Patents

Literature

96 results about "Normal teeth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

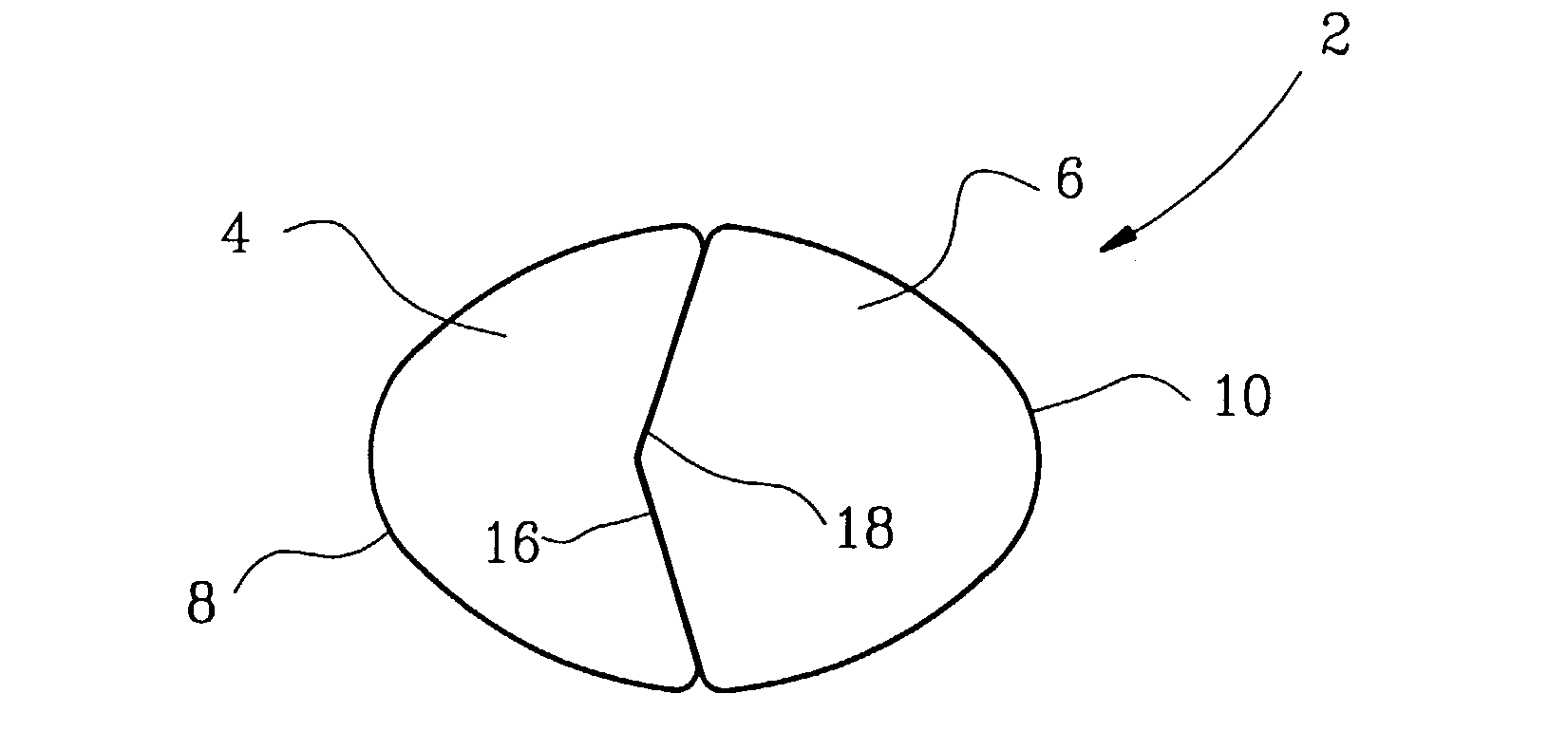

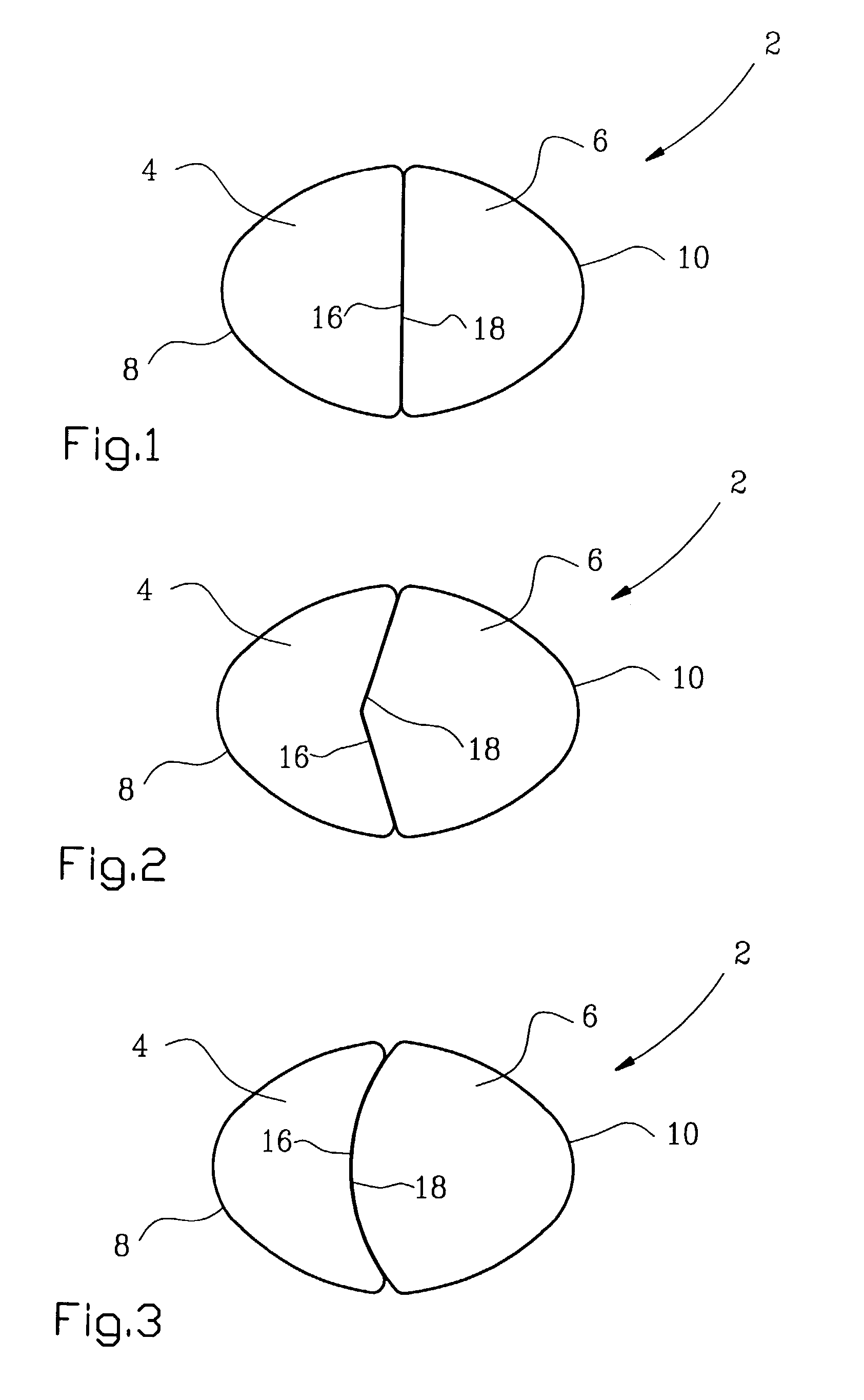

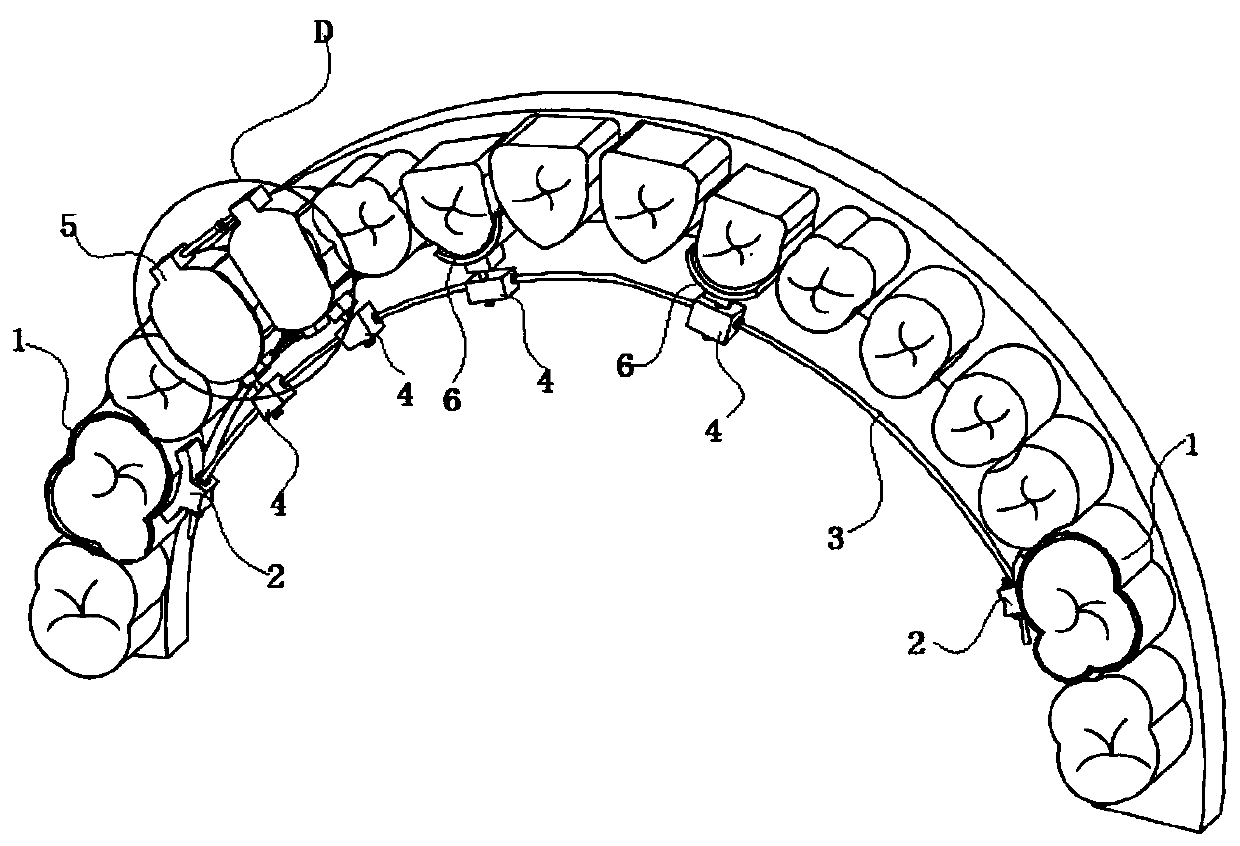

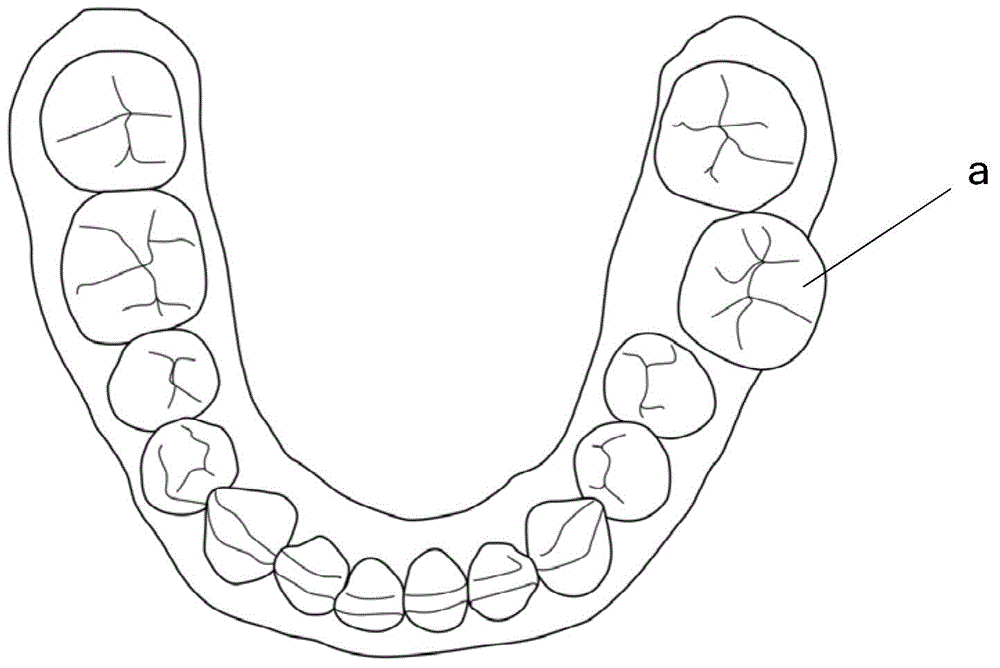

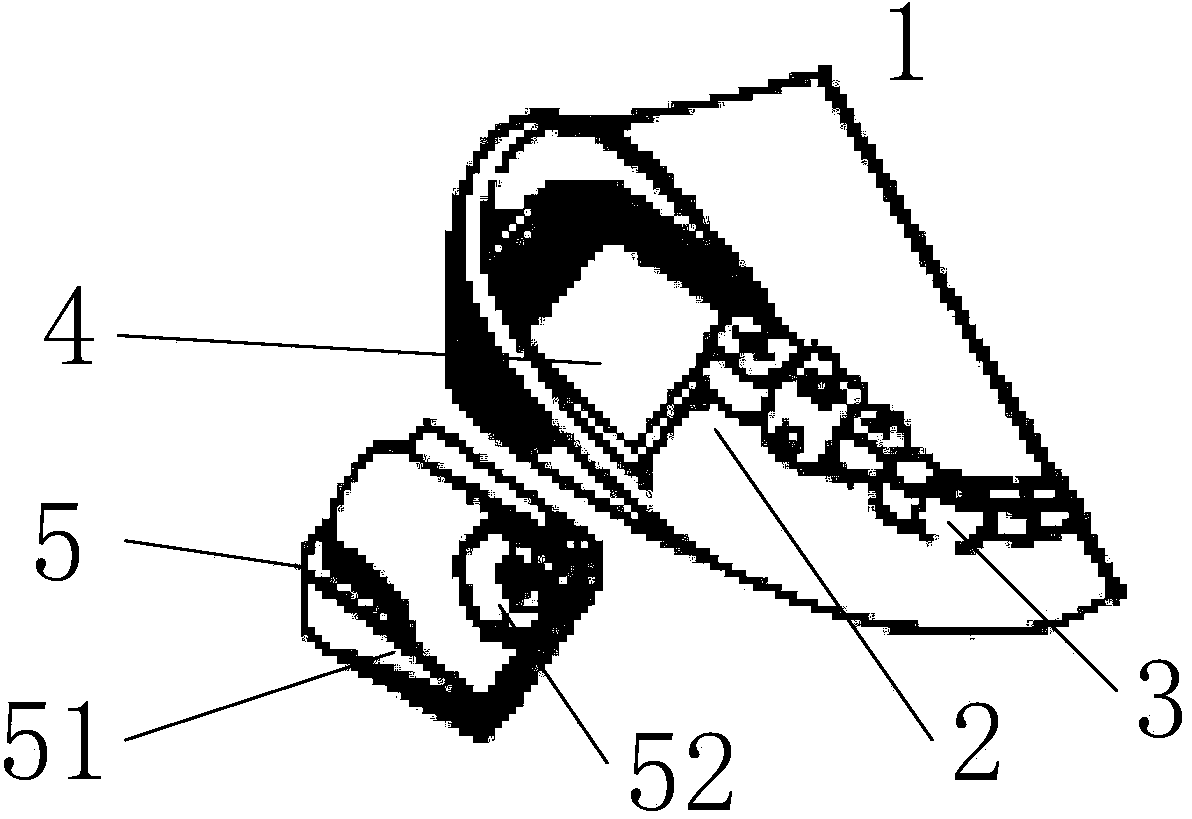

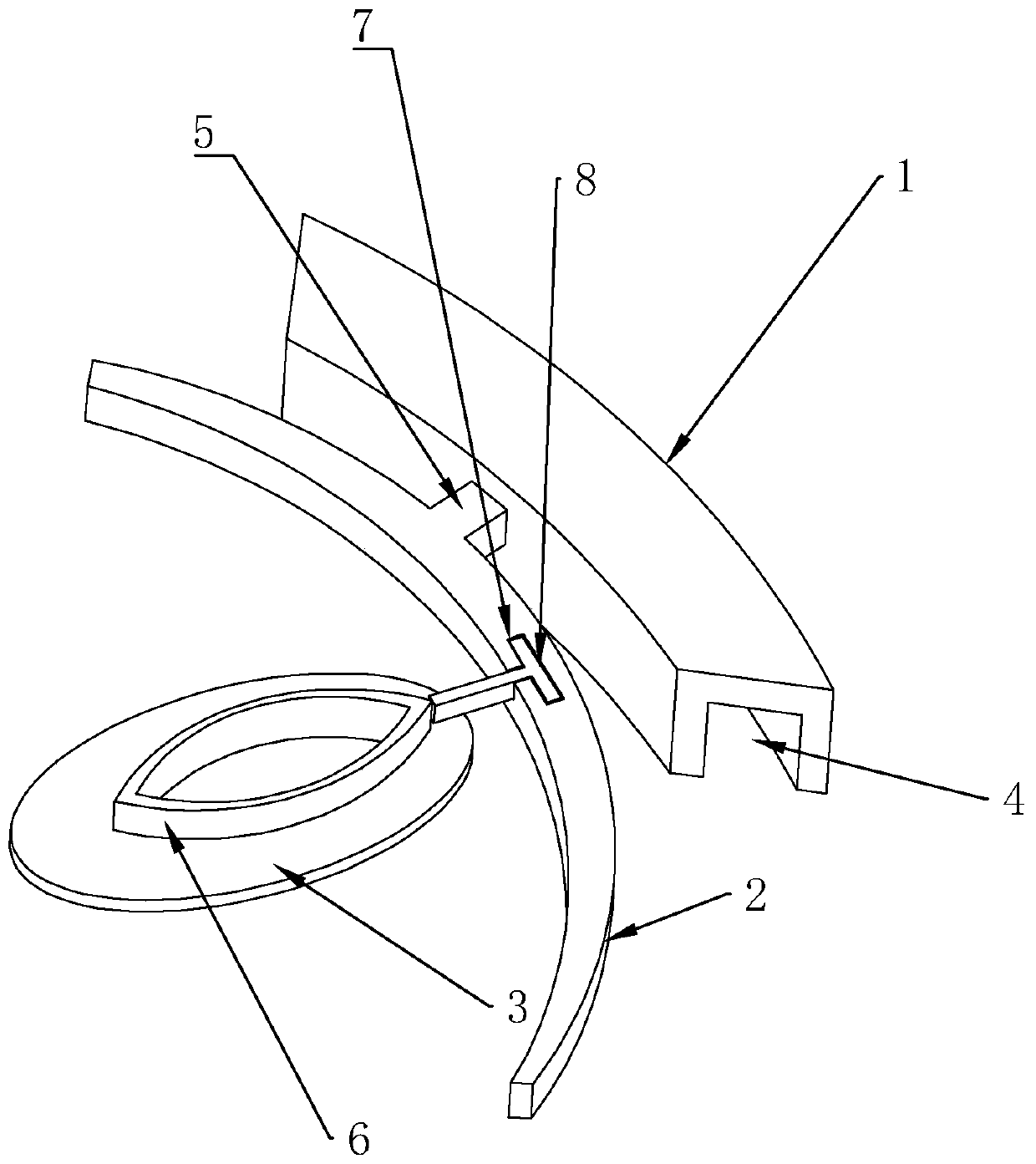

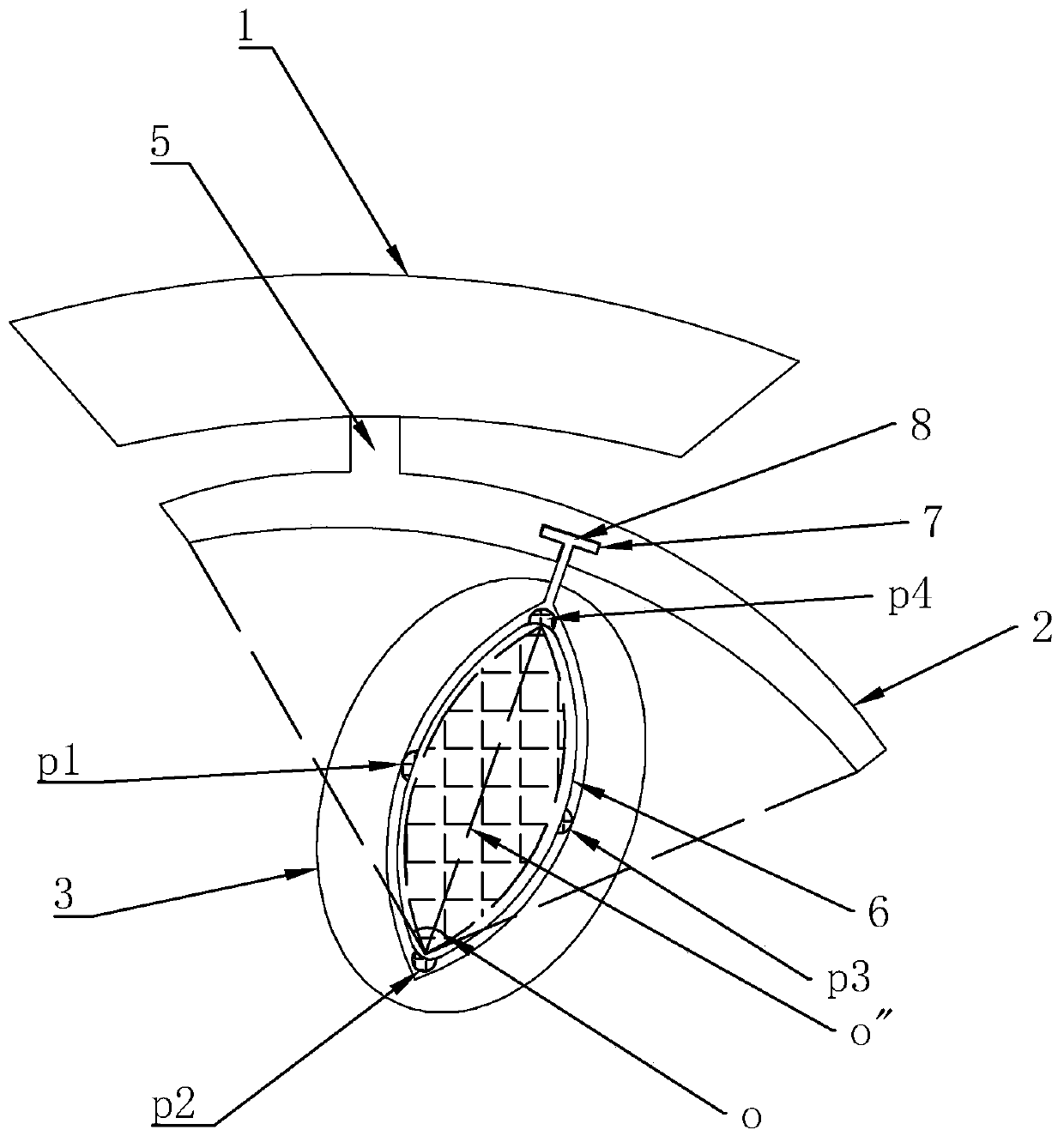

Orthodontic retainer elements

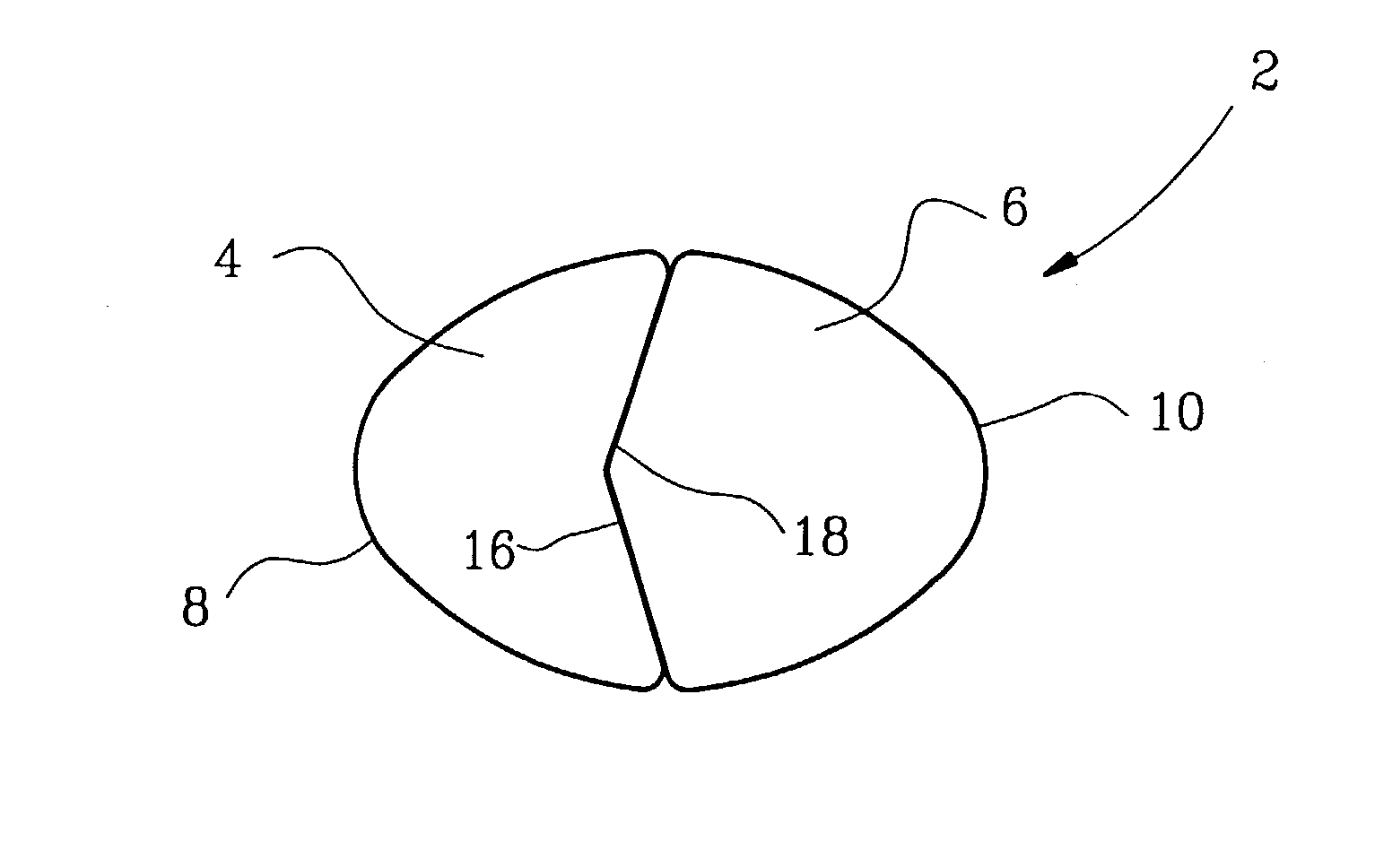

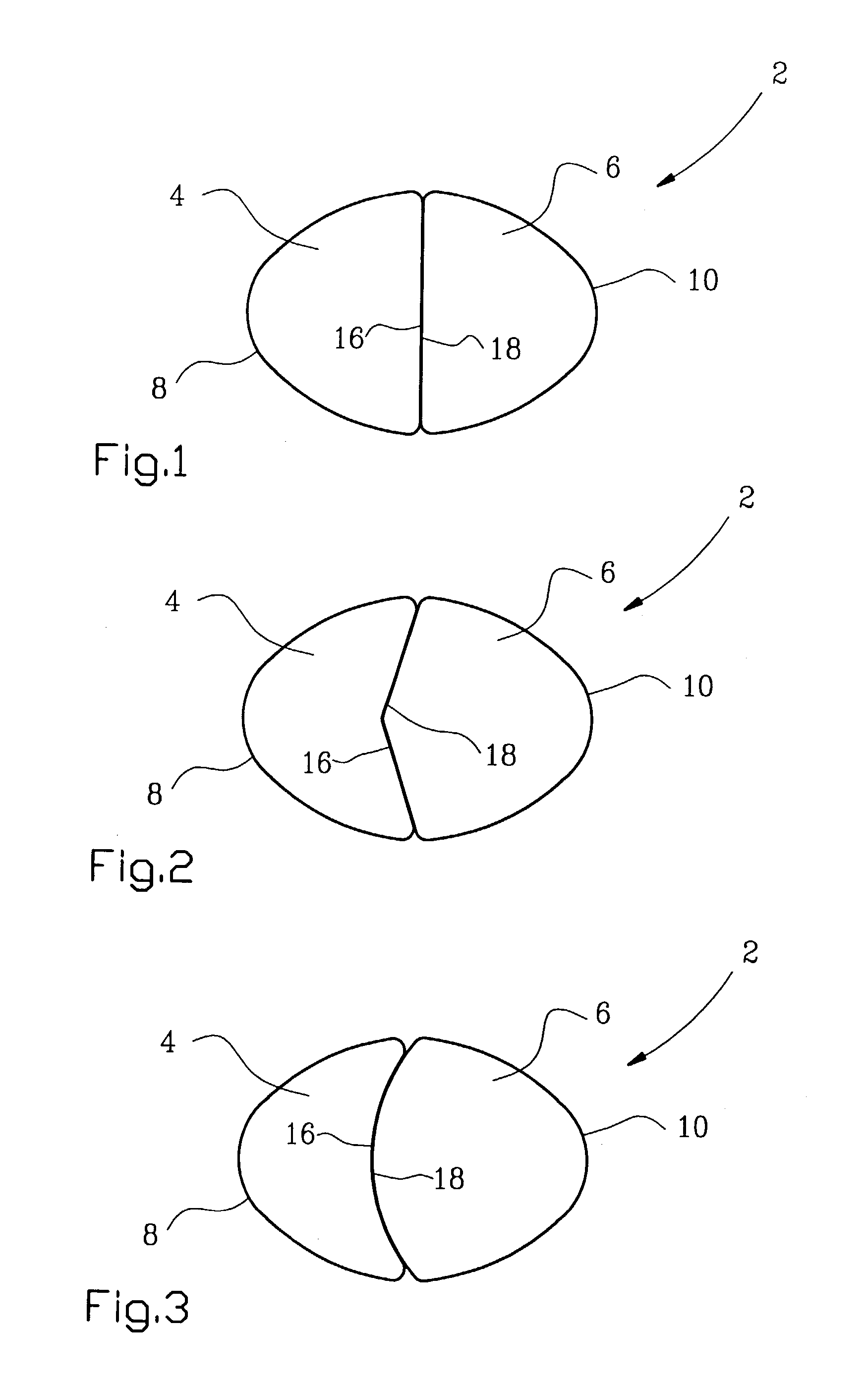

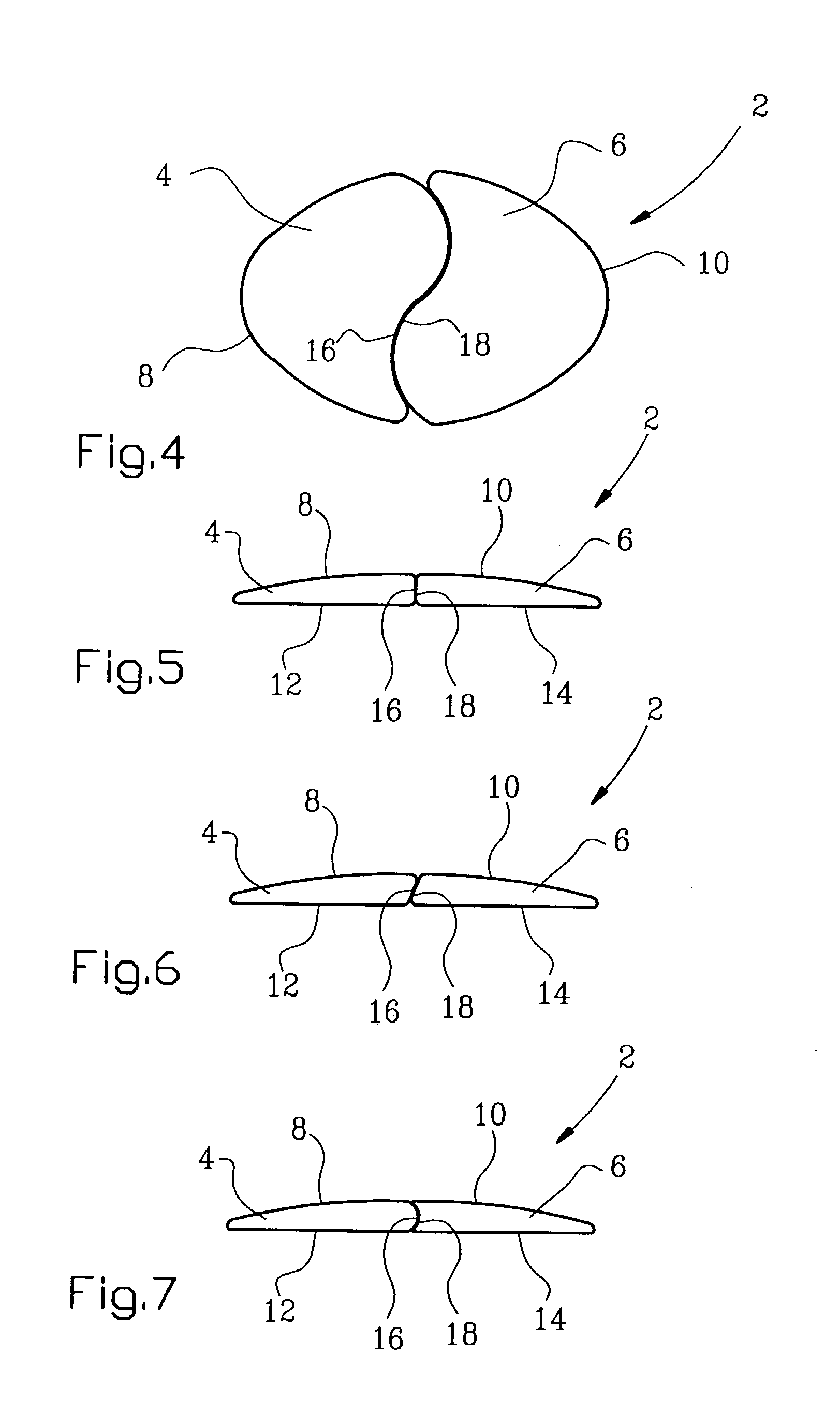

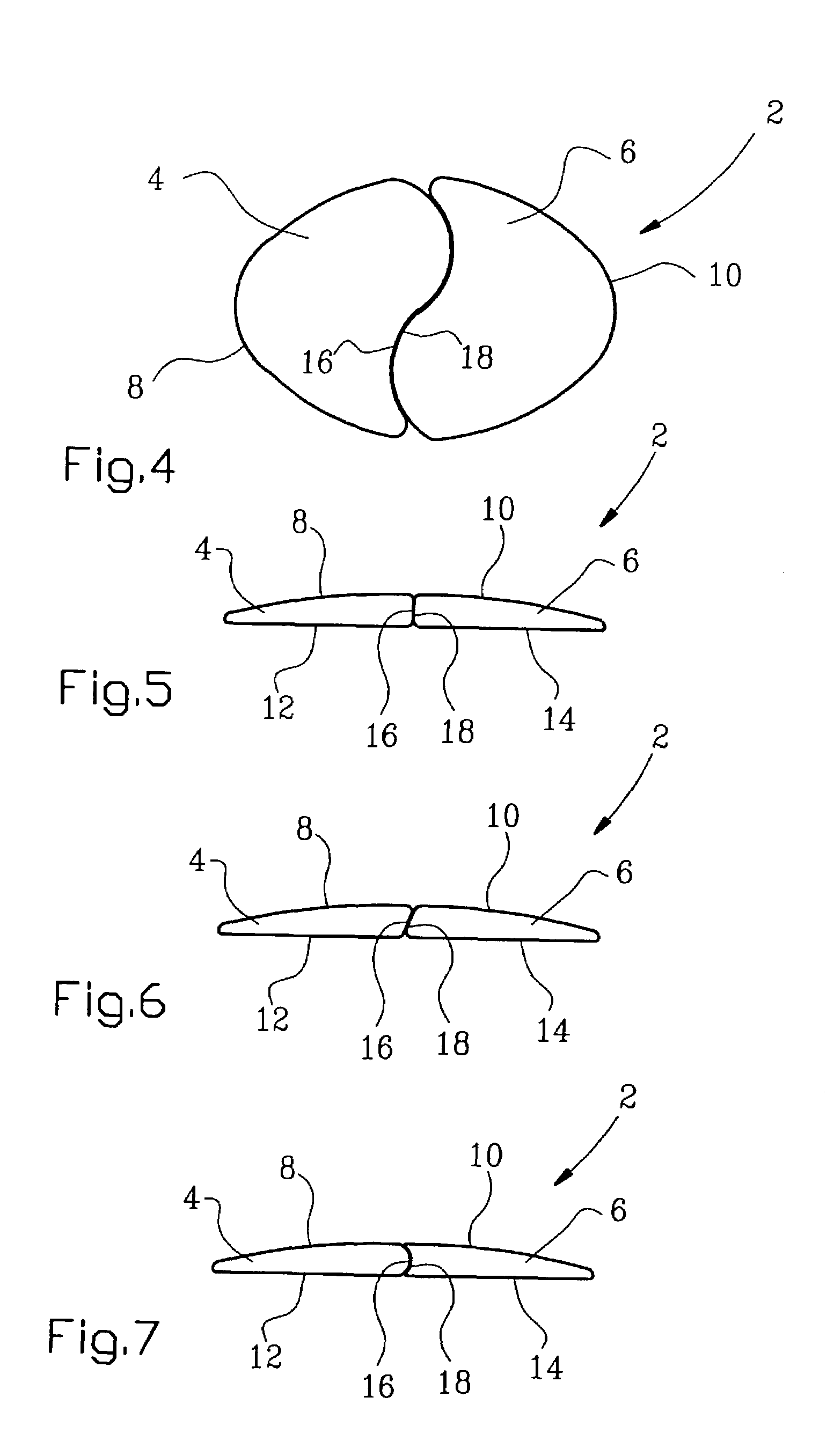

A dental retainer device for stabilization, so-called retention, of pairs of teeth or groups of teeth in a lower jaw and / or an upper jaws in orthodontic treatment. The retainer device is formed of a pair (2) of retainer elements, consisting of two preferably individual, but in the position of use cooperating, retainer elements (4, 6). Each of the retainer elements (4, 6) is formed in with a retainer approximal surface (16, 18), the retainer approximal surfaces (16, 18) being formed complementary relative to one another. In use, one or more pairs (2) of retainer elements is / are positioned and secured with its / their individual elements (4, 6) preferably on the inner face of a tooth (20, 22) each of a pair of adjacent teeth, so that in the position of use the retainer approximal surfaces (16, 18) bear on each other and support, possibly lock, each other. Thereby pairs of teeth or groups of teeth are stabilized while it is possible at the same time to carry out normal dental hygiene by means of a toothbrush, dental floss or toothpicks, which is otherwise difficult to carry out when known retainers are used.

Owner:AMUNDSEN OLE CHRISTIAN

