Patents

Literature

470 results about "Small teeth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

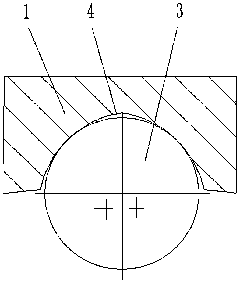

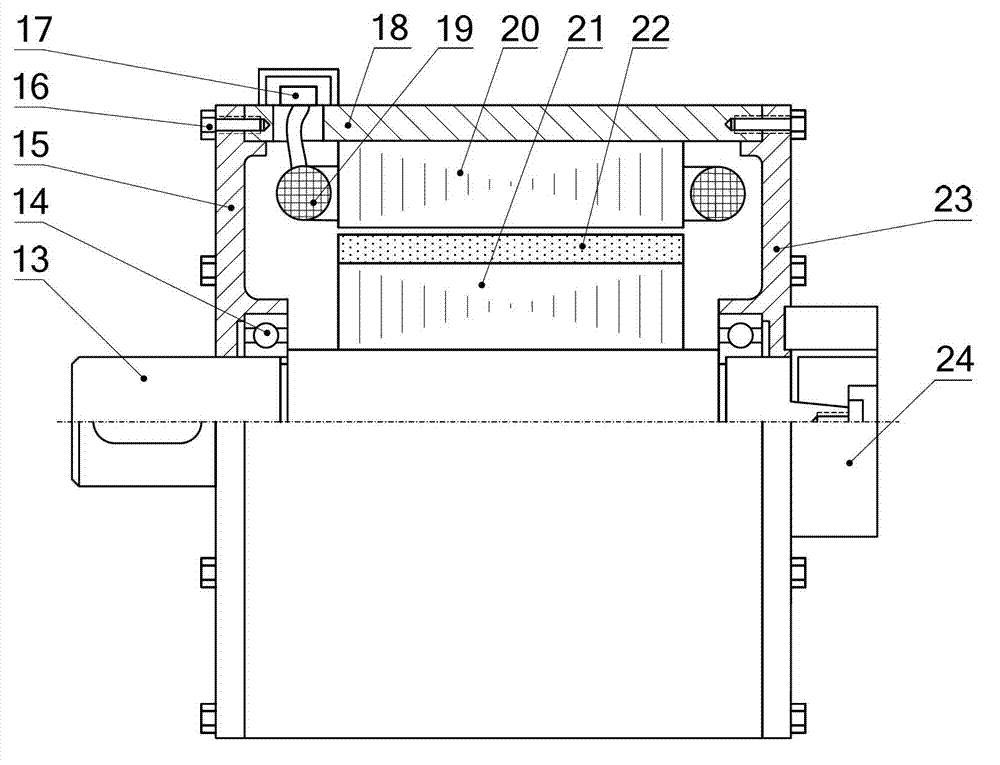

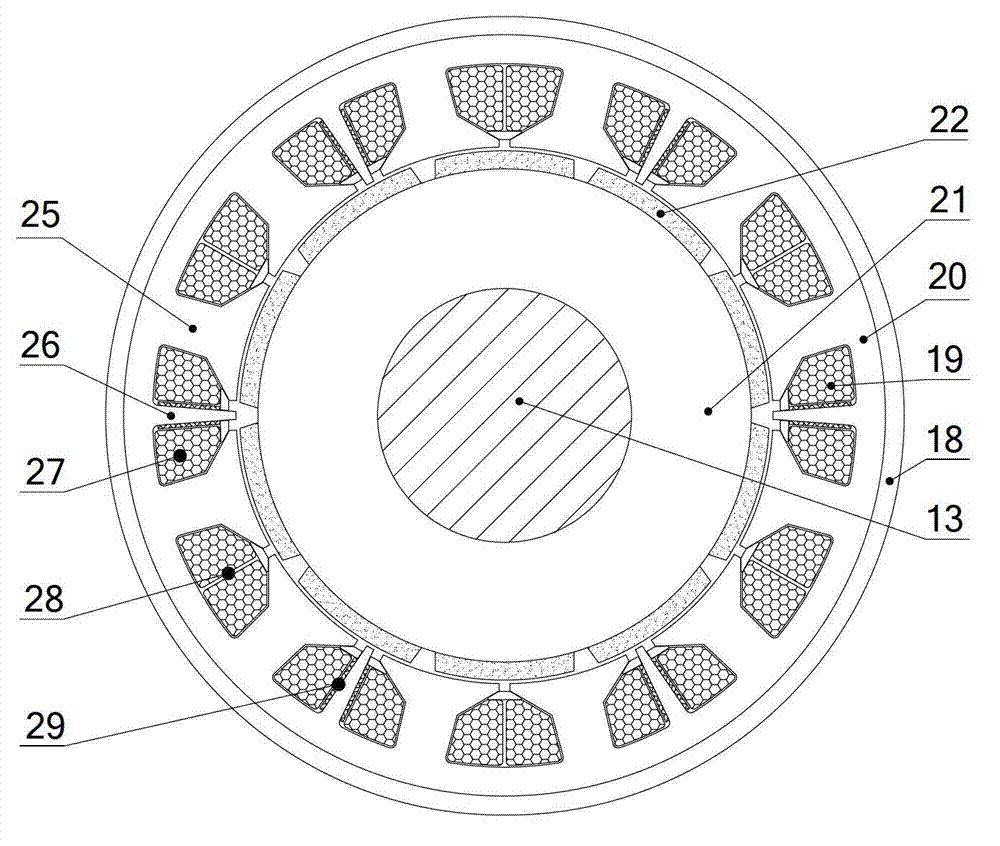

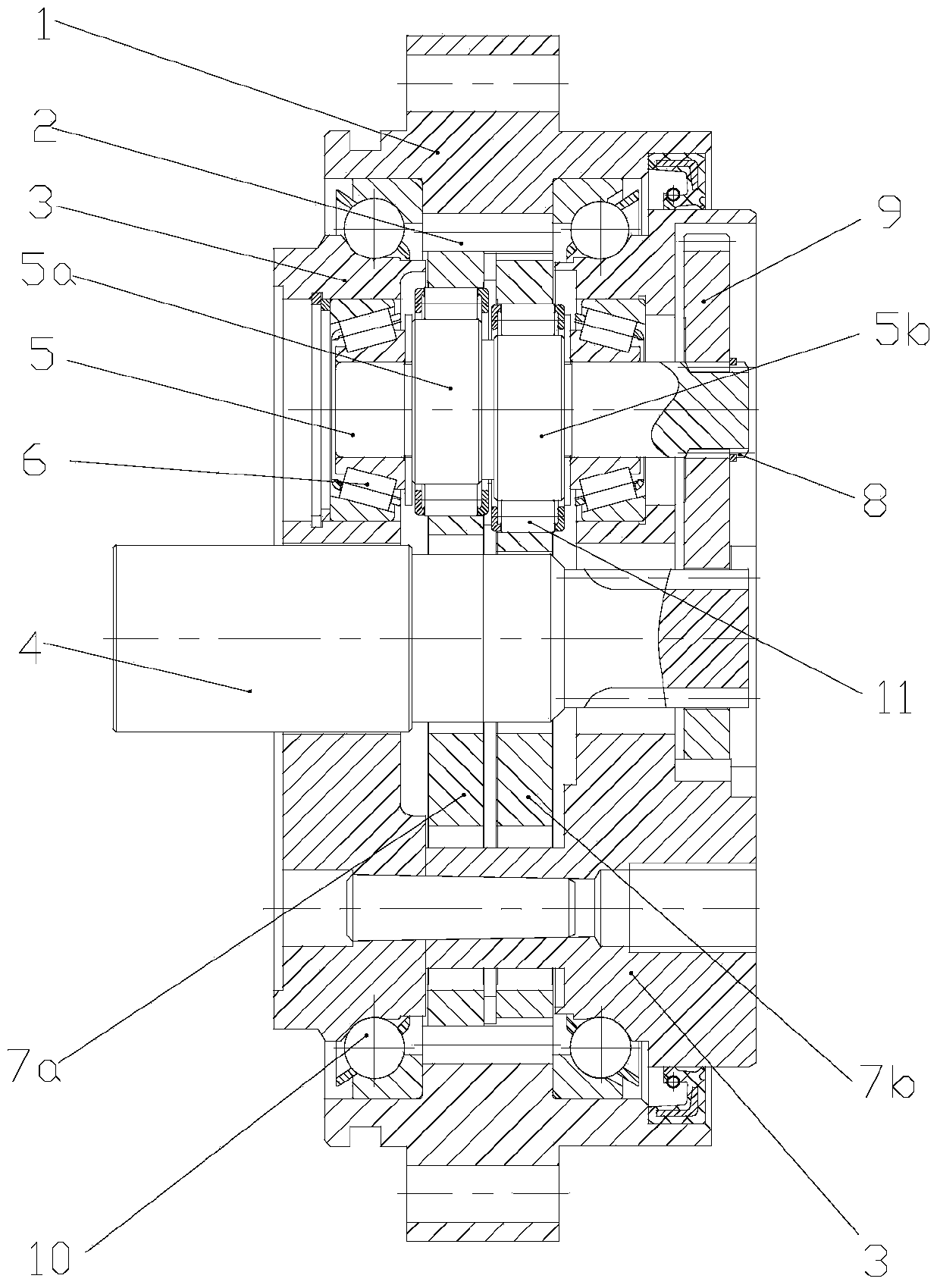

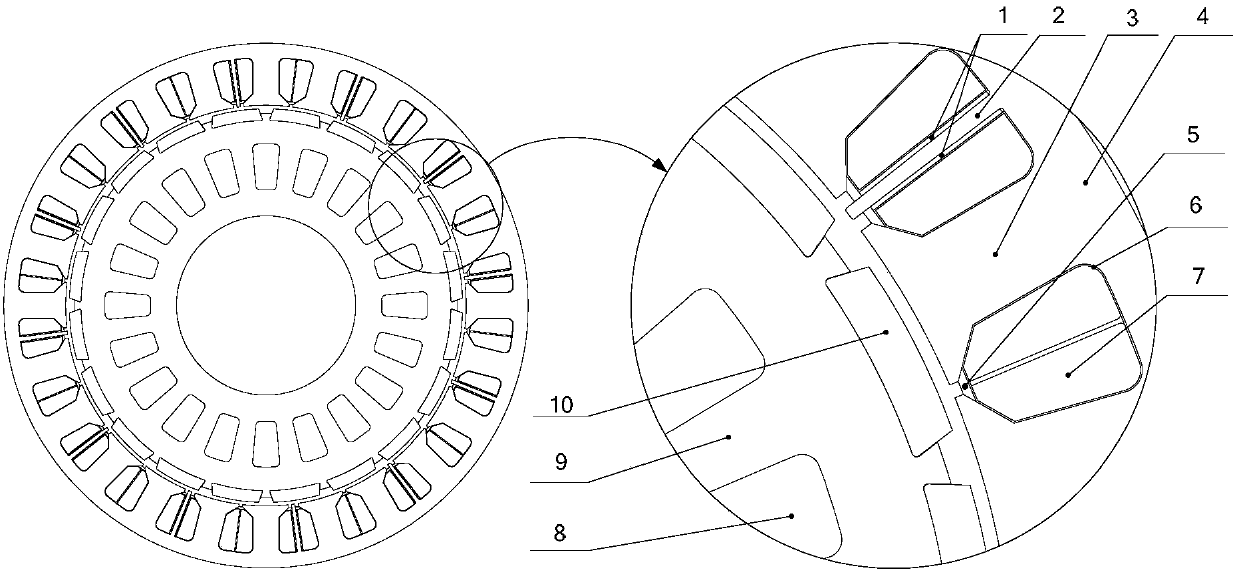

Square wave three-phase brushless permanent magnetic DC motor

ActiveCN101371425ASmall positioning torqueSimple structureMagnetic circuit rotating partsMagnetic circuit stationary partsLarge toothMagnetic poles

