owner:SHANGHAI ROAD & BRIDGE (GRP) CO LTD +1

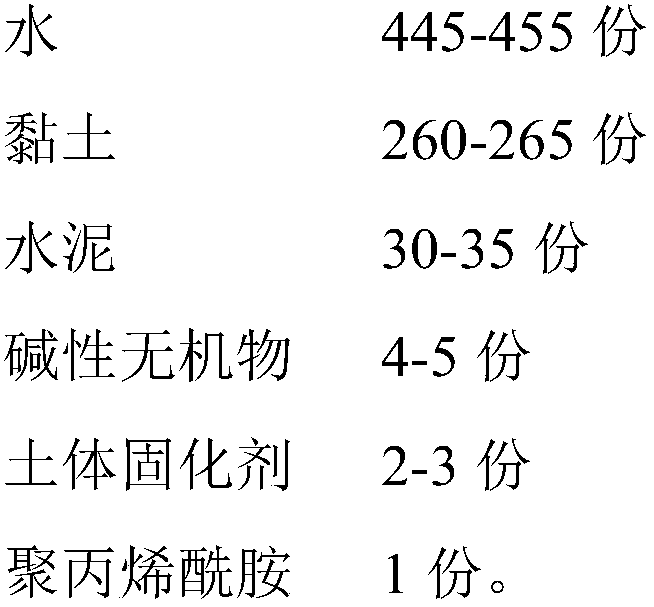

Grouting treatment method for strip mining goaf

ActiveCN109162758AConsolidate the Balanced StructureAchieve long-term stabilityMaterial fill-upSlurryRaw material

The invention belongs to the technical field of mining engineering and particularly relates to a grouting treatment method for strip mining goaf. The method comprises the steps of (1) drill hole position and arrangement planning, (2) instrument fixation, drilling, casing laying, and grouting pipe laying, (3) slurry raw material preparation, (4) slurry cooperation and mixture, (5) grouting operation, and (6) grouting pipe collection. The method has the advantages that the overburden strata balance structure of the strip mining is consolidated, the long-term stability of a ground surface is achieved, the stability of a building foundation is ensured, materials are saved, the environment is protected, and the method has good social and economic values and is easy to promote.

Owner:COAL IND JINAN DESIGN & RES

Double-fluid synchronous grouting block and construction method thereof

PendingCN109763843AAvoid cloggingAvoid enteringUnderground chambersTunnel liningHigh pressure waterPressure difference

The invention discloses a double-fluid synchronous grouting block and a construction method thereof. A passage I and a passage II are formed in the grouting block; a flow rate increase device is arranged at an outlet of the passage I; and a back seepage prevention device is arranged at an outlet of the passage II. The construction method comprises the following modes: a double-fluid grouting modein which flow rates of A fluid and B fluid are respectively increased by the flow rate increase device and the back seepage prevention device and a pressure difference is formed in the passages so asto implement rapid mixing of the A fluid and the B fluid; and a single-fluid grouting mode in which the A fluid sucked from an A fluid tank enters the passage I to carry out single-fluid grouting. Thedouble-fluid synchronous grouting block and the construction method thereof, which are disclosed by the invention, have the advantages that a double-fluid mixing region is positioned outside a shieldshell so as to prevent blockage of a grouting pipe; both A and B fluid pipelines can be cleaned by high-pressure water, and the A fluid pipe also can be dredged by adopting a steel chisel; the volumeis low, the grouting amount is low and equipment cost and construction cost are low; an existing single-fluid synchronous grouting and double-fluid secondary replenishing shield machine can be transformed; and a new machine also can adopt the grouting scheme.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