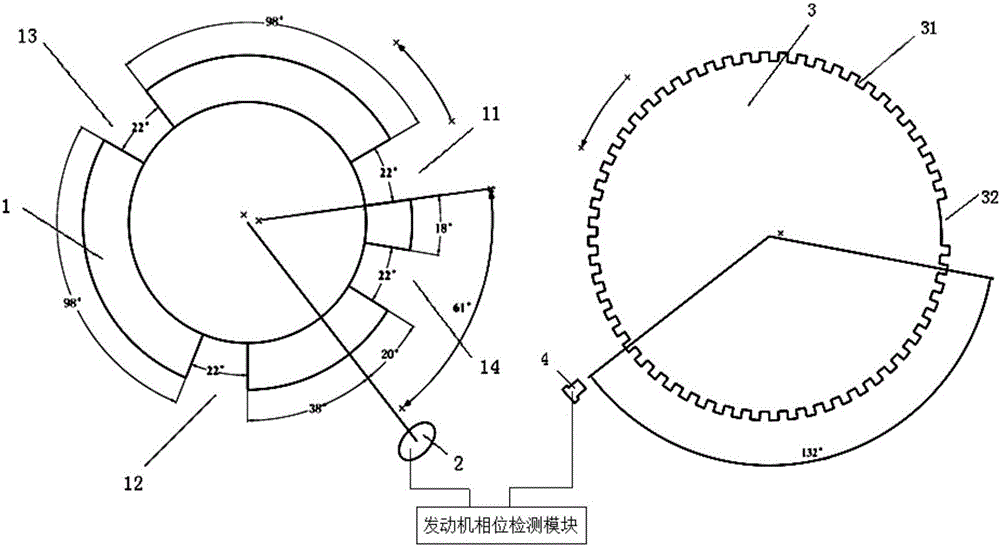

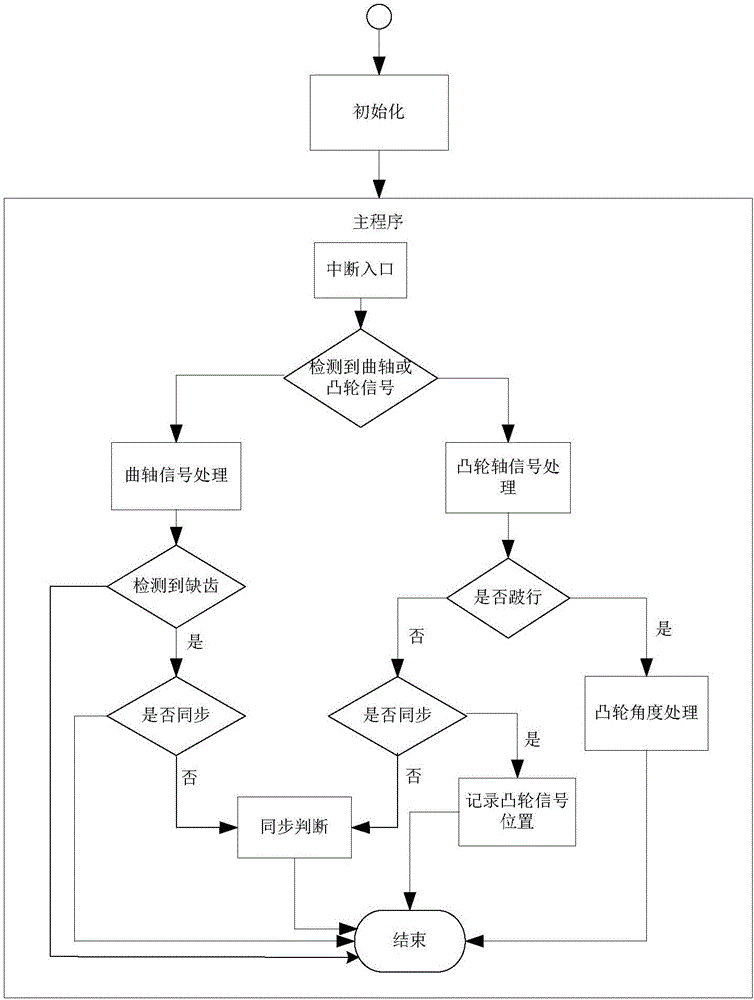

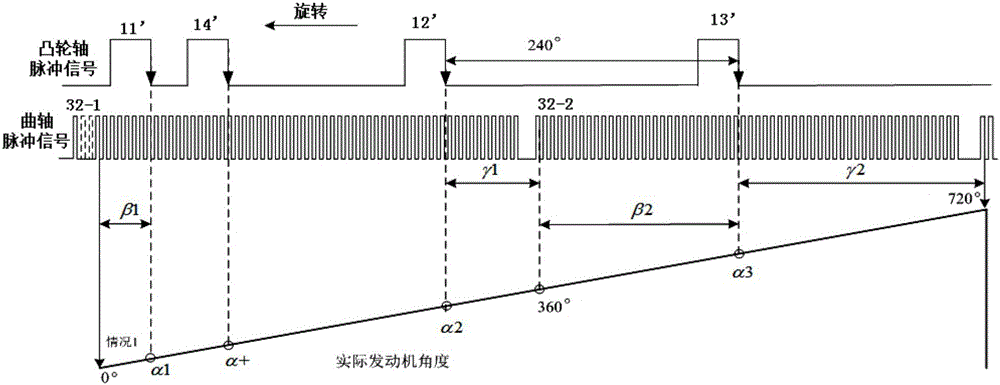

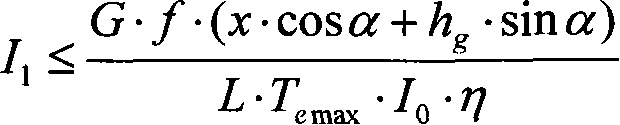

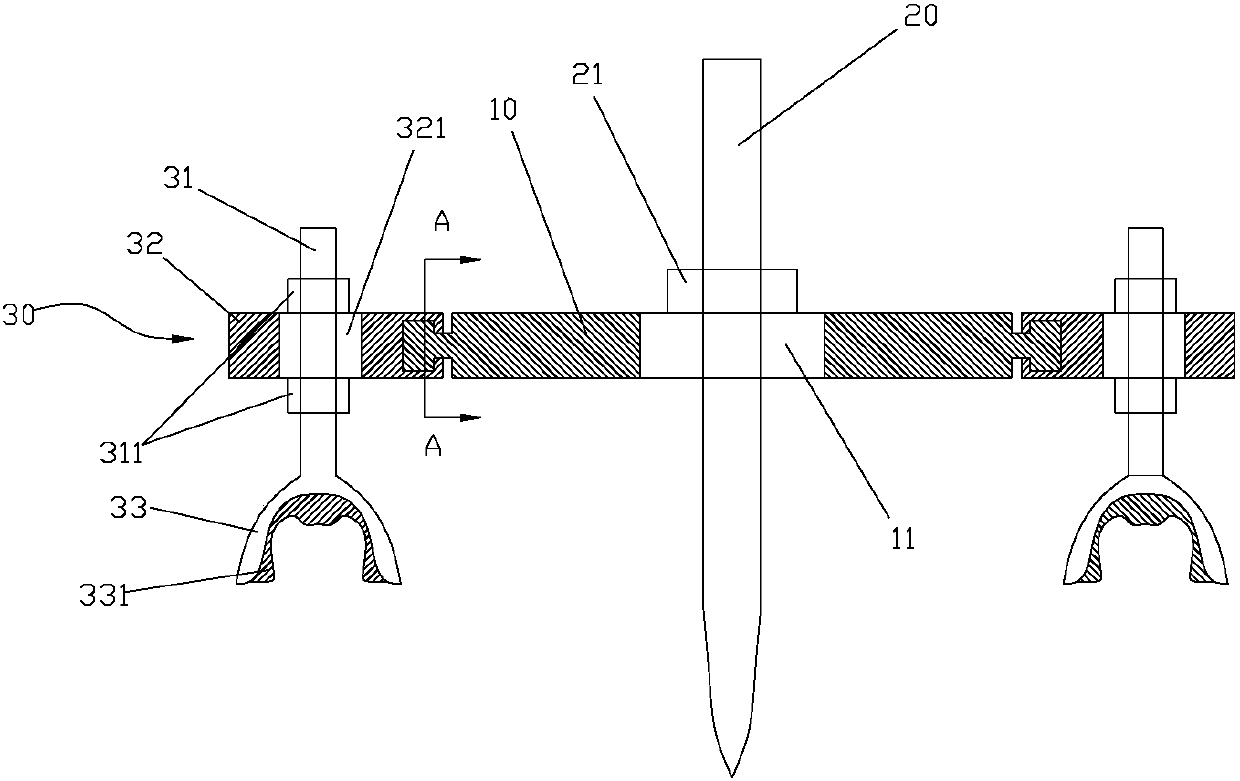

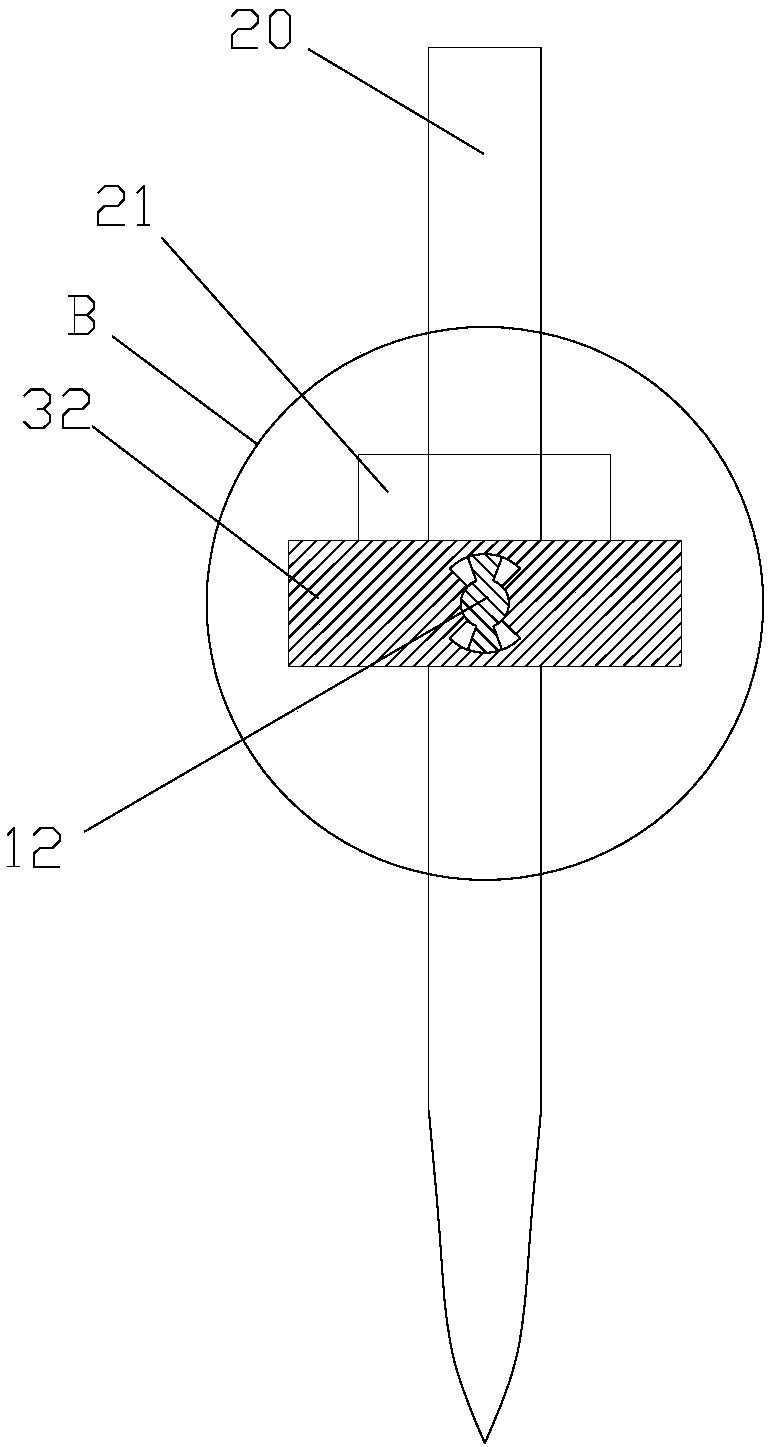

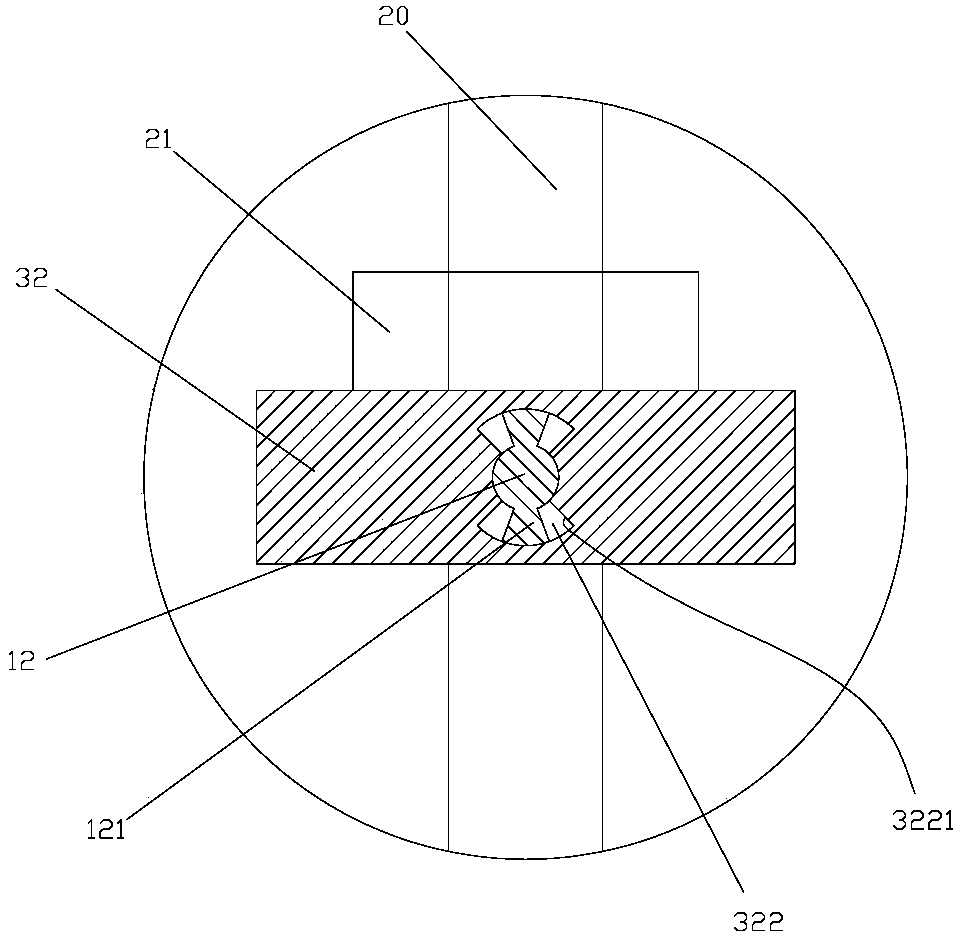

Phase detection device and system of engine

InactiveCN105840327AReduce startup timeImprove performanceElectrical controlMachines/enginesSpacing toothStart time

The invention relates to a phase detection device of an engine. A cam shaft signal panel of the device is fixedly installed on a cam shaft. A crankshaft signal panel is fixedly installed on a crankshaft. Three normal teeth and an extra tooth are distributed at the edge of the cam shaft signal panel at equal intervals, and the extra tooth is located between two of the three normal teeth. N continuous equally-spaced teeth and a missing tooth are distributed at the edge of the crankshaft signal panel. A first Hall sensor is fixed to the edge of the cam shaft signal panel, and a second Hall sensor is fixed to the edge of the crankshaft signal panel. A cam shaft pulse signal which is generated by the first Hall sensor and represents cam shaft phase information and a crankshaft pulse signal which is generated by the second Hall sensor and represents crankshaft phase information are transmitted to an engine phase detection module. The engine phase detection module carries out analysis treatment on the cam shaft pulse signal and the crankshaft pulse signal so that engine phase data can be obtained. By means of the phase detection device of the engine, the start time of the engine is shortened, performance of an electric control system of the engine is improved, and the robustness of the electric control system is enhanced.

