Machine tool for machining jaws of bench vices

A technology for processing machine tools and bench vices, which is applied in metal processing machinery parts, metal processing equipment, milling machine equipment, etc., can solve the problems of large processing errors, increase manufacturing costs, and affect the occlusal performance of workpiece clamping in bench vices. The effect of avoiding accumulated errors and improving occlusal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

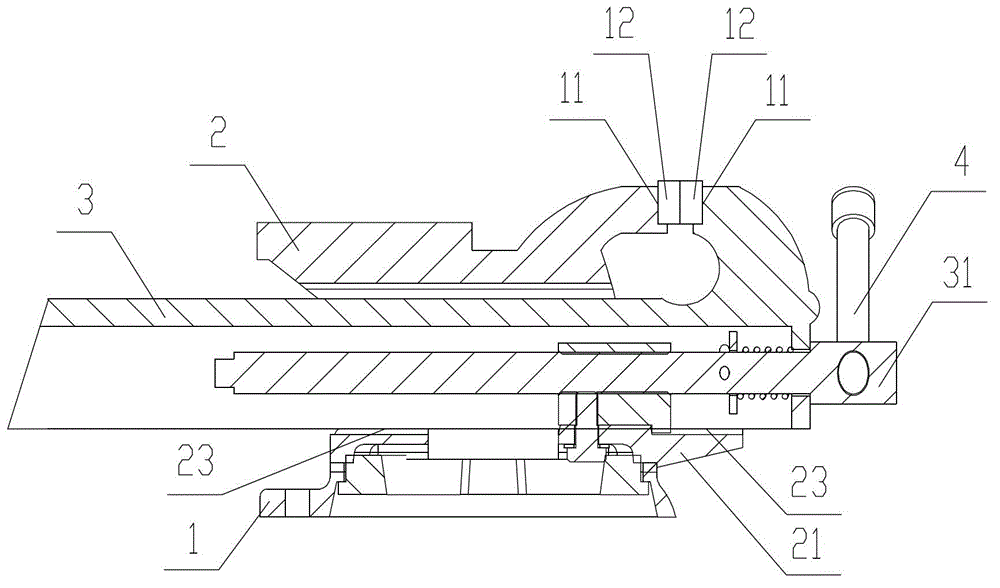

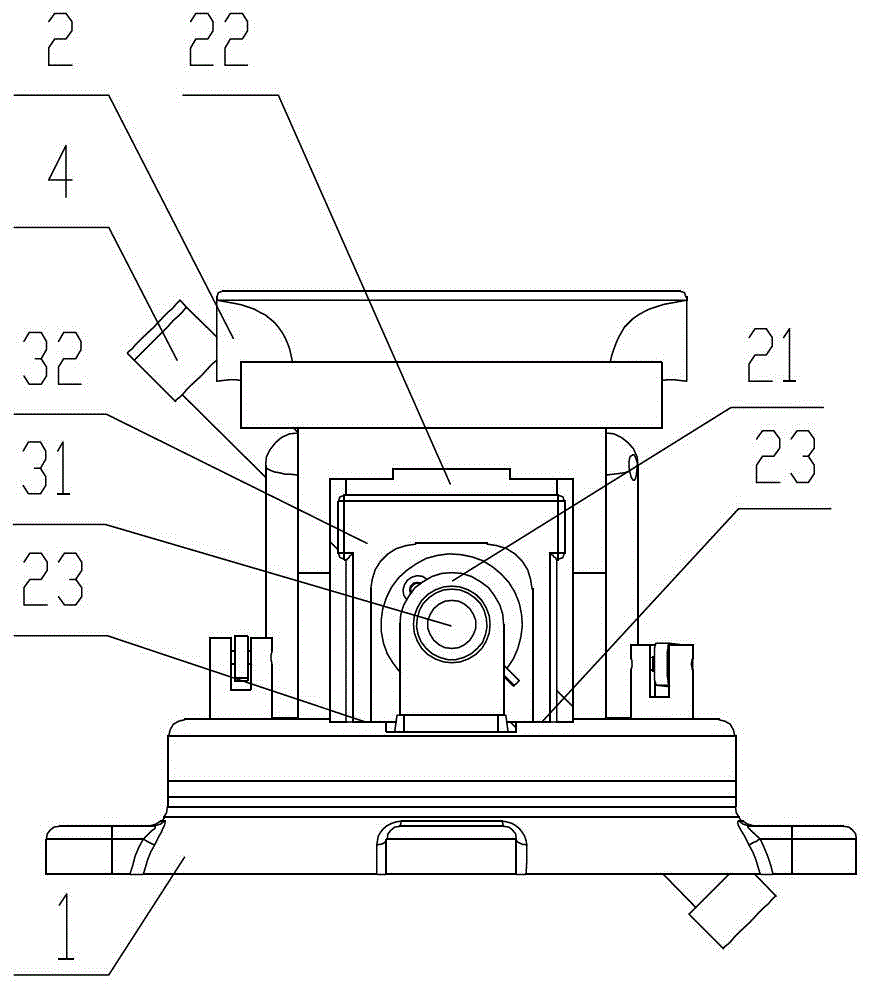

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments (the horizontal direction described in this specification refers to the attached image 3 The left-right direction in this manual refers to the vertical