Design method for tooth profile of double-base cone spiral bevel gear

A design method and technology of bevel gears, applied in the direction of components with teeth, belts/chains/gears, mechanical equipment, etc., can solve problems such as tooth tip breakage and gear transmission failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

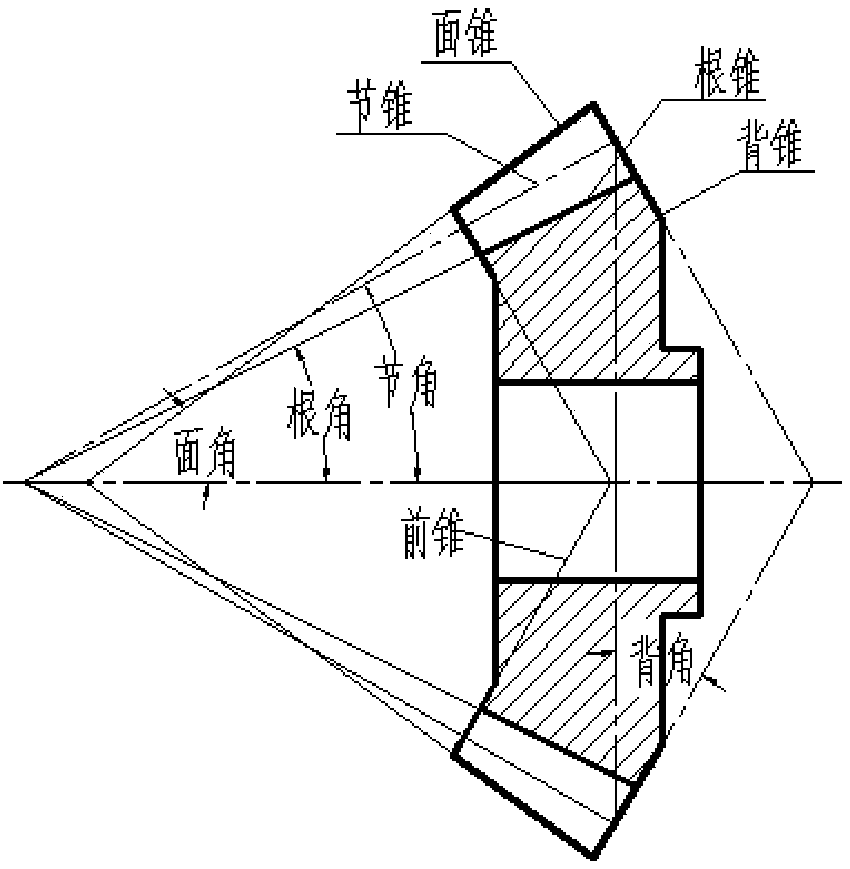

[0085] see Figure 1-5 , the double-base bevel spiral bevel gear has 5 cone surfaces, 4 cone angles, and 2 base cones; the normal tooth profile of a single tooth is composed of addendum circle, dedendum circle, driving side tooth profile curve, non-driving side tooth The five cone surfaces are respectively face cone, root cone, pitch cone, back cone and front cone, and the four cone angles are face angle, root angle, pitch angle and back angle respectively; Such as figure 1 shown.

