FRP externally-wrapped crossed steel reinforced concrete column-H-shaped steel beam connecting joint and mounting method

A steel-reinforced concrete, connecting node technology, applied in columns, girders, joists, etc., can solve the problems of reduced structural performance of FRP materials, affecting structural safety and durability, and corrosion of steel pipes. Flexural bearing capacity, improve construction quality and construction efficiency, and improve the effect of bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The structural design and installation process of the node of the present invention will be further elaborated below in conjunction with the embodiments and the accompanying drawings, and the details are further described as follows.

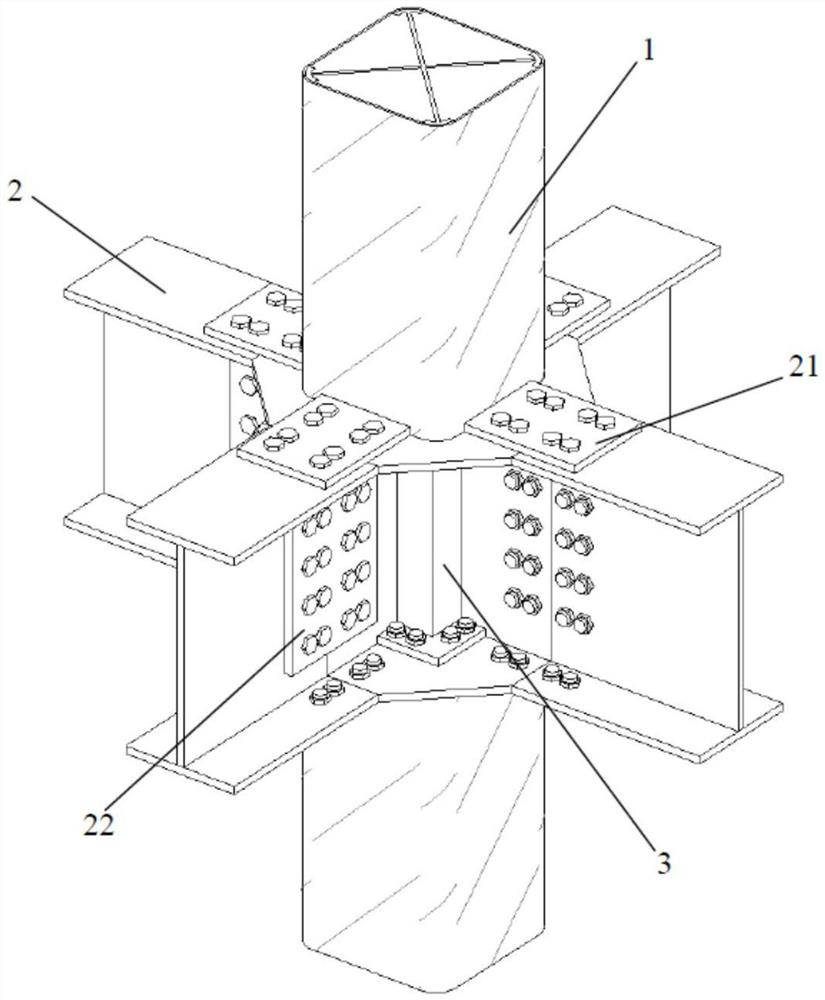

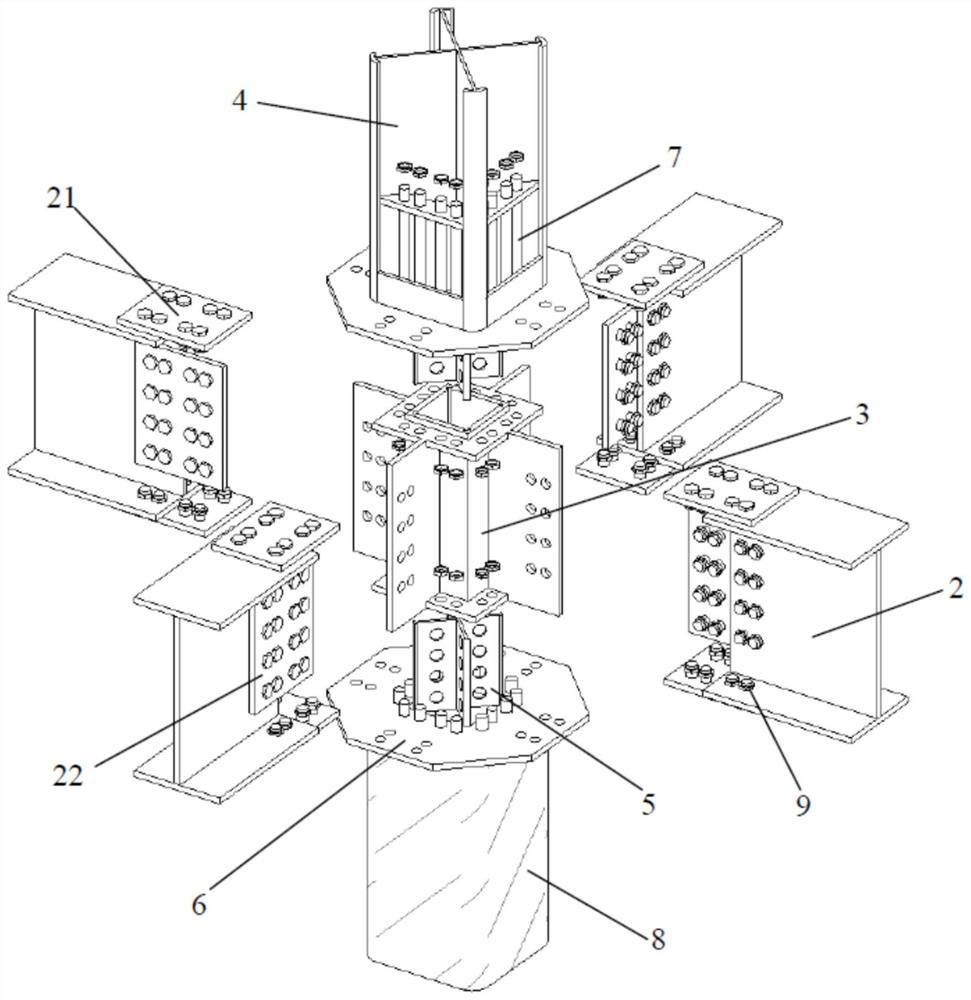

