Patents

Literature

72results about How to "Improve bite ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cut roll crusher and construction waste roll-in crushing station based on same

ActiveCN102974420AFacilitate strippingGuaranteed requirements for pretreatment purificationGrain treatmentsReinforced concreteResource utilization

The invention discloses a cut roll crusher and a construction waste roll-in crushing station based on same in the field of the comprehensive resource utilization technology. A plurality of groups of cut-off components which are axially arranged at intervals are arranged on the surfaces of two oppositely arranged rollers of cut roll crusher, the cut-off components comprise a plurality of cut-off knives and a plurality of cut-off teeth evenly distributed on the surfaces of the rollers, the cut-off knives and the cut-off teeth are all arranged on the axial positions of the surface of the same roll, and the plurality of cut-off teeth are arranged between the two adjacent cut-off knives. When being used for rolling-in and crushing construction wastes, the cut roll crusher can achieve the comprehensive action on cut-off crushing, shearing crushing, bending crushing, separation crushing, roll-in crushing, extrusion crushing and the like, so as to facilitate the cut-off of reinforced concrete, prestressed floors, and lintel slabs, and also facilitate the stripping between the prestressed reinforcement and the concrete.

Owner:SHANGHAI GUOTONG ENVIRONMENTAL PROTECTION EQUIP

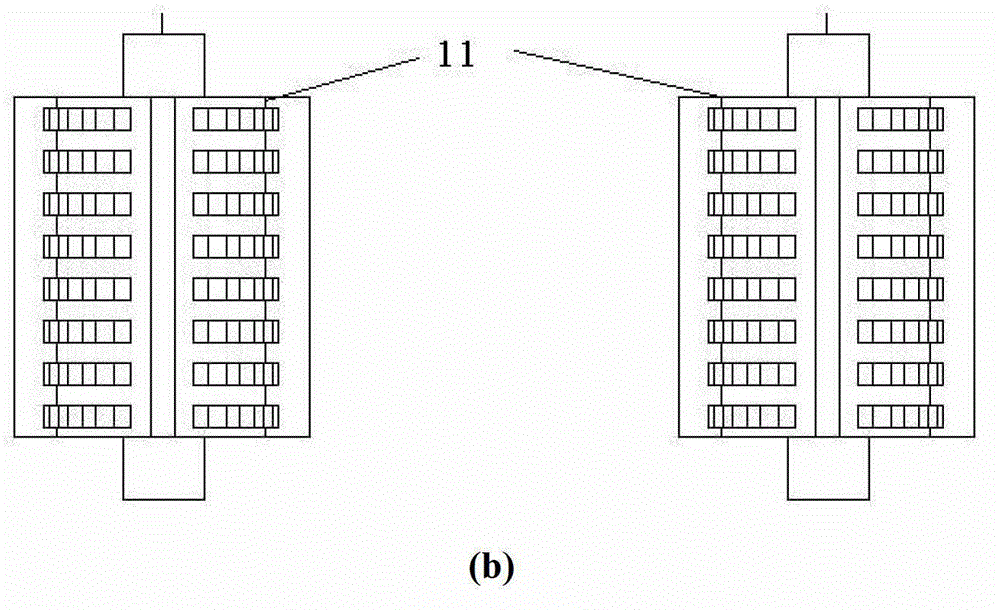

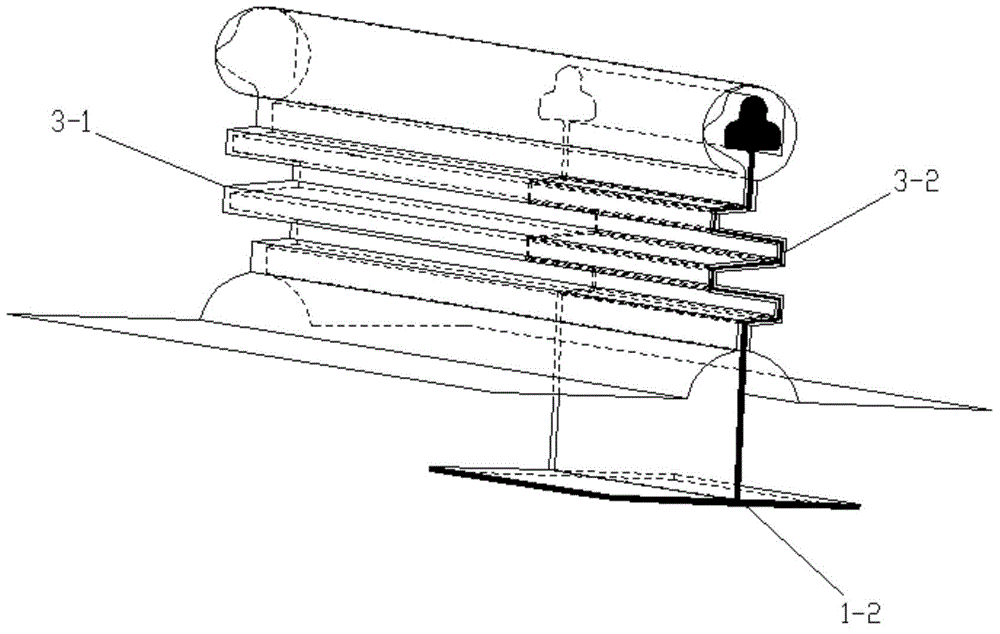

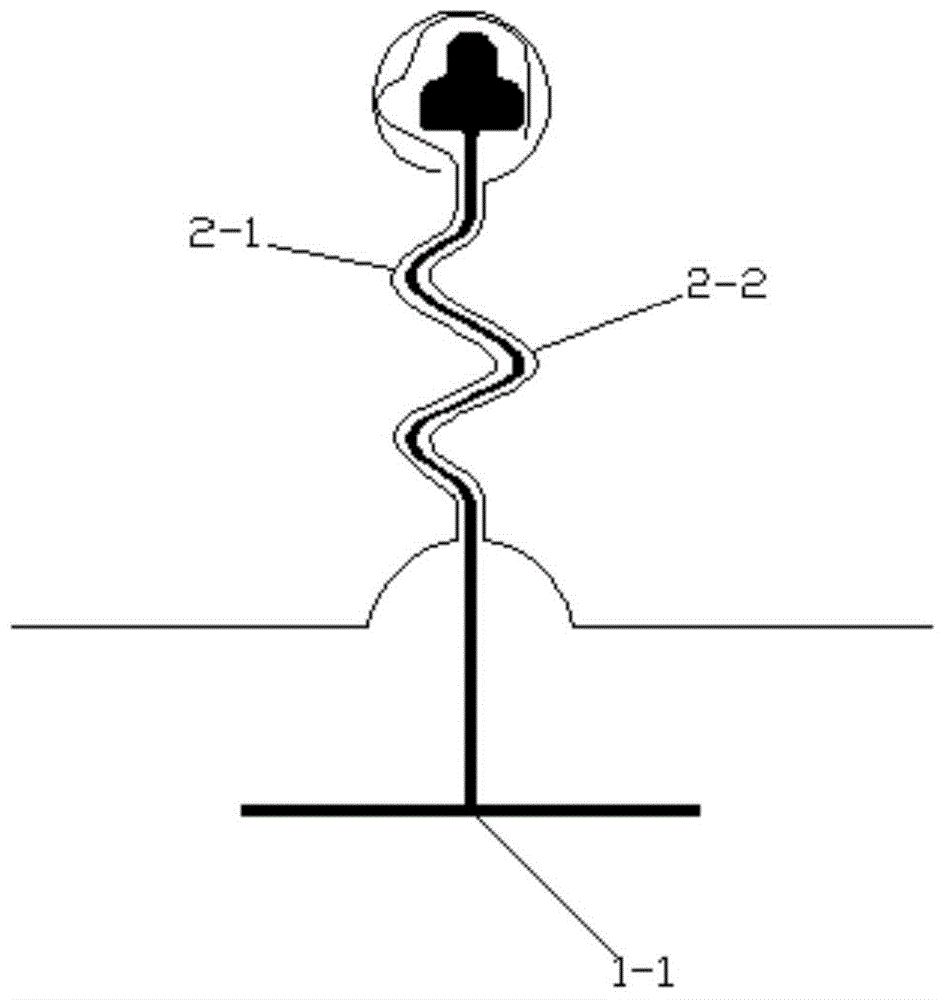

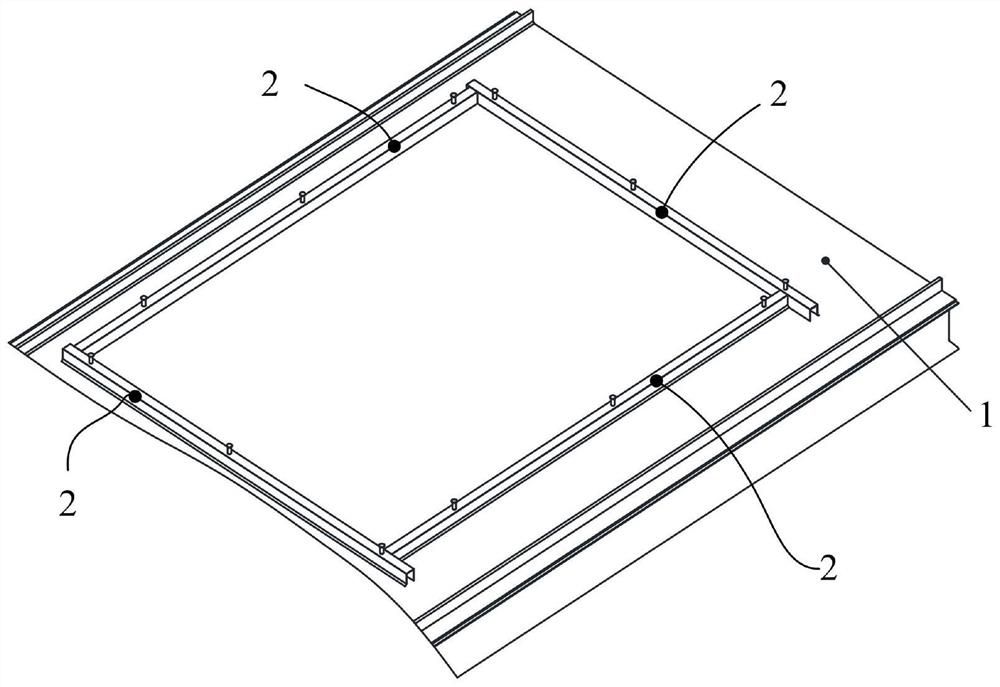

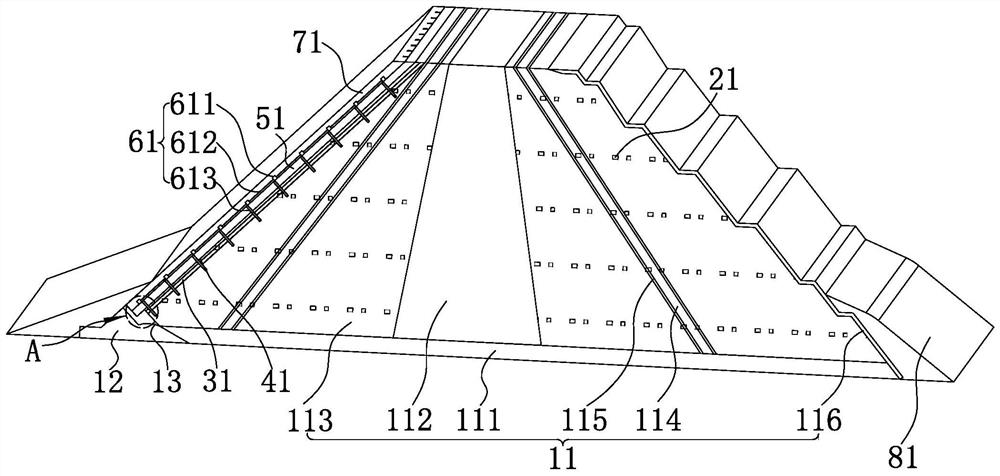

Curved vertical seam metal roof panel system

ActiveCN104594570AImprove bite abilityIncrease binding forceRoof covering using slabs/sheetsSpandrelMetal roof

The invention relates to a curved vertical seam metal roof panel system used for long-span light roof covers, such as, civil engineering, stations, airports, and the like, and especially relates to a wind-resisting metal roof panel and a supporting base. The curved vertical seam metal roof panel system is characterized in that a curved vertical seam supporting base 1-1 is meshed with a left curved vertical seam roof panel rib 2-1 and a right curved vertical seam roof panel rib 2-2, so that the curved vertical seam metal roof panel system is formed; or a folded curved vertical seam supporting base 1-2 is meshed with a left folded curved vertical seam roof panel rib 3-1 and a right folded curved vertical seam roof panel rib 3-2, so that a folded curved vertical seam metal roof panel system is formed. The curved vertical seam metal roof panel system has the advantages that the meshing capacity among the metal roof panels is enhanced, the constraint force of the supporting base for the roof panel is increased and the capacity of the metal roof panel for resisting wind is increased.

Owner:BEIJING JIAOTONG UNIV

Photocureable coating for anodization

InactiveCN102604529AReduce drying shrinkageGood adhesionPolyurea/polyurethane coatingsSolventFunctional monomer

The invention discloses a photocureable coating for anodization. The photocureable coating comprises the following compositions by weight: a photoinitiator, a flatting agent, an adhesion promoter, hexa-functional polyurethane resin, bifunctional polyurethane resin, tri-functional solvent polyurethane, a bifunctional monomer, a single-functional monomer, a tri-functional monomer and thermoplastic acrylic resin, wherein the hexa-functional polyurethane resin and the bifunctional polyurethane resin are aliphatic functional polyurethane acrylates, and the tri-functional solvent polyurethane is modified solvent polyurethane resin. Based on such a mode, the photocureable coating for anodization provided by the invention can be used for carry outing one-time coating without pretreatment, thereby saving the cost, the working hour and labor; meanwhile, the adhesion of the coating on anodic metal polar materials is ensured, and the strict performance test requirements of products can be guaranteed, so that the photocureable coating for anodization achieves a good protective anti-scratching and aesthetic effect on anodic electrophoretic workpieces coated with the photocureable coating.

Owner:CHANGSHU FANGTA COATING CHEM

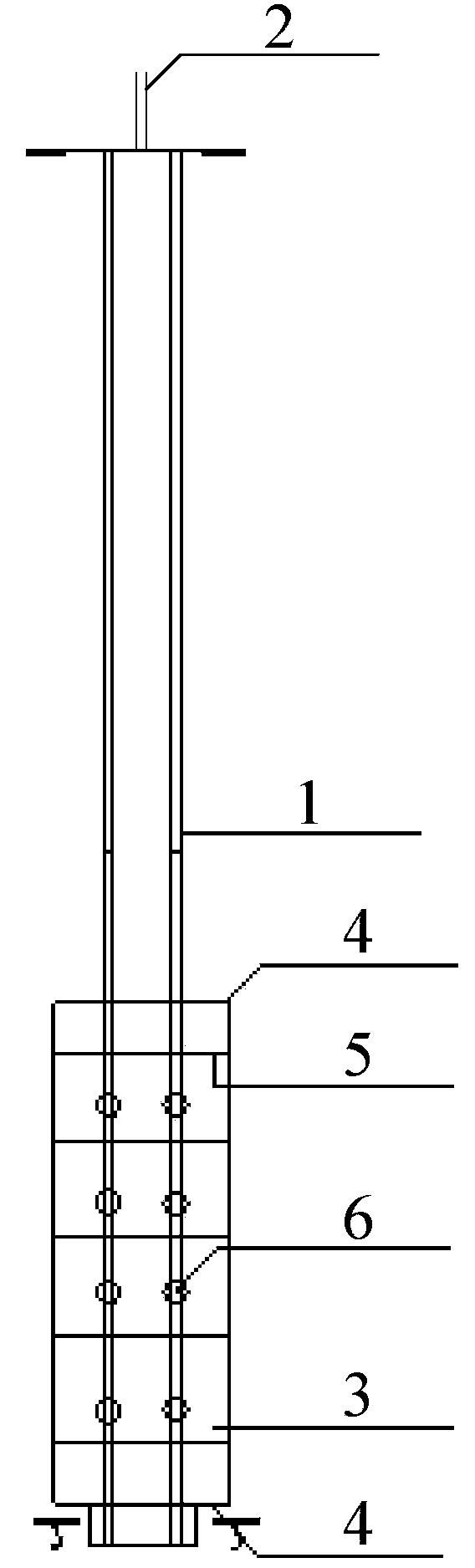

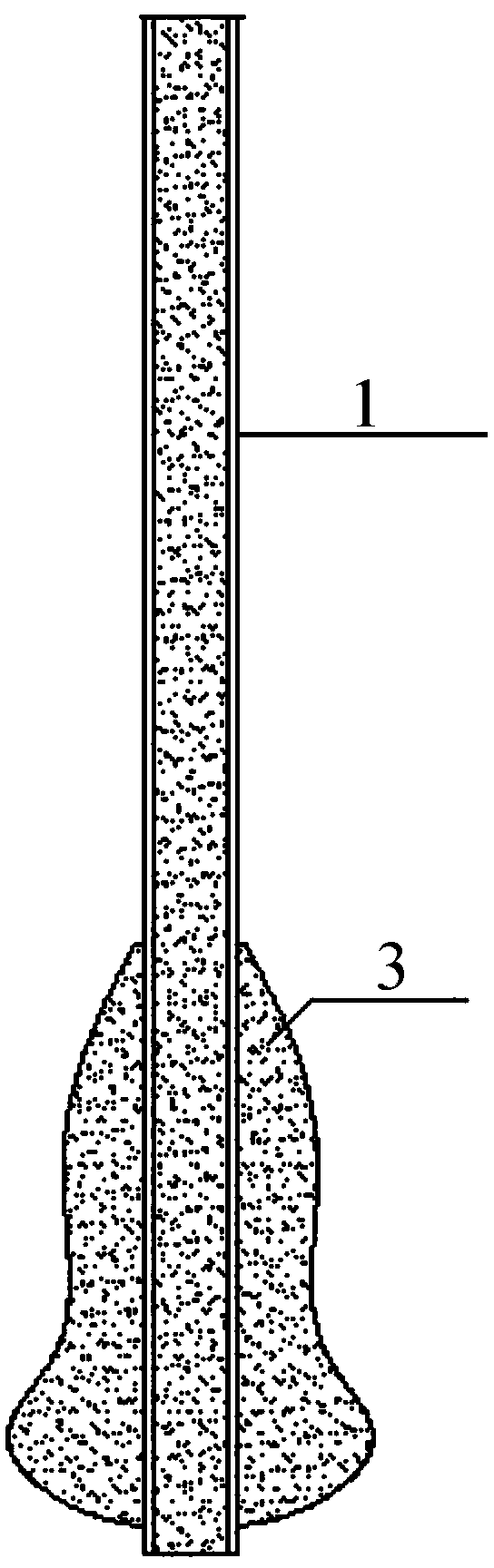

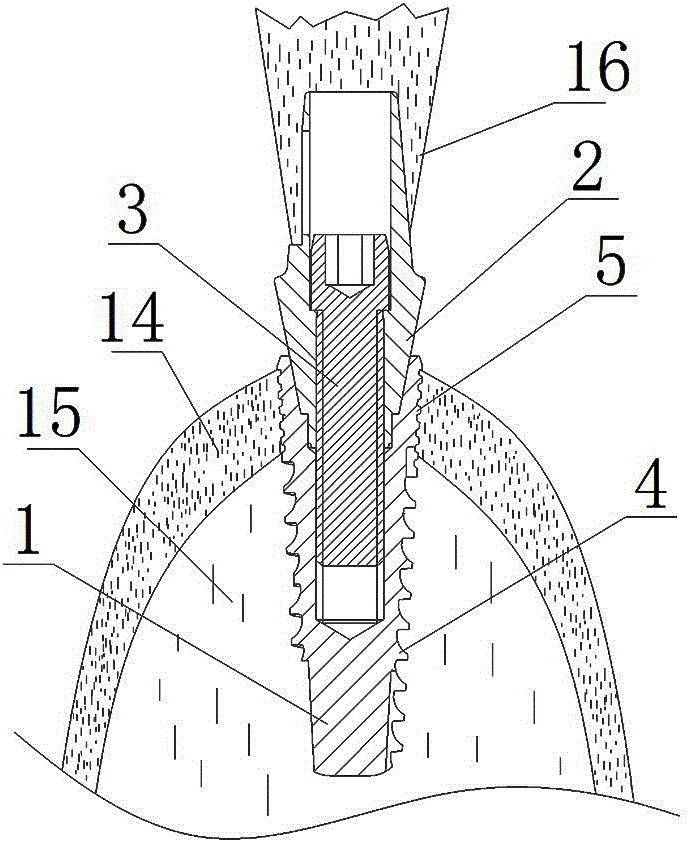

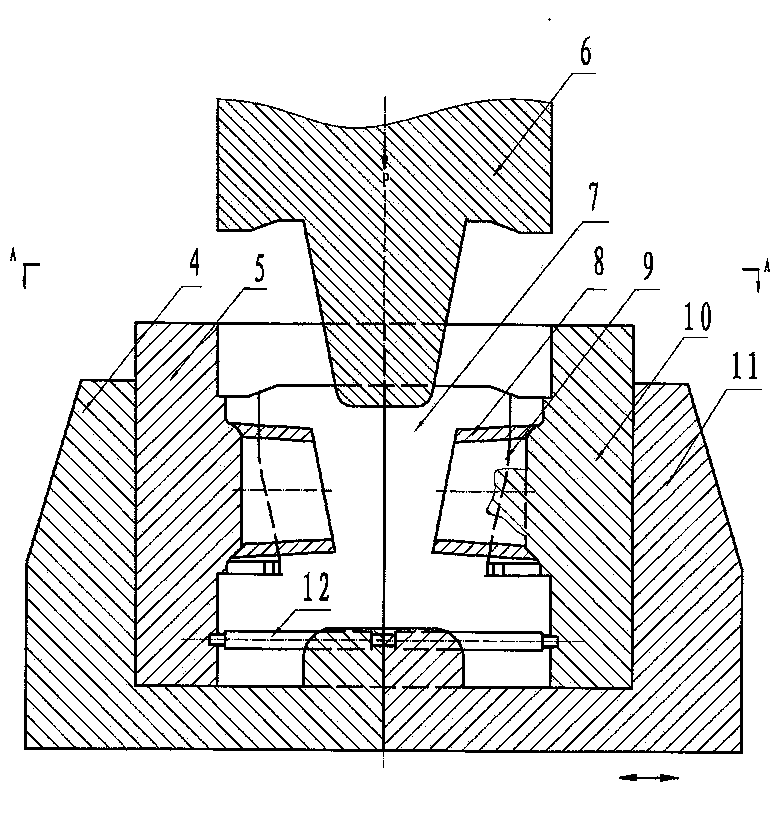

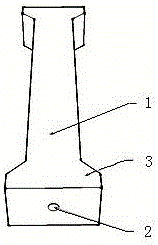

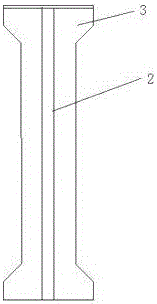

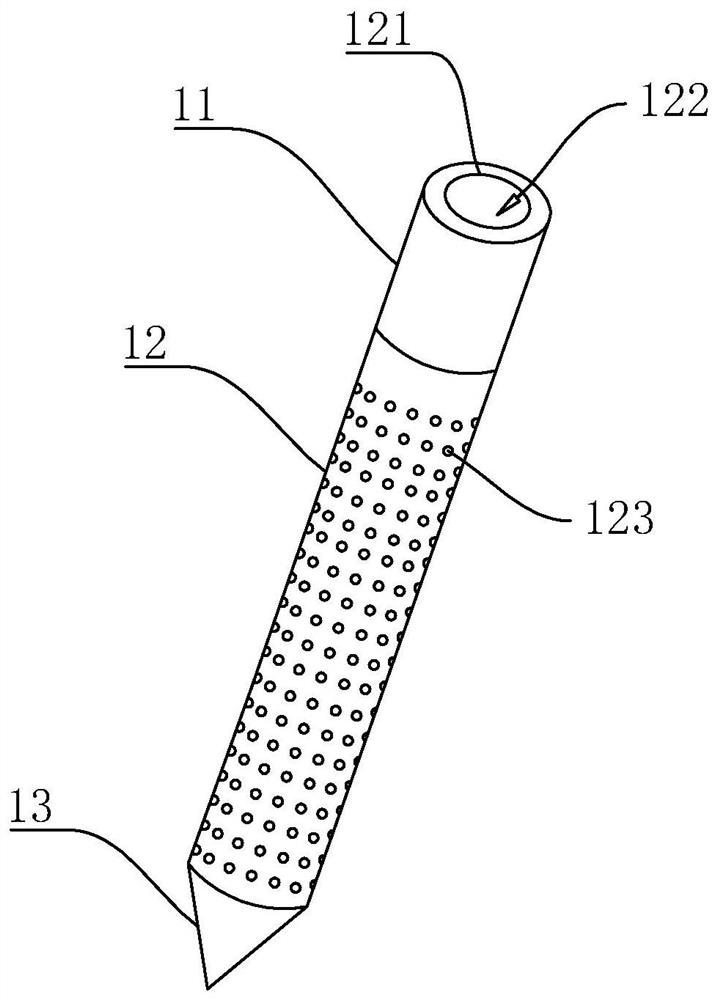

Construction method of slip-casting variable-cross section steel pipe pile and expansion and extrusion device of slip-casting variable-cross section steel pipe pile

The invention provides a construction method of a slip-casting variable-cross section steel pipe pile and an expansion and extrusion device of the slip-casting variable-cross section steel pipe pile. According to the construction method of the slip-casting variable-cross section steel pipe pile and the expansion and the extrusion device of the slip-casting variable-cross section steel pipe pile, provided by the invention, hole forming is firstly carried out by utilizing a drilling machine, slurry in a drill hole can be replaced by utilizing cement slurry after the hole forming is completed, a steel pipe pile which is provided with the expansion and extrusion device is then put in the drill hole, high-pressure cement slurry is pressed into the steel pipe pile or the expansion and extrusion device after the cement slurry in the drill hole is solidified, the expansion and extrusion device is used for expanding to extrude and strengthen a surrounding soil body under the action of the high-pressure cement slurry, a cement slurry body expansion and extrusion head is finally formed around the steel pipe pile, thus the occlusion action between the steel pipe pile and the surrounding soil body is greatly increased, a slurry leakage phenomenon which is easily caused in a post-grouting technology is avoided, and the operation reliability of the expansion and extrusion device is increased.

