Cut roll crusher and construction waste roll-in crushing station based on same

A crushing station and garbage roller technology, applied in the field of comprehensive utilization of resources, to achieve the effects of controllable particle size, uniform discharge, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Embodiment 1, be used for the cutting roller broken equipment of rough breaking

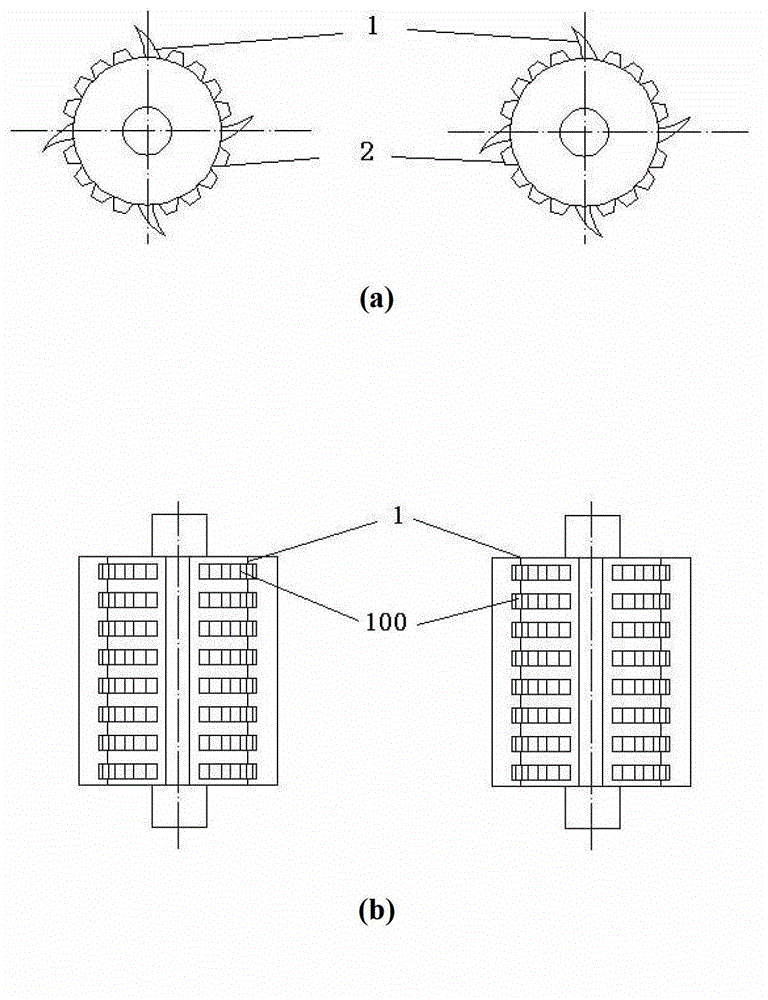

[0062] Such as figure 1 As shown, several sets of axially spaced cutting assemblies 100 are arranged on the roller surfaces of two opposing rollers of the cutting and crushing equipment of this embodiment.

[0063] The cut-off assembly 100 includes four cut-off knives 1 and sixteen cut-off teeth 2 evenly distributed on the roller surface of the pair of rollers, and the cut-off knives 1 and the cut-off teeth 2 are all arranged at the same axial position of the roller surface of the opposite roller, Four cutting teeth 2 are arranged between two adjacent cutting knives 1 .

[0064] The cutting knife 1 is a hook-shaped knife.

[0065] The cross section of the hook-shaped cutter is such that one end of the two arcs is respectively connected to the roller surface of the counter roller, and the other end of the two arcs is connected.

[0066] The diameter of the pair of rollers is 1200mm, and ...

Embodiment 2

[0072] Embodiment 2, cutting roll crushing equipment for medium crushing

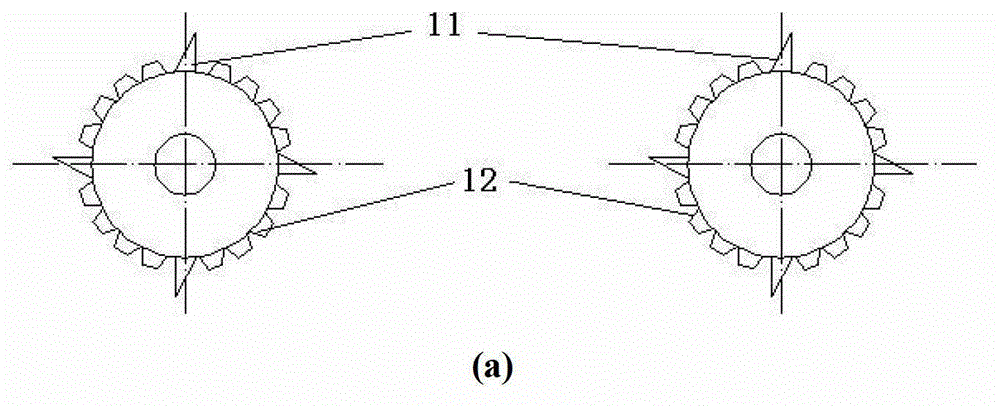

[0073] Such as figure 2 As shown, the difference between this embodiment and Embodiment 1 is that, in the roll-cutting equipment for intermediate crushing in this embodiment, the diameter of the pair of rollers is 1000mm, and the length of the pair of rollers is 1200mm.

[0074] The cutting knife 11 is a triangular knife.

[0075] The cross section of the triangular cutter is such that one end of the two straight lines is respectively connected to the roller surface of the counter roller, and the other end of the two straight lines is connected.

[0076] The cutting knife 11 is a triangular knife with a height of 100mm and a length of 1200mm. One side of the triangular cut-off knife 11 is 90 degrees to the roller surface, and one side is 45 degrees to the roller surface;

[0077] Distributed between the cut-off knives 11 are trapezoidal square cut-off teeth 21 with a trapezoidal cross-section. The ...

Embodiment 3

[0081] Embodiment 3. Construction waste roller crushing station based on cutting roller crushing equipment 32

[0082] Such as image 3As shown, the construction waste rolling crushing station based on the roller crushing equipment 32 of this embodiment is a closed module device, and the closed module device includes a feeder 31, a roller crushing equipment 32, a steel structure conveyor 33, a magnetic separation Equipment 34, slag hopper 35, slag belt conveyor 36, module frame 37 and two dust collection devices 38, 39, feeder 31, roller cutting equipment 32, steel structure conveyor 33, magnetic separation equipment 34, The slag hopper 35, the slag belt conveyor 36 and the two dust collection devices 38, 39 are all connected to the module frame 37, and the feeder 31, the steel structure conveyor 33 and the slag belt conveyor 36 are arranged in turn from top to bottom , the cutting roller crushing equipment 32, the magnetic separation equipment 34 and the first dust collectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com