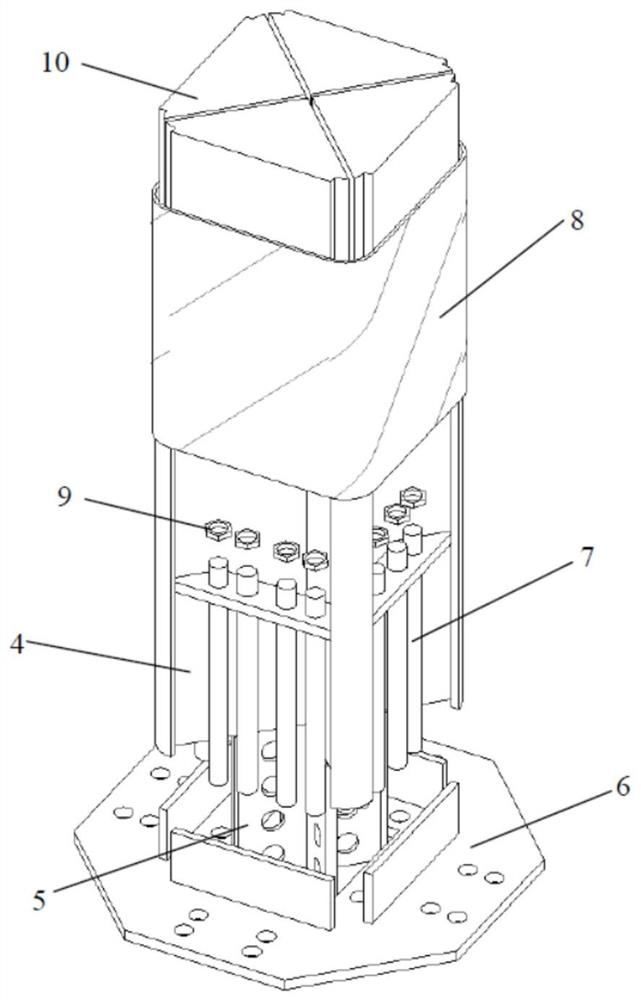

[0048] A FRP outsourcing cross-shaped steel reinforced concrete column-H-shaped steel beam connection node, such as figure 1 and 2As shown, it includes FRP outsourcing cross-shaped steel-reinforced concrete column 1, H-shaped steel beam 2, and square node connecting sleeve 3. FRP outsourcing cross-shaped steel-reinforced concrete column 1 includes an upper column and a lower column, and square node connecting sleeve 3 is located on the upper column Between the upper column and the lower column, the upper column and the lower column are connected through the square joint connecting sleeve 3, the upper and lower flanges of the H-shaped steel beam 2 are fixedly connected with the connecting plate 6 of the column end opening through the flang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com