Patents

Literature

45results about How to "Reduce rotation frequency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

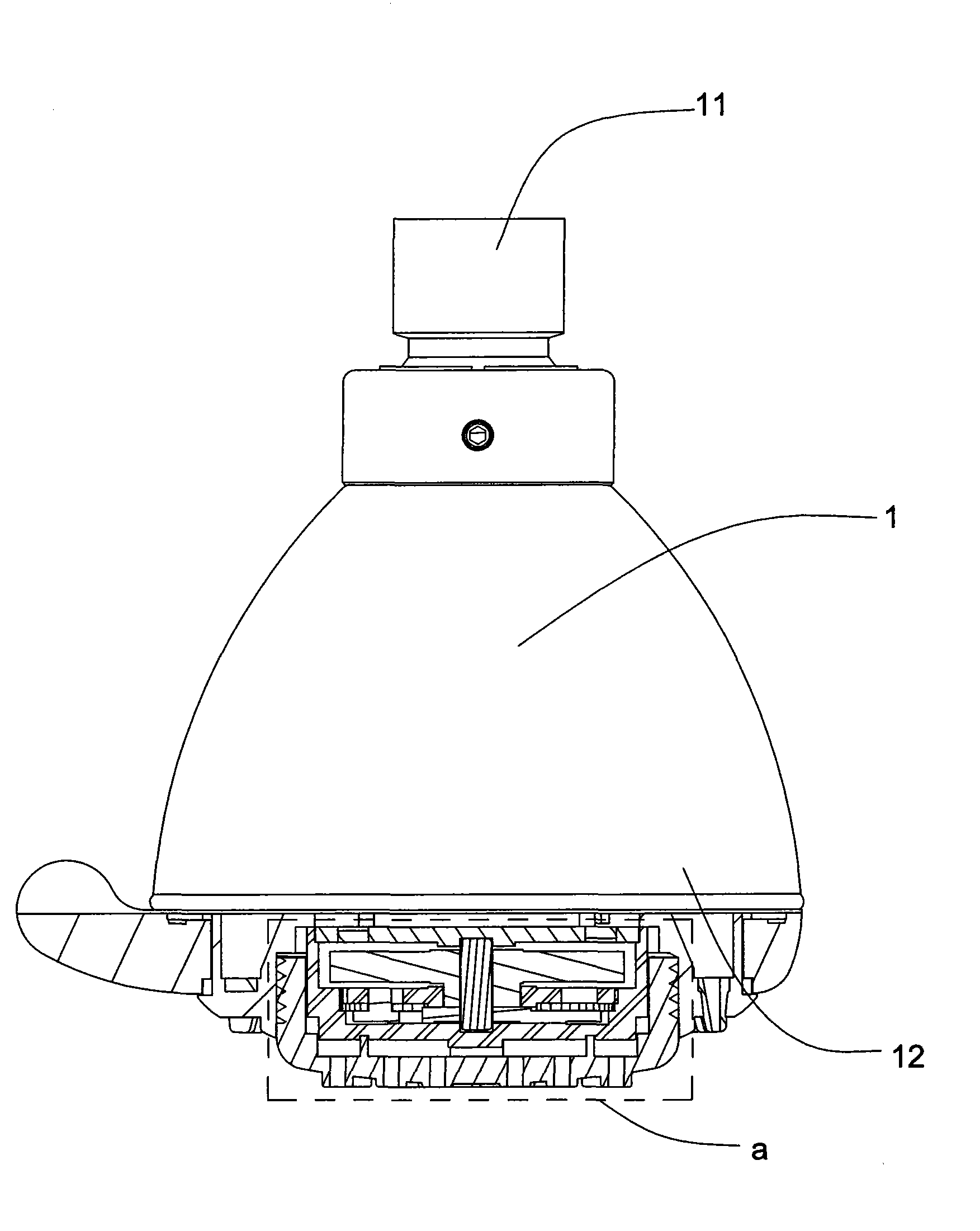

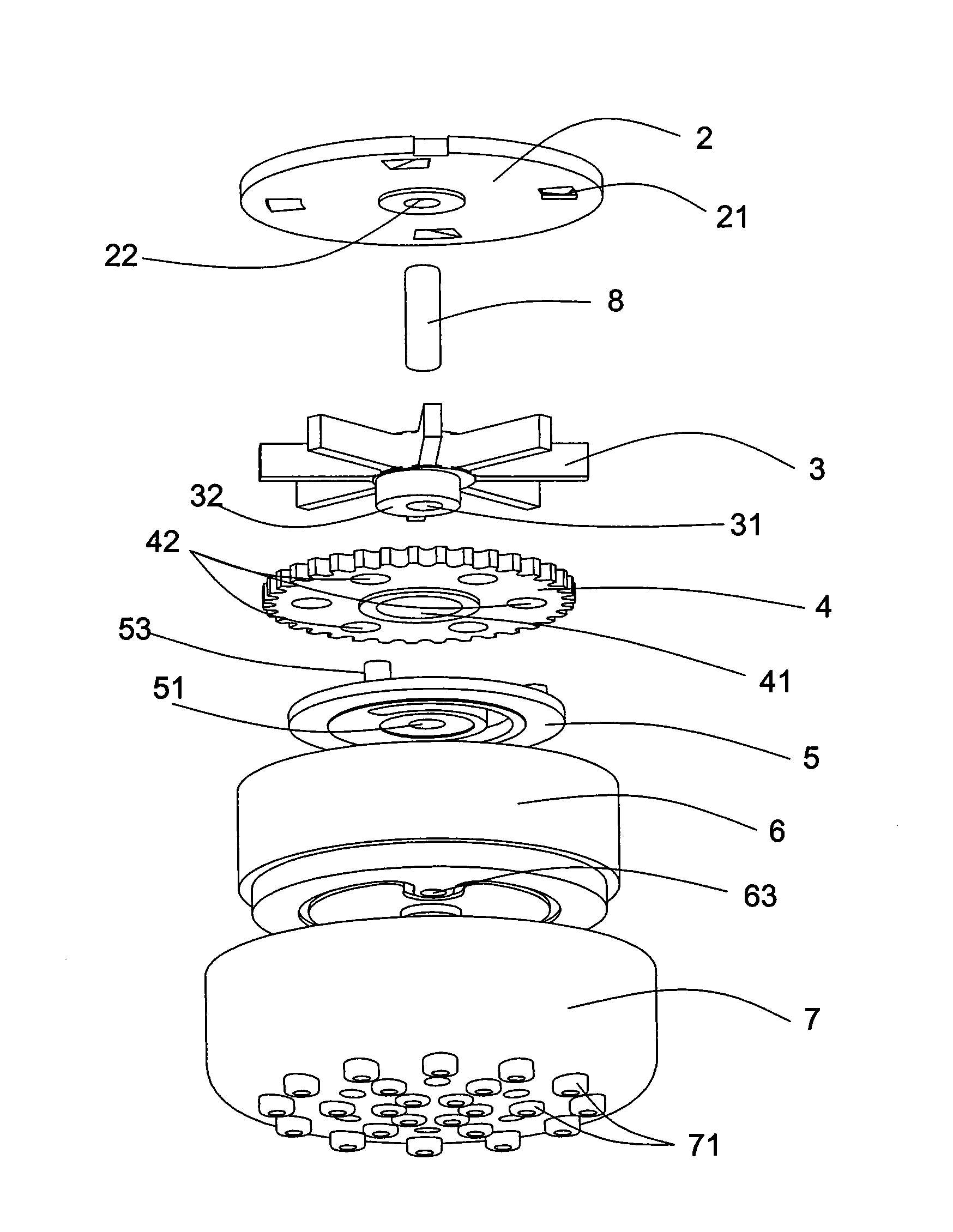

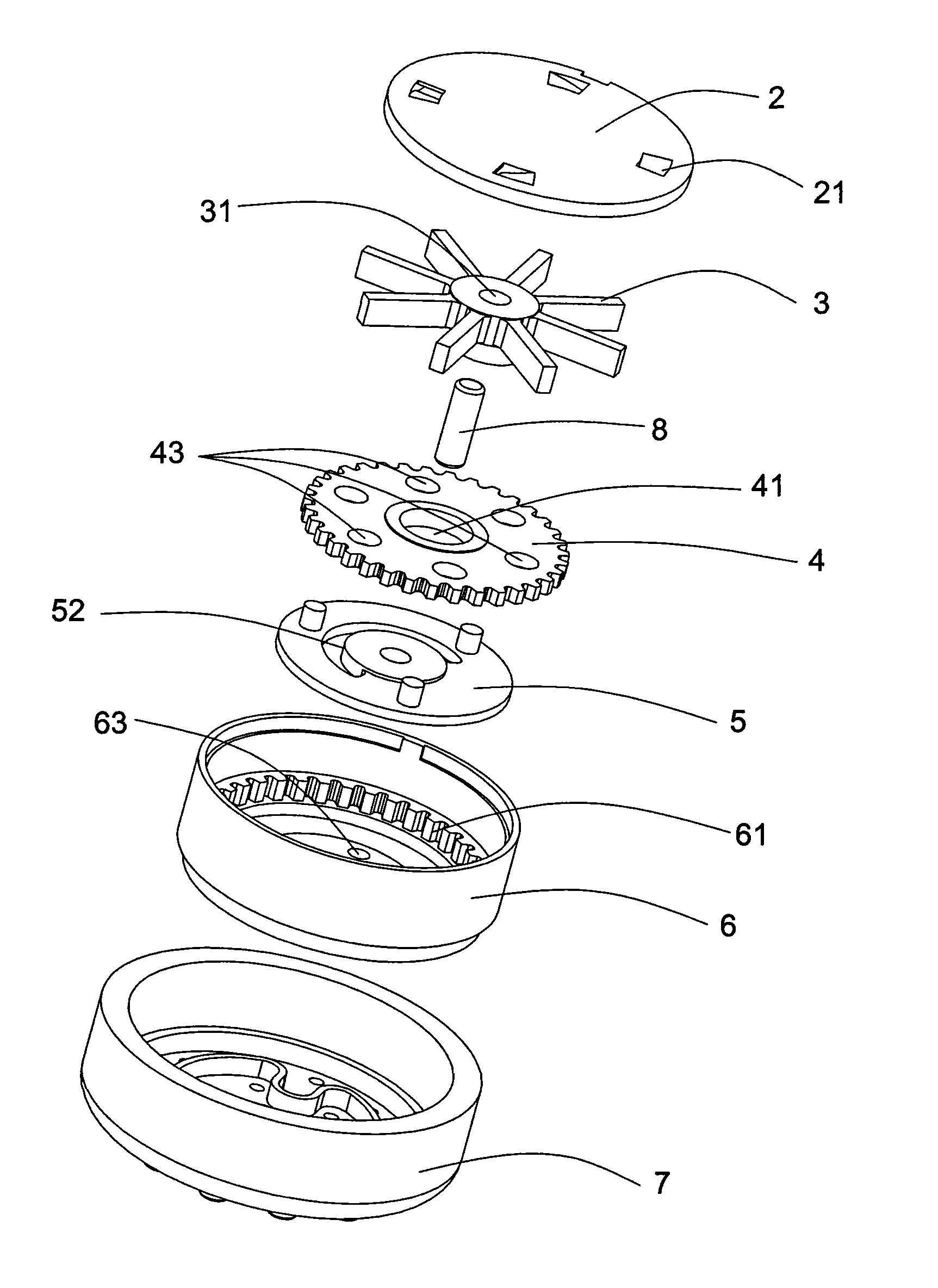

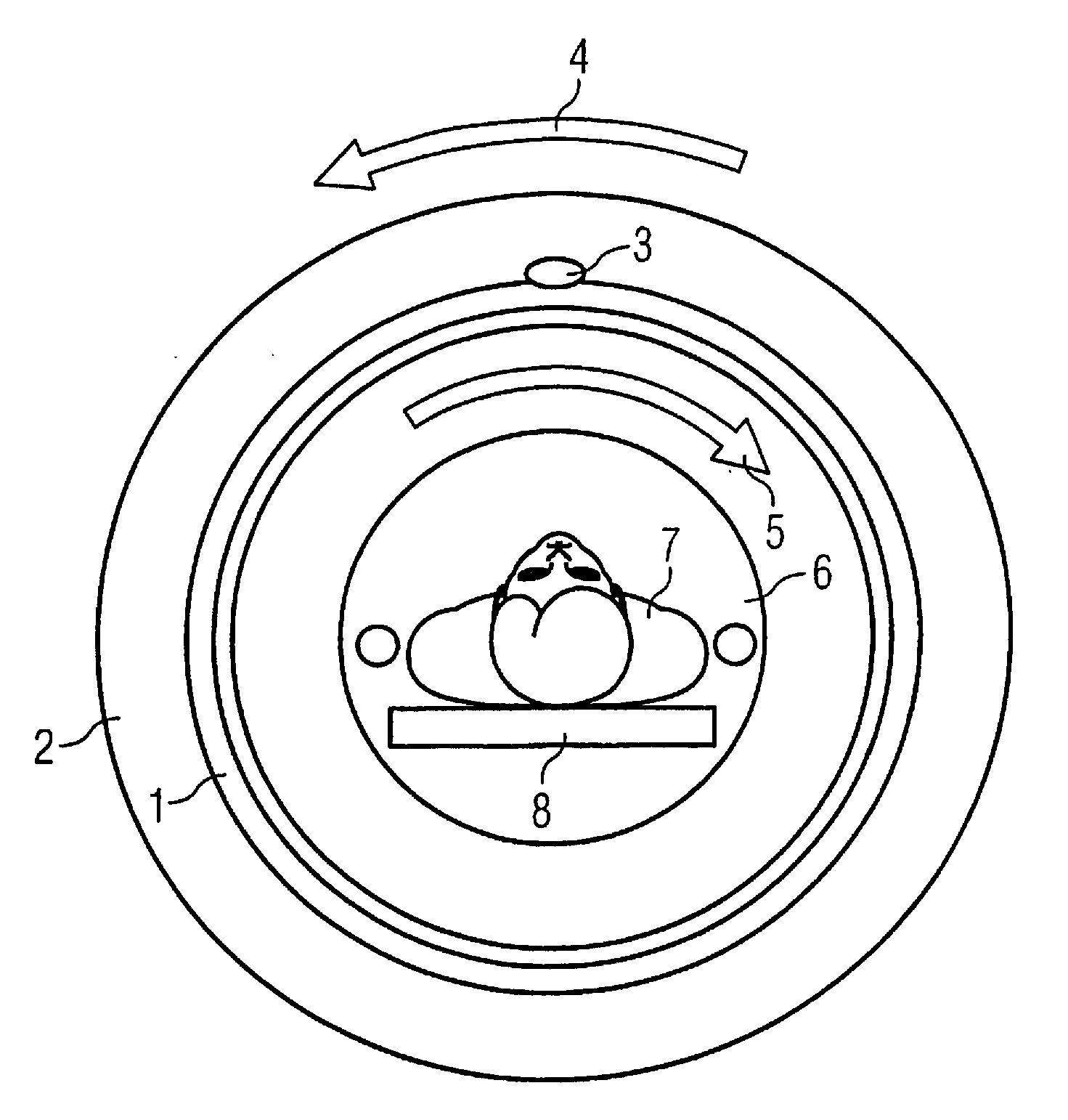

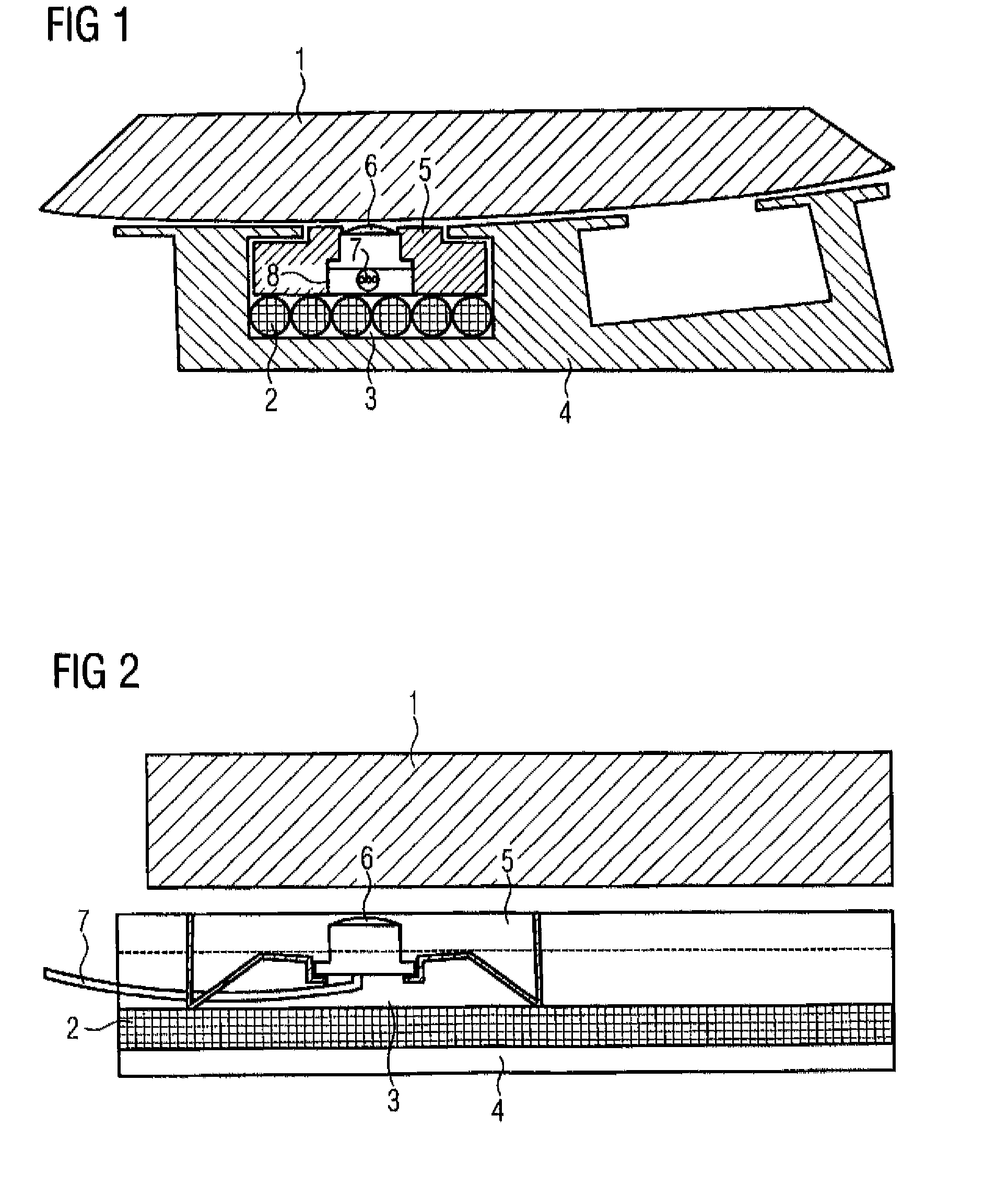

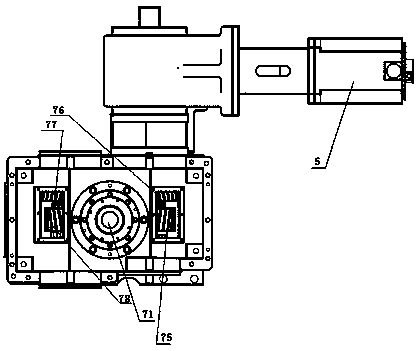

Massage shower head capable of realizing water flow dynamic switching

InactiveCN101773880ASimple structureReduce rotation frequencyPhysical therapySpray nozzlesImpellerWater flow

The invention discloses a massage shower head capable of realizing the water flow dynamic switching, which comprises a hollow body, an inclined water body, an impeller, a surface cover assembly and a movable sheet, wherein the impeller is positioned under the inclined water body, the surface cover assembly is provided with water outlets, the movable sheet is used for switching the conduction of water outlets in different regions of the surface cover assembly, and the impeller and the movable sheet are in transmission connection through a small-tooth-difference planetary gear transmission speed reducing mechanism. When in use, the massage shower head can realize the dynamic switching of different water outlets on the surface cover of the shower head, and can realize good massage effect.