Owner:CHINA FIRST AUTOMOBILE

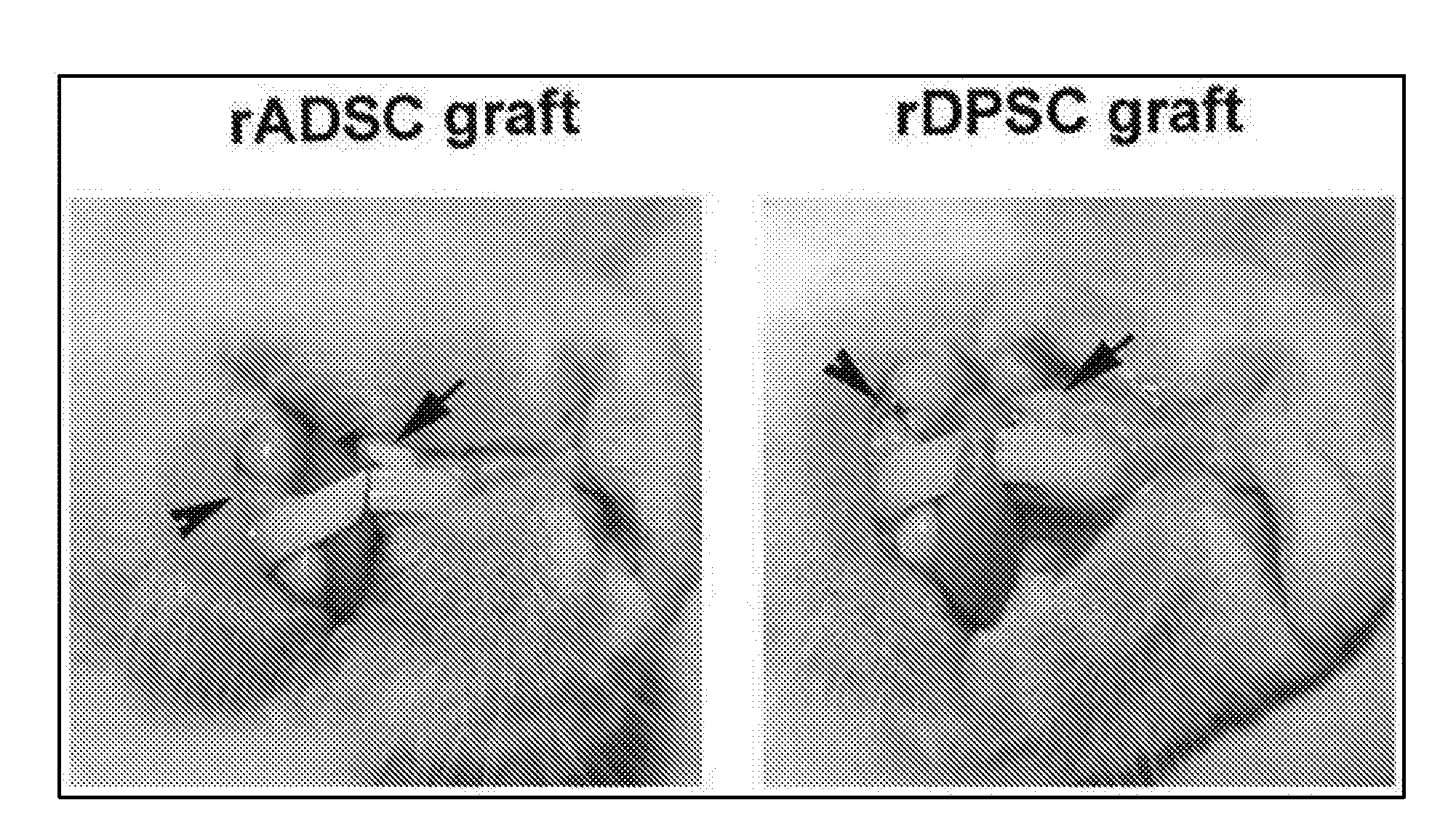

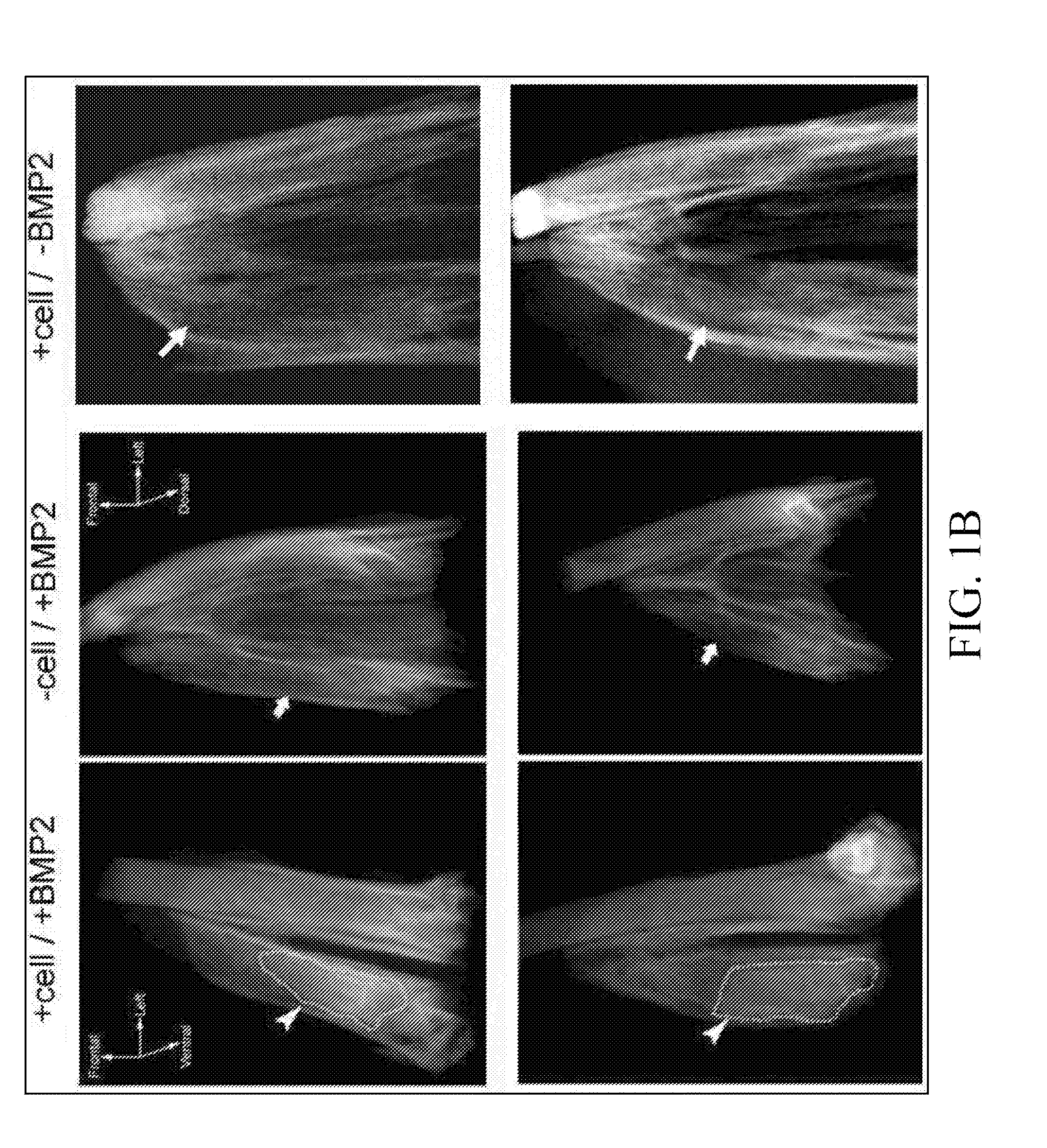

Method of implanting mesenchymal stem cells for natural tooth regeneration in surgically prepared extraction socket and compositions thereof

The present invention provides a method and compositions for tooth regeneration. Both implants of adipose-derived stem cell and dental pulp stem cell are able to grow self-assembled new teeth in extraction sockets when adding BMP2. The regenerated tooth is not only structurally similar to a normal tooth, but also well-developed in vascular and nervous systems with functions of growth, communication, and sensation. They are natural living teeth derived from this invented implantation method without any engineering procedure. It is ready for clinical testing and may be applied to future dental clinics.

Owner:MAR KWEI +2

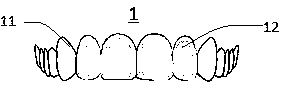

Invisible brace with beautification layer

InactiveCN105616018AImprove aestheticsEffectively conceal gaps between teethOthrodonticsPatient satisfactionDentition

The invention provides an invisible brace with a beautification layer. The invisible brace comprises an invisible brace main body. The surface of the part of the invisible brace main body at the position of a tooth to be beautified is provided with the beautification layer. The form of the beautification layer matches with the form of the lip side at the position of a tooth to be beautified according to correction design demands. The beautification layer comprises a thin layer accessory or a colored coating and can be designed according to the human dentition case. The designed brace can effectively cover dentition gaps of a patient, prevents exposure of teeth with large color difference from that of the normal teeth, improves dentition beauty of the patient in correction or after correction and improves patient satisfaction to a polymer brace.

Owner:SHANGHAI SMARTEE DENTI TECH CO LTD

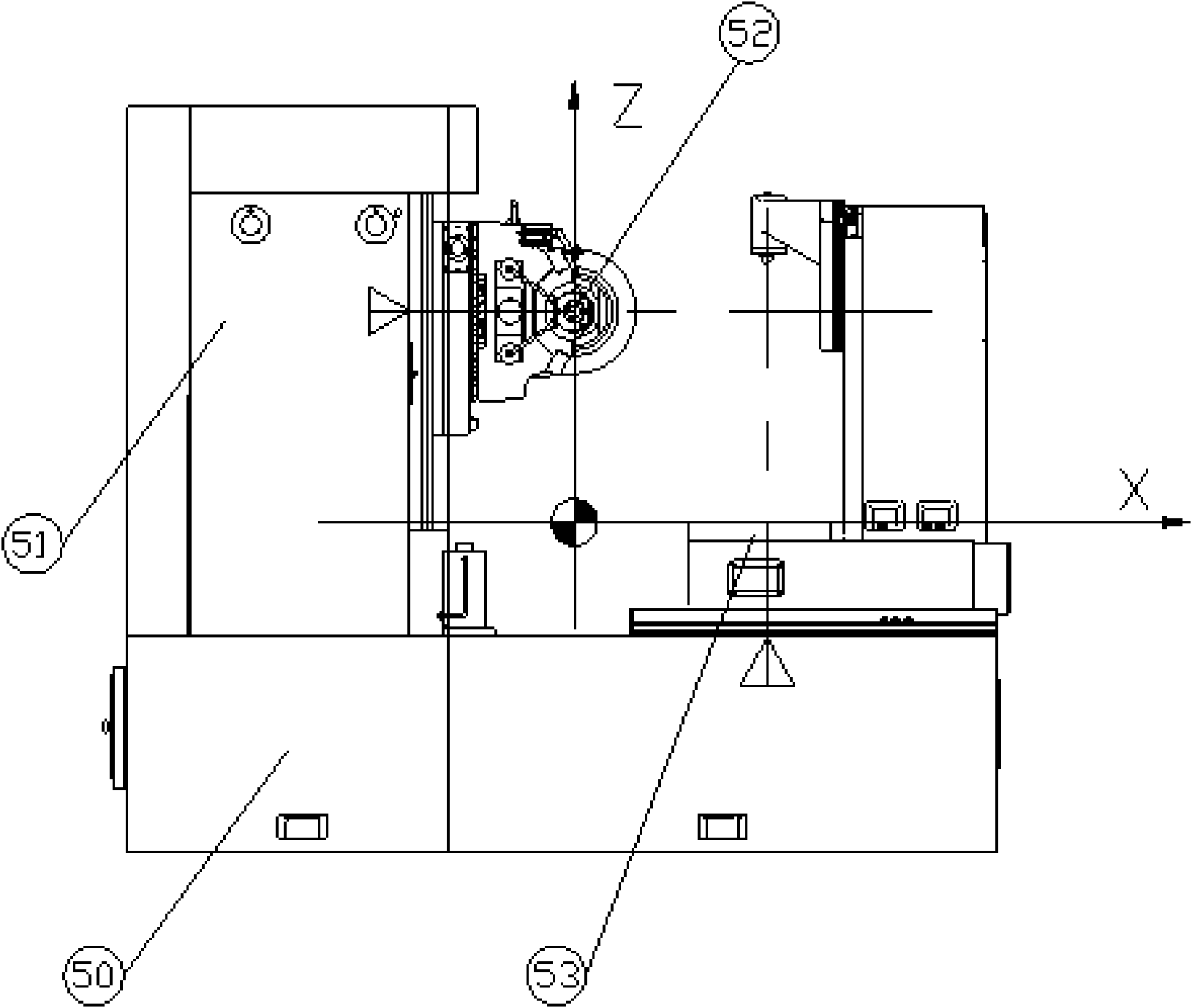

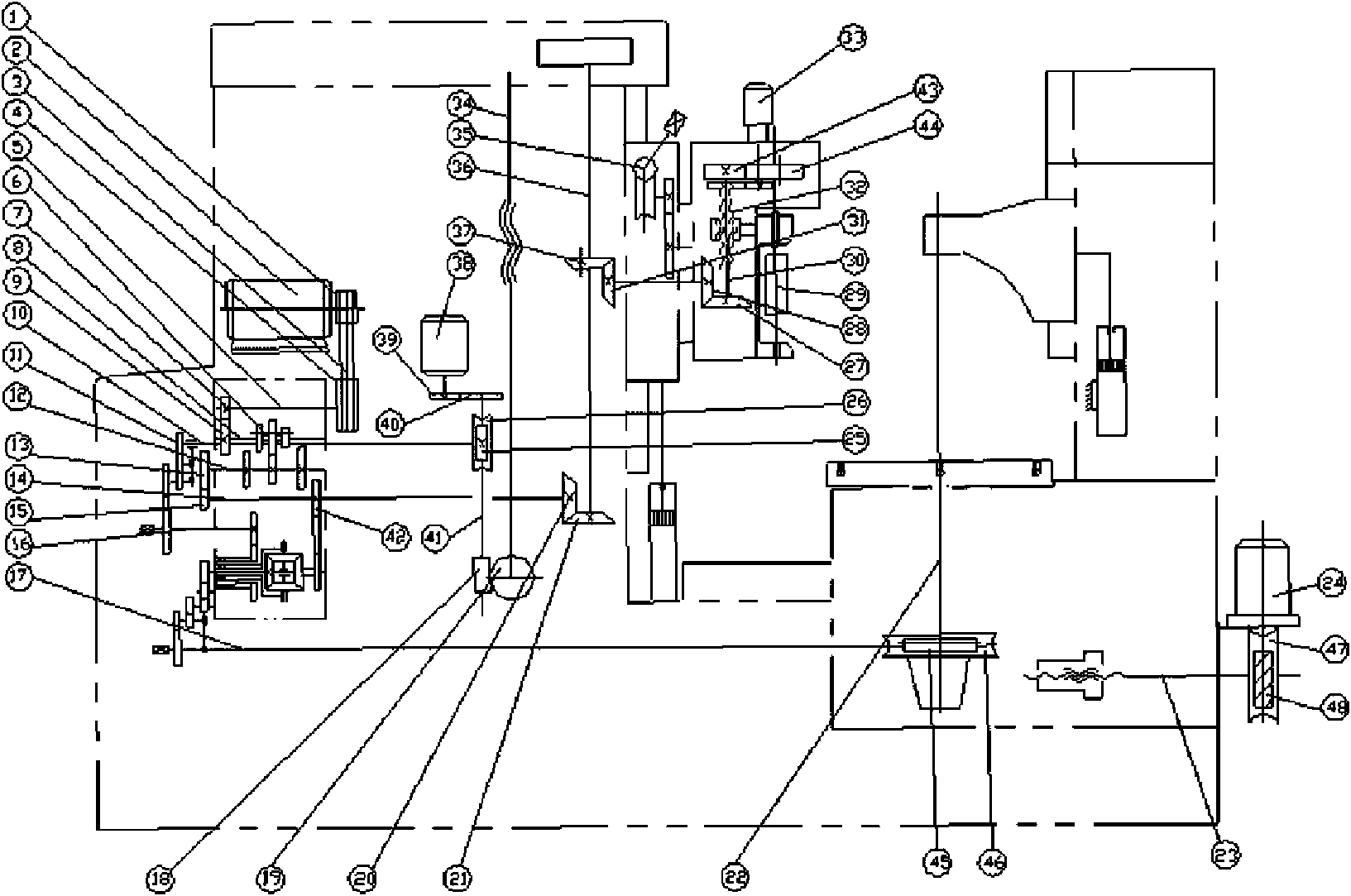

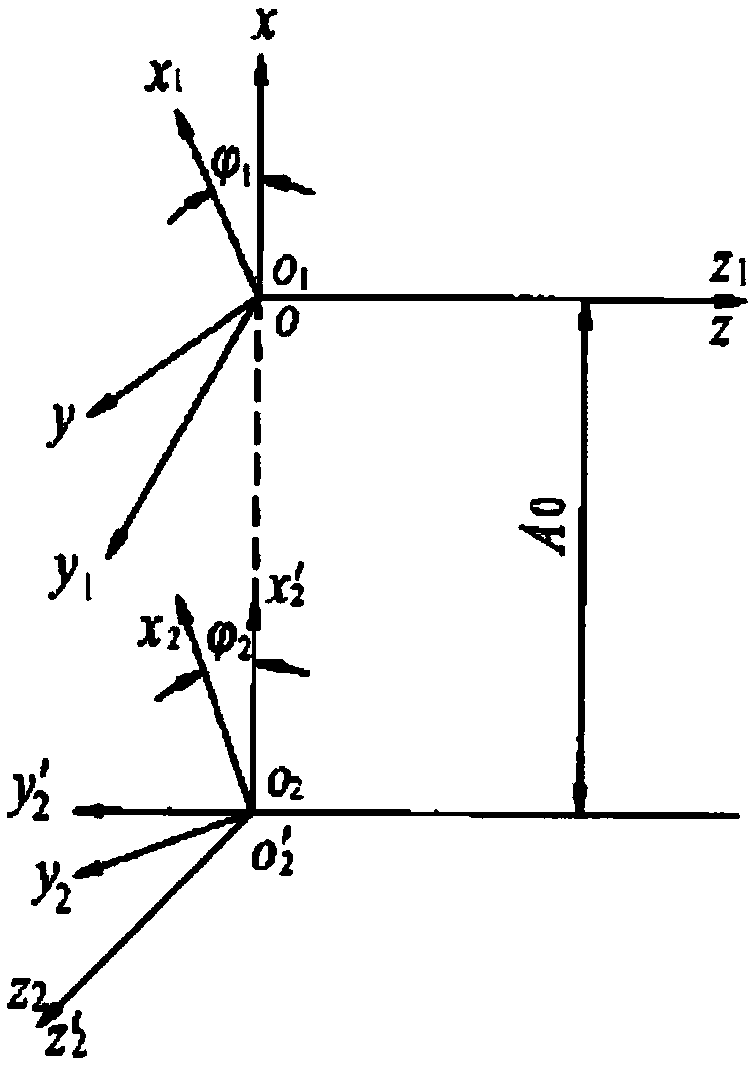

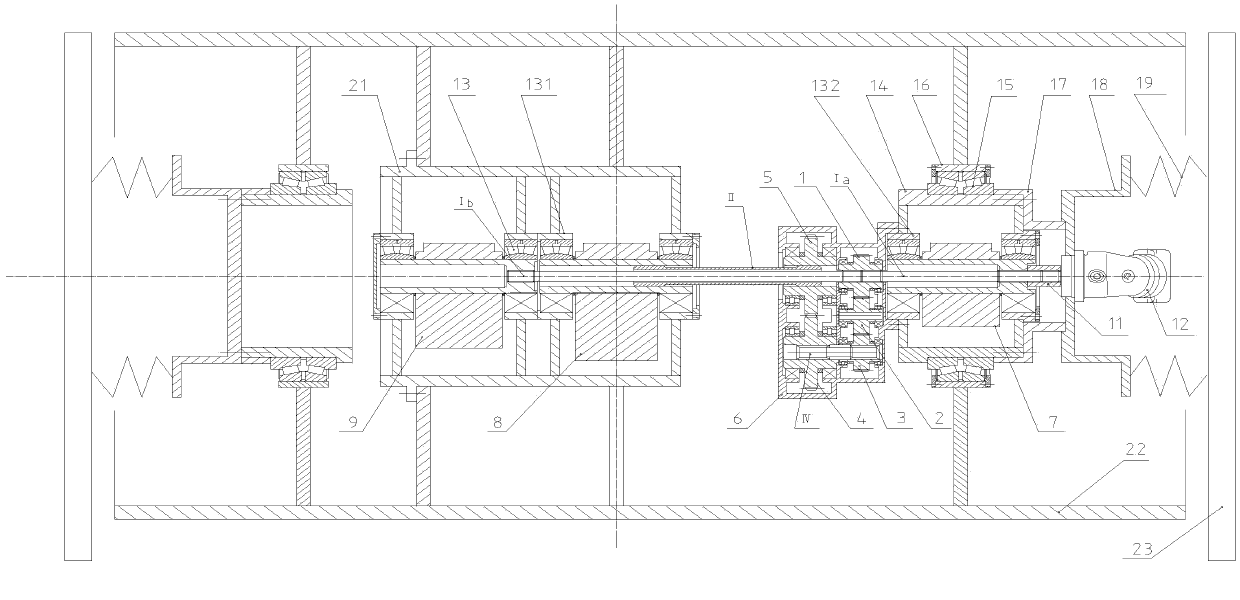

Diagonal rolling cut three-axis numerical control hobbling machine

InactiveCN101596624APrevent tooth cuttingFeeding apparatusLarge fixed membersNumerical controlGear wheel

The invention relates to a three-axis numerical control hobbling machine for realizing diagonal rolling cut by replacing a flee cutter saddle with a tangential cutter saddle, which solves the problems that in the prior art, the Y axis and the C axis of the three-axis numerical control hobbling machine cannot realize linkage and consequently normal teeth separation cannot be guaranteed. The three-axis numerical control hobbling machine comprises a machine tool body, an upright post mechanism, a rolling cutter saddle mechanism and a workbench mechanism, wherein the lifting upright post mechanism comprises a Z axis; a roller arranged in the rolling cutter saddle rotates around the roller; the workbench moves along an X axis which is vertical to the Z axis and the Y axis respectively and rotates around the C axis which is parallel to the Z axis; the roller is driven to rotate by a main motor; the Z axis is driven by a Z-axis servo motor; the rolling cutter saddle is driven by a Y-axis servo motor; the workbench is driven by a X-axis servo motor; the speed at which the rolling cutter saddle axially moves along the Z axis is equal to that at which the rolling cutter moves along the Y axis axially so as to form linkage; the output end of the upright post mechanism is provided with a first gear pair; the output end of the main motor is provided with a second gear pair; the output of the upright post mechanism is combined with that of the main motor to be connected to the workbench mechanism to drive the workbench to rotate along the C axis; the rotating speed of the Z axis is equal to that of the Y axis; and the Z axis is linked with the C axis of the workbench, so that the Y axis is connected with the C axis to form the linkage. Thus, the rotation of the C axis can get comprehension during rolling cut to avoid generating gear cutting.

Owner:浙江嘉力宝传动设备有限公司

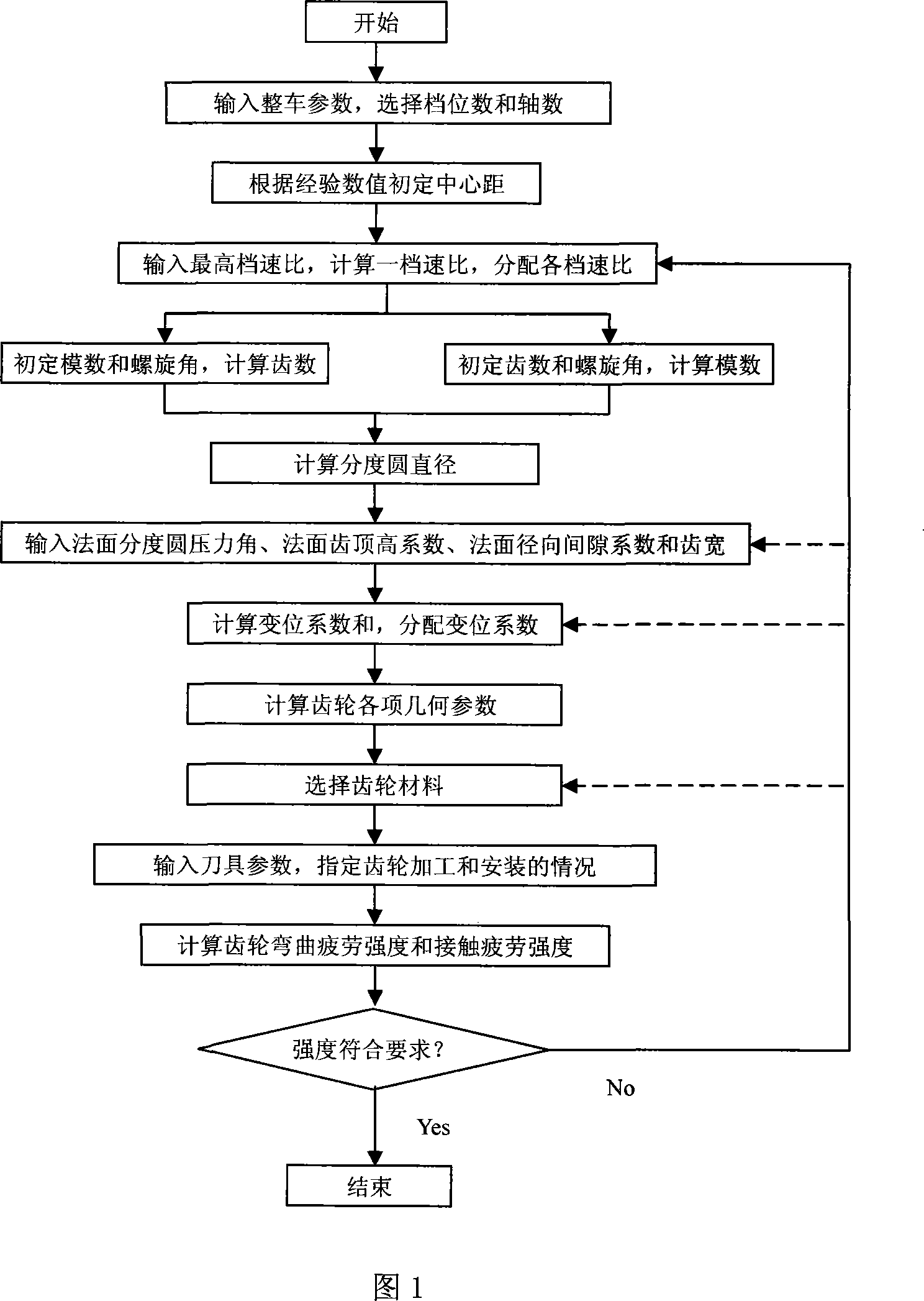

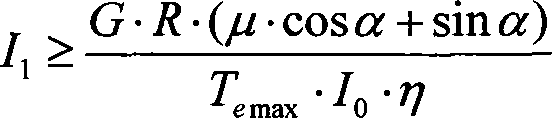

Design method of gear transmission system of automobile transmission based on Web technology

InactiveCN101196956AAchieve normalizationSolve the difficult problems of development and designSpecial data processing applicationsEngineeringTooth number

A design method of a Web technology-based automobile transmission gear drive system is provided, which belongs to the technology field of computer application. The steps are that: the system computes actual center distance or user directly gives the actual center distance; the system determines the range of lowest grade speed ratio and highest grade speed ratio value and allocates the grade speed ratio of the transmission; tooth number determination module is called to determine the tooth number, module number and helix angle; the system computes diameter of reference circle, inputs normal reference circle pressure angle, normal radial gap coefficient, normal tooth addendum coefficient and tooth width, calls addendum coefficient to compute and allocate the module, computer normal addendum coefficient sum and allocates the normal addendum coefficient; the system gives warning if the selected addendum coefficient is not in compliance with the requirement; the design result is checked. The invention can effectively solve the problem of difficult development and design of transmission gear drive system products and facilitate the design of the automobile transmission gear simple, convenient and fast and accurate.