direction in this manual. image 3 In the direction perpendicular to the paper surface inward or outward, the "left" in this manual is the same as the attached figure 1 The left side in the middle is the same, and the "right side" is the same as the attached figure 1 same as the right side in ):

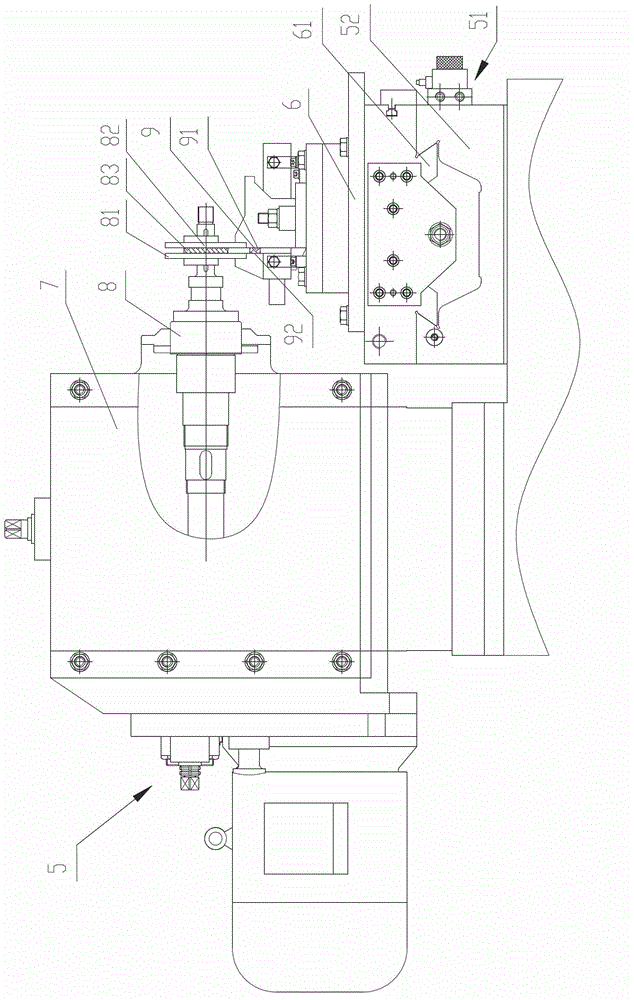

[0027] attached image 3 It is the front view of the bench vise jaw processing machine tool of the present invention, the processing machine tool includes a bed 5, a fixed mounting seat 6 for fixing the bench vise base 1, and a driving fixed mounting seat movably arranged on the bed 5 along the longitudinal direction 6 a moving feed mechanism 51, a column 7 provided on the bed 5, and a spindle 8 provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com