Pre-applied force anchoring system for slope protection device and construction method thereof

An anchoring system and construction method technology, applied in excavation, foundation structure engineering, construction, etc., can solve the problem of unsatisfactory bond strength and frictional resistance between anchor rods or anchor cables and cement mortar, and the inability to apply preloading to anchor rods and anchor cables Unsatisfactory pull-out strength of the anchorage system and other problems, to achieve the effect of improving the slope protection effect, improving the pull-out and shear strength, and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

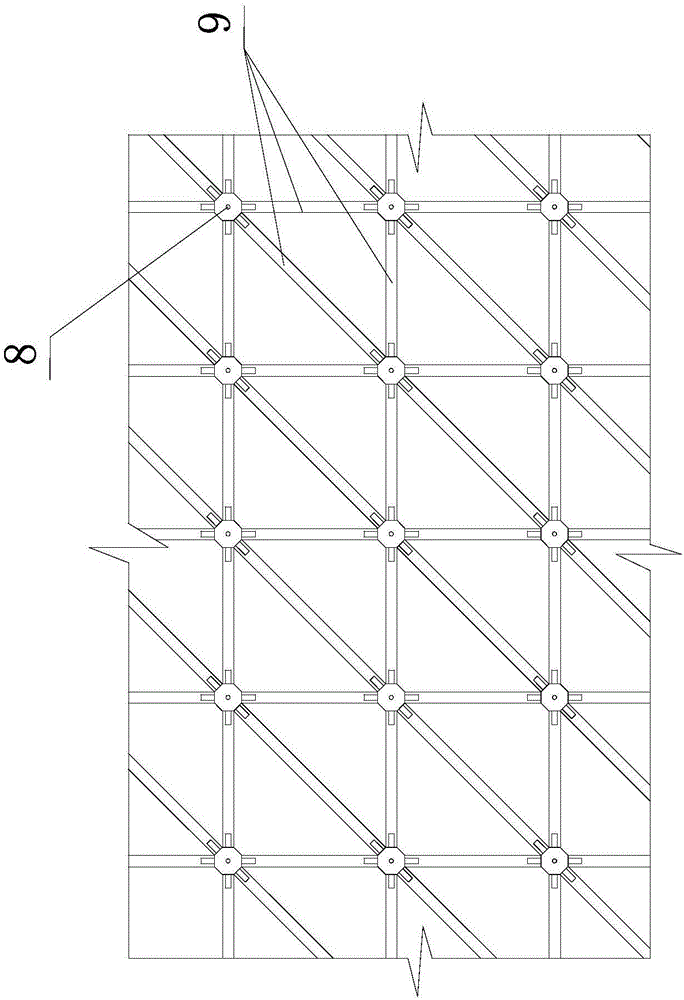

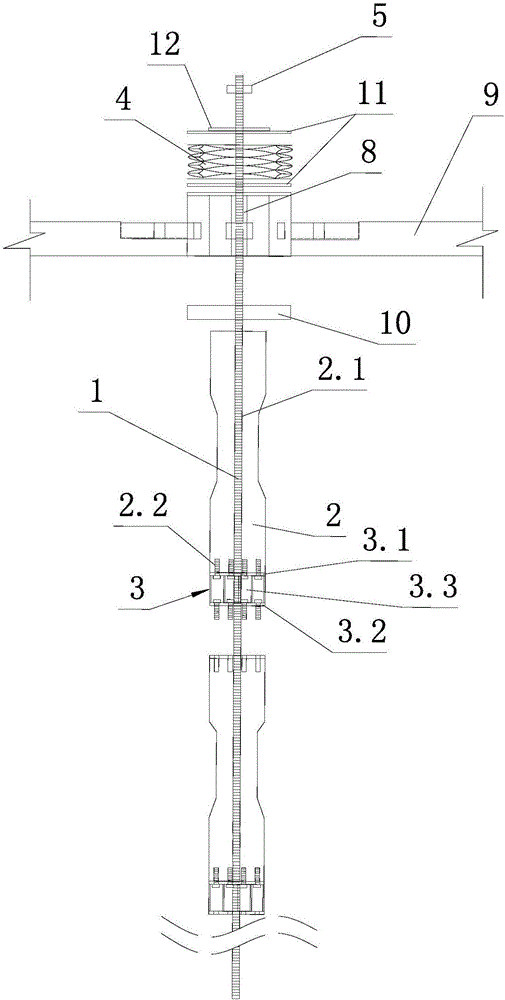