Owner:上海市建工设计研究总院有限公司

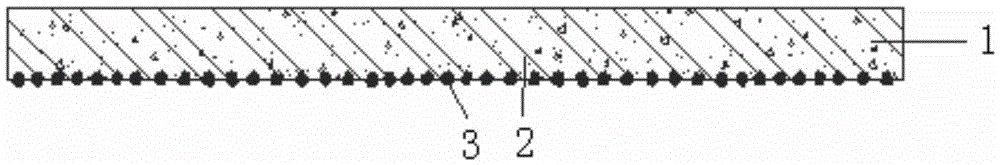

Ballastless track plate and manufacturing method thereof

The invention discloses a ballastless track plate and a manufacturing method thereof. The ballastless track plate comprises a concrete track plate and a coarse aggregate layer which is evenly embedded to the bottom face of the concrete track plate. The manufacturing method of the ballastless track plate comprises the steps of 1, pouring construction of reinforcing steel bars and concrete of the concrete track plate, 2, evenly spreading of coarse aggregate, 3, rolling and leveling of the coarse aggregate, 4, maintenance of the concrete track plate, and 5, storage, transportation and hoisting of the track plate. By the adoption of the outward-convex type roughness treating method that the coarse aggregate is embedded to the bottom of the plate, the contact area of the bottom face of the track plate and the filling material is increased, the coarse aggregate matching effect of the track plate-filling layer interface is improved, and the bonding performance of the track plate-filling layer interface is improved. The manufacturing method of the ballastless track plate is high in mechanical degree, rapid and efficient in interface treatment, low in equipment energy consumption, small in environmental pollution, low in construction cost and capable of being widely applied to standard production of high-speed railway track plates.

Owner:CENT SOUTH UNIV +1

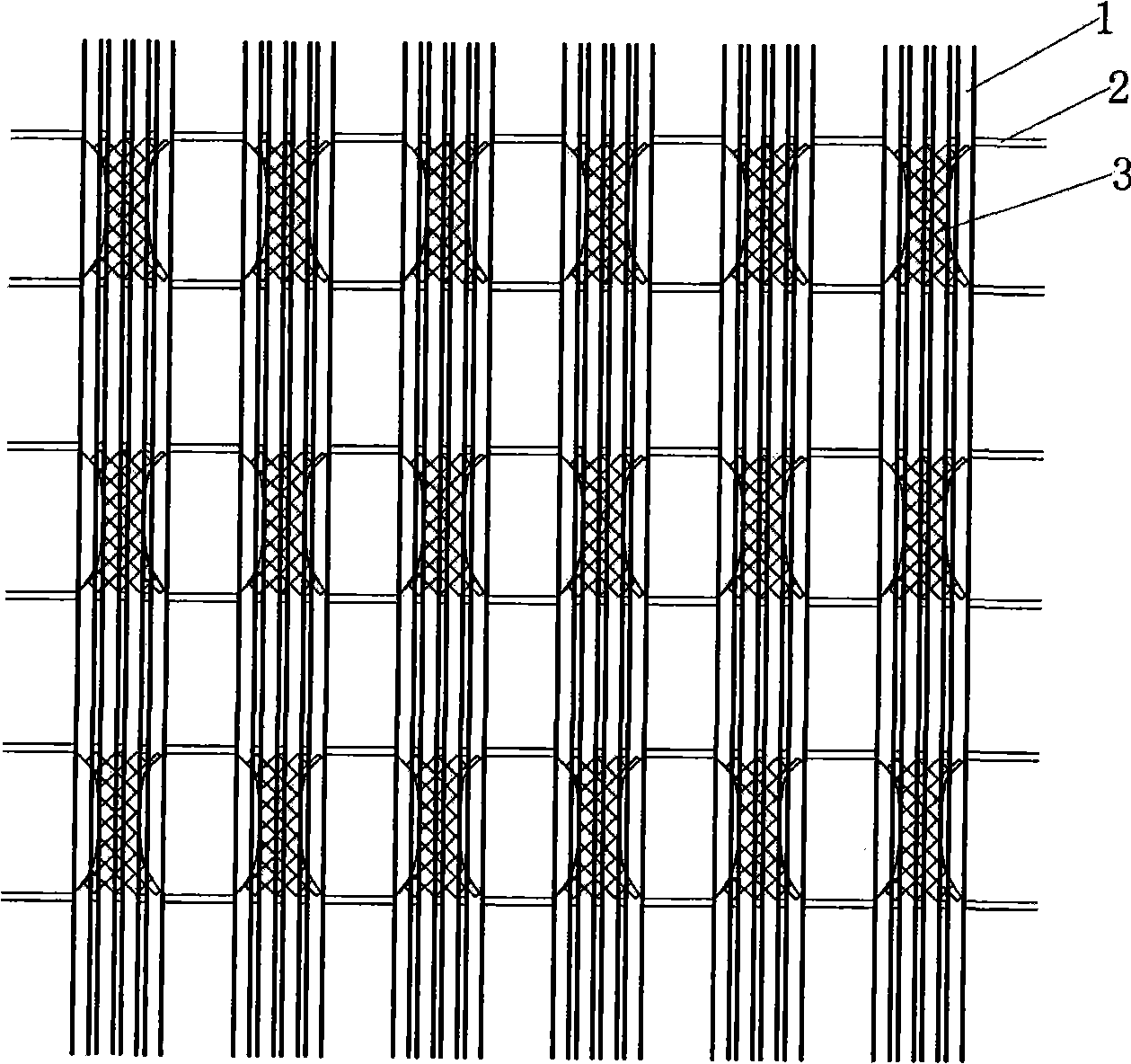

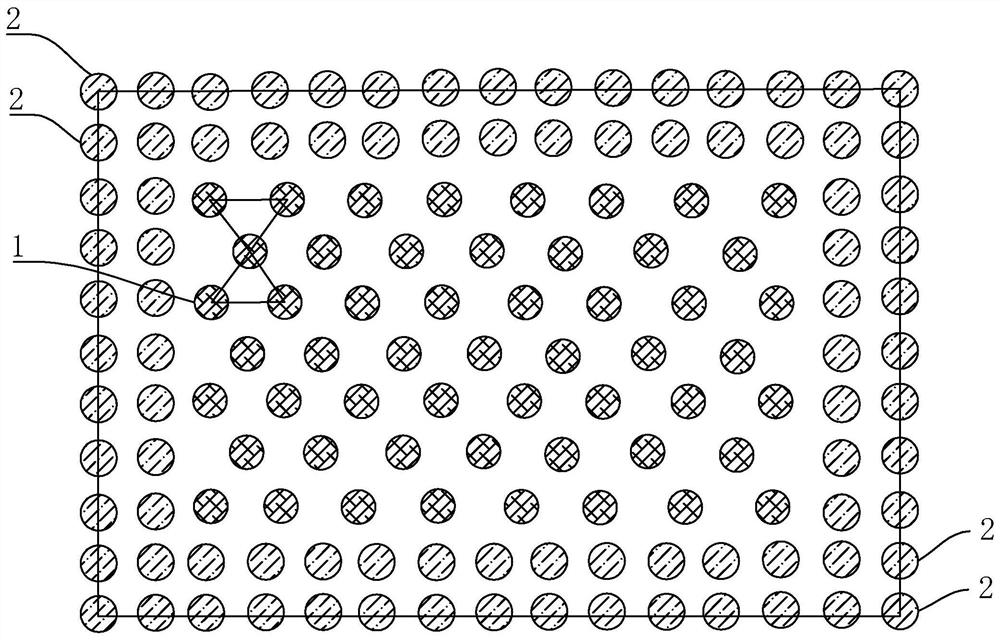

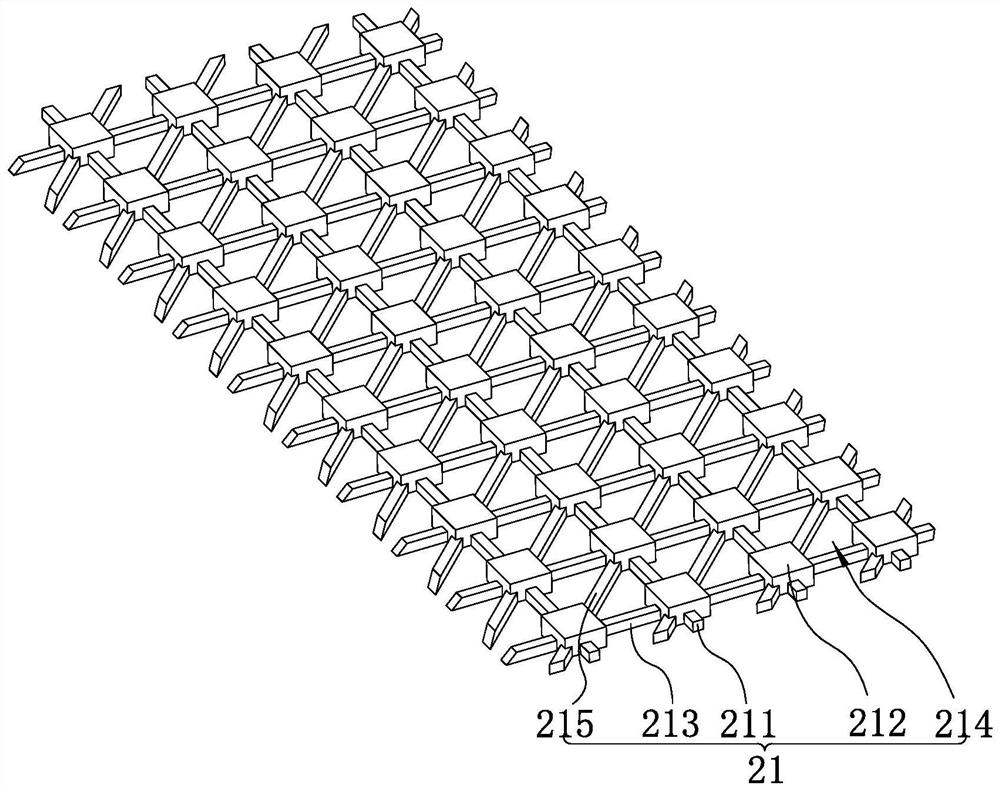

High-strength earth work grille net

InactiveCN101255686AHigh tensile strengthImprove corrosion resistanceExcavationsSoil preservationHigh intensityHigh wear resistance

A high-strength earth work grille net is characterized in that the grille net is waved by the high-strength high-modulus northylen. The grille net is weaved by a plurality of high-strength high-modulus polythene cords. Each cord comprises a plurality of folds, and each fold comprises a plurality of threads. Each lattice of the grille net is quadrangle. The outer layer of the grille net is coated with art glue. The grille net of the invention has the advantages of remarkably high tensile strength, high corrosion resistance, high wearing resistance, low specific elongation, less creep deformation, stronger locking and engaging function to the soil body, effectively processing the soft earth base and the steep bank, restricting the lateral displacement of the soil body, overcoming the differential descending of the soil body, greatly increasing the bearing capacity of the ground work and increasing the whole capability of the ground work.

Owner:SHANGHAI NEW TECHTEXTILES

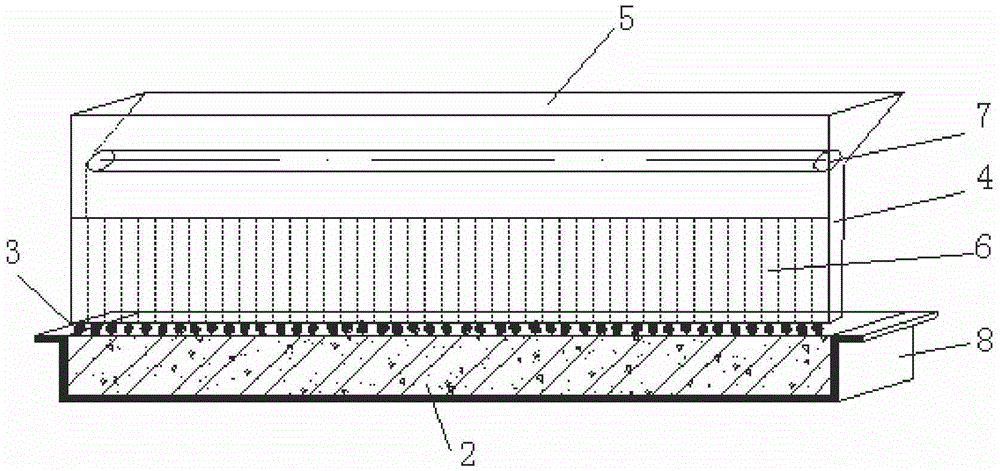

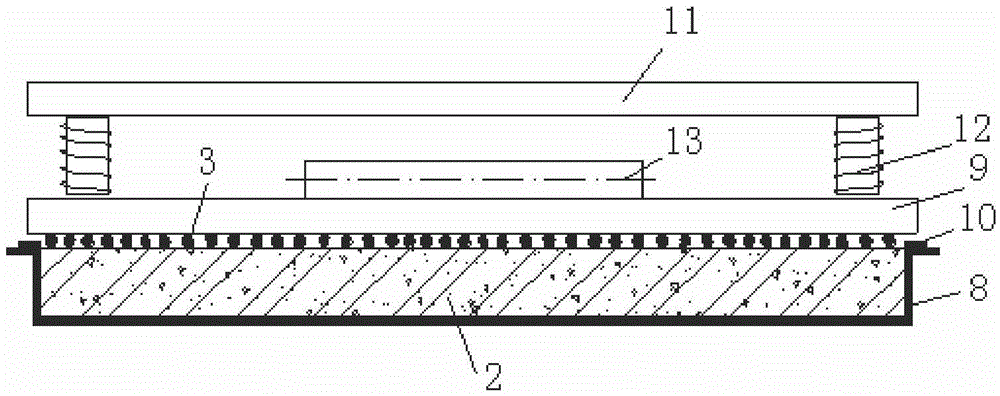

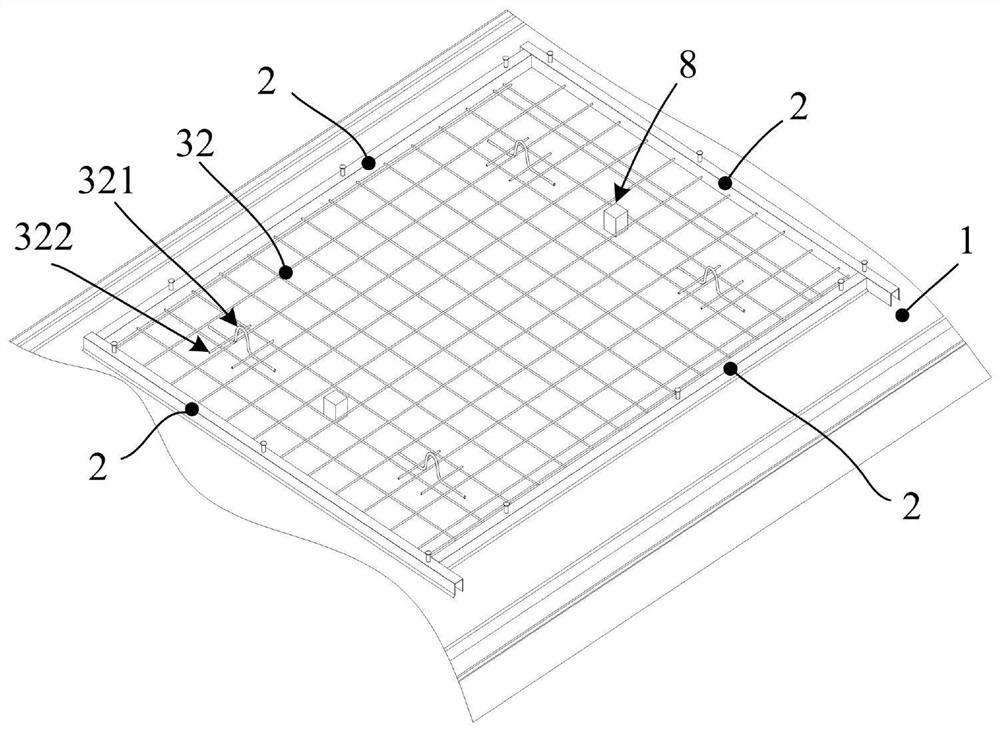

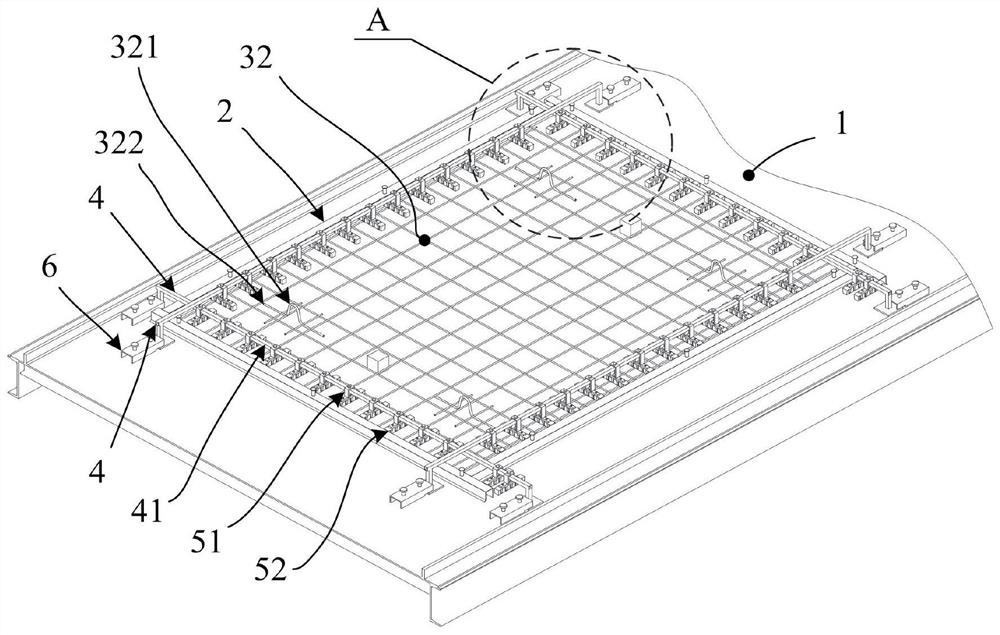

Production device and production method of grooved laminated slab without bars on periphery

InactiveCN113043419AIncrease productivityImprove product qualityMouldsMould fastening meansProduction lineCrack resistance

The invention discloses a production device and a production method of a grooved laminated slab without bars on the periphery. In the production process of prefabricated slabs, an automated production line is adopted. Before the prefabricated slabs are poured, a plurality of equidistant groove assemblies are arranged and the groove assemblies are inserted into the surface layers of the prefabricated slabs. After the prefabricated slabs are poured and fully solidified, groove holes capable of containing middle connecting steel bars are formed, and then the middle connecting steel bars are mounted in a matched mode, so that reliable connection of every two adjacent prefabricated slabs and adaptive matched connection of a subsequently poured laminated slab and a building body are achieved. The prefabricated slabs are produced through the automated production line, groove blocks are placed through a mechanical arm, wedge-shaped ribbed groove blocks are formed through synthetic resin, and the connecting bars are sequentially placed in the groove holes during field mounting, so that the crack resistance and the meshing effect of the concrete laminated slab are enhanced, the production efficiency is improved, and the total construction cost is reduced. Reliable supporting and pouring safety are ensured through a supporting mechanism.

Owner:CHINA CONSTR SCI & TECH CO LTD +1

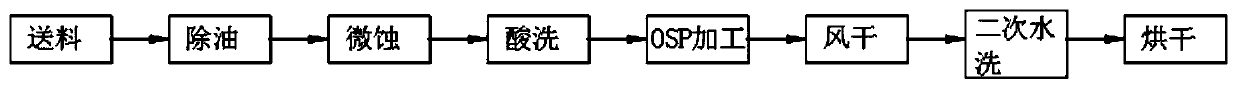

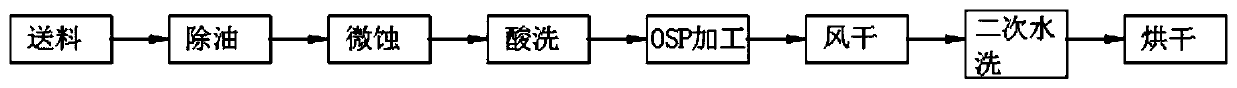

OSP processing technology for circuit board production

InactiveCN110049630AEasy to controlGuaranteed cleanlinessConductive pattern polishing/cleaningCircuit precursor manufactureEtchingAcid washing

The invention discloses an OSP processing technology for circuit board production, which comprises following steps of feeding, oil removing, micro-etching, acid washing, OSP processing, air drying, secondary water washing and drying. Before feeding, firstly quality detection is carried out on the PCB, the cleanness of the copper surface is guaranteed before the OSP film is coated, and then a qualified product before the processing is guaranteed. During micro-etching, copper in the solution is controlled to be 3.5 g / L, the biting and etching capability is strong, and then the film is formed under the good OSP condition. The film is protected in the processes of inspection, transportation and packaging after the film is formed. The strict process control aiming at the OSP pre-processing, OSPprocessing, and the OSP post-processing, the control of the OSP processing quality of the PCB board is convenient.

