Curved vertical seam metal roof panel system

A roof panel and metal house technology, which is applied to roofs, roofs using flat/curved panels, and roof coverings, etc., can solve problems that endanger the safety and normal use of buildings and their internal personnel and facilities, loosening, and easy leakage of bolted joints. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

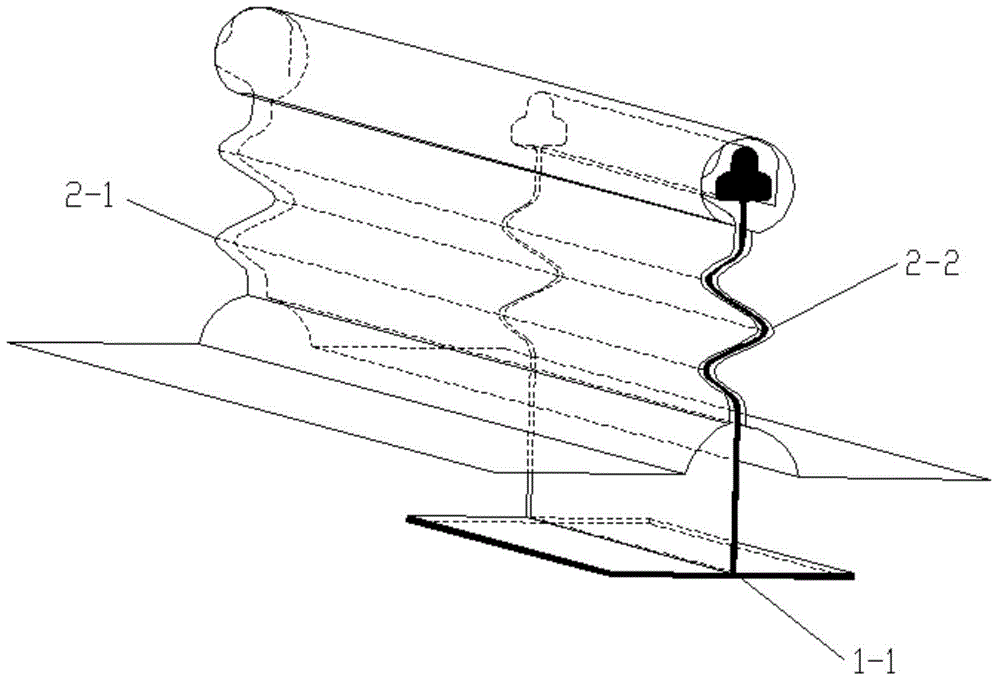

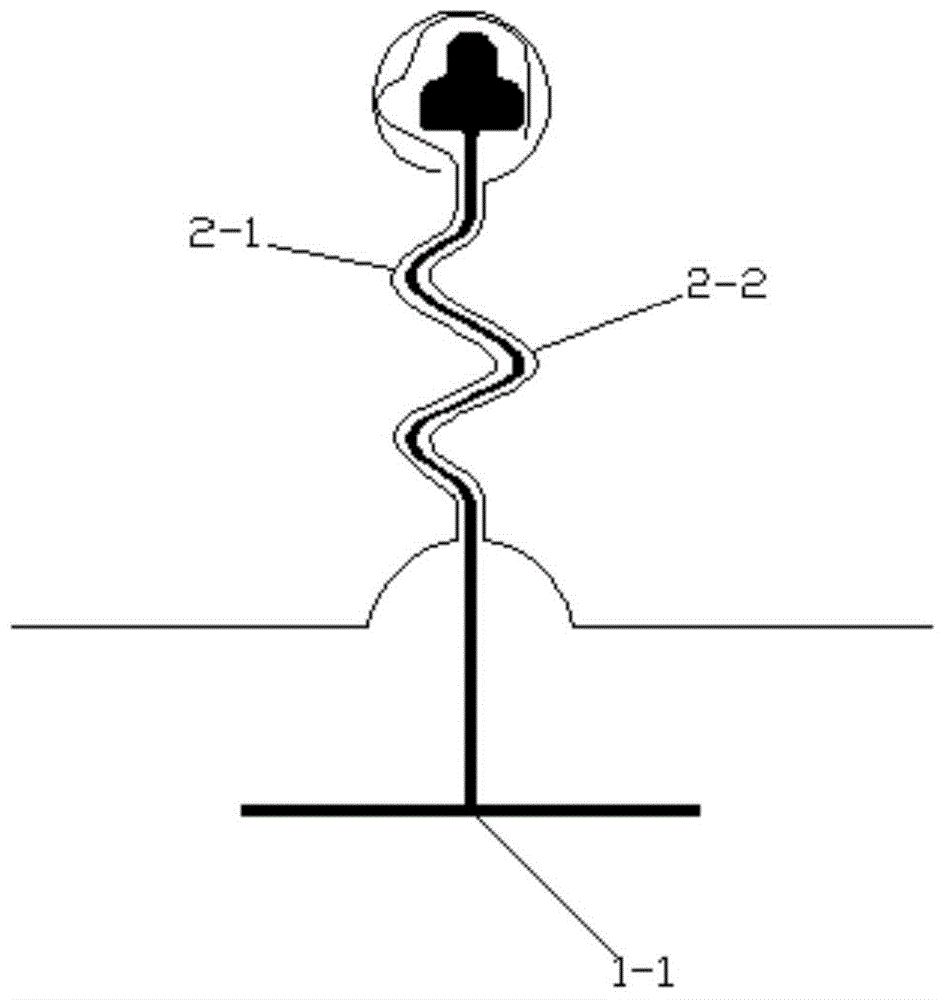

[0021] Example 1 The roof of a large railway station adopts a curved metal roof panel system with curved vertical seams, using curved curved vertical seam supports 1-1, curved curved vertical seam roof panels left rib 2-1, curved curved vertical seam The right rib 2-2 of the roof panel, the above curved standing seam support and the left rib and the right rib of the curved curved standing seam roof panel are composed of 3 crests and troughs, ie n=3.

[0022] Step 1: According to the design requirements, process and manufacture the metal roof panel with the left rib 2-1 of the curved standing seam roof panel and the right rib 2-2 of the curved standing seam roof panel, such as Figure 5 ;Brackets 1-1 with curved standing seams, such as image 3 .