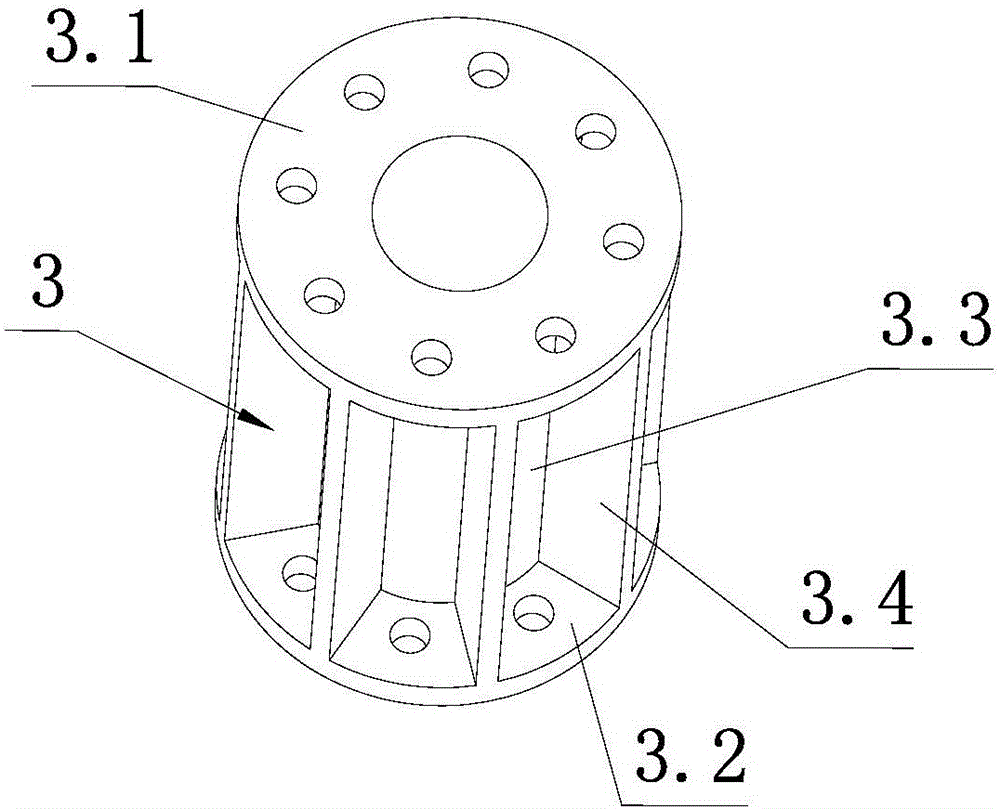

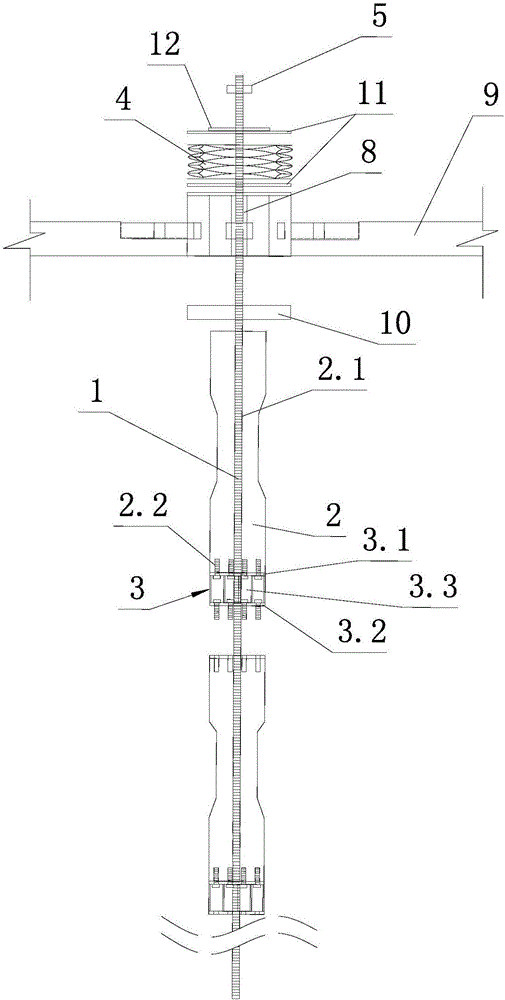

Pre-applied force anchoring system for slope protection device and construction method thereof

InactiveCN105804098AIncrease binding forceIncrease constraintsExcavationsEngineeringSystem construction