Owner:广州迅磊科技有限公司

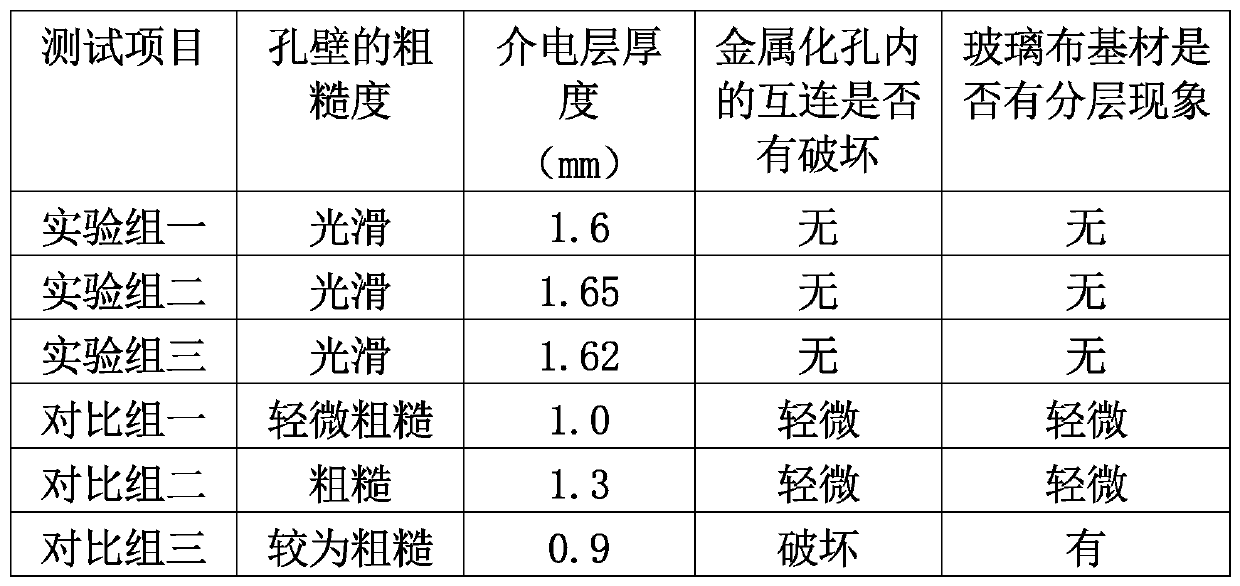

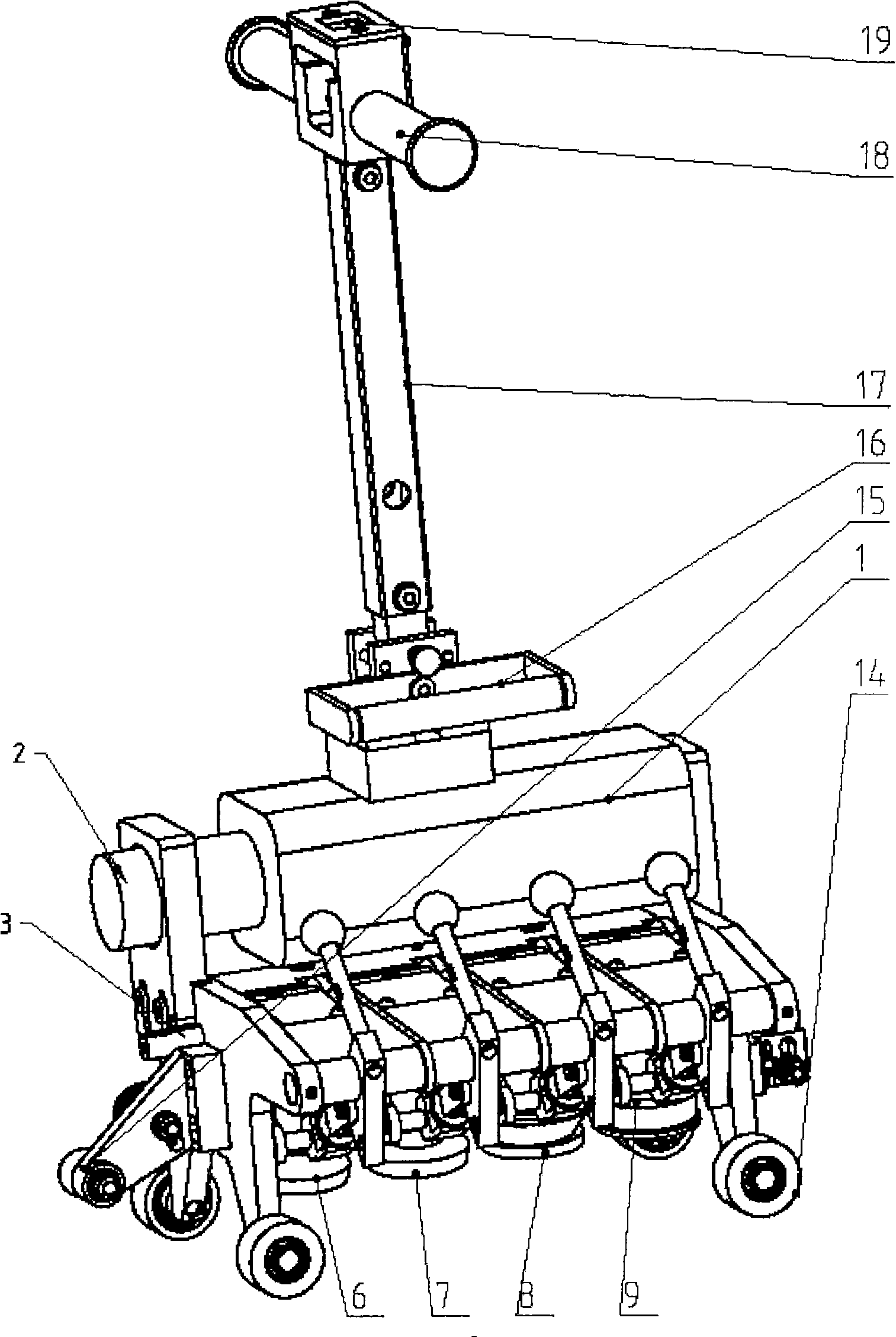

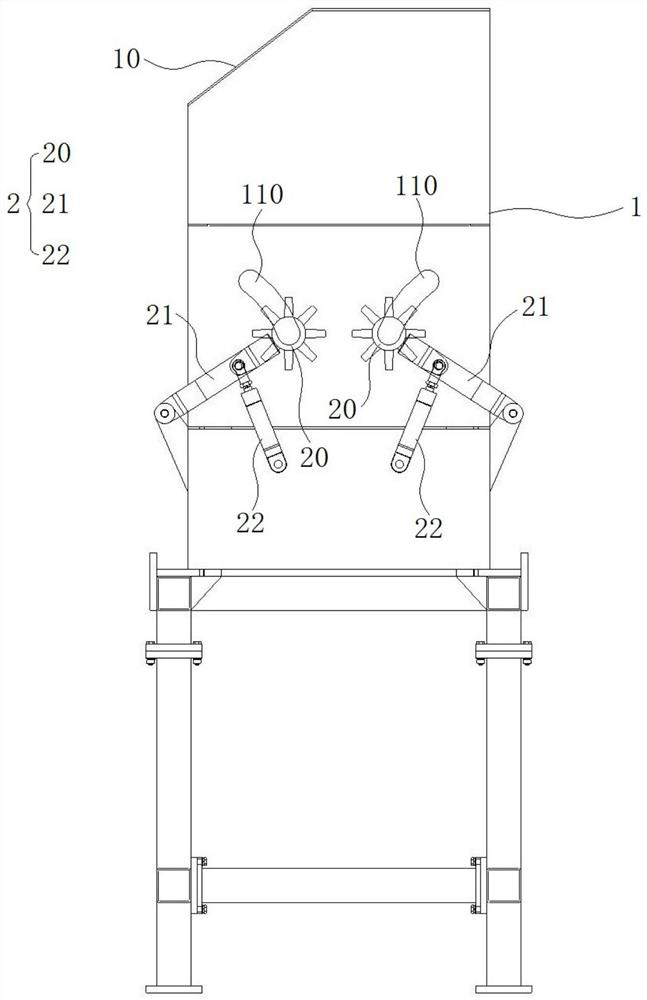

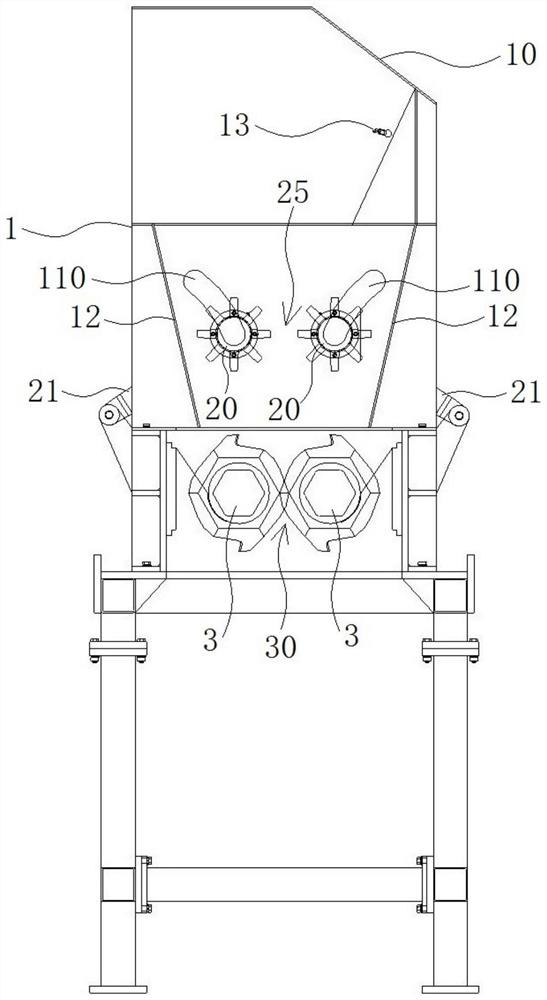

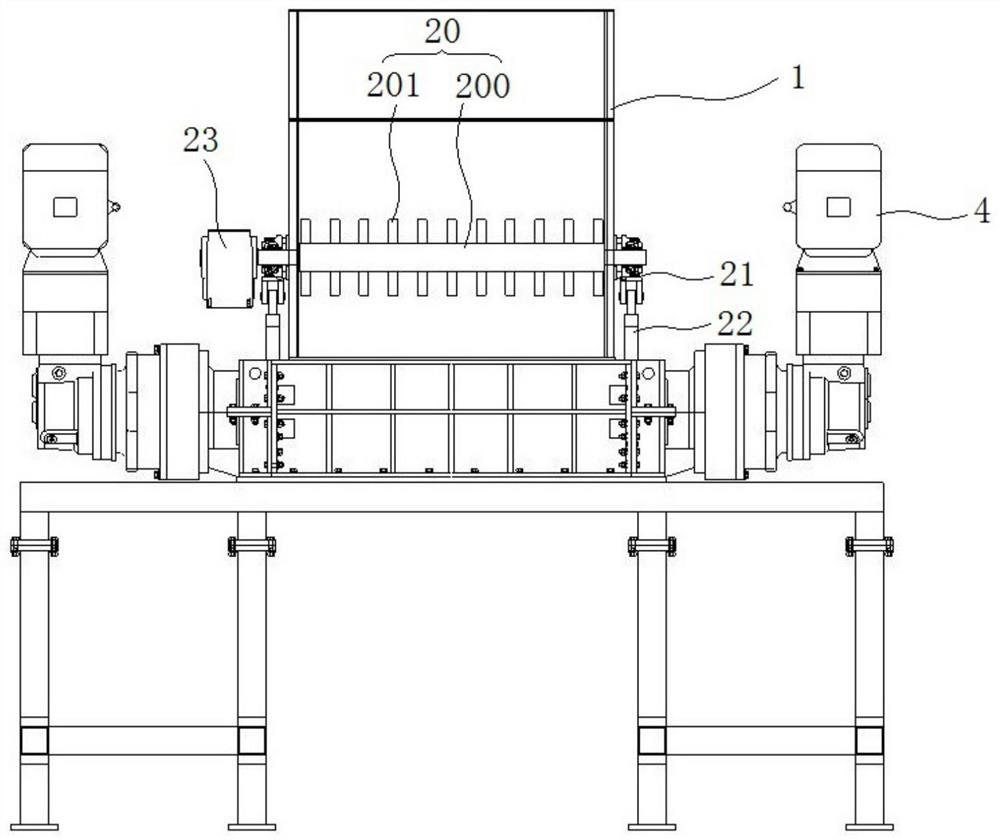

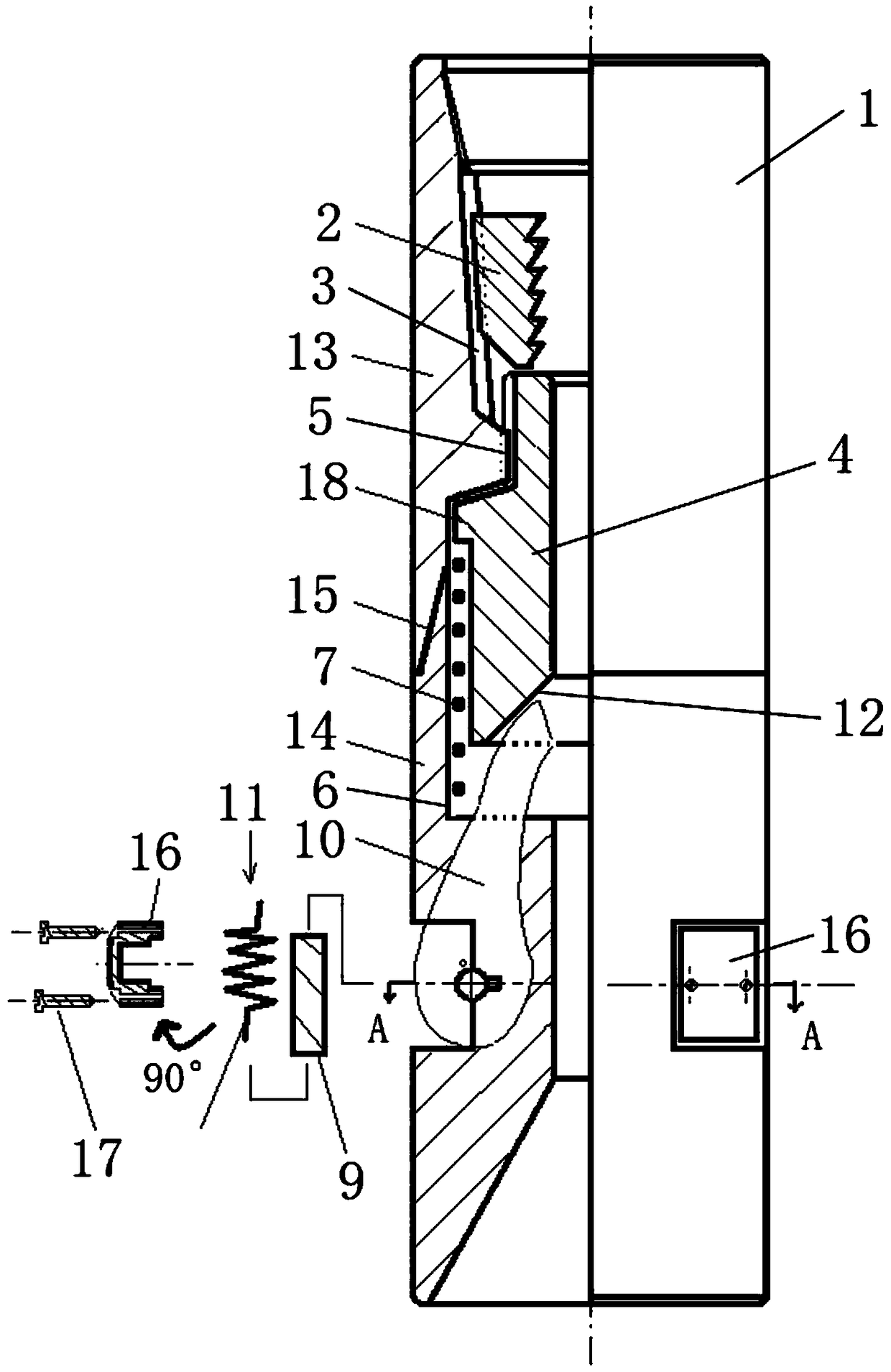

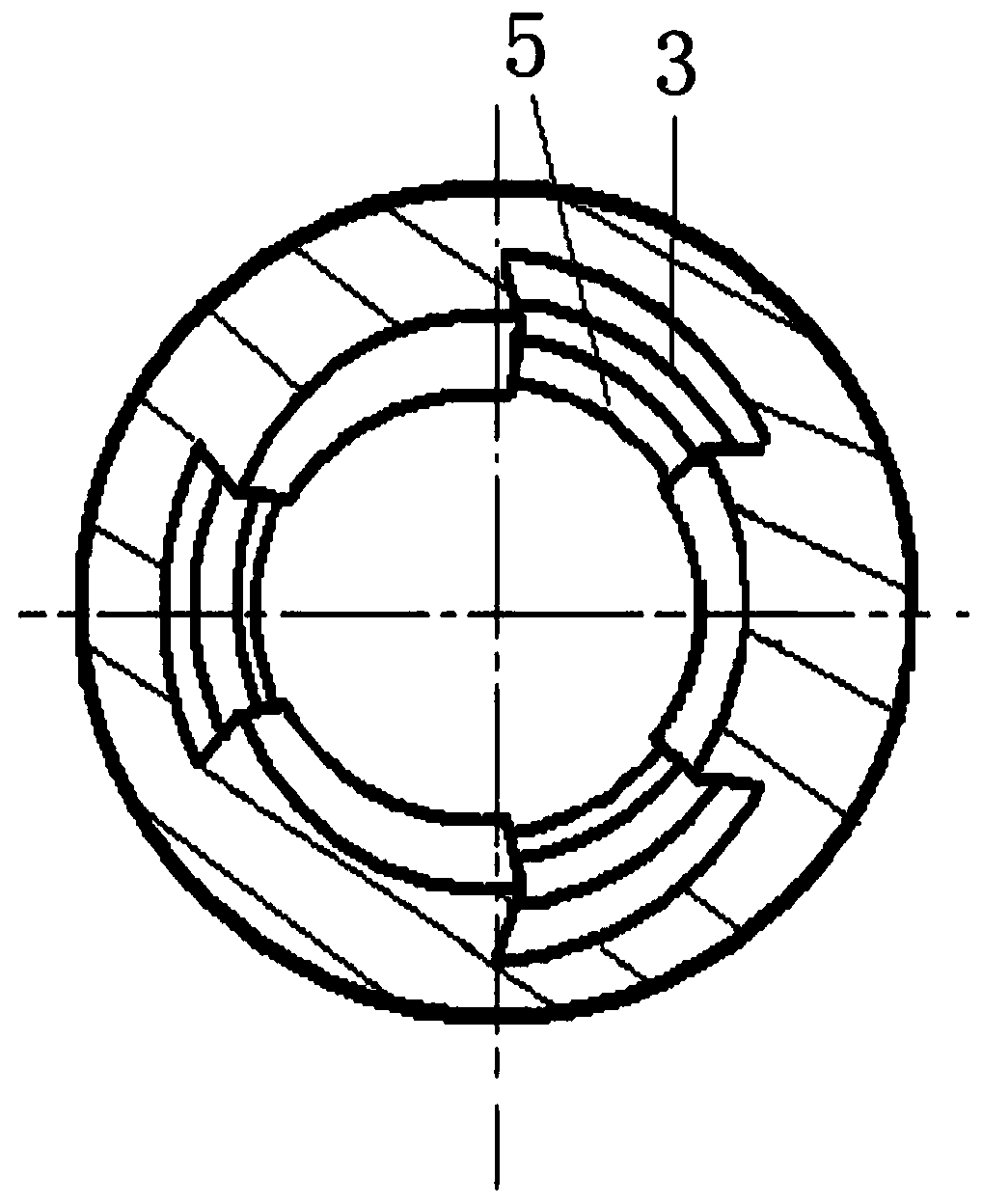

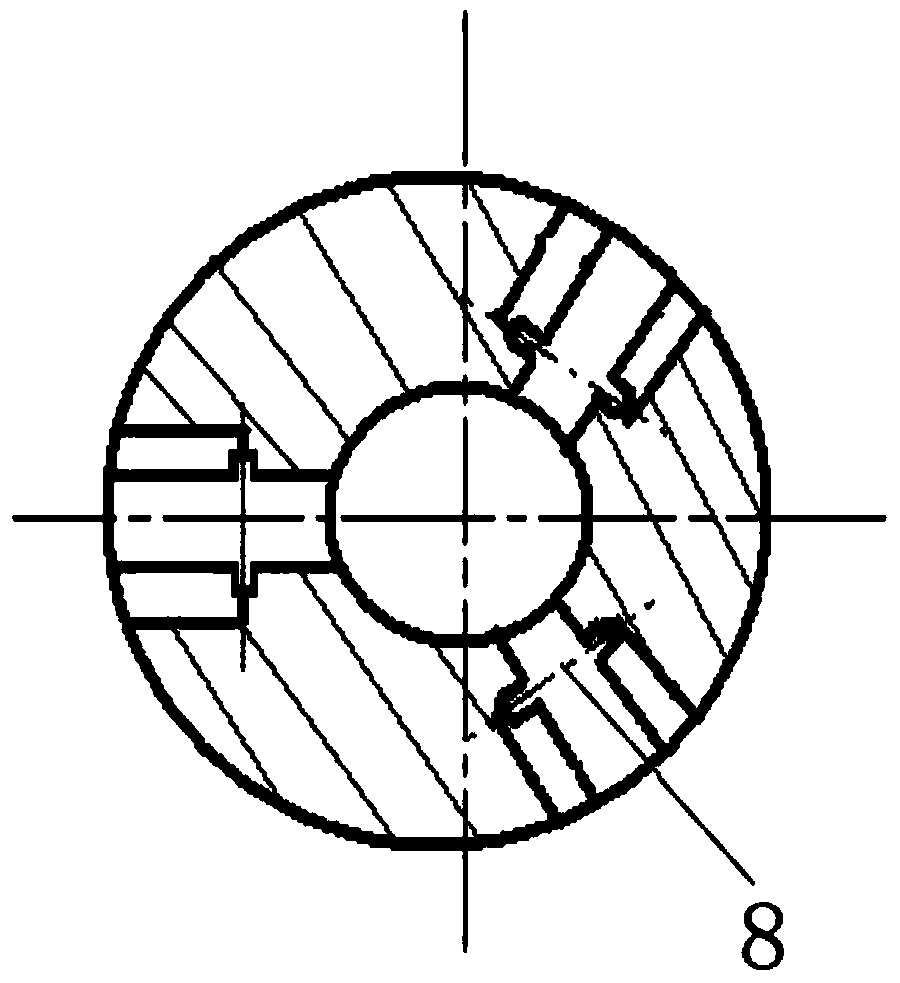

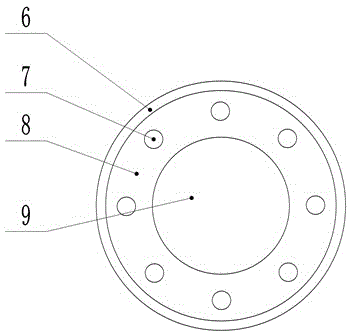

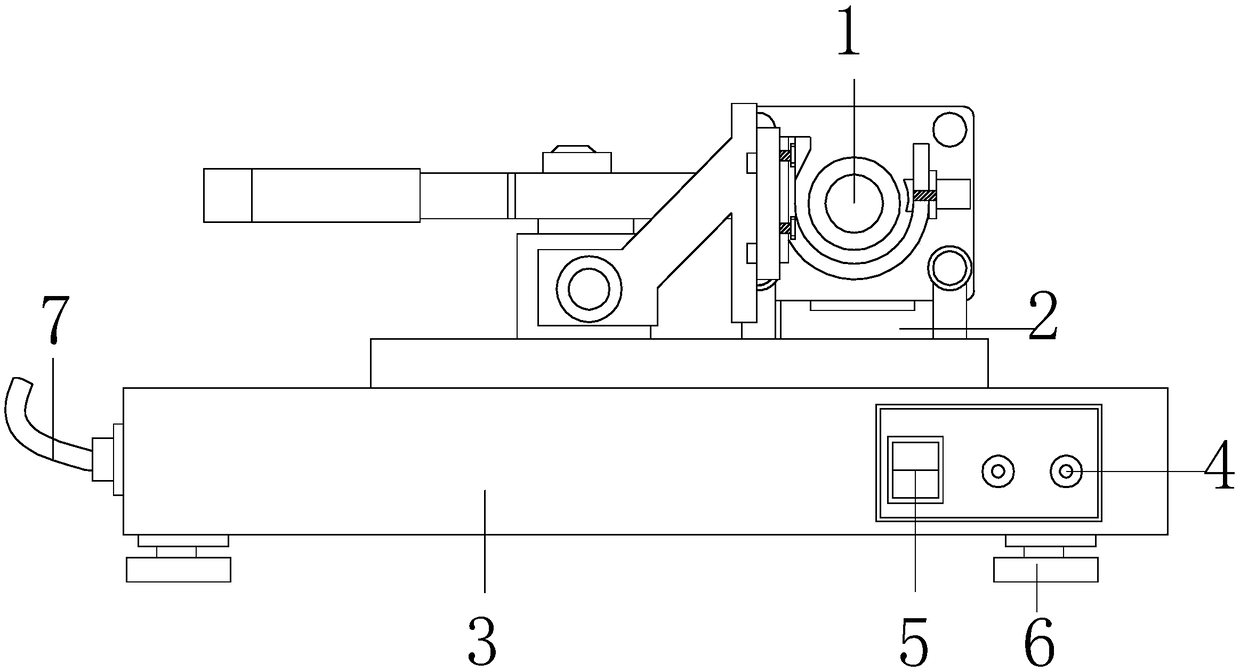

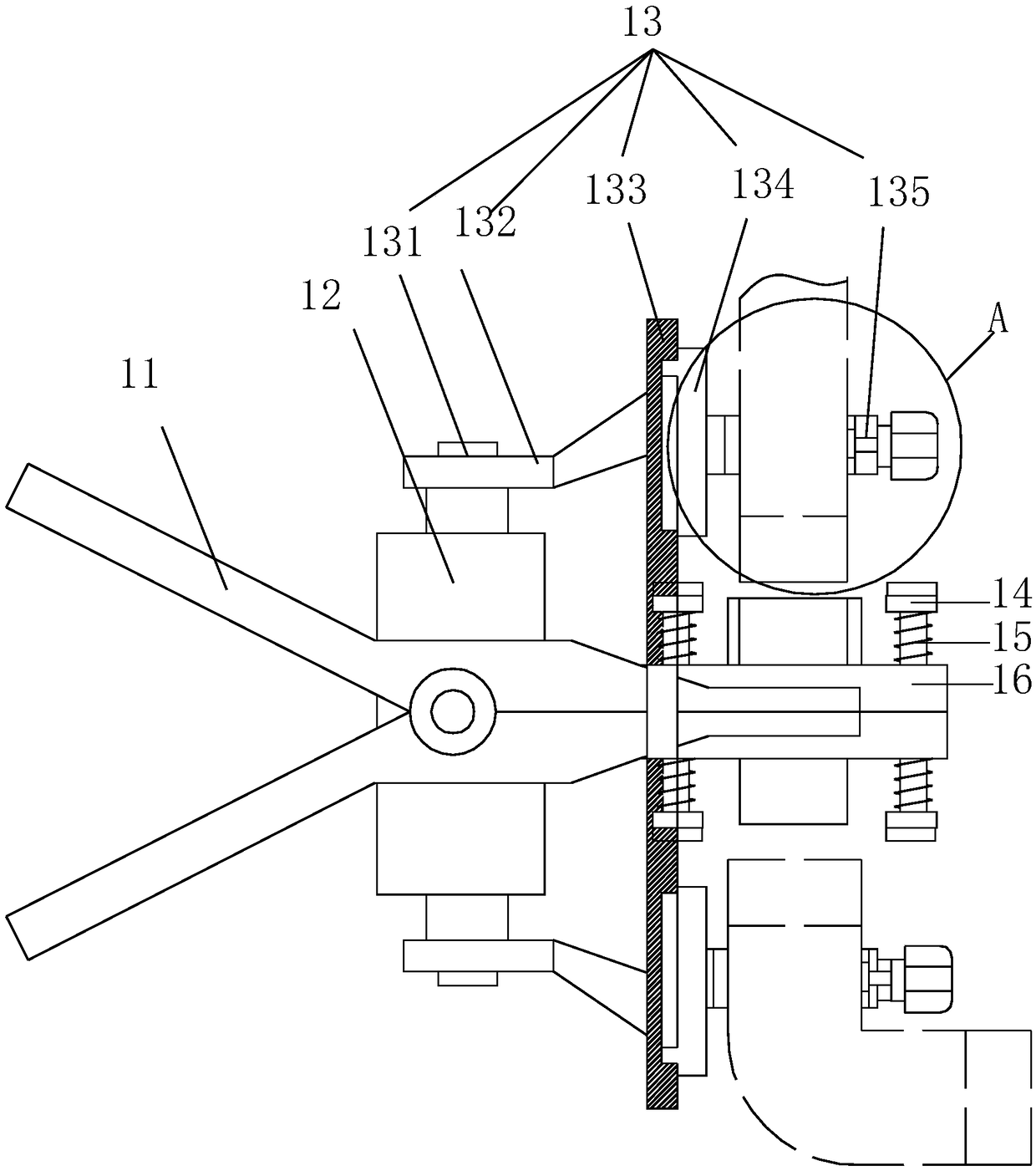

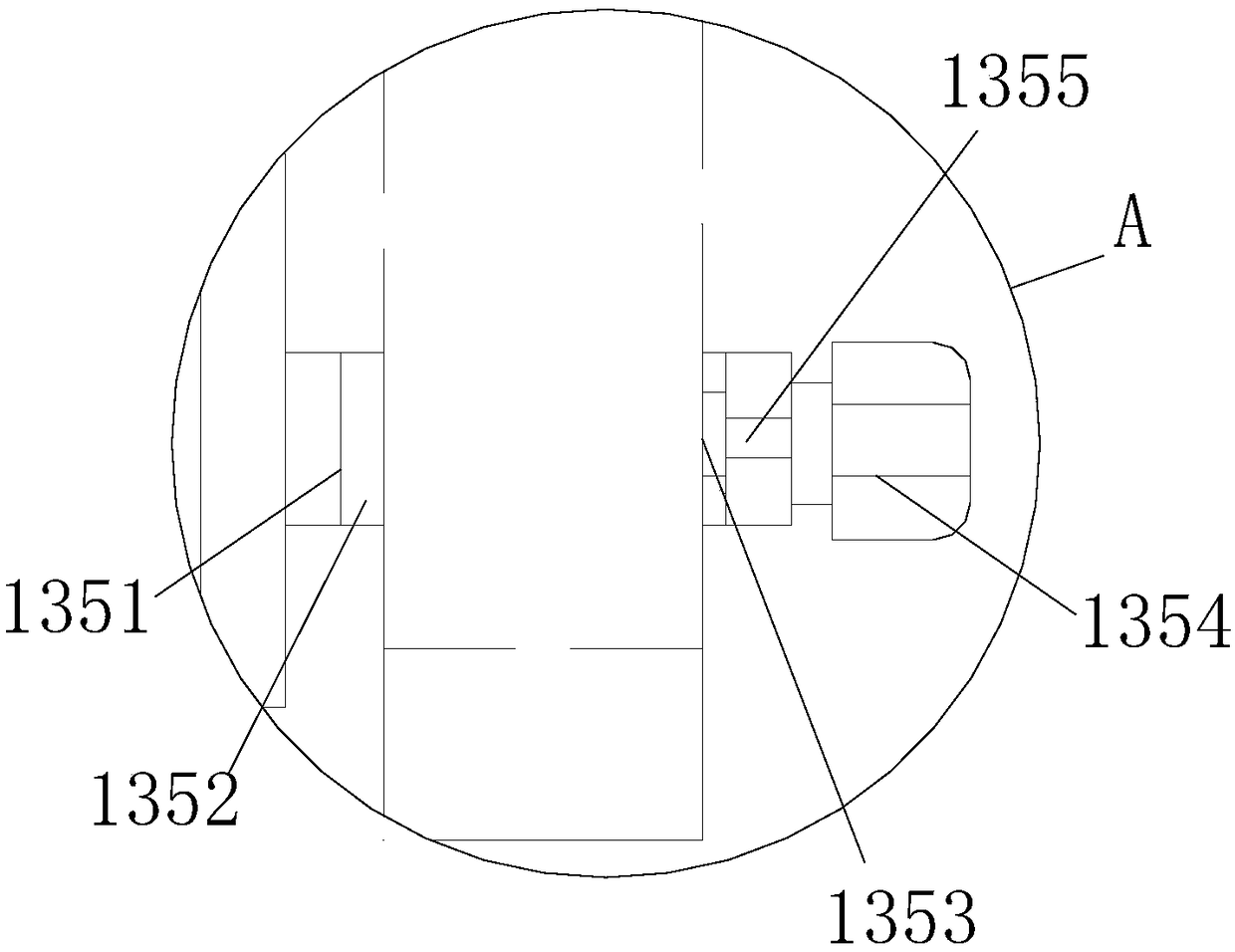

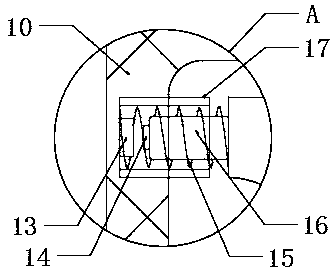

Automatic nip machine for roof plate

The invention provides a roofing plate automatic nip machine, which belongs to the technical field of manufacturing the building material forming equipment. The machine mainly comprises a motor(1) provided with a chain wheel(2), a connecting rod(17) arranged on the upper part of the motor(1) and provided with a grab bar(16), a handle(18) arranged on the top part of the connecting rod(17) and provided with an electric switch(19), an angle wheel(14) and a guide wheel(15) which are arranged on the lower part of the motor(1), a transmission worm shaft(3) connected with the chain wheel(2), four sets of locking forming mechanisms arranged on both sides of the transmission worm shaft(3) and the like, wherein each set of locking forming mechanism comprises two worm wheels meshed with the transmission worm shaft(3), moving wheels(6, 7, 8 and 9) and fixing wheels(10, 11, 12 and 13), both of which are arranged on the bottom parts of the two driving shafts(5) respectively. The machine has the advantages of reasonable and compact design, low manufacturing cost, stable performance, convenient use and high working efficiency, and can effectively improve locking effect and finished product quality.

Owner:孙国飞

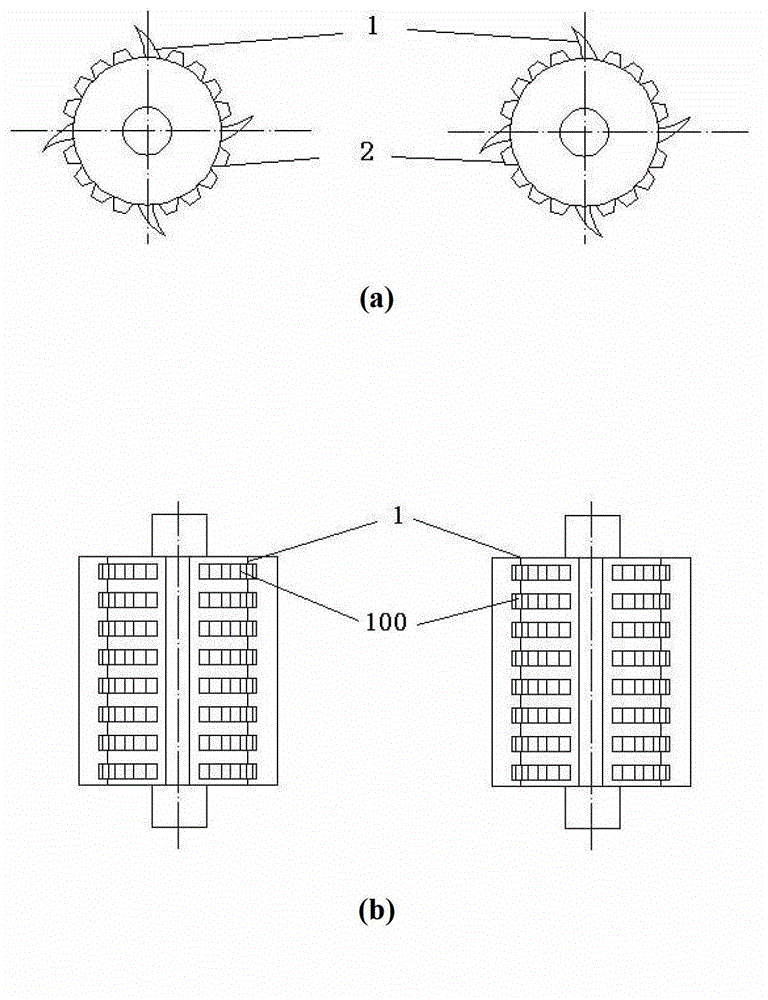

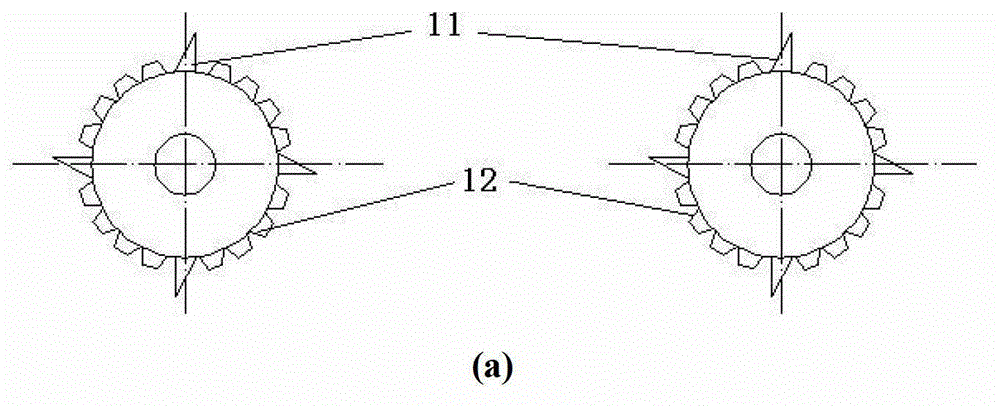

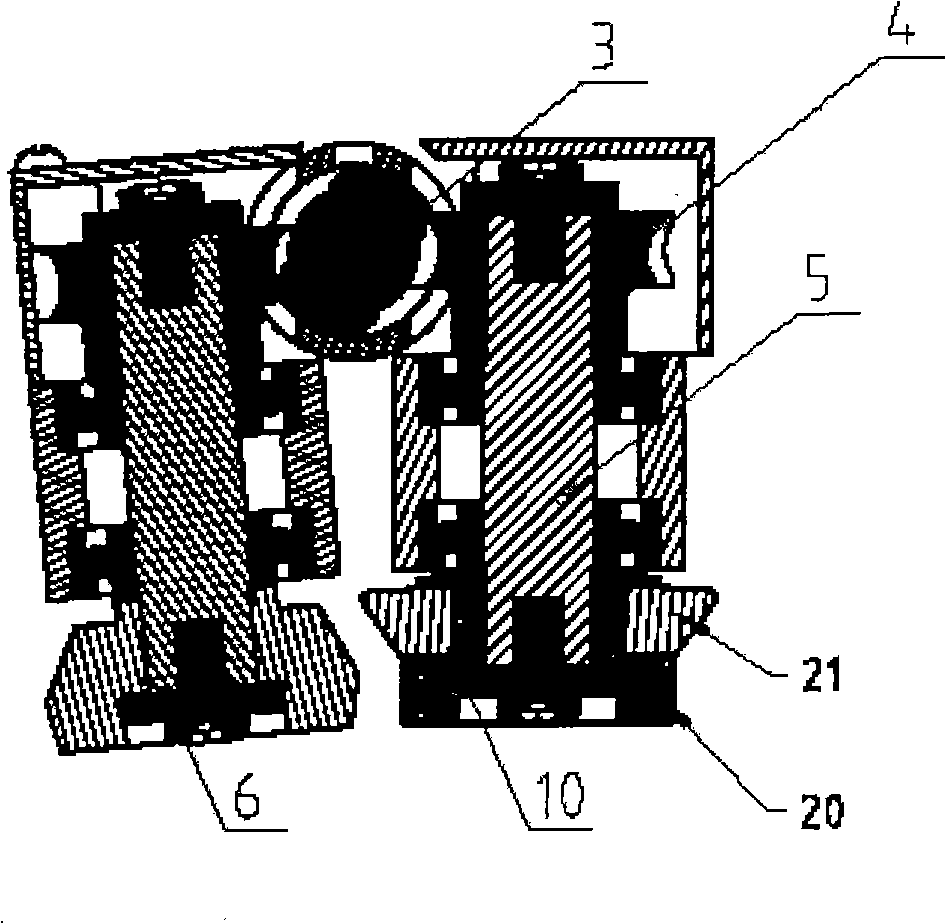

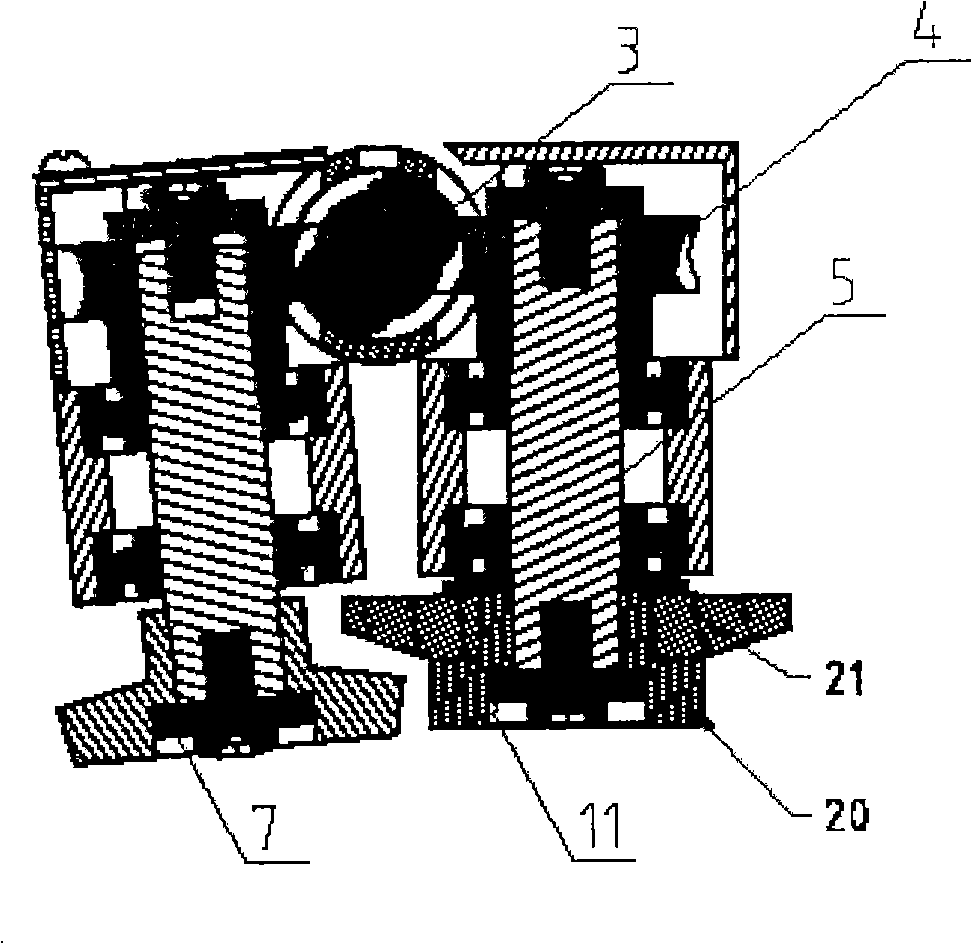

Squeezing-adjustable crushing device

The invention provides a squeezing-adjustable crushing device and relates to the field of crushing devices. The squeezing-adjustable crushing device comprises a machine shell, crushing rollers and a squeezing mechanism, wherein the crushing rollers are rotatably mounted in the machine shell; the squeezing mechanism comprises squeezing rollers and a squeezing driving structure; the squeezing rollers are