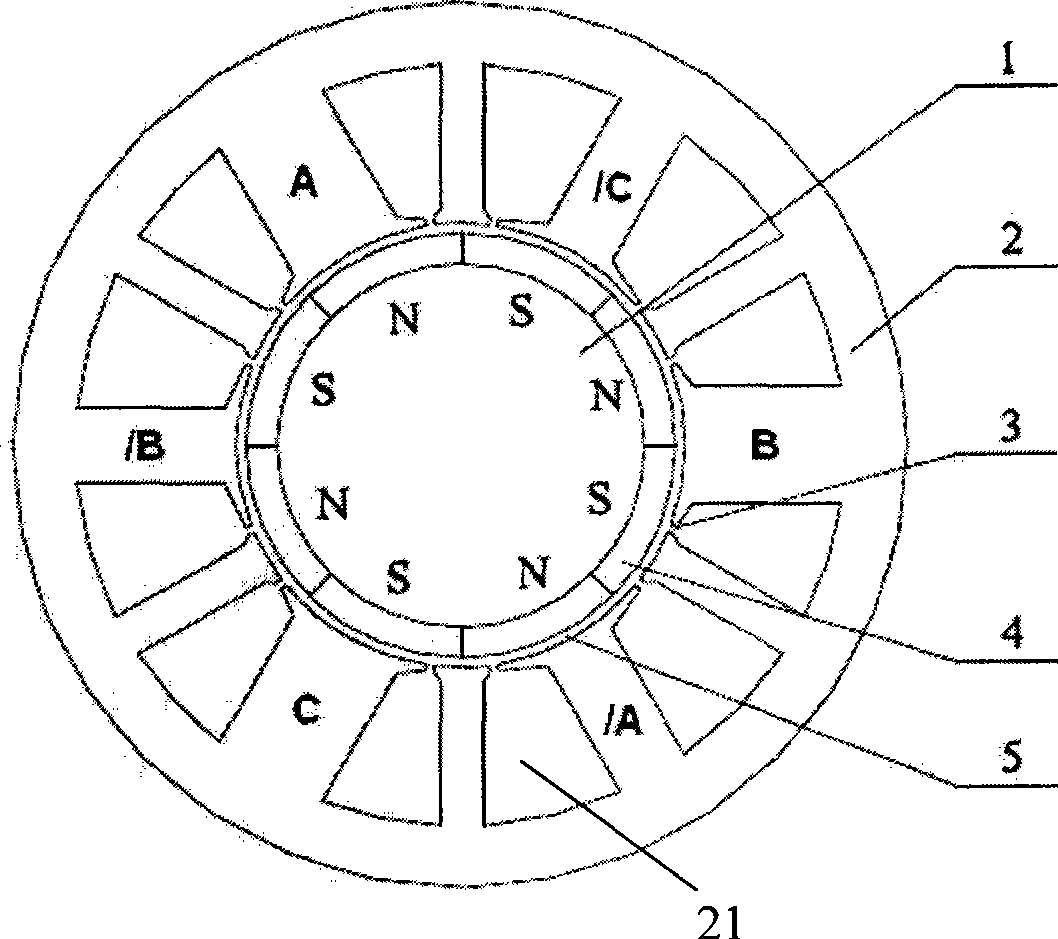

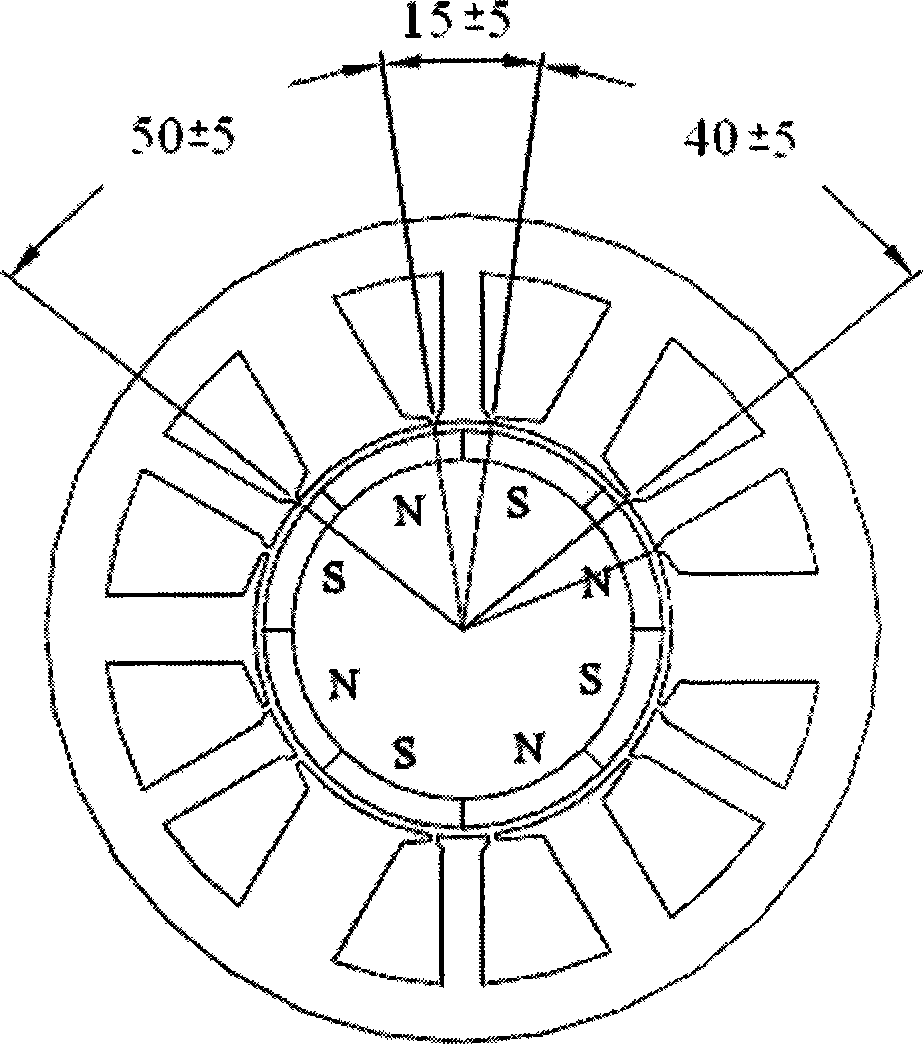

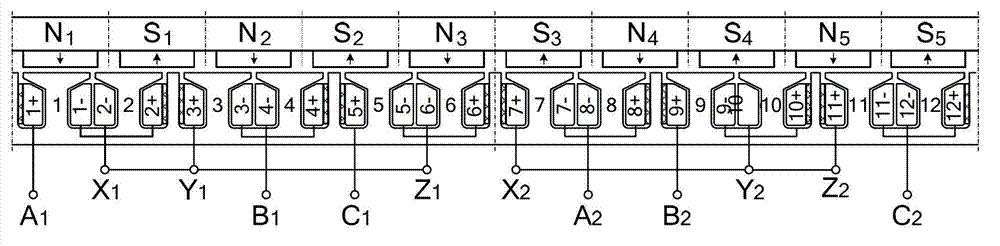

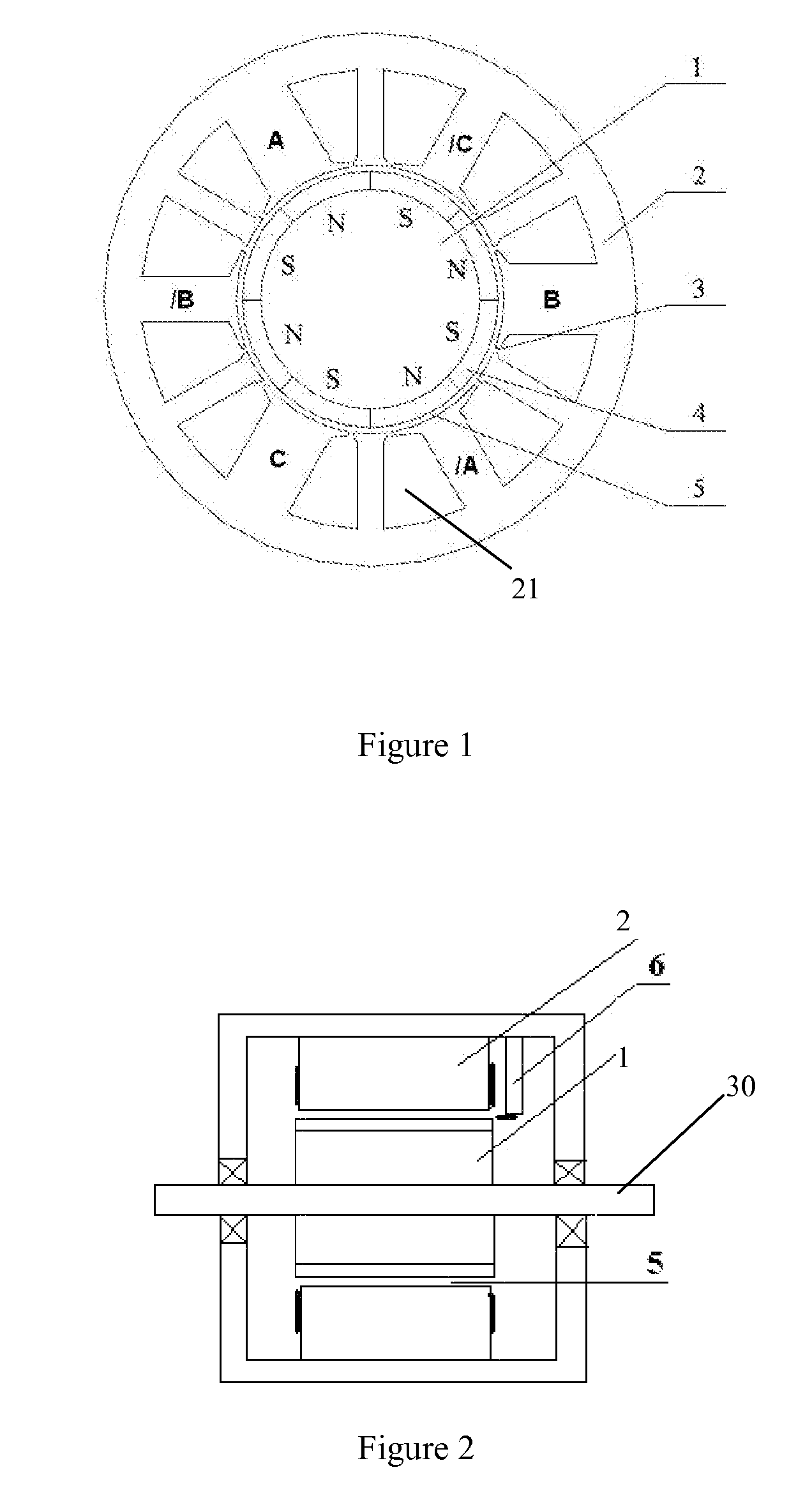

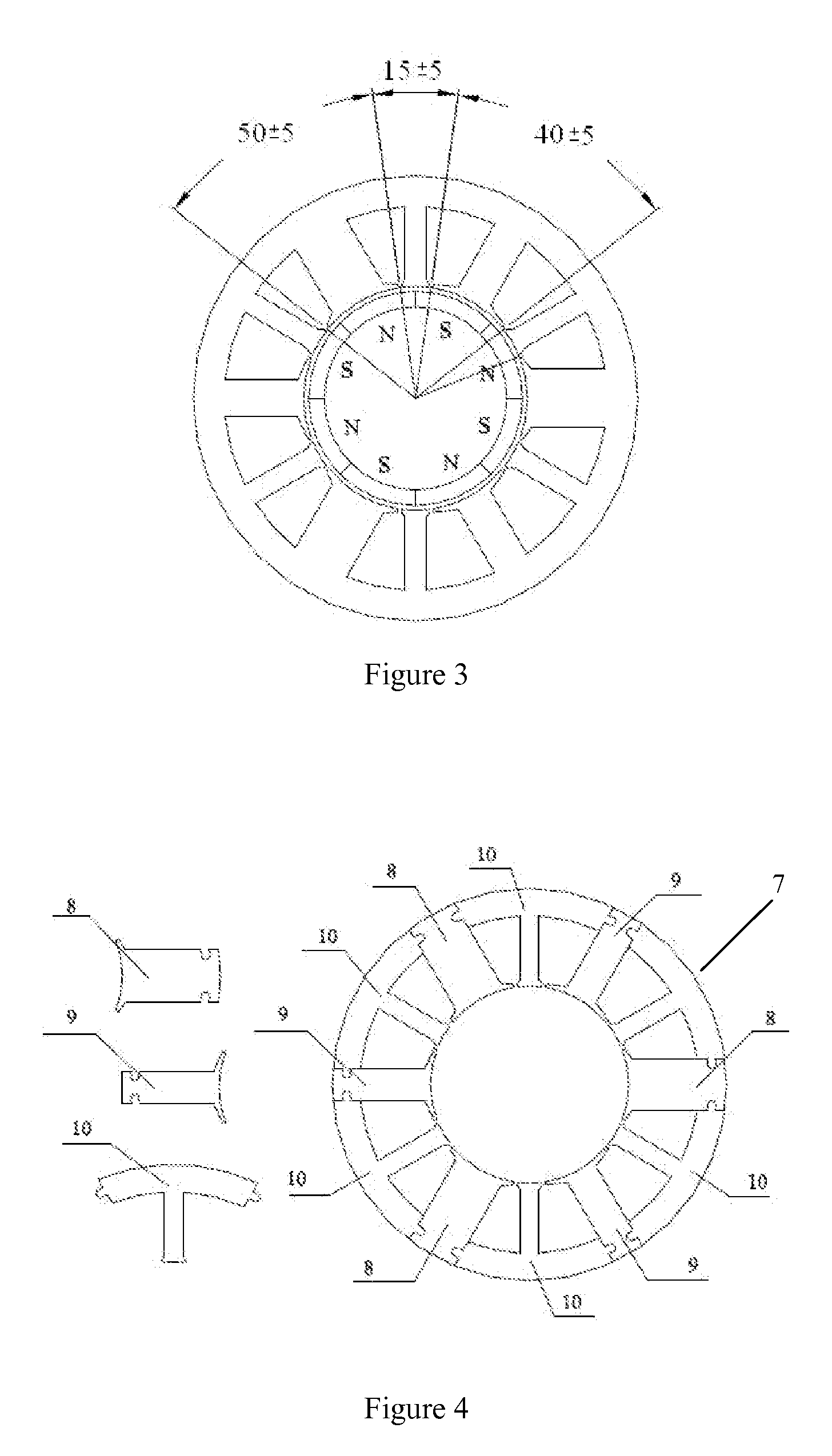

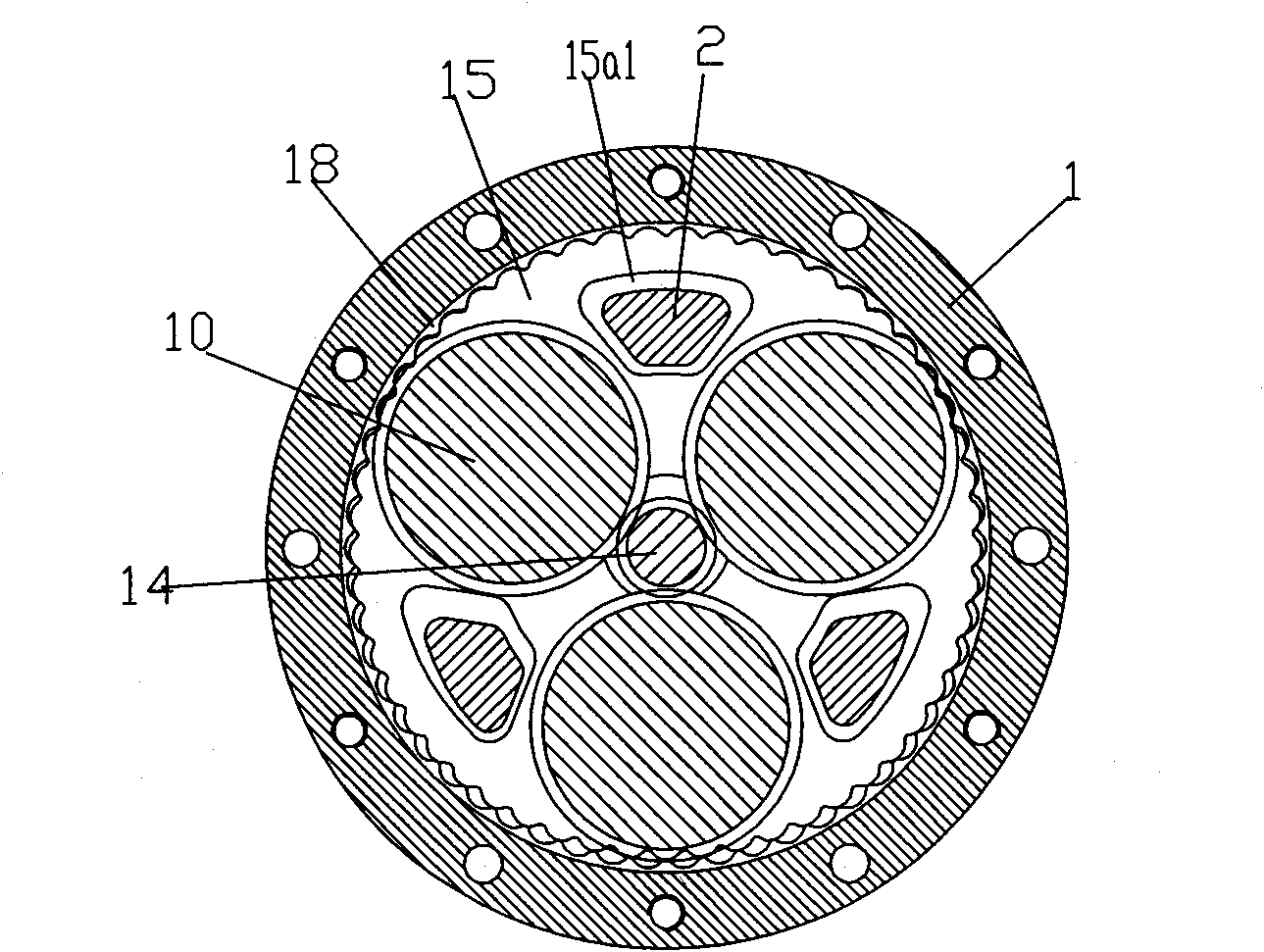

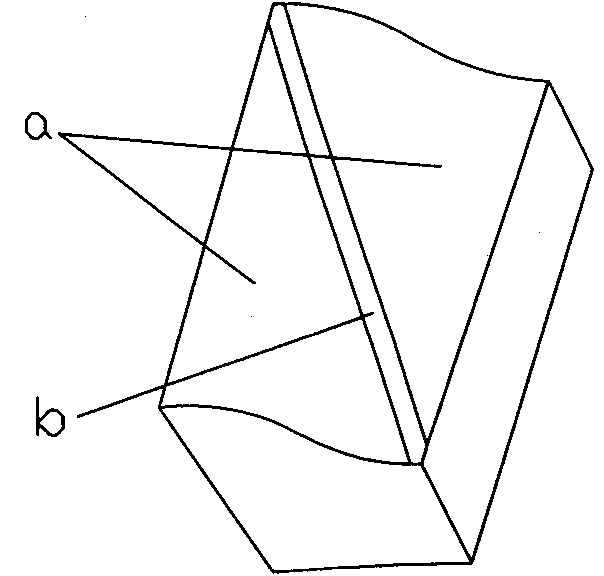

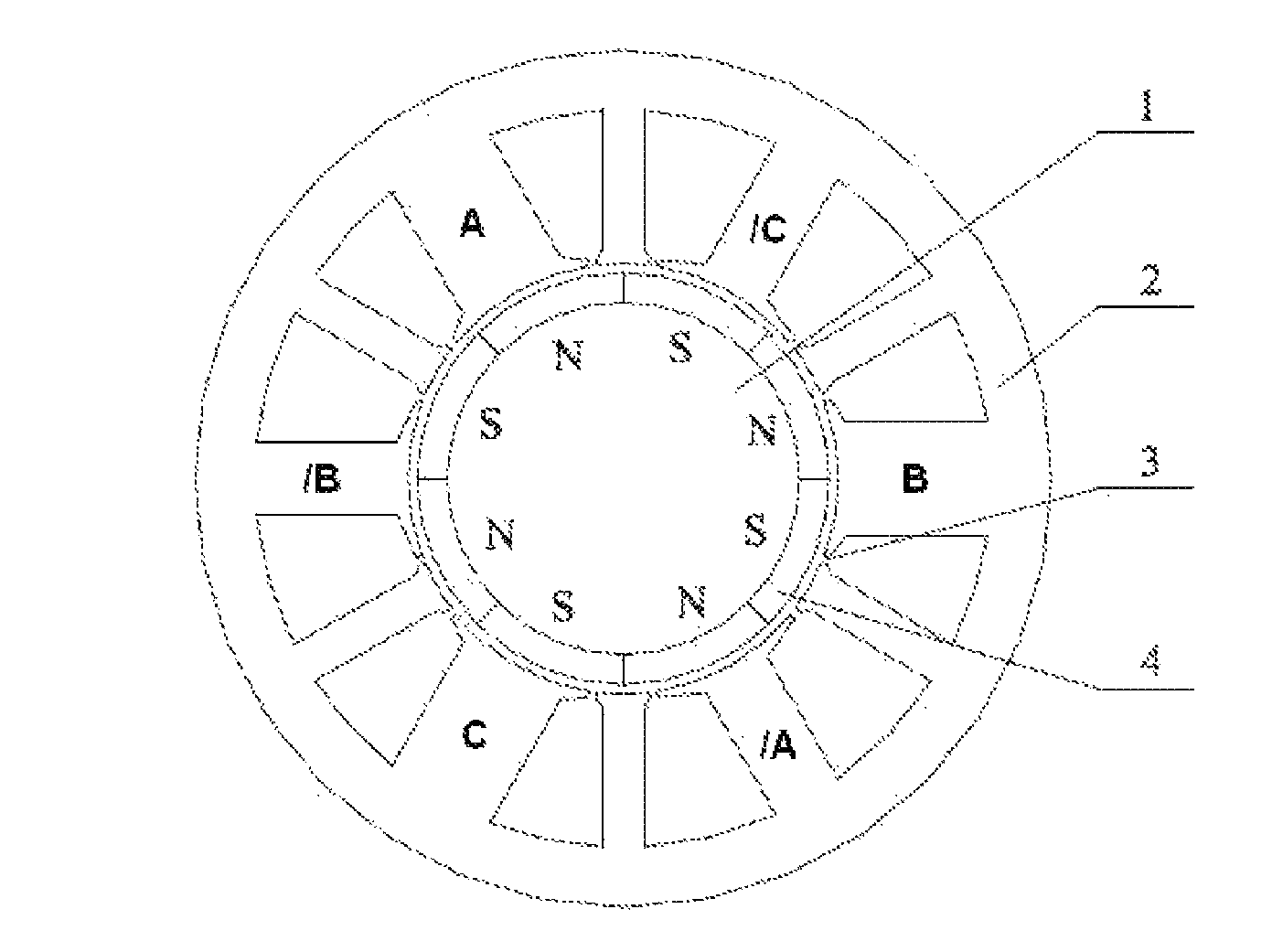

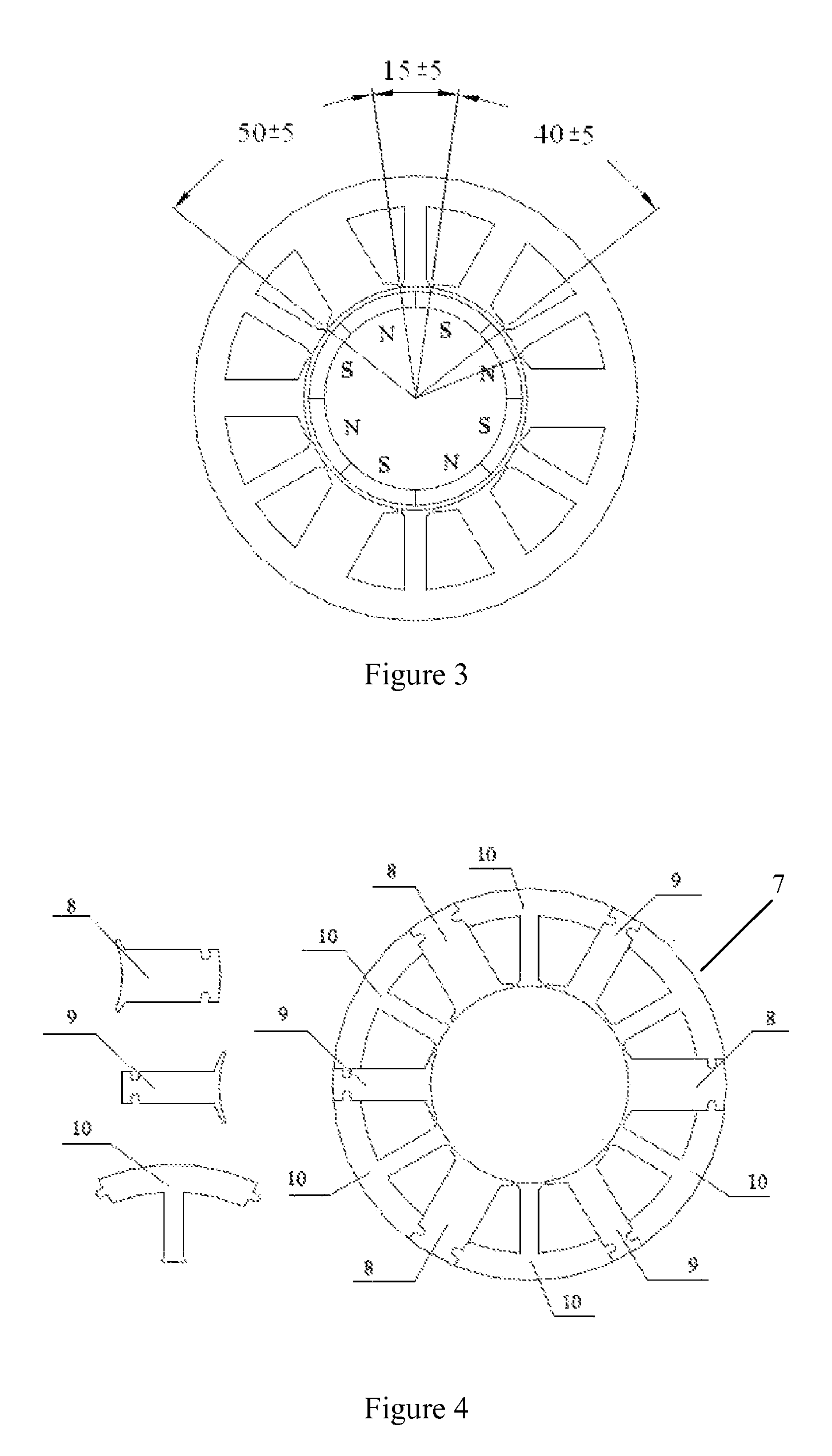

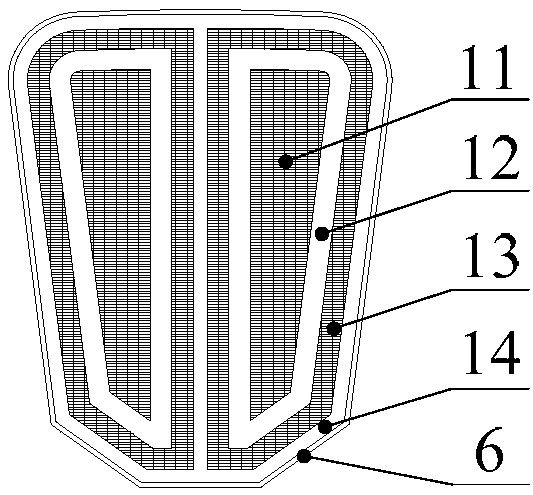

The invention relates to a square wave three phase brushless permanent magnet dc motor. In order to solve the problems existed in the prior square wave permanent magnet motor and sine wave permanent magnet motor, a magnetic pole number 2P is equal to 8 on a rotor iron core; a slot number Z is equal to 12 of a stator iron core, twelve teeth comprises three big teeth, three middle teeth and six small teeth;a mechanical angle ratio of the big teeth is 50 degree + / - 5 degree, the mechanical angle ratio of the middle teeth is 40 degree + / - 5 degree,the mechanical angle ratio of the small teeth is 15 degree + / - 5 degree,and a total mechanical angle ratio of one big tooth plus one middle tooth plus two small teeth is equal to 120 degree.The three phase concentrated windings respectively wind on the big teeth and middle teeth, each phase only has two concentrated windings and the three phase motor only has six concentrated windings. The motor can generate a stable torque when driven by a three phase square wave current and a torque fluctuation index is equivalent to that of the sine wave permanent magnet. The motor of the invention has a series of advantages of minimum winding end, minimum air gap, minimum material, minimum locating torque and minimum loss or the like.

Owner:SCBD (ANHUI) E TECH CO LTD

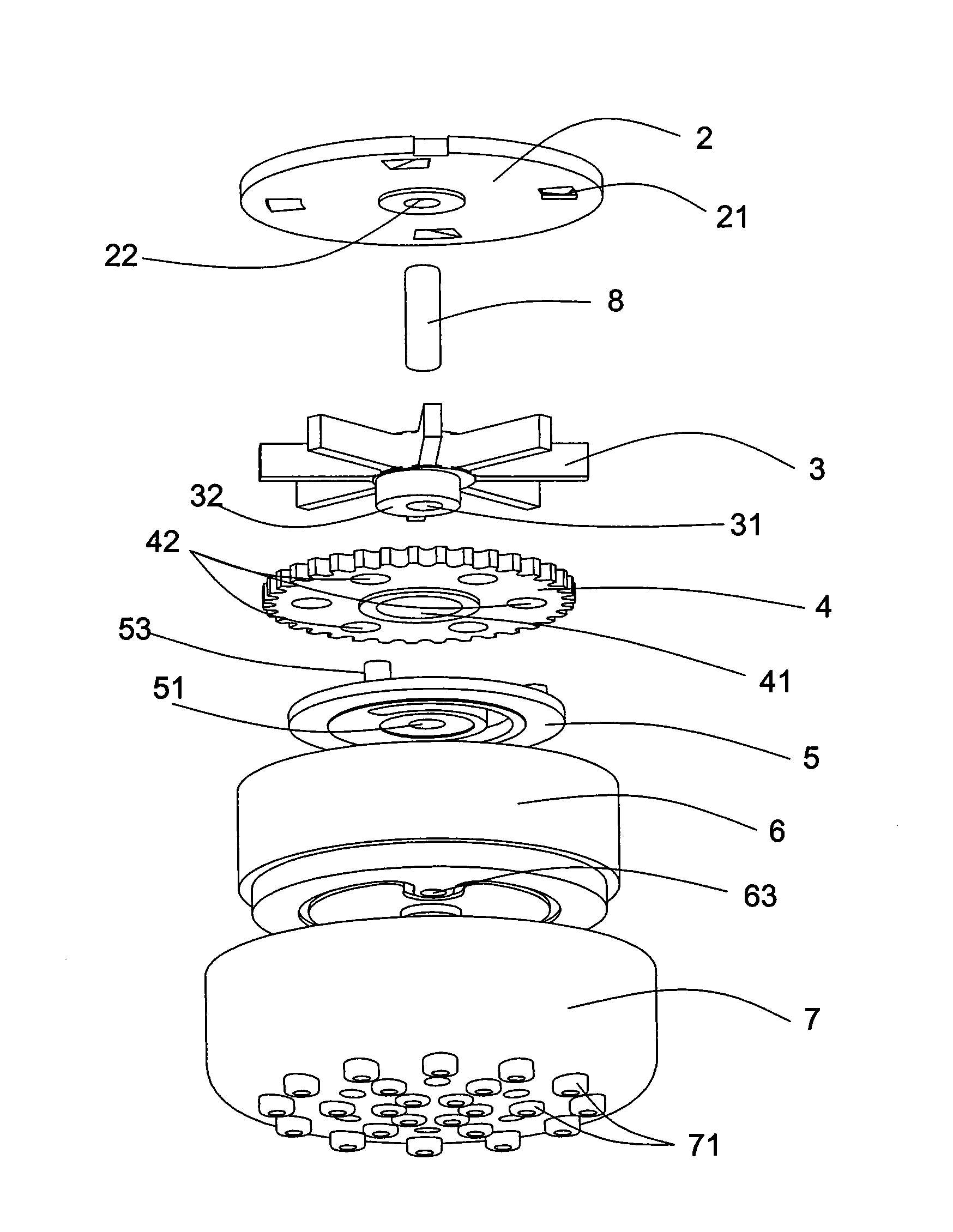

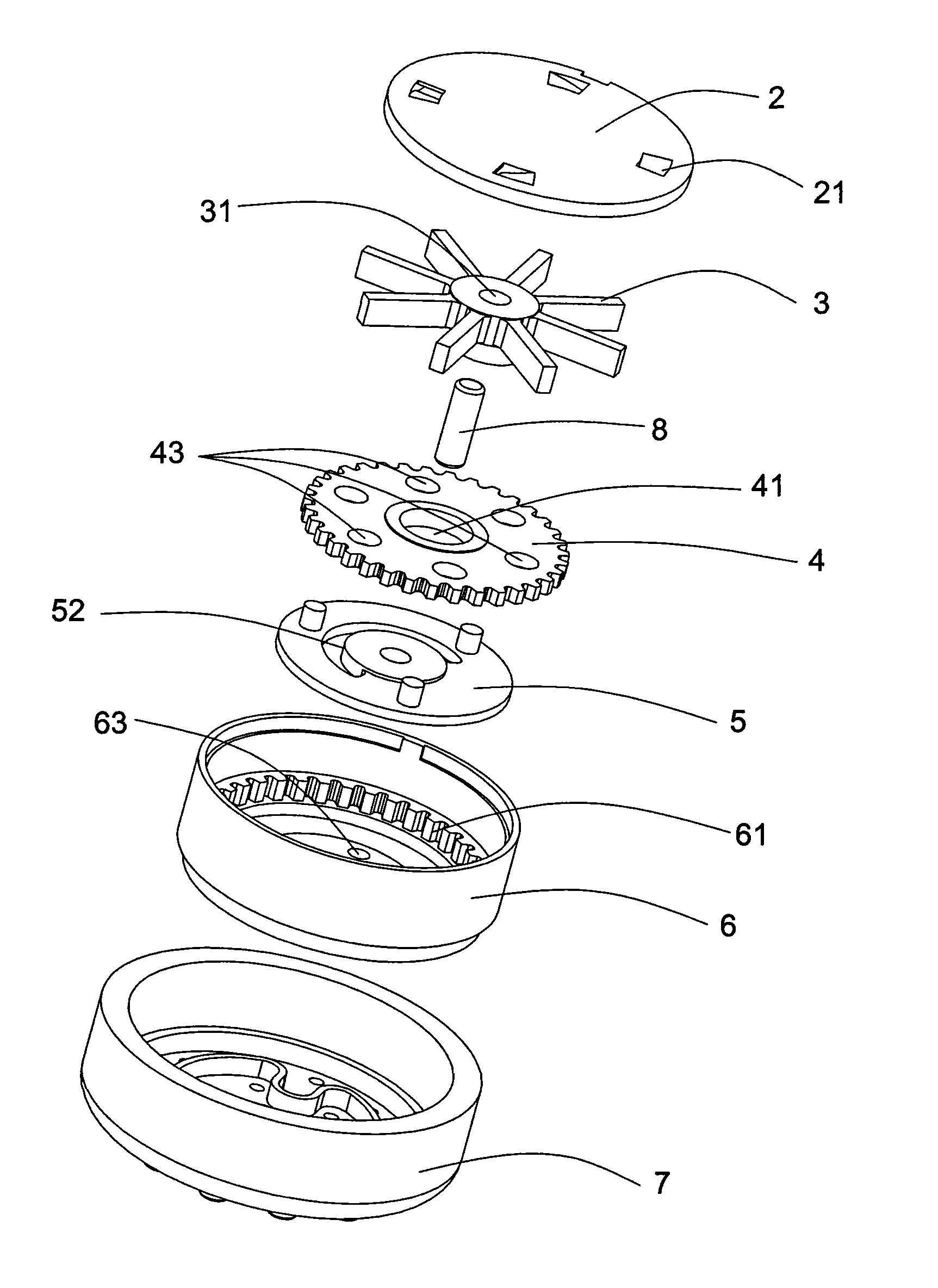

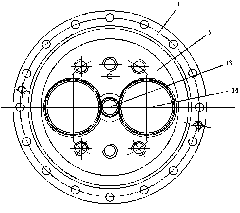

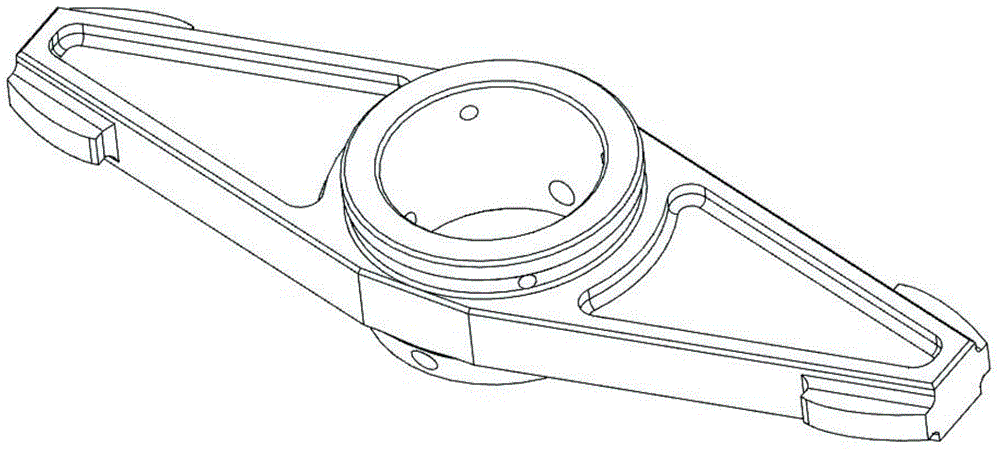

Massage shower head capable of realizing water flow dynamic switching

InactiveCN101773880ASimple structureReduce rotation frequencyPhysical therapySpray nozzlesImpellerWater flow

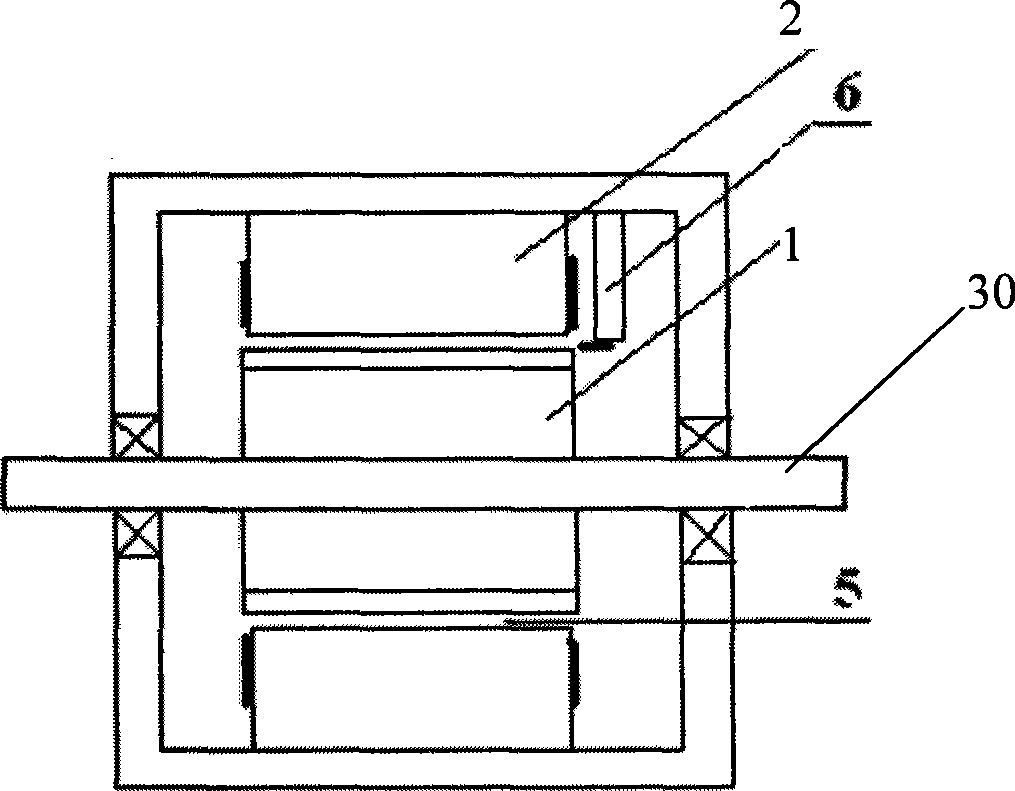

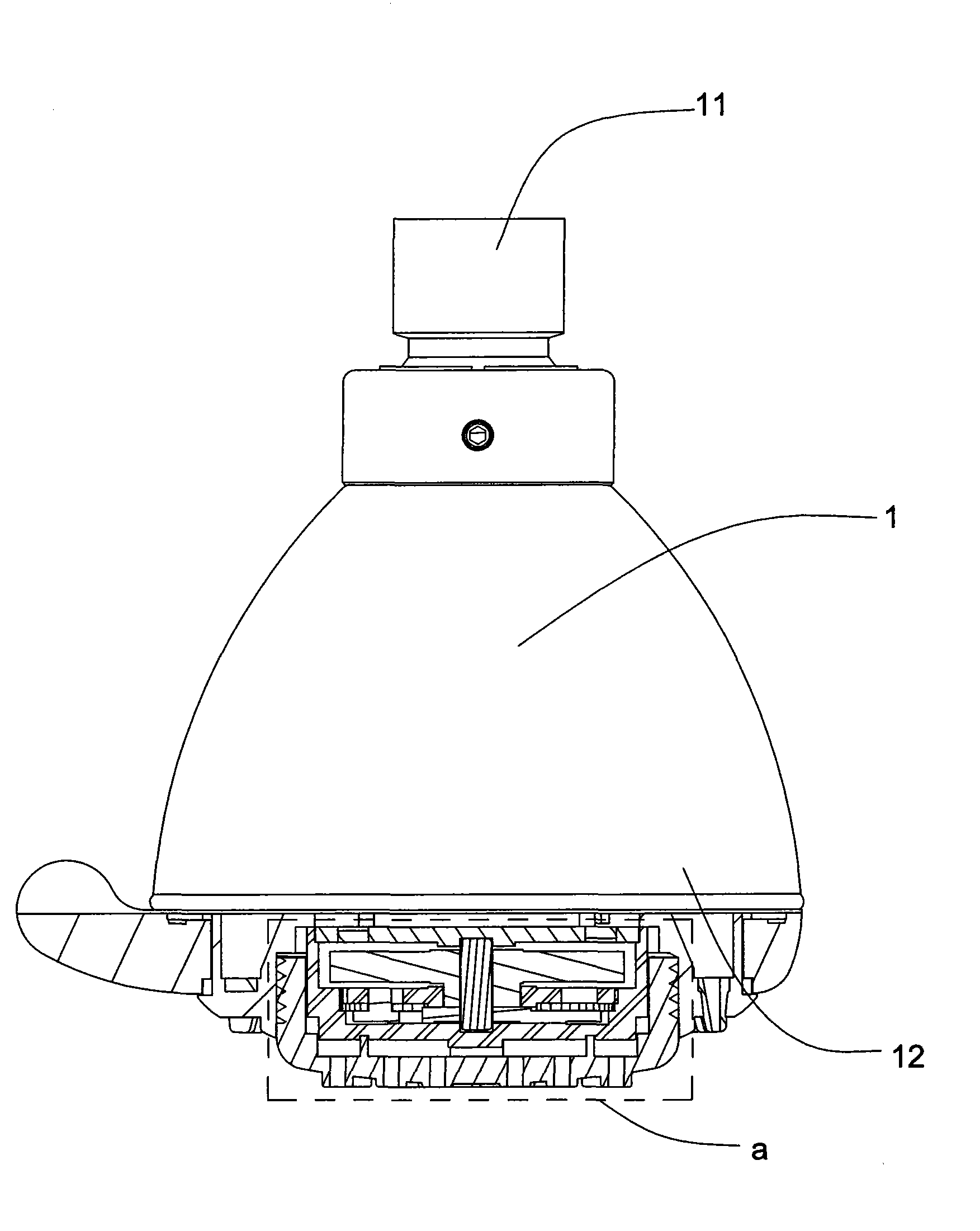

The invention discloses a massage shower head capable of realizing the water flow dynamic switching, which comprises a hollow body, an inclined water body, an impeller, a surface cover assembly and a movable sheet, wherein the impeller is positioned under the inclined water body, the surface cover assembly is provided with water outlets, the movable sheet is used for switching the conduction of water outlets in different regions of the surface cover assembly, and the impeller and the movable sheet are in transmission connection through a small-tooth-difference planetary gear transmission speed reducing mechanism. When in use, the massage shower head can realize the dynamic switching of different water outlets on the surface cover of the shower head, and can realize good massage effect.

Owner:XIAMEN SOLEX HIGH TECH IND CO LTD +1

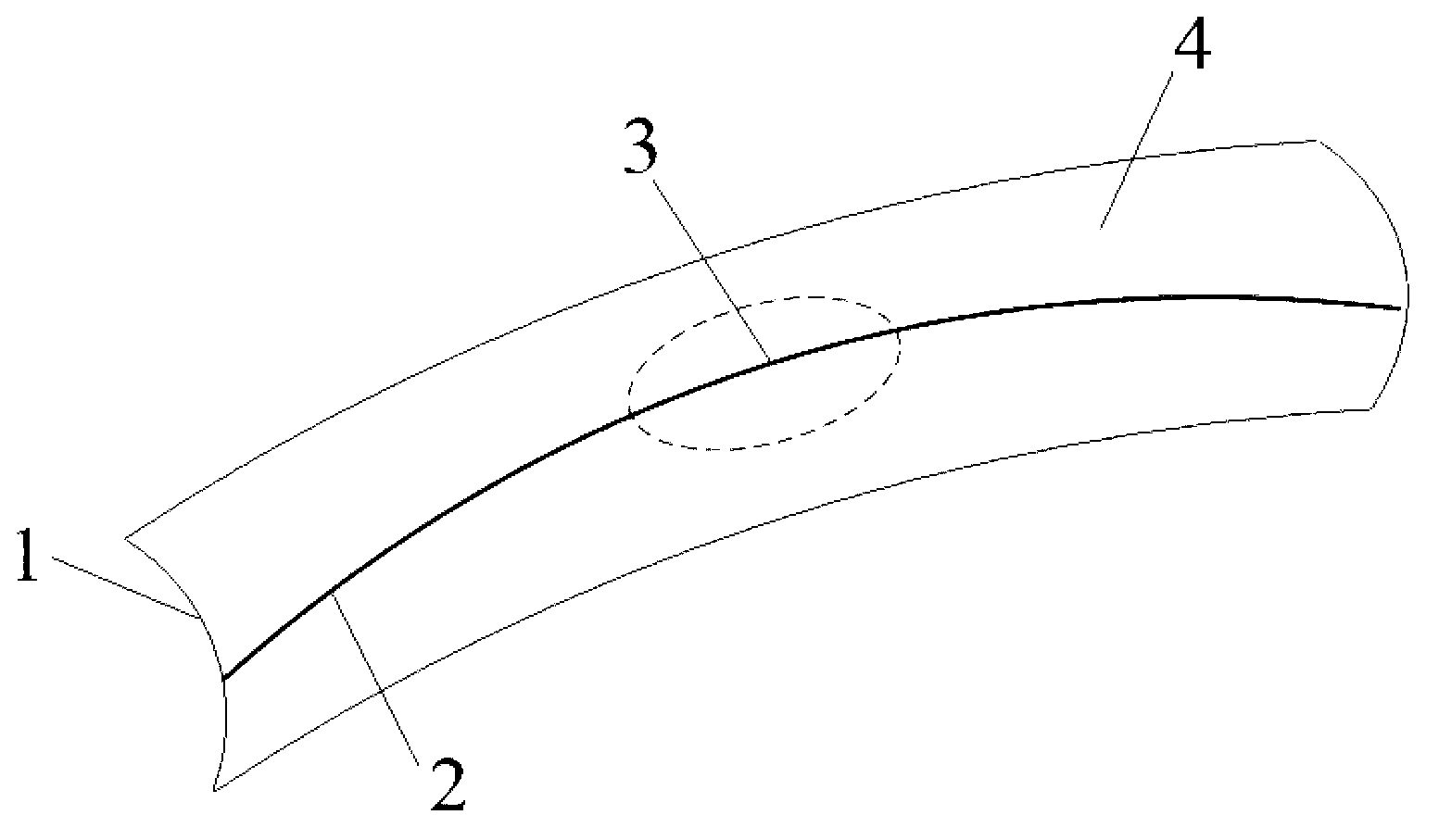

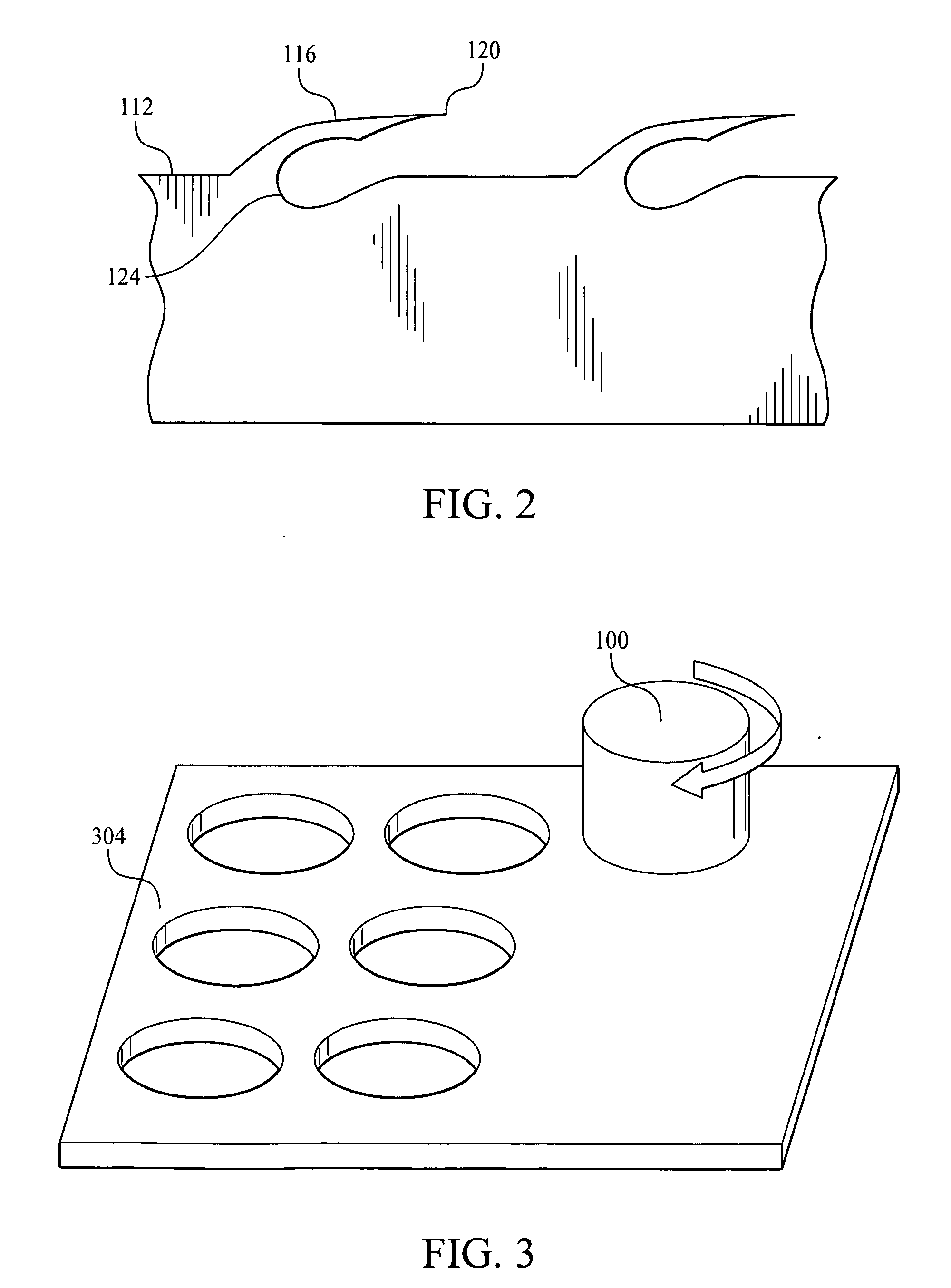

Band saw blade

The present disclosure relates to band saw blades often used for cutting wood at a sawmill. A band saw blade has teeth, and at least one tooth has a back angle that is greater than the back angle of conventional band saw blades. The greater back angle results in teeth having a smaller tooth angle so that the teeth make deeper penetration into wood or other materials that are cut by the blade.