The invention discloses a pre-applied force anchoring system for a slope protection device and a construction method thereof. The pre-applied force anchoring system comprises a threaded rod (1), concrete bamboo joint blocks (2), connection discs (3), a spring (4) and a nut (5). The concrete bamboo joint blocks (2), the connection discs (3) and the threaded rod (1) form an integrated anchoring body (6), and the concrete bamboo joint blocks (2) and the connection discs (3) are arranged at intervals. The anchoring body (6) is placed into an anchor hole (7), and the gap between the anchoring body (6) and the anchor hole (7) is filled with concrete mortar. The nut (5) is screwed on the threaded rod (1) in a matched mode. The nut (5) tightly presses the slope protection structure and the concrete bamboo joint blocks (2) through the spring (4). The construction method is characterized in that all the concrete bamboo joint blocks (2), all the connection discs (3) and the threaded rod (1) form the integrated anchoring body (6), the anchoring body (6) is placed into the anchor hole (7), and the gap between the anchoring body (6) and the anchor hole (7) is filled with the concrete mortar. According to the pre-applied force anchoring system for the slope protection device and the construction method thereof, the construction speed can be increased, site construction is convenient and quick, the anti-drawing strength and the shearing strength are both ideal, and the constraint effect on soil bodies is good.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

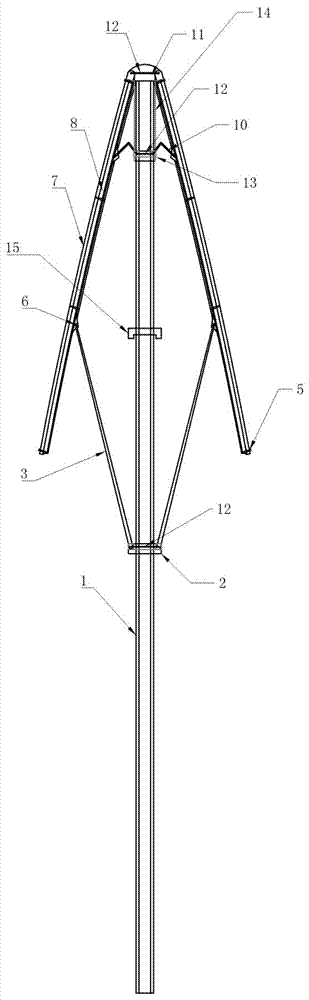

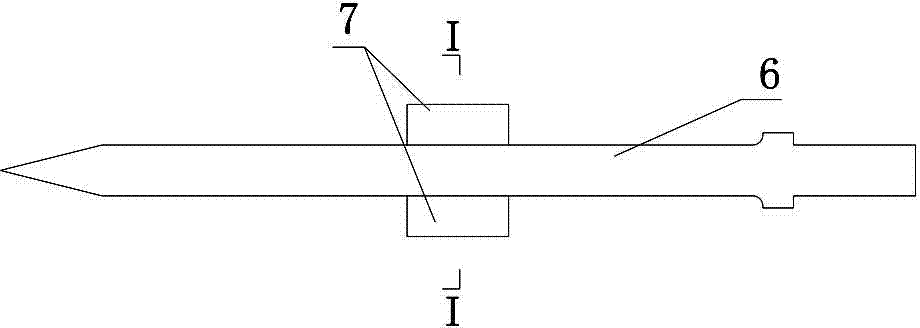

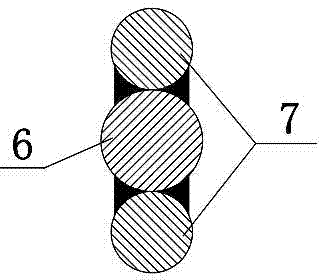

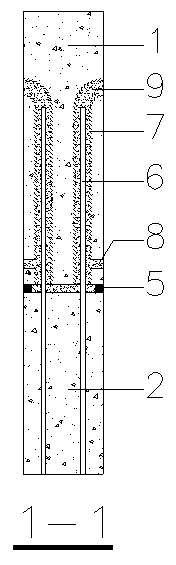

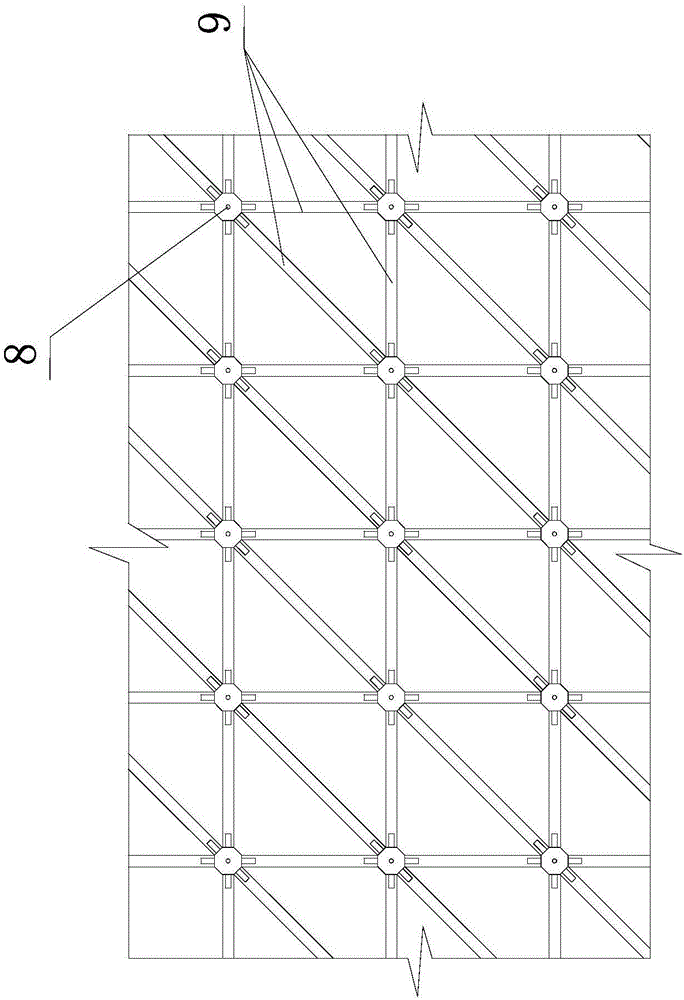

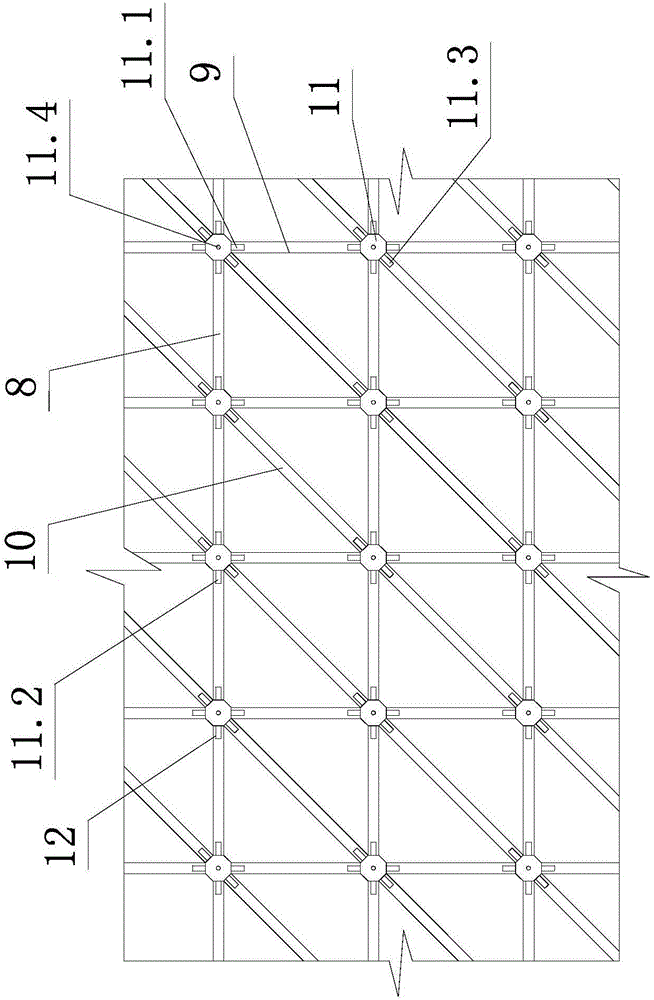

Prestressing anchor body assembly type frame hoop slope protection device and construction method

InactiveCN105862871AReduce the amount of groutReduce labor intensityExcavationsBulkheads/pilesBuilding construction