arranged on the feeding side of the crushing rollers in parallel at intervals; and the squeezing driving structure is in transmission connection with the squeezing rollers. The device also comprises a squeezing adjusting bracket movably installed on the machine shell, the squeezing rollers are rotationally installed on the squeezing adjusting bracket, and an adjustable squeezing roller gap is formed between the squeezing rollers. A material enters the machine shell and is extruded and righted through the squeezing roller gap of the squeezing rollers; after the material is subjected to preliminary extrusion, the material enters the subsequent crushing rollers to be crushed; and the extruded material is easier to enter a crushing roller gap between the crushing rollers, and the material biting effect of the crushing rollers is effectively improved. The squeezing rollers rotate opposite to each other to achieve extrusion in the squeezing process, the continuity of squeezing is ensured, and the crushing effect of a whole machine is better.

Owner:GUANGZHOU 3E MACHINERY

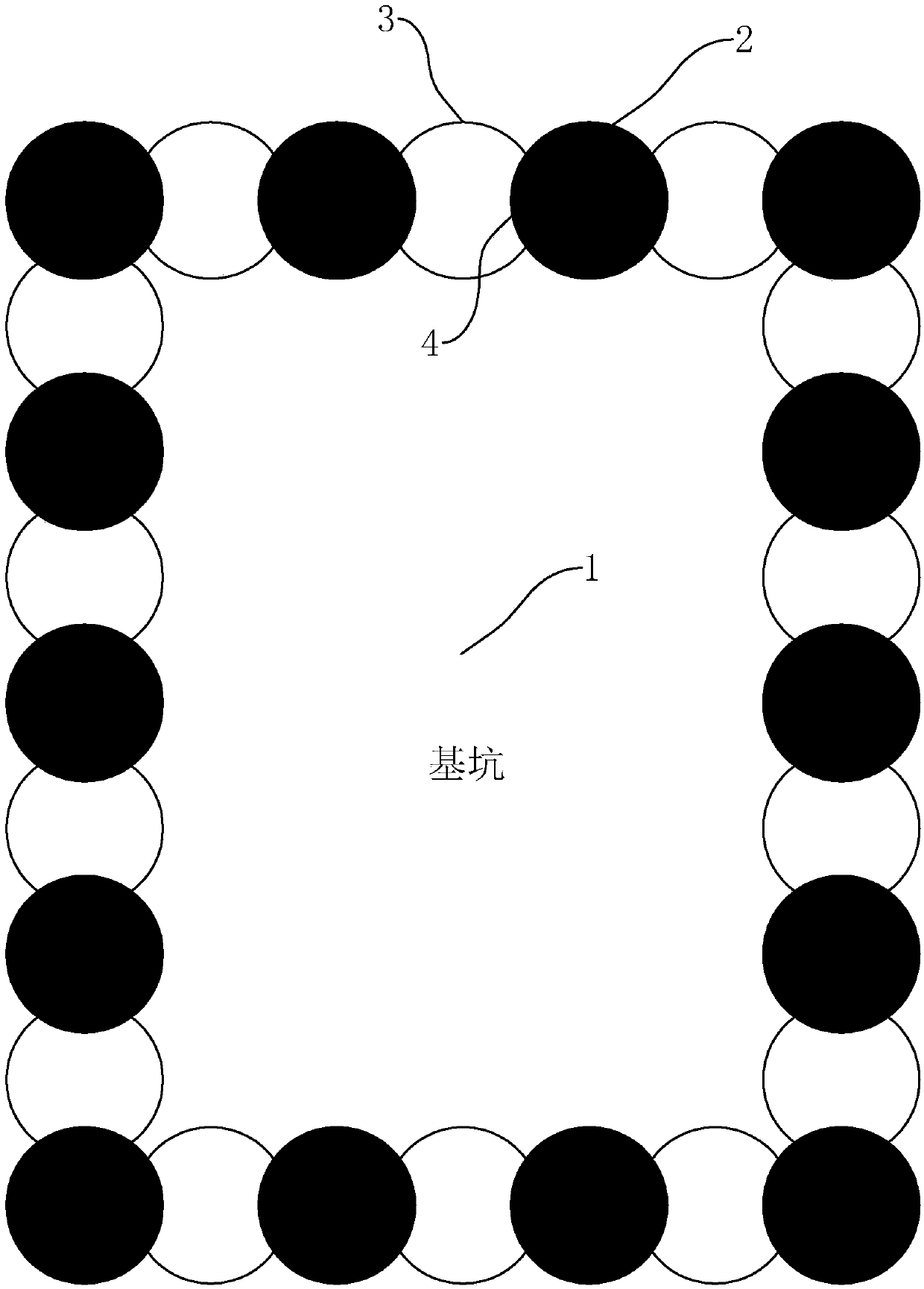

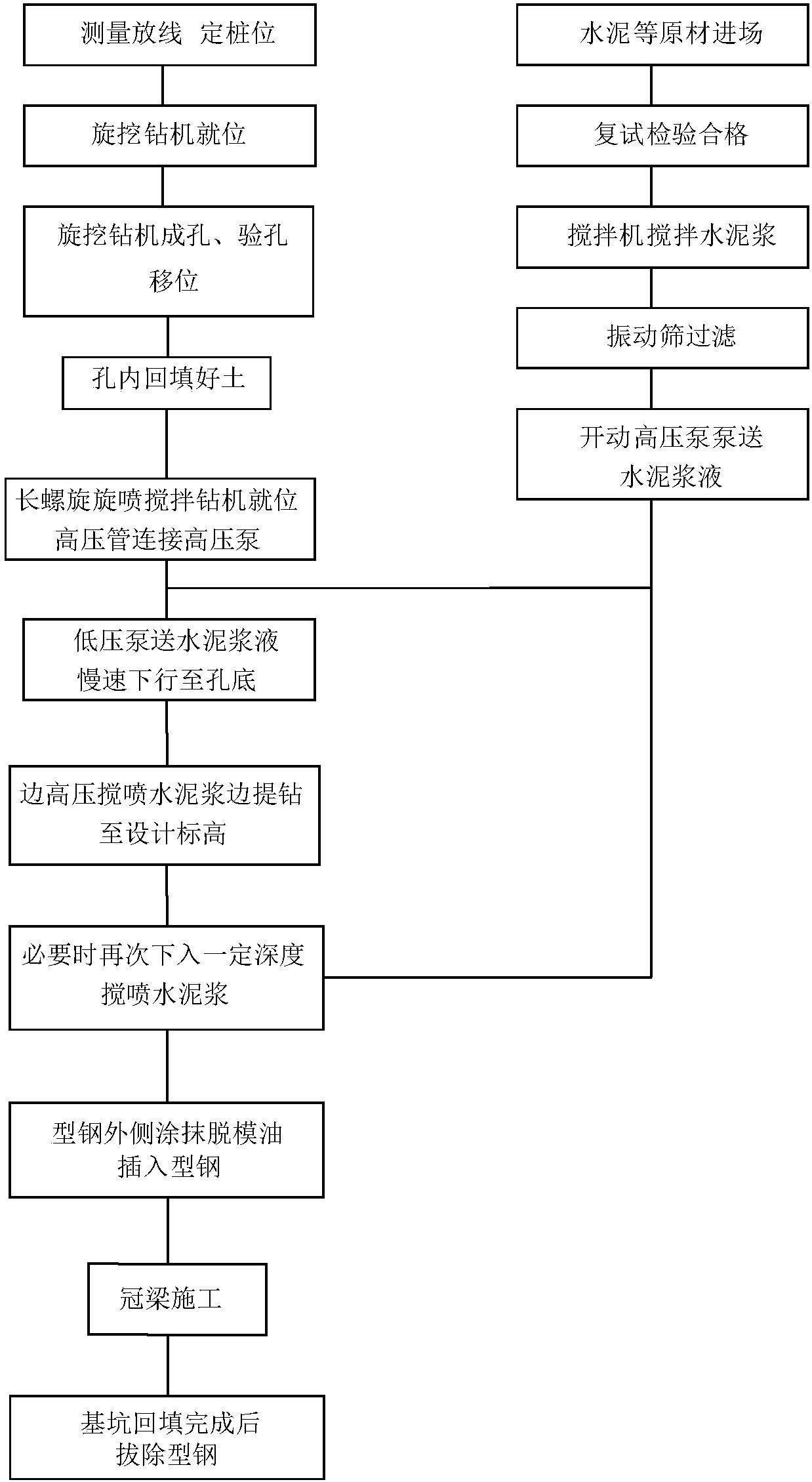

Construction method of profile steel and mixing-jetted cement soil curtain support pile

InactiveCN107700508AImprove reliabilityMinimize Disturbance and DisruptionExcavationsBulkheads/pilesEngineeringWaterstop

The invention discloses a construction method of a profile steel and mixing-jetted cement soil curtain support pile. According to key points of the technical scheme, the construction method comprisesthe following construction steps that survey and setting out are performed; a rotary drilling rig is arranged in place; drilling is performed; holes are filled with soil, and slurry is mixed outside the holes; a long auger rotary-jetting stirring drilling jig is arranged in place; cement soil pile mixing-jetting construction is performed; profile steel is inserted into piles; top beam constructionis performed; and the profile steel is pulled out. The method is applicable to construction on hard pan and gravel layers; the support pile after construction is completed achieves the combined effect of water stopping and supporting, and the inserted profile steel can be recycled, so that sources are saved, and the environment is protected; and the mixing-jetted support pile is independent of undisturbed soil, and is good in pile forming quality.