Owner:XIAMEN SOLEX HIGH TECH IND CO LTD +1

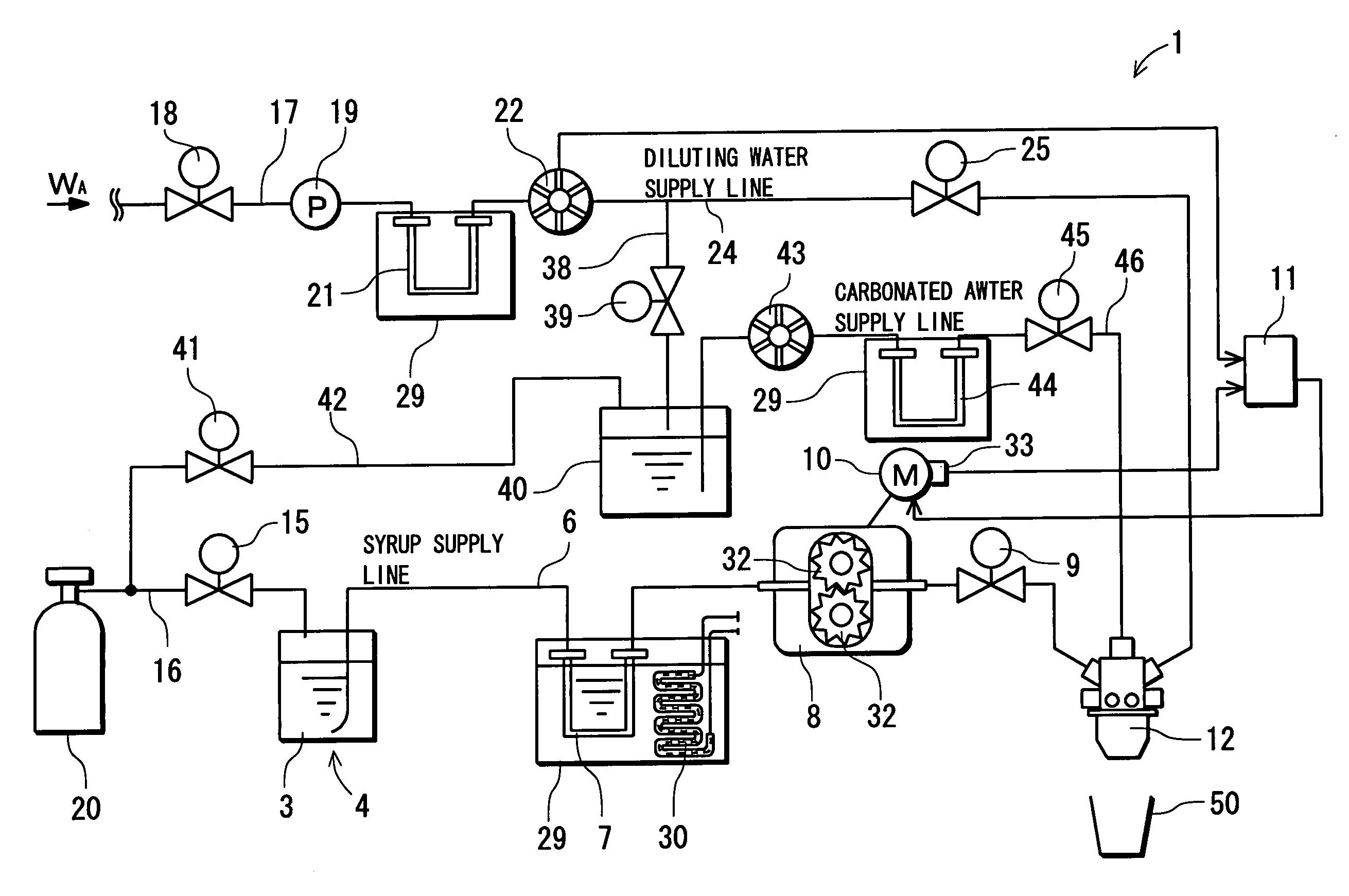

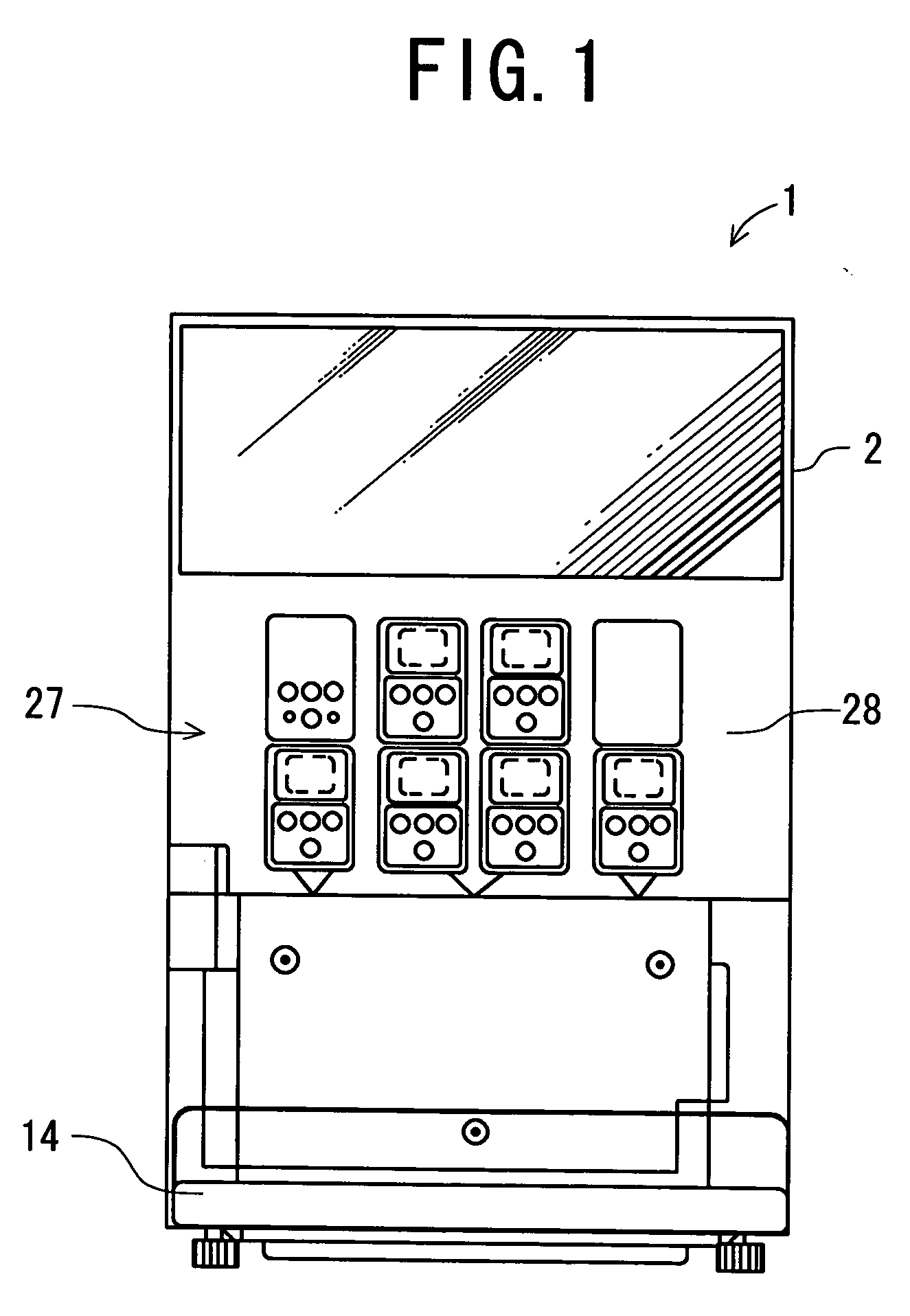

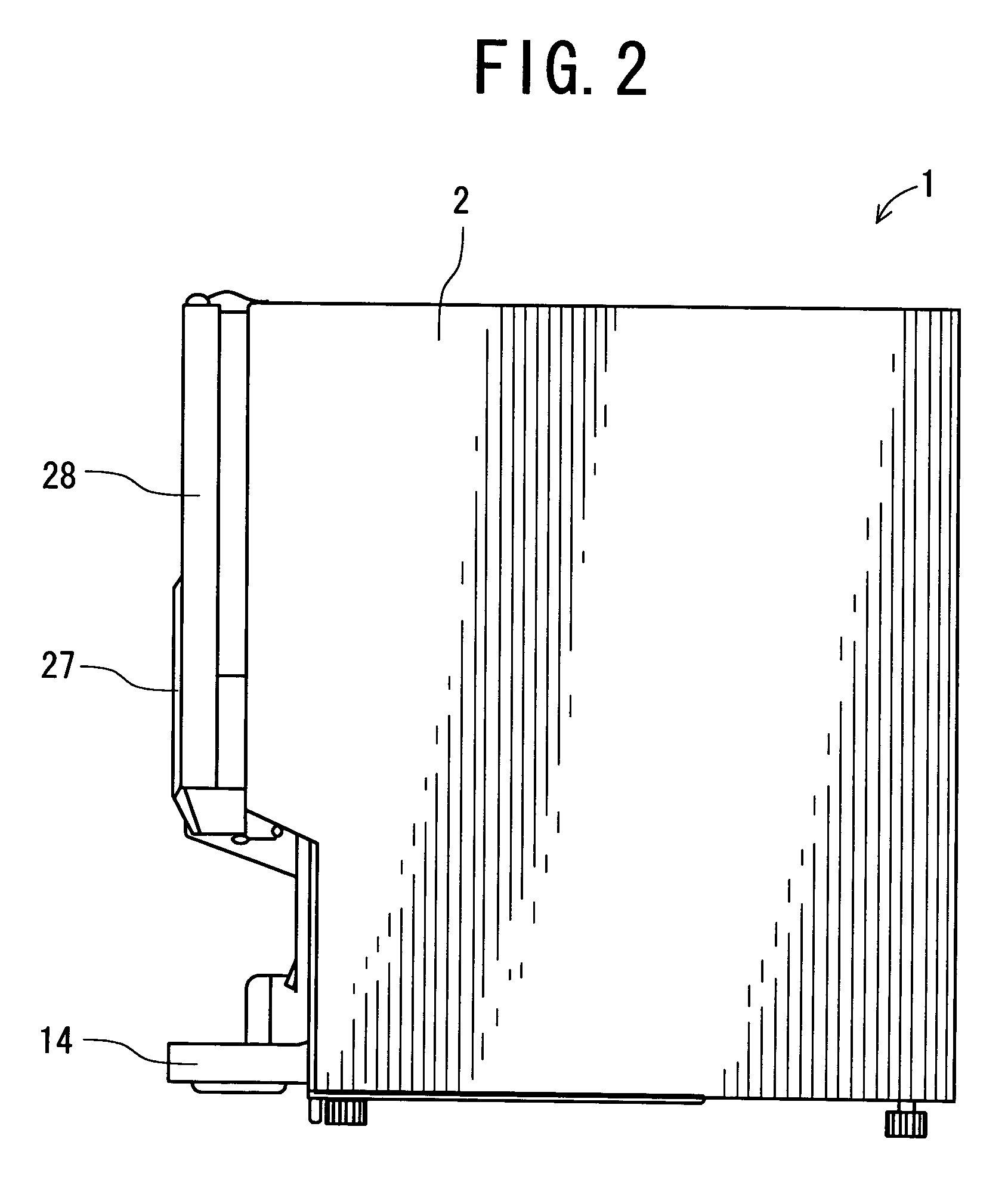

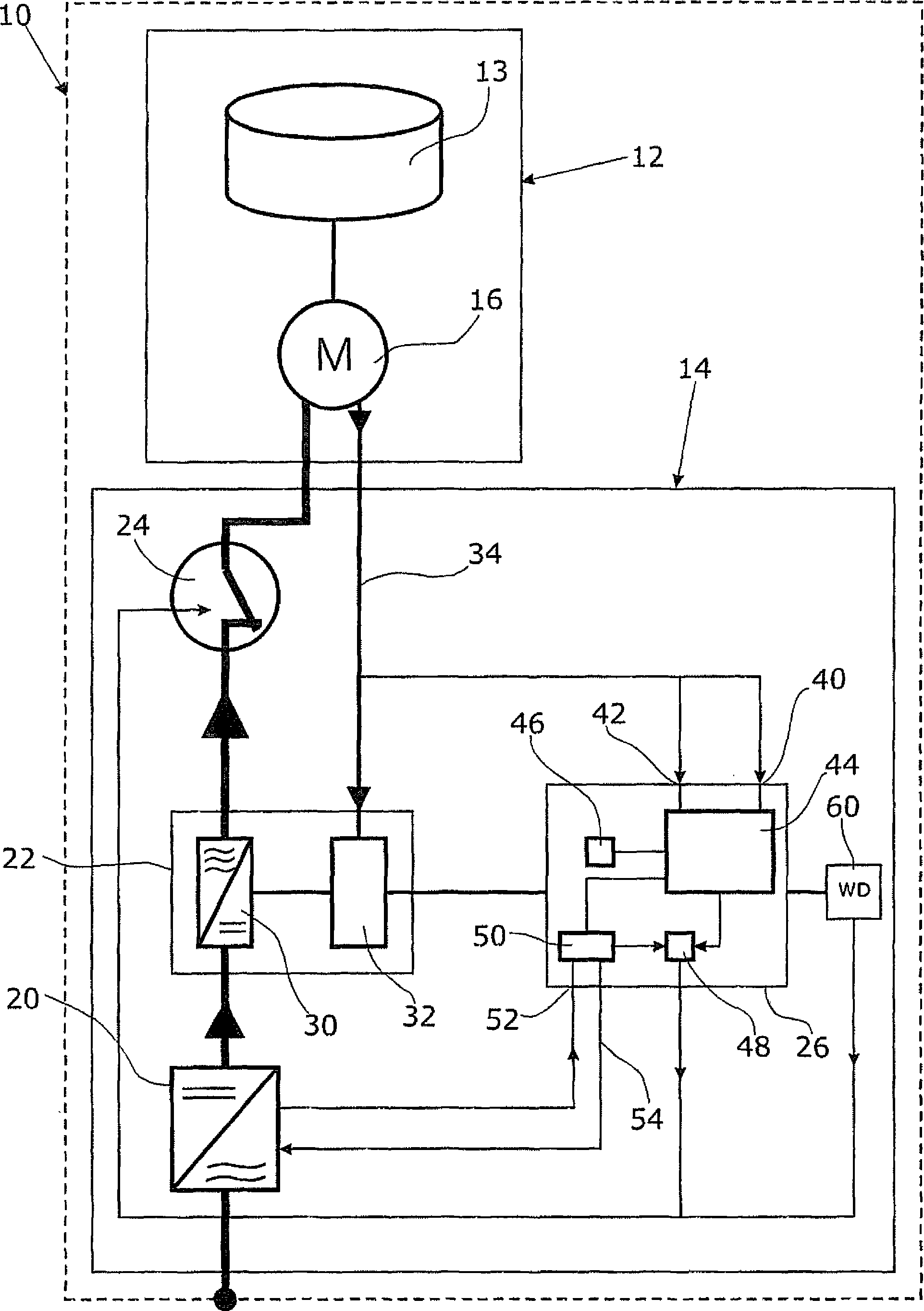

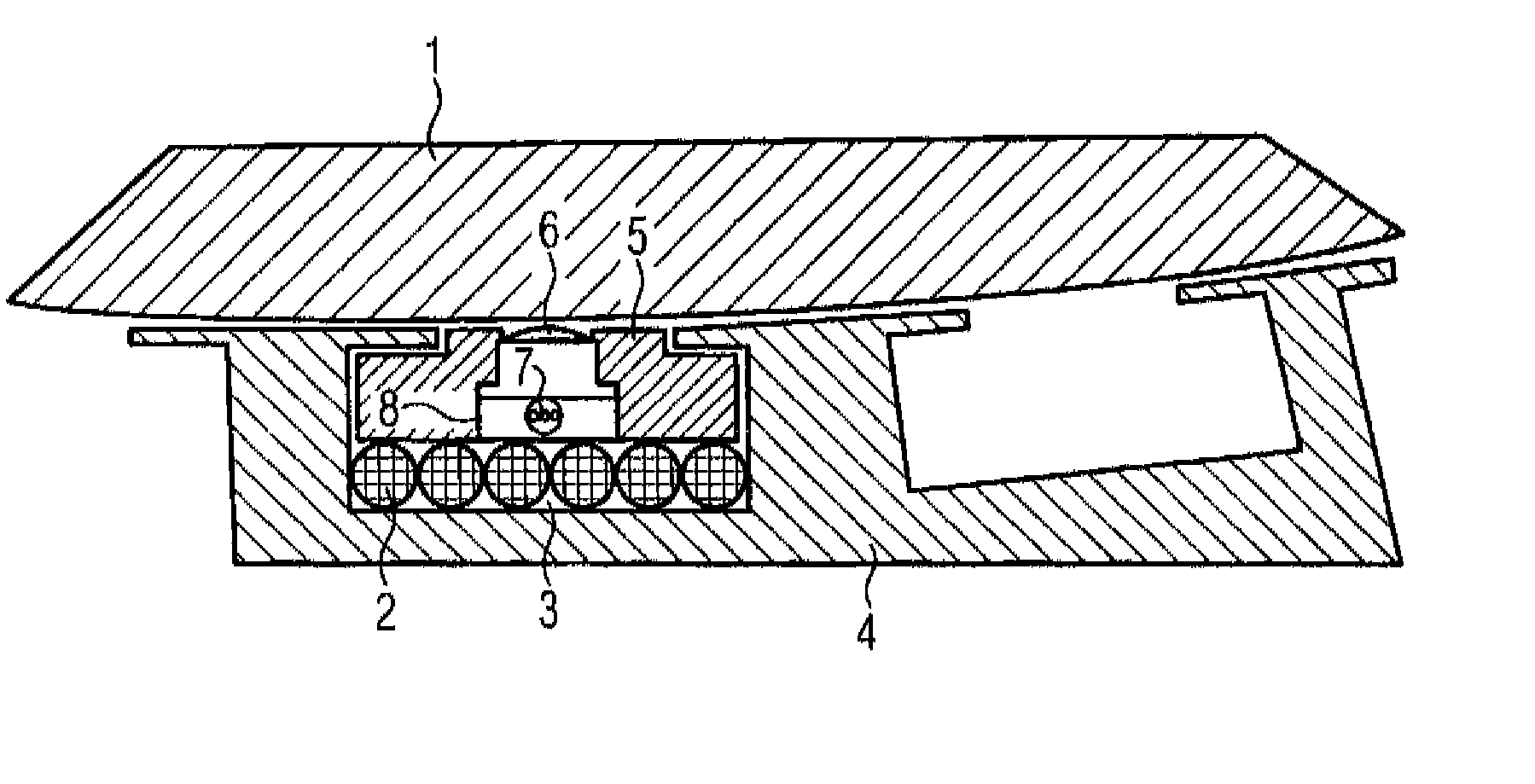

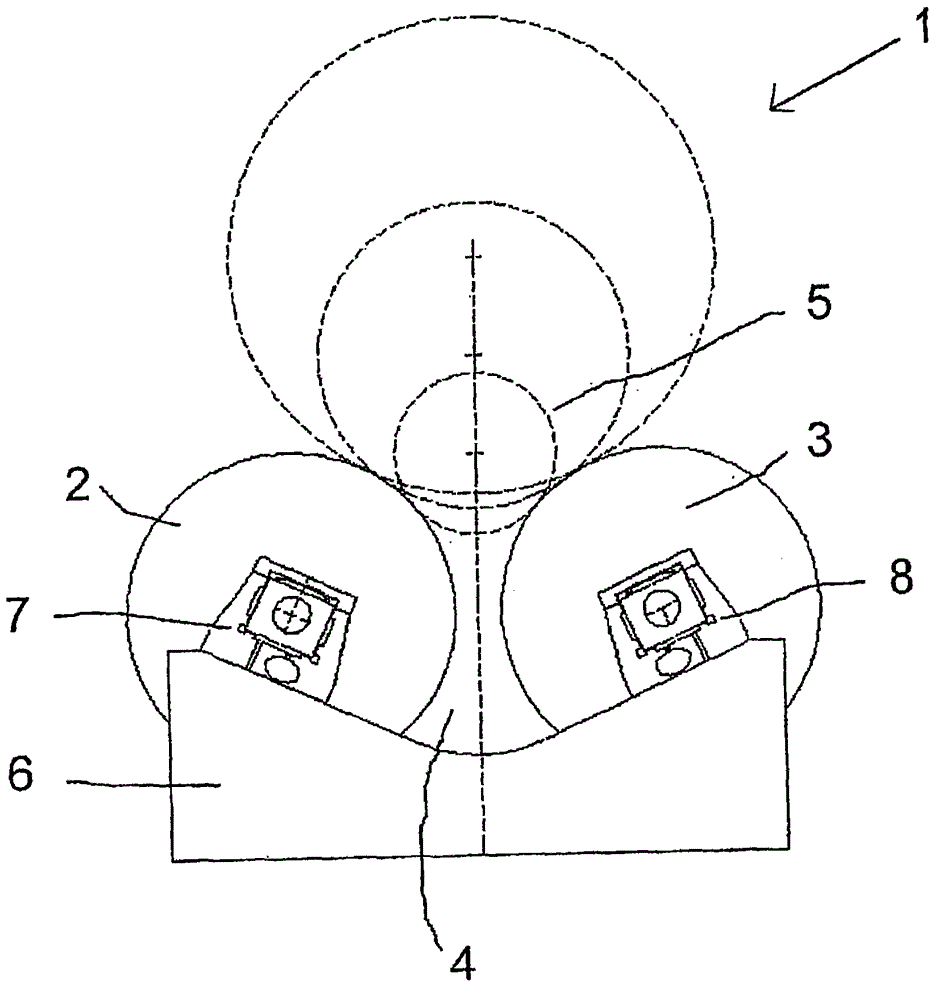

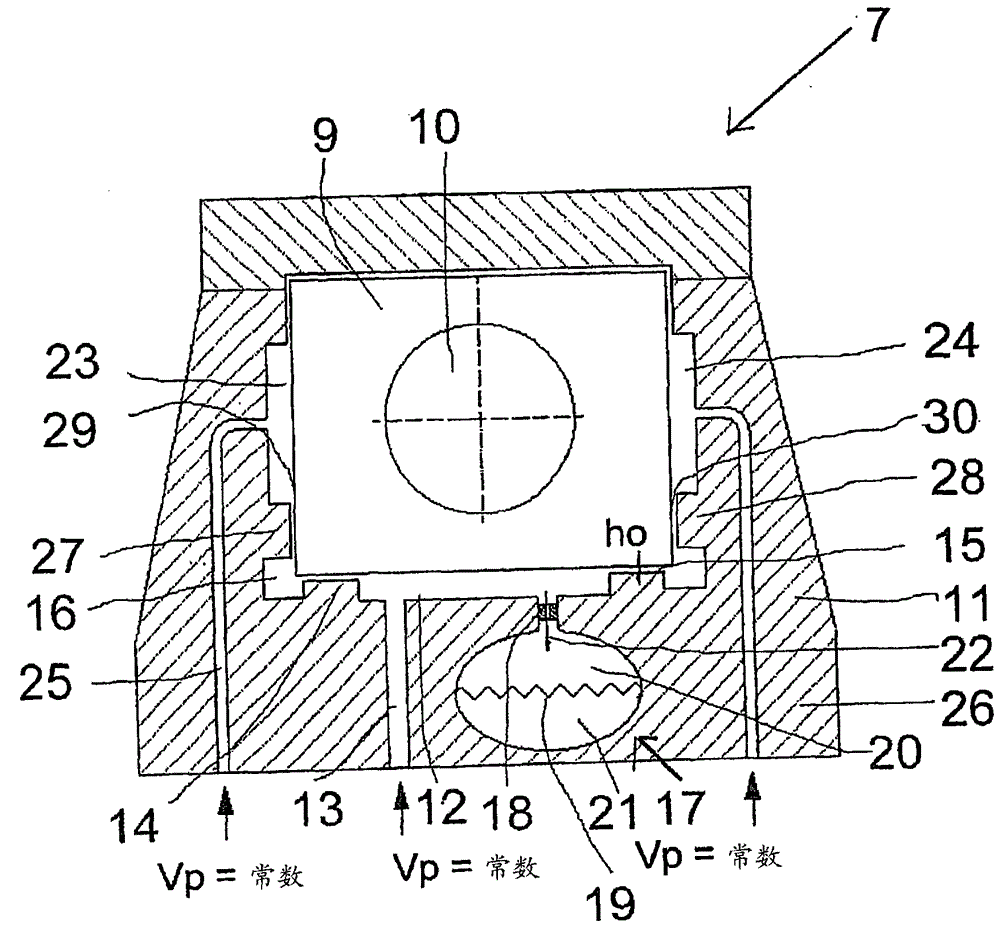

Beverage supply device

InactiveUS20060168986A1Reduce rotation frequencyIncrease air volumeCompression machines with non-reversible cycleLiquid transferring devicesEvaporationEngineering