The invention discloses a prestressing anchor body assembly type frame hoop slope protection device and a construction method. The prestressing anchor body assembly type frame hoop slope protection device comprises a frame hoop used for restraining a slope surface and an anchor structure used for tightly pressing the frame hoop. An integrated anchor body (6) is formed by concrete bamboo joint blocks (2), connecting discs (3) and a screw (1), wherein the concrete bamboo joint blocks (2) and the connecting discs (3) are arranged and distributed alternately. An anchor hole (7) is formed in the slope surface of a soil body. The anchor body (6) is placed in the anchor hole (7), and the gap between the anchor body (6) and the anchor hole (7) is filled with concrete mortar. The construction method comprises the key steps that the integrated anchor body (6) is formed by all the concrete bamboo joint blocks (2), all the connecting discs (3) and the screw (1); and the anchor body (6) is placed in the anchor hole (7), and the concrete motor is poured into the gap between the anchor hole (7) and the anchor body (6). By the adoption of the structure and method, the construction speed can be increased, the construction period can be shortened, field construction is convenient and fast, the anti-drawing strength and the shearing strength are both ideal, the restraining effect on the soil body is good, the tightness degree can be adjusted along with the expansion and contraction of the soil body conveniently, and the slope protection area of the frame loop can be changed freely.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

Tunnel karst fracture zone slip collapse half-section curtain advancing type grouting reinforcement treatment method

PendingCN114109442AIncrease success rateReduce wasteUnderground chambersTunnel liningEmergency treatmentFracture zone

The invention discloses a tunnel karst fracture zone slip collapse half-section curtain advancing type grouting reinforcement treatment method. Comprising the following steps that back pressure backfill plugging emergency treatment is conducted on a tunnel face, and slip collapse bodies are reinforced through grouting; arranging a concrete grout stopping wall with the thickness of 2-5m on the tunnel face; a loose body and surrounding rock within the range of 3-4.5 m outside a contour line are excavated in a hole forming section 3 m at the rear end of the grouting reinforcement grouting stopping wall, and an annular grouting stopping curtain layer is formed; grouting reinforcement is conducted on the horizontal section, 3 m away from the top of the tunnel, of the slip collapse body in a segmented advancing type grouting mode, and a horizontal grout stop curtain layer is formed; for a geological weak section, advanced segmented advancing type grouting reinforcement construction is carried out; and after grouting is finished, three advanced horizontal manholes are evenly drilled within the range of 1 m near the arch contour line, and the grouting effect is analyzed and judged. The grouting reinforcement effect can be better guaranteed, the success rate of successful tunneling through the karst fracture zone is increased, safety is high, the construction treatment progress of the unfavorable geological section can be accelerated, and the construction period and cost are saved.

Owner:CHINA RAILWAY NO 10 ENG GRP NO 1 ENG CO LTD

Construction method for improving bearing capacity of inclined steel pipe pile

The invention discloses a construction method for improving bearing capacity of an inclined steel pipe pile. The construction method comprises the following steps that (1) the inclined steel pipe pileis obliquely inserted into a soil layer to a predetermined depth by a sinking machine, the inclined steel pipe pile comprises a steel pipe pile body, and a variable diameter pipe section and a guidepipe are sequentially arranged at the lower end of the steel pipe pile body; (2) a high-pressure rotary jet drill rod on a drilling machine is extended into the steel pipe pile body, and is drilled tothe design top elevation position of a to-be-constructed rotary jet strengthening section in the soil layer under the guidance of the guide pipe; (3) after drilling to the design top elevation position, the high-pressure rotary jet drill rod rotarily jets cement slurry with high pressure while drilling, and a rotary jet strengthening section is formed; and (4) the high-pressure rotary jet drill rod is lifted off the inclined steel pipe pile, then the inclined steel pipe pile is subjected to sinking construction to the depth of the rotary jet strengthening section, and thus the inclined steelpipe pile and the rotary jet strengthening section form a coaxial integrated structure. The construction method has the advantages of simple and fast construction method, high reliability and low project cost.