Owner:北京建材地质工程有限公司 +2

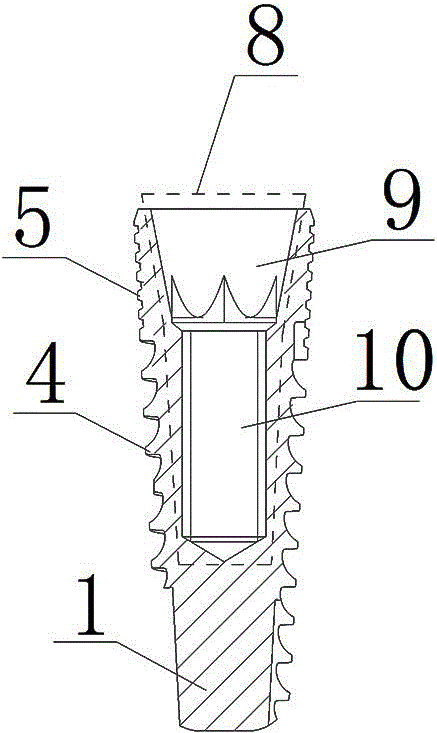

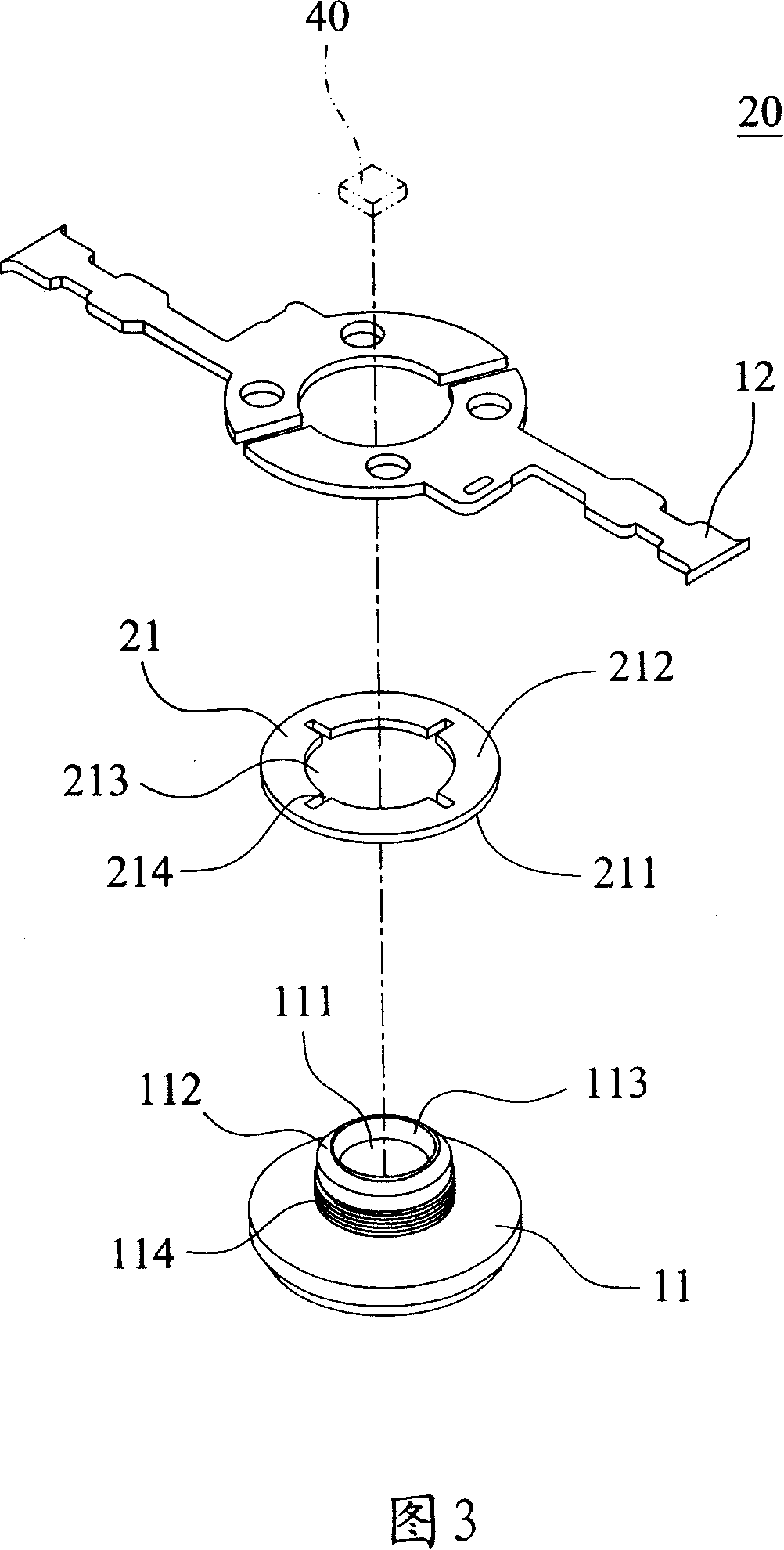

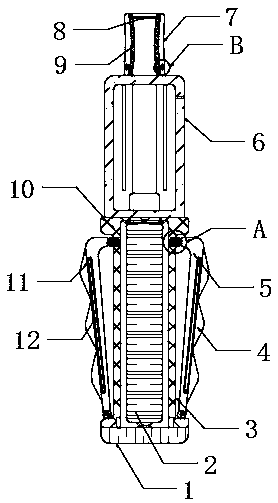

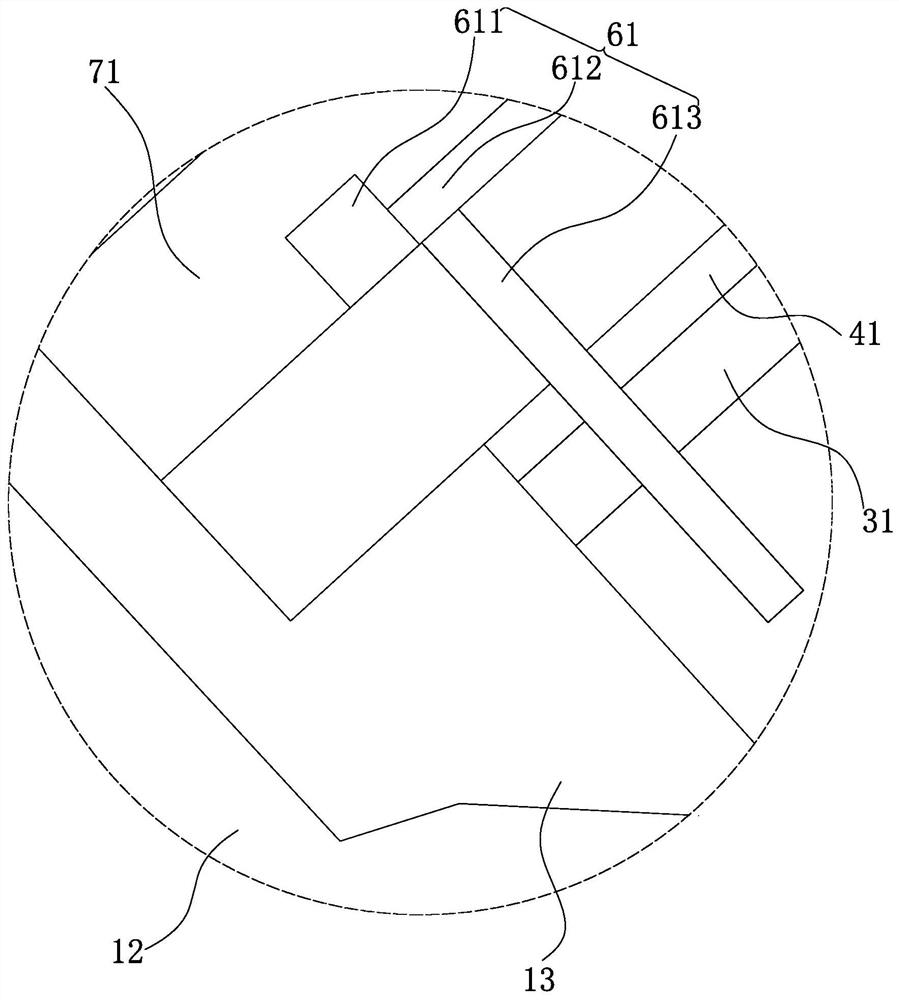

Novel dental implant system

The invention discloses a novel dental implant system. The system comprises a dental implant body, a dentalcrown abutment and a center screw, wherein the dental implant body is divided into an upper part, a middle part and a lower part from top to bottom, screw threads A are formed in outer surfaces of the middle part and the lower part of the dental implant body, a screw thread B is formed in the outer surface of the upper part of the dental implant body, and an inner cavity A is formed in the dental implant body; the dental crown abutment is arranged above the dental implant body and is inserted into the inner cavity A, and an inner cavity B is formed in the dental crown abutment; and the dental implant body and the dental crown abutment are fixedly connected by virtue of the center screw, and the center screw is positioned in the inner cavity A and the inner cavity B. The novel dental implant system has the beneficial effects of simple structure and firm connection, and can be used for reducing adverse influence onsurrounding normal teeth, reducing operation steps and preventing destruction of mandibular alveolar nerves and bacterial invasion.

Owner:CHENGDU BESMILE BIOTECH

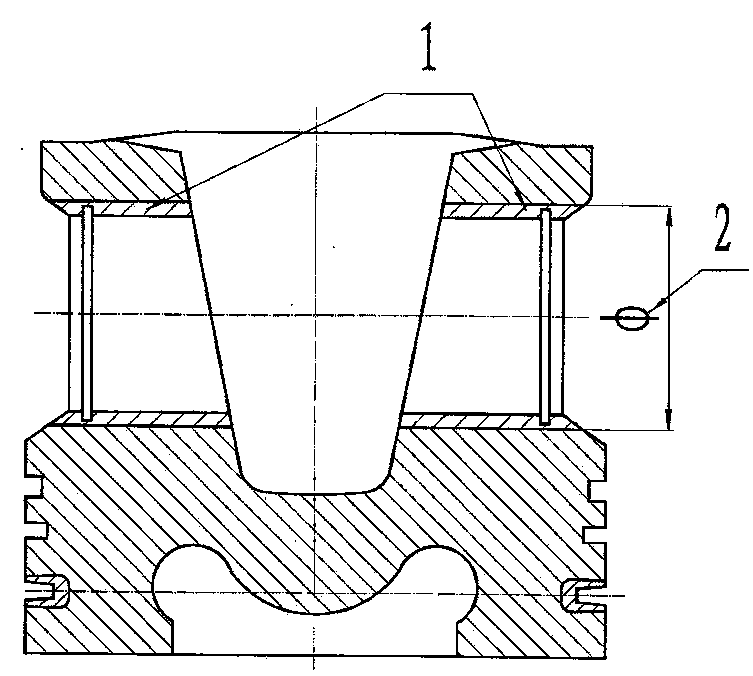

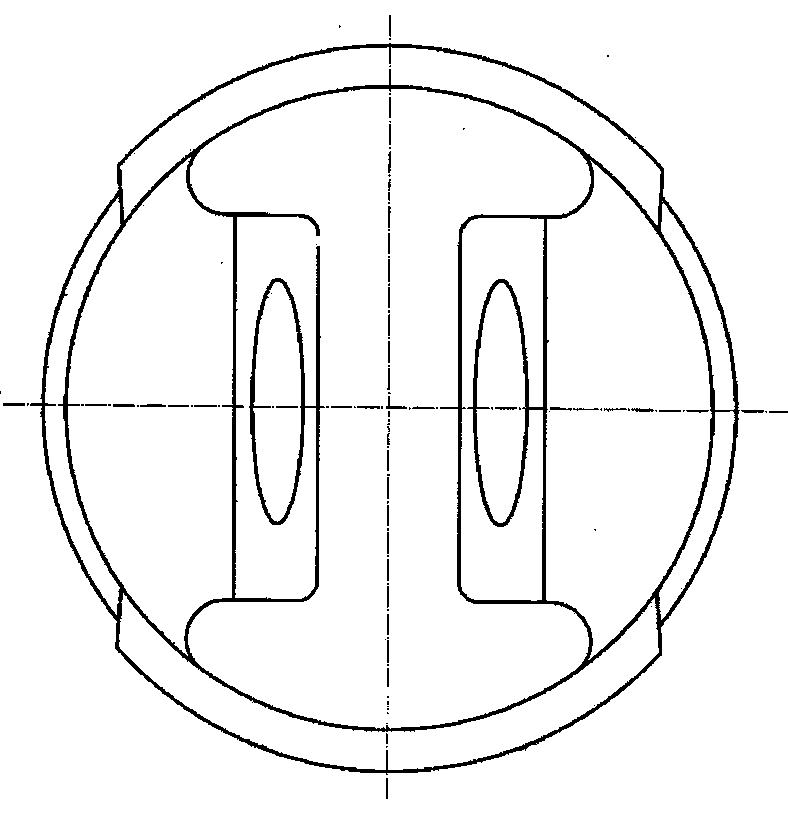

Method for casting copper sleeve and piston into whole

The invention discloses a method for casting a copper sleeve and a piston into a whole. The copper sleeve and the piston are cast into a whole by adopting an extrusion casting technology. Firstly, a mold is installed on an extruder in the extrusion process of the piston, the processed copper sleeve semi-finished product is arranged on a pin hole shaft of a piston extrusion model; aluminum melt is fully cast into a cavity, and extruded and cast, so that the copper sleeve semi-finished product and the piston are cast into a whole. The method comprises the following steps: 1, processing the copper sleeve semi-finished product according to a piston product drawing; 2, cleaning the copper sleeve semi-finished product, putting the cleaned copper sleeve semi-finished product into an electric furnace, preheating the copper sleeve semi-finished product, installing the copper sleeve semi-finished product on the pin hole shaft of a piston model, casting the aluminum melt into a piston cavity, and extruding and casting at the specific pressure of over 90Mpa; 3, carrying out heat treatment and machining on a piston product cast with the copper sleeve, and checking out to form the product. The piston produced by the method does not affect the matching precision of the piston and the cylinder due to the copper sleeve in operation of an engine, and the copper sleeve and a pin boss hole of the piston are tightly combined, and firm and reliable.

Owner:BINZHOU DONGHAILONG PISTON

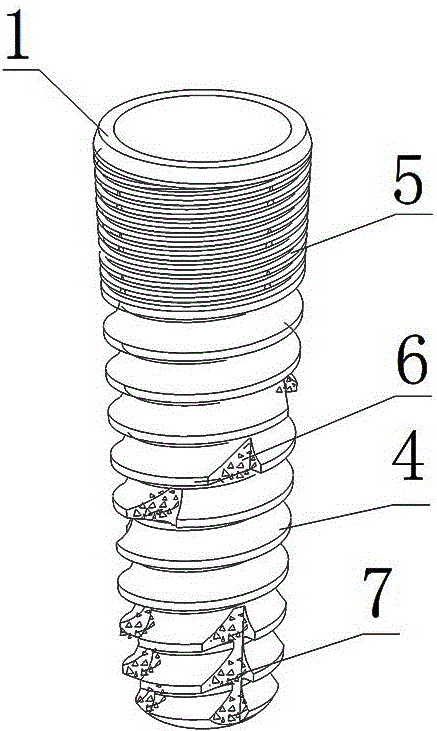

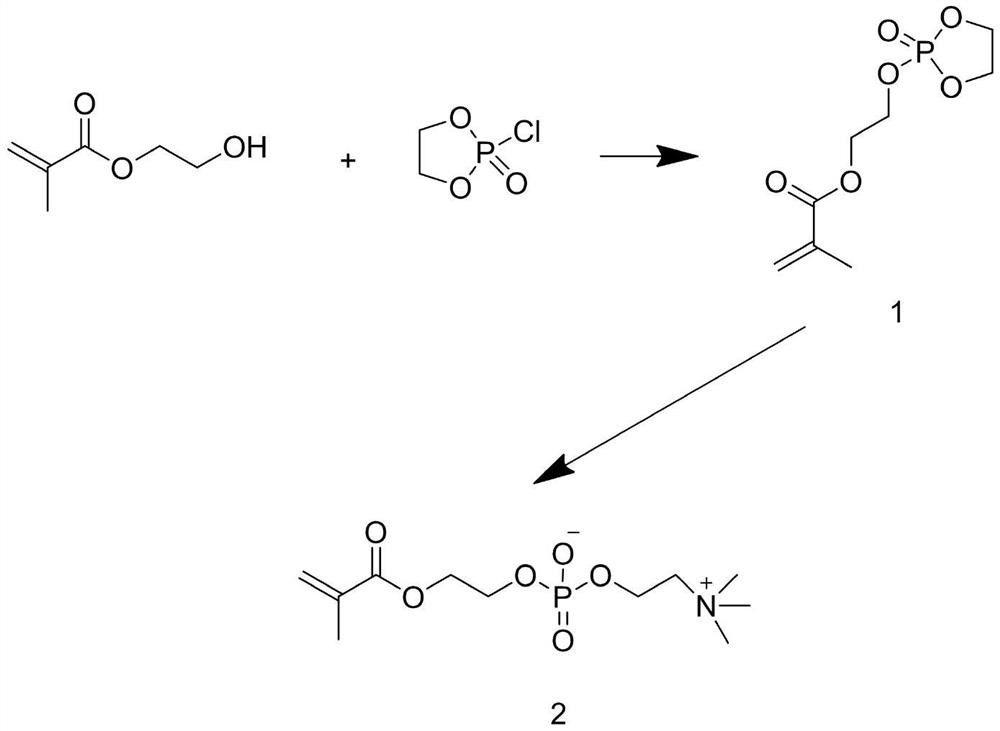

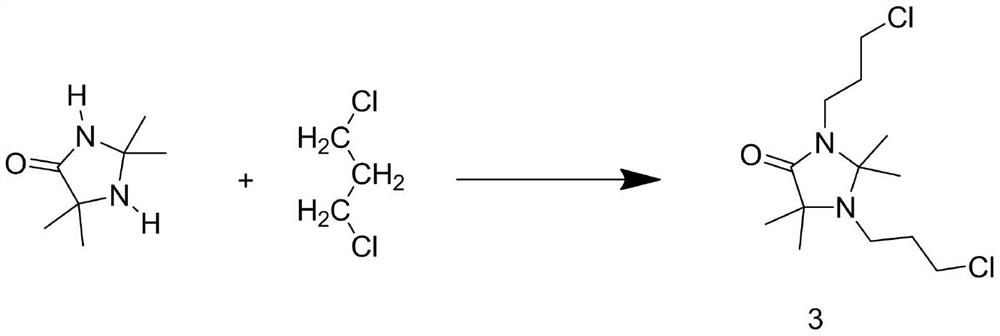

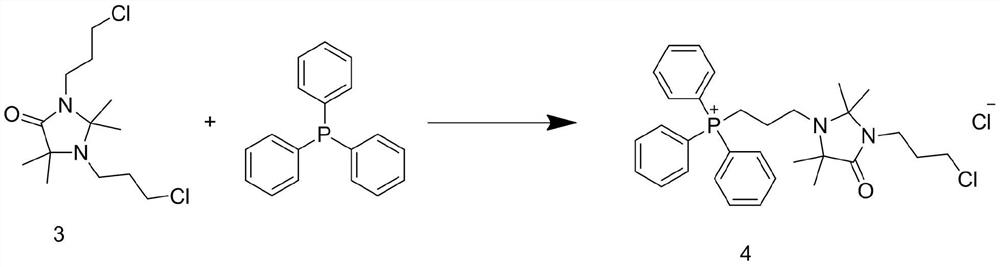

Dental implant with hydrophilic and antibacterial properties

ActiveCN113197690AInhibition of reproductionIncrease contact areaDental implantsDental prostheticsMethacrylatePhosphorylcholine

The invention discloses a dental implant with hydrophilic and antibacterial properties, which comprises a titanium base material and an antibacterial coating, belongs to the technical field of dental implant materials, and aims to solve the problem that the hydrophilicity and antibacterial property of the dental implant still need to be improved. The preparation method comprises the following steps: ultrasonically cleaning a titanium substrate with acetone, absolute ethyl alcohol and deionized water in sequence, drying, carrying out anodic oxidation treatment and calcining, and coating the surface of the titanium substrate with an antibacterial coating to obtain the dental implant with hydrophilic and antibacterial properties. The antibacterial coating disclosed by the invention comprises a polymer and Ag-ZnO nanoparticles, the polymer is a polymer formed by copolymerizing phosphorylcholine lipids, polyacrylic acid, methoxy polyvinyl ether and trimethoxysilyl propyl methacrylate, and the phosphorylcholine lipids belong to zwitterionic lipids, so that the coating is endowed with biocompatibility and has bionic performance; the Ag-ZnO nano particles are more easily accepted by organisms, and the Ag-ZnO nano particles have excellent antibacterial performance.

Owner:山东恒泰医疗器械有限公司

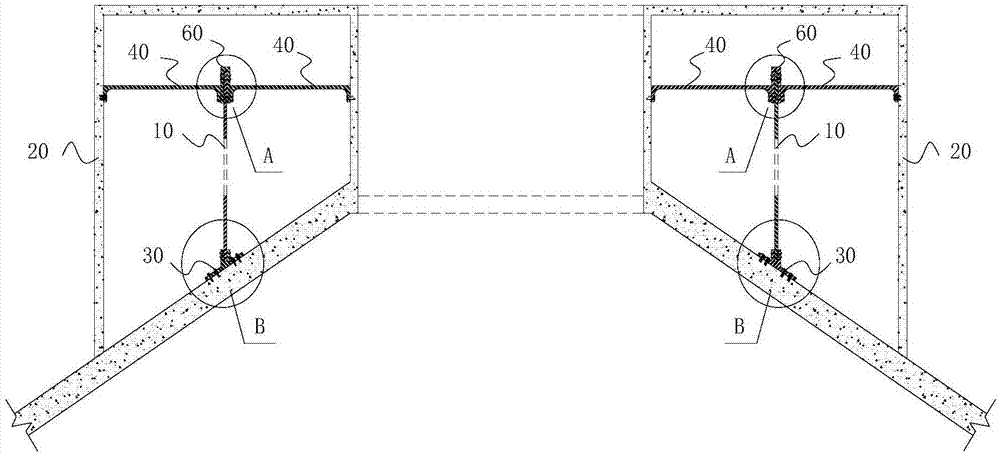

Open caisson non-drainage sinking construction method

The invention relates to an open caisson non-drainage sinking construction method. The method comprises the following steps that S1, water jetting pipes are arranged around an open caisson, high-pressure water is sprayed on a soil body around the open caisson, and the soil body in the side wall area of the open caisson is cut and softened; S2, high-pressure water is sprayed into the open caisson so that the high-pressure water punches a soil body at the bottom of the open caisson, the bottom of the open caisson is punched into a pot bottom shape with a concave center, the soil body and the water are mixed to form slurry, then the slurry is pumped out of the open caisson, and the open caisson squeezes soil and sinks at the positions of blade feet; S3, every time the open caisson sinks by acertain distance, high-pressure water spraying is conducted on a soil body in a newly-sinking area of the open caisson through the water jetting pipes in a segmented water injection mode; S4, after the open caisson sinks to the designed position, grouting is conducted on a soil body outside the open caisson in a retreating type segmented grouting mode through the water jetting pipes, and the soilbody outside the open caisson is reinforced; and S5, concrete bottom sealing is conducted on the bottom of the open caisson. According to the open caisson non-drainage sinking construction method, theproblems of inclination, sudden sinking and water gushing during sinking of the open caisson can be reduced.

