Test method for shear bond strength of refractory mud

A technology for refractory mud and strength detection, applied in the field of refractory materials, can solve the problems of inability to guide actual production, inaccurate measurement results, high hardness of refractory bricks, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

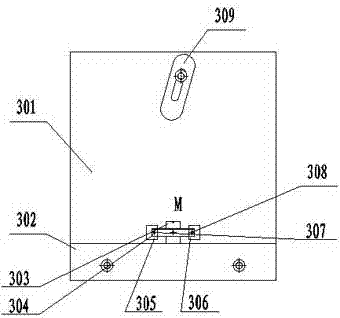

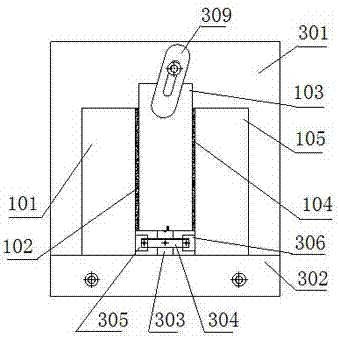

[0040] The present invention will be further described below in conjunction with the accompanying drawings.

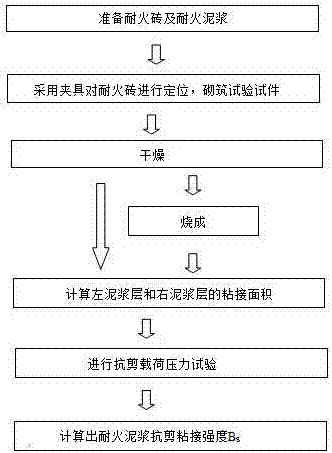

[0041] see Figure 1-Figure 4 , a method for detecting the shear bond strength of refractory mud, comprising the steps of:

[0042] Step 1. Prepare refractory bricks and refractory mud

[0043] 1. Prepare refractory bricks

[0044] Prepare the left refractory brick 101, the middle refractory brick 103 and the right refractory brick 105, and the 3 refractory bricks should match the refractory mud required for testing; the 3 refractory bricks should not have cracks, melting holes, missing edges and corners, distortion, etc. Apparent defects; the three refractory bricks should be standard straight bricks; if there are many types of straight standard bricks to choose from, T2, T3, T1, T5, T6 types are preferred; if the mud masonry object is non-standard For bricks or other types of straight standard bricks, on the basis of retaining two relatively parallel faces as the or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com