Owner:SHANGHAI AUTOMOBILE GEAR WORKS +1

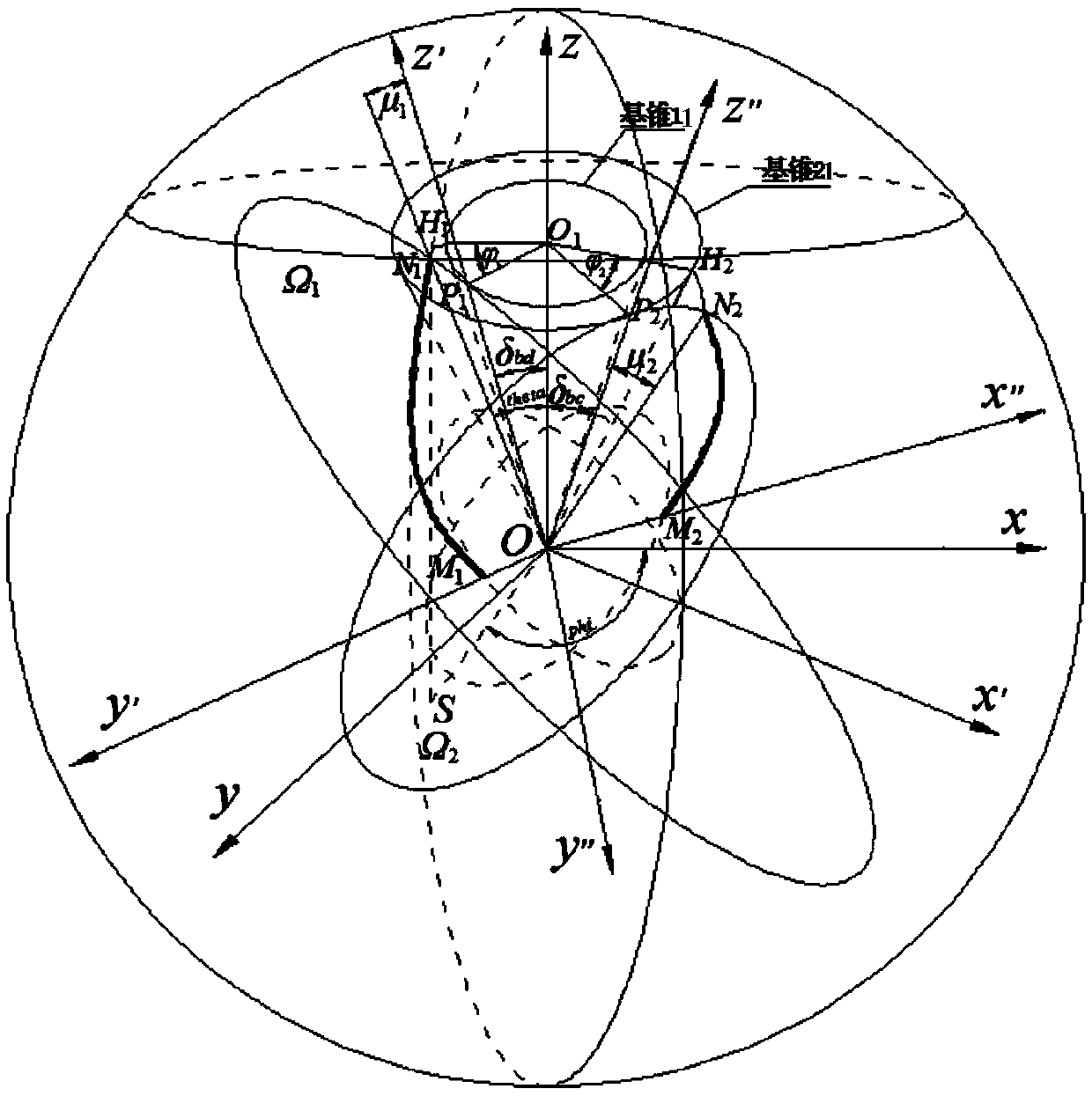

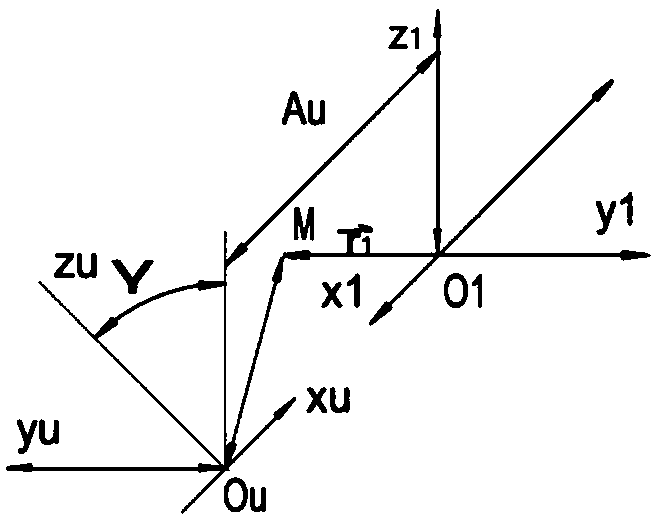

Plane secondary enveloping ring surface worm measuring method

ActiveCN103791870ARealize detectionEfficient measurement speedMeasurement devicesSpecial data processing applicationsMathematical modelGear wheel

The invention discloses a plane secondary enveloping ring surface worm measuring method and belongs to the field of the precise testing technology and the instrument and machine transmission technology. According to the method, a tooth surface equation of a worm is set up based on the gear space meshing principle, and the modeling method conforms to the machining method of the plane secondary enveloping ring surface worm; a mathematic model of an error term of the worm is set up according to the definition of the error term of the worm, coordinate conversion is performed on the mathematic model, the mathematic model is converted into coordinates of three axes of motion of a worm measuring machine, and three coordinate numerical solutions are obtained with the numerical solution method; a computer performs sampling route planning according to coordinate values, the coordinate values are input into a numerical control system to control movement of the measuring machine, a data collecting system synchronously collects grating values and measuring head data of the three axes and processes the collected data, and therefore high-precision measurement on the spiral line errors, the axial tooth shape errors, the normal tooth shape errors, the division errors and the axial tooth thickness deviation of the plane secondary enveloping ring surface worm is achieved.

Owner:BEIJING UNIV OF TECH

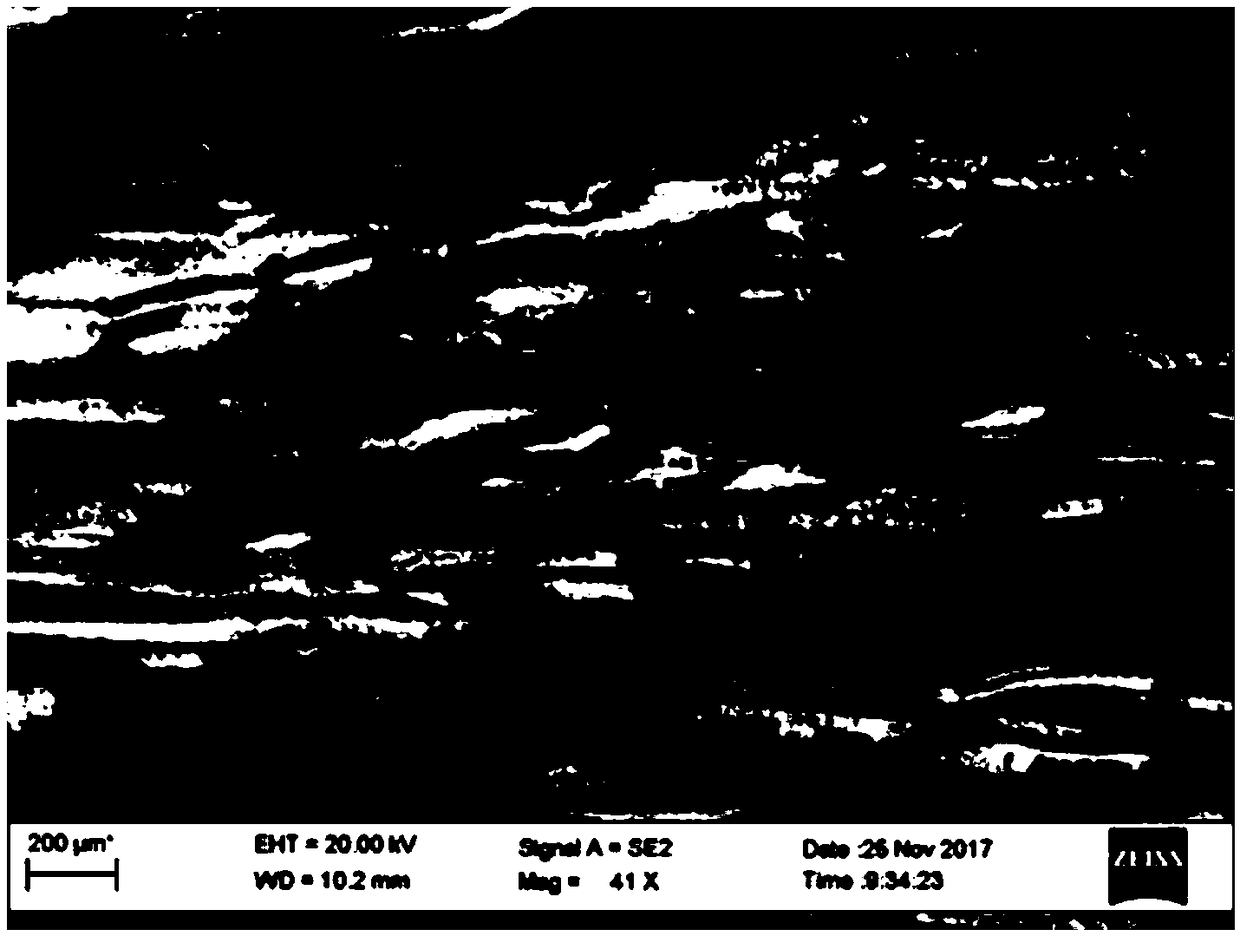

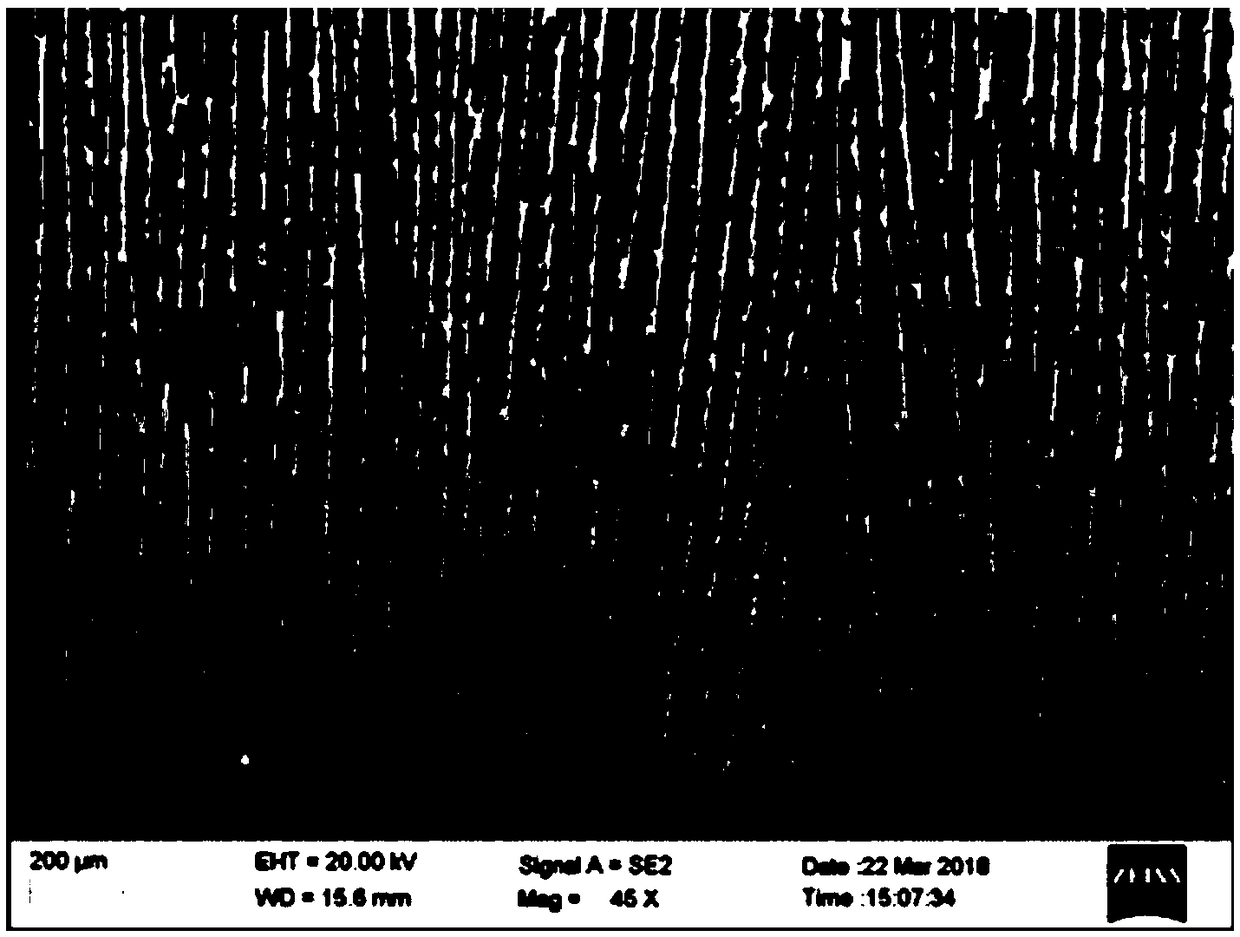

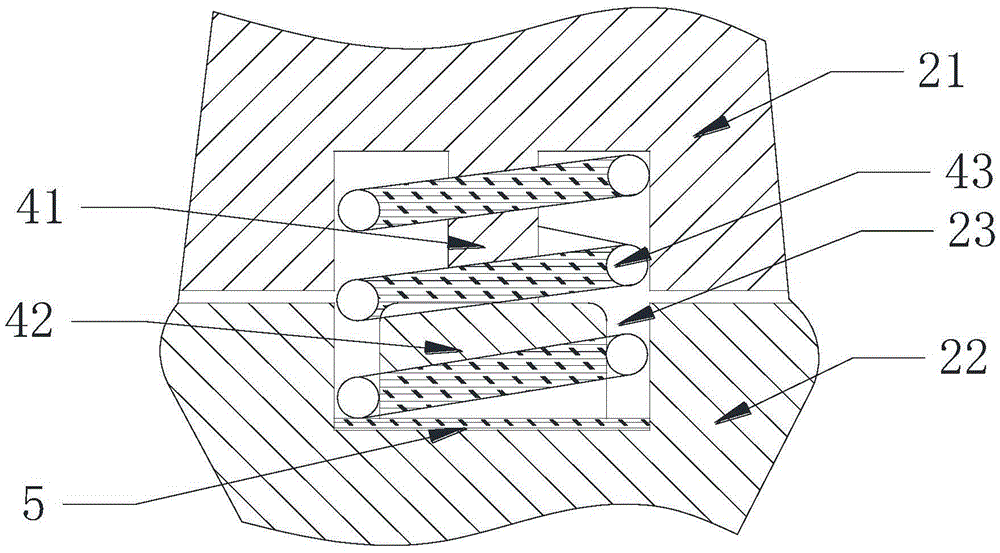

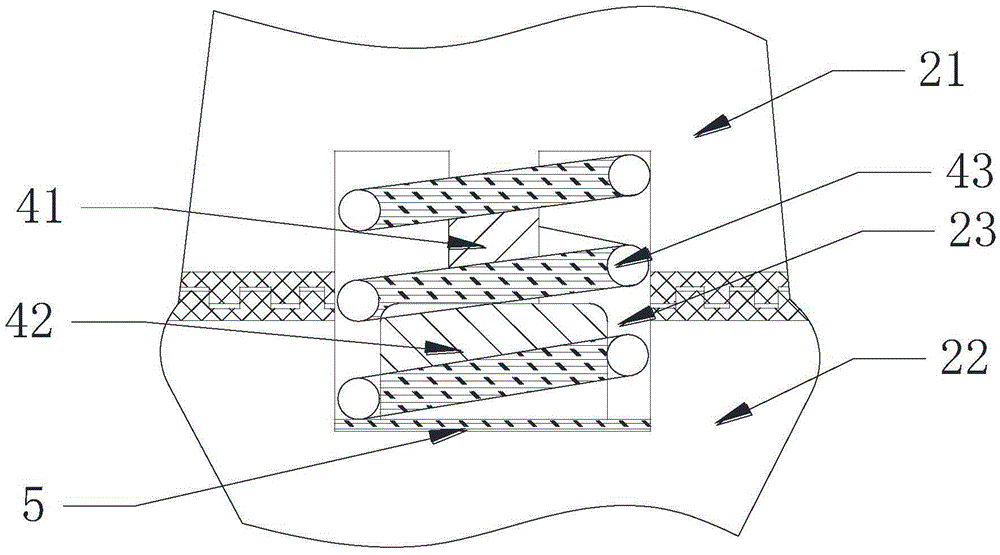

Zirconium oxide/resin bionic composite material for denture and preparation method thereof

ActiveCN108743405AGood biocompatibilityAccelerated corrosionImpression capsDentistry preparationsBrickFreeze-drying

The invention relates to the field of composite materials for denture, in particular to a zirconium oxide / resin bionic composite material for the denture and a preparation method thereof. The zirconium oxide / resin bionic composite material is prepared from the following components of 20vol% to 97vol% of zirconium oxide and biocompatible resin, and is of a bionic lamellar structure, a brick-wall structure or a crossed laminating structure in a microscopic way. The zirconium oxide / resin bionic composite material has the advantages that the oriented porous blank with the lamellar structure is obtained by slurry preparation, freezing-casting and vacuum freeze-drying, and is compressed along the lamellar structure direction to form the crossed laminating structure; the zirconium oxide skeletonwith the lamellar structure or crossing laminating structure can be prepared by removing organic matters and sintering, and the zirconium oxide skeleton of the brick-wall structure can be obtained through the vertical compression of the lamellar structure skeleton and the secondary sintering; the surface is subjected to surface modifying and liquid resin monomer permeating, and the resin is polymerized, so as to obtain the zirconium oxide / resin bionic composite material for the denture with the bionic structure; the prepared zirconium oxide / resin bionic composite material is mainly used as thedenture, so as to reduce the abrasion to the normal teeth of a human body by the denture.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

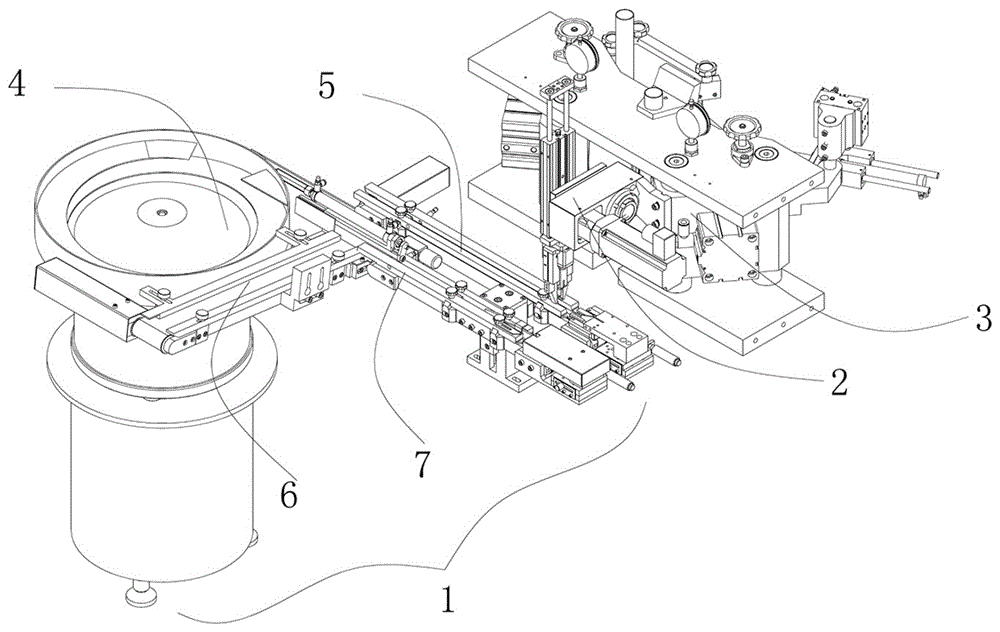

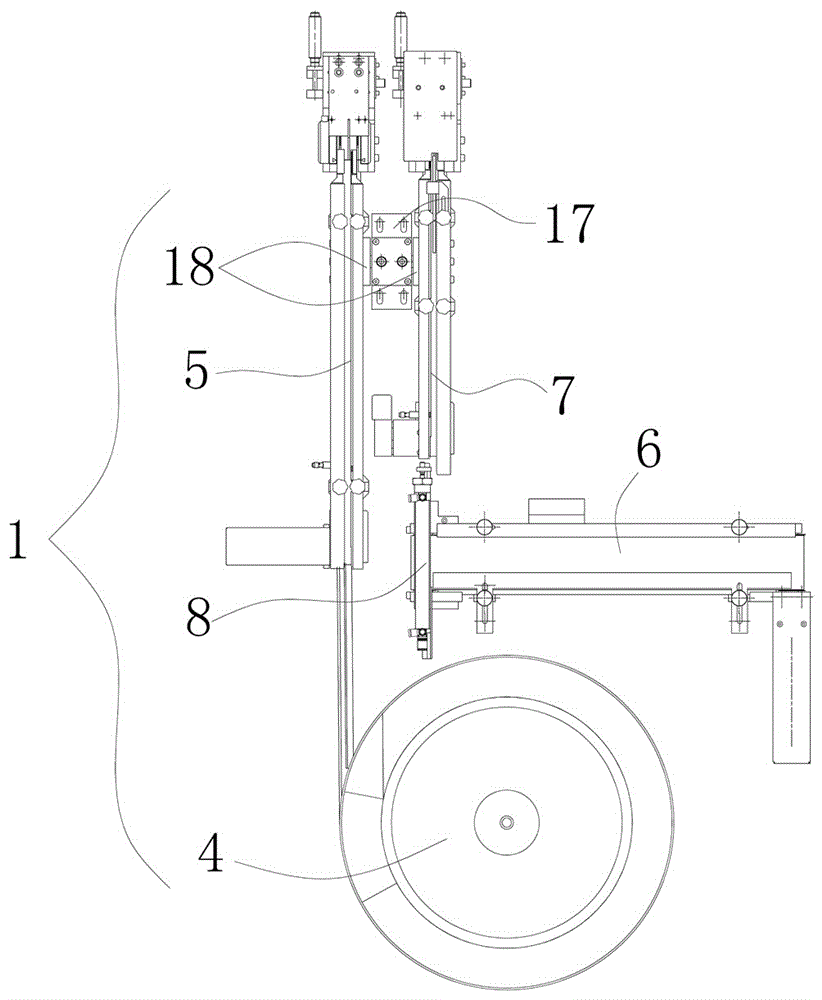

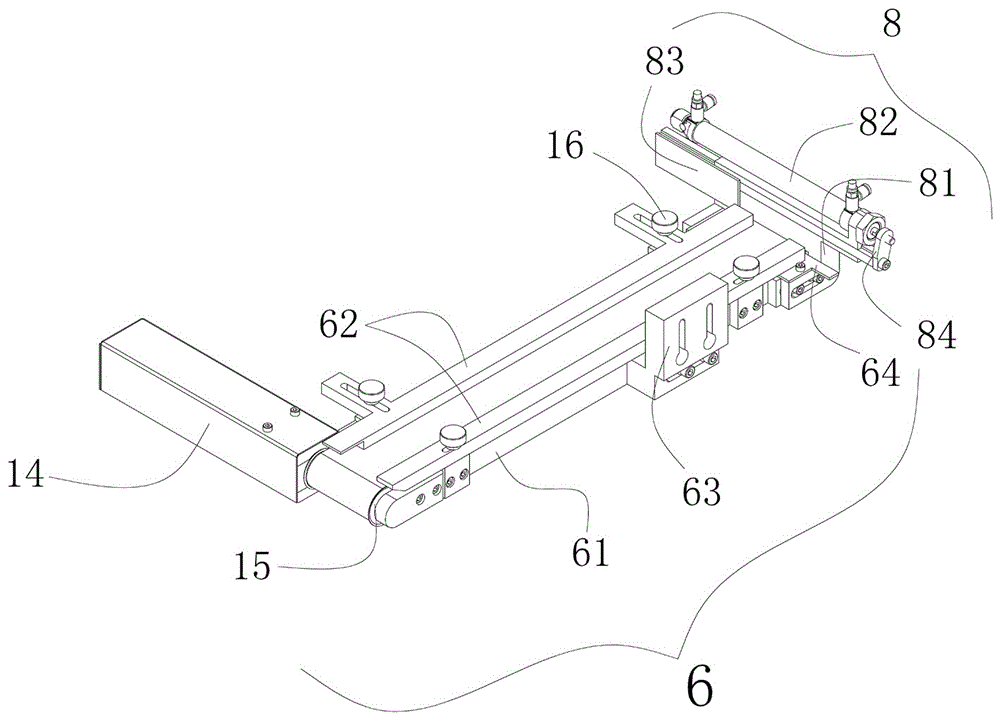

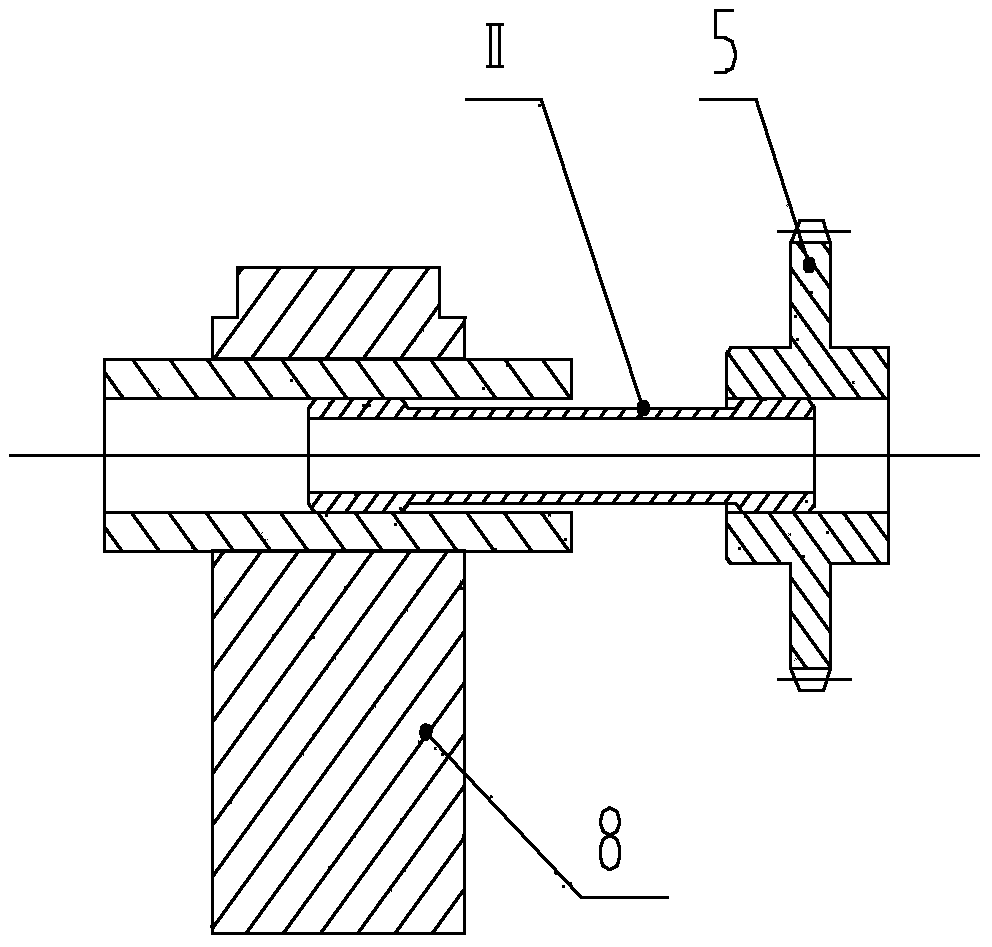

Tool bit conveying, catching and clamping system of saw web laser welding machine

ActiveCN106271137AReasonable structural designCompact designLaser beam welding apparatusTool bitNormal teeth

The invention belongs to the technical field of diamond saw web welding. A tool bit conveying, catching and clamping system of a saw web laser welding machine comprises a rack, a tool bit conveying device, a tool bit catching device and a tool bit clamping device, wherein the tool bit conveying device comprises a supporting vertical column and a normal tooth conveying unit and a protection tooth conveying unit which are arranged on the supporting vertical column; the normal tooth conveying unit and the protection tooth conveying unit respectively array normal tooth tool bits and protection tooth tool bits in a fixed direction, and convey the tool bits to a tool bit catching station; the tool bit catching device catches the normal tooth tool bits or the protection tooth tool bits according to a welding working procedure, and conveys the normal tooth tool bits or the protection tooth tool bits which are caught to a clamping station of the tool bit clamping device, and the tool bits are located and clamped by the tool bit clamping device. The tool bit conveying, catching and clamping system of the saw web laser welding machine is integrated and high in mechanical degree, can automatically realize tool bit conveying and clamping, is accurate in location, can greatly reduce the labor intensity of a worker, and is relatively low in labor cost; and the production cost of an enterprise is reduced.