Owner:BEIJING NO 2 MUNICIPAL CONSTR ENG LTD

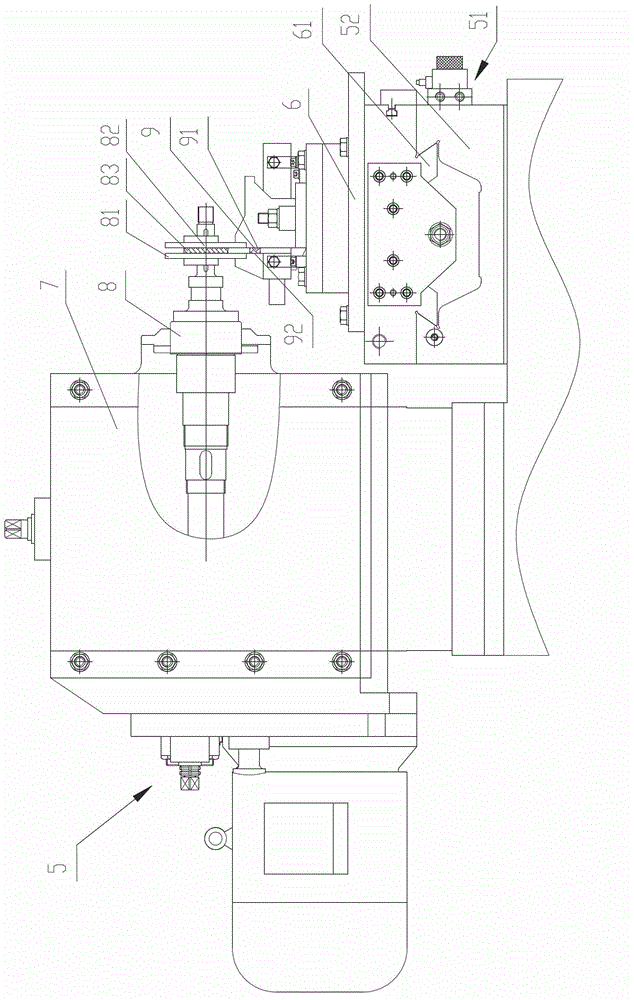

Coiled tubing external cutting and fishing integrated device

PendingCN109138891AAchieve reductionRealize the integration of salvageDrilling rodsDrilling casingsCoiled tubingHydraulic pump

The invention discloses a coiled tubing external cutting and fishing integrated device, which includes a barrel body. The inner side of the barrel body is successively provided with a clamping mechanism, a boosting mechanism and a cutting mechanism. The clamping mechanism comprises a sliding block slip and a trapezoidal taper groove, the boosting mechanism includes a hydraulic boosting piston, a trapezoidal groove and a limiting groove, the position of the trapezoidal groove corresponds to the trapezoidal taper groove, the limiting groove limits an up-down moving stroke of the hydraulic boosting piston, and a piston reset structure is arranged between the hydraulic boosting piston and the limiting groove; the cutting mechanism comprises a plurality of blade chambers arranged in the circumferential direction of the barrel body, the blade chambers are internally provided with blades through a pin shaft, and the blade chambers are further internally provided with blade reset structures; and the end, facing toward the blades, of the hydraulic boost piston is provided with a guiding inner cone face. According to the coiled tubing external cutting and fishing integrated device, cutting and fishing are completed through an up-lifting and down-placing operation with a hydraulic pump, integration of cutting and fishing from the outer side of a coiled tubing is realized, the processing progress of stuck tubing is accelerated, the risk of oil-gas well abandonment is lowered, the structure is simple, and control is reliable.

Owner:中国石油集团川庆钻探工程有限公司川东钻探公司

Assembly type breakwater protective block body

InactiveCN106436647AImprove bite abilityMake fastCoastlines protectionCement boardArchitectural engineering

The invention discloses an assembly type breakwater protective block body. The assembly type breakwater protective block body is of an assembly type structure. The assembly type breakwater protective block body is of a hollow square frame structure formed by splicing two cuboid cement boards with the middle hollowed-out parts of the same specifications and four cuboid cement columns of the same specifications. A precast upper ring beam is a square frame. The four sides of the precast upper ring beam are provided with first safety limiting grooves. A reserved steel dowel hole is reserved in the center of each first safety limiting groove. The stand columns are arranged under the first safety limiting grooves. A precast lower ring beam is arranged below the stand columns. Tail-end threaded anchor rods penetrate through corresponding steel dowel reserved holes, corresponding column center reserved holes and the corresponding reserved steel dowel holes in sequence to fix the whole center control protective block. The assembly type breakwater protective block body has the advantages that construction waste recycled aggregates are adopted and are friendly to environment; industrialized production of the assembly type structure is realized, less manpower and material resources are consumed, and construction is simple and fast; the assembly type breakwater protective block body is low in self-weight, convenient transport and high in safety, and cannot cause chain destruction; and the assembly type breakwater protective block body is flexible and changeable in use and can be used in cooperation with existing protective block bodies.

Owner:NANCHANG UNIV

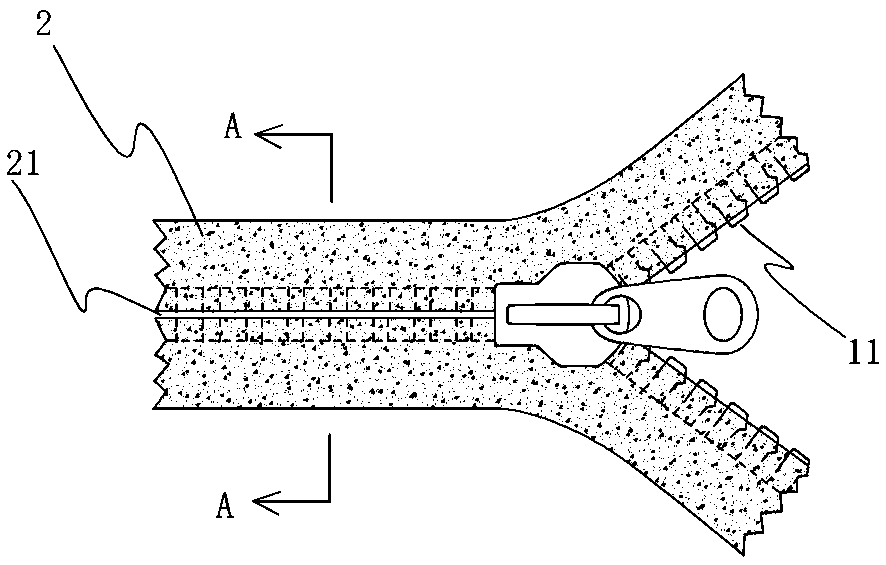

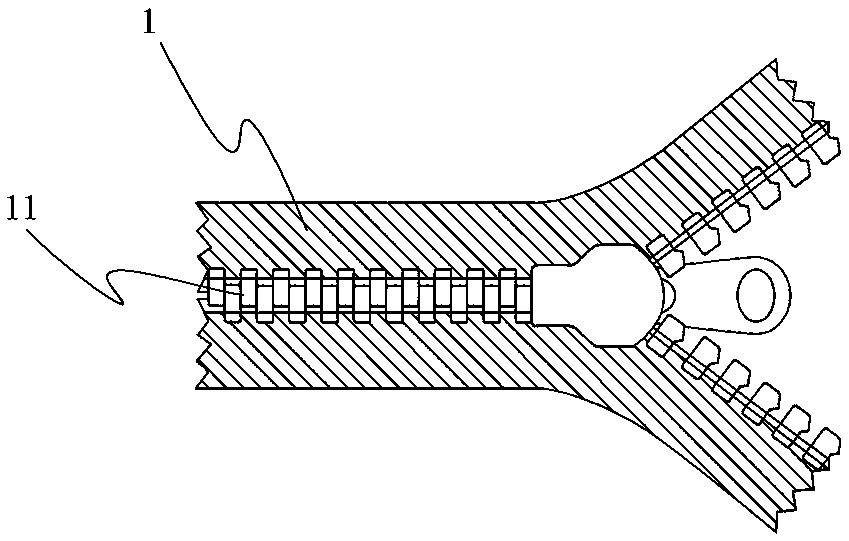

Micro-prism monomer reflective waterproof zipper and manufacturing method thereof

PendingCN108783769AReflective and waterproofSimple structureSlide fastenersOptical elementsResin embeddingPrism

The invention relates to a zipper, and provides a micro-prism monomer reflective waterproof zipper and a manufacturing method thereof. The micro-prism monomer reflective waterproof zipper has reflective and waterproof function, effectively simplifies product structure and product manufacturing process, effectively improves product manufacturing efficiency, reduces production cost and is suitable for mass production. The zipper comprises a zipper body. The zipper body is provided with chains that can mesh and separate each other and a reflective waterproof film, the reflective waterproof film is a transparent film made of hot melt gum resin embedded with micro-prism monomer, and the micro-prism monomer is a triangular pyramid tetrahedral structure formed by integrally molding a transparentresin. The three pyramid sides of the micro-prism monomer are respectively plated with a metal layer, and the pyramid bottom surface of the micro-prism monomer is not plated with the metal layer.

Owner:YEAGOOD INC

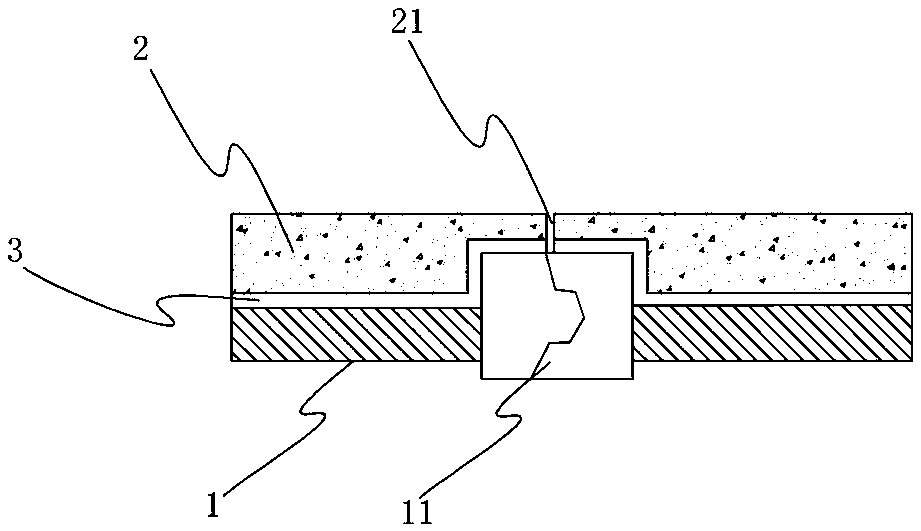

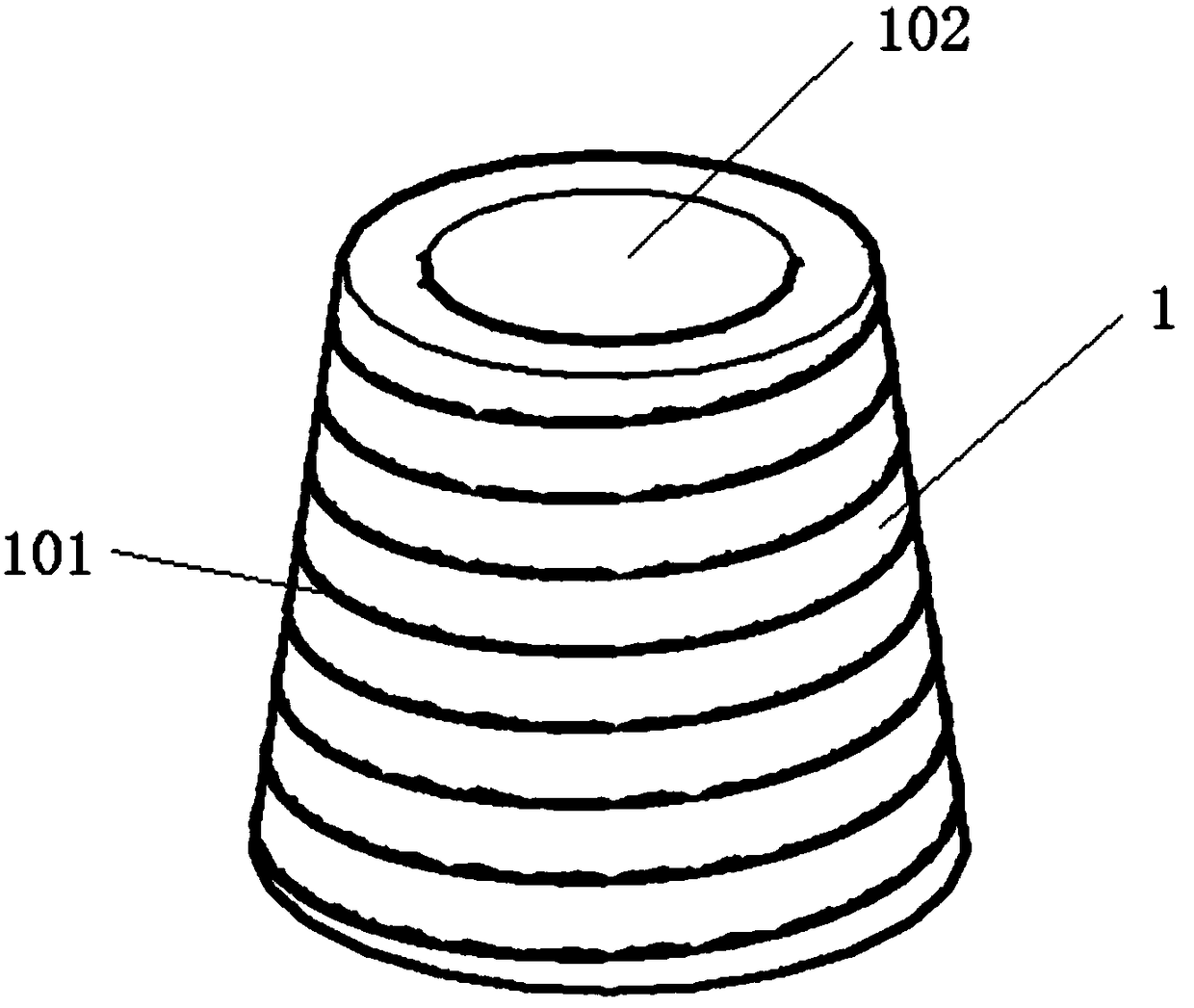

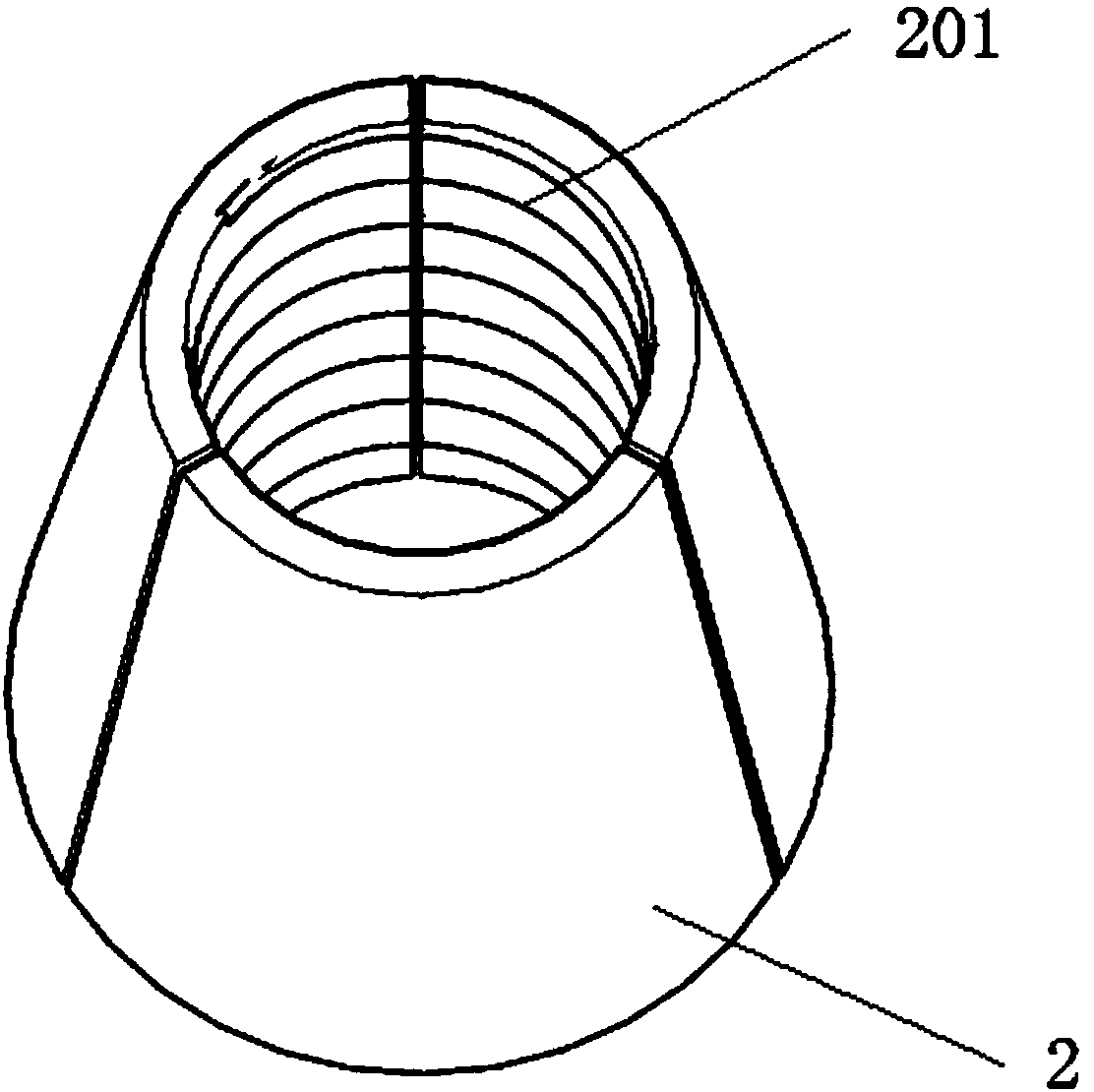

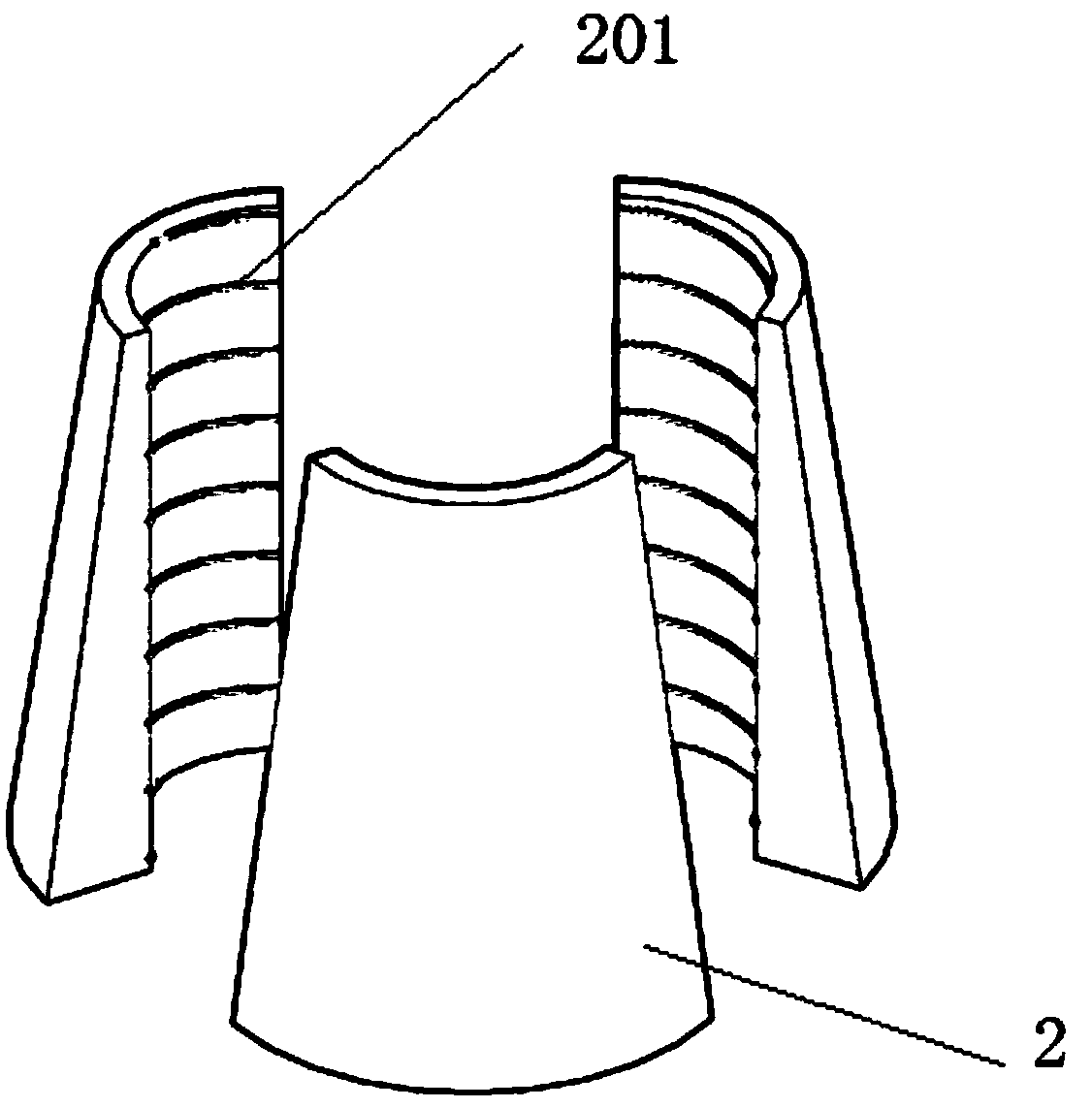

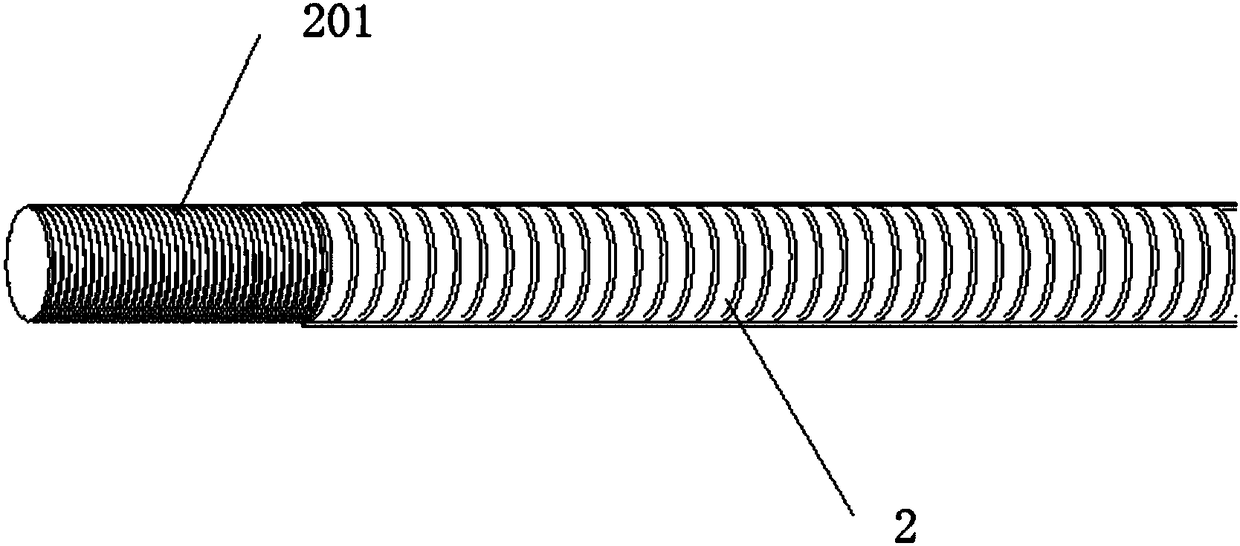

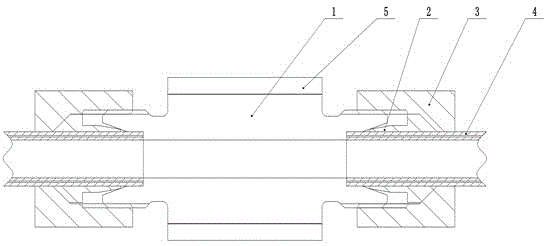

Wedge-shaped clamping piece anchor head of large-diameter high-strength steel bar for reinforced concrete beam column joint and application

PendingCN108331259AAvoid bending rebarReduce construction difficultyBuilding reinforcementsSteel barComplex problems

The invention belongs to the field of civil engineering, and specifically relates to a wedge-shaped clamping piece anchor head of a large-diameter high-strength steel bar for a reinforced concrete beam column joint and application. The wedge-shaped clamping piece anchor head of the large-diameter high-strength steel bar for the reinforced concrete beam column joint is characterized by comprising an anchor ring and three clamping pieces, wherein the anchor ring is in a cone frustum shape; a spiral anti-skid groove is formed in the outer part of the anchor ring; an inclined through hole is formed in the anchor ring; the three clamping pieces are in the same shape, and a wedge-shaped annular body is formed by the three clamping pieces; spiral grooves are formed in the clamping pieces; the three clamping pieces are wedged between the anchor ring and a beam steel bar of an assembly type concrete beam. According to the wedge-shaped clamping piece anchor head disclosed by the invention, the problems that the column section area in a multi-layer prefabricated concrete frame structure is small, the anchorage length of a steel bar cannot meet the requirements, the joint manufacturing cost ishigh, and the operation is complicated are solved.