[0025] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the pre-stressed anchoring system of the slope protection device of the present invention includes a screw rod 1, a plurality of concrete bamboo joint blocks 2 with large two ends and a small middle, a plurality of connection plates 3, a spring 4 and a nut 5; The spring adopts wave spring.

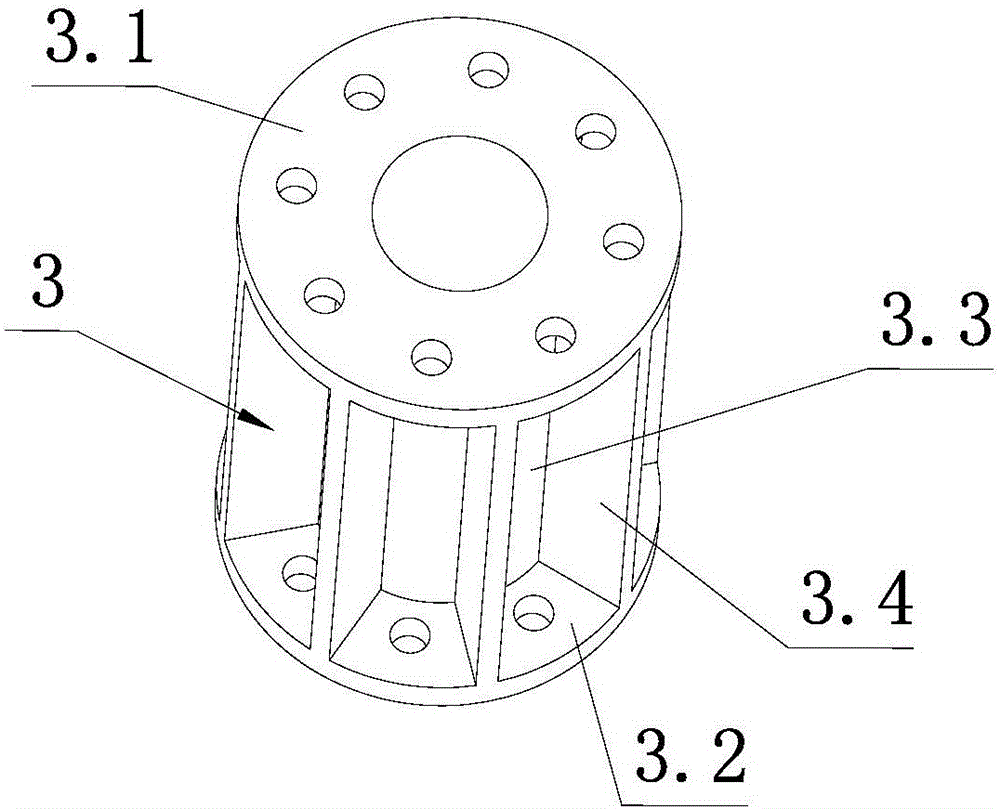

[0026] The center of the concrete bamboo block 2 has a threaded through hole 2.1, and the upper and lower ends of the concrete bamboo block 2 are provided with a circle of threaded blind holes 2.2; The connecting cylinder 3.3 of the flange, the upper flange 3.1 and the lower flange 3.2 are all provided with screw through holes. The center of the connecting cylinder 3.3 is provided with a hole for the screw rod 1 to pass through. Specifically, the center of the connecting cylinder 3.3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com