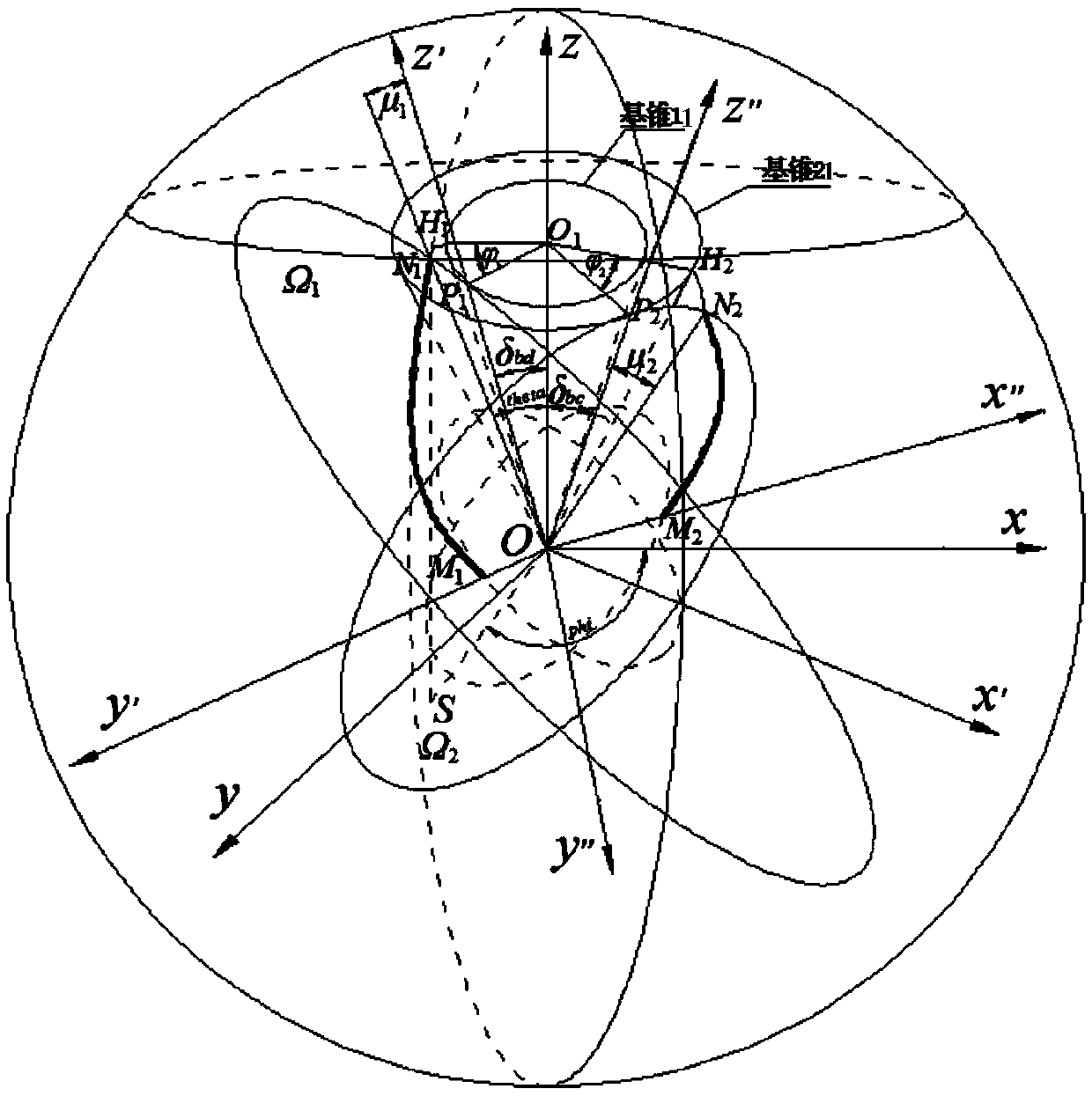

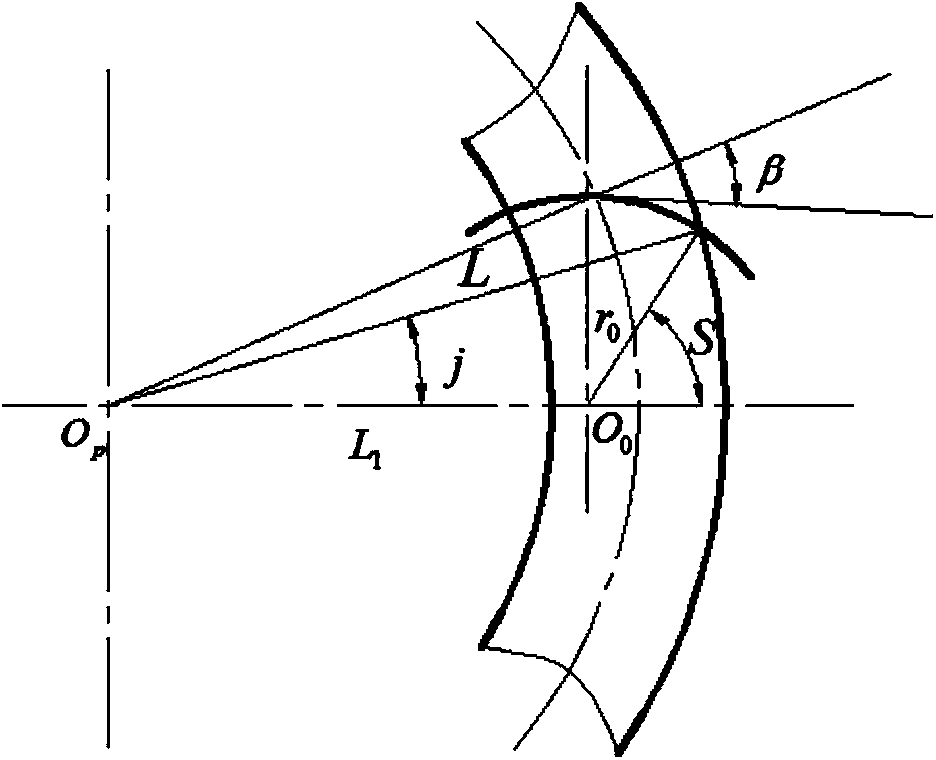

[0086] Double base bevel spiral bevel gear driving side tooth surface Ω 1 The base cone angle is δ bd The first base cone of figure 2 denoted as base cone 11) tangent to OP 1 , when Ω 1 When doing pure rolling along the base cone 1, the arc on the plane with O as the center of rotation is like M 1 N 1 with M 2 N 2 The drive side and non-drive side tooth surfaces of the spiral bevel gear will be formed in space. Because the tooth profile angles on both sides of the spiral bevel gear are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com