Owner:郑州金海威科技实业有限公司

Orthodontic retainer elements

InactiveUS7300279B2Easy accessPrevent or reduce the risk of breakage of the bonding materialBracketsDental toolsDental flossEngineering

Owner:AMUNDSEN OLE CHRISTIAN

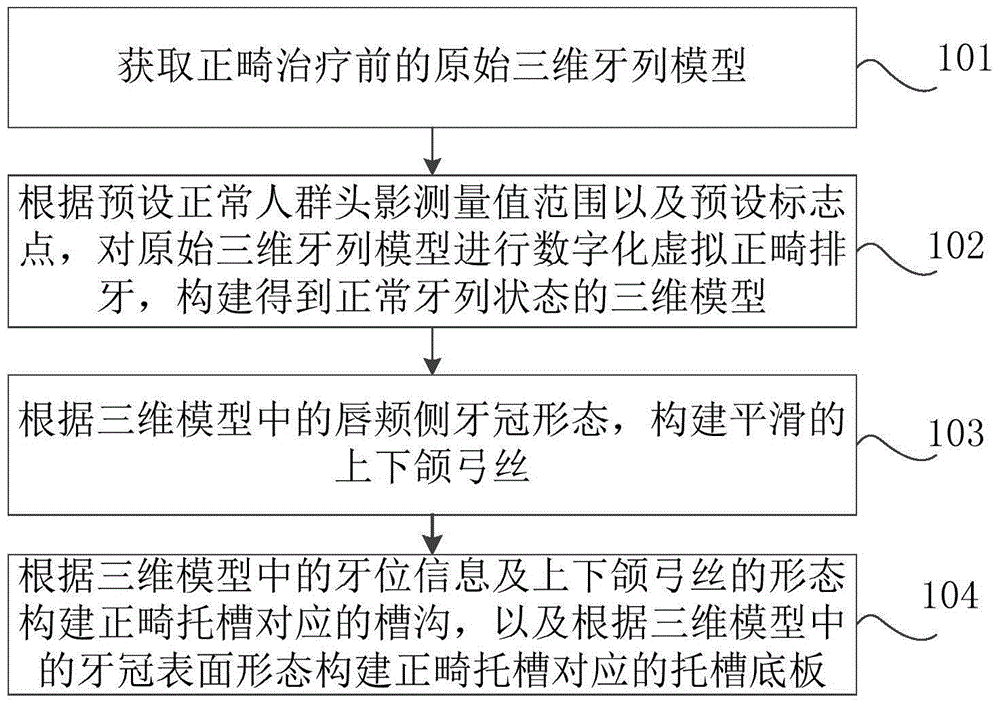

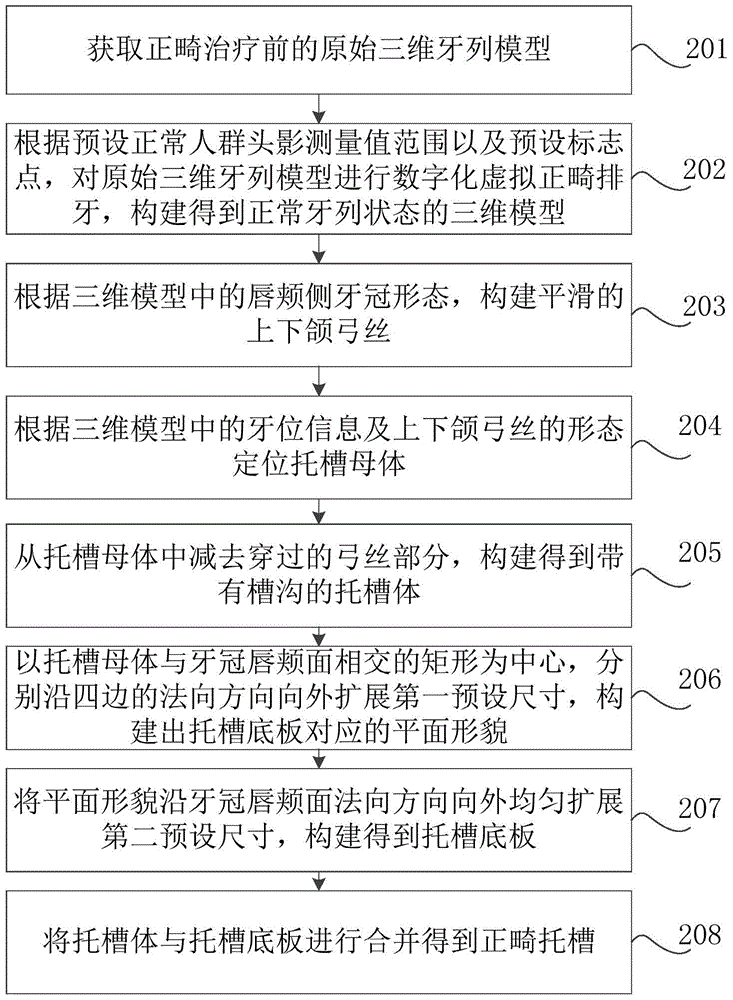

Method and device for manufacturing orthodontic bracket

InactiveCN105708565AGood effectImprove efficiencyBracketsAnatomical structuresManufacturing technology

The invention discloses a method and device for manufacturing an orthodontic bracket and relates to the technical field of orthodontic bracket manufacturing, by means of the method and device for manufacturing the orthodontic bracket, the personalized orthodontic bracket can be manufactured according to the unique tooth three-dimensional anatomical structure of each patient, and the effect and efficiency of orthodontic treatment can be improved.The method includes the steps that firstly, an original three-dimensional tooth column model before orthodontic treatment is obtained; then, digital virtual orthodontic tooth arrangement is conducted on the original three-dimensional tooth column model according to the preset head shadow measurement value range of normal people and preset mark points, and a three-dimensional model of a normal tooth column state is constructed; smooth maxillary arch wires and mandibular arch wires are constructed according to the lip buccal side tooth crown state in the three-dimensional model; finally, a bracket gutter corresponding to the orthodontic bracket is constructed according to the tooth position information in the three-dimensional model and the states of the maxillary arch wires and mandibular arch wires, and a bracket bottom plate corresponding to the orthodontic bracket is constructed according to the dental crown surface form in the three-dimensional model.The method and device are suitable for processing the orthodontic bracket.

Owner:北京正齐口腔医疗技术有限公司

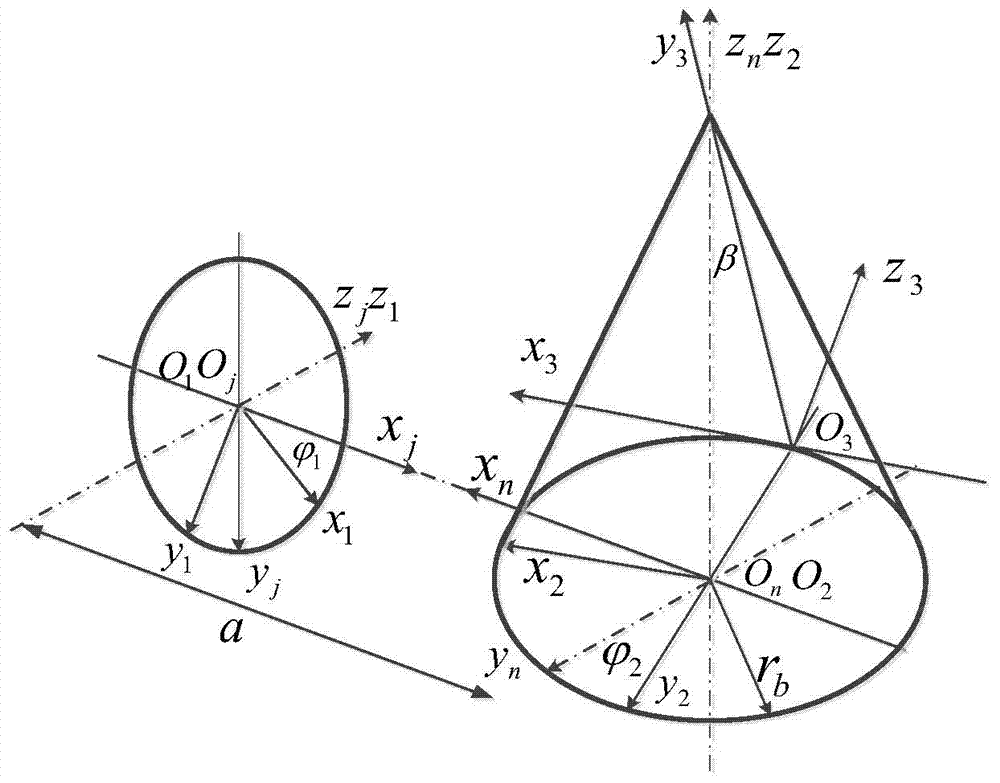

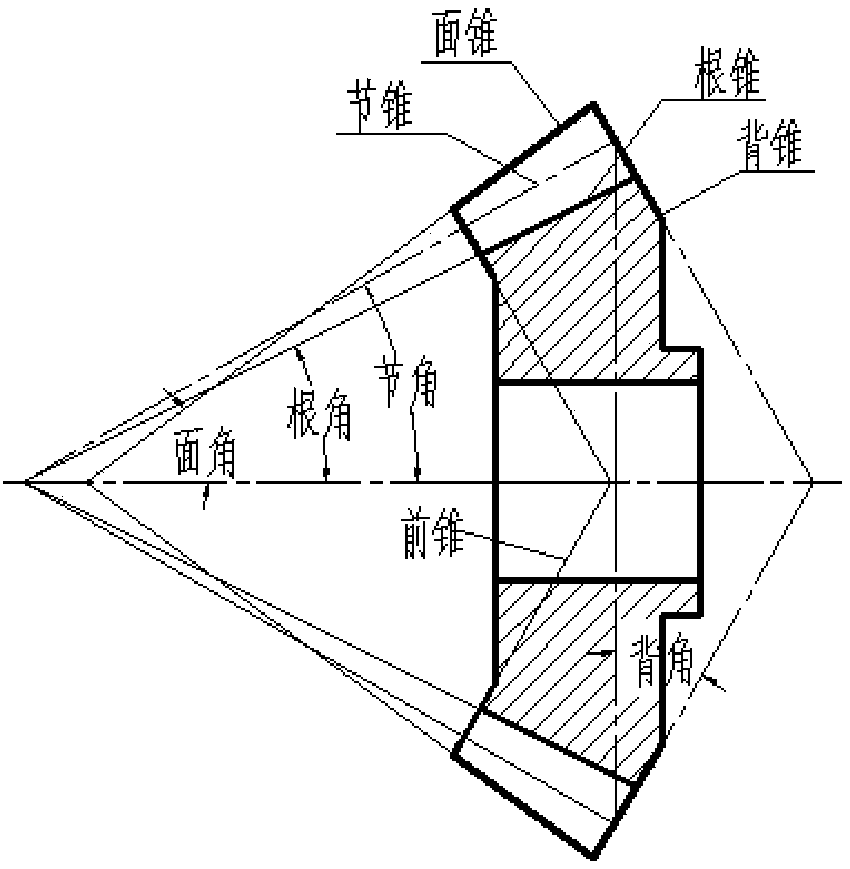

Design method for tooth profile of double-base cone spiral bevel gear

ActiveCN104196981AImprove performanceImprove carrying capacityPortable liftingGearing elementsLarge toothGear wheel

The invention provides a design method for a tooth profile of a double-base cone spiral bevel gear and relates to gears. According to the double-base cone spiral bevel gear, five conical surfaces, four cone angles and two base cones are arranged; the normal tooth profile of each gear tooth comprises an addendum circle, a root circle, a driving side tooth curve, a non-driving side tooth curve and a tooth directional line; the five cone surfaces are a surface cone, a root cone, a pitch cone, a back cone and a front cone respectively; the four cone angles are a face angle, a root angle, a pitch angle and a back angle respectively; for vehicles with gear transmission mechanisms mainly depending on one-way transmission, the property of the spiral bevel gear is improved; the design method for the tooth profile of the double-based cone spiral bevel gear provided by the invention has the advantages that as large tooth profile angles are adopted in the driving surface and small tooth profile angles are adopted in the non-driving surface, the bearing capacity of the gear in the driving direction is increased and the top of tooth is prevented from being tapered, the bearing capacity, fatigue life and output torque of the spiral bevel gear are improved effectively and the vibration and noise in the transmission are reduced.

Owner:XIAMEN ZHEN-WEI TECH CO LED

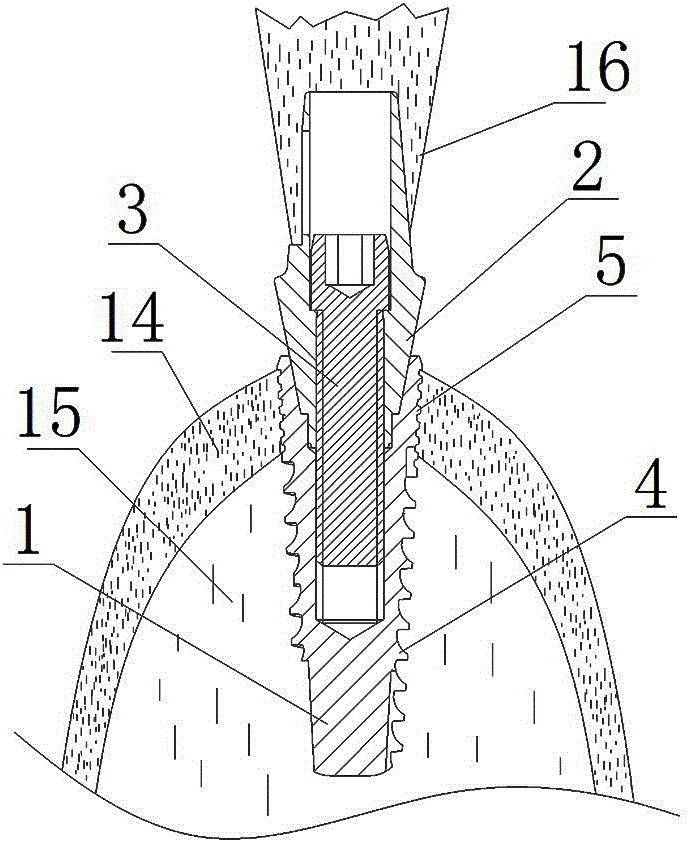

Integrated oral cavity implanting base with buffered and physiological sensation

ActiveCN105455909AAvoid damageServes as a buffer for bite forceDental implantsDental implantNormal teeth

The invention discloses an integrated oral cavity implanting base with the buffered and physiological sensation. The integrated oral cavity implanting base with the buffered and physiological sensation comprises an implant which is in threaded connection with the alveolar bone, a base body which is in threaded connection with the implant and an artificial dental crown arranged on the base body; the base body comprises an upper base body and a lower base body which are connected in a clearance fit mode, and a damping assembly and a pressure-sensitive element are arranged between the upper base body and the lower base body and are elastically connected; the wire end of the pressure-sensitive element penetrates out of the base body to be arranged on the outer side of the base body. The dental implant not only can meet daily food chewing, but also can simulate the chewing action of a normal tooth and also can transmit the chewing action to the gum nerve to generate chewing perception.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

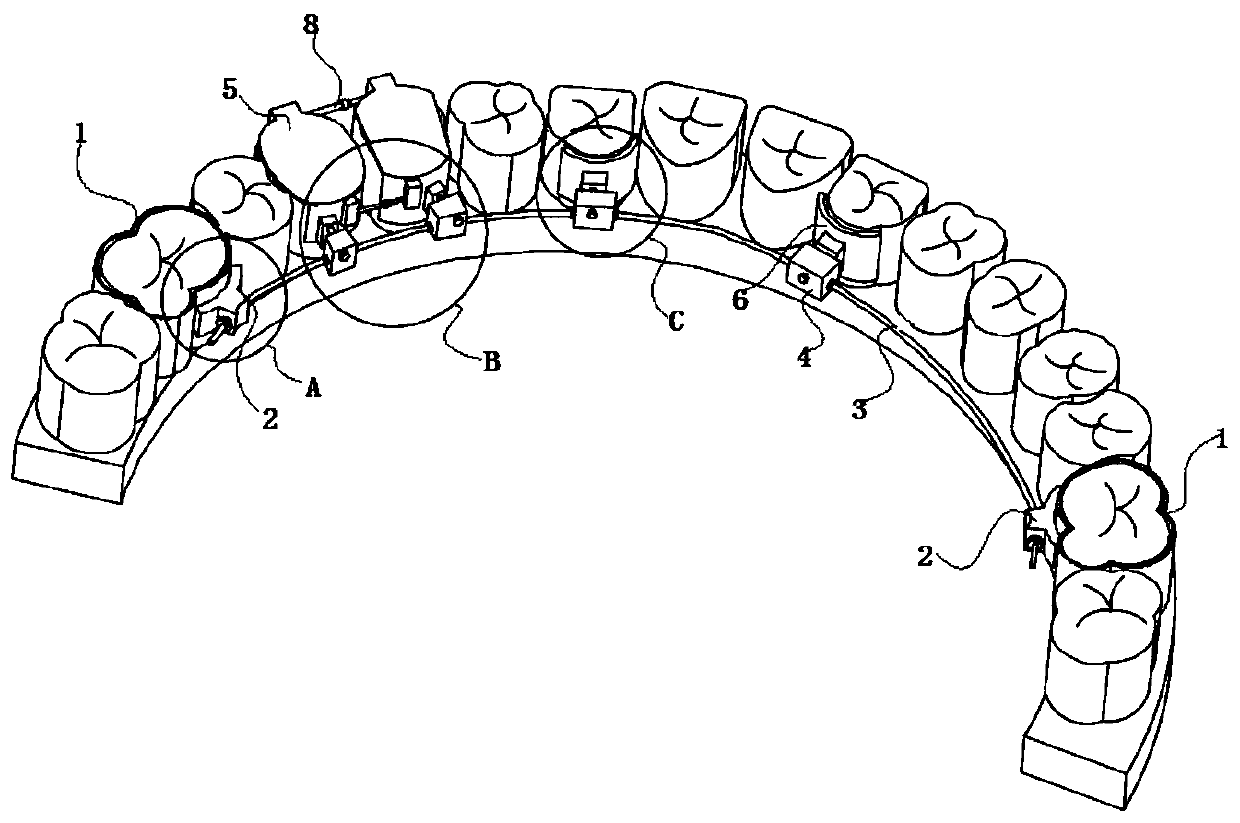

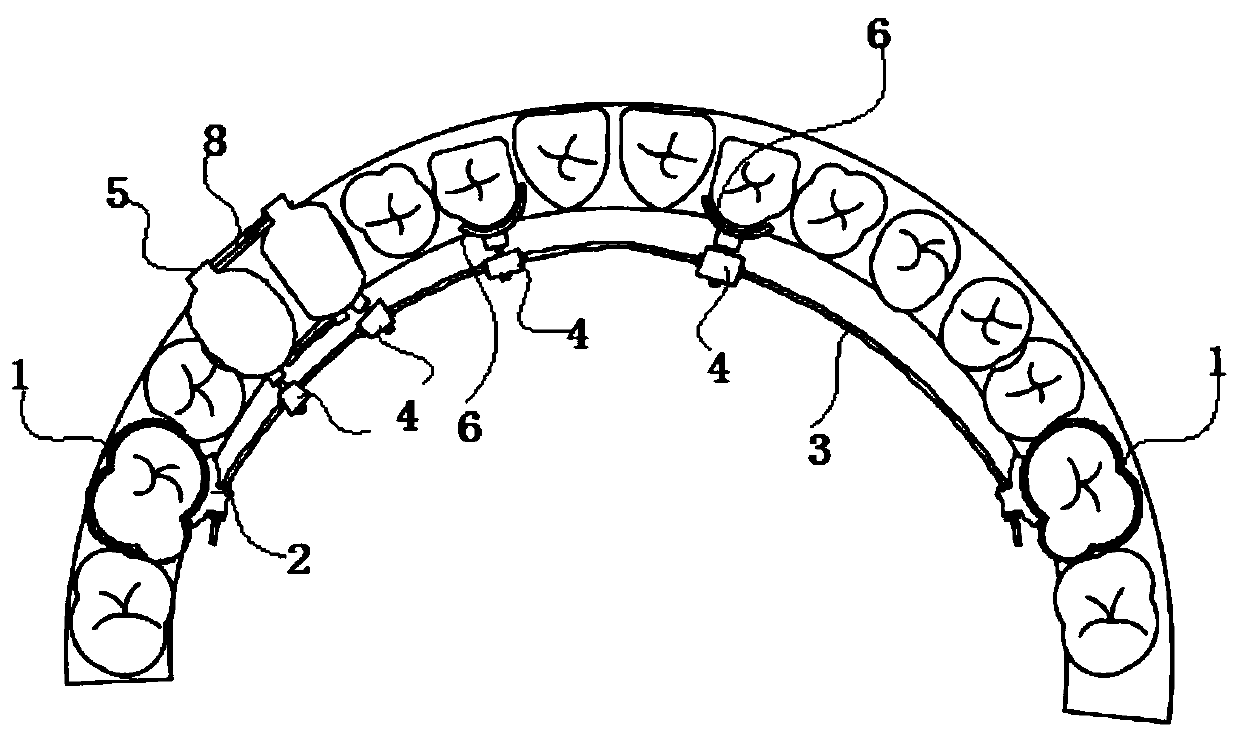

Orthodontics device

InactiveCN111407441AImprove targetingImprove the correction effectArch wiresBracketsOral problemsBiomedical engineering

The present invention discloses an orthodontics device and relates to the technical field of medical supplies. The orthodontics device comprises fixed sleeves, mounting seats, a dental arch wire, adjusting blocks, dental brace single bodies and dental patches; the mounting seats are connected with the fixed sleeves; the mounting seats are inserted with the dental arch wire; the dental arch wire isprovided with the regulating blocks; limiting holes and second arc-shaped through-holes are formed in the adjusting blocks; each dental brace single body is arranged on a single tooth and each two dental brace single bodies are fixedly connected through a telescopic rod; and each telescopic rod is provided with a spiral fastening sleeve. The orthodontics device is provided with the fixed sleeves,mounting seats, dental arch wire, adjusting blocks, dental patches, dental brace single bodies, etc., solves problems that existing orthodontics devices have no targeting on deformed teeth and original normal teeth are easy to move abnormally, and improves targeting of deformed tooth correction.

Owner:太和县卡巴拉医疗设备有限公司

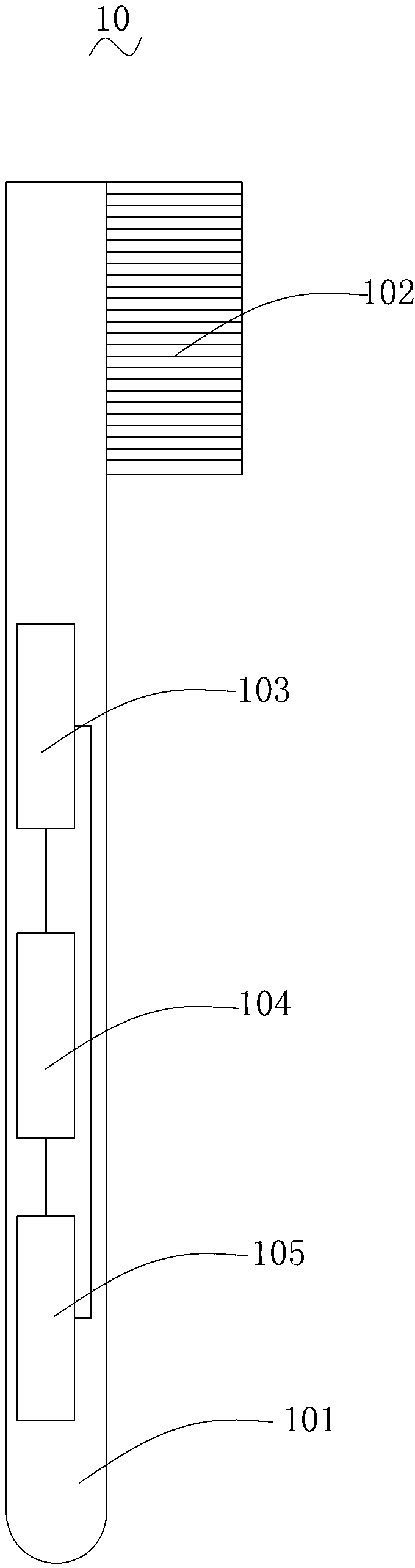

Toothbrush

A toothbrush comprises a strip-shaped handle, a brush arranged at one end of the handle, a motion sensor arranged inside the handle, a reminding module and a battery, wherein the battery is used for providing working electric energy for the motion sensor and the reminding module, the motion sensor senses the vertical motion and the horizontal motion of the motion sensor and sends sensing signals produced to the reminding module, and the reminding module is used for recording the number of times of vertical reciprocating motions and the number of times of horizontal reciprocating motions according to the sensing signals and sends a reminding signal when the number of times of the vertical reciprocating motions and the number of times of the horizontal reciprocating motions both reach to given threshold values. The toothbrush is capable of reminding and supervising a user to complete normal tooth brushing motions and guarantees cleanliness of teeth by detecting whether the number of times of the vertical reciprocating motions and the number of times of the horizontal reciprocating motions both reach to the given threshold values and further reminding the user whether the normal tooth brushing motions are completed.

Owner:张晶

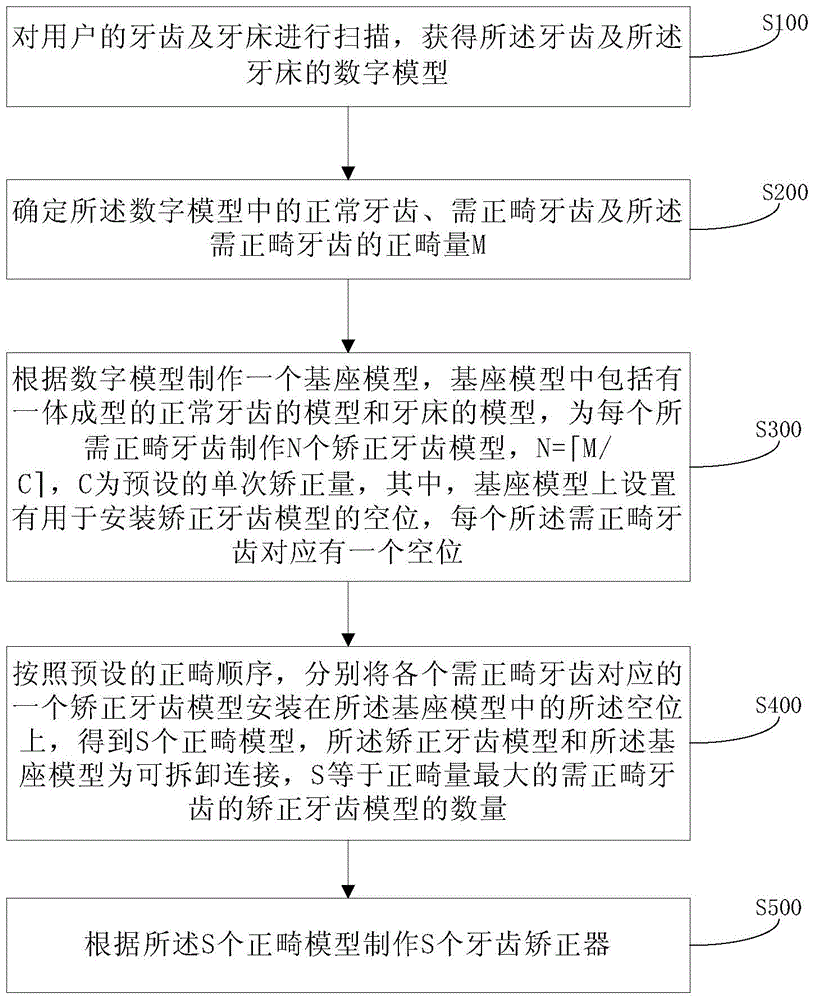

Method and system for producing dental brace

InactiveCN104414758AImprove production efficiencyReduce manufacturing costOthrodonticsMethods of productionNormal teeth

The embodiment of the invention provides a method and a system for producing a dental brace. The dental brace can be manufactured independently for an orthodontic model of a to-be-corrected tooth, and the rest teeth are normal teeth, so that only one base model including a normal tooth model and a tooth model is needed to be manufactured. Compared with a scheme that a complete model is needed to be manufactured in every correcting stage, the method and the system have the advantage that time and cost in the tooth model manufacturing process can be greatly reduced. The method and the system can be used for improving the manufacture efficiency of the dental brace and reducing the manufacture cost.

