Quick centering and melting device for PPR water feeding pipes

A fast technology for water supply pipes, which is applied in the field of fast centering welding devices for PPR water supply pipes, can solve problems such as bursting and water leakage, affecting the fixing and bending of pipes, and achieves the effect of strong occlusal ability and avoiding poor sealing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

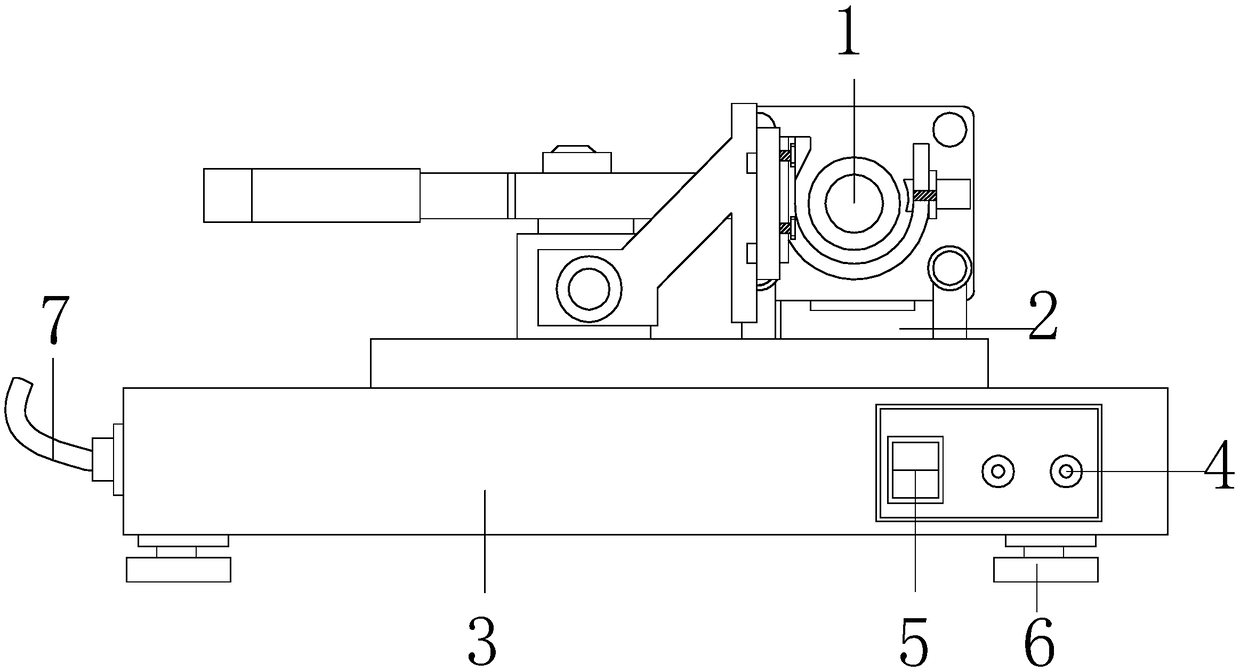

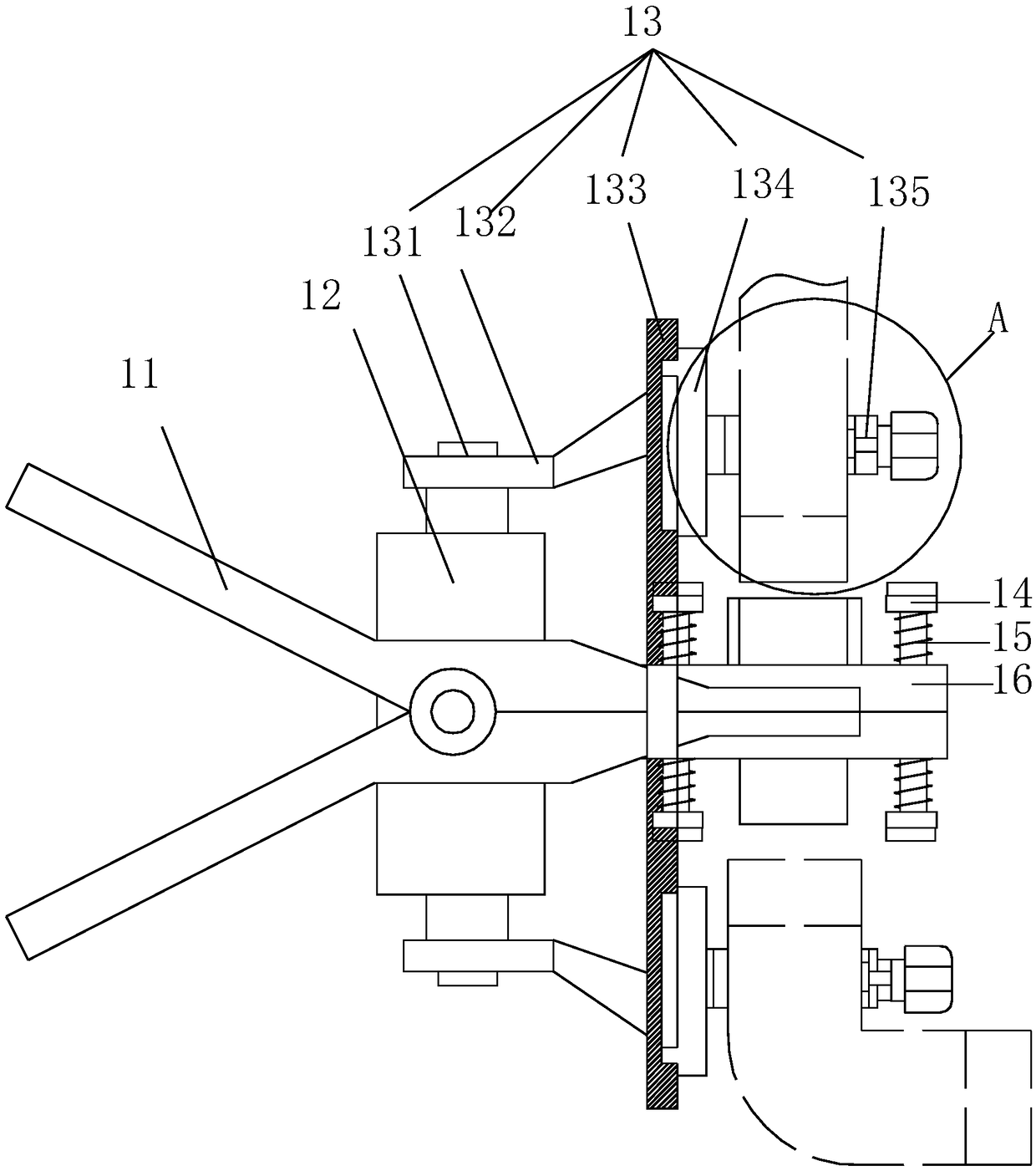