Owner:SHENYANG JIANZHU UNIVERSITY

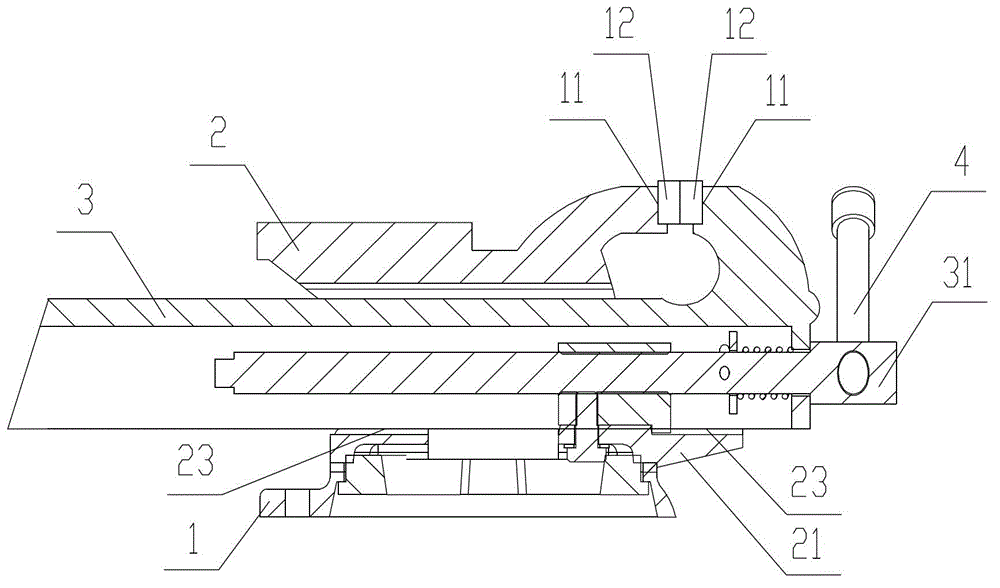

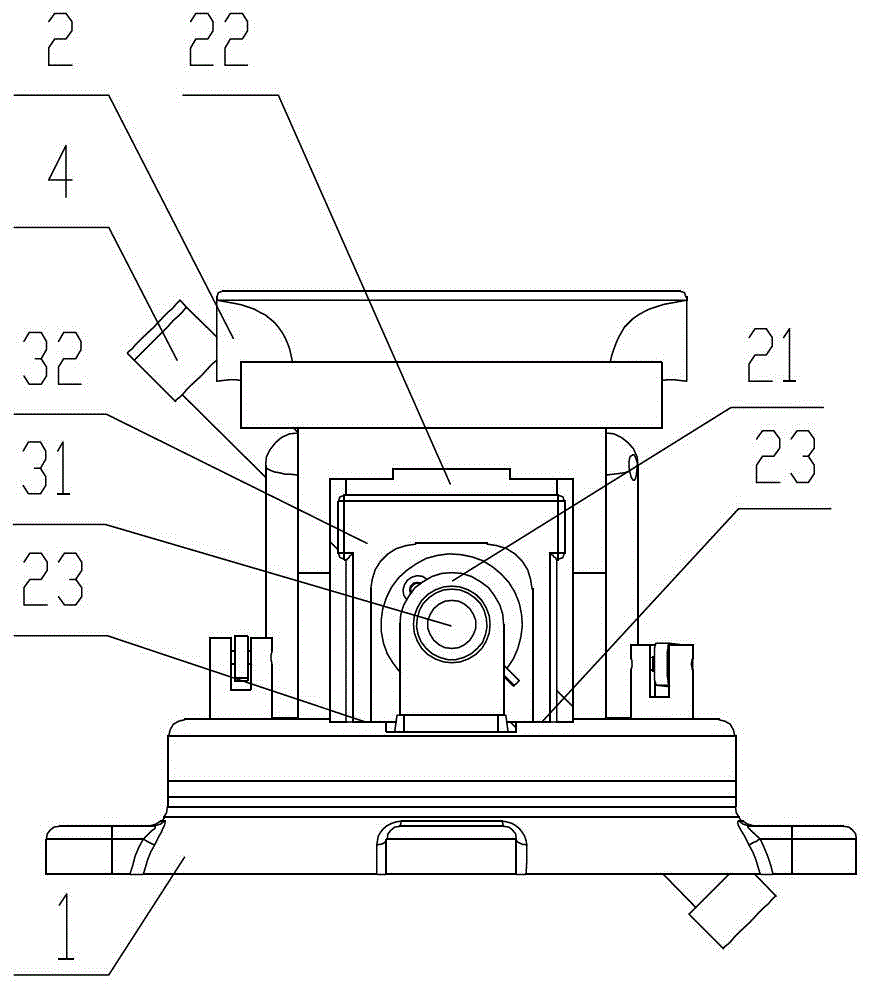

Machine tool for machining jaws of bench vices

InactiveCN102909416APrecise control of parallelismImprove bite abilityFeeding apparatusLarge fixed membersMilling cutterMachine tool

The invention relates to a machine tool for machining jaws of bench vices. The machine tool for machining jaws of bench vices comprises a tool body, a fixed installing seat, a feed mechanism, a stand column and a main shaft, wherein a cushion block is tightly clamped between a fixed vice body and a movable vice body, two end faces of the cushion block, respectively tightly pressed against the jaw end face of the fixed vice body and the jaw end face of the movable vice body, are parallel to each other, one end part of the main shaft can be fixed on the stand column in a rotating way, a first end-face milling tool, a second end-face milling tool and a cushion sleeve are coaxially fixed at the other end part of the main shaft, the second end-face milling tool is parallel to the first end-face milling tool, and the cushion sleeve is arranged between the first end-face milling tool and the second end-face milling tool. According to the invention, when a jaw of a bench vice is machined, the machining of jaw installing grooves is performed in the last step of bench vice machining, and two jaw installing grooves are completely machined once through a pair of parallel end-face milling tools, so that cumulative errors are avoided, and the parallelism of a pair of installing grooves is precisely controlled more easily, thereby improving the occlusion performance of bench vices in the process of clamping workpieces.

Owner:ZHANGJIAGANG YUCHENG MASCH C0 LTD

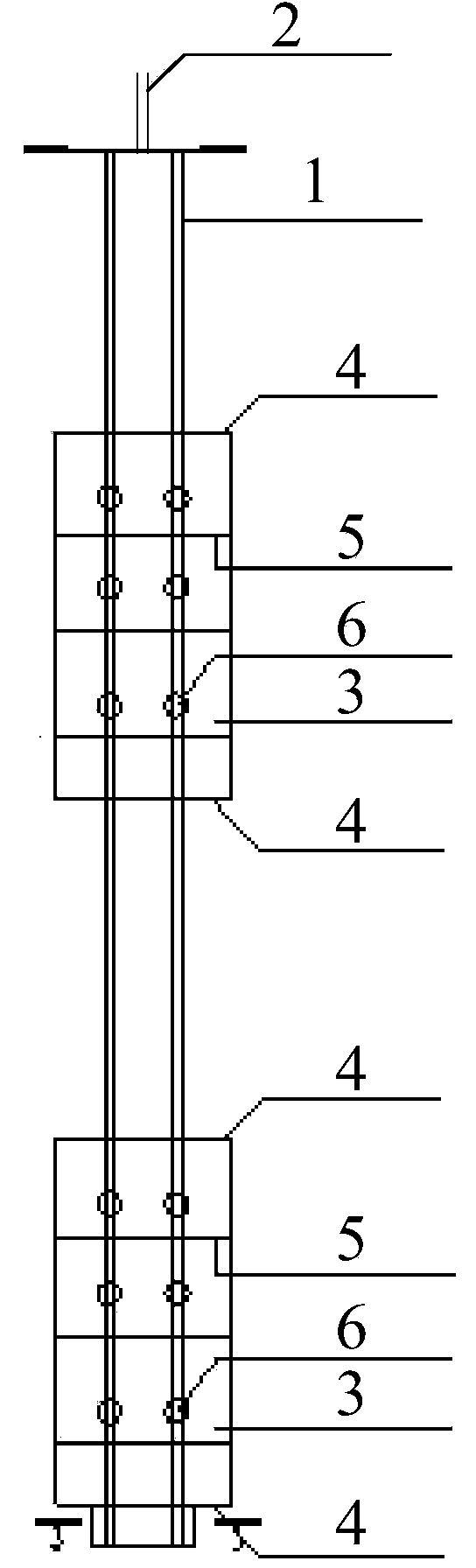

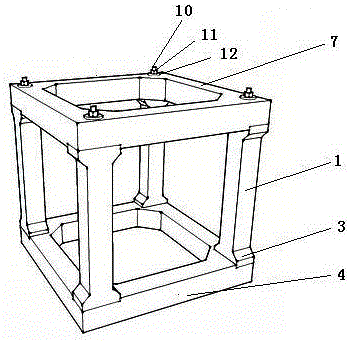

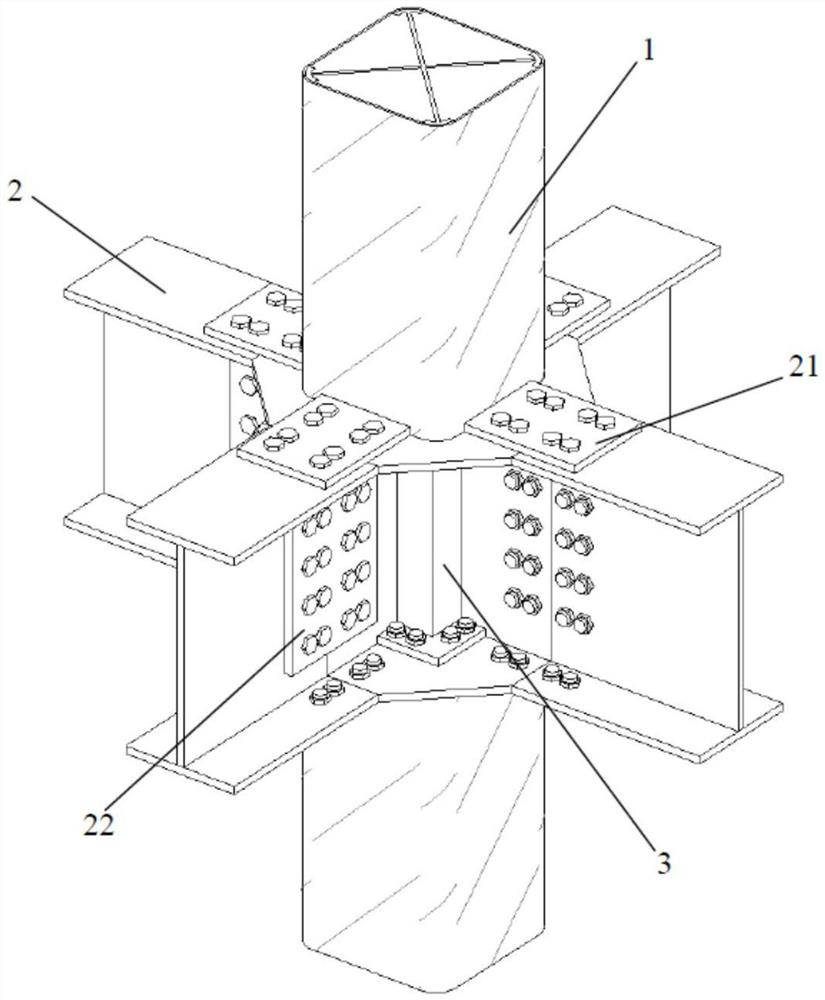

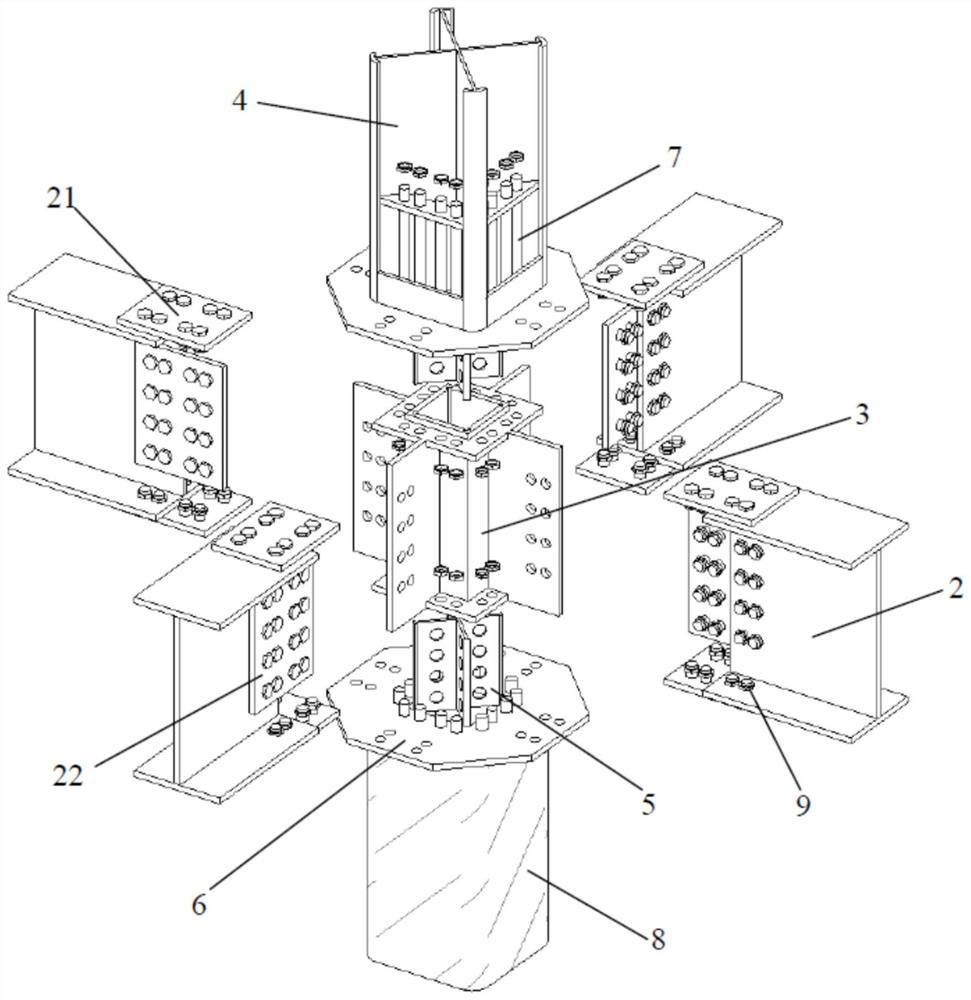

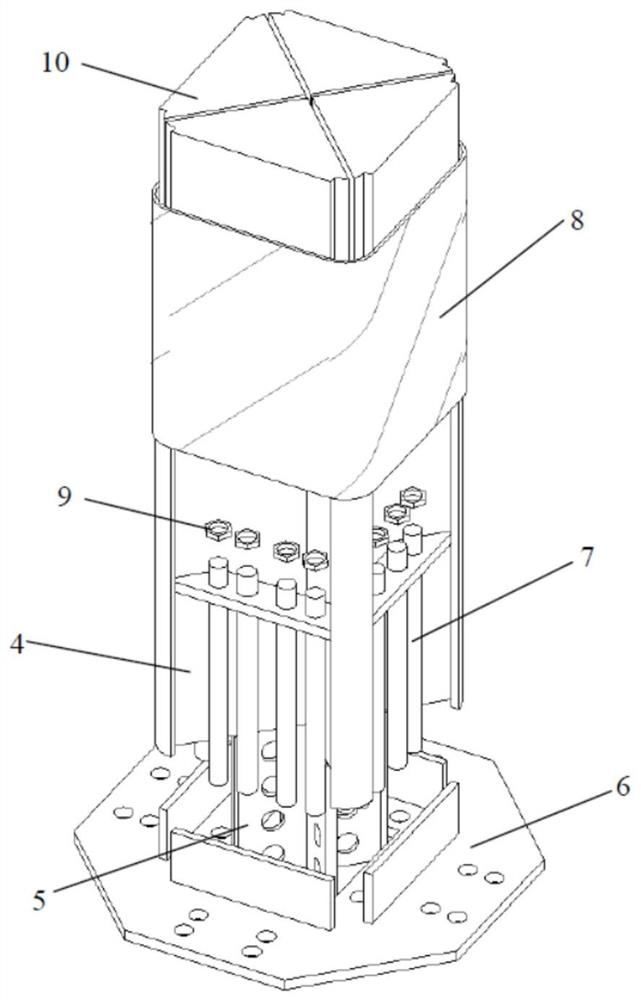

FRP externally-wrapped crossed steel reinforced concrete column-H-shaped steel beam connecting joint and mounting method

ActiveCN113513089AImprove quality and efficiencyImprove construction efficiencyStrutsClimate change adaptationReinforced concrete columnEngineering

The invention relates to an FRP externally-wrapped crossed steel reinforced concrete column-H-shaped steel beam connecting joint and a mounting method, and belongs to the field of design of a building structure beam-column joint. The FRP externally-wrapped crossed steel reinforced concrete column-H-shaped steel beam connecting joint comprises an FRP externally-wrapped cross-shaped steel reinforced concrete column, an H-shaped steel beam and a square joint connecting sleeve, the FRP externally-wrapped cross-shaped steel reinforced concrete column comprises an upper column and a lower column, the square joint connecting sleeve is located between the upper column and the lower column, and the upper column and the lower column are connected with the square joint connecting sleeve through column end opening connecting plates correspondingly; and the H-shaped steel beam is fixedly connected with the column end opening connecting plates and the square joint connecting sleeve. By adopting the design of vertical force transfer of steel bars, the vertical connection of the joint is greatly enhanced, and the overall structural performance of the joint is enhanced.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

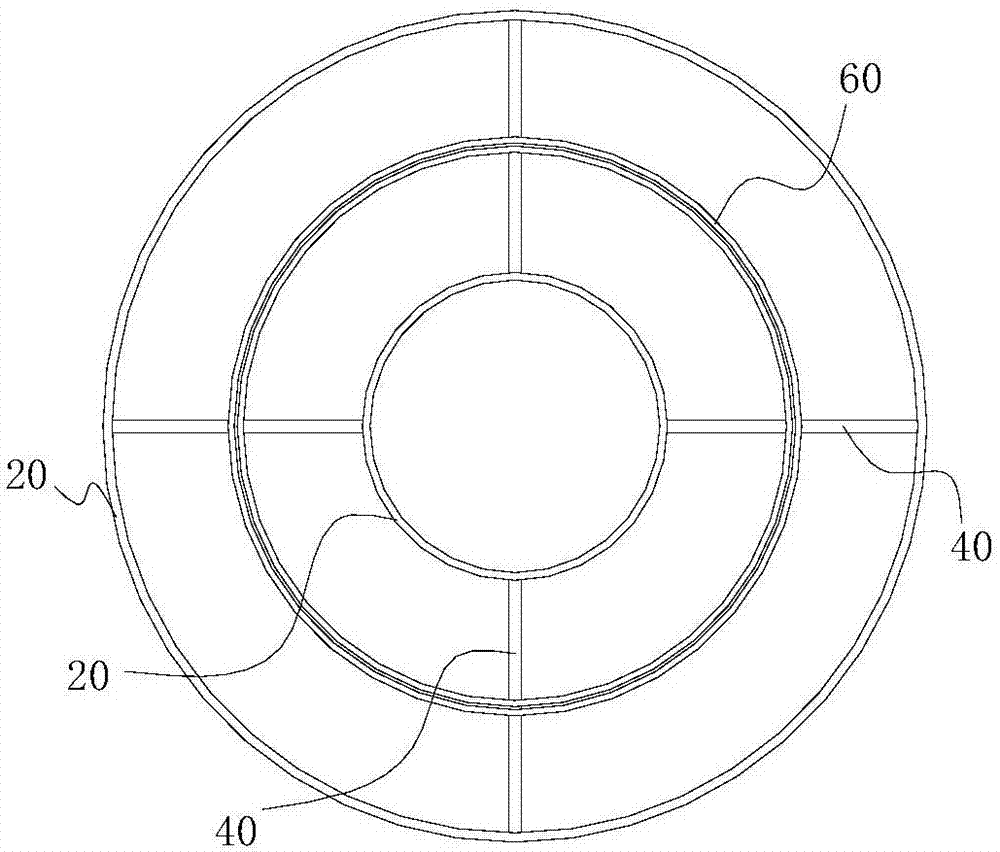

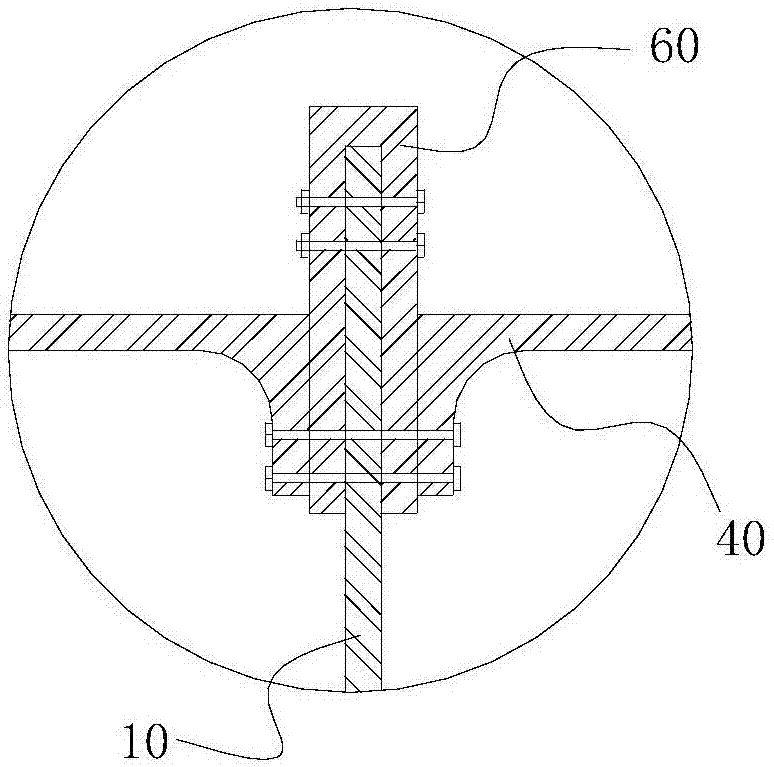

Anti-cold-consolidation circular pipe connecting structure

InactiveCN105156785ANot easy to fall offGuaranteed clamping forceJoints with sealing surfacesScrew threadConical surface

The invention discloses an anti-cold-consolidation circular pipe connecting structure. The anti-cold-consolidation circular pipe connecting structure comprises a connector, circular pipes and clamping sleeves, wherein the connector is provided with a fluid channel, and the clamping sleeves are arranged at the two ends of the connector. The inner end faces of the two ends of the connector are conical surfaces. External threads are arranged on the outer end faces of the two ends of the connector. Each clamping sleeve is formed by welding a locking nut and a clamping device together. A gap used for allowing the end opening of the connector to be arranged therein in a sleeved mode is reserved between each locking nut and the corresponding clamping device. The sizes of the locking nuts are matched with the diameters of the outer end faces of the connector, and the locking nuts are provided with internal threads engaged with the external threads on the outer end faces of the connector. The clamping devices are arranged between the locking nuts and the connector. Pipe insertion through holes with the diameters being matched with the diameters of the circular pipes are formed in the middles of the clamping devices. Conical surfaces are further arranged at the ends, facing the connector, of the clamping devices. The axial included angles of the conical surfaces of the connector are larger than the axial included angles of the conical surfaces of the clamping devices. By the adoption of the anti-cold-consolidation circular pipe connecting structure, rapid pipe connection can be achieved.