Owner:SHENZHEN UPCERA DENTAL TECH

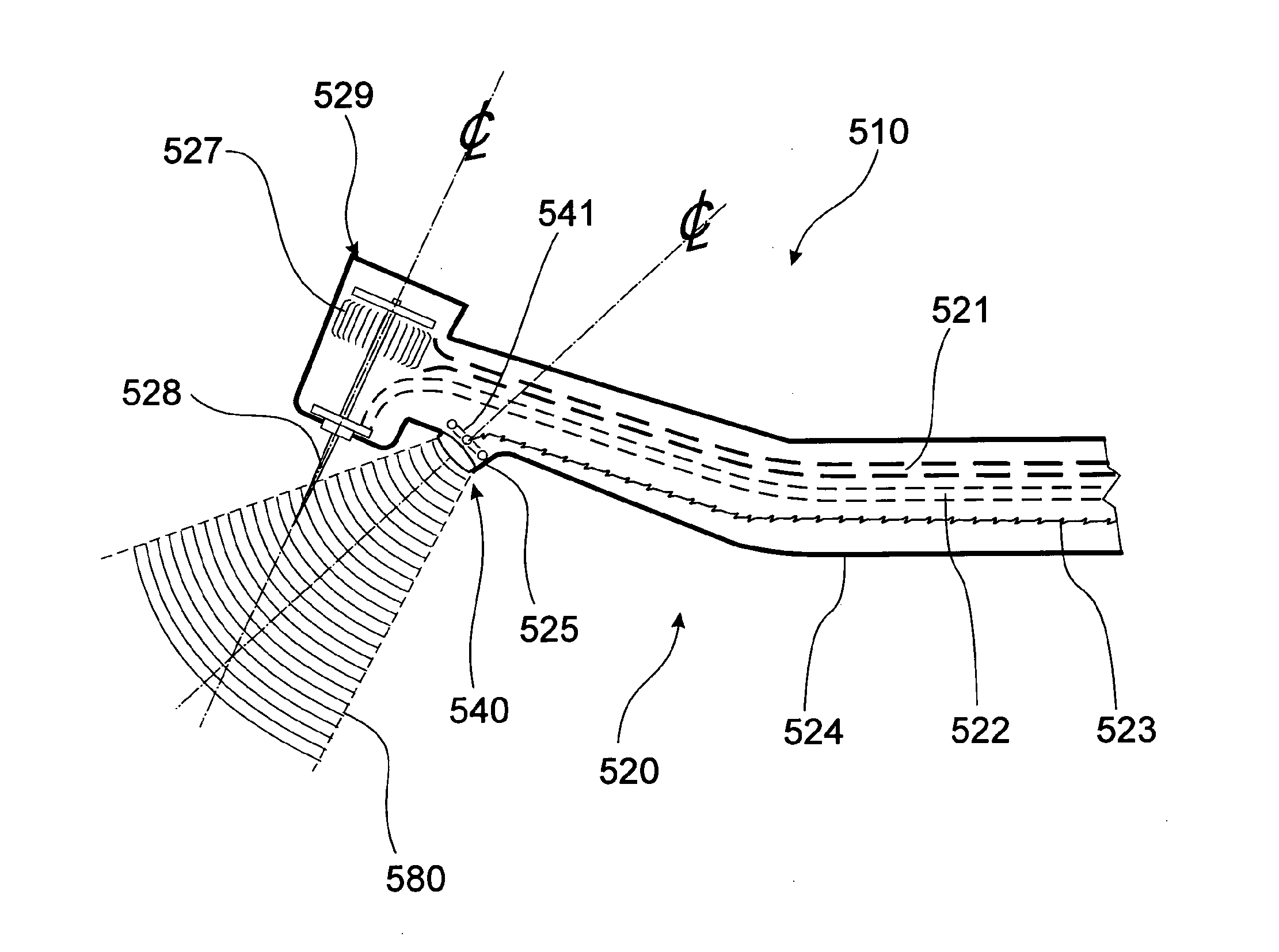

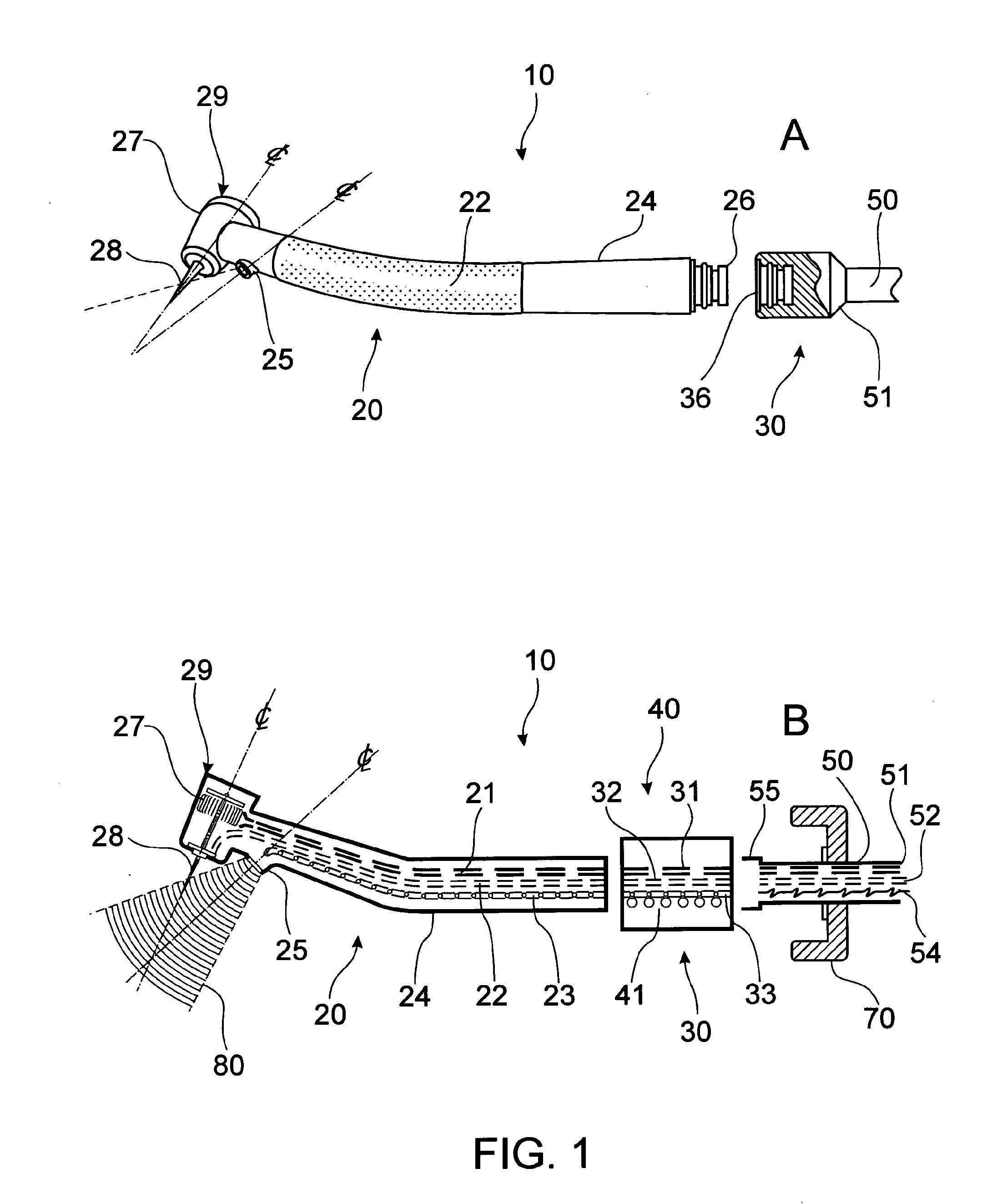

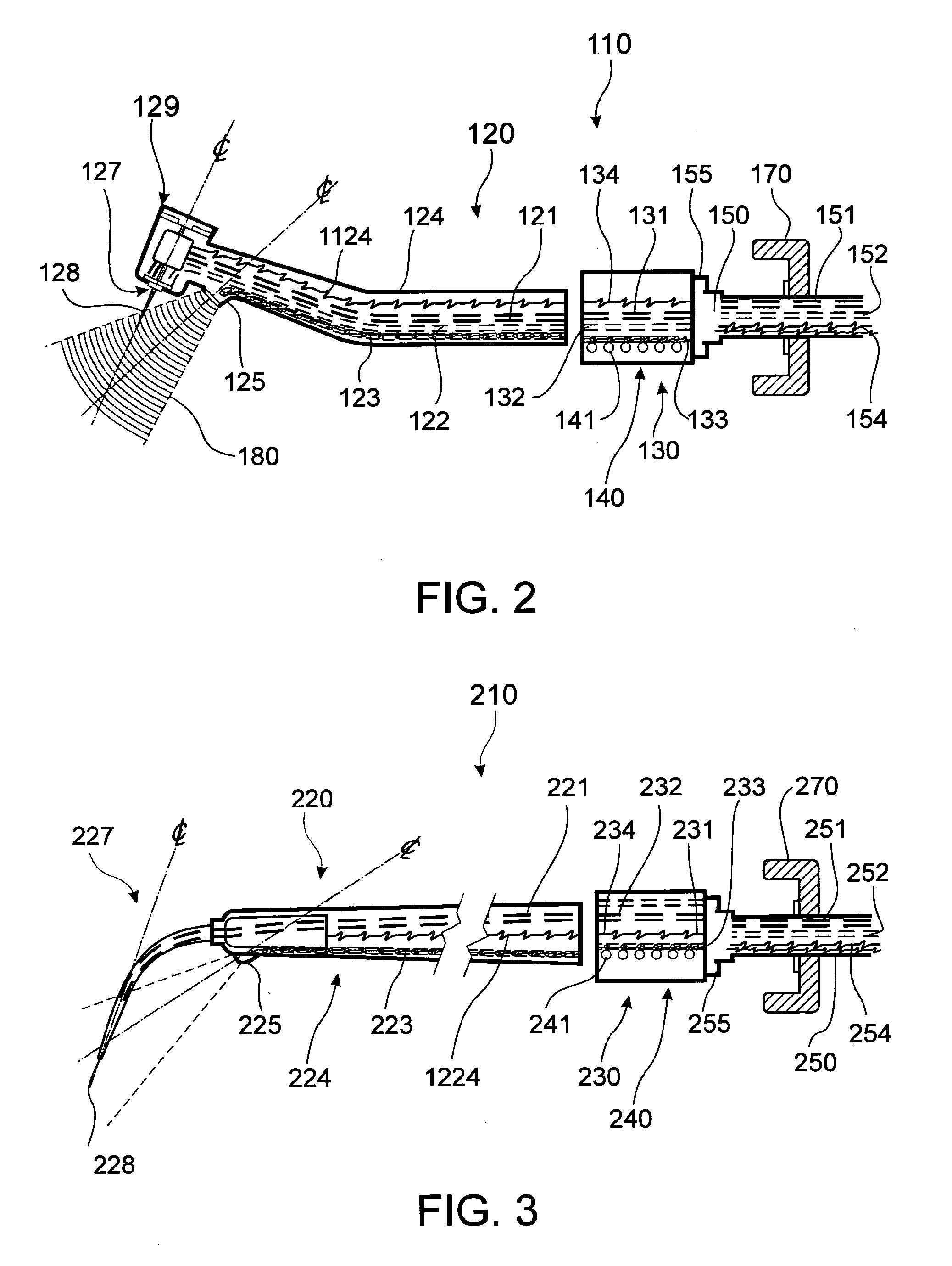

Illuminating dental instrument, coupling and method of use

A dental instrument, or a coupling connectable to the dental instrument, comprises an illuminator having a plurality of light emitting diodes that are each capable of emitting light at a selected wavelength in a range 260 to 880 nm. White or near white light emitting diodes may also be included together with a switch. Fluorescence-based diagnosis can be assisted by the use of a single dye or mixture of dyes. Light of about 400-540 nm wavelength may be used to distinguish composite, porcelain or other tooth coloured filling materials from normal tooth structures. Light of about 260-450 nm wavelength may be used to identify dental caries, calculus and / or dental plaque. Light of about 350-500 nm wavelength may be used to cure dental composite. Typically, the dental instrument is, or comprises, a drill, de-scaler, or other instruments such as for cleaning, examination or diagnosis of dental conditions.

Owner:LJ WALSH DENTAL +1

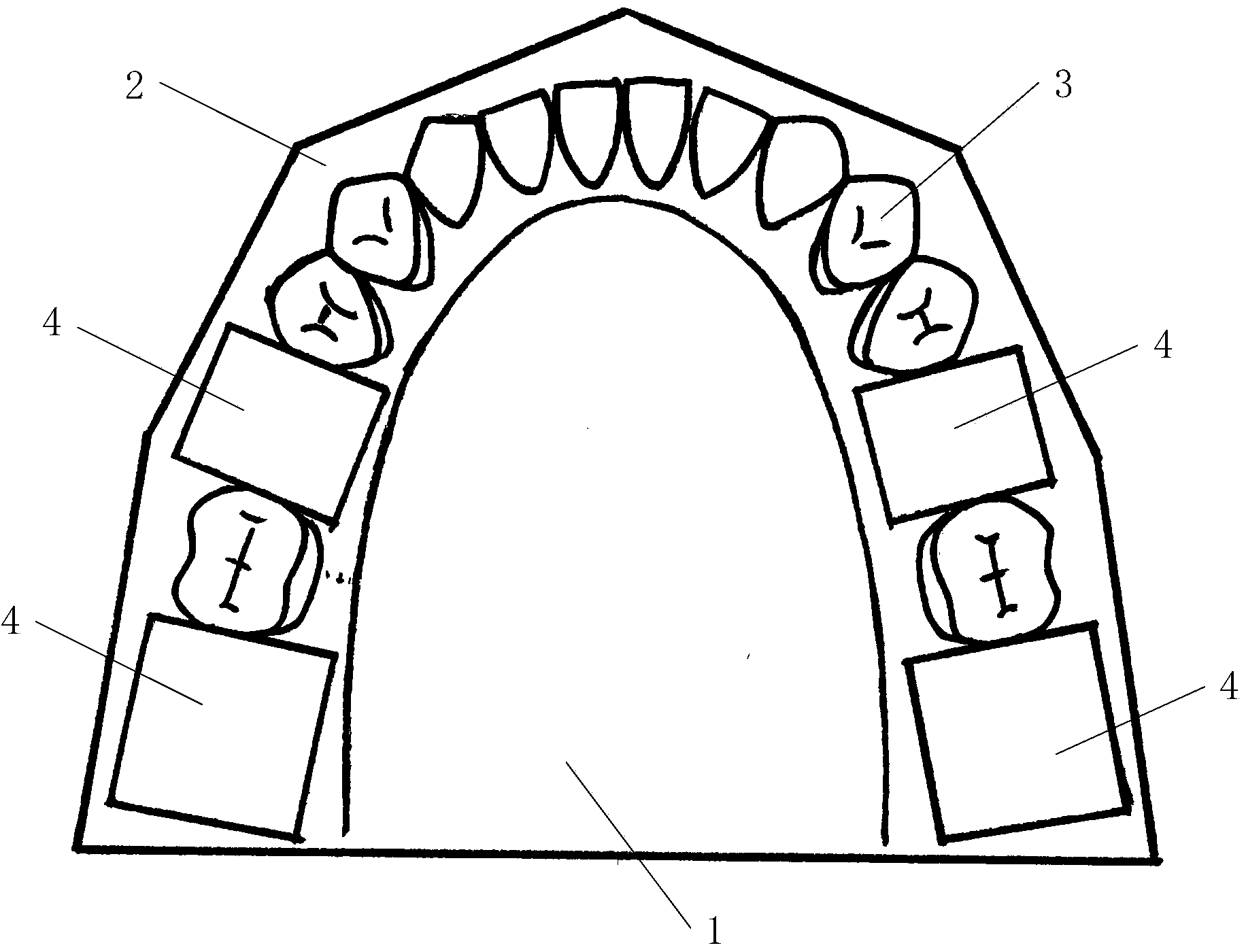

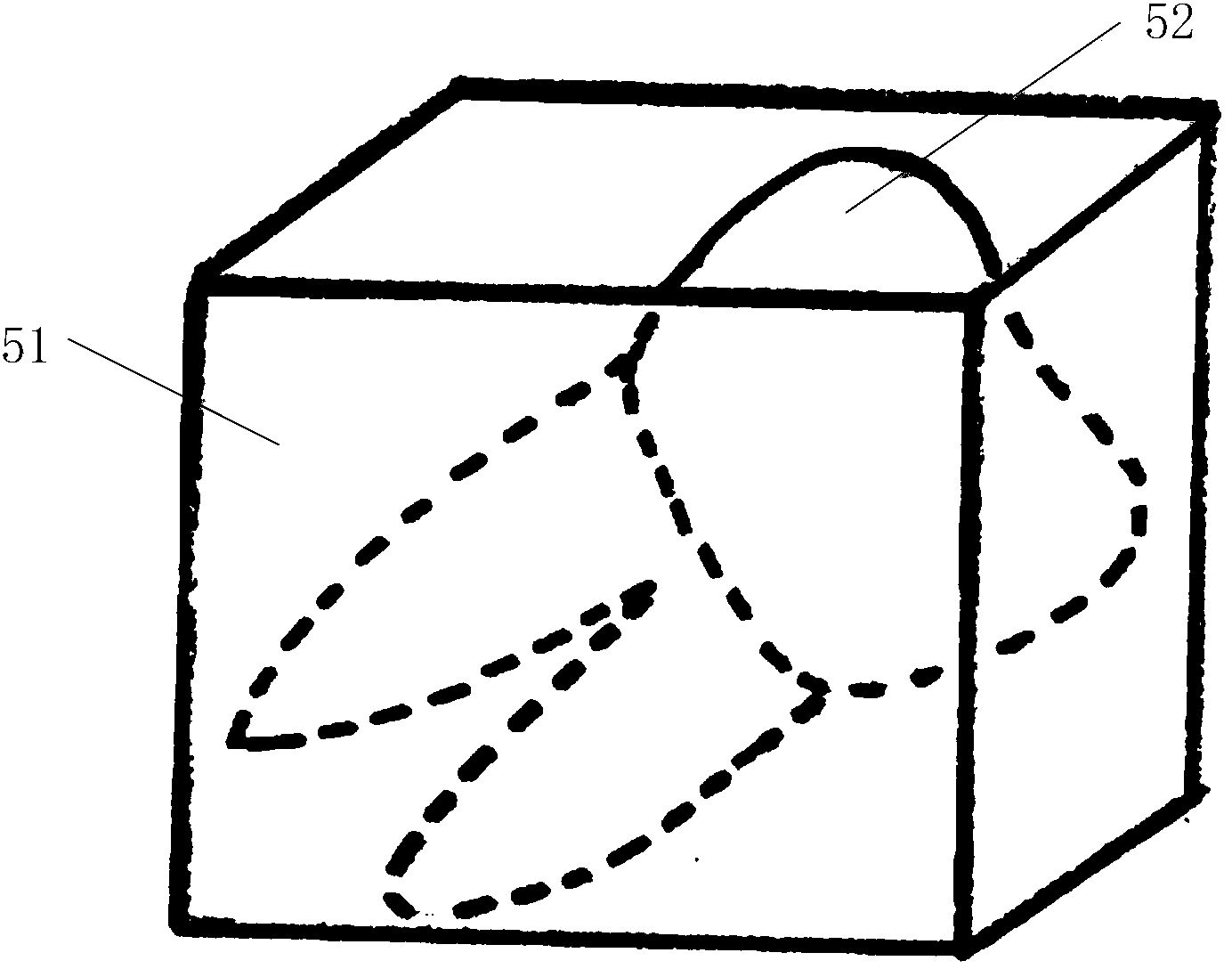

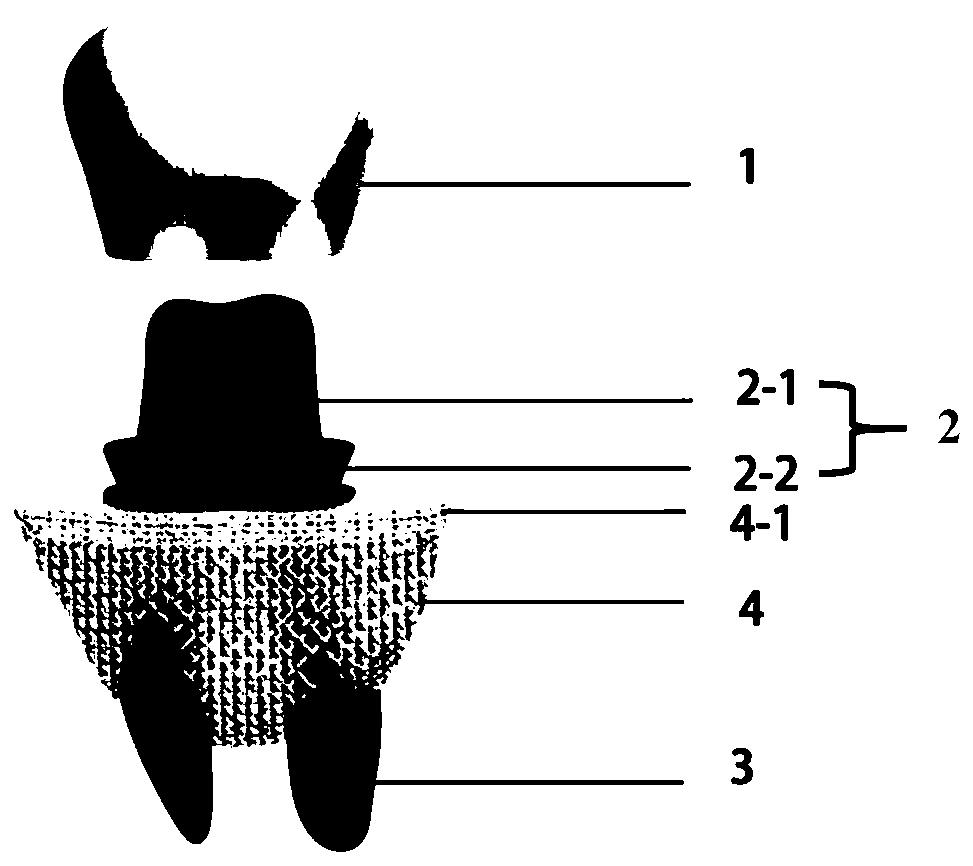

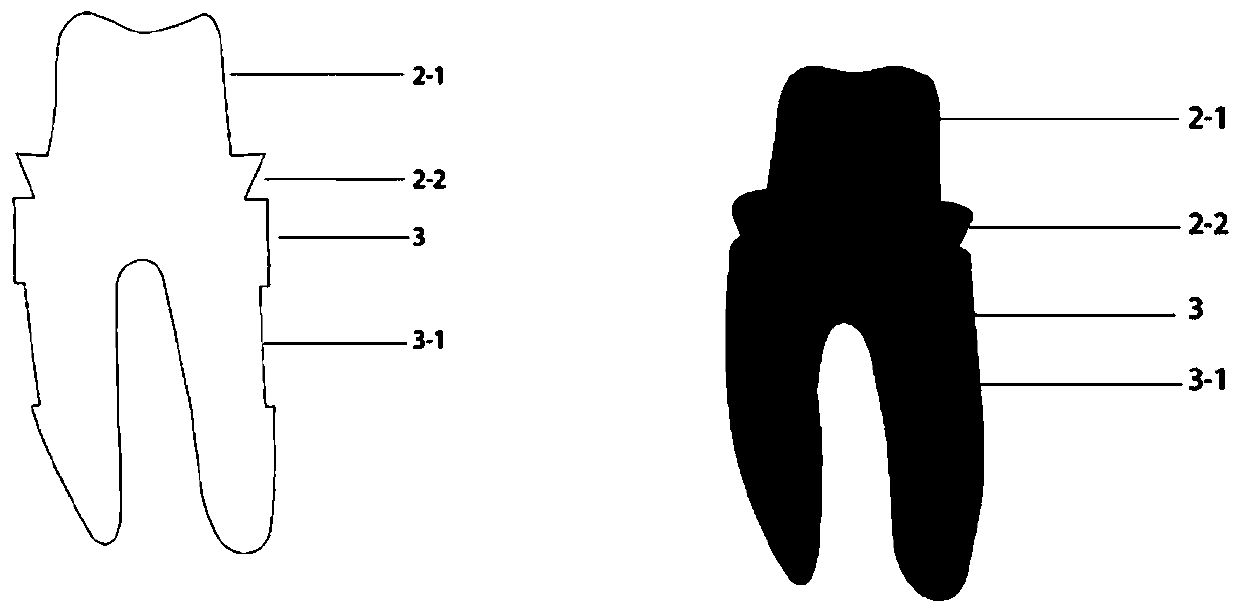

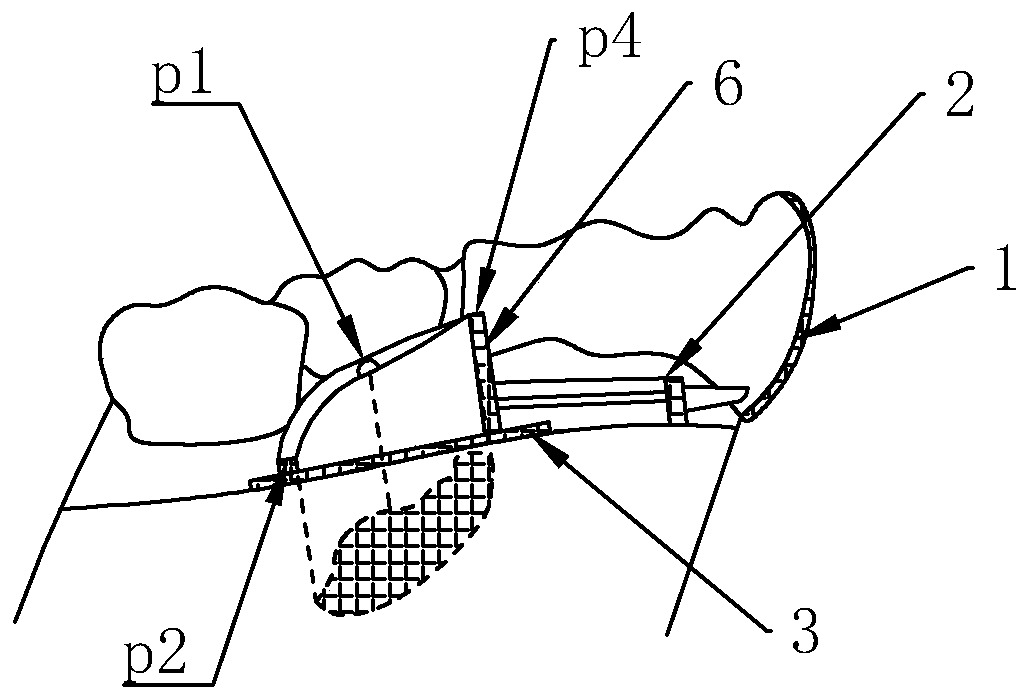

Complex tooth extraction model

InactiveCN104112387AMeeting tooth extraction practice needsMeet the needs of extraction operation practiceEducational modelsDiseaseTooth position

The invention discloses a complex tooth extraction model. The complex tooth extraction model comprises a base (1), a simulated alveolar bone (2) and normal teeth (3), wherein the simulated alveolar bone (2) is fixed on the base (1), and the normal teeth (3) are directly embedded into the simulated alveolar bone (2); at least one tooth position where a complex tooth is prone to appear on the simulated alveolar bone (2) is a vacancy, and the vacancy extends towards the base (1) to form a vacancy groove (4); a detachable complex tooth model block (5) is mounted in the vacancy groove (4); the complex tooth model block (5) comprises a model block alveolar bone (51) and a complex tooth (52) which is embedded into the model block alveolar bone (51). According to the complex tooth extraction model, disease conditions of various complex teeth can be simulated, and the complex tooth extraction model can be repeatedly used and is applicable to tooth extraction exercises of various complex serious destroyed teeth.