An object is to provide a beverage supply device which can cool cooling water in a water tank provided with a beverage cooling pipe by use of a cooling unit using a refrigerant having little influence on global environment, a beverage dispenser is provided with the beverage cooling pipe (syrup cooling pipe, diluting water cooling pipe, carbonated water cooling pipe) disposed in the water tank to store cooling water, the water tank being cooled by an evaporation pipe, the beverage dispenser passes syrup, diluting water, and carbonated water as beverage ingredients through the beverage cooling pipe to extract beverage, and the beverage dispenser comprises: a cooling unit in which a compressor, a radiator, a capillary tube, the evaporation pipe and the like are connected to one another via a pipe to constitute a refrigerant circuit and which is filled with carbon dioxide as the refrigerant.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

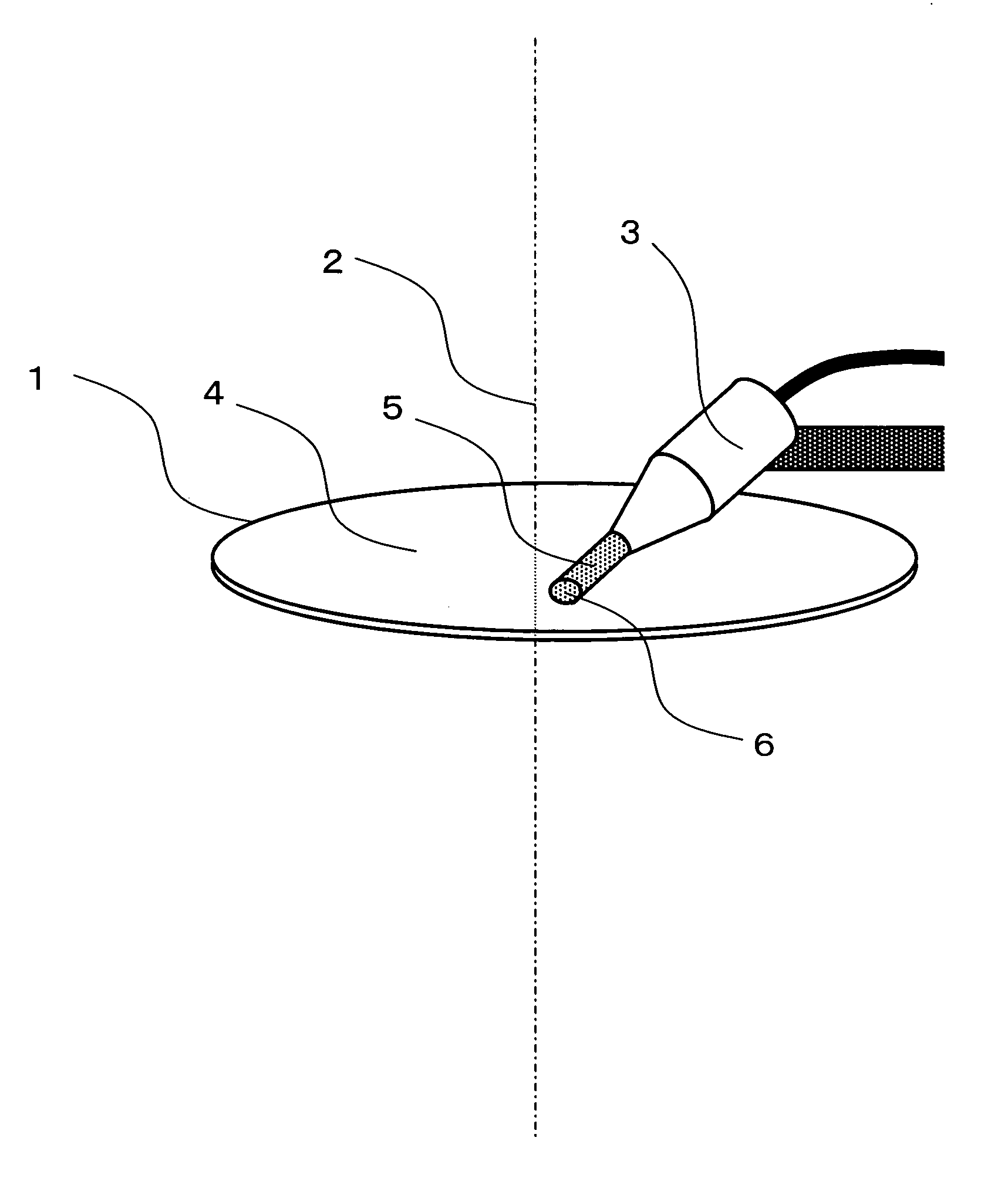

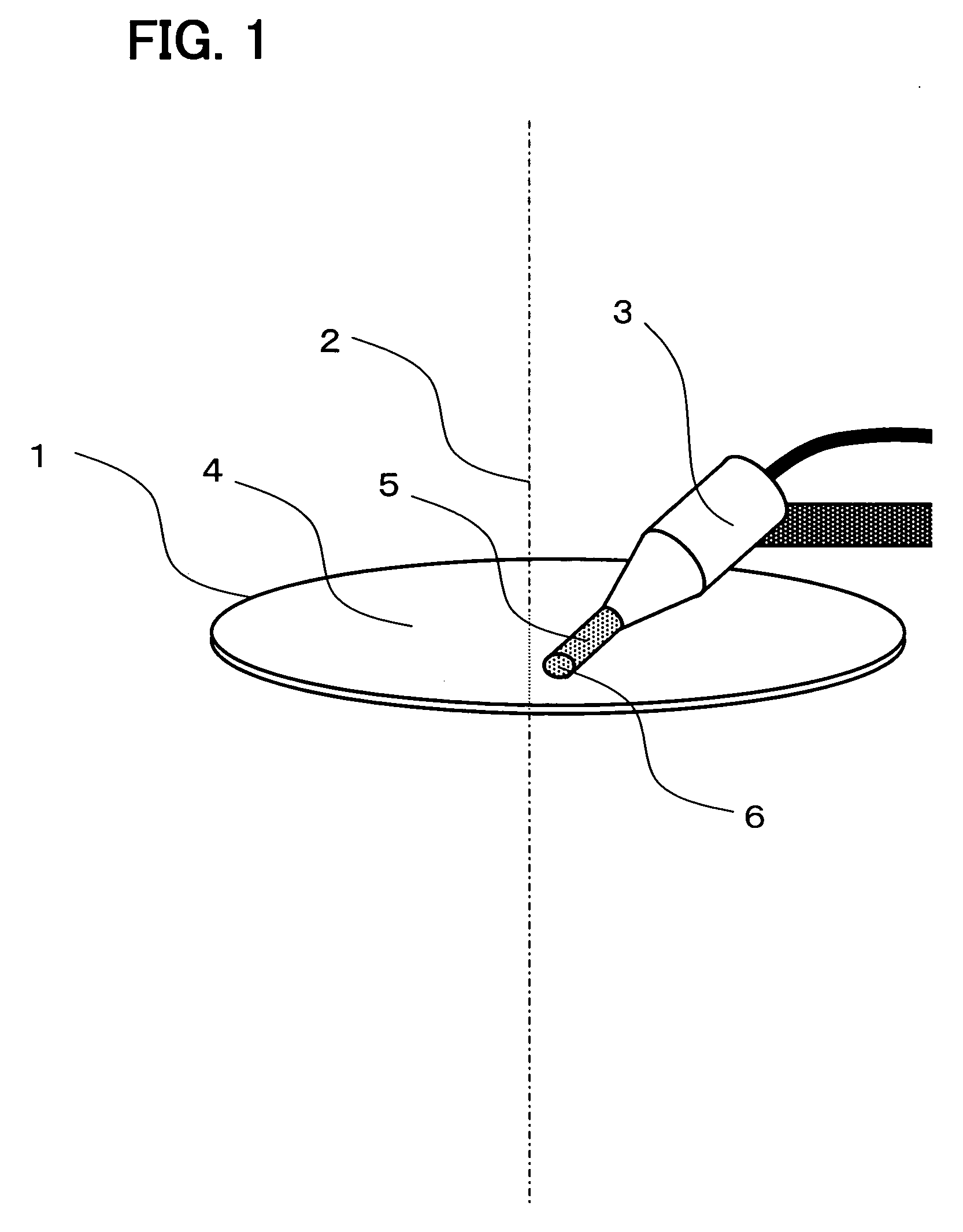

Spin cleaning apparatus and wafer cleaning method

InactiveUS20070137672A1Suppressing breakage of fine structureDamage suppressionSemiconductor/solid-state device manufacturingElectrostatic cleaningFine structureElectrical and Electronics engineering

