Tool bit conveying, catching and clamping system of saw web laser welding machine

A laser welding machine and cutter head technology, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of the implementation and promotion of laser welding technology, insufficient welding strength, and the collision of the cutter head and hurting people, etc. Large market prospects and market value, high degree of mechanization, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

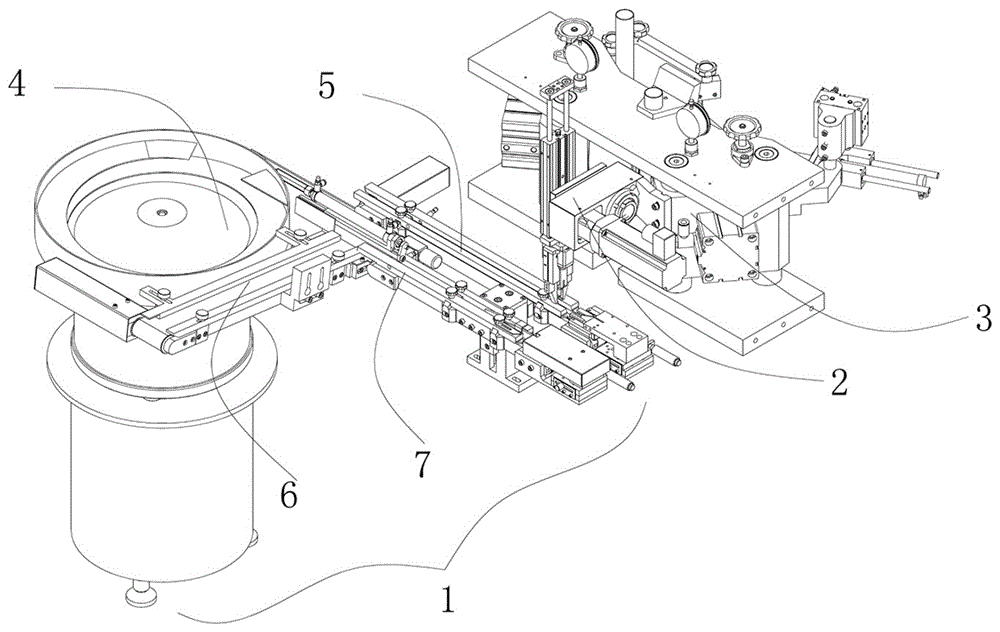

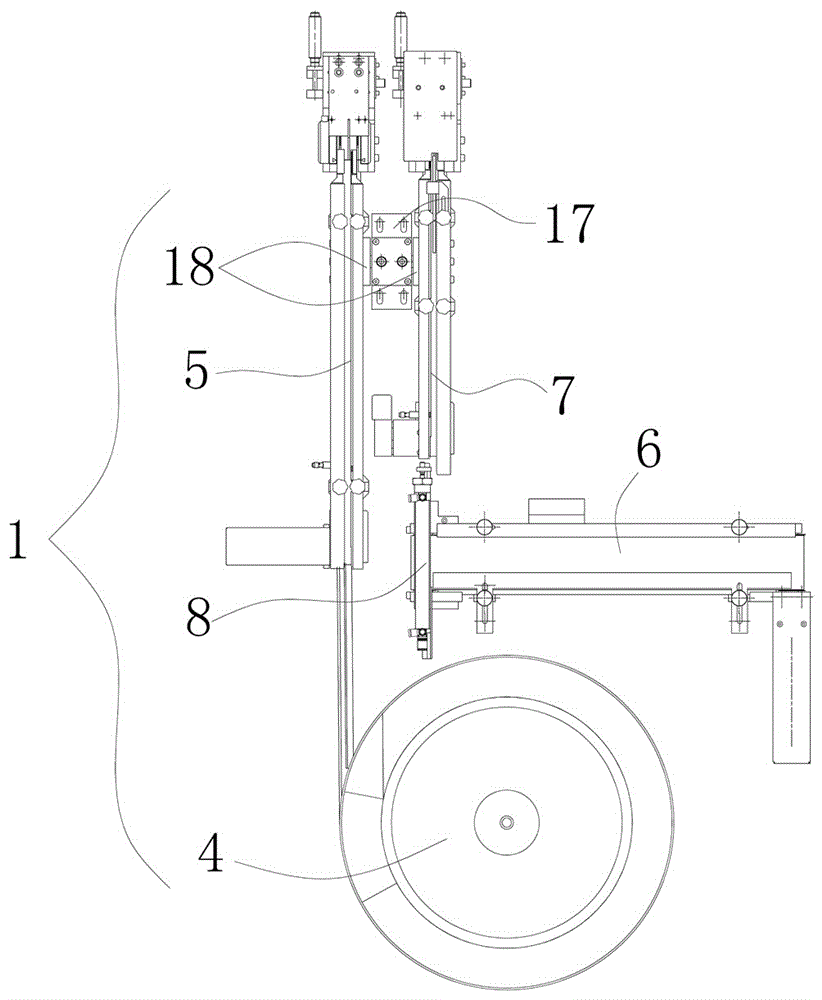

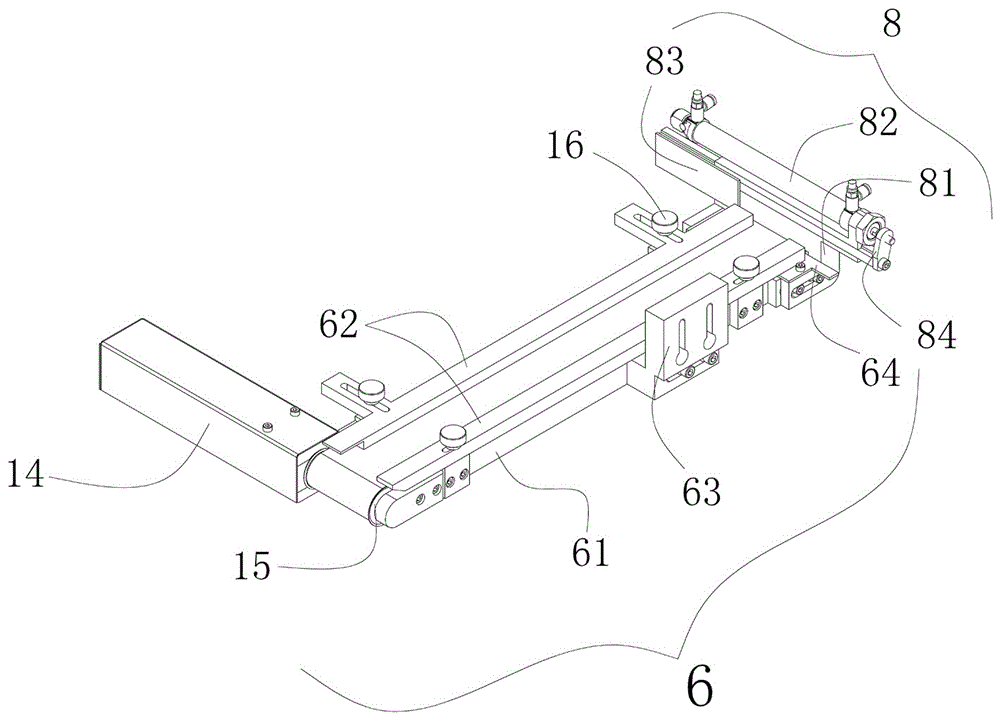

[0026] see Figure 1-Figure 6 , the present invention is a saw blade laser welding machine cutter conveying gripping and clamping system, comprising a frame, a cutter head conveying device 1, a cutter head grabbing device 2 and a cutter head clamping device that are sequentially arranged on the frame 3. The cutter head delivery device 1 includes a support column 17, and a constant-tooth delivery unit and a mouthpiece delivery unit arranged on the support column 17. Orientation arrangement of the cutting head and the mouthguard cutter head, and transport to the cutter head grabbing station; the cutter head grabbing device grabs the normal tooth or the mouthguard according to the welding process, and grabs the normal tooth cutter The head or tooth guard cutter head is transported to the clamping station of the cutter head clampin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com