[0023] Step 2: Install and fix the curved standing seam support 1-1 at the designed position of the roof purlin of the railway station.

[0024] Step 3: On the left side of the curved standing seam support 1-1, install the left rib...

example 2

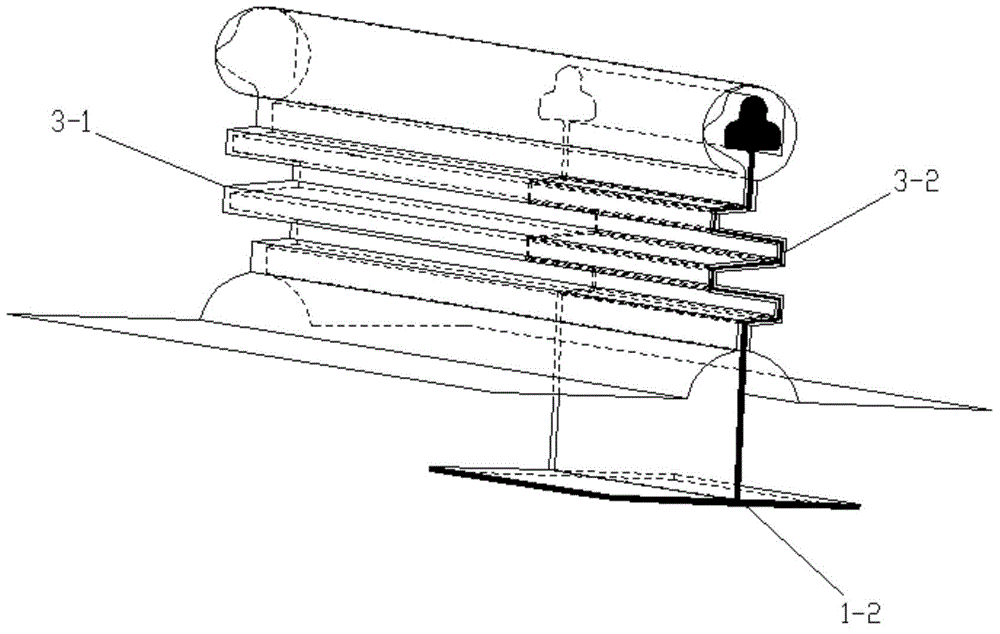

[0026] Example 2 The roof of an airport terminal building adopts a zigzagging curved standing seam metal roof panel system, using zigzagging curved standing seam supports 1-2, zigzagging curved standing seam roof panel left rib 3-1, zigzagging curved standing seam The right rib 3-2 of the seam roof panel, the above broken line curved standing seam support 1-2, the left rib 3-1 of the broken line curved standing seam roof panel and the right rib 3-2 of the broken line curved standing seam roof panel are composed of 4 crests and troughs, that is, m=4.

[0027] Step 1: According to the design requirements, process and manufacture the metal roof panel with the left rib 3-1 of the broken-line curved standing seam roof panel and the right rib 3-2 of the broken-line curved standing seam roof panel, such as Figure 6 ;Bracket 1-2 with zigzag curved standing seam, such as Figure 4 .

[0028] Step 2: Install and fix the broken-line curved standing seam support 1-2 at the designed pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com