Owner:COOKS SAW MFG

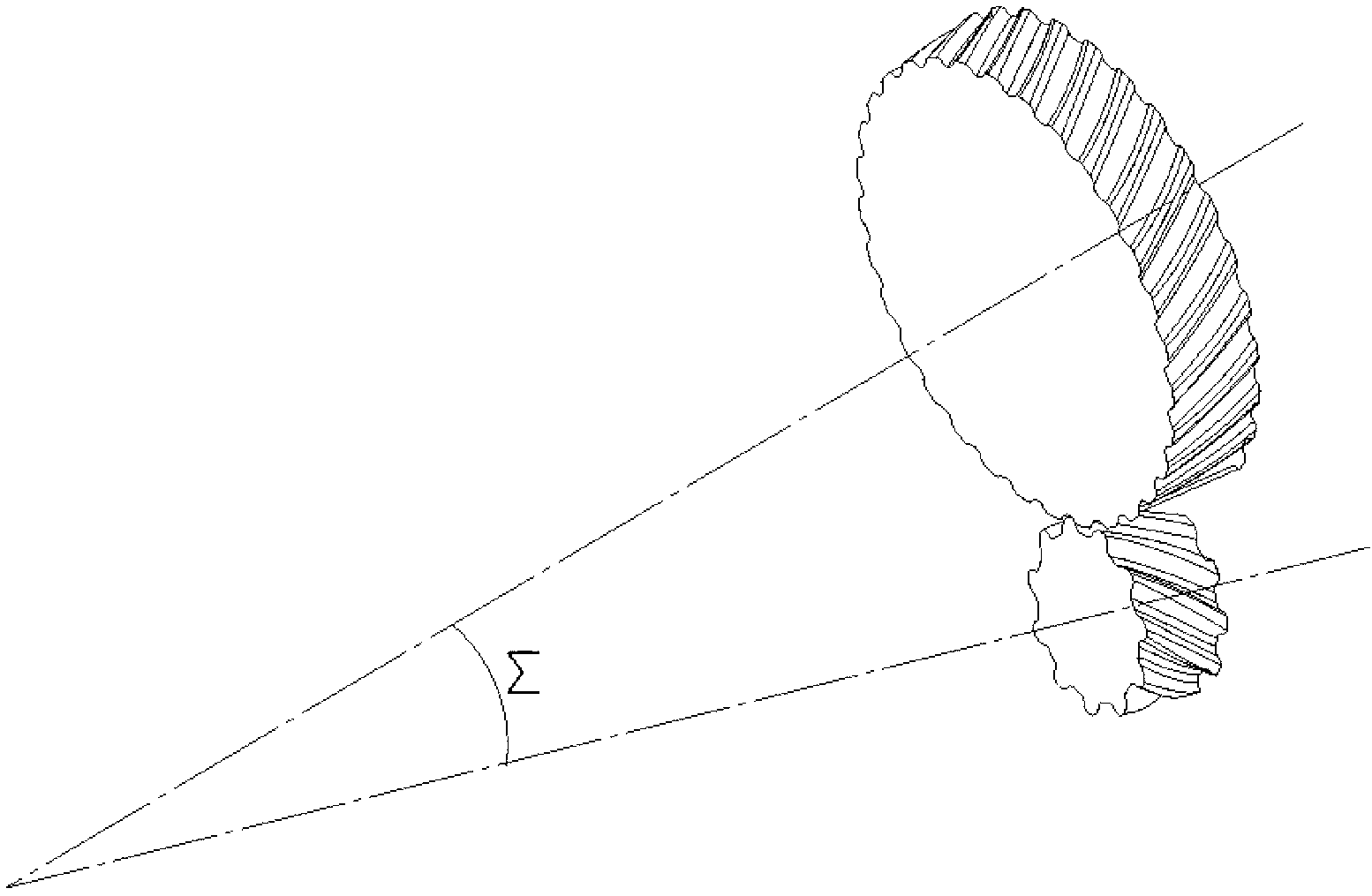

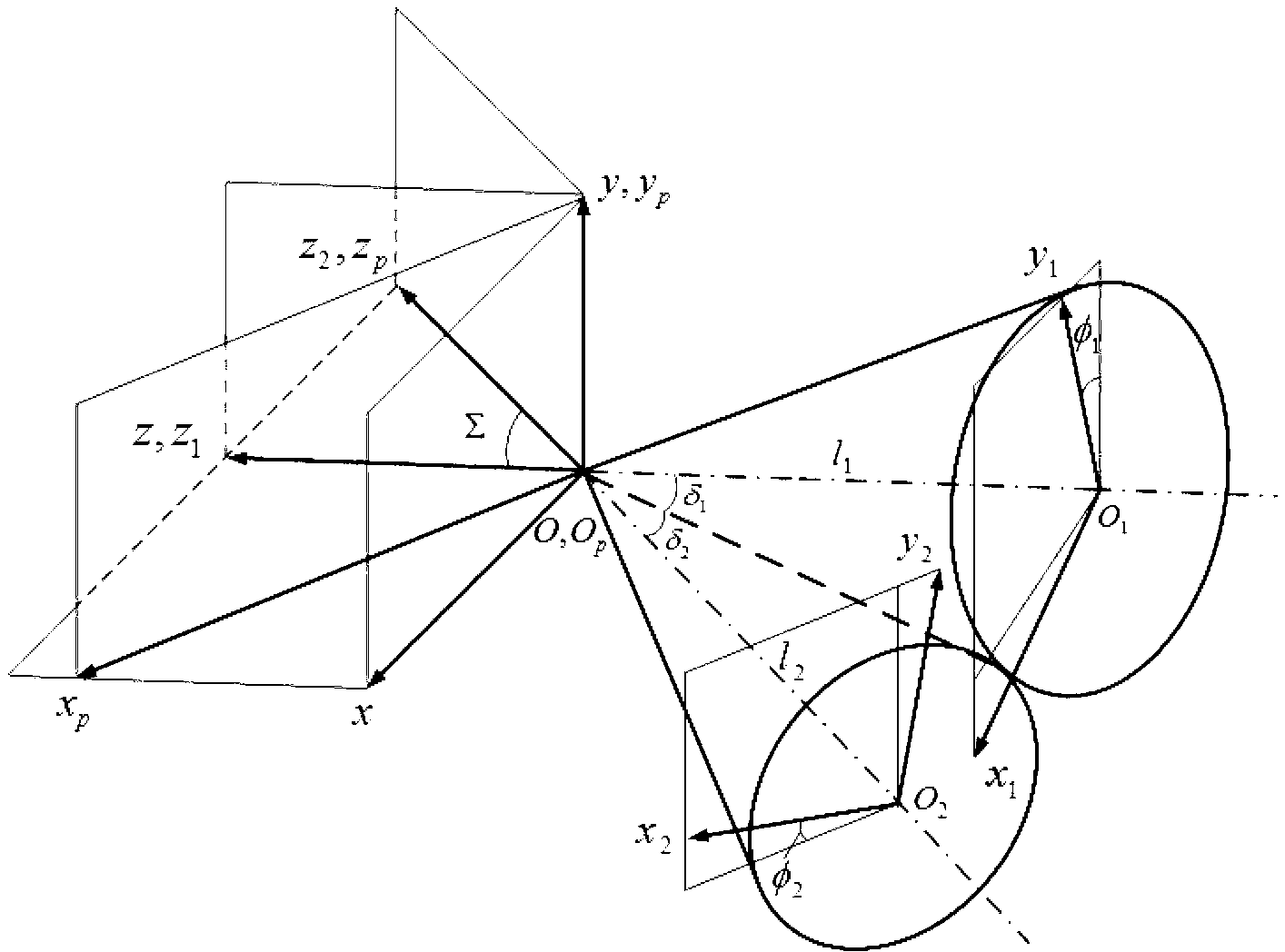

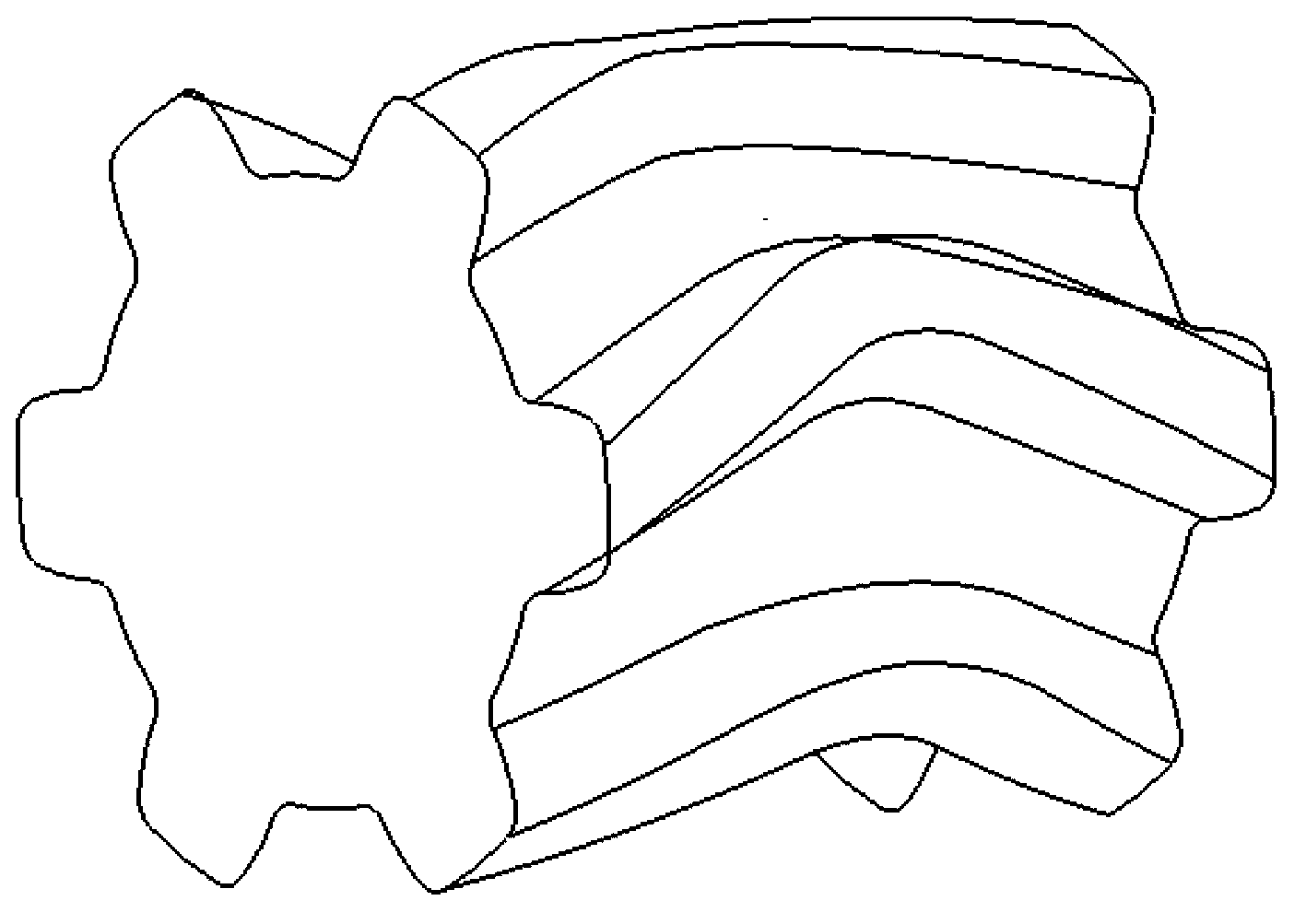

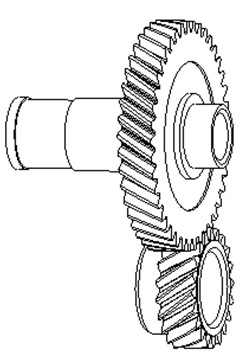

Bevel gear based on conjugate curves and meshing pair thereof

ActiveCN103075493AEasy to processImprove contact strengthToothed gearingsPortable liftingEngineeringContact Transmission

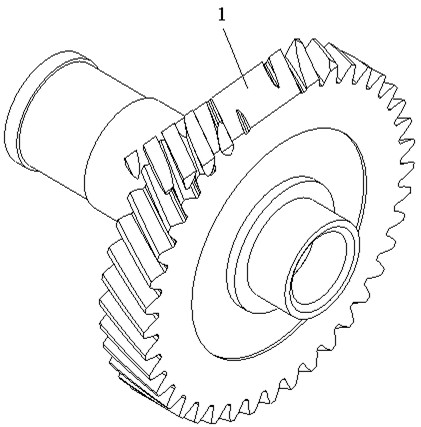

The invention discloses a bevel gear based on conjugate curves and a meshing pair thereof. The meshing pair comprises a bevel gear I and a bevel gear II which are mutually in point meshing and have arc tooth profile curves, and a contact curve gamma1 consisting of meshing points on the tooth profile curve of the bevel gear I and a contact curve gamma2 consisting of meshing points on the tooth profile curve of the bevel gear II are conjugate curves. According to the bevel gear transmission meshing pair based on the conjugate curves, the tooth profile curves of the mutually meshed bevel gear I and bevel gear II are respectively in an arc shape, the meshed tooth surfaces of the bevel gear I and the bevel gear II move along the conjugate curves, the meshing characteristics of the contact curves are succeeded, and the meshing of the contact curves between the tooth surfaces is high in contact strength; a contact transmission process is close to pure rolling along an axial direction, and the transmission efficiency is high; the tooth surfaces are easy to process and manufacture, transmission errors are small, and the service life is long; under the conditions of equivalent transmission ratio and center distance, the selection and determination of a small tooth number and a large modulus can be realized; and the transmission requirements of high speed, heavy load, large power and high efficiency can be met.