To provide a wafer cleaning method capable of restricting breakage of fine structures disposed on a wafer, and a spin cleaning apparatus enabling such cleaning. The spin cleaning apparatus injects a cleaning liquid on a wafer surface while moving a nozzle, and at the same time, with an ultrasonic wave generated inside the nozzle, irradiates a cleaning liquid collision spot, thereby cleaning the wafer surface. The above apparatus includes at least one of the following functions: (1) a function of varying the rotation frequency of the wafer; (2) a function of varying the traveling speed of the nozzle in the direction parallel to the wafer; (3) a function of varying the output of the ultrasonic wave; and (4) a function of varying the distance between the nozzle and the cleaning liquid collision spot, all corresponding to the position of the cleaning liquid collision spot on the wafer.

Owner:FUJITSU LTD

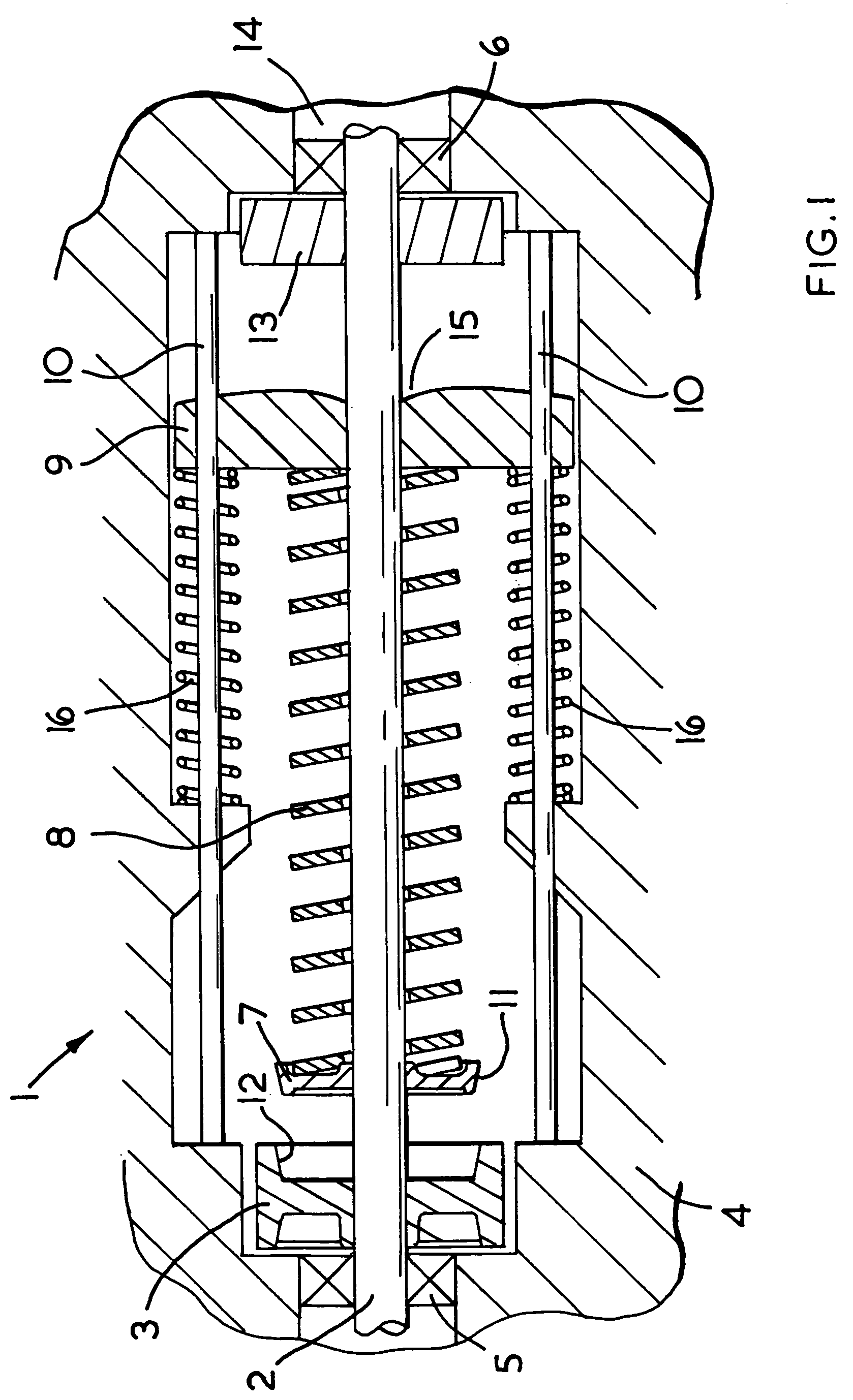

Apparatus for producing self-exciting hammer action, and rotary power tool incorporating such apparatus

InactiveUS7036608B2Risk minimizationMaximising extent of actuationConstructionsReciprocating drilling machinesEngineeringPower tool

An apparatus for providing percussion action in a rotary power tool having a rotary output shaft, the apparatus comprising at least one moveable mass adapted to have a component of movement parallel to the axis of the rotary output shaft to cause impacts to be applied to a working member of the tool; and a device for intermittently converting rotary movement of the rotary output shaft into movement of at least one the moveable mass to cause the impacts to be applied to the working member.