Owner:SHANGHAI CHANGKAI GEOTECHN ENG

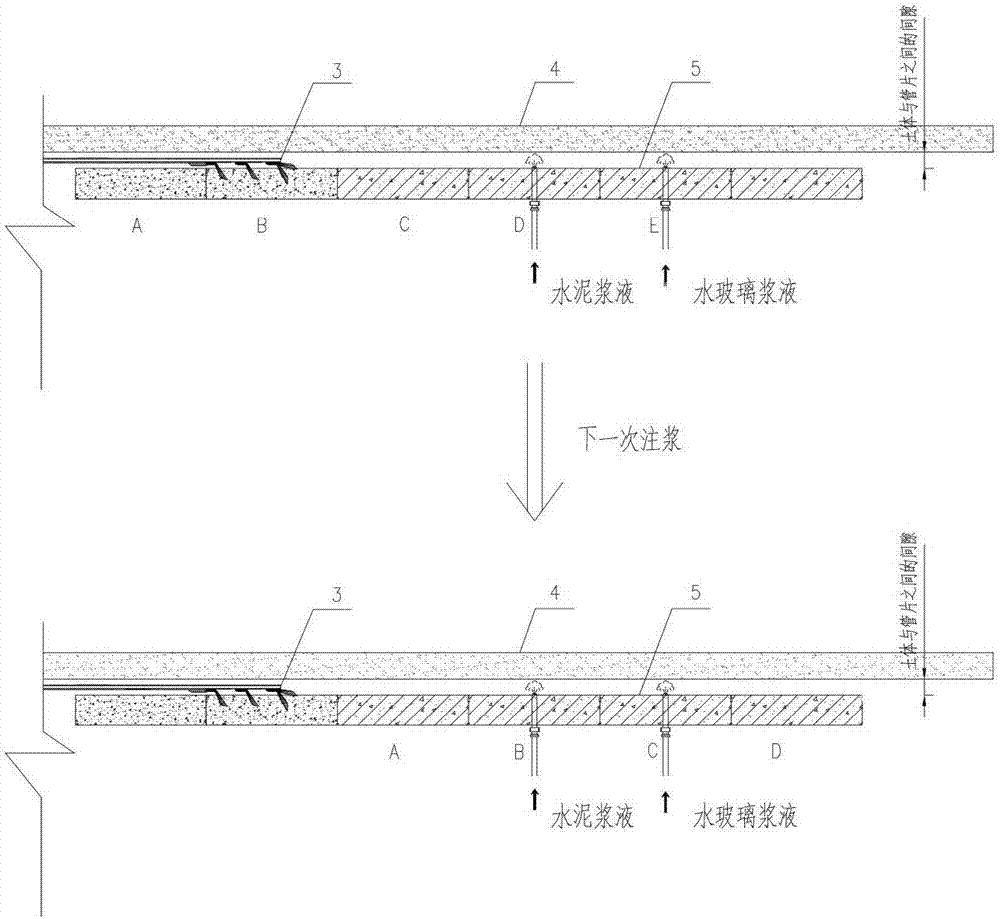

Accurate tracing compensation grouting construction method

ActiveCN110528522AReduce the amount of groutShorten the grouting periodFoundation testingDepth directionEnvironmental geology

The invention provides an accurate tracing compensation grouting construction method. The method comprises the following steps of laying a plurality of displacement meters in a settlement region, wherein the multiple displacement meters are arranged in parallel in the depth direction; acquiring detection data of each displacement meter; and if the distance between any two adjacent displacement meters changes, performing grouting construction on a corresponding position. According to the accurate tracing compensation grouting construction method, the actual settlement condition is acquired through the displacement meters arranged in an array, and grouting is performed according to the actual settlement condition, and thus, the grouting condition corresponds to the actual settlement condition, so that the grouting volume is reduced to the maximum extent, and the grouting construction period is shortened.

Owner:CHINA RAILWAY NO 3 GRP CO LTD +2

A real-time supplementary grouting anti-settlement control method for shield tunneling construction

ActiveCN107120121BImprove timelinessImprove effectivenessUnderground chambersTunnel liningMaterial resourcesSlurry

The invention discloses an anti-subsidence control method by supplying grouting in real time in shield construction. According to the anti-subsidence control method, a shield machine cutter, a shield shell, a shield tail brush, around soil layers, segments, a first annular segment, a second annular segment, a third annular segment, a water glass grout grouting pipe, an auxiliary synchronous grouting pipe, a main synchronous grouting pipe, a water glass grout grouting pump, a water glass grout preparation barrel, a shield machine cement grout synchronous grouting box and a ball valve are included. Synchronous grouting and secondary grout supplying are effectively integrated, cement injection and water glass injection are organically combined, therefore the timeliness and the effectiveness of filling of gap in the backs of the segments are strengthened, disturbances caused by intersection construction of a traditional secondary grouting and normal tunneling of the shield machine are eliminated, compared with the traditional secondary grouting method, cement grout does not need to be prepared separately, the grouting amount is greatly decreased by separately pumping the water glass grout, the construction schedule is speeded up, the automation level is improved by taking full use of self equipment of the shield machine, and the manpower and material resources are saved.

Owner:CCTEB INFRASTRUCTURE CONSTR CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com