Owner:CHENGDU MATSUKAWA METAL MATERIALS

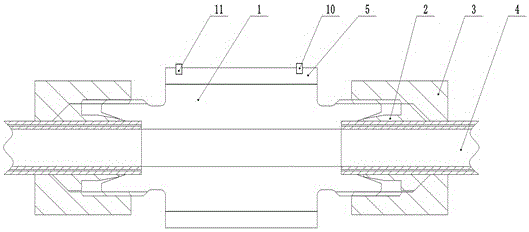

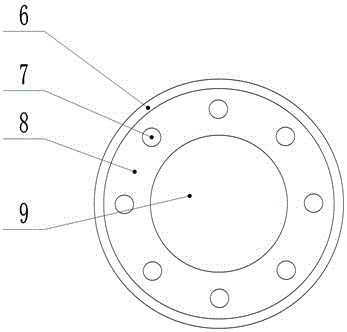

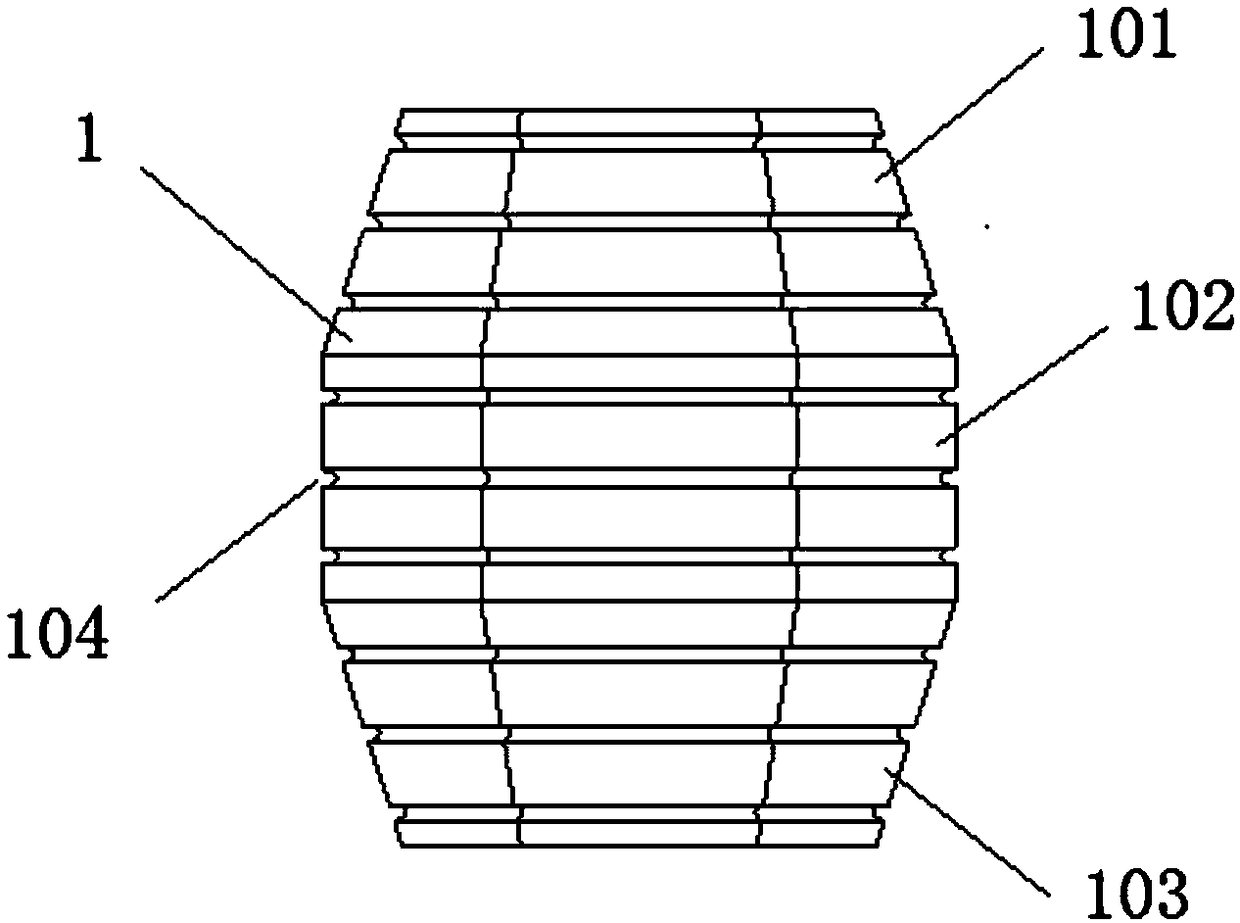

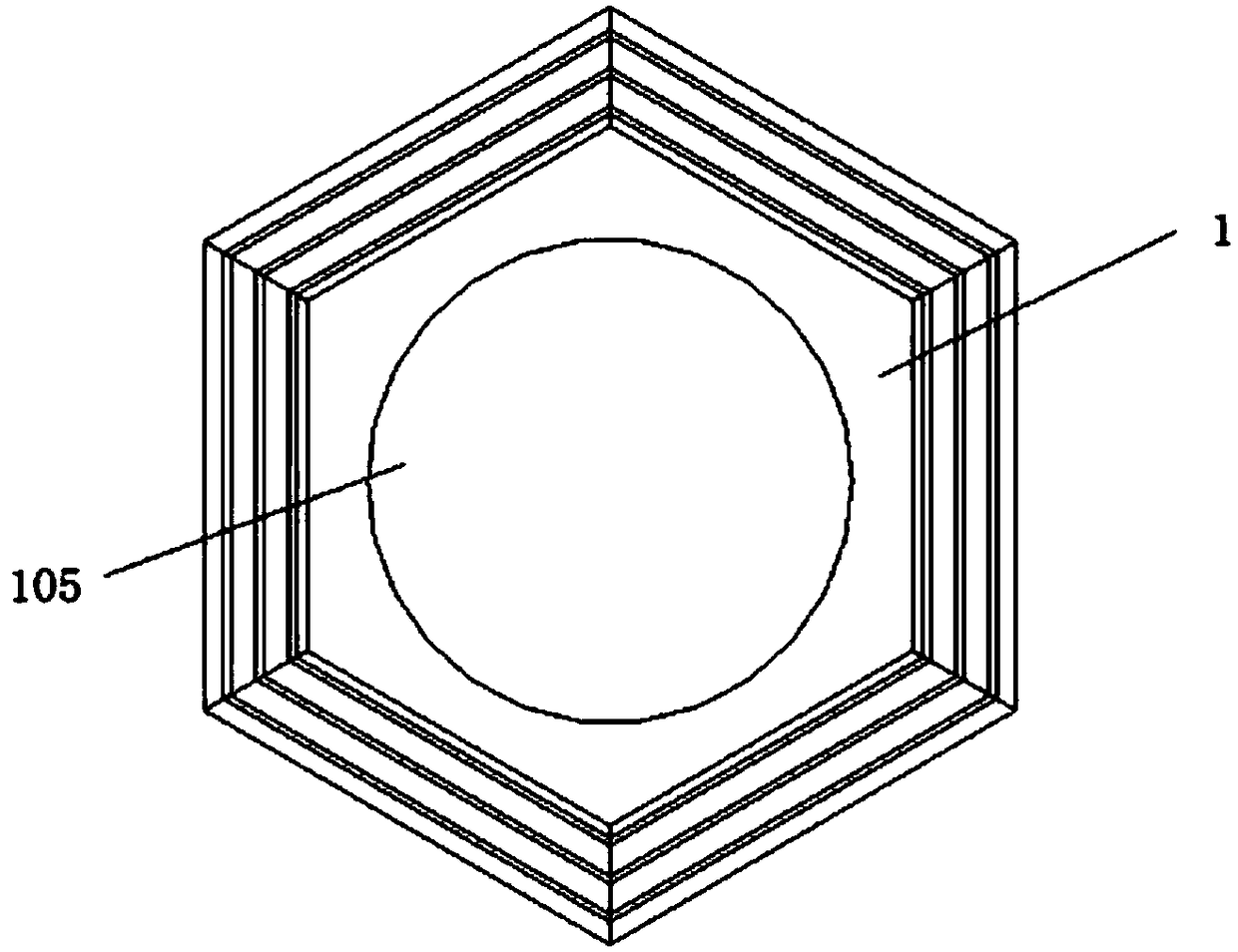

Fusiform anchor head for large-diameter high-strength reinforcements of reinforced concrete beam-column joints and application of fusiform anchor head

PendingCN108086596AMeet the section size requirementsMeet size requirementsBuilding reinforcementsReinforced concreteFusiform shape

The invention belongs to the field of civil engineering, and particularly relates to a fusiform anchor head for large-diameter high-strength reinforcements of reinforced concrete beam-column joints and application thereof. The technical solution is as follows: the fusiform anchor head comprises an upper anchor head part, a middle anchor head part and a lower anchor head part, wherein the middle anchor head part is a hexagonal prism, the upper anchor head part and the lower anchor head part are hexagonal frustums, the center of the fusiform anchor head is a through hole and is provided with internal threads, the external surface of the fusiform anchor head is provided with annular grooves, an end of a beam reinforcement is provided with external threads, and the internal threads of the fusiform anchor head and the external threads of the end of the beam reinforcement are screwed together. The performance of the design of the fusiform anchor head is reasonable, construction is simple andhighly efficient, energy can be saved and consumption can be reduced in terms of economy, and the fusiform anchor head can help achieve a design concept and a construction method in which members areeasy to produce and convenient to mount and cost is appropriate.

Owner:SHENYANG JIANZHU UNIVERSITY

Pipe connecting structure

InactiveCN105020499ANot easy to fall offGuaranteed clamping forceJoints with sealing surfacesPipe heating/coolingEngineeringMechanical engineering

The invention discloses a pipe connecting structure which comprises a connector provided with a fluid channel, round pipes in butting connection with the fluid channel, and clamping sleeves arranged at the two ends of the connector. The inner end faces the two ends of the connector are each a conical face, and the outer end faces of the two ends of the connector are each provided with an external thread. Each clamping sleeve is formed by welding a lock nut and a clamping device, and a gap is reserved between each lock nut and the corresponding clamping device and used for containing the port of the connector in a sleeving mode. The size of each lock nut is matched with the diameter of the outer end face of the connector, and the middle of each clamping device is provided with an internal thread engaged with the external thread on the outer end face of the connector. The clamping devices are arranged between the lock nuts and the connector, and pipe inserting through holes matched with the round pipes in diameter are formed in the middles of the clamping devices. The ends, facing the connector, of the clamping devices are also conical faces. The axial included angle of the conical face of the connector is larger than that of the conical face of each clamping device. By means of the pipe connecting structure, rapid pipe connection can be achieved.

Owner:CHENGDU MATSUKAWA METAL MATERIALS

Soft foundation reinforcing construction method with good reinforcing effect

InactiveCN112227344AHigh strengthImprove bearing capacityBulkheads/pilesSoil preservationCrushed stoneStructural engineering

The invention relates to a soft foundation reinforcing construction method with a good reinforcing effect. The soft foundation reinforcing construction method comprises the following steps of S1, siltremoval, wherein floating silt on the upper layer of an area to be subjected to reinforcing construction is removed; S2, first-stage reinforcing pile burying, wherein multiple first-stage reinforcingpiles are buried in the area where the floating silt is removed in the step S1; S3, second-stage reinforcing pile burying, wherein second-stage reinforcing piles are buried in the periphery of the area where the first-stage reinforcing sand piles are buried; S4, gravel layer laying, wherein a graded gravel layer is laid at the tops of the first-stage reinforcing piles; and S5, overload pre-pressing, wherein an overload pre-pressing layer is arranged on the graded gravel layer, and overload pre-pressing reinforcing is conducted on the to-be-reinforced area through the overload pre-pressing layer. The method has the advantage that the soft foundation reinforcing effect is remarkably improved.

Owner:福建新华夏建工集团有限公司

Swing prevention device for passive gravity water tank for AP1000 nuclear power plant

The invention belongs to the technical field of nuclear power and particularly relates to a swing prevention device for a passive gravity water tank for an AP1000 nuclear power plant. The swing prevention device comprises a swing prevention baffle assembly arranged in the passive gravity water tank. The bottom end of the swing prevention baffle assembly is detachably connected with the bottom wall of the passive gravity water tank through first connecting pieces. The top end of the swing prevention baffle assembly is detachably connected with the side wall of the passive gravity water tank through second connecting pieces. The swing prevention device has the beneficial effects that the swing prevention device for the passive gravity water tank for the AP1000 nuclear power plant is a combined device formed by swing prevention baffles, oval drag reduction holes, filtering screens, the U-shaped clamping openings, galvanized bolts, H-shaped connecting pieces, arc-shaped beams and inverted-U-shaped connecting pieces. The swing prevention device has the beneficial effects of being simple in principle, capable of being prefabricated in a factory, low in cost, capable of being assembled in a site, convenient to replace, capable of reducing vibration and preventing the swing and the like.

Owner:HEFEI UNIV OF TECH

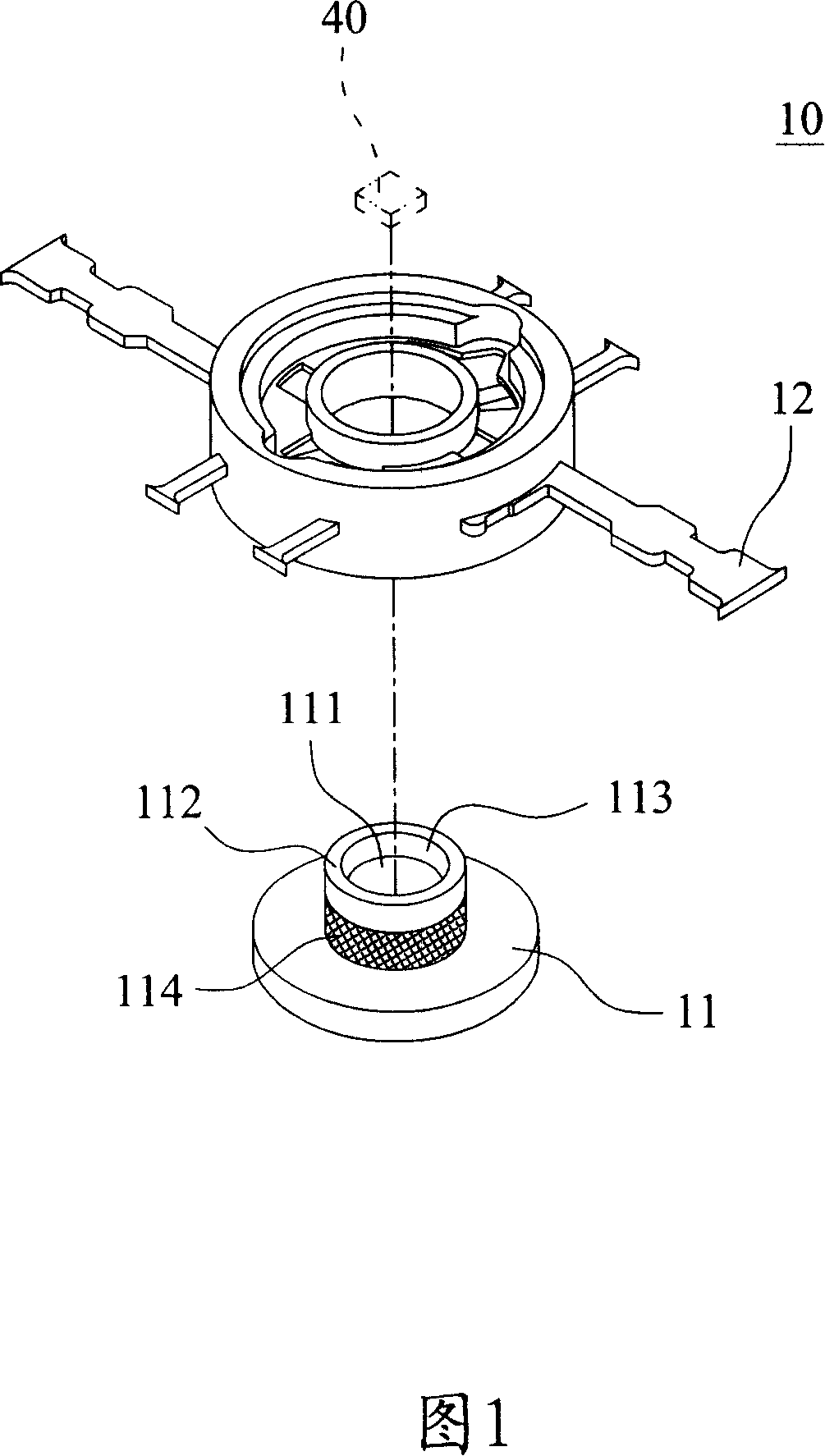

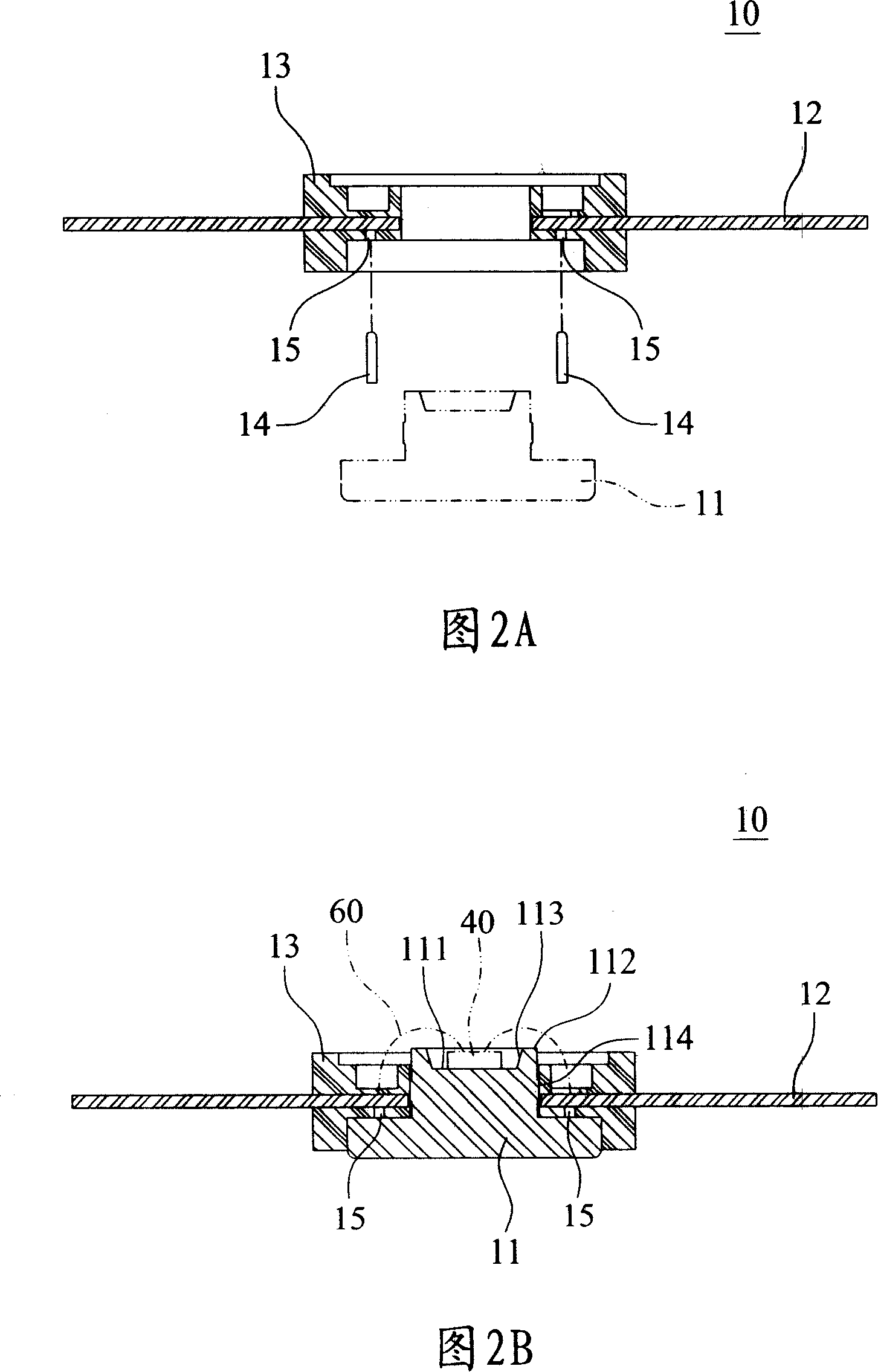

Seat structure of LED

InactiveCN101132038AImprove process quality and excellent rateImprove the occlusal effectSolid-state devicesSemiconductor devicesEngineeringCrystal

The present invention relates to a kind of Light Emitting Diode (LED) base structure, and includes: a heat-dissipated base with a crystal-fixed area; an insulating component has a first side and a second side, in which the first side clings to the heat-dissipated base, and an opening is set on the position of which the insulating component relates to the crystal-fixed area; at least one line frame set on the second side, keeps insulation and a certain distance from the heat-dissipated base by the insulating component; a insulating base covers the heat-dissipated base, the insulating component and the line frame, and forms complete structure of the LED base substrate. The electric connection between the heat-dissipated base and the line frame can be broken by the insulating component; the density and strength of the structure can be added by the cover structure of the insulating base to improve quality and good-production ratio of the LED base substrate structure.

Owner:KOREA AEROSPACE INDUSTRIES

Quick centering and melting device for PPR water feeding pipes

The invention discloses a quick centering and melting device for PPR water feeding pipes. The device comprises a hot melting frame, a heat conducting head, a machine body, indicating lamps, a switch,movable foot supports and a power supply wire; the hot melting frame is horizontally fixed on the plate surface at the bottom of the heat conducting head; two indicating lamps are provided, and are arranged on one horizontal line with the switch on the left side; four movable foot supports are provided, and are engaged with nuts at the bottom of the machine body through external threads at the tops; the bottom of the heat conducting head is tightly bonded on the upper surface of the machine body; and the power supply wire penetrates through a wire clip on the right side of the machine body, and is fixedly welded with a circuit board inside. After improvement, the device melts pipes more tidily and quickly, and prevents the condition of bad sealing condition caused by deformation of the pipe walls in the heating process; and through synchronous heating of two ends, the engagement capacity of joints is higher, and meanwhile, the borne water pressure is higher.

Owner:HENAN ZHONGPEN TIANRUN IND CO LTD

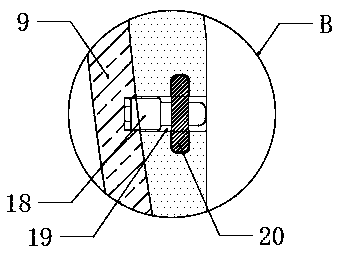

Novel straight cylinder type electronic cigarette switch

The invention discloses a novel straight cylinder type electronic cigarette switch. The switch comprises a cigarette body, and a battery is movably mounted at the middle lower end in the cigarette body; a bottom cover is movably mounted at the bottom end of the cigarette body; grooves are formed in the two sides of the bottom end of the outer portion of the cigarette body; movable handles are movably mounted at the bottom ends of the interiors of the grooves through springback hinges; mounting grooves are formed in the middles of one sides of the outer parts of each movable handles; small lamptubes are movably mounted in the mounting grooves; a silica gel sleeve is movably mounted on one side of the outer part of each movable handle and is positioned outside the corresponding mounting groove; the small lamp tubes are connected with a battery through wires, trigger grooves are formed in the top ends of one sides of the interiors of the grooves, second trigger blocks are fixedly installed in the middles of one sides of the interiors of the trigger grooves, and trigger rods are movably installed at the upper ends of the sides, close to the trigger grooves, of the movable handles. Thefilter baffle is movably mounted at the upper end in the mouthpiece, so that foreign matters can be prevented from entering the mouthpiece to cause blockage, and the smoking experience is reduced.

Owner:涟水县金泽电子科技有限公司

Grid type concrete face rockfill dam

ActiveCN113250149AImprove deformation resistanceImprove tensile propertiesClimate change adaptationEarth-fill damsArchitectural engineeringStructural engineering

The invention relates to the technical field of rockfill dams, in particular to a grid type concrete face rockfill dam. The grid type concrete face rockfill dam comprises a rockfill area, a plurality of layers of first grids, a transition area, a cushion layer area, a concrete face, a second grid and an asphalt concrete face, wherein the plurality of layers of first grids are horizontally laid in the rockfill area, the transition area is arranged on the side surface of the rockfill area, the cushion layer area is arranged on the surface of the transition area, the concrete face is arranged on the cushion layer area, the second grid is arranged on the concrete face, the asphalt concrete face is arranged on the concrete face and is fixedly connected with the second grid, a toe board is arranged on one side of the bottom of the rockfill area, and a bearing sealing gasket which is used for supporting the bottom of the concrete face and the asphalt concrete face is arranged on the toe board. According to the grid type concrete face rockfill dam, the tensile and deformation resistance of the concrete face rockfill dam can be increased, so that the structural damage to the concrete face rockfill dam is not easy to occur.

Owner:SHANDONG WATER GENERAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com