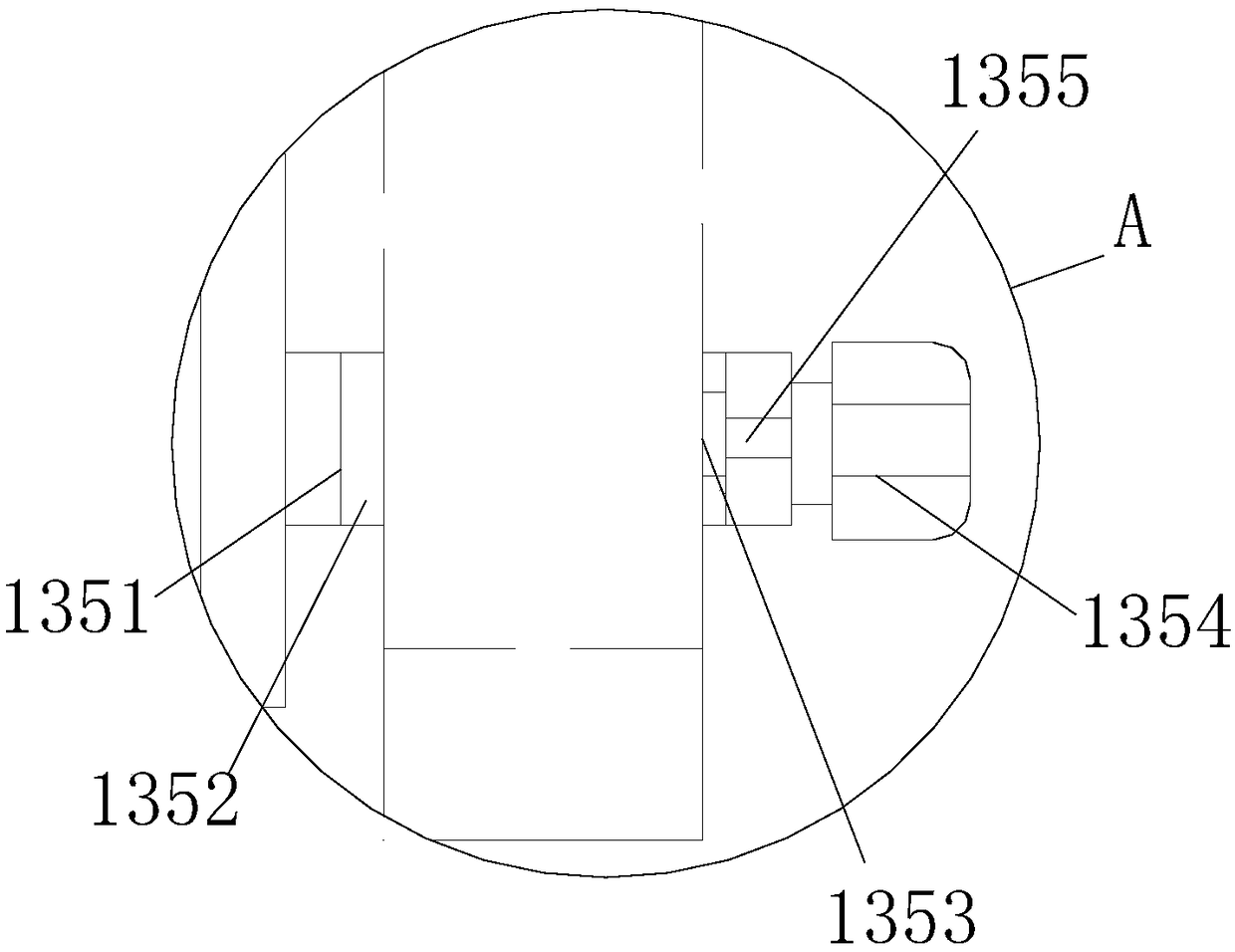

[0024] Such as Figure 1-Figure 5 As shown, the present invention provides a fast centering welding device for PPR water supply pipes. The hot melt frame 1 is horizontally fixed on the bottom surface of the heat conduction head 2, the indicator light 4 is provided with two and is in a horizontal line with the switch 5 on the left side, and the movable feet 6 are provided with four and pass through the top The external thread of the body 3 is engaged with the nut at the bottom of the body 3, the bottom of the thermal head 2 is close to the upper surface of the body 3, the power cord 7 passes through the clamp on the right side of the body 3 and is welded and fixed with the internal circuit board, the The internal structure of the hot-melt rack 1 includes: a working clamp 11, a two-way support seat 12, a movable pipe seat 13, a telescopic rod 14, a return spring 15, and a movable heating plate 16. The middle part of the action clamp 11 is embedded in the two-way support seat 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com