Owner:CHONGQING UNIV

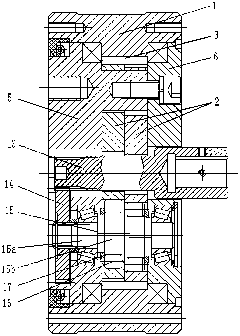

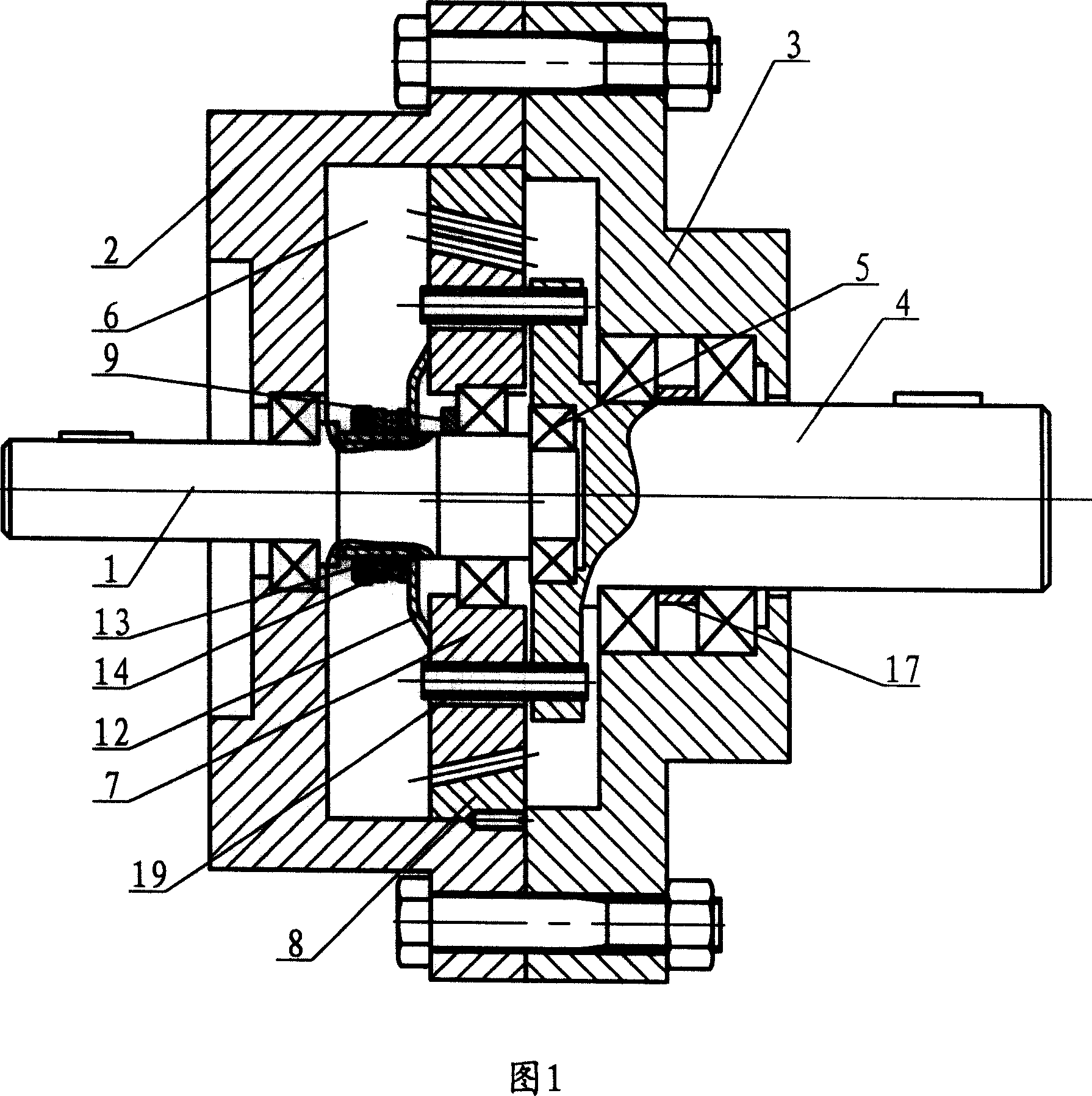

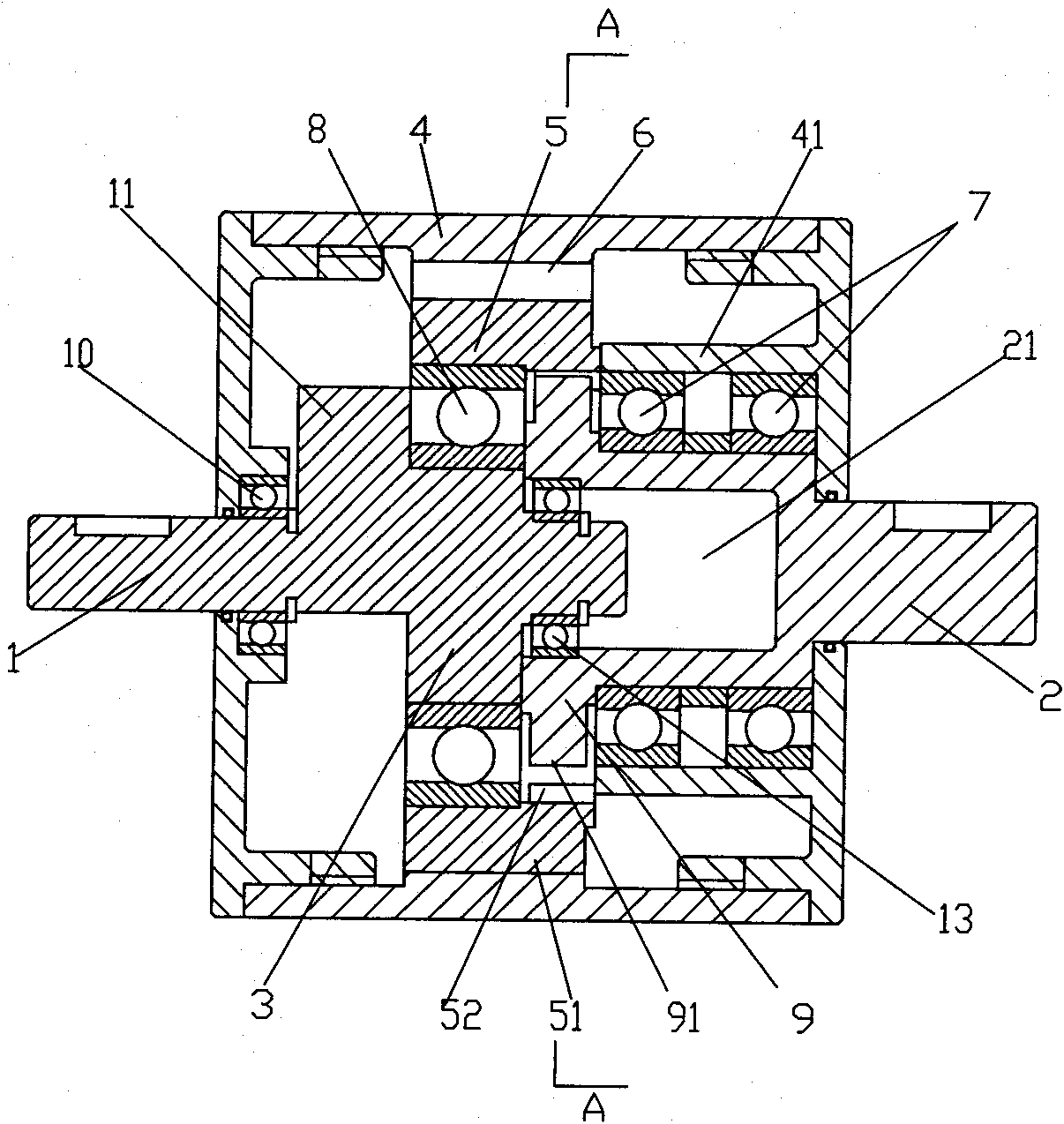

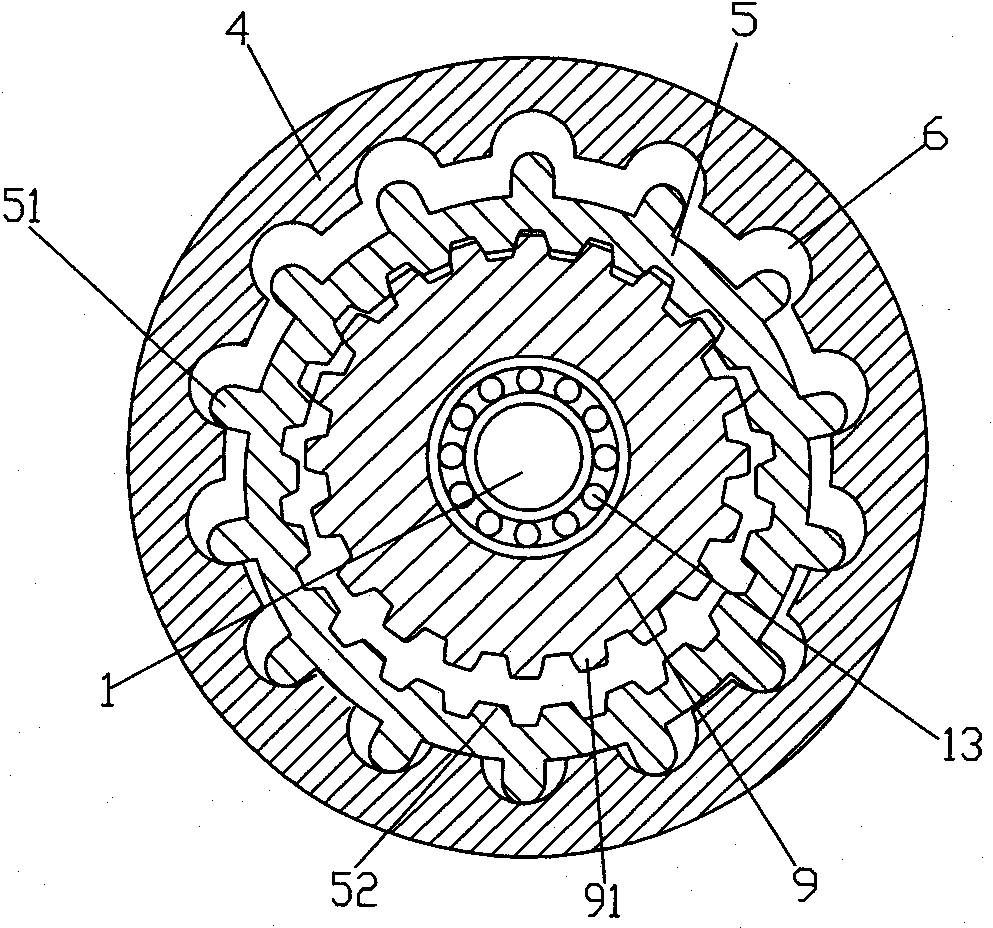

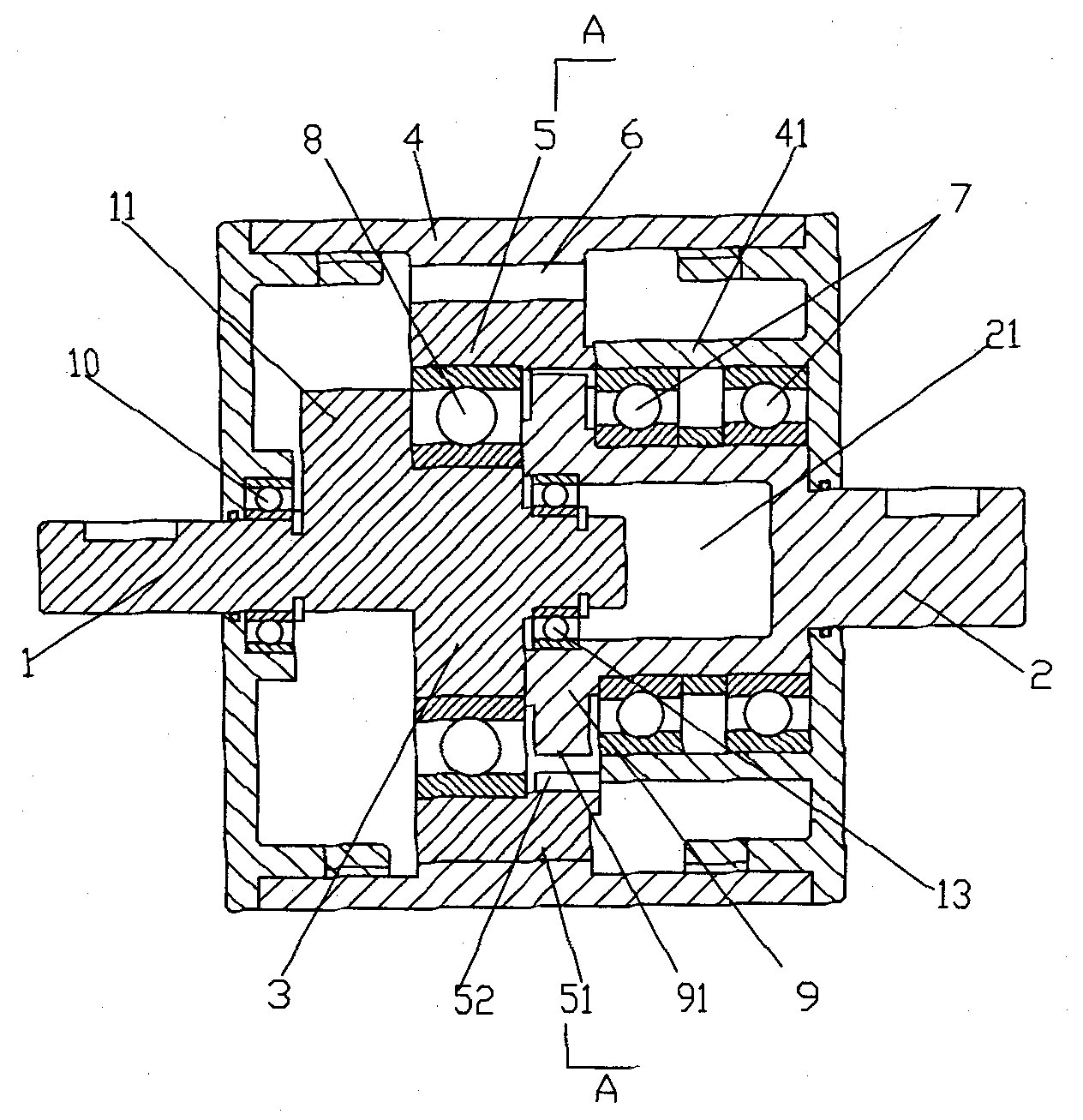

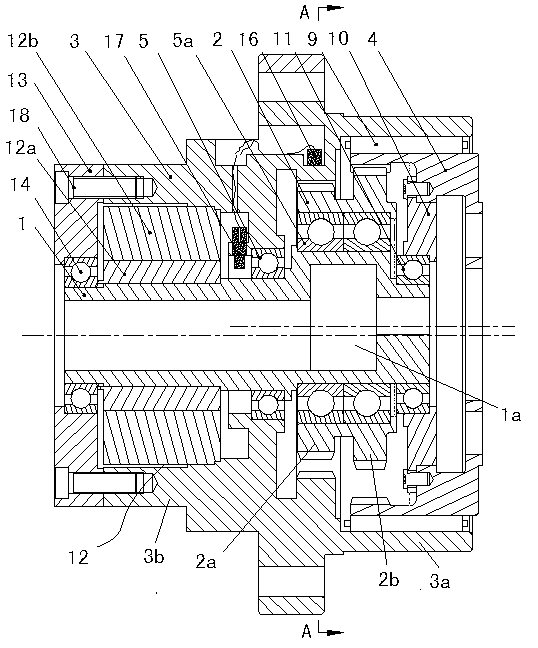

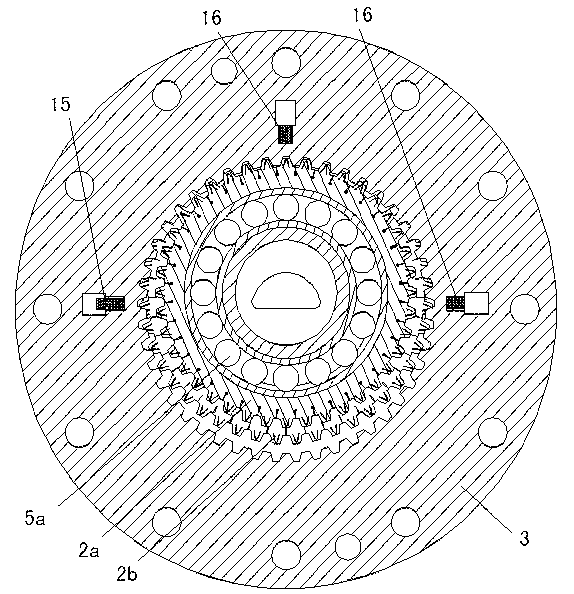

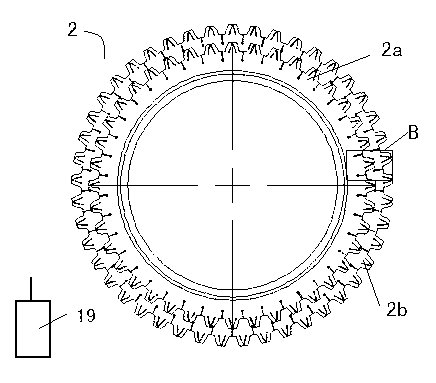

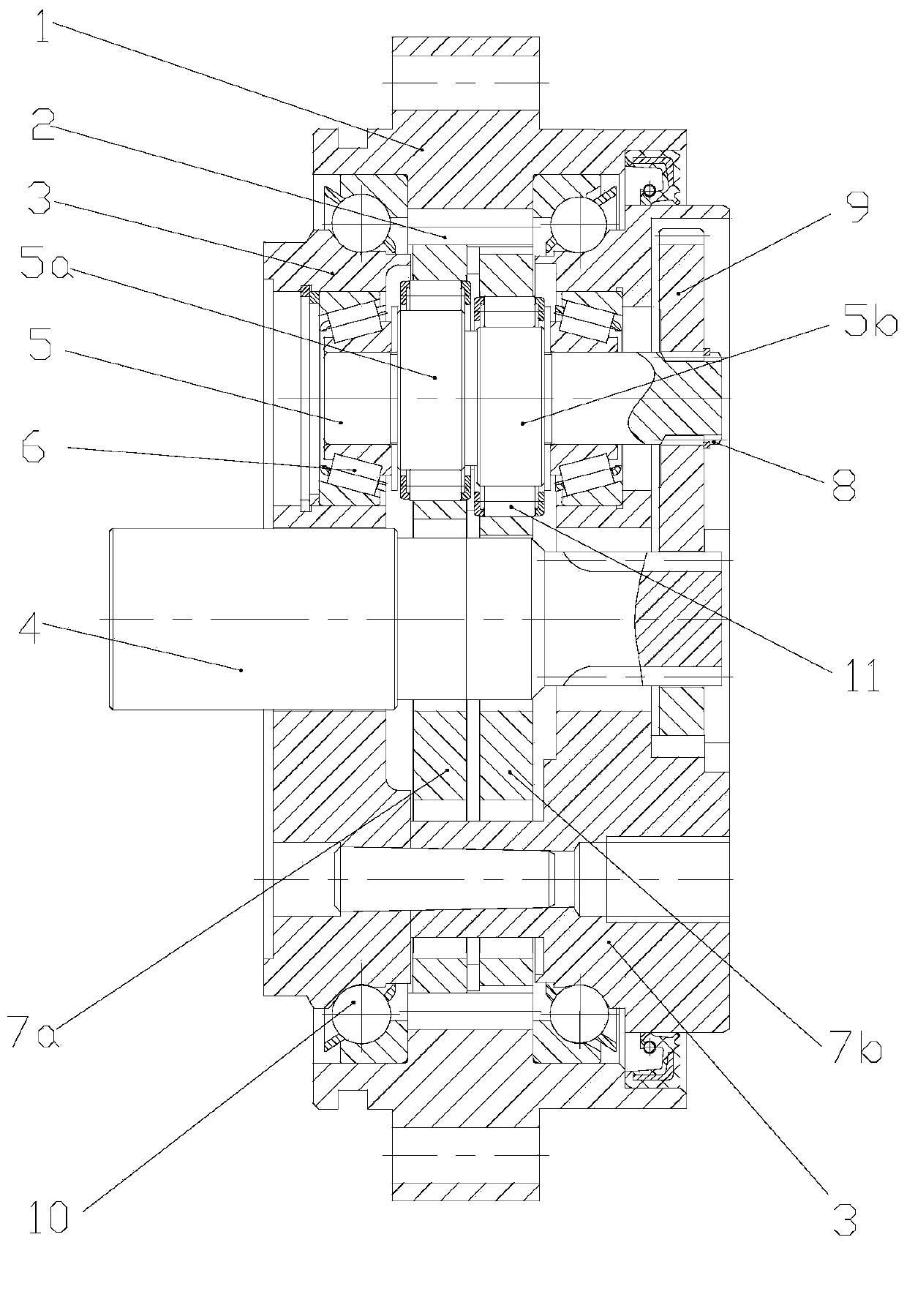

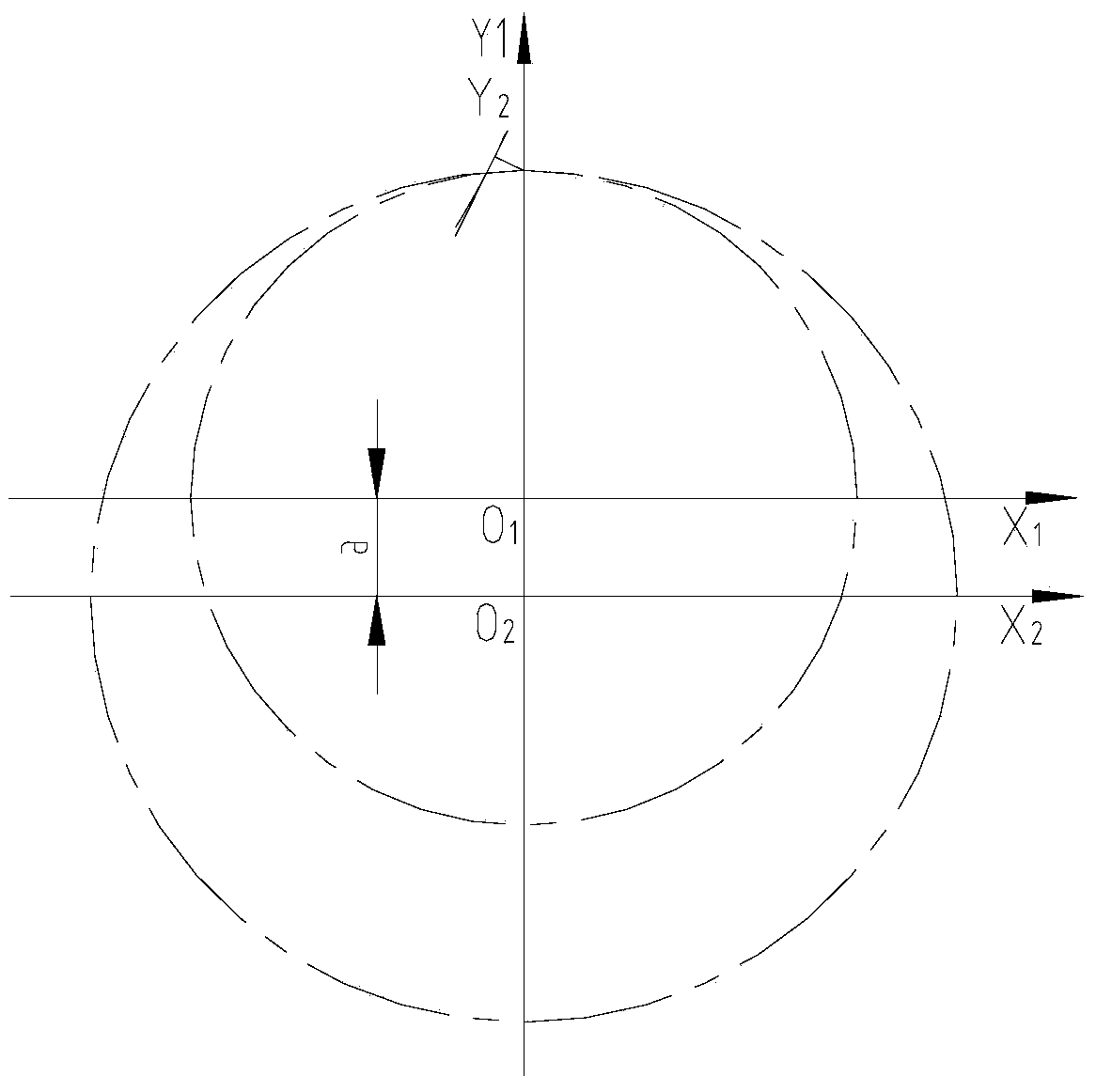

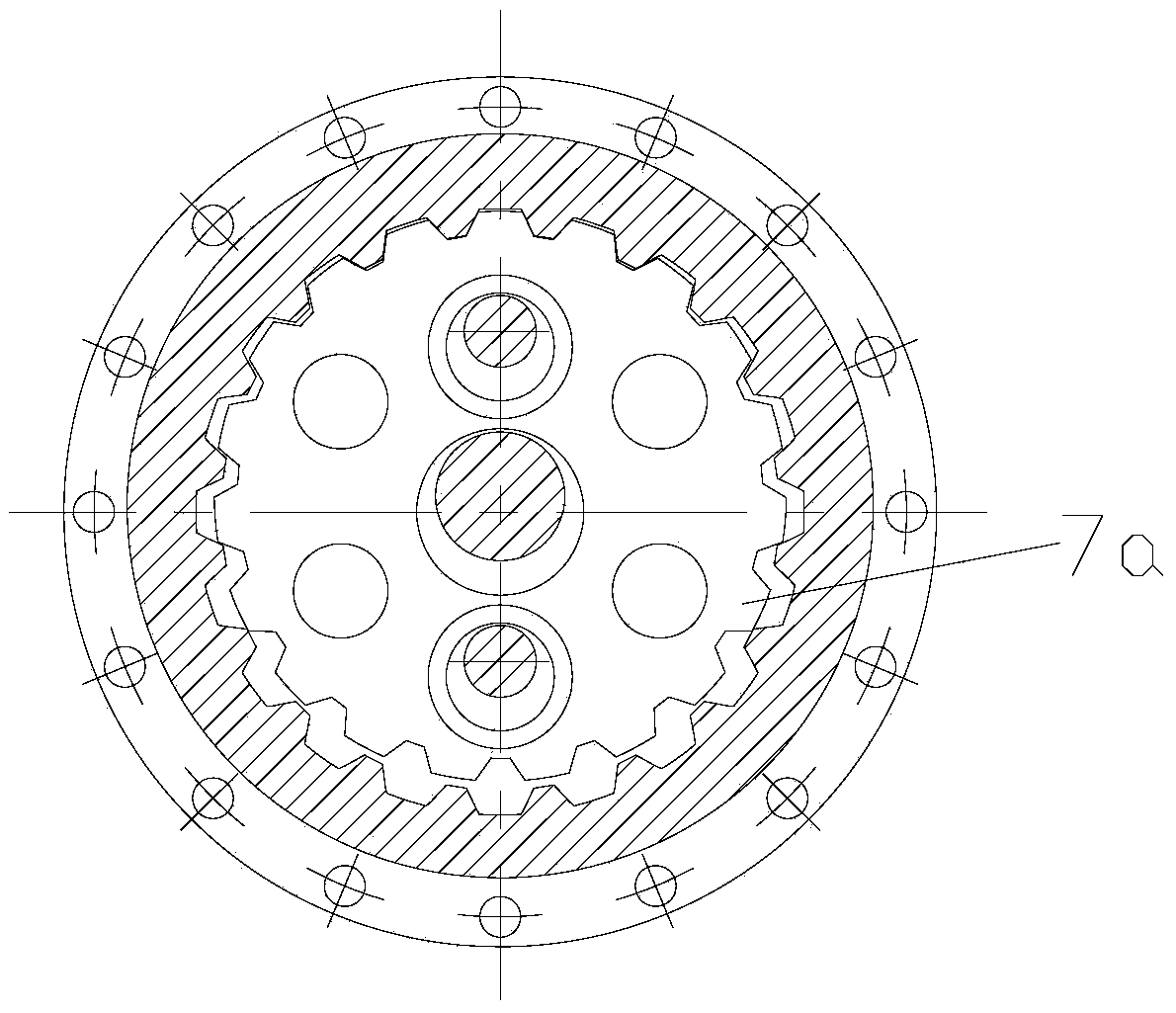

Closed cycloid precision gear reducer

ActiveCN103994184AImprove bending strengthImprove carrying capacityPortable liftingToothed gearingsLeveling effectCarrying capacity

The invention discloses a closed cycloid precision gear reducer. The closed cycloid precision gear reducer comprises an input part, a pin wheel housing, an output part and a small-tooth-difference inside-gear reducing mechanism. Wheel pins used for being meshed with a cycloidal gear of the small-tooth-difference inside-gear reducing mechanism are arranged on the inner ring of the pin wheel housing in the circumferential direction. The inner ring of the pin wheel housing is provided with containing grooves which correspond to the wheel pins in a one-to-one mode and are used for containing the wheel pins. The wheel pins make double-line contact with the inner walls of the corresponding containing grooves. According to the closed cycloid precision gear reducer, the double-line contact characteristic exists between the wheel pins and the containing grooves in the pin wheel housing; as the wheel pins make double-line contact with the corresponding containing grooves in the tooth width direction, the bending strength is enhanced, and carrying capacity is improved; meanwhile, due to the increase of the number of contact lines, the achievement of the error leveling effect is facilitated, transmission accuracy can be improved, and then the requirements for machining errors and assembly errors can be lowered. Compared with an existing RV gear reducer, the return difference of the closed cycloid precision gear reducer is smaller; besides, the closed cycloid precision gear reducer is compact in structure, long in service life, simple in machining process and low in manufacturing cost.

Owner:CHONGQING UNIV

High-precision radial adjustable involute master of gear and adjusting method

ActiveCN104655080AHigh precisionImprove connection stiffnessMeasurement devicesMeasuring instrumentShape deviation

The invention discloses a high-precision radial adjustable involute master of gear and an adjusting method. One tooth face of four tooth faces is selected to be not precisely ground, has higher tooth profile shape deviation and is used for detecting a frequency response characteristic, a filtering effect and sensitivity of an instrument; another three tooth faces are precisely processed and have smaller tooth profile shape deviation, one precisely processed surface has certain tooth profile slope deviation and is used for detecting an amplification factor of the instrument, and other two tooth faces on opposite sides have tooth profile slope deviation which is approximate to zero and are used for representing the precision grade of the involute master of gear, transmitting involute parameter values and determining and correcting an indication error of an involute measurement instrument. The high-precision radial adjustable involute master of gear is simple in structure, convenient to adjust, high in connecting rigidity and reliable in connection with a master core shaft and high in precision, has a stable size, and can simultaneously meet demands for frequency response characteristic, filtering effect, sensitivity, amplification factor detection and instrument indication error correction of the involute measuring instrument.

Owner:DALIAN UNIV OF TECH

Low-heat coupling and non electromagnetic coupling dual-redundancy permanent-magnet synchronous motor between phase windings

ActiveCN103095081ALow leakage mutual inductanceSmall leakage mutual inductanceMagnetic circuit rotating partsMagnetic circuit stationary partsSynchronous motorThermal insulation

Owner:江苏盐新汽车产业投资发展有限公司

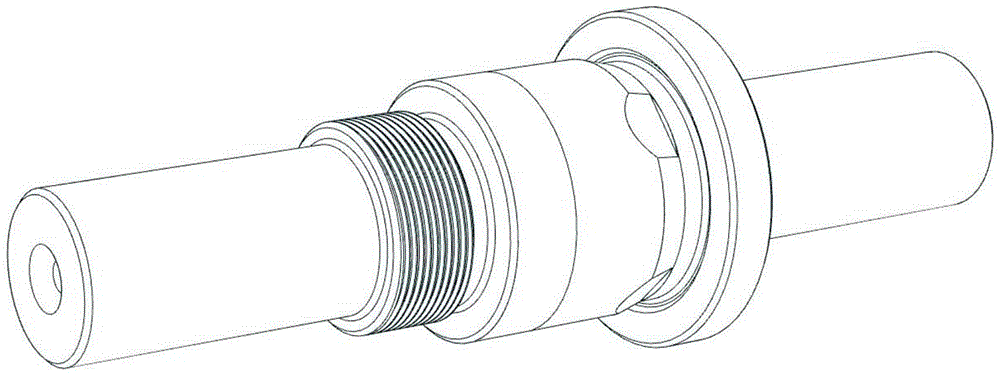

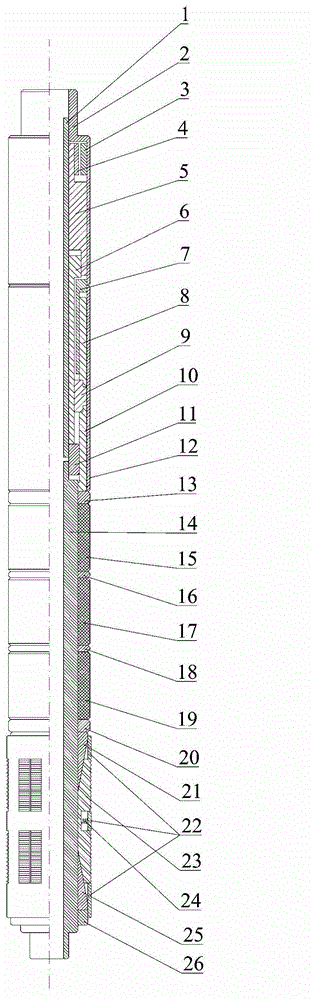

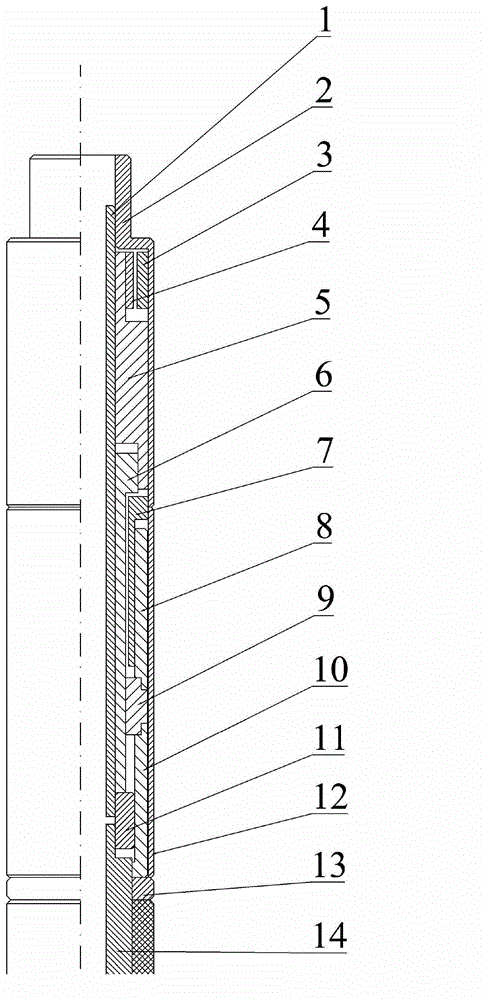

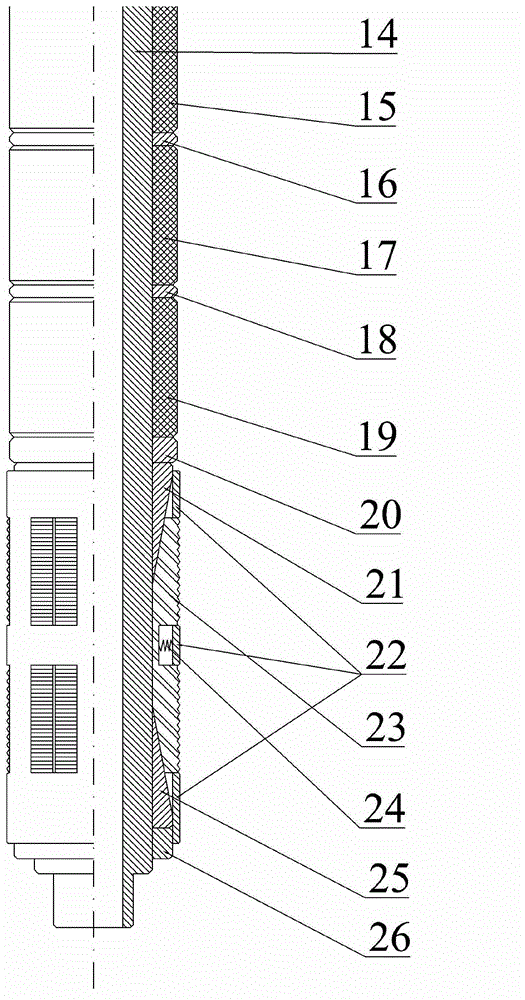

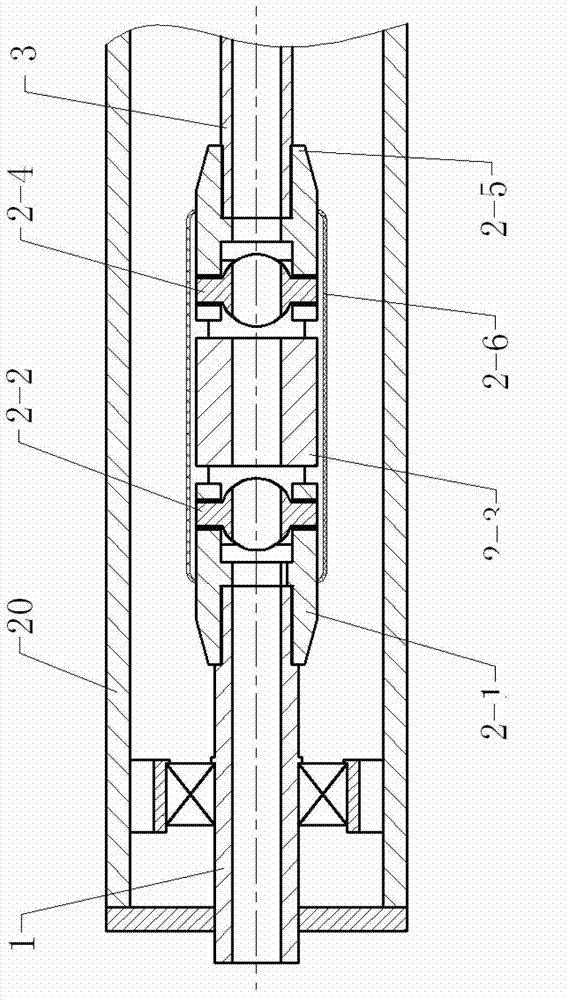

Downhole electric control compression type packer

ActiveCN102979477AAchieving tightnessAccurate data feedbackSealing/packingThreaded pipeElectric machine

The invention provides a downhole electric control compression type packer, which comprises a base pipe, a motor, a speed reduction device, a transmission device and a packing device, wherein the motor, the speed reduction device, the transmission device and the packing device are sheathed on the base pipe, the motor comprises a circular motor output shaft, the circular motor output shaft is rotatably sheathed on the base pipe, the speed reduction device comprises a circular NN-shaped planetary gear speed reducer with small teeth difference (5), the circular NN-shaped planetary gear speed reducer with small teeth difference (5) comprises a circular input shaft and a circular output shaft, the input shaft of the circular NN-shaped planetary gear speed reducer with small teeth difference (5) is connected with the circular motor output shaft, and the transmission device comprises a thread pipe (6), a transmission nut sleeve (9) and a lower sleeve (10).

Owner:PETROCHINA CO LTD

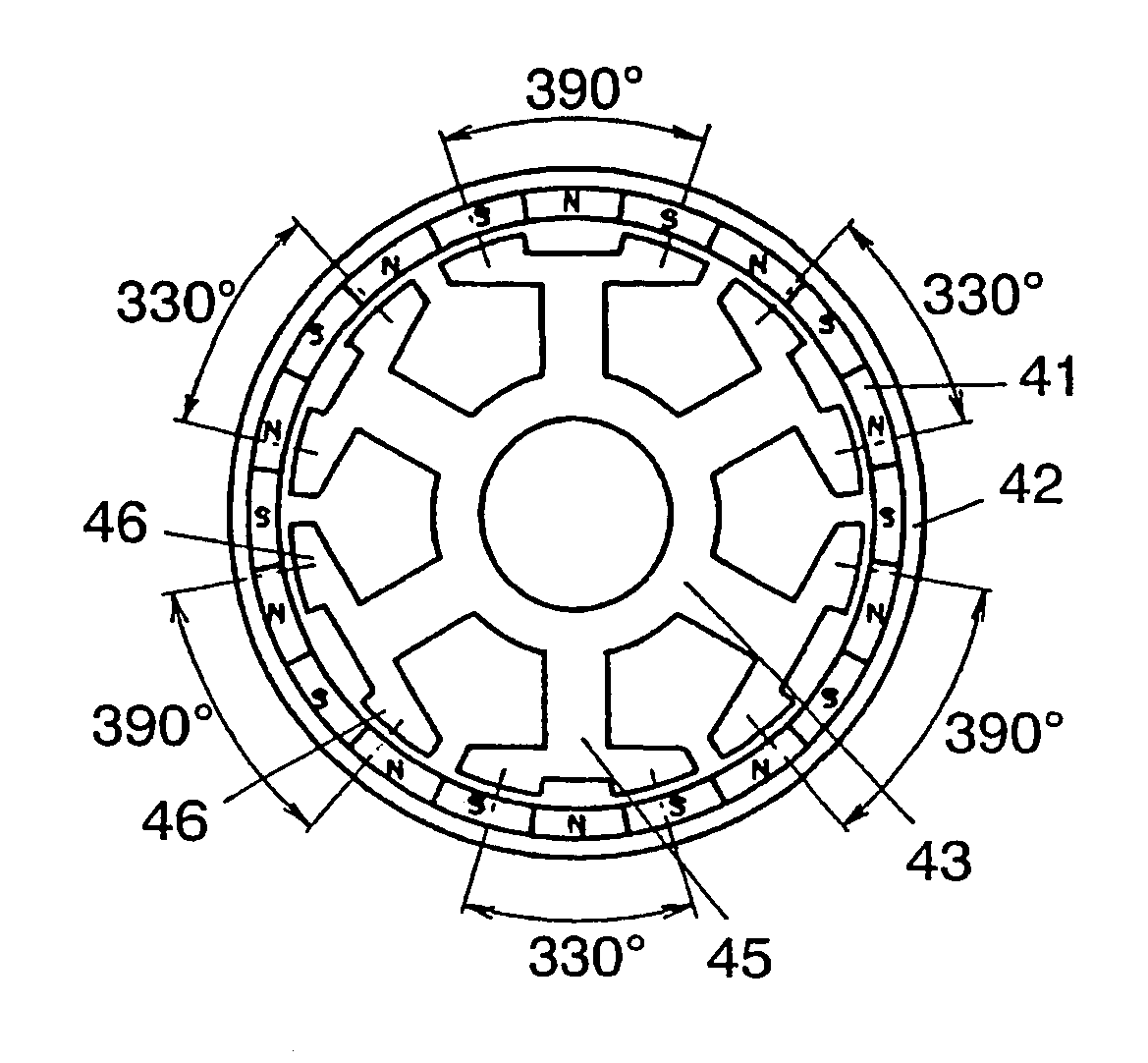

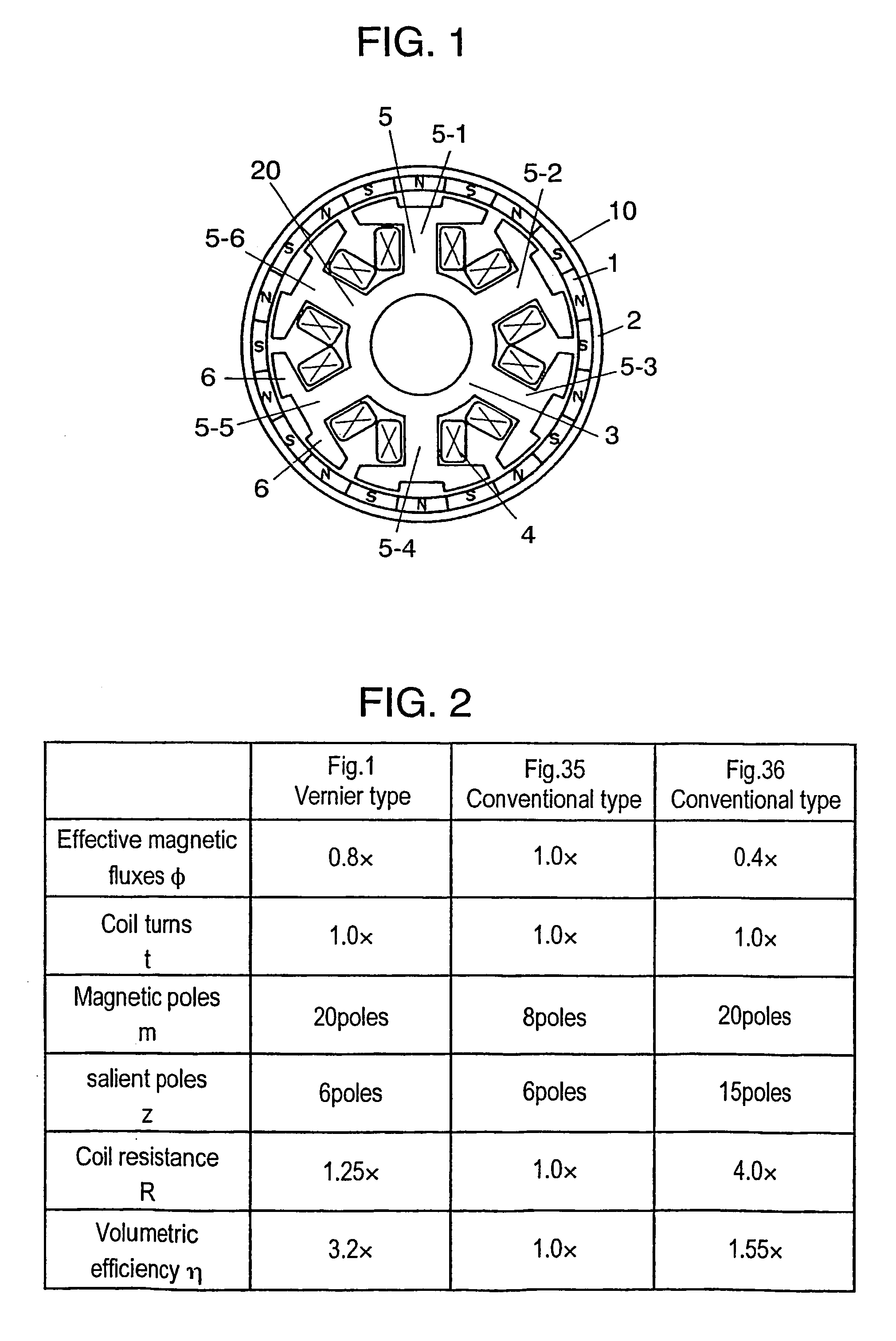

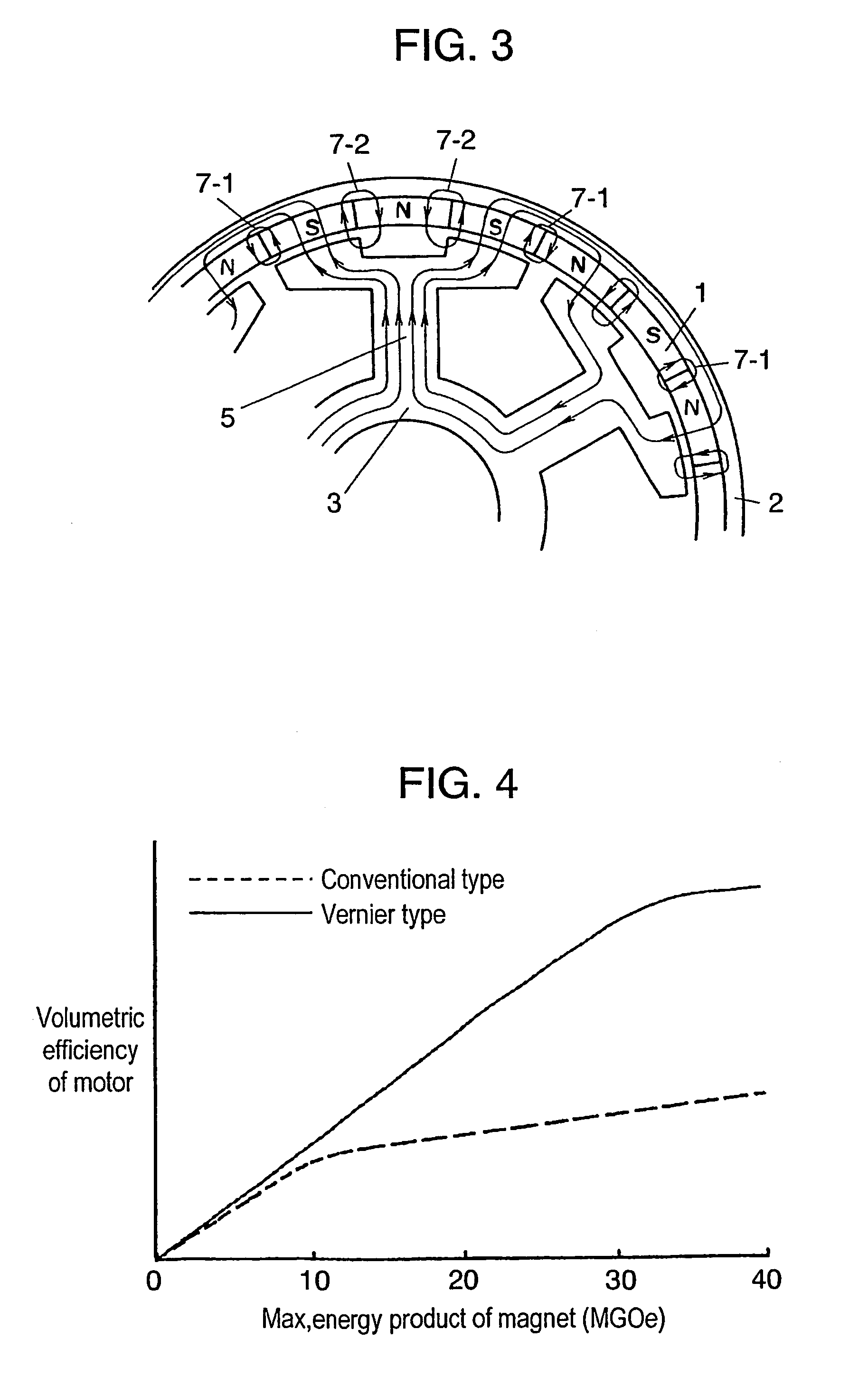

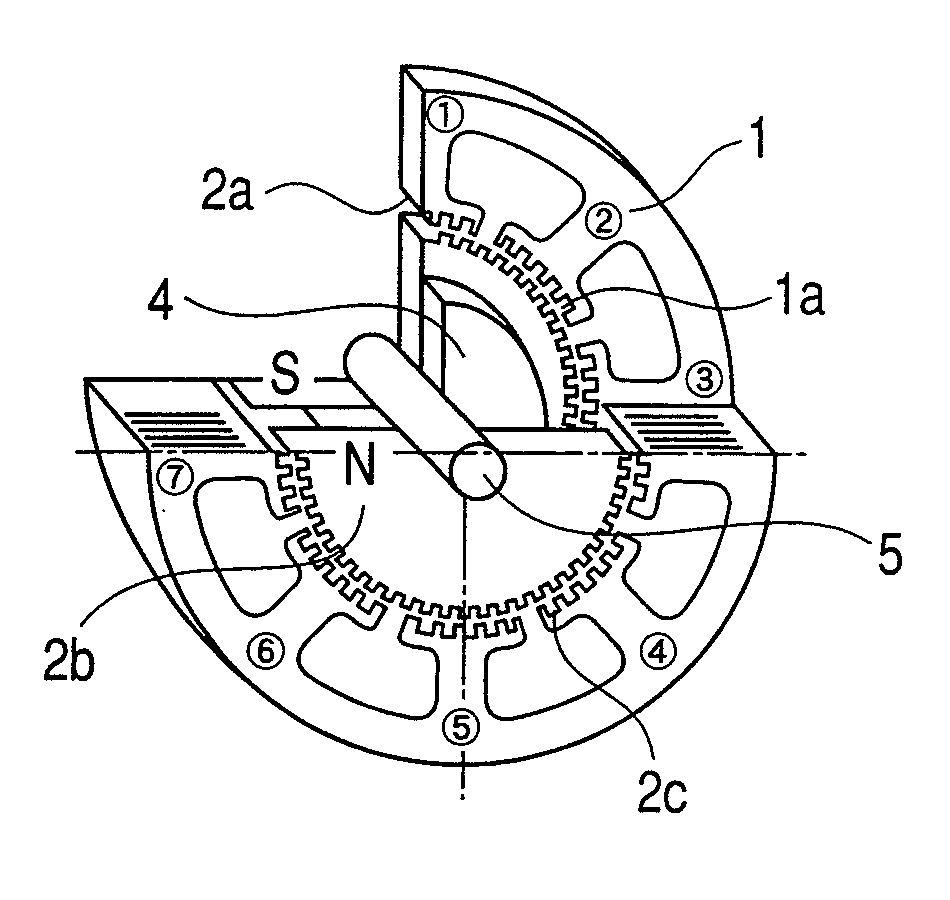

Brush-less motor using vernier structure

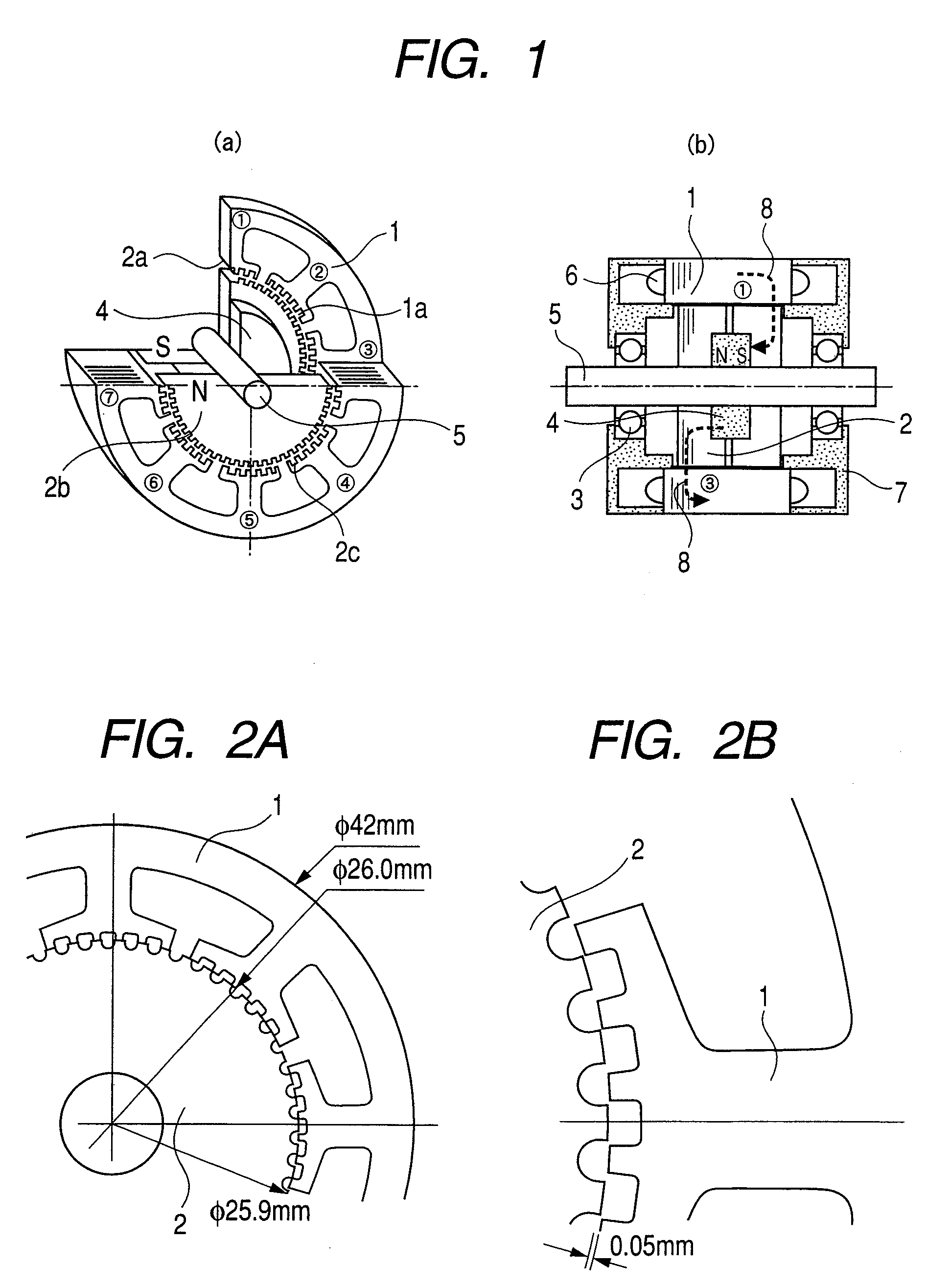

InactiveUS7064468B2Improve volumetric efficiencyIncrease productionMagnetic circuit rotating partsMagnetic circuit stationary partsBrushless motorsSmall tooth

A brush-less motor includes a rotor with a magnet alternately magnetized N pole and S pole in a rotating direction, and a core with plural salient poles on which coils are wound. The core faces the magnet to form a magnetic circuit. Each one of the salient poles are toothed and provided with small teeth at an edge facing the magnet. The small teeth have a pitch corresponding to two poles of the magnet. Powering to the coil responsive to a rotor position drives the rotor. This structure substantially increases volumetric efficiency of the motor.