Owner:PEKING UNIV SCHOOL OF STOMATOLOGY

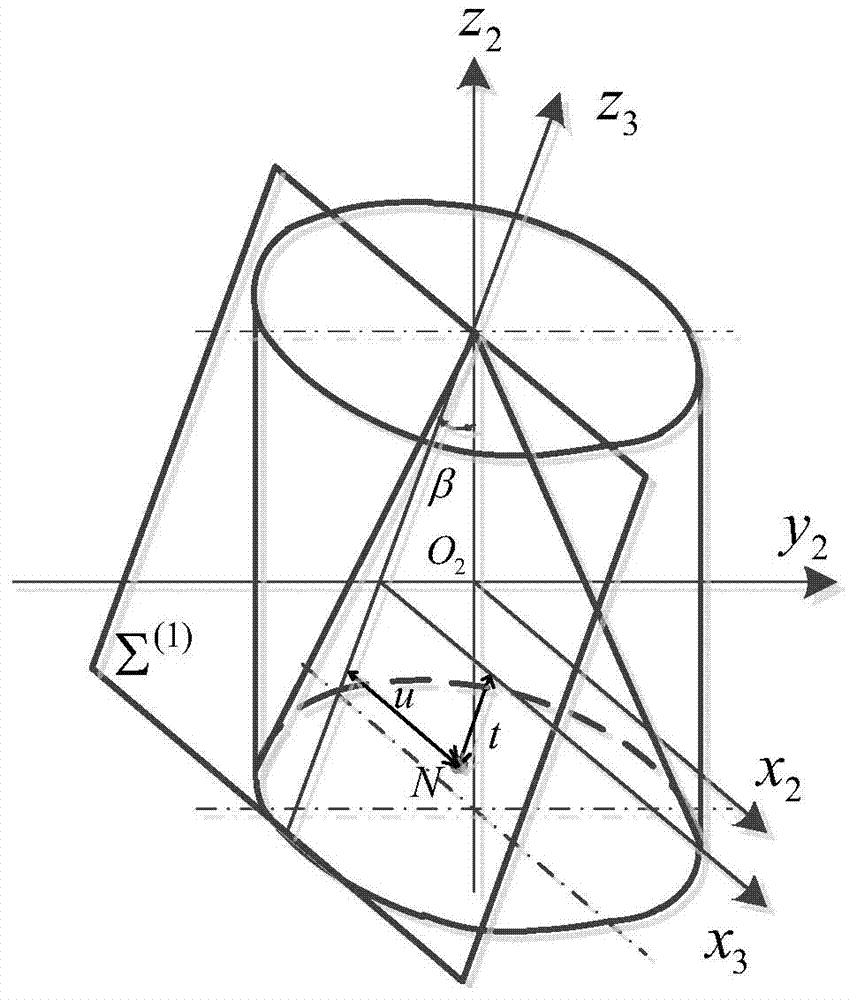

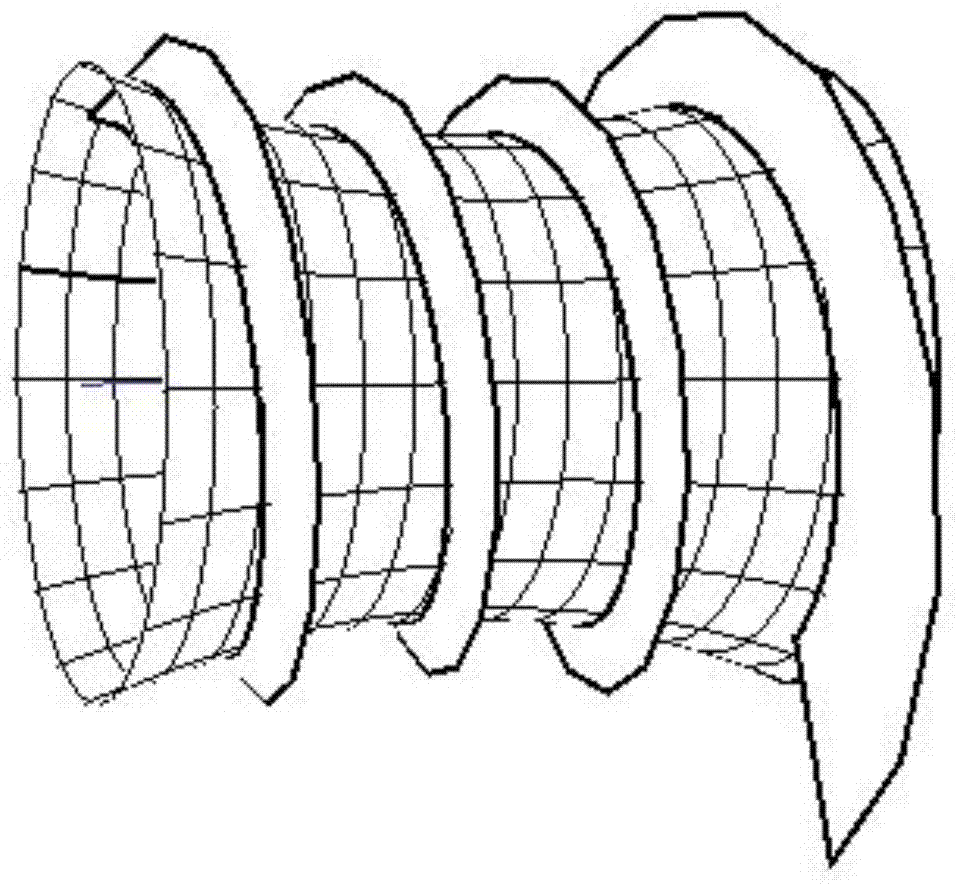

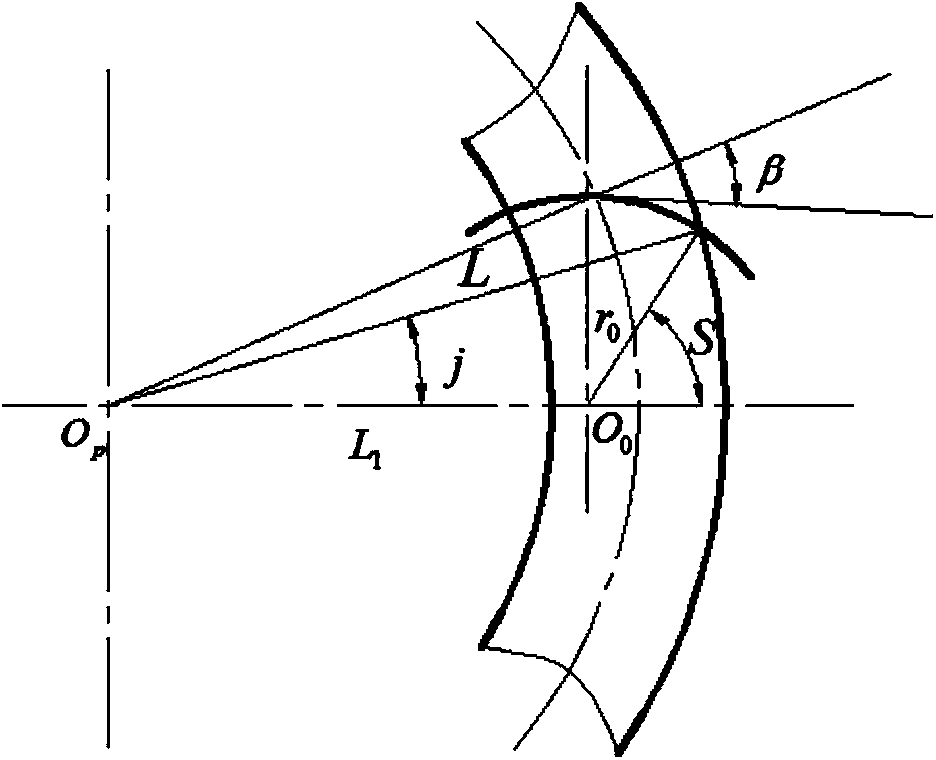

A modeling method of non-linear contact arc tooth surface

InactiveCN109543340AImprove efficiencyImprove flexibilityGeometric CADDesign optimisation/simulationEngineeringMATLAB

The invention discloses a modeling method of a non-linear contact arc tooth surface, which comprises the following steps of: establishing a convex circular arc turning tool and a worm coordinate system; establishing The worm tooth surface equation, and obtaining the worm axial tooth profile equation and the worm normal tooth profile equation; establshig The meshing coordinate system of worm gear and worm is established, and establishing the transformation relation of each coordinate system; Establishing a worm gear tooth surface equation; According to the established worm gear and worm arc tooth surface equations, simulating the three-dimensional entity of worm gear arc tooth surface, worm arc tooth surface and worm gear-worm transmission pair arc tooth surface. According to the established worm gear and worm arc tooth surface equation, the invention adopts MATLAB software for data processing and simulation to construct the arc tooth surface with low induced curvature, lubrication angle closer to 90 DEG and more easy to form oil film, which establishes a good foundation for manufacturing and modifying the arc tooth worm gear tooth surface.

Owner:HAIAN COUNTY SHENLING ELECTRICAL APPLIANCE MFG +1

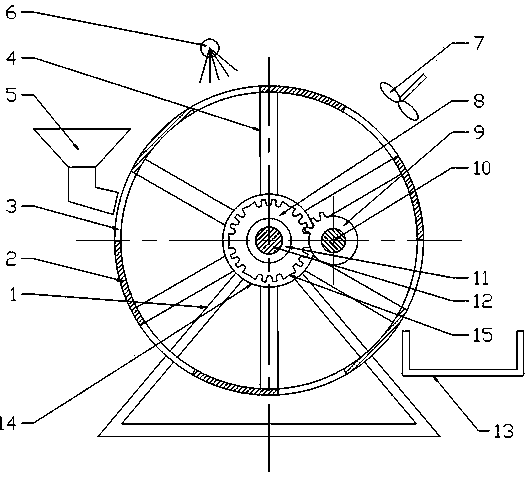

Incomplete-gear type scrubbing-and-drying unit

InactiveCN105363715AAvoid idlingGuaranteed continuityDrying gas arrangementsCleaning using liquidsDrive shaftEngineering

The invention discloses an incomplete-gear type scrubbing-and-drying unit which comprises a machine frame and a working cavity. A driven shaft is fixed to the machine frame. A fixed plate is hinged to the driven shaft. A plurality of partition plates are fixed to the periphery of the fixed plate in the circumferential direction. The outer ends of the partition plates are fixed to the inner wall of the working cavity. The working cavity is divided into a plurality of separated sections through the partition plates. An opening is formed in the arc-shaped surface of each section. The three openings in the working cavity serve as a feeding station, a scrubbing station and a drying station in sequence. The feeding station is provided with a feeding hopper, and a scrubbing water pipe and a drying fan are arranged. A driven gear of an incomplete gear mechanism is fixed to the fixed plate. A plurality of thick teeth are uniformly distributed on the driven gear. Normal teeth are equally divided into a plurality of sections through the thick teeth. The driven gear is engaged with an incomplete gear. A driving shaft is fixed to the incomplete gear. By means of the automatic scrubbing-and-drying unit, four working procedures including feeding, scrubbing, drying and discharging are conducted intermittently in a sectioned mode, continuous working can be achieved, and the scrubbing-and-drying unit does not need to be stopped.

Owner:CHONGQING SHUNTAI FOOD

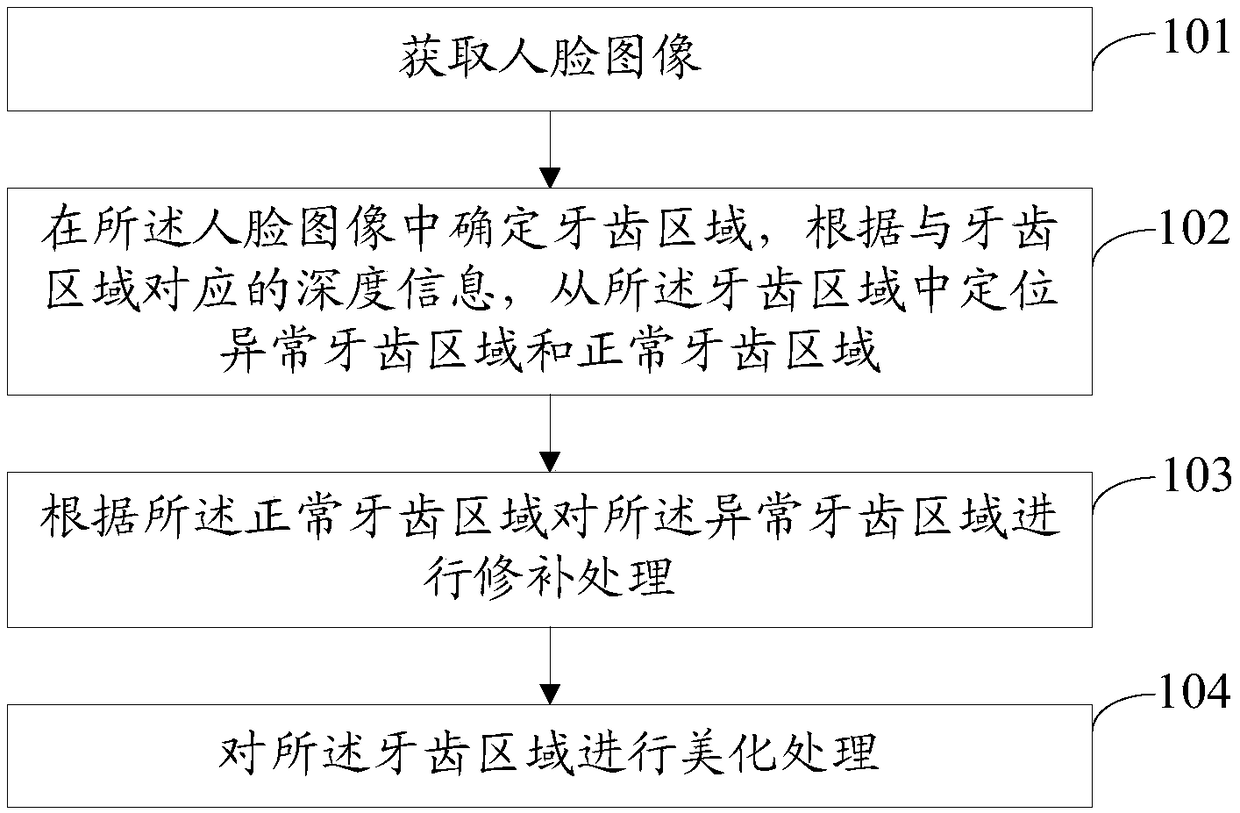

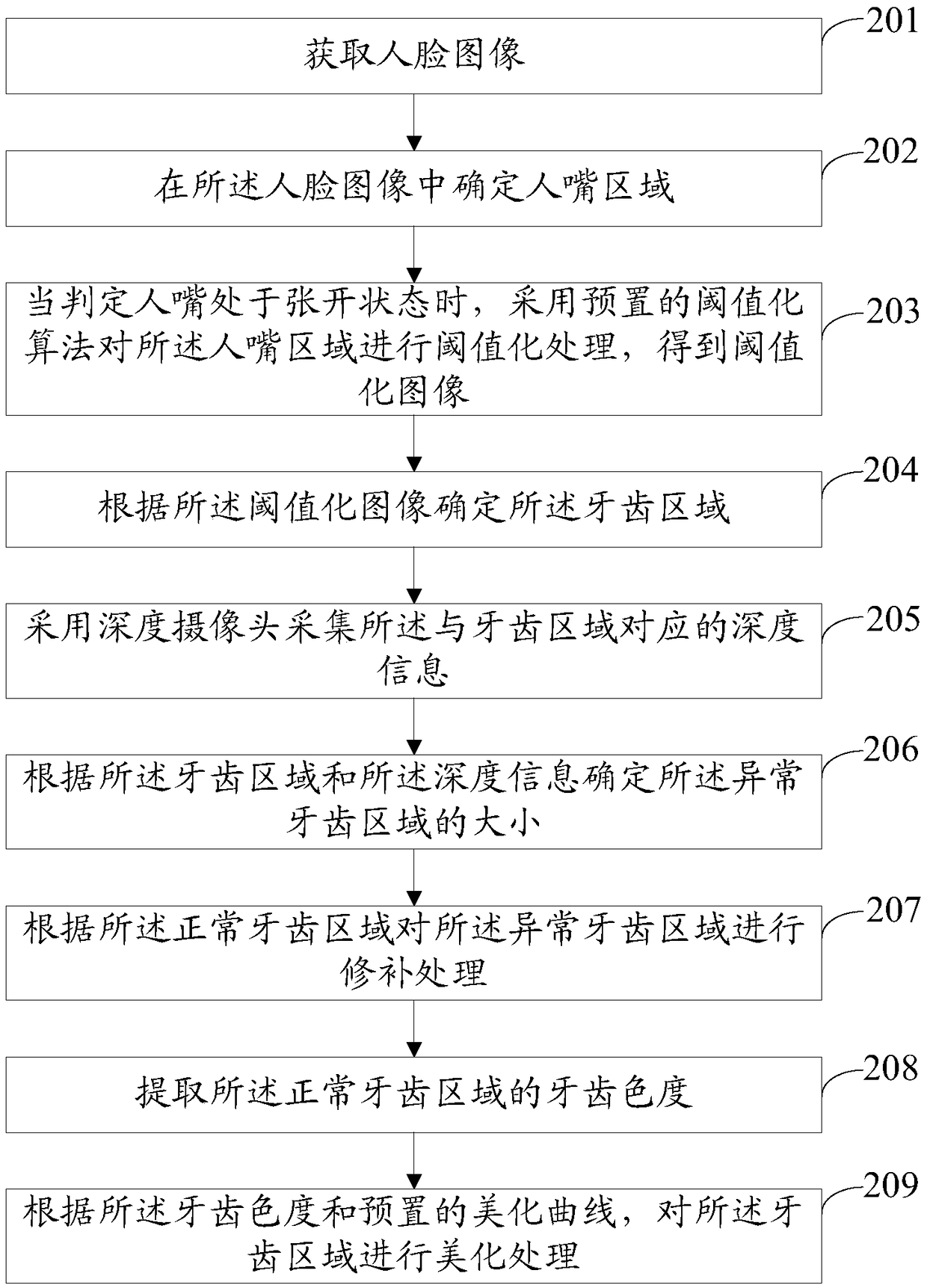

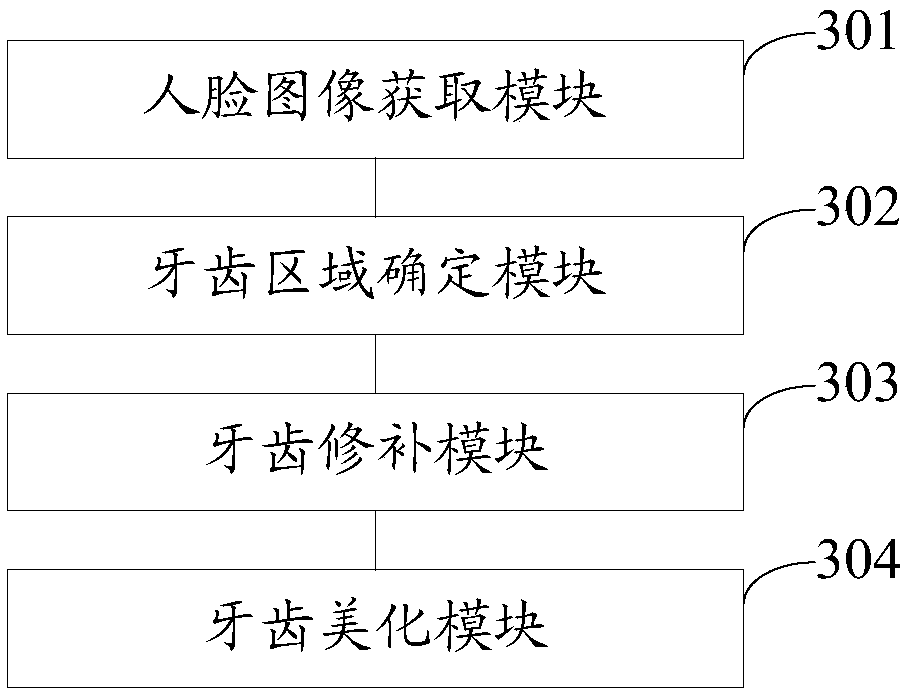

A method and apparatus for beautifying teeth

InactiveCN109272466AImprove experiencePrecise RepairImage enhancementImage analysisSelf adaptiveAbnormal teeth

A method and apparatus for beautifying teeth are provided, and are applied to a terminal. The method comprises the following steps: acquiring a face image; determining a tooth region in the face image, and positioning an abnormal tooth region and a normal tooth region from the tooth region according to depth information corresponding to the tooth region; performing repair processing on the abnormal tooth region according to the normal tooth region; and beautifying the tooth area. Through the embodiment of the invention, not only are the teeth whitened, but also the treatment of self-adaptive tooth repair and the like can be realized, the user with defective teeth can open his mouth at will when taking photos, and the user experience is improved.

Owner:VIVO MOBILE COMM CO LTD

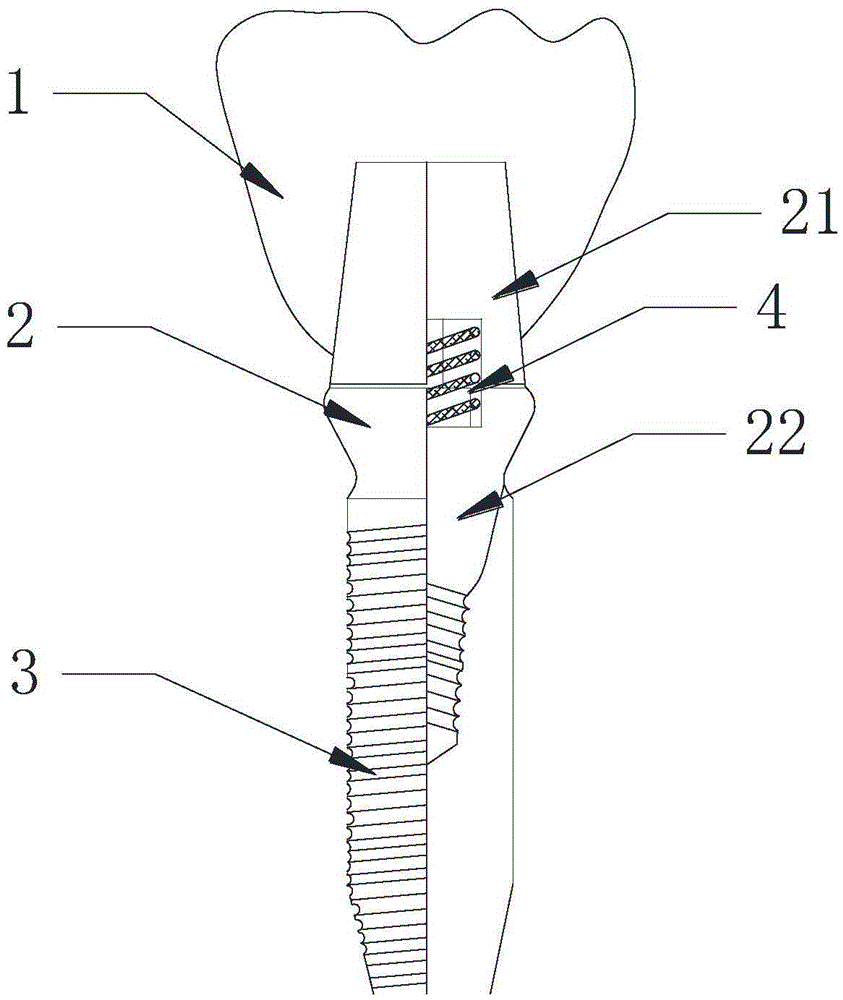

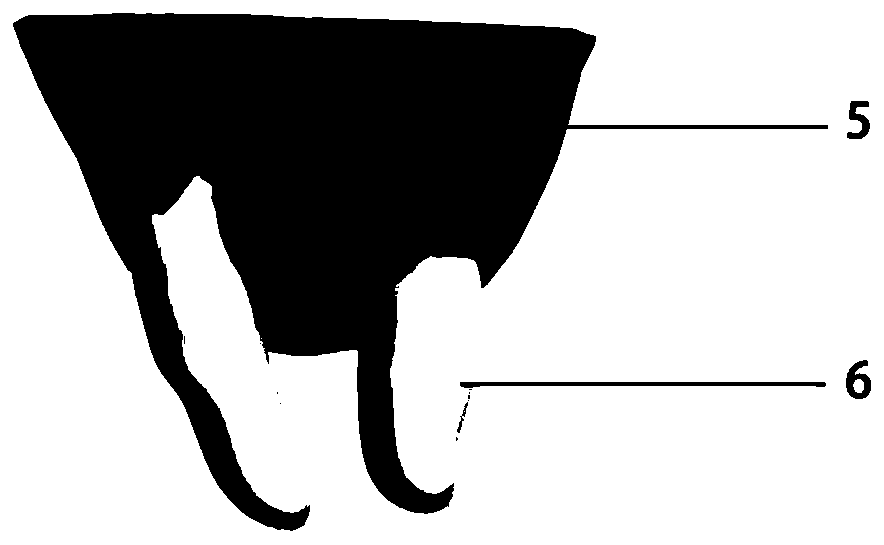

Personalized bionic implant for synchronously repairing tooth and peripheral alveolar bone defects and forming method thereof

ActiveCN111544139AImprove stabilityGood for long termDental implantsAdditive manufacturing apparatusBone qualityBone defect

The invention discloses a personalized bionic implant for synchronously repairing tooth and peripheral alveolar bone defects and a forming method of the personalized bionic implant. The implant comprises a dental crown meshed with normal teeth, an abutment used for connecting an implantation part and the dental crown, an implant bionic tooth root used for personalized restoration of tooth defects,and an alveolar bone defect restoration body used for restoration of alveolar bone defects, the implant bionic tooth root part and the alveolar bone defect restoration body jointly form an implant part; the dental crown is designed according to the shapes of involution dentition and mesio-distal teeth, is formed by cutting an all-ceramic block and sleeves the upper part of the abutment; the alveolar bone defect restoration body is consistent with the bone defect form of a patient and has a porous structure. The tooth implantation device can be used for immediate implantation of teeth accompanied by bone defects, and the operation and waiting time of a clinical implantation operation can be greatly shortened; the implant is matched with original tooth roots and bone defects, so that good initial stability can be achieved, and quicker recovery of an operation area and long-term stability of the implant are facilitated.