Owner:BLACK & DECKER INC

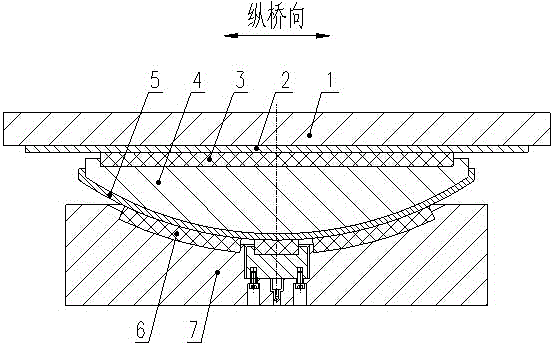

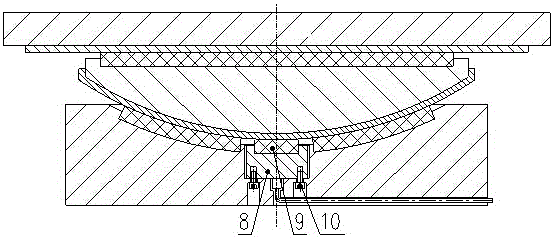

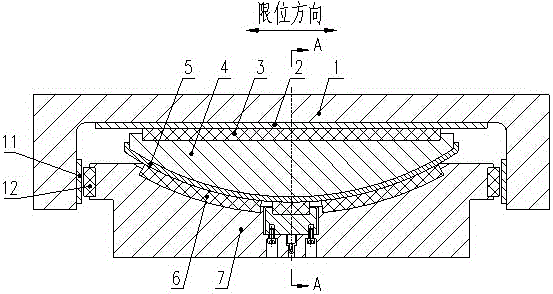

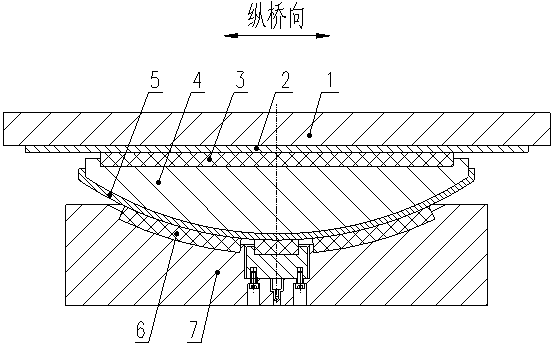

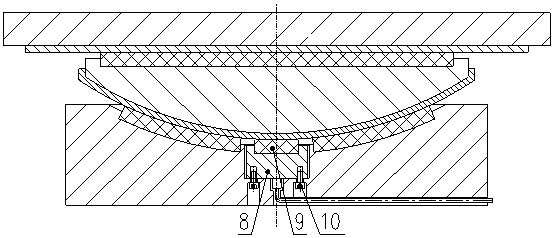

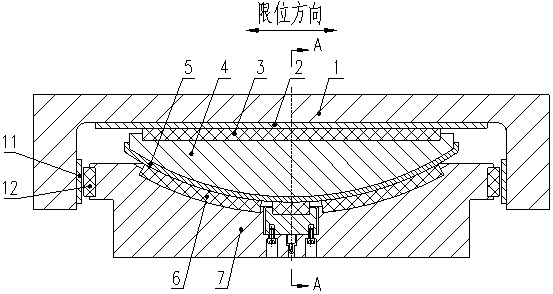

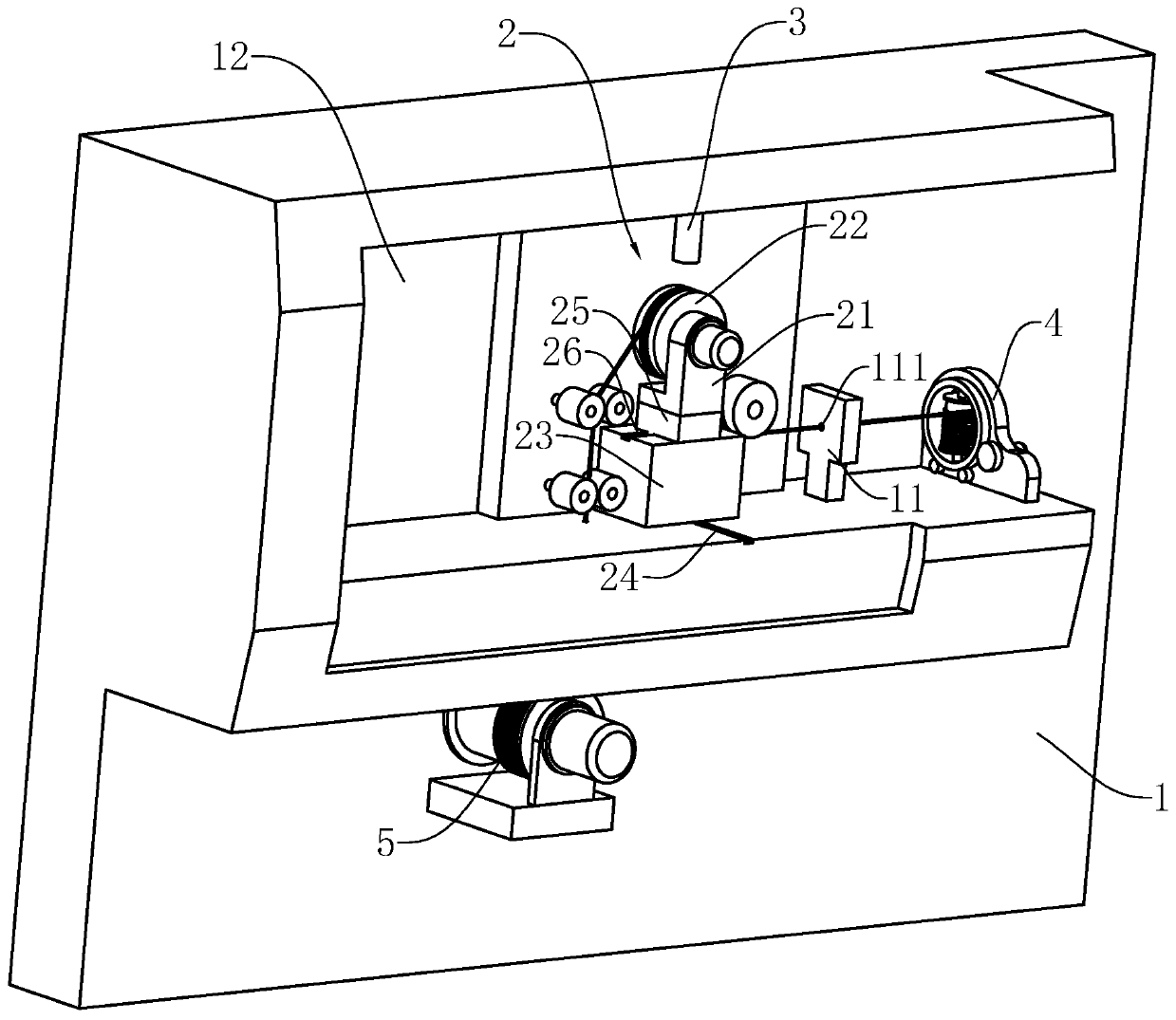

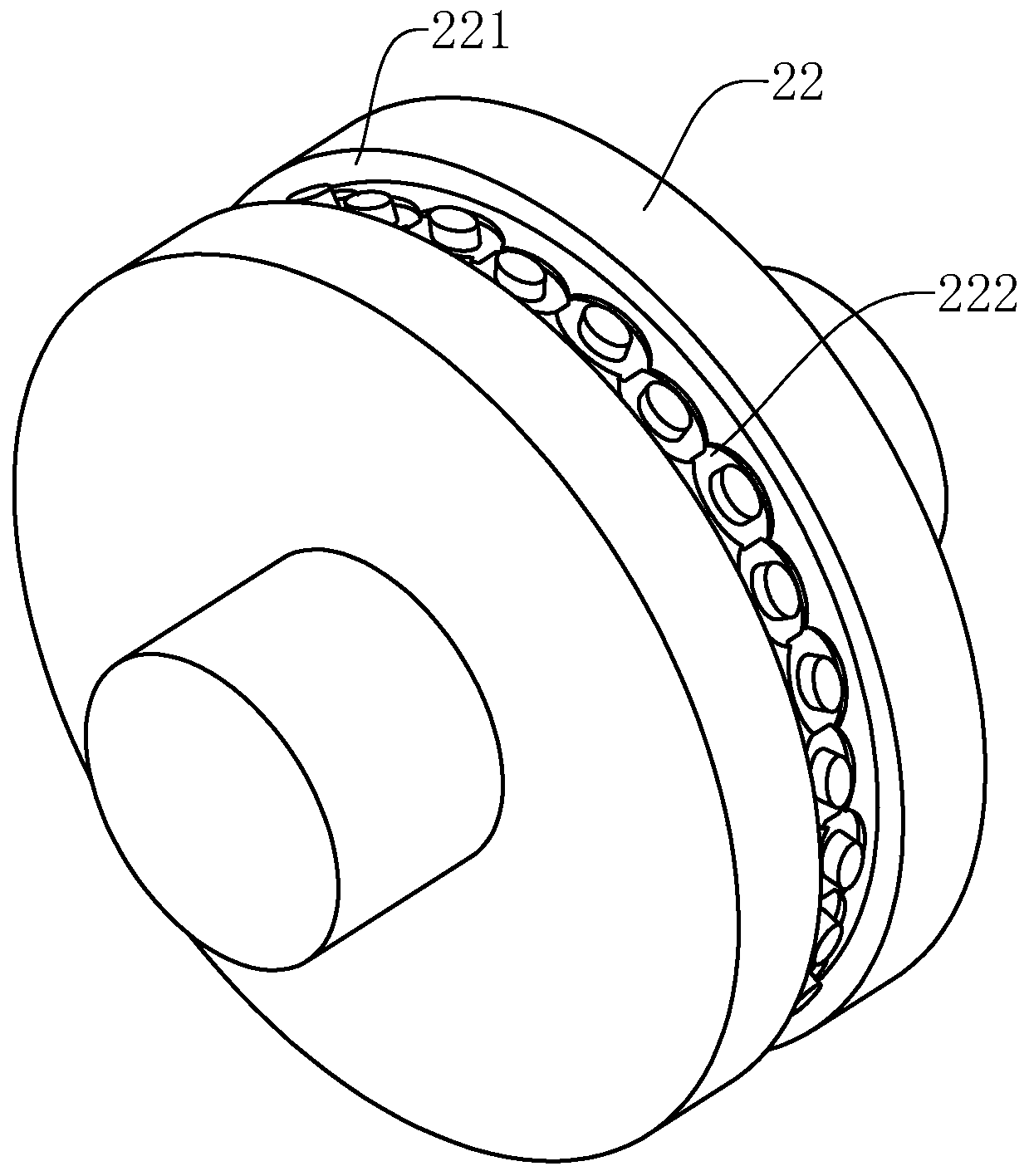

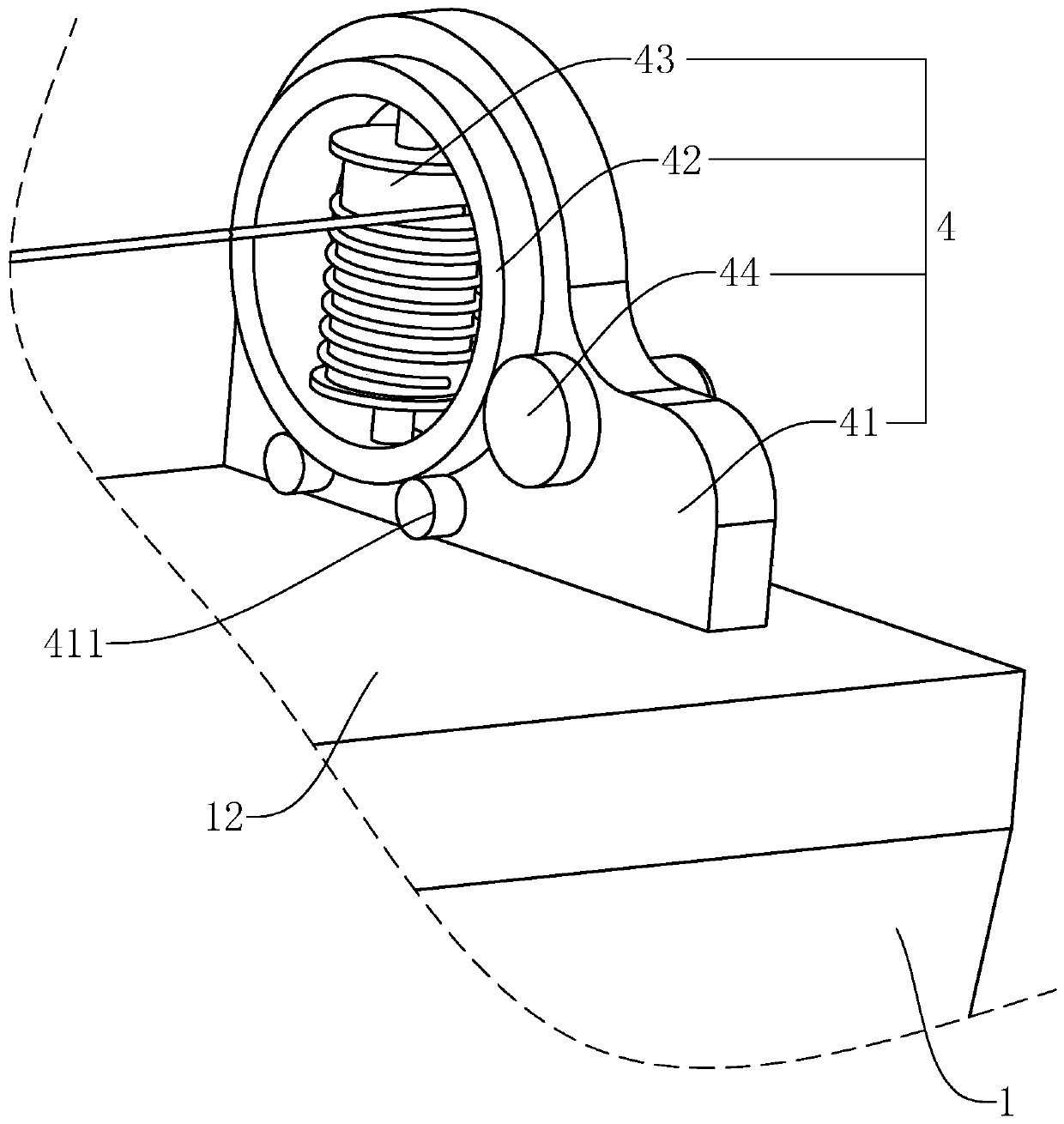

Vertical force measurement type bridge bearing and force measuring method thereof

ActiveCN106192739ARealize the function of vertical force measurementSolve the problem of vertical force measurementBridge structural detailsApparatus for force/torque/work measurementSize increaseEngineering

The invention relates to a vertical force measurement bridge bearing and a force measuring method thereof. Through measurement and whole demarcation of local stress, the whole stress of the bearing is determined. The bridge bearing is simple in structure, size increase and weight increase are small, force measurement is reliable, the vertical force measurement function of the bridge bearing can be realized, the vertical force measurement difficult problem of the bearing is solved, and technical support is provided for bridge monitoring.