Owner:PANASONIC CORP

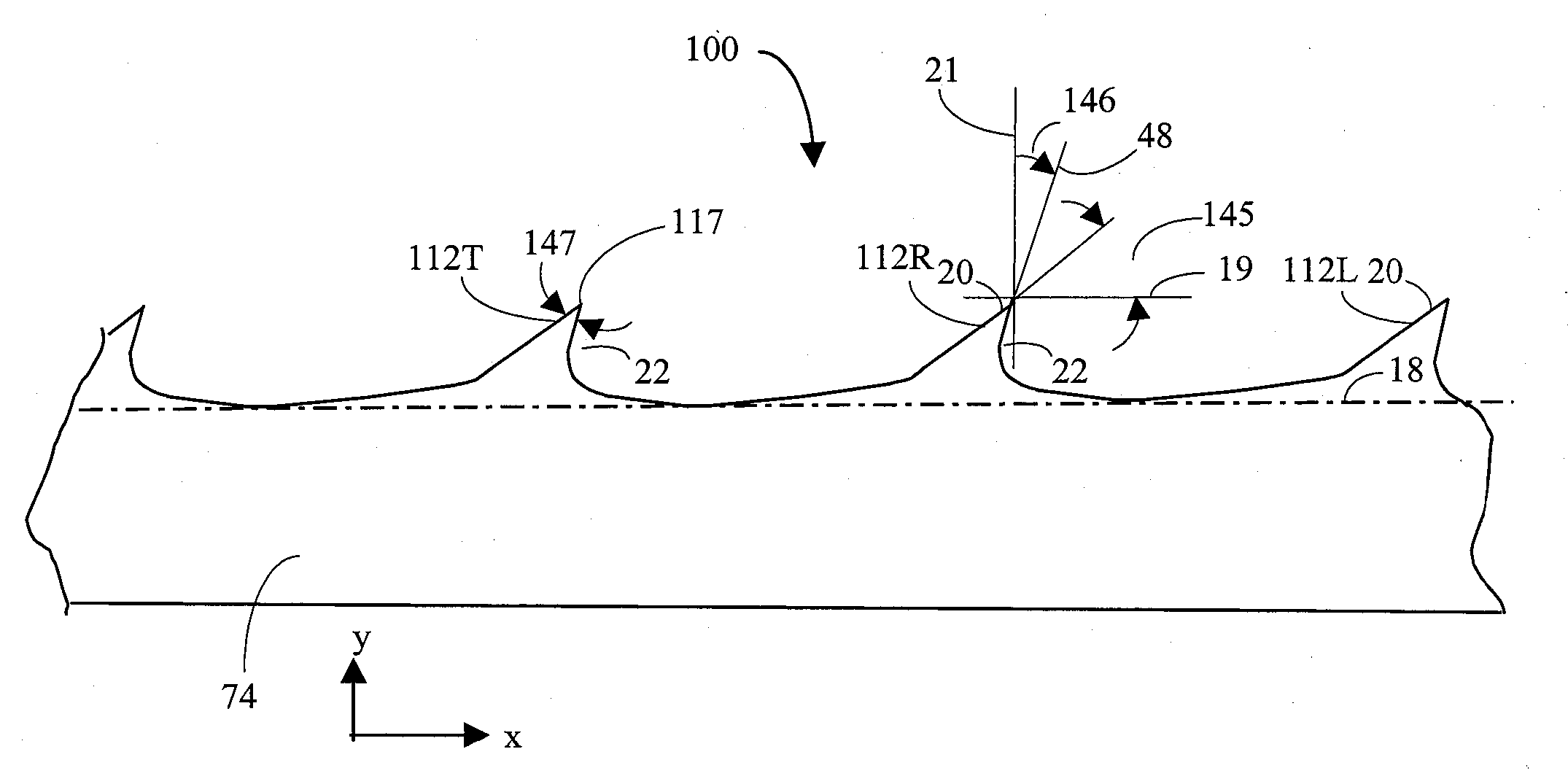

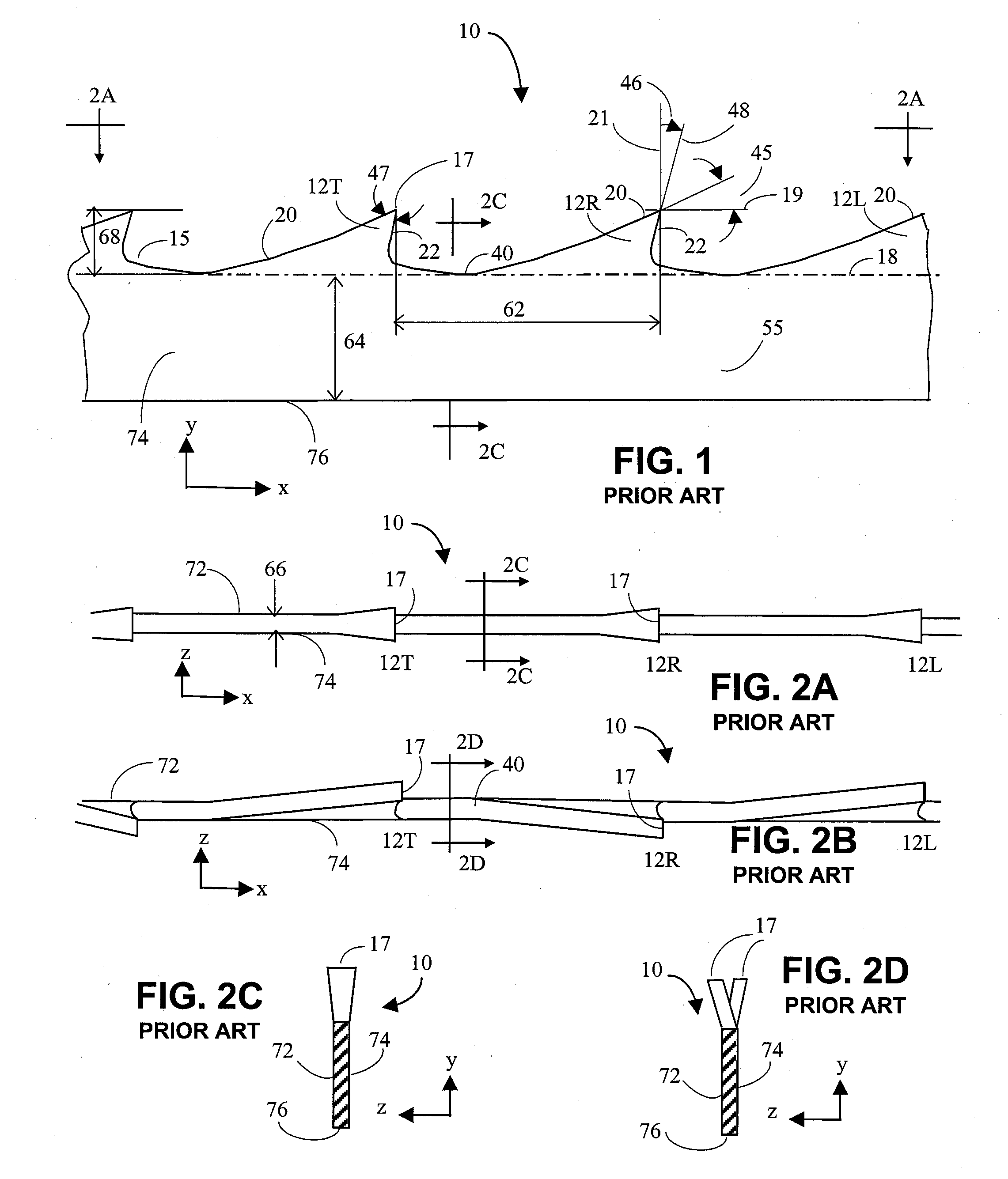

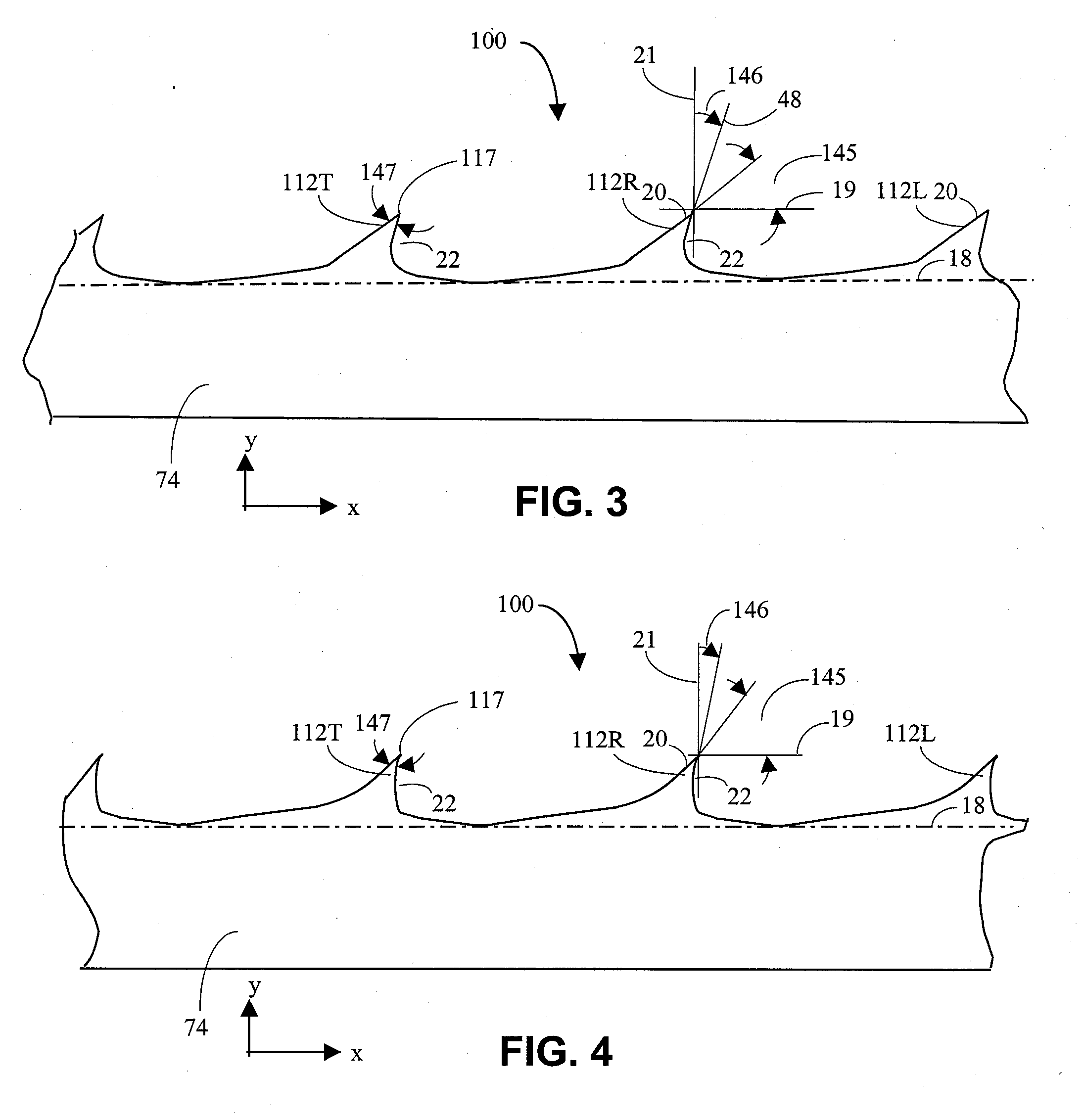

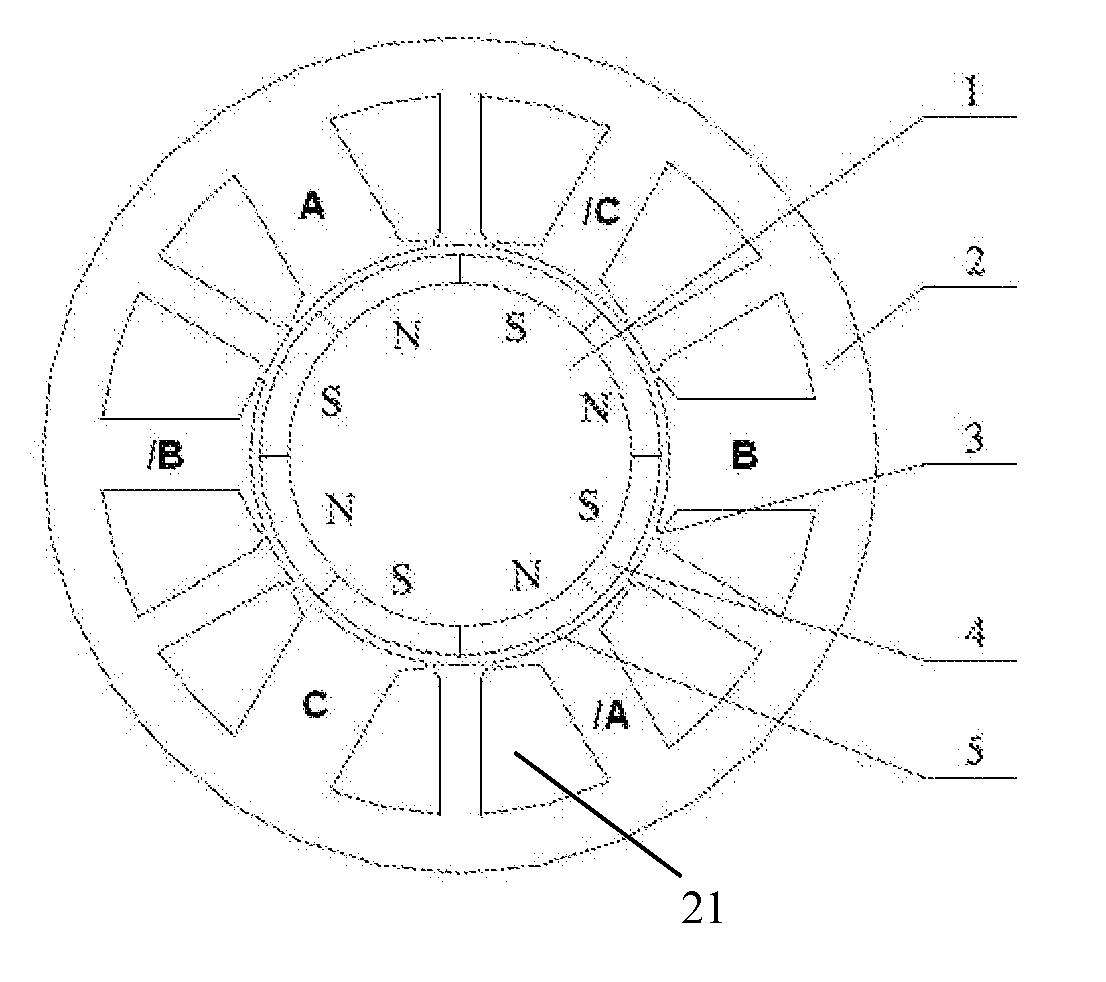

Three-Phase Square-Wave Permanent Magnet Brushless DC Motor

ActiveUS20090108699A1Improve performanceLow costWindingsMagnetic circuit rotating partsMagnetic polesPermanent magnet motor

This invention relates to a three-phase square-wave permanent magnet brushless DC motor for solving problems of the existing square-wave permanent Magnet Motor and sine-wave permanent magnet motor. In this invention, the number 2P of magnetic poles on the said rotor core is 8; the slot number Z of the said stator core is 12, accordingly there are 12 teeth, including three big teeth, three medium teeth and six small teeth; the ratio of their mechanical angles is 50° (±5°) for big teeth: 40° (±5°) for medium teeth: 15° (±5°) for small teeth, and the sum of the mechanical angles of one big tooth, one medium tooth and two small teeth must be 120°. Three-phase concentrated windings are respectively wound on the big teeth and the medium teeth, in which there are only two concentrated windings for each phase, thus there are only 6 concentrated windings for the three-phase motor. With driven by three-phase square-wave current, the said motor can produce a smooth torque which ripple index corresponds to that of the sine-wave permanent magnet servo motor, at the same time, it also has a plurality of advantages including windings end minimization, air-gap minimization, material minimization, cogging torque minimization and loss minimization and so on.