Owner:杭州牙自然生物科技有限公司

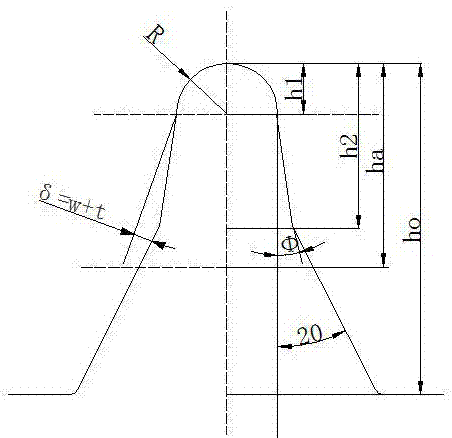

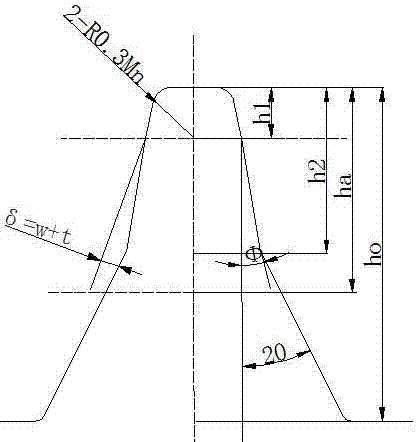

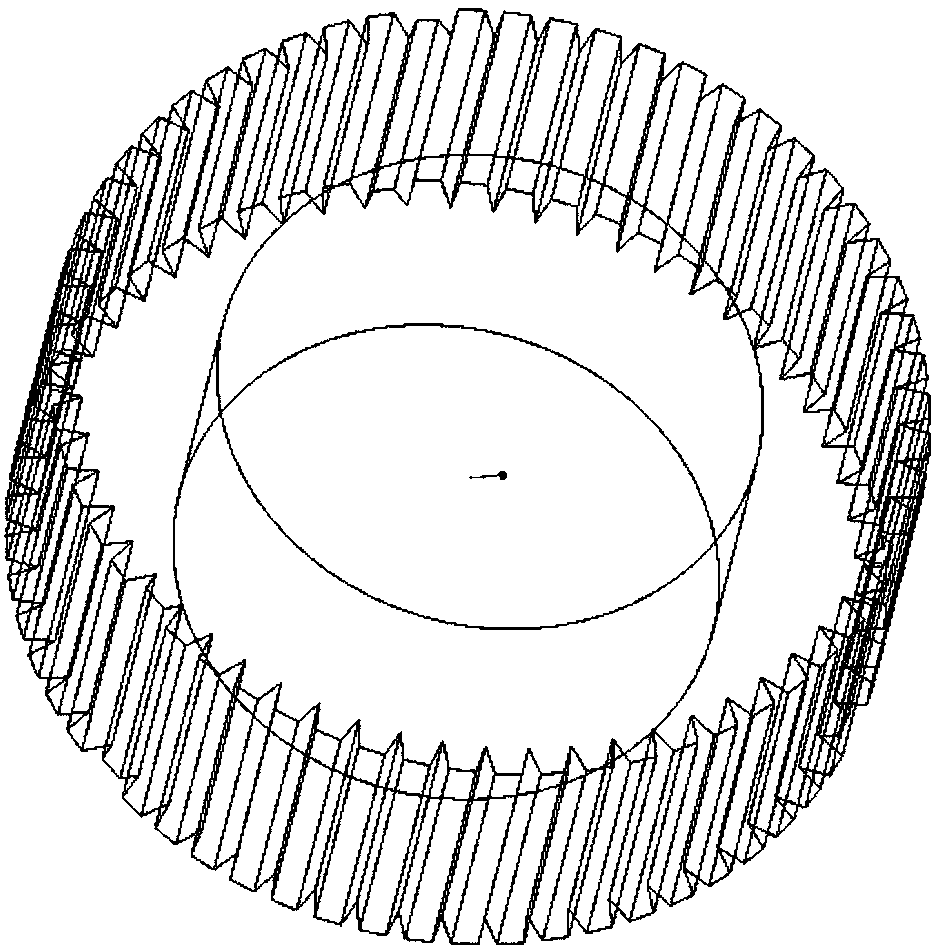

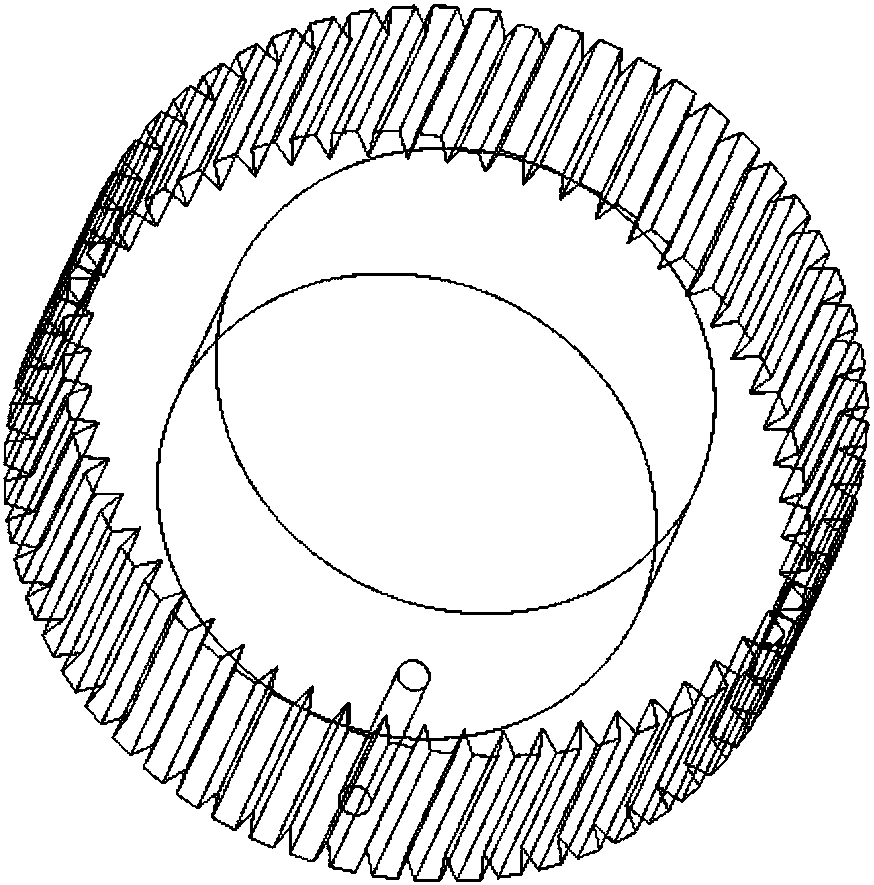

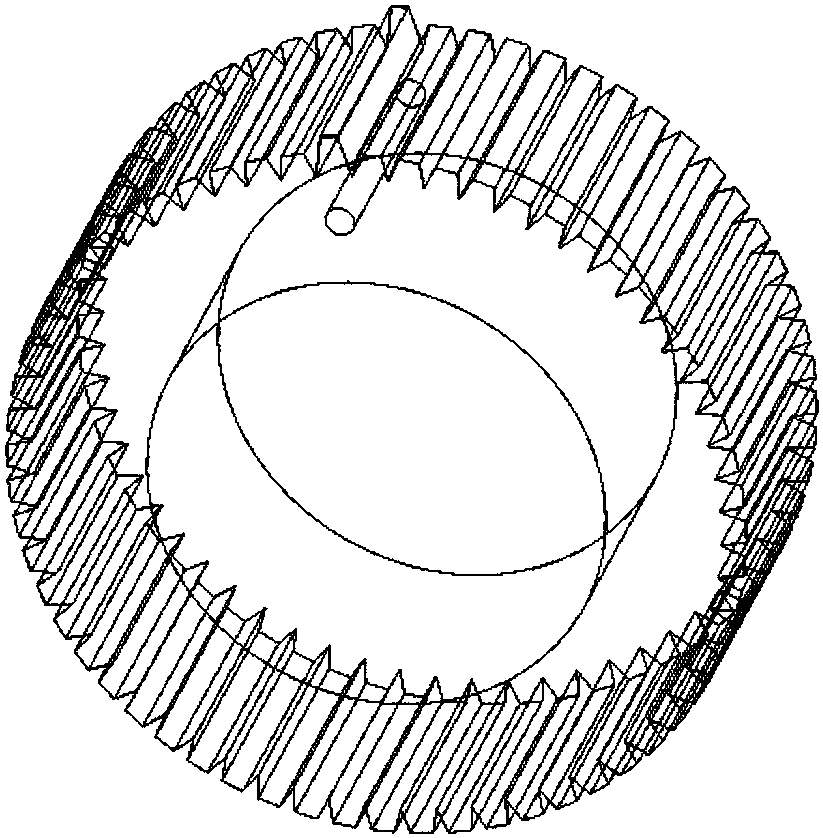

Pre-grinding hob and machining method thereof

PendingCN107350569AGuaranteed accuracyReduce facetGear teeth manufacturing toolsGear teethRooted toothGonial angle

The invention relates to a pre-grinding hob which comprises front teeth and back teeth. A small tooth is formed at the back portion of a tooth root of each normal tooth of the pre-grinding hob, the small teeth are tooth profiles of tooth tops of the pre-grinding hob, the original normal teeth of the pre-grinding hob are called as the front teeth, and the small teeth formed at the back portions of the tooth roots of the normal teeth of the pre-grinding hob are called as back teeth; the front teeth and the back teeth of the pre-grinding hob are designed on one equally-divided part, and angles of front tooth blade ditches and back tooth blade ditches are different; the pressure angle of the front tooth blade ditches is 20 degrees, the front tooth root transition circular bead R is 0.3 modulus, and tooth profile curves of the tooth tops of the front teeth and the back teeth are oval; and the cross section of the bottom of the tooth profile of the tooth top of each front tooth is an elliptic long shaft, wherein the distance between the center of the long shaft and the tooth top end of the front tooth is a short semi shaft, and the length of the short semi shaft is 0.65 time that of a long semi shaft. Hob materials are subject to cobalt-contained high-speed steel or powder metallurgy, the technology for heating processing is used in cooperation, a TiAlN or TiN coating is adopted for surface processing, and the hob surface hardness is greatly improved on the original basis.

Owner:NANJING GAOJING ENG EQUIP

Positioning guide plate for removing unerupted supernumerary teeth in anterior tooth area, and manufacturing method thereof

The invention discloses a positioning guide plate for removing unerupted supernumerary teeth in an anterior tooth area, and a manufacturing method thereof. A mucous membrane positioning guide plate and a boning positioning piece are detachably arranged, and can be conveniently used in a matching manner, a positioning ring for guiding the route of a boning device is arranged on the inner side surface of the boning positioning piece, the inner side surface of the positioning ring is a boning guide surface, and the boning guide surface is provided with a preset boning direction and the height ofthe positioning ring for guiding the boning depth of a machine needle. By means of the device, accurate incision positioning can be conducted on the unerupted supernumerary teeth, meanwhile, through the design of the positioning guide plate, the deboning area, depth and angle are accurately guided, incision and deboning are conducted in a small range, it is avoided that important permanent teeth and normal teeth are damaged due to positioning errors, and the supernumerary teeth are smoothly exposed.

Owner:温州医科大学附属口腔医院

Dentarpage for stomatology department

InactiveCN107582189AAvoid damageFree from direct pressureDental toolsDental aidsEngineeringUrology department

The invention discloses a dentarpage for a stomatology department. The dentarpage comprises a support plate, a threaded rod that goes through the support plate, and a nut, which sleeves on the threaded rod. The dentarpage also comprises two joint parts, which are arranged on two ends of the support plate. The joint parts comprise sleeves. Two sleeves of the joint parts sleeve on the normal teeth,which are on two sides of an infected tooth respectively. The sleeves sleeve on the normal teeth, when the threaded rod is drilled into the infected tooth, the force on the support plate is applied onthe normal teeth through the sleeves of the joint parts, thus the support plate will not be directly pressed on the normal teeth, and the damage of the normal teeth is avoided.

Owner:SICHUAN UNIV

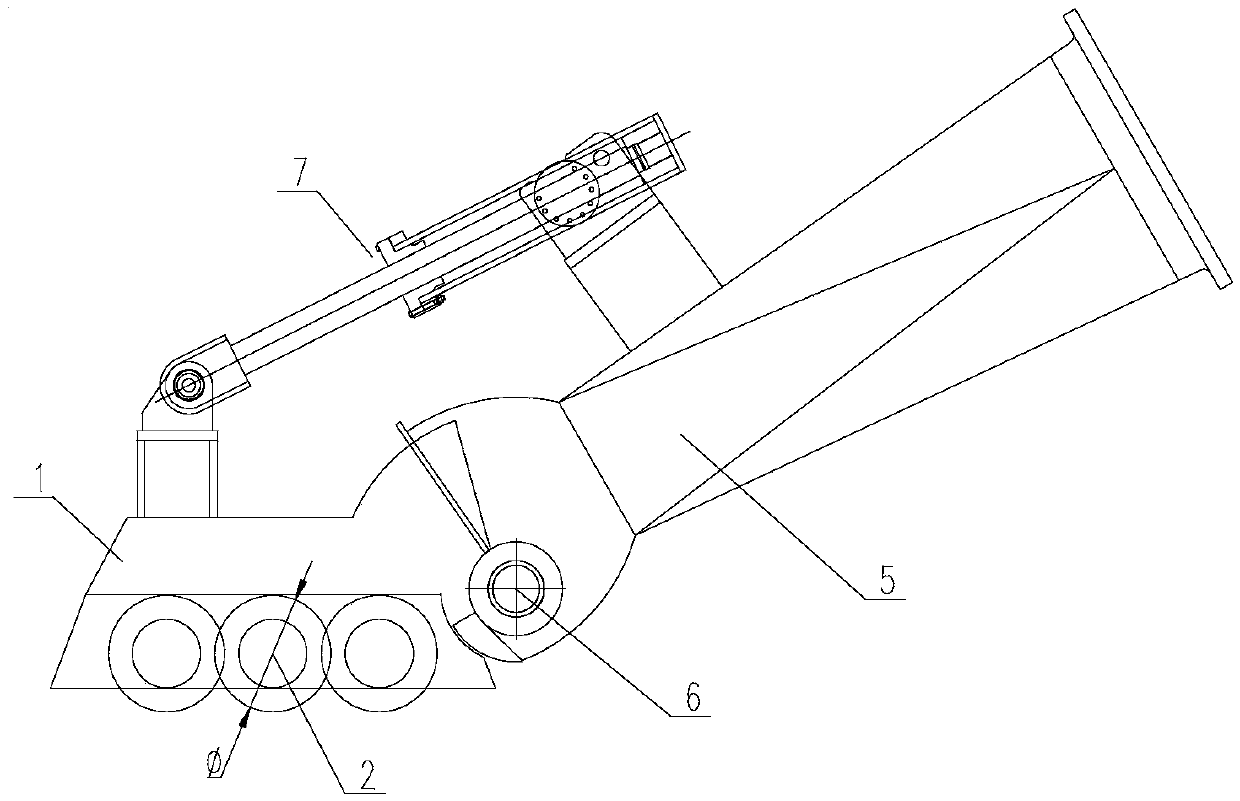

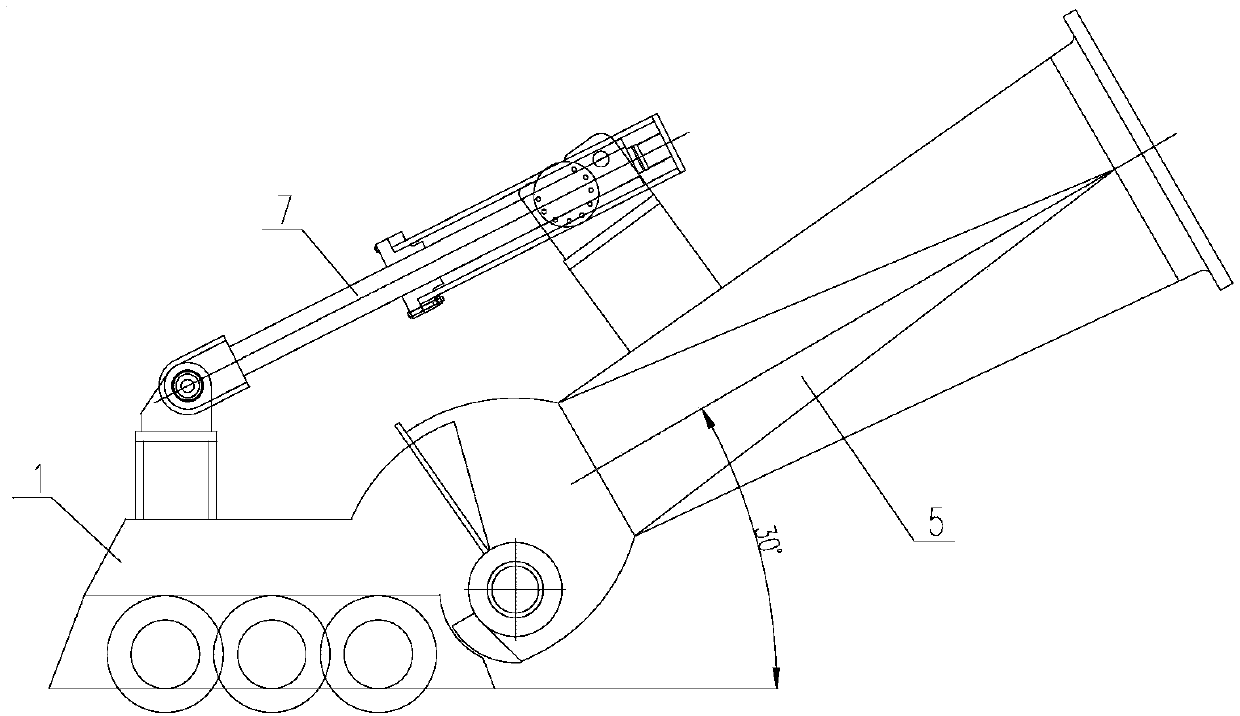

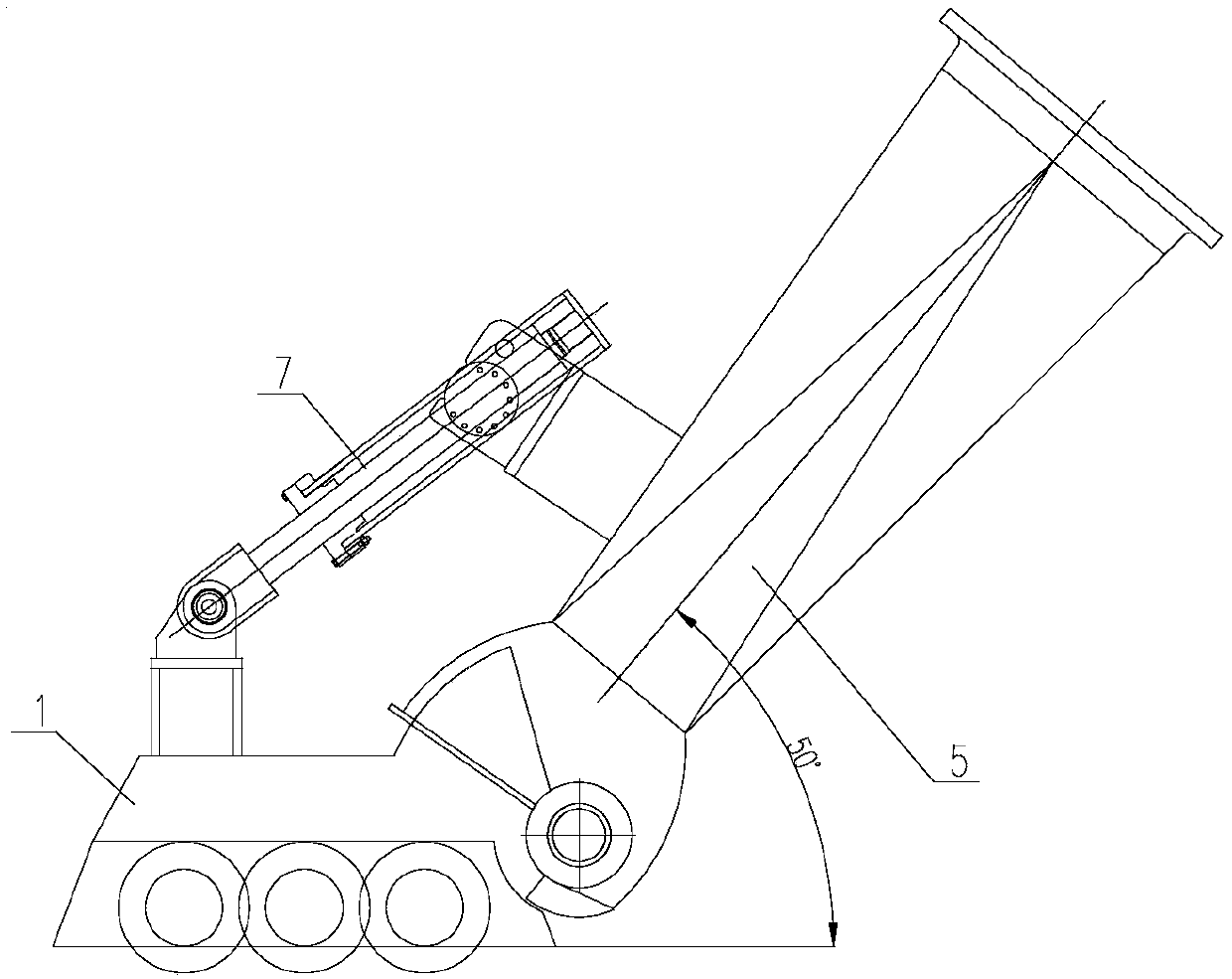

Environmentally friendly dredging device with hobbing cutters

PendingCN107740457AReduce disturbanceAvoid spreadingMechanical machines/dredgersHydraulic cylinderWater flow

The invention discloses an environmentally friendly dredging device with hobbing cutters, and belongs to the technical field of dredging engineering. The environmentally friendly dredging device withthe hobbing cutters comprises a movable cutter box, a hobbing cutter shaft system, a driving device, transmission gears, a sludge suction tube, a hinge pin and a hydraulic cylinder, wherein the movable cutter box is connected with the sludge suction tube through the hinge pin; two ends of the hydraulic cylinder are separately fixed on the movable cutter box and the sludge suction tube; the hobbingcutter shaft system comprises a plurality of rows of hobbing cutters which are arranged in the movable cutter box side by side and are successively in transmission connection through the transmissiongears; the driving device is connected with the hobbing cutter shaft system; and each row of hobbing cutters comprises a rotating shaft and cutter teeth which are spirally arranged on the rotating shaft. The tooth profile of the cutter teeth on an axial section is a straight line, the tooth profile of the cutter teeth on a normal section is an outwards projected curve, and the tooth profile of the cutter teeth on an end surface is an Archimedes spiral. Disturbance to water flow is quite small, and agitated sludge can be prevented from being diffused to the periphery; and meanwhile, the embedded depth is controlled through the cutter teeth, the thickness of a dredging layer is controlled, and bottom mud on the lower layer is protected against being damaged while a harmful sludge layer is cleared.

Owner:NAT ENG RES CENT OF DREDGING TECH & EQUIP

Tooth whitening powder

InactiveCN102090998AInhibit plaquePrevent periodontal diseaseCosmetic preparationsToilet preparationsBrush toothTooth whitening

The invention relates to tooth whitening powder and a preparation method thereof. The tooth whitening powder comprises the following eight raw materials: natural antibacterial polyphenol, vitamin D, calcium powder, sodium iron chlorophyllin, natural menthol, a rubbing agent, sodium lauryl sulfonate and sodium hydrogen carbonate. The preparation method of the tooth whitening powder comprises the following steps of: respectively crushing and sieving the raw materials; uniformly mixing; and then subpackaging. A toothbrush is dipped in water to be wet and then dipped in the tooth whitening powder to brush teeth for one time everyday according to a normal tooth brushing mode; effect is generated after 4-7 days; and the about 1.5-2 grams of the tooth whitening powder is used every time. The invention has the advantages of tooth whitening, scale removal, dental plaque inhibition, parodontopathy prevention, ozostomia prevention and breath freshening without health danger or environmental pollution.

Owner:蒋健

Speed and key phase integrated detection system for rotating machines

InactiveCN108287070AHigh precisionCompact structureMachine gearing/transmission testingEngineeringSignal processing

Owner:HUAZHONG UNIV OF SCI & TECH

Connecting structure of multiple eccentric shafts and synchronous driving device thereof

The invention discloses a connecting structure of multiple eccentric shafts and a synchronous driving device thereof. The connecting structure mainly comprises a synchronous reverse output gear shaft, a second output shaft gear sleeve and a middle eccentric shaft, wherein the synchronous reverse output gear shaft is arranged in a gear box of the synchronous driving device; the middle eccentric shaft is arranged in a left exciter shell; straight tooth splines are arranged in inner holes of the synchronous reverse output gear shaft and the middle eccentric shaft; the left end meshed segment and the right end meshed segment of the second output shaft gear sleeve are provided with drum-shaped teeth; the normal tooth profiles of the drum-shaped teeth are the same as those of the straight tooth splines in the inner holes of the synchronous reverse output gear shaft and the middle eccentric shaft; the synchronous reverse output gear shaft and the middle eccentric shaft are connected with each other through a drum-shaped tooth meshing pair.

Owner:TENGHU MECHANICAL TECH CHIZHOU

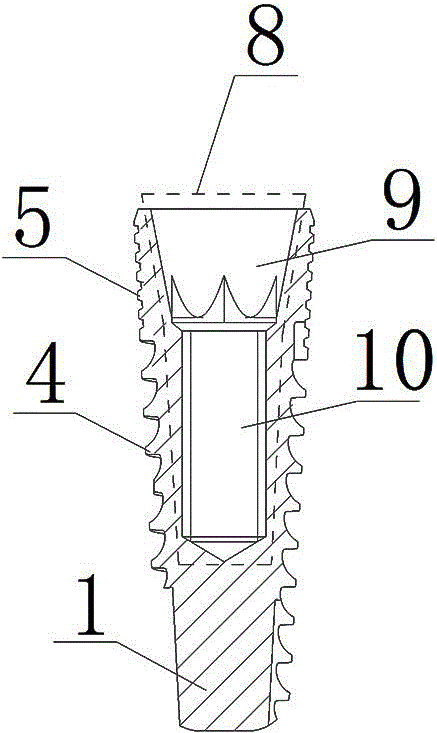

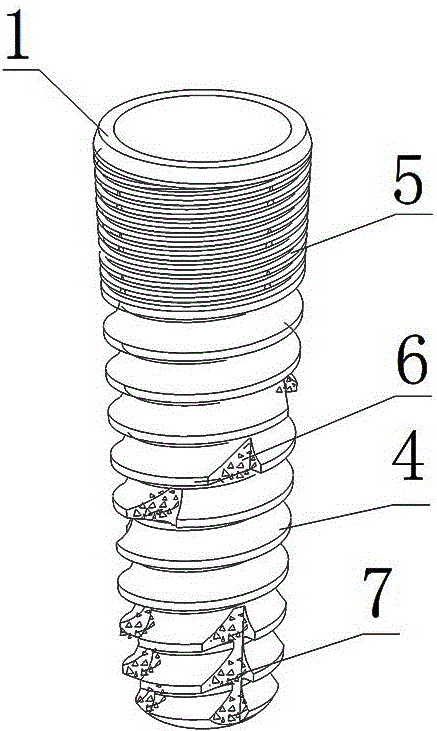

Novel dental implant system

The invention discloses a novel dental implant system. The system comprises a dental implant body, a dentalcrown abutment and a center screw, wherein the dental implant body is divided into an upper part, a middle part and a lower part from top to bottom, screw threads A are formed in outer surfaces of the middle part and the lower part of the dental implant body, a screw thread B is formed in the outer surface of the upper part of the dental implant body, and an inner cavity A is formed in the dental implant body; the dental crown abutment is arranged above the dental implant body and is inserted into the inner cavity A, and an inner cavity B is formed in the dental crown abutment; and the dental implant body and the dental crown abutment are fixedly connected by virtue of the center screw, and the center screw is positioned in the inner cavity A and the inner cavity B. The novel dental implant system has the beneficial effects of simple structure and firm connection, and can be used for reducing adverse influence onsurrounding normal teeth, reducing operation steps and preventing destruction of mandibular alveolar nerves and bacterial invasion.

Owner:CHENGDU BESMILE BIOTECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com