Owner:SCBD (ANHUI) E TECH CO LTD

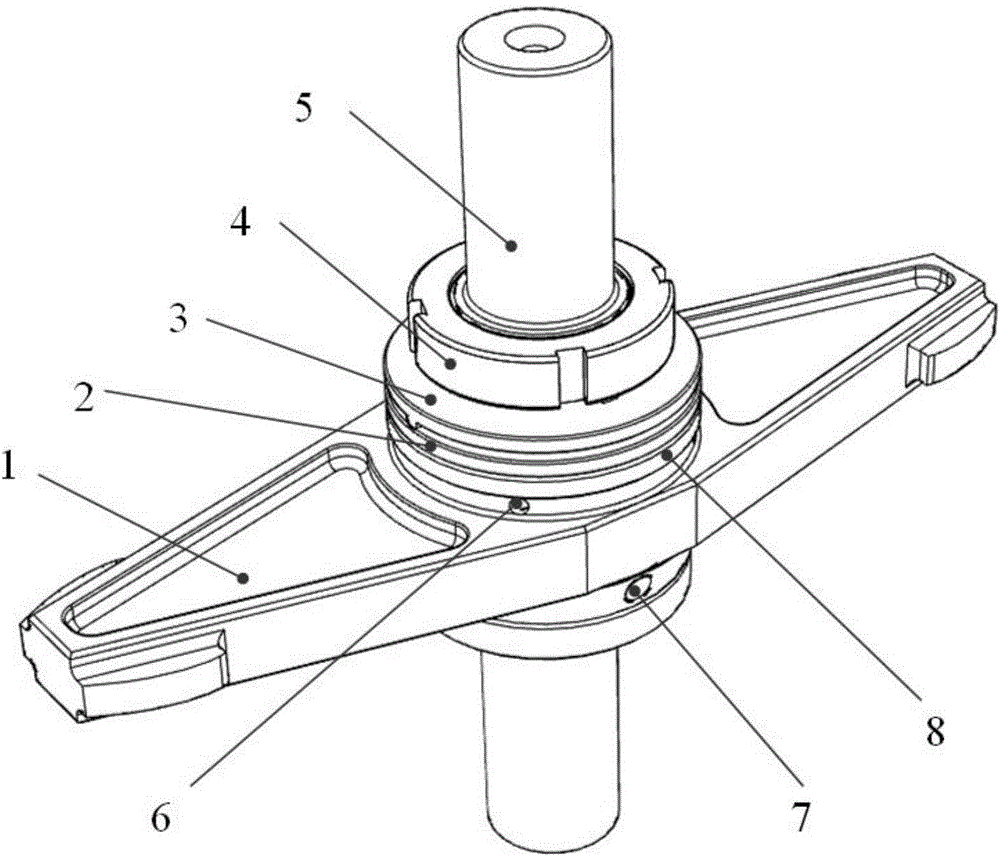

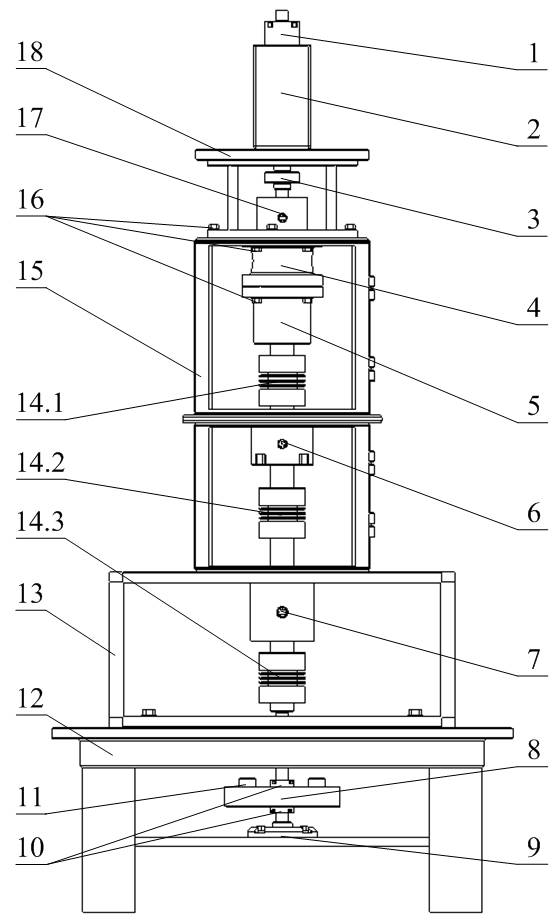

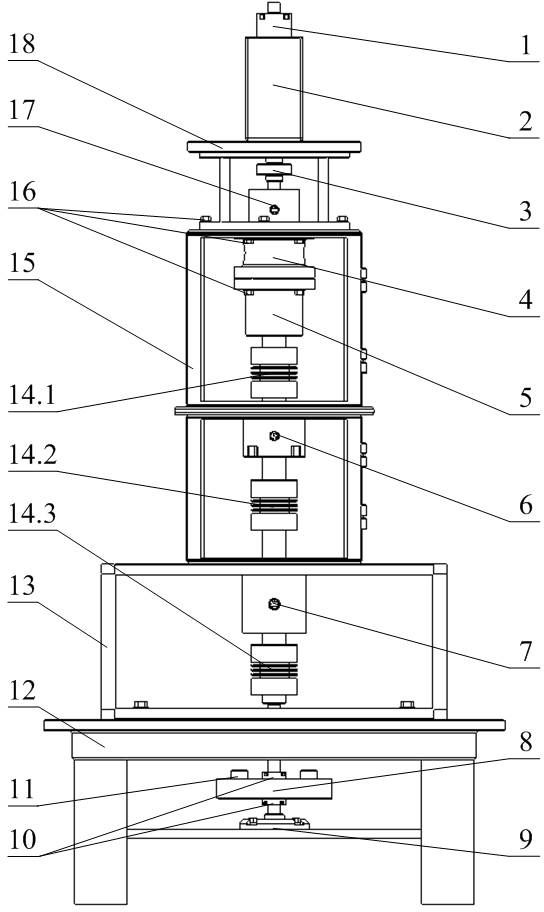

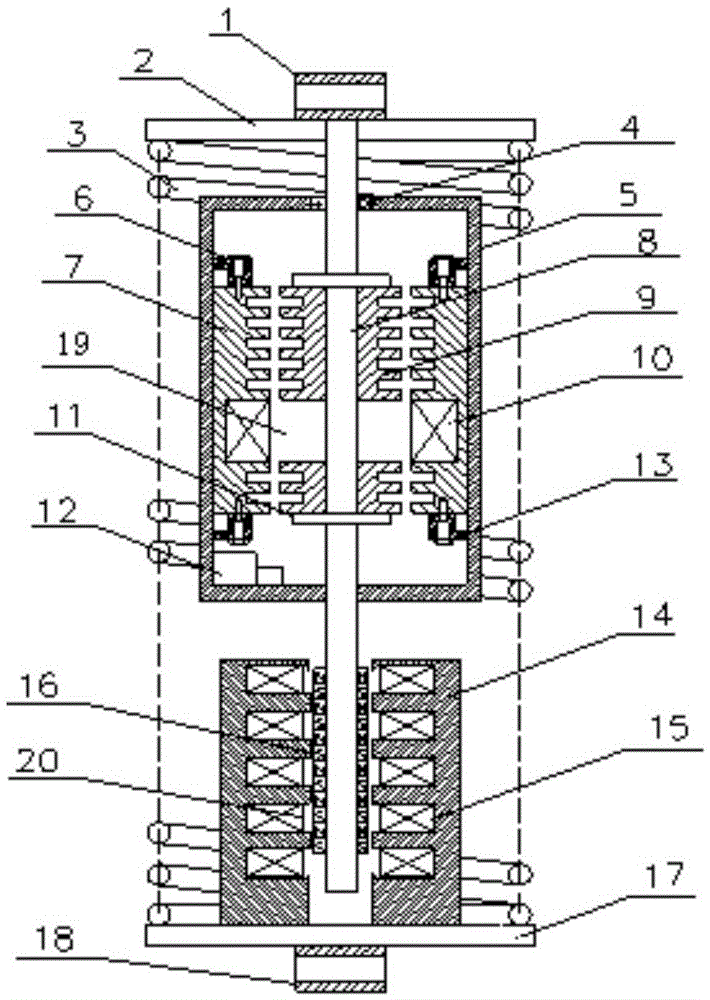

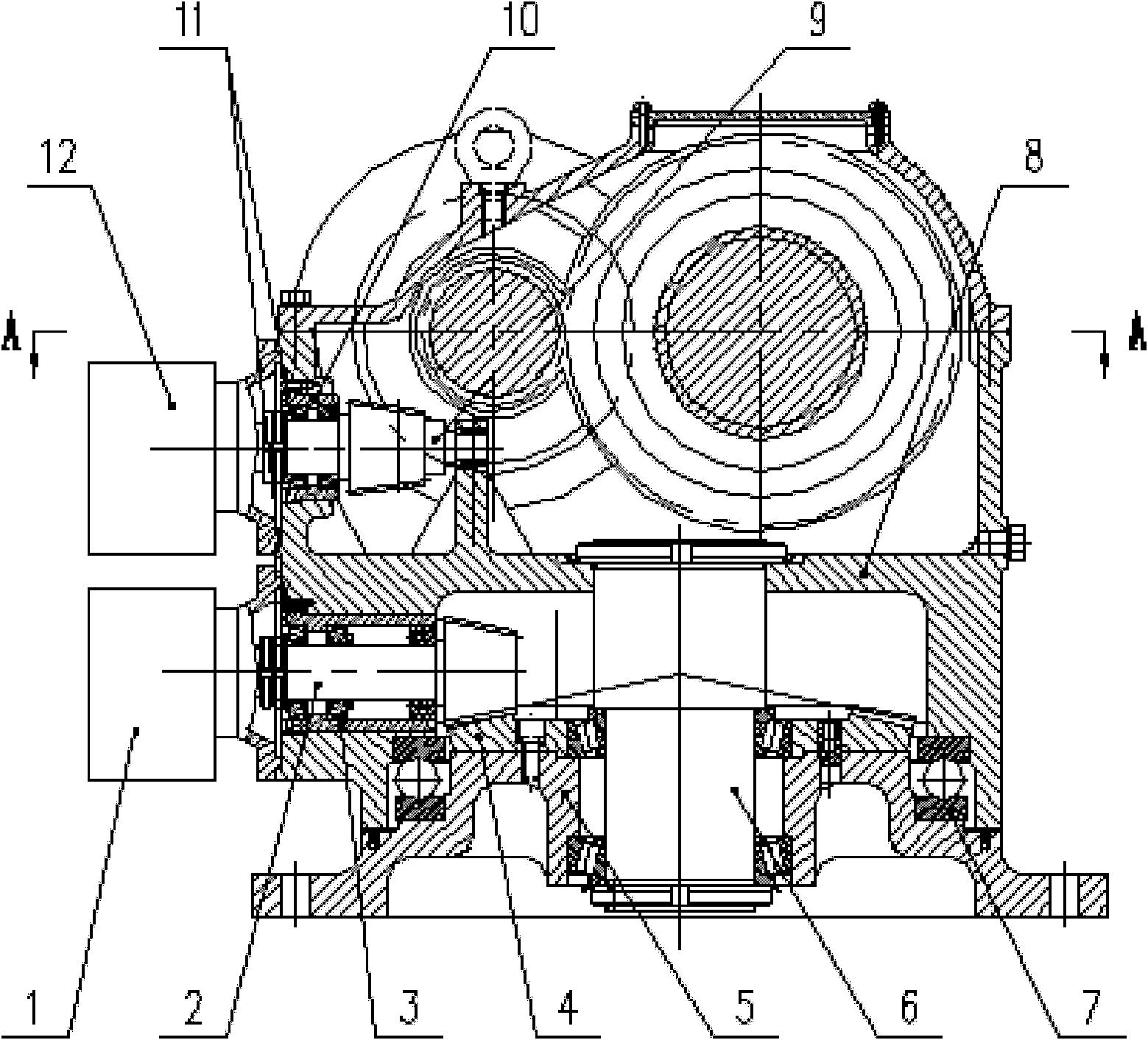

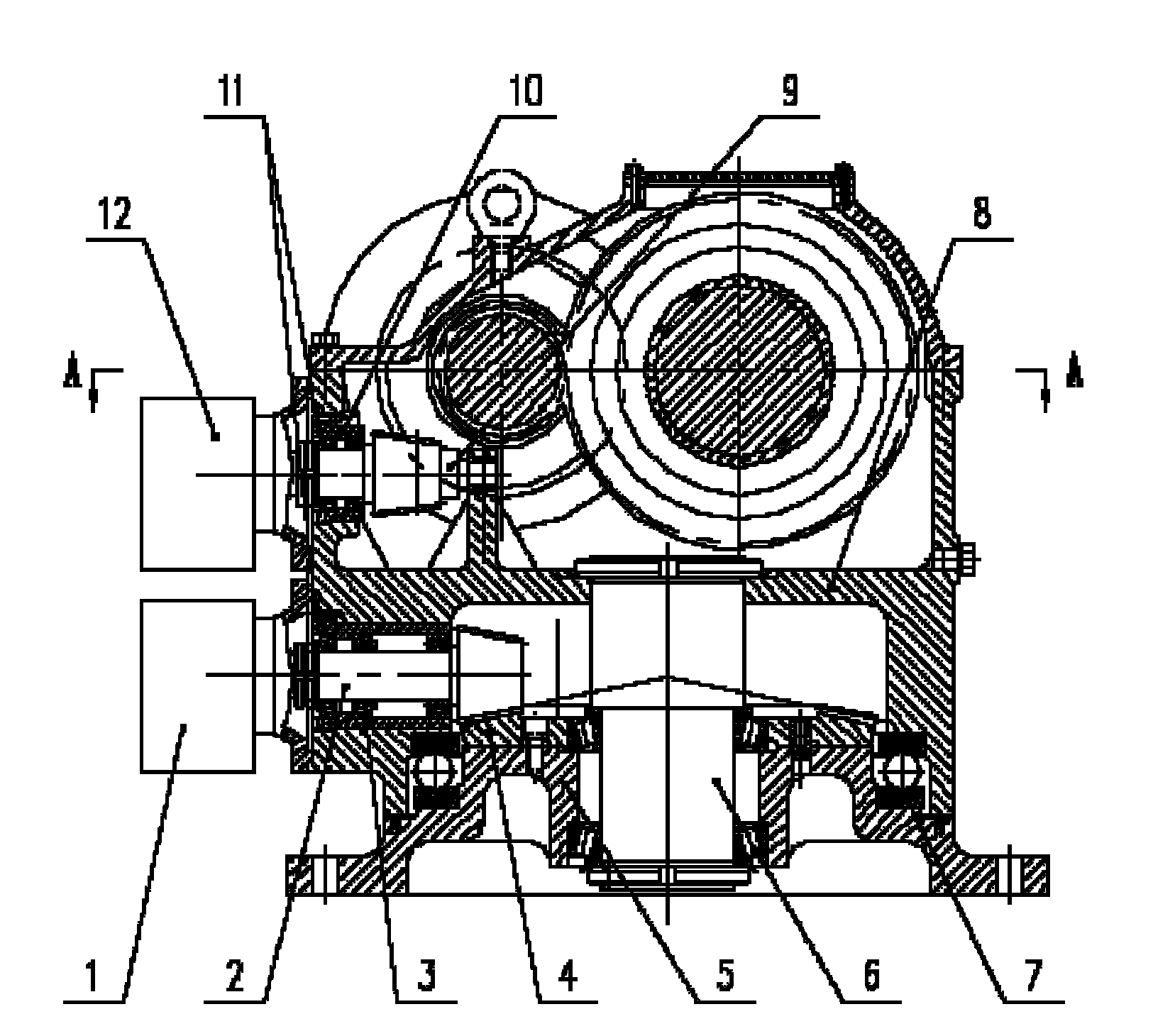

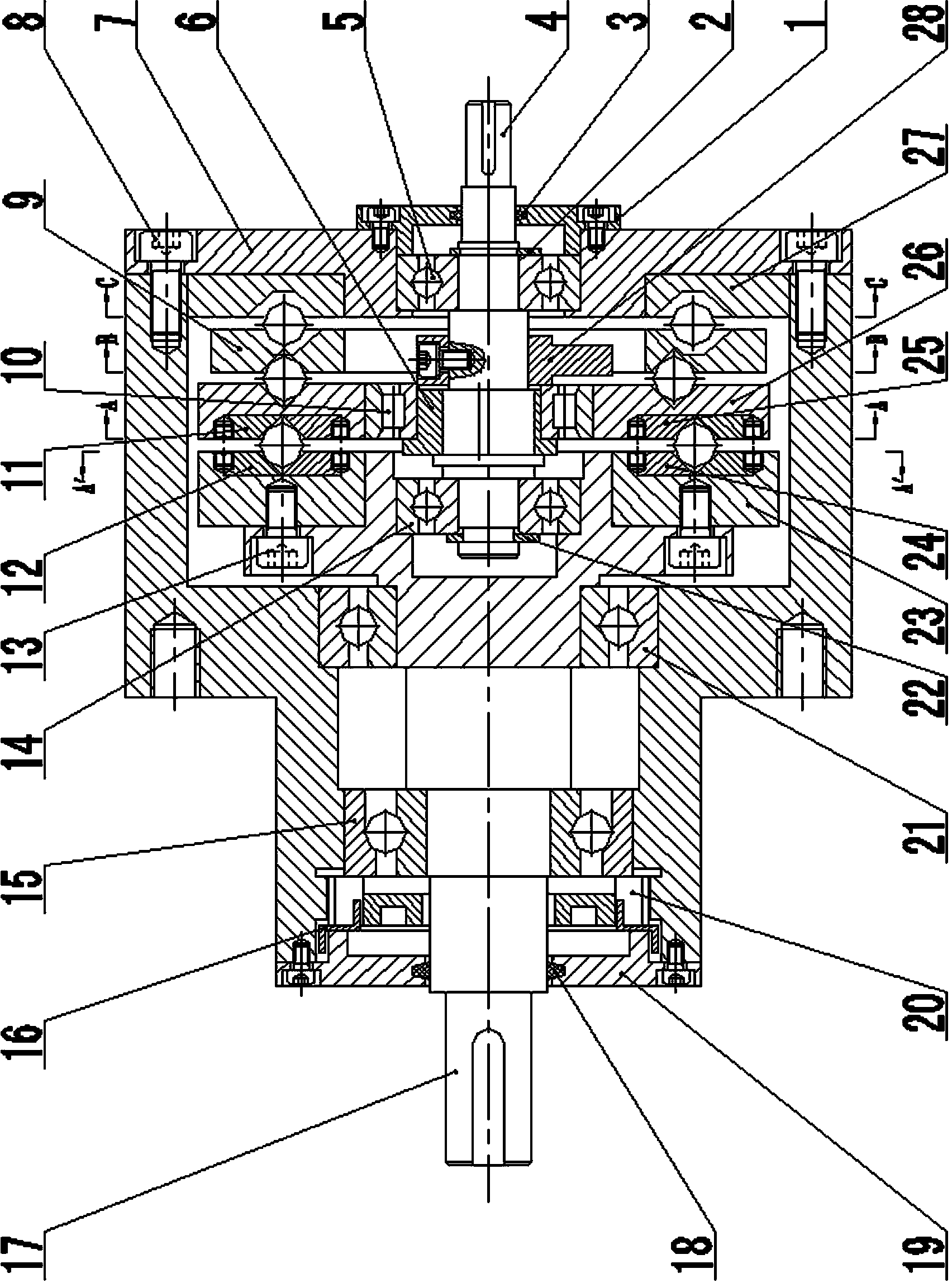

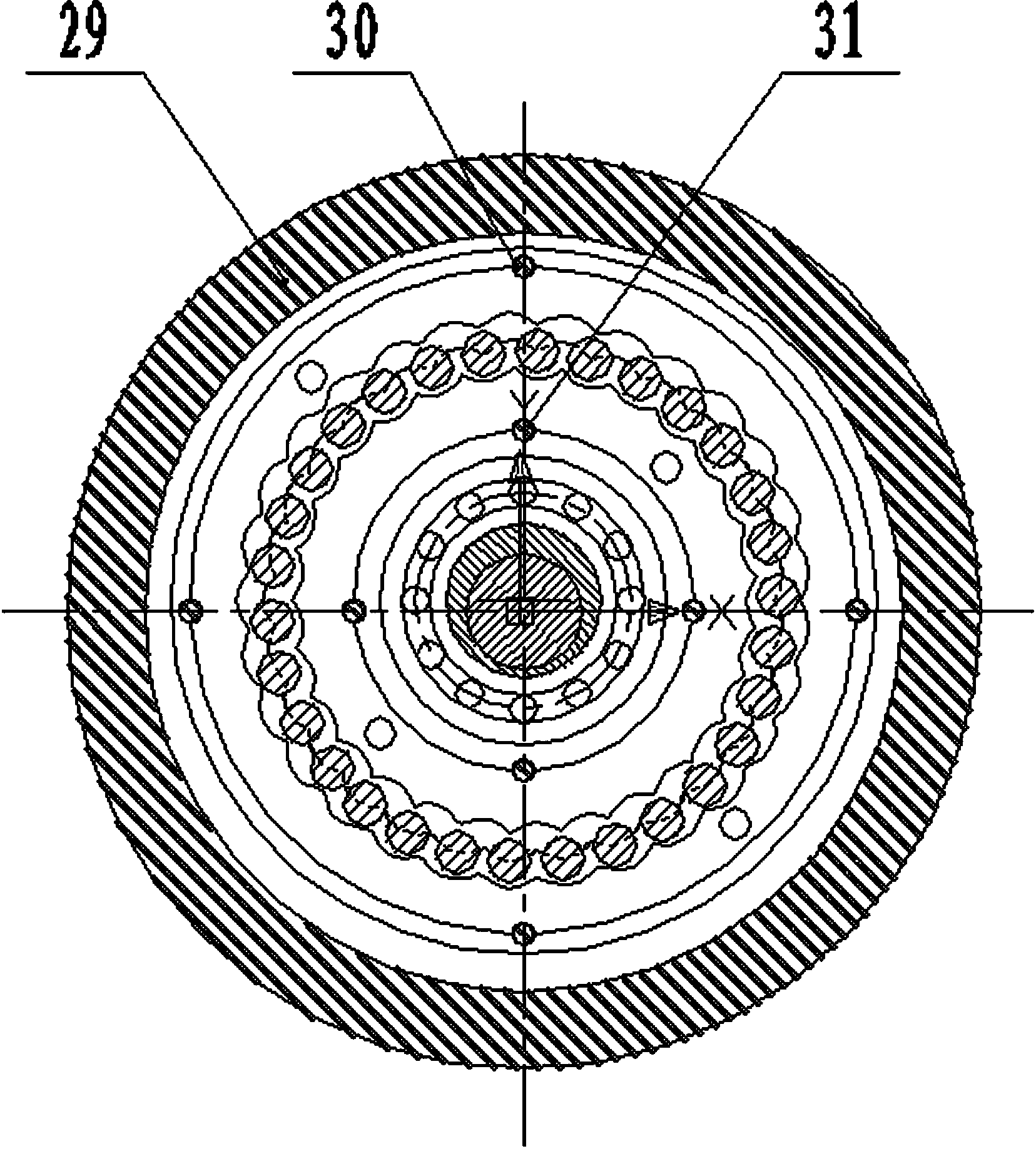

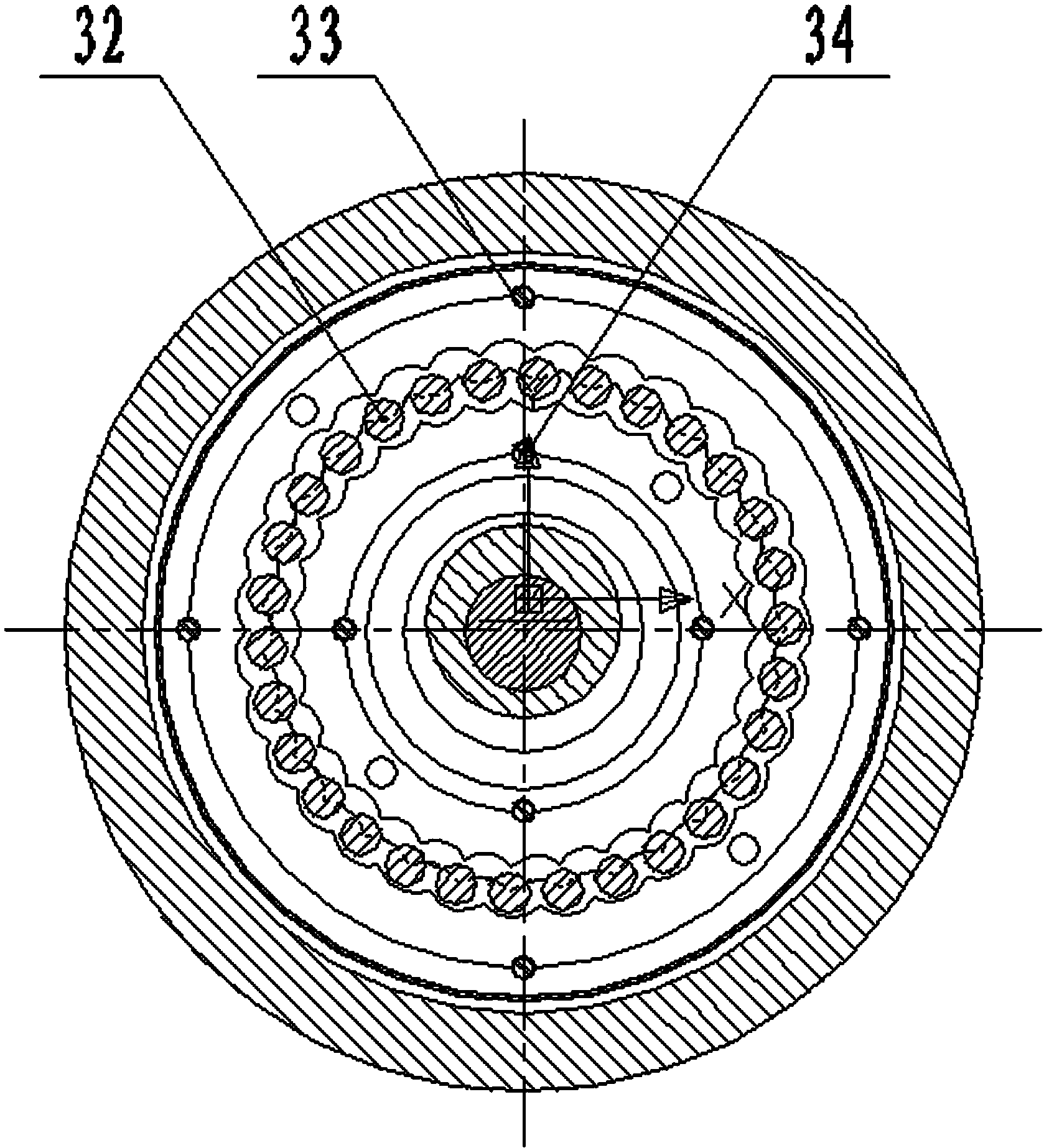

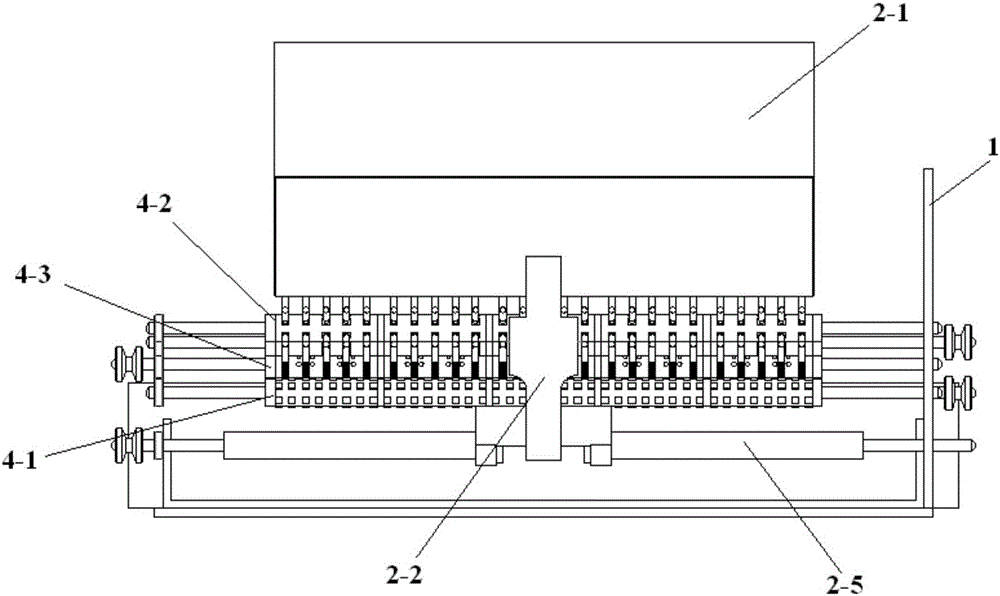

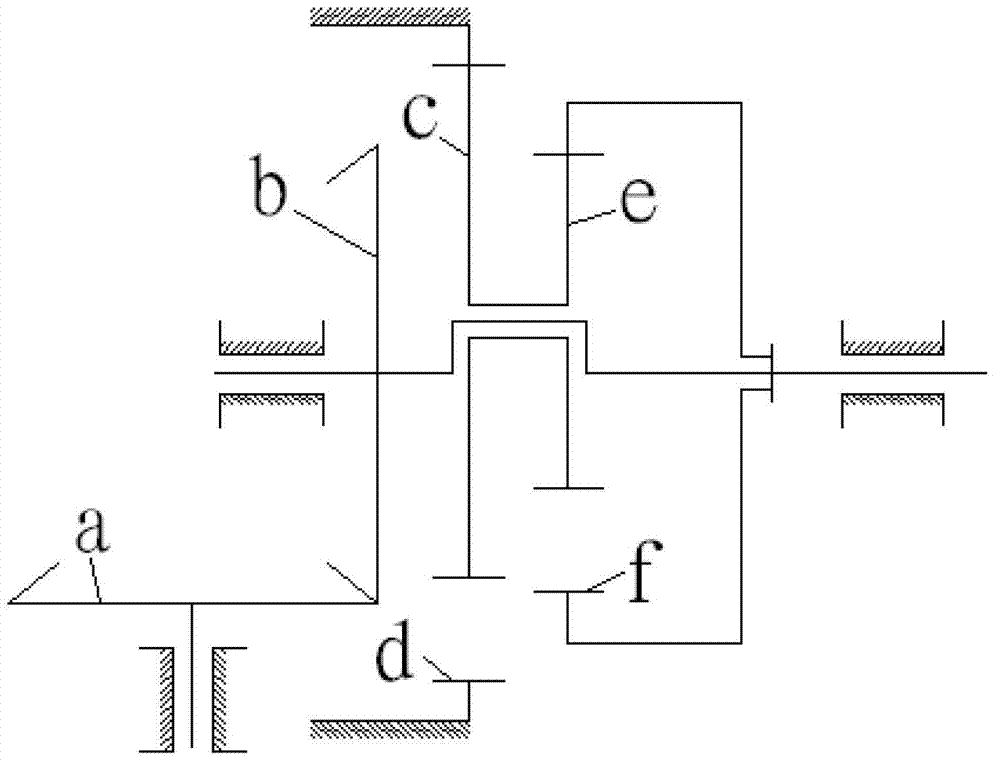

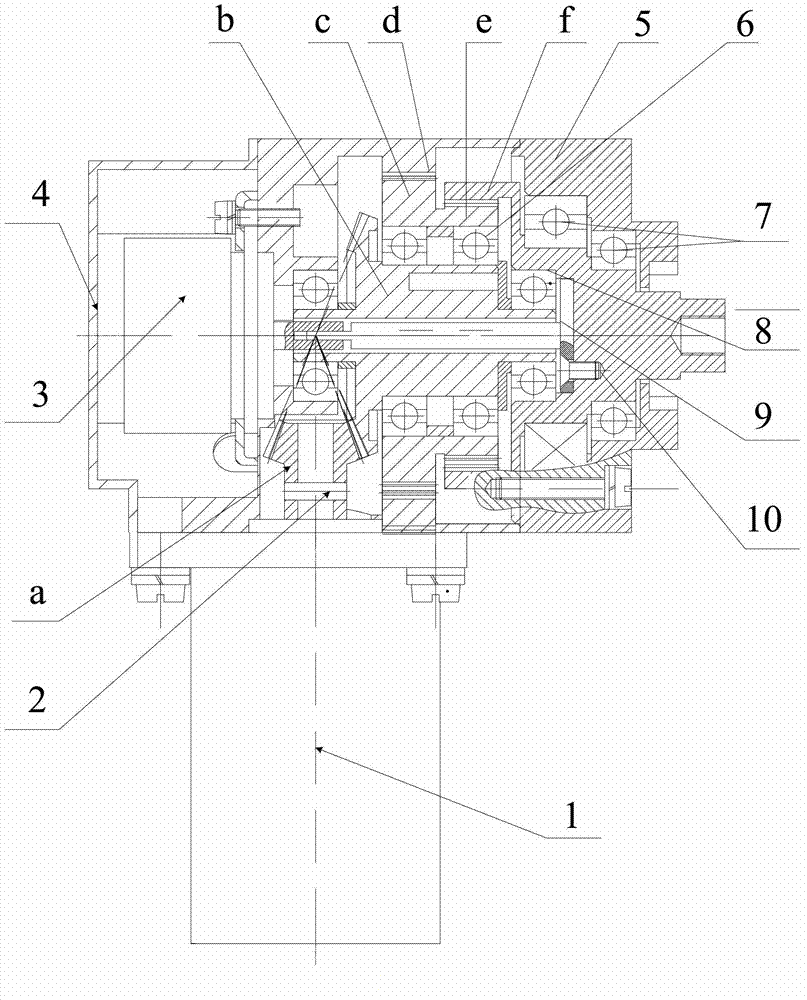

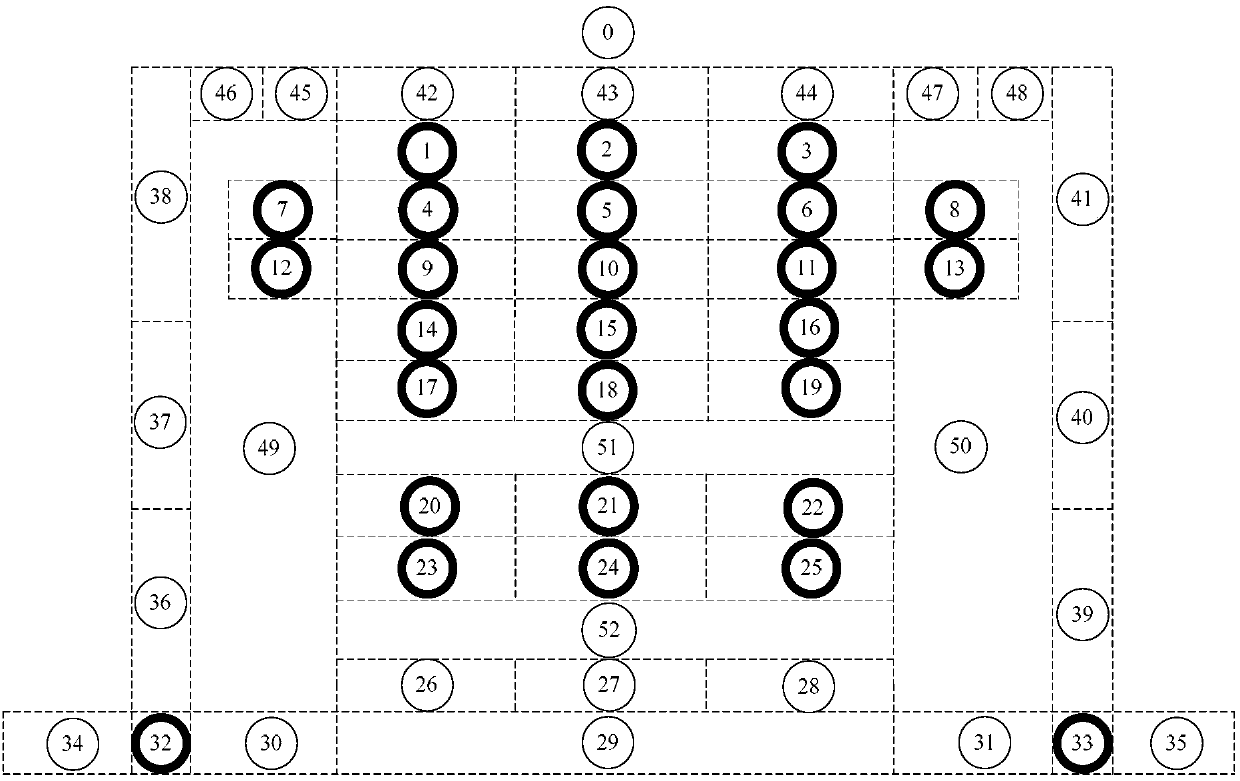

Vertical experiment table for precise performance test of small-tooth-difference planetary reducer

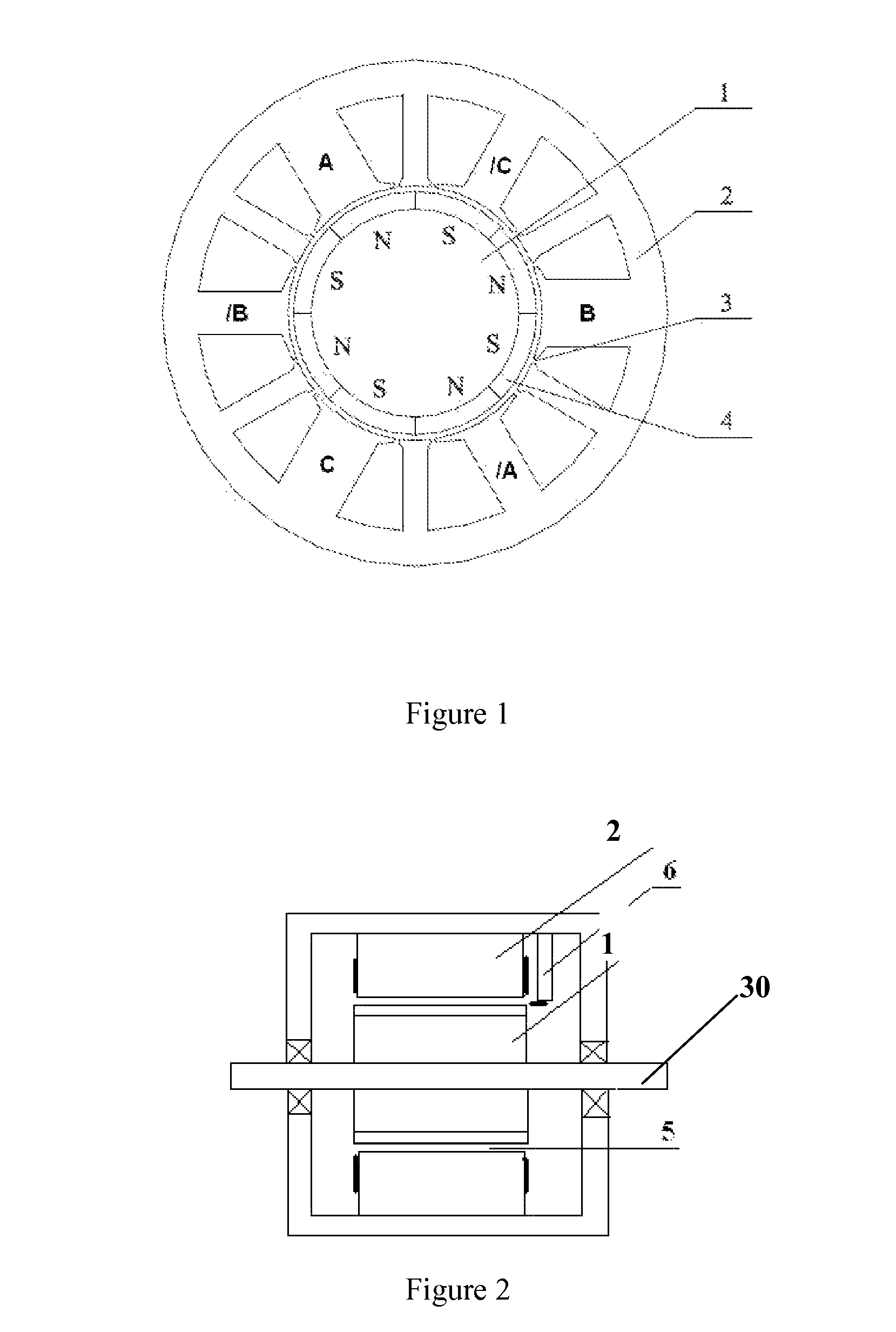

InactiveCN102607844AAvoid assembly errorsEasy to install and debugMachine gearing/transmission testingReduction driveCoupling

The invention discloses a vertical experiment table for a precise performance test of a small-tooth-difference planetary reducer. The vertical experiment table comprises a mounting bracket, a drive motor, an input end torque instrument, an output end angle encoder, an output end torque instrument and a thrust disc, wherein the drive motor is vertically mounted on the mounting bracket; the input end torque instrument is connected with the output shaft of the drive motor and the input shaft of the tested reducer respectively; the output end angle encoder is connected with the output shaft of the tested reducer; the output end torque instrument is connected with the output shaft of the output end angle encoder; the thrust disc is connected with the output shaft of the output end torque instrument; the drive motor is provided with a motor end angle encoder; and the drive motor and the input end torque instrument are connected through a rigid coupling. By vertically arranging the drive motor, the tested reducer, the output end angle encoder and the output end torque instrument, the vertical experiment table effectively avoids the assembly error caused by gravity, is convenient to mount and debug, is high in degree of automation, high in test precision and great in generality, and can test multiple dynamic characteristics of the tested reducer at the same time.

Owner:重庆奔腾智能装备技术有限公司

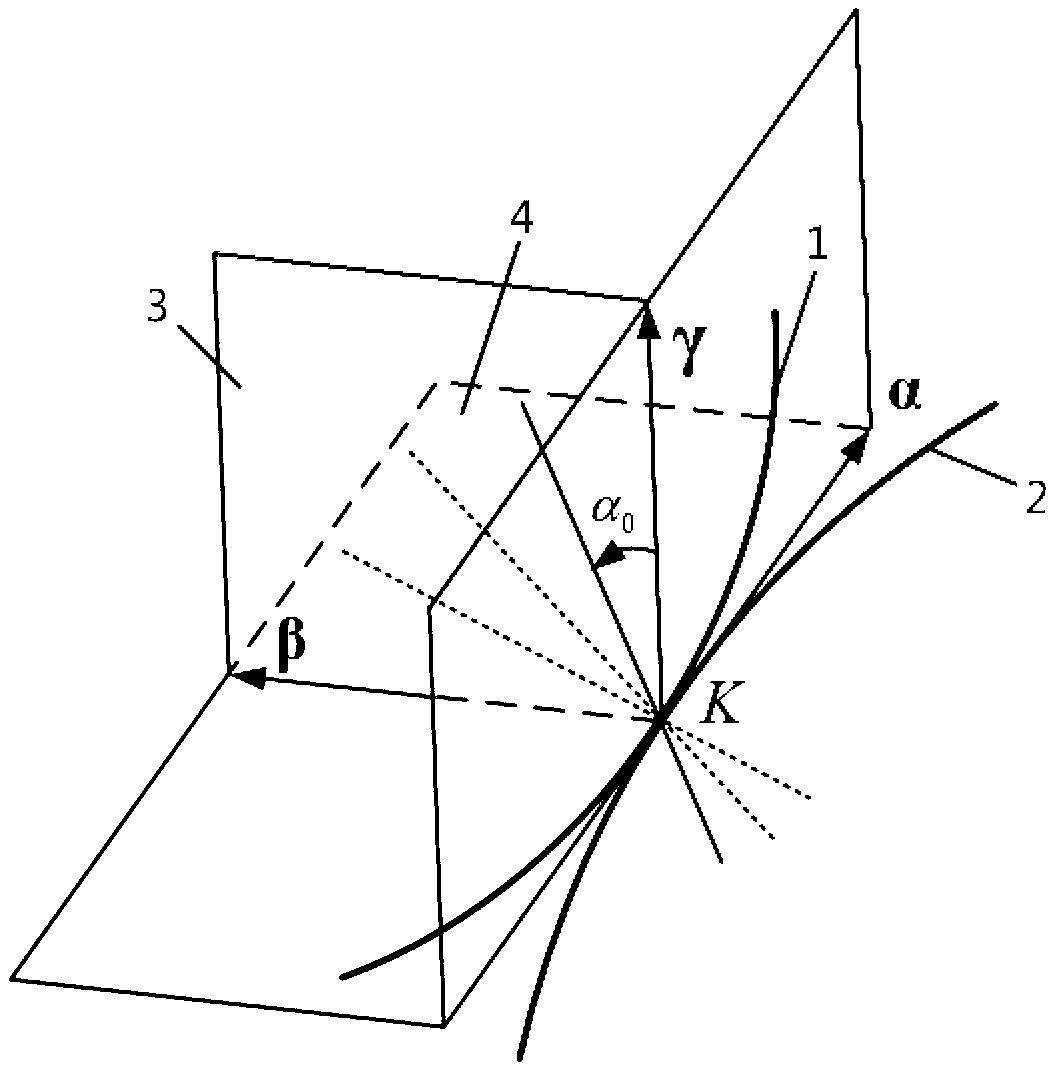

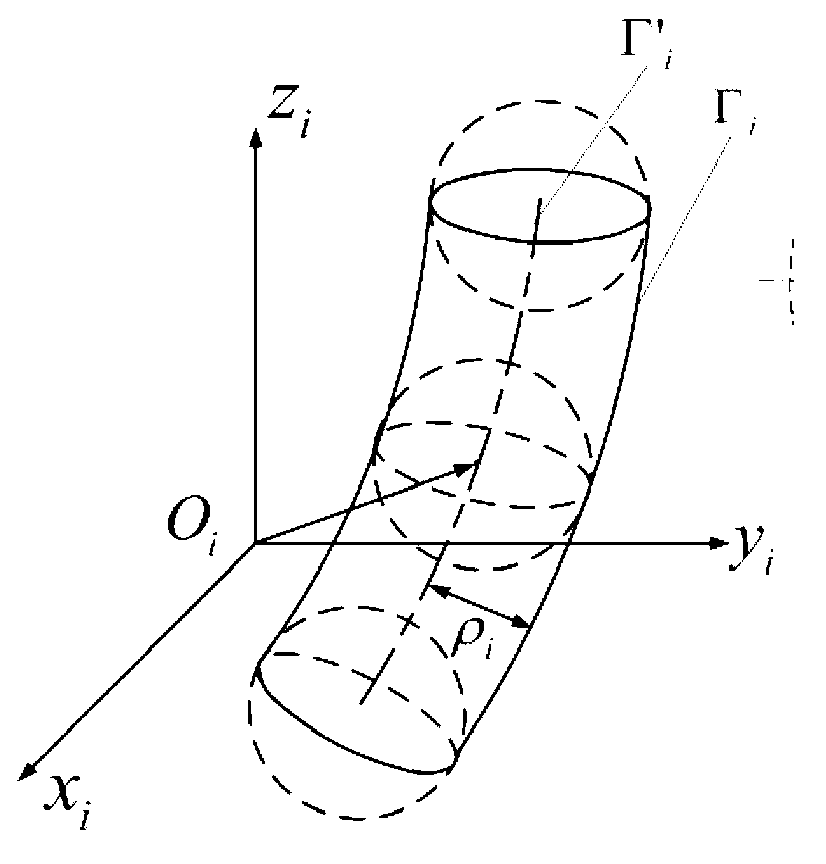

Curve conjugation based symmetrical cambered surface conjugate curve gears and engagement pair thereof

ActiveCN102853054AImprove contact strengthImprove transmission efficiencyPortable liftingGearing elementsSmall toothContact Transmission

The invention discloses curve conjugation based symmetrical cambered surface conjugate curve gears and an engagement pair thereof. The engagement pair comprises a gear I and a gear II, wherein the gear I and the gear II are engaged with each other in a point contact mode, and a contact curve gamma 1 which is composed of engagement points on a tooth profile cambered surface of the gear I and a contact curve gamma 2 which is composed of engagement points on a tooth profile cambered surface of the gear II are conjugate curves. According to the engagement pair of the curve conjugation based symmetrical cambered surface conjugate curve gears, the contact curve gamma 1 of the gear I and the contact curve gamma 2 of the gear II which form the engagement pair are conjugate curves, and engagement points between the gear I and the gear II move along contact curves; the engagement pair has the advantages of point contact engagement, tooth profiles of point contact have the high contact strength, the contact transmission process is close to pure rolling along the axial direction, and the transmission efficiency is high; and the selection and the determination of the small tooth number and the large modulus can be achieved on the conditions of the same transmission ratio and the same center-to-center distance, the transmission requirements of high speed, heavy load, high power and high efficiency can be met, and the engagement pair has broad application prospects.

Owner:CHONGQING UNIV

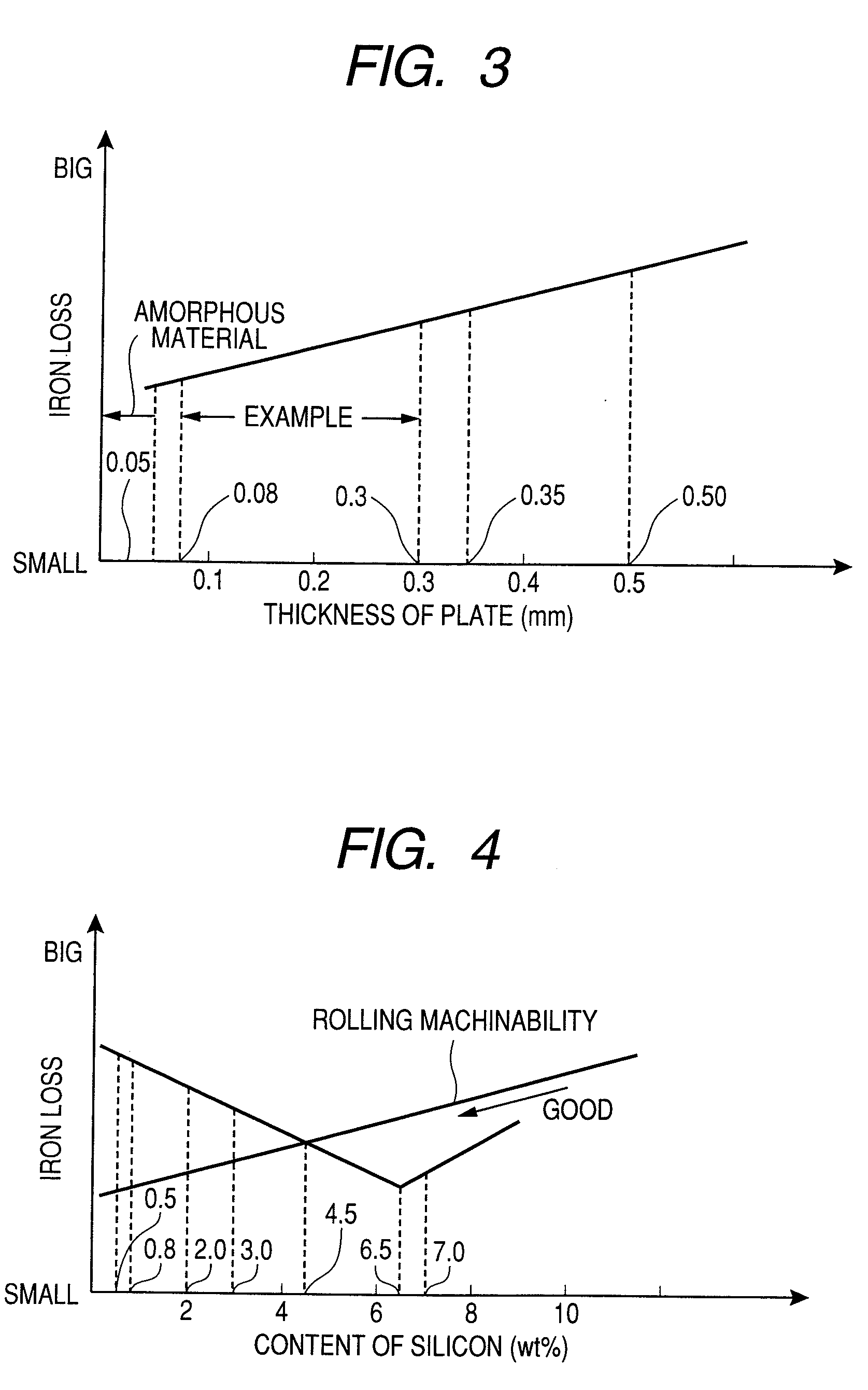

Stepping motor and steel plate for manufacturing the stepping motor

InactiveUS20080224574A1Reduce stepsImprove efficiencyDecorative surface effectsMagnetic circuit stationary partsStator coilSmall tooth

A stepping motor comprising:a stator iron core with a plurality of salient poles each having a small tooth at the tip thereof and stator coils each disposed between the salient poles;a rotor core with a plurality of teeth in the faces opposite to the stator; andpermanent magnets sandwiched by the rotor cores in an axial direction,wherein the stator iron core and the rotor core are formed by laminated steel plates. The salient poles of the stator iron cores of the steel plates and small teeth are shaped by etching, and a thickness of the steel plates is 0.05 to 0.30 mm.

Owner:HITACHI LTD

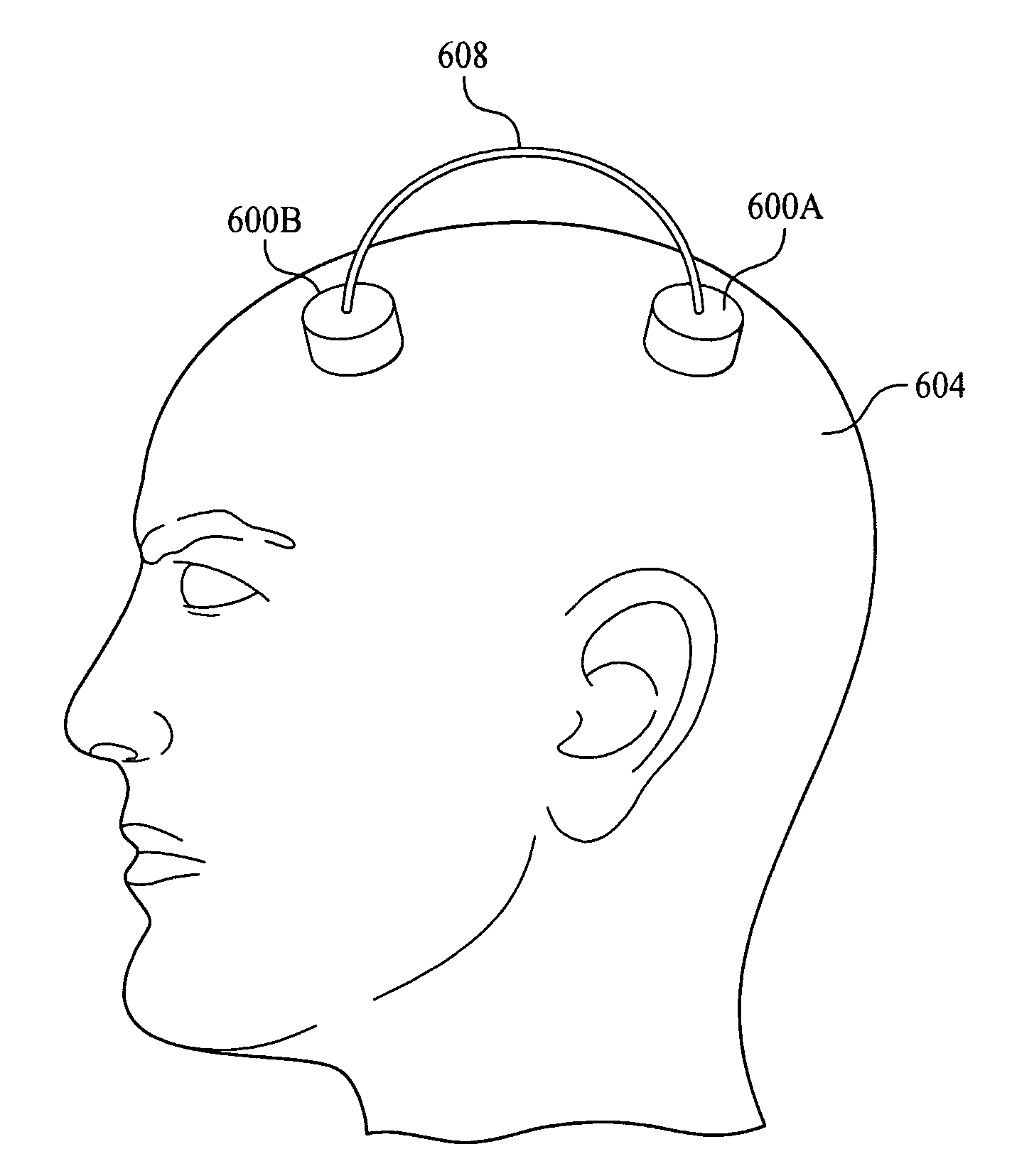

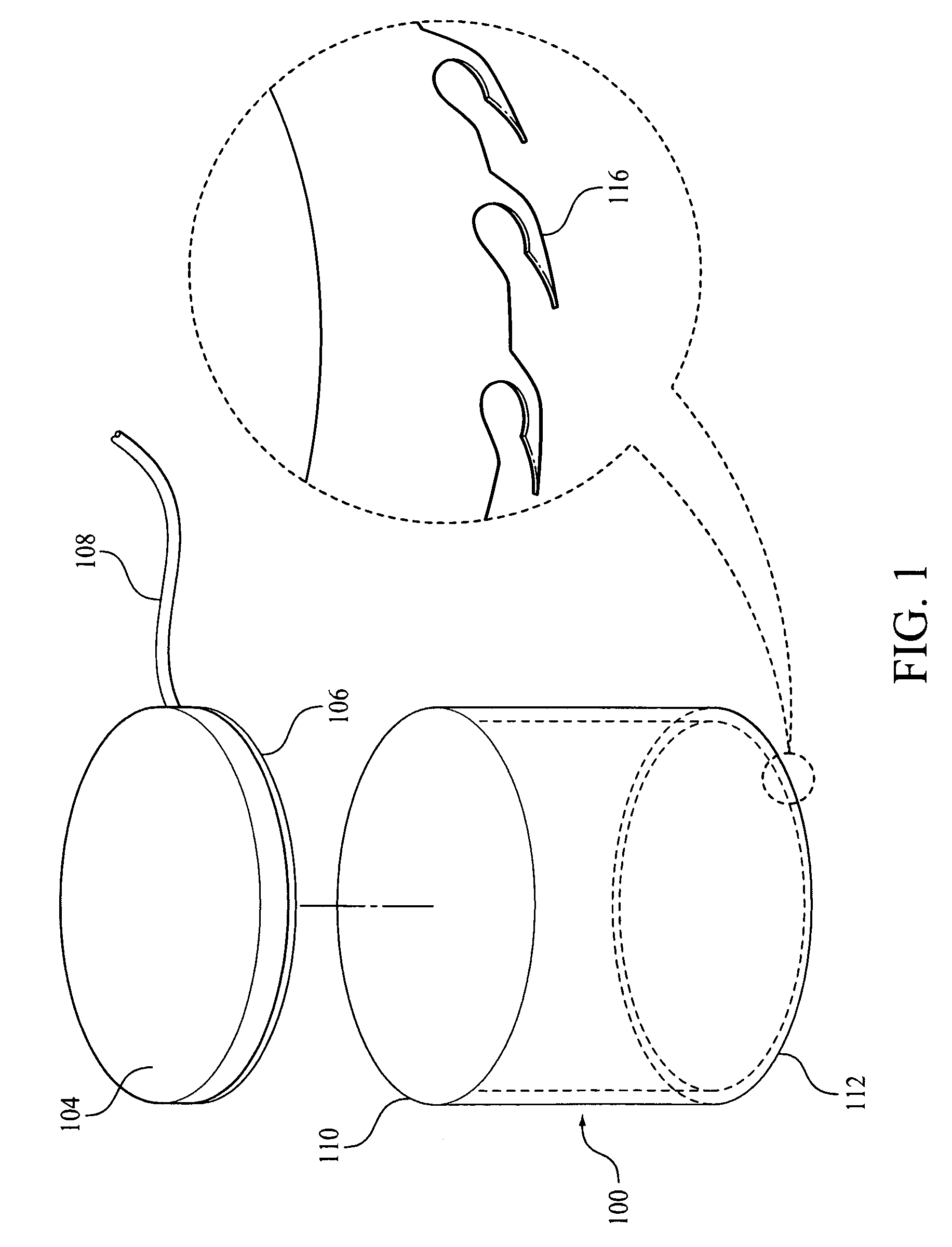

Skin screw electrode

ActiveUS20080262335A1Easily and stably attached to skinExcellent electrical accessElectroencephalographyElectrotherapyFiberStratum corneum

Electrodes providing excellent recording and physical stability. The present invention encompasses electrodes that include a plurality of small teeth that possess a novel design shape and orientation. The shallow and relatively long teeth preferably run parallel to the rim of the electrode that presses against the patient's skin. When the electrode is twisted onto skin, the tiny teeth penetrate the stratum corneum and move nearly horizontally under the stratum corneum, thus anchoring the electrode securely to the skin. The electrodes of the present invention cause minimal discomfort to the patient since the small teeth do not extend to the pain fibers which are located in deeper layers of the skin. The electrodes may house a wide diversity of electronic components to enable numerous experimental and medical implementations. The electrodes the present invention may also be used wirelessly either singularly or as an array so that no electrode leads extend away from the patients body. The electrodes of the present invention may be fabricated using precision photo-chemical etching techniques that are well known in the art. The present invention also includes an electrode installation device that preferably employs the electrodes of the present invention.

Owner:UNIVERSITY OF PITTSBURGH

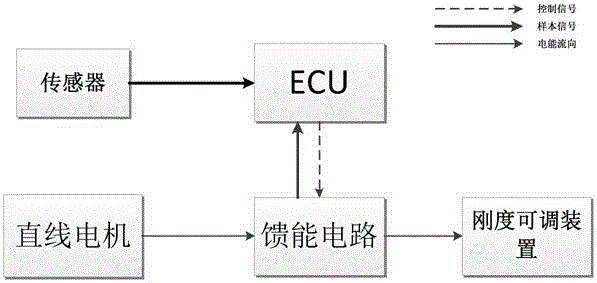

Variable-rigidity semi-active suspension

InactiveCN105584310AAdjustable stiffnessOvercome the disadvantage of not being able to adjust the stiffness of the systemResilient suspensionsSemi activeAxial distribution

The invention provides a variable-rigidity semi-active suspension which comprises an upper connecting ring, a lower connecting ring, an upper spring support, a lower spring support and a rigidity adjusting device. The upper spring support is fixed to the lower end face of the upper connecting ring. The lower spring support is fixed to the upper end face of the lower connecting ring. The rigidity adjusting device comprises a piston rod, a rotor, a stator and a sleeve. The rotor and the stator are located in the sleeve, and the rotor, the stator and the sleeve are coaxial. The piston rod penetrates the centers of the rotor, the stator and the sleeve. The piston rod is fixed to the lower end of the upper connecting ring. The rotor is fixed to the outer wall of the piston rod. The stator is fixed to the inner wall of the sleeve and a magnet exciting coil is fixed to the stator. A gap is reserved between working surfaces of the rotor and the stator and small teeth which are arranged at equal intervals and are equal in width are distributed in the axial directions of the working surfaces. The magnet exciting coil is connected with a controller. By the adoption of the variable-rigidity semi-active suspension, the rigidity and damping can be controlled independently, the smoothness and comfort of a vehicle can be improved, and vibration is attenuated; and when a control part of the suspension fails, the vibration reducing performance of a passive suspension still can be achieved.

Owner:JIANGSU UNIV

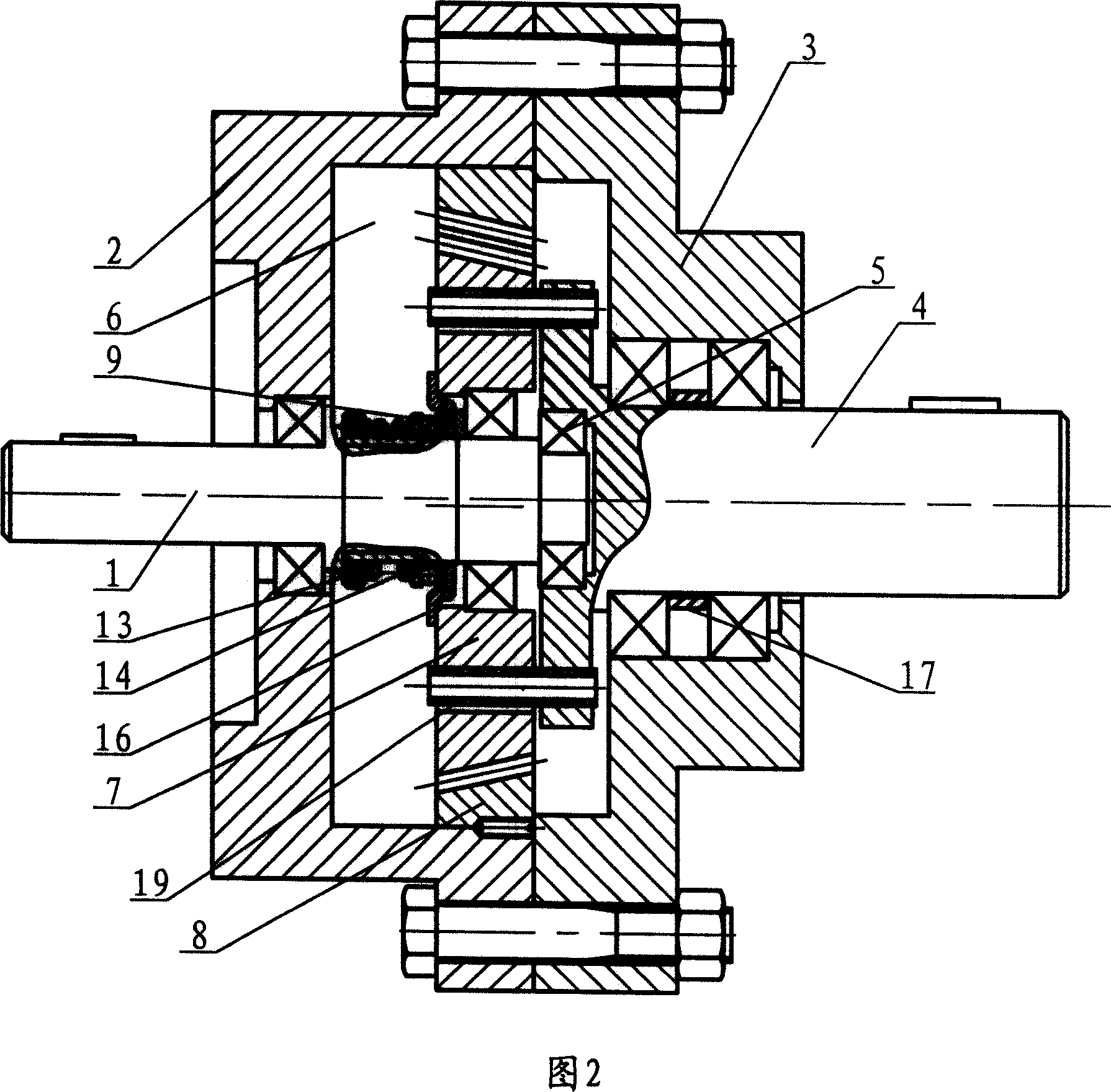

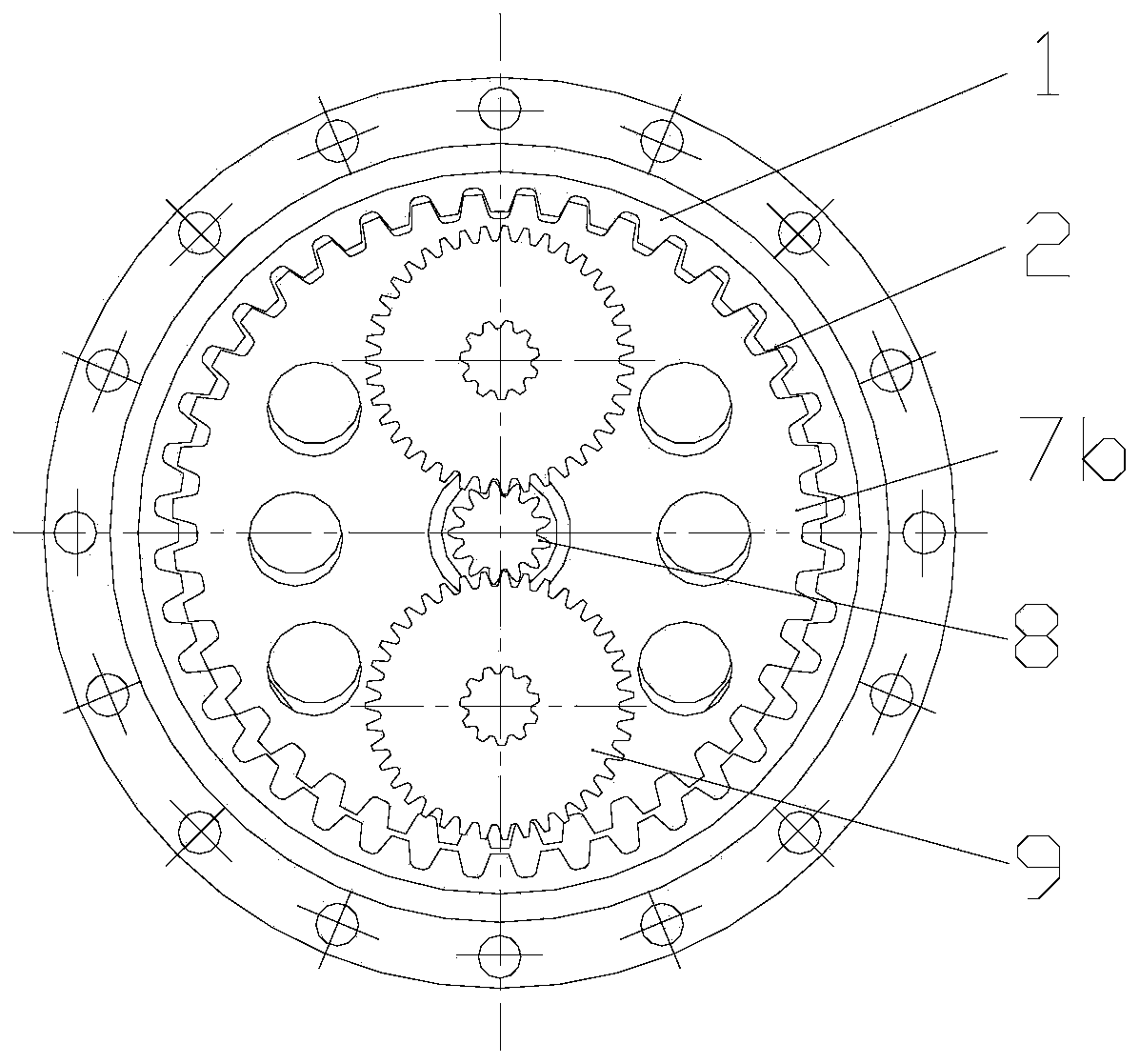

Planetary speed reducer with small tooth number difference

The invention discloses a planetary speed reducer with small tooth number difference, which comprises a housing, a power input shaft matched with the rotation of the housing and a power output tray, wherein a sun wheel is fixedly matched and arranged on the power input shaft in the circumferential direction, at least two planetary wheels are meshed with the sun wheel, and planetary wheel shafts of the planetary wheels are provided with eccentric sleeves; a cycloidal gear is arranged on the housing in a manner of being meshed with a fixed pin gear with small tooth number difference; each eccentric sleeve respectively penetrates the cycloidal gear along the axial direction and is in running fit with the cycloidal gear, the end parts of each planetary wheel shaft penetrates into the power output tray along the axial direction and is in running fit with the power output tray in the circumferential direction, the tooth profile of the cycloidal gear is formed by leading the pin gear to do primary envelope motion, and the tooth profile of an internal gear is formed by leading the cycloidal gear to do secondary envelope motion. The planetary speed reducer with the small tooth number difference not only has the characteristic of multi-tooth meshing of the ordinary cycloidal pin gear planetary transmission, but also has the doublet contact characteristic, and can further fully play the error averaging effect by increasing contact points and improve the transmission precision.

Owner:CHONGQING UNIV

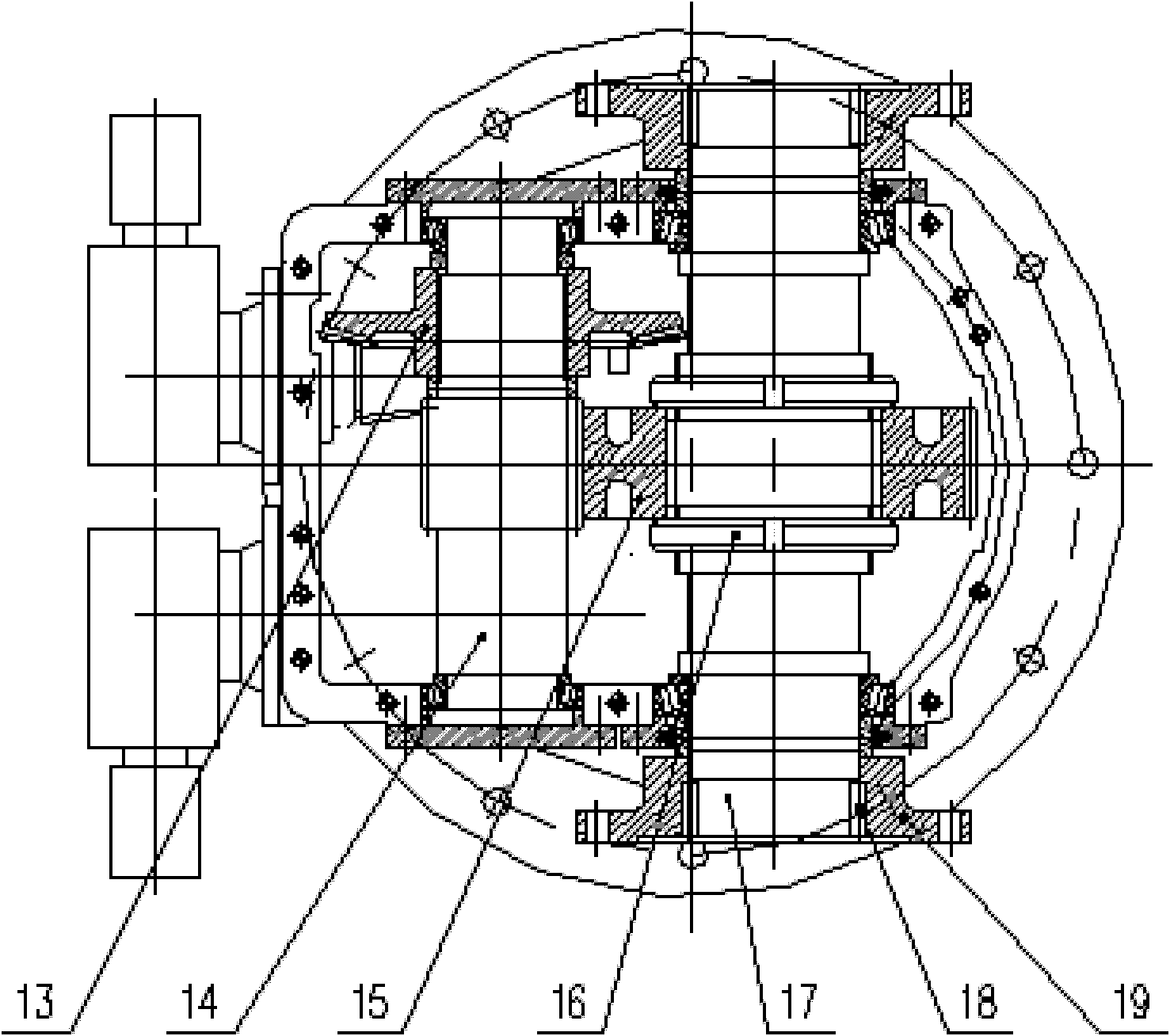

Solar heliostat driving device

ActiveCN101806351AImprove rigidityReduce volumePhotovoltaic supportsSolar heating energyHeliostatThrust bearing

The invention relates to a solar heliostat driving device which comprises a driving box body and a driving box pedestal, wherein the driving box body is coaxially installed on the driving box pedestal, the driving box body is installed on the driving box pedestal through a box body connecting shaft and a thrust bearing, an azimuth driving system is installed on the driving box pedestal, and a pitching driving system is installed on the driving box body. The invention has small tooth side gap of a driving gear, high driving precision, large bearing capacity, light weight and convenient installation, adjustment and maintenance, the tooth side gap can be adjusted at any moment in the installation and use processes according to the tooth side gap size of the gear, and the tooth side gap of the gear can be adjusted to be below 0.1mm and theoretically can reach a zero side gap. Calculated according to the gear diameter of 400mm, a tracking error is below 0.5mrad, the minimum tooth side gap of the output gear of a general heliostat driving device is above 0.2mm, the tracking error is above 1.0mrad, and the tracking precision is improved by more than one time than that of an ordinary driving device.

Owner:王锐

Gare changing thick involute planetary decelerating unit

The invention is a variable-tooth thickness involute planetary reducer, comprising input eccentric shaft, left end cover, right end cover and output shaft, where the left and right end covers are fixed with each other to form a working cavity, in which a reducing mechanism is arranged; and it is characterized in that: the reducing mechanism comprises variable tooth thickness involute planetary gear, and variable tooth thickness involute inner gear, where the variable tooth thickness involute planetary gear is installed by bearing on the eccentric section of the input eccentric shaft and forms power connection with the output shaft, and the variable tooth thickness involute inner gear is fixed on the inner wall of the left end cover to form small tooth difference planetary engaging auxiliary, and the input eccentric shaft is equipped with compensating mechanism and spring adjusting mechanism. And it has advantages of precision transmission and simple mechaning, able to eliminate the gap and automatically keep no-side gap engaging with the variable tooth thickness involute inner gear and automatically compensate after abrasion.

Owner:CHONGQING UNIV

General reducer with eccentric engagement pairs

InactiveCN101881318AFew partsAvoid high frequency wavesPortable liftingToothed gearingsState of artReduction drive

The invention discloses a general reducer with eccentric engagement pairs, comprising a shell, a power input shaft and a power output shaft, wherein an eccentric sleeve is fixedly arranged in the circumferential direction of the power input shaft, is engaged with engaging coggings on the shell by one-to-one correspondence through engaged teeth and is engaged with external gears on the power output shaft in small teeth difference through internal gears. The power input mechanism of the invention adopts the engagement pairs without teeth difference, which is similar to spline engagement, therefore, the relative autorotation speed of the engaging coggings and the engaged teeth is zero and autorotation of a driving fluted disc is eliminated, thus eliminating the high-frequency waves generated in the driving process of the reducers with small teeth different in the prior art, avoiding unnecessary additional motion, improving the driving efficiency and ensuring the motion to be output without hindrance. The general reducer has fewer components than the cycloidal pinwheel reducers in the prior art and has simple and compact structure, small volume and low cost.

Owner:CHONGQING UNIV

Virtual detection method for tooth error of involute bevel gear model

InactiveCN102184301ARealize virtual inspectionOptimization parametersSpecial data processing applicationsSmall teethEngineering

The invention relates to a virtual detection method for a tooth error of an involute bevel gear model. For a pair of gear models assembled together, the contact area of the pair of the gears is obtained through Boolean minus operation by simulating the engaging process of the pair of the gear models, utilizing the characteristic that an engagement surface and the base circle of a bevel gear are kept in tangency all the time and perform the movement of pure rolling, and utilizing an X-section function of Pro / E software. Because the contact lines of the gears are on the internal common tangent surface of two base cylinders all the time and are parallel to the cross line of the internal common tangent surface and an involute spiral surface, the distance between the contact lines of the pair of the bevel gears can be measured on the engagement surface by utilizing the measurement function of the Pro / E software. For a gear pair model with small tooth error and high precision, the spacing fluctuation of the contact lines of a large gear and a small gear of the gear pair model is small, namely the two contact lines are approximate parallel lines. By the method, the tooth error can be analyzed and judged in a gear modeling stage, so that the failure of computer aided education (CAE) analysis caused by the inefficiency of the model precision in a later stage is avoided.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Three-phase square-wave permanent magnet brushless DC motor

ActiveUS8089192B2Minimize the cogging torqueSimple structureWindingsMagnetic circuit rotating partsSquare waveformMagnetic poles

This invention relates to a three-phase square-wave permanent magnet brushless DC motor for solving problems of the existing square-wave permanent Magnet Motor and sine-wave permanent magnet motor. In this invention, the number 2P of magnetic poles on the said rotor core is 8; the slot number Z of the said stator core is 12, accordingly there are 12 teeth, including three big teeth, three medium teeth and six small teeth; the ratio of their mechanical angles is 50° (±5°) for big teeth: 40° (±5°) for medium teeth: 15° (±5°) for small teeth, and the sum of the mechanical angles of one big tooth, one medium tooth and two small teeth must be 120°. Three-phase concentrated windings are respectively wound on the big teeth and the medium teeth, in which there are only two concentrated windings for each phase, thus there are only 6 concentrated windings for the three-phase motor. With driven by three-phase square-wave current, the said motor can produce a smooth torque which ripple index corresponds to that of the sine-wave permanent magnet servo motor, at the same time, it also has a plurality of advantages including windings end minimization, air-gap minimization, material minimization, cogging torque minimization and loss minimization and so on.

Owner:SCBD (ANHUI) E TECH CO LTD

Frame for Aiding in Screen Protector Application

InactiveUS20170190160A1Cutting time necessaryReduce wasteLamination ancillary operationsCasings/cabinets/drawers detailsEngineeringSmall tooth

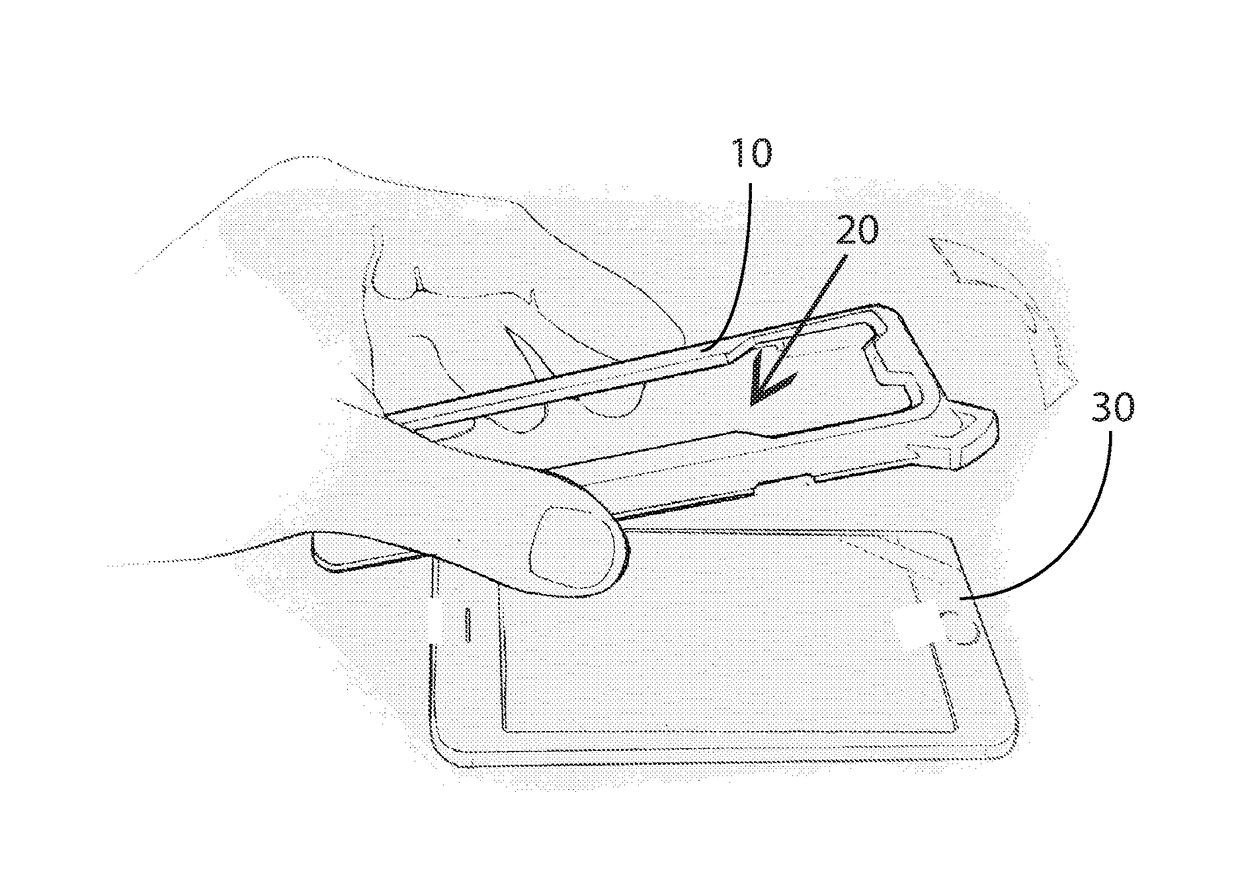

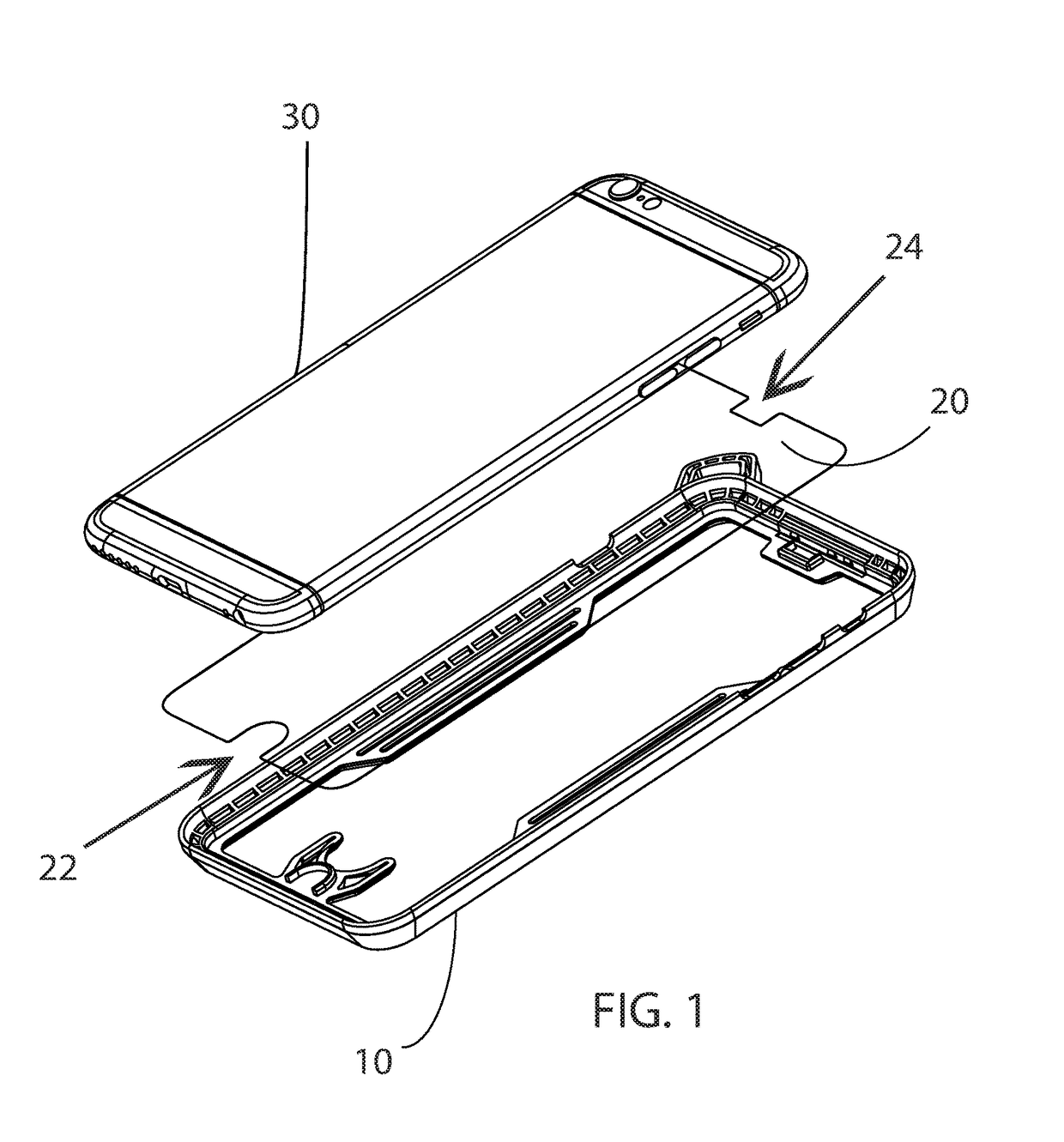

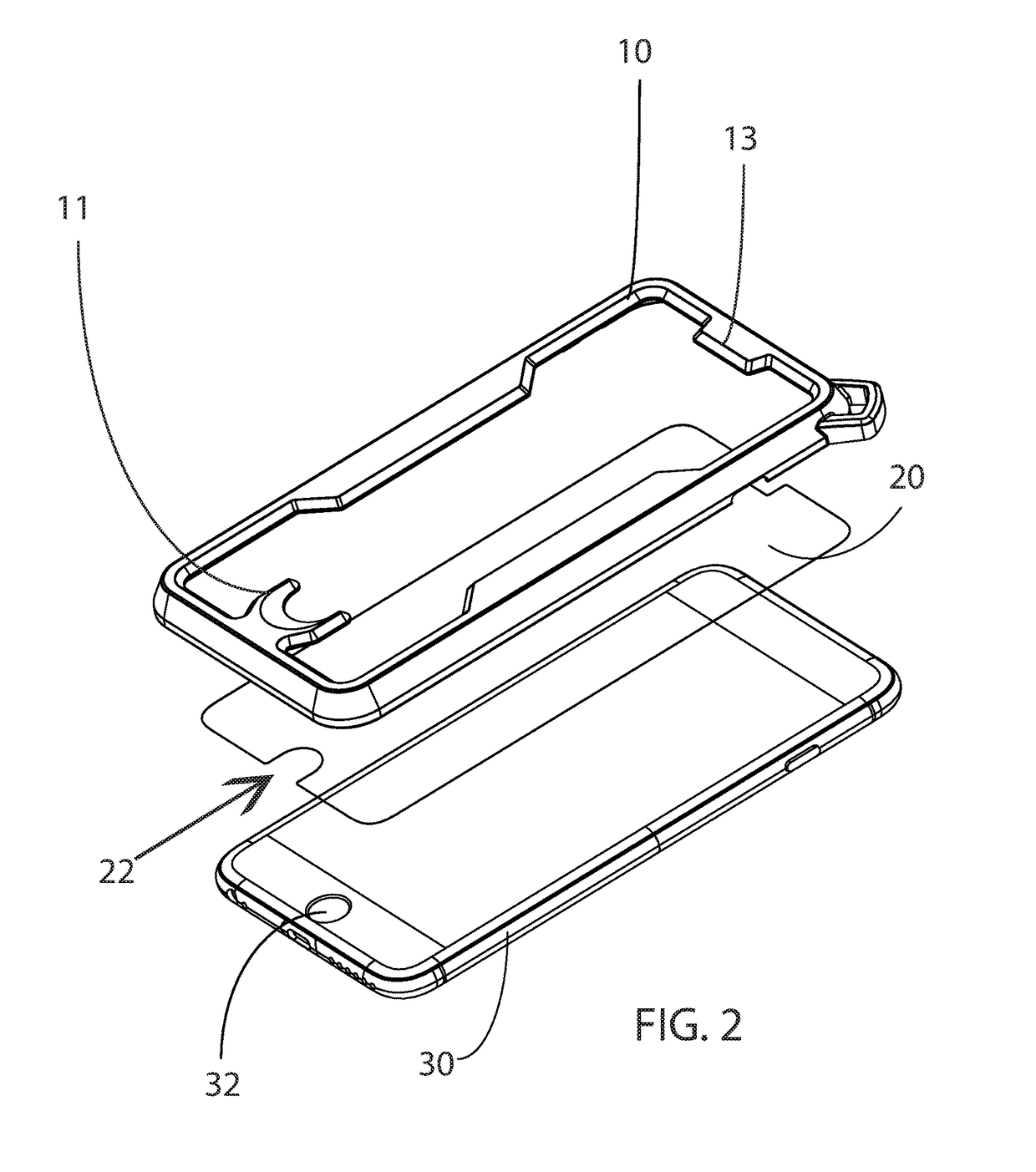

A system and method for applying a screen protector to a handheld electronic device may provide a frame to surround the device and secure a screen protector over the device prior to final installation. The frame may provide supports to interface with screen protector cutouts to ensure a uniform fit. For rigid protectors, sets of small teeth may secure the protector to the frame and provide audible confirmation of proper mounting and eventual installation. When fitted over a device, a user may then push the screen protector downward for a perfect mounting of the protector to the device every time.

Owner:PENUMBRA BRANDS LLC

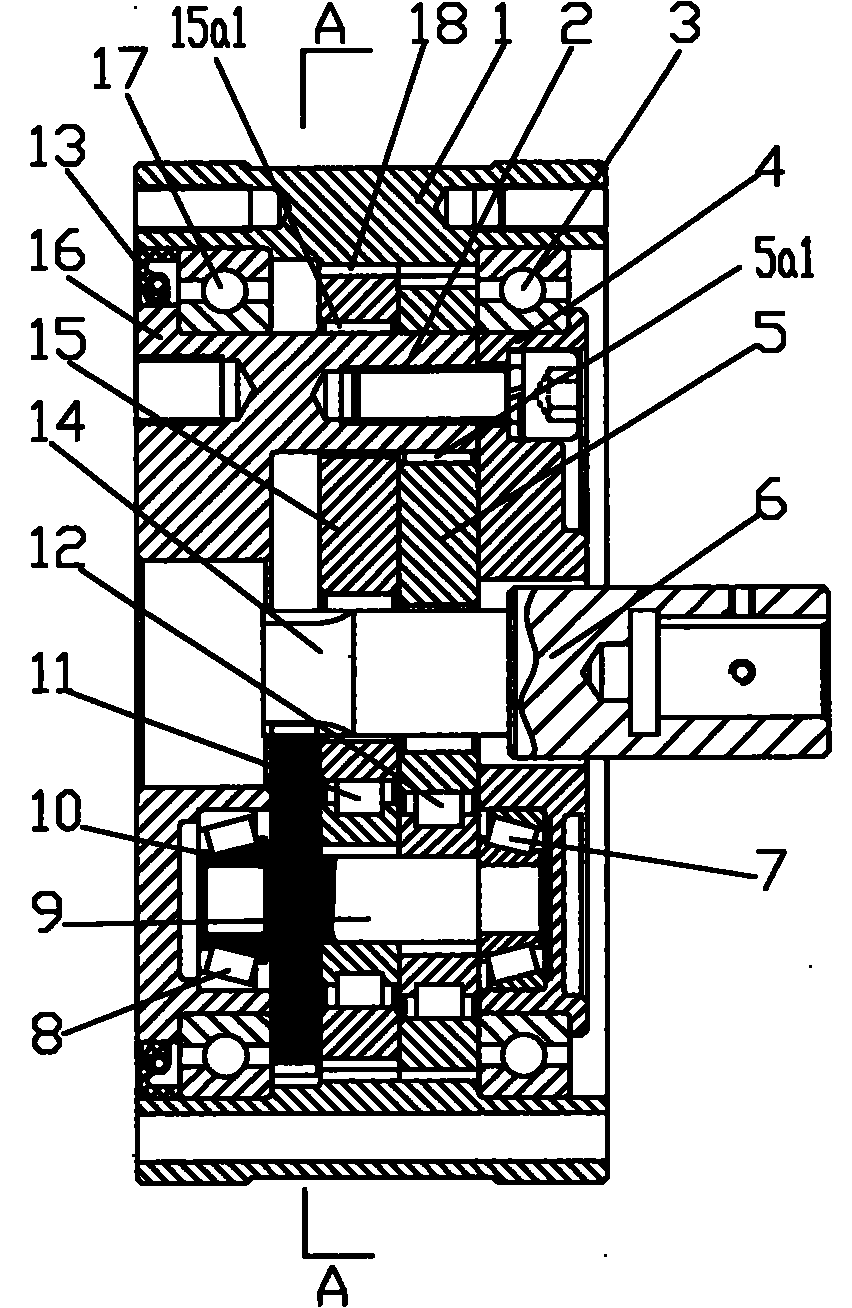

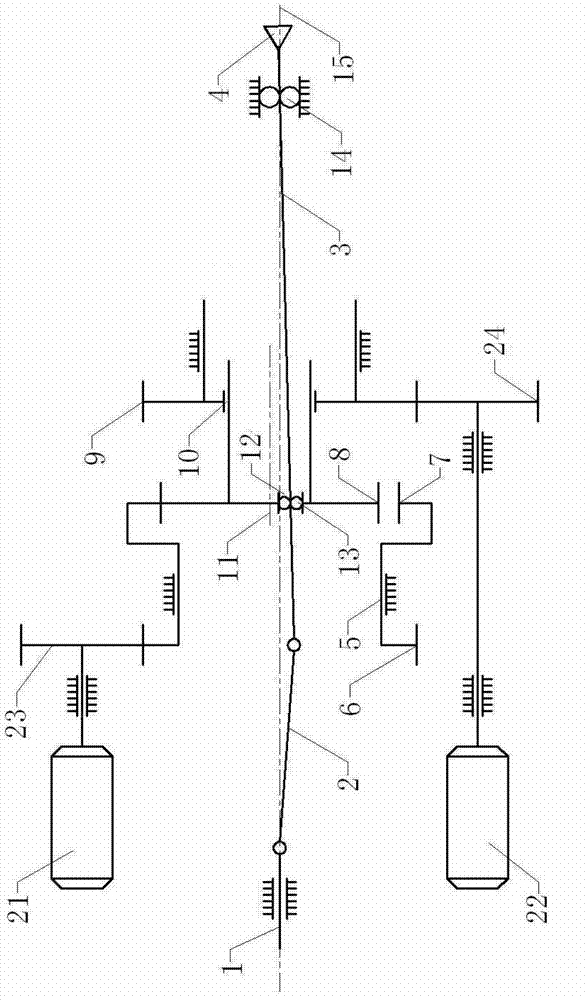

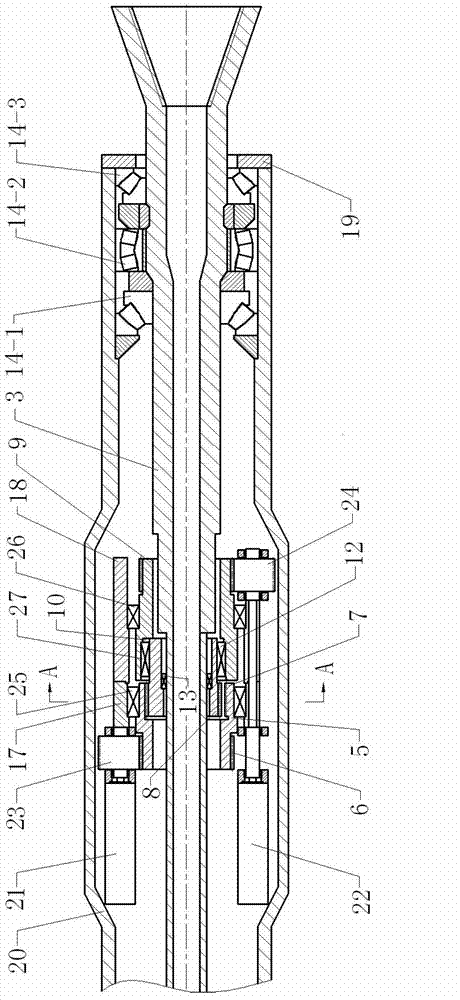

Static pointing type rotary guiding drilling tool

The invention discloses a static pointing type rotary guiding drilling tool which comprises an outer cylinder. A drilling column, a hollow universal coupling and a mandrel are connected in sequence from top to bottom and arranged in the outer cylinder, the drilling column is rotatably connected into the outer cylinder, a polarization mechanism located in the outer cylinder is arranged at the upper end of the mandrel, a knuckle bearing assembly located in the outer cylinder is arranged at the lower end of the mandrel, a sealing assembly installed on the outer cylinder is arranged below the knuckle bearing assembly, and the lower end of the mandrel is fixedly connected with a drill. An eccentric planetary gear with small tooth difference is adopted for achieving polarization of the mandrel, and the static pointing type rotary guiding drilling tool is not influenced by geological stratification, can obtain stable build-up rate, and achieves accuracy control of well track. A plurality of working states can be achieved without drilling, and purposes of angle gain, angle drop and angle maintenance are achieved. Stress condition of the mandrel during polarization can be improved effectively, and service life of the rotary guiding tool is improved.

Owner:TIANJIN UNIV

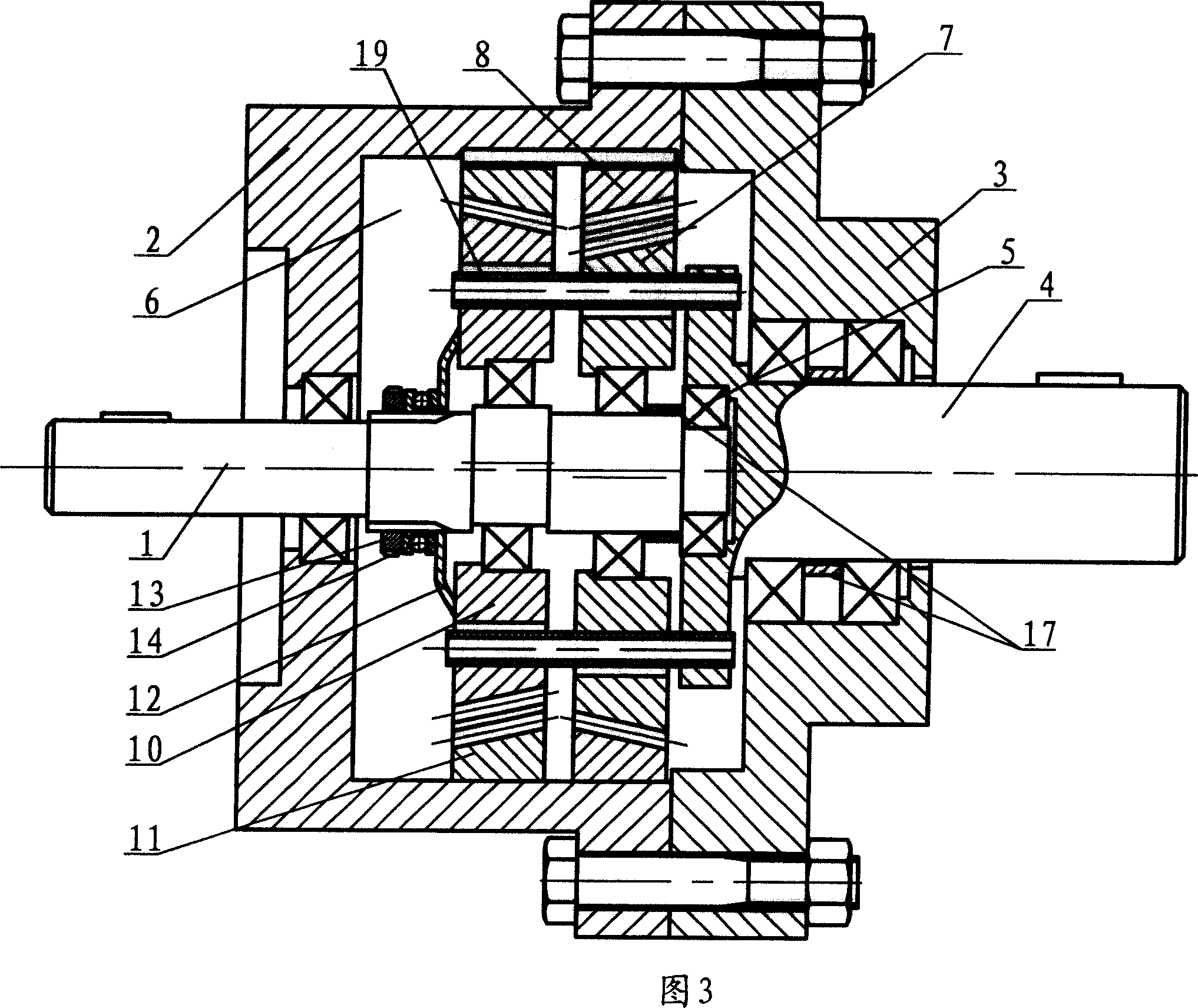

2K-V speed reducer

InactiveCN103742610AEasy to processReduce manufacturing difficultyToothed gearingsPortable liftingEngineeringSmall tooth

The invention provides a 2K-V speed reducer. The speed reducer comprises a primary planetary gear mechanism and an involute small tooth difference gear mechanism. A planetary mechanism is composed of a central gear and a planetary gear. The involute small tooth difference gear mechanism is composed of an eccentric shaft, an outer gear and an inner gear casing. Under the drive of the eccentric shaft of the involute small tooth difference gear mechanism, the outer gear performs planar motion by the action of the inner gear casing, rotates around own axis reversely while revolving around the axis of the inner gear casing and outputs own rotation through a planet carrier. The speed reducer can be used for being connected with joint portions of industrial robots.

Owner:秦川机床工具集团股份公司

Intelligent drive device

InactiveCN103185109AReal-time monitoring of working statusHigh transmission precisionToothed gearingsPortable liftingReduction driveReducer

The invention discloses an intelligent drive device, comprising a drive motor and a speed reducer, wherein the speed reducer comprises a power input eccentric shaft, a duplicate gear, a fixed inner gear and a power output inner gear, wherein the duplicate gear comprises an outer gear I and an outer gear II, and is rotatably matched with an eccentric section sleeved on the power input eccentric shaft; the fixed inner gear and the outer gear I form a meshing pair I with smaller teeth difference; the power output inner gear and the outer gear II form a meshing pair II with smaller teeth difference; a slotting elastic filter structure is respectively arranged inside the meshing pair I with smaller teeth difference and the meshing pair II with smaller teeth difference; each slotting elastic filter structure comprises a wheel tooth groove and / or a gear grove; the wheel tooth groove is arranged on the wheel teeth of the gear; the gear groove is arranged inside the tooth groove of the gear; elastic bodies are arranged inside the wheel tooth groove and the gear groove; and the intelligent drive device also comprises a monitoring device; the monitoring device comprises a data receiving device and sensors; the sensors are arranged inside the elastic bodies and used for respectively monitoring the operating conditions of the meshing pair I with smaller teeth difference and the meshing pair II with smaller teeth difference; and the sensors are wirelessly connected with the data receiving device.

Owner:SICHUAN UNIV

Single-stage rigid tooth surface cycloid steel ball planetary gear reducer

InactiveCN103883683ABacklash freeHigh transmission precisionToothed gearingsPortable liftingSmall teethEngineering

The invention provides a single-stage rigid tooth surface cycloid steel ball planetary gear reducer which comprises a reducer shell, an input shaft, an eccentric sleeve, steel ball sets, an end cover, an end cover disc, a cross-shaped disc, a planetary disc, a center disc, an output shaft, a pre-fastening nut, back-up bearings and bearing end covers. The single-stage rigid tooth surface cycloid steel ball planetary gear reducer is of a K-K-V type single-stage small-tooth-difference planetary transmission basic structure, inner cycloid grooves and outer cycloid grooves in the end faces of the center disc and the end faces of the planetary disc serve as tooth profiles, steel balls serve as mediators to carry out meshed transmission, tooth gaps are eliminated through four-point contact between the steel balls and the cycloid grooves, meanwhile, a tooth-gap-free cross-shaped steel ball constant speed mechanism is cooperated, and the single-stage rigid tooth surface cycloid steel ball planetary gear reducer has the advantages of being simple in structure, small in size, free of the tooth gaps, high in transmission accuracy and high in efficiency; meanwhile, the inner cycloid grooves and the outer cycloid grooves of the single-stage rigid tooth surface cycloid steel ball planetary gear reducer are respectively formed by two cycloid split discs in an assembled mode, surface heat treatment and grinding are conveniently carried out on the cycloid tooth surfaces of the split discs, and the single-stage rigid tooth surface cycloid steel ball planetary gear reducer further has the advantages of being high in tooth surface rigidity, small in heat treatment deformation, resistant to abrasions and long in service life.

Owner:JIANGSU TAILONG MACHINERY GRP CO CO LTD

Planetary reducer

InactiveCN103742609AGood workmanshipReduce manufacturing difficultyToothed gearingsGearing detailsEngineeringSmall tooth

The invention provides a planetary reducer which is composed of a first-level planetary gear mechanism and a first-level novel small-tooth-difference gear mechanism. The planetary gear mechanism is composed of a sun gear and a planetary gear. The small-tooth-difference gear mechanism is composed of an eccentric shaft, an outer gear and an inner gear casing. The inner gear casing is fixed, the eccentric shaft is fixedly connected with the first-level planetary gear to serve as an input shaft of a second-level small-tooth-difference gear mechanism, the outer gear conducts planar motion under the combined effect of the eccentric shaft and the inner gear casing to enable the outer gear to revolve around the axis of the inner gear casing and rotate reversely around the self axis, the rotating motion of the outer gear is output through a W mechanism, and the planetary reducer can be connected with a joint portion of an industrial robot.

Owner:秦川机床工具集团股份公司

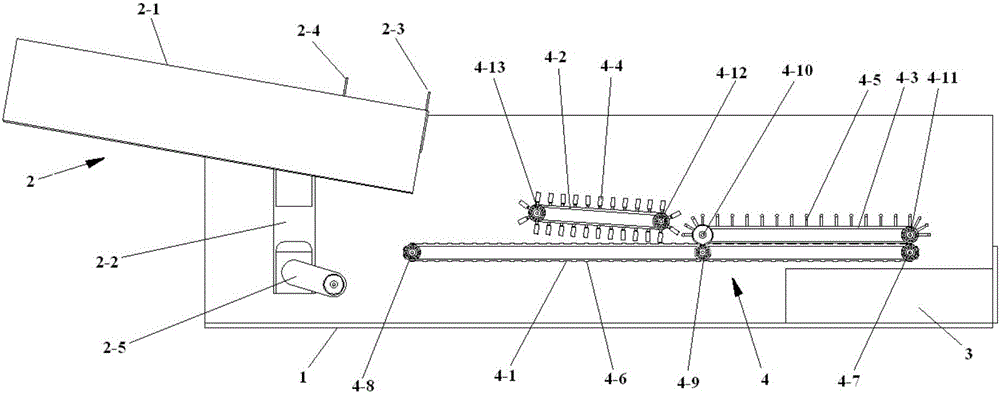

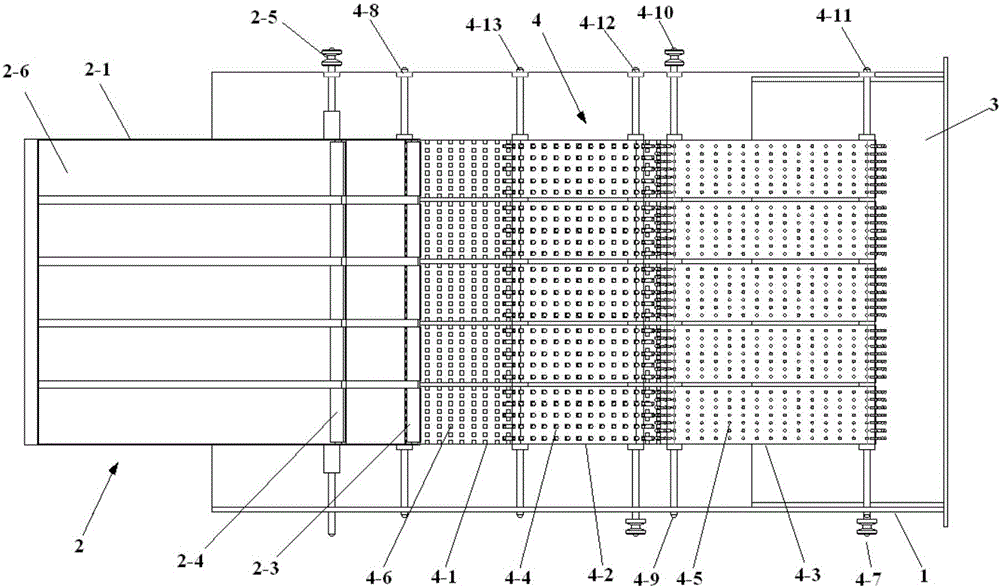

Friction bank note flattening sorting device

InactiveCN105844787ASolve processing problemsFlattening and finishingCoin/currency accepting devicesEngineeringSmall tooth

The invention provides a friction bank note flattening sorting device. The device comprises a frame, wherein the frame is internally equipped with a bank note spreading flattening mechanism, the bank note spreading flattening mechanism comprises a lower conveying belt horizontally mounted in the frame, the lower conveying belt is equipped with a spreading conveying belt and an upper conveying belt, the spreading conveying belt is close to a hopper mechanism, the upper conveying belt is close to a collection hopper, the spreading conveying belt is obliquely arranged, height of one end of the spreading conveying belt close to the upper conveying belt is smaller than height of one end of the spreading conveying belt away from the upper conveying belt, the spreading conveying belt and the lower conveying belt have an included angle, the upper conveying belt and the lower conveying belt are vertically mounted in a parallel contact mode, the outer surface of the spreading conveying belt is hinged with multiple uniformly-distributed hanging teeth, and the outer surface of the upper conveying belt is provided with multiple uniformly-distributed flexible small teeth. According to the device, a processing problem of wrinkled bank notes is solved, so bank note sorting mechanization is realized, functions are practical, and the wrinkled bank notes are flattened and sorted and are easy for market development and popularization.

Owner:CHANGAN UNIV

Aircraft and long-service-life electric steering engine thereof

InactiveCN102777545AReduce usageMeet long life requirementsToothed gearingsSelf-propelled projectilesFlight vehicleReduction drive

The invention discloses a long-service-life electric steering engine which comprises a potentiometer, a motor, a bevel gear pair driven by the motor, and a speed reducer driven by the bevel gear pair, wherein the speed reducer comprises a first small-teeth-difference internal gear pair consisting of a first external gear and a first internal gear, a second small-teeth-difference internal gear pair consisting of a second external gear and a second internal gear, and an eccentric shaft driven by the bevel gear pair, wherein the first external gear and the second external gear are fixedly connected to the eccentric shaft to form two stages of planet transmission, the second internal gear is fixedly connected to a housing of the long-service life electric steering engine, the first internal gear is used for driving a load to rotate, and the transmission ratio of the first small-teeth-difference internal gear pair is more than that of the second small-teeth-difference internal gear pair. The long-service life electric steering engine disclosed by the invention realizes the long service life and high reliability based on a small-teeth-difference planet gear speed reducer, and meets the requirement of an intermediate and long-range aircraft on the long service life. The invention also discloses an aircraft employing the long-service life electric steering engine.

Owner:SICHUAN AEROSPACE FENGHUO SERVO CONTROL TECH CO LTD

Dual-redundancy permanent magnet synchronous motor temperature rise calculation method based on equivalent thermal network model

ActiveCN107391884AThe temperature field takes less timeShort timeDesign optimisation/simulationSpecial data processing applicationsElectrical conductorPermanent magnet synchronous motor

The invention discloses a dual-redundancy permanent magnet synchronous motor temperature rise calculation method based on an equivalent thermal network model. The method includes: building the three-dimensional equivalent thermal network model, solving heat resistance and heat sources, building a thermal balance equation, and solving to obtain the temperature rise of each temperature rise node of a motor. The method has the advantages that the special small-tooth structure of a dual-redundancy permanent magnet synchronous motor with low-heat coupling and without electromagnetic coupling among various phases of windings is considered in modeling, the windings in grooves adopt a double-layer equivalent model with two layers of conductors and two layers of insulators being arranged in a contacted and spaced manner, the temperature rise nodes are built at other solid part nodes and fluid area nodes, contacted different nodes are connected through equivalent resistors, parts contacting with external environment nodes are connected with the external environment nodes through convection radiating resistors, and the heat sources are distributed at active nodes; when the method is used for calculating the temperature rise, calculation quantity is moderate, time consumption is low, accuracy is high. And the obtained temperature rise result can be used for guiding the determination of the motor insulating level and the configuration of a cooling manner.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com