Owner:LUOYANG SUNRUI SPECIAL EQUIP

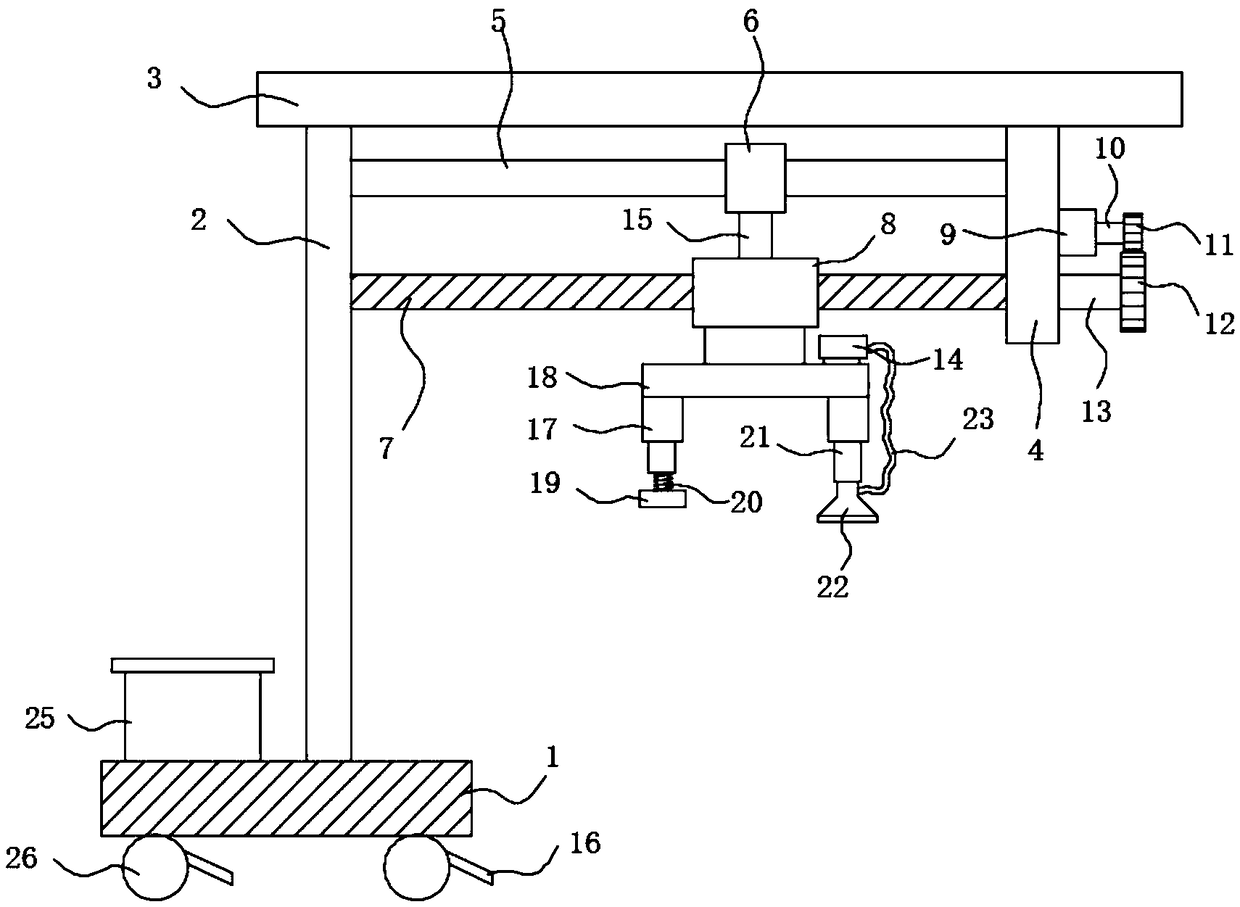

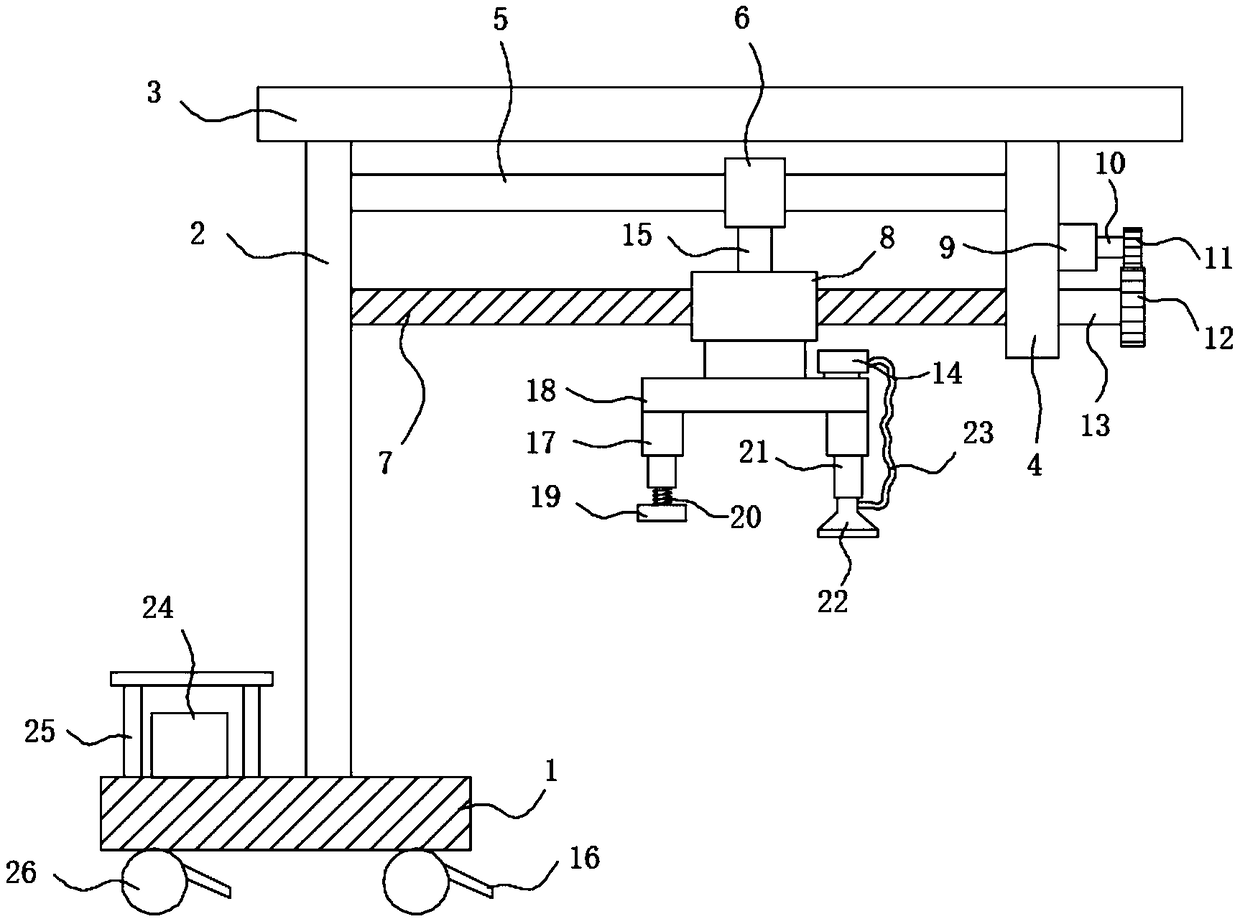

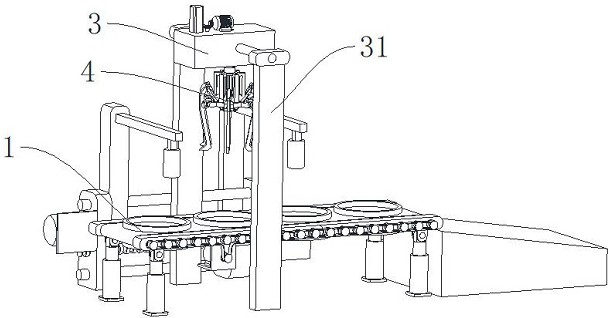

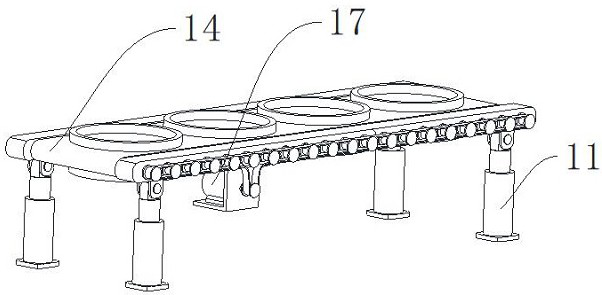

Auxiliary brick paving device used for building construction

InactiveCN108894478AFit tightlyAvoid uneven fitBuilding constructionsBrake padArchitectural engineering

The invention discloses an auxiliary brick paving device used for building construction. The auxiliary brick paving device comprises a base and wheels on the base, brake pads are installed on the wheels, a platform plate is arranged above the base, the platform plate is fixedly connected with the base through a supporting plate, and an installation block is fixedly connected with the side, away from the supporting plate, of the platform plate. A screw is rotationally connected between the installation block and the supporting plate, the screw is sleeved with a threaded block through a thread,the threaded block is connected with the supporting plate and the installation block through a guide mechanism, the installation block is fixedly connected with a servo motor which is connected with the screw through a reducing mechanism, the reducing mechanism comprises a first rotary shaft which is fixedly installed at the output end of the servo motor, and a first gear is fixedly installed on the first rotary shaft. The auxiliary brick paving device is compact in structure, simple in operation, physical output of workers is helped to be reduced, and the paving efficiency is effectively improved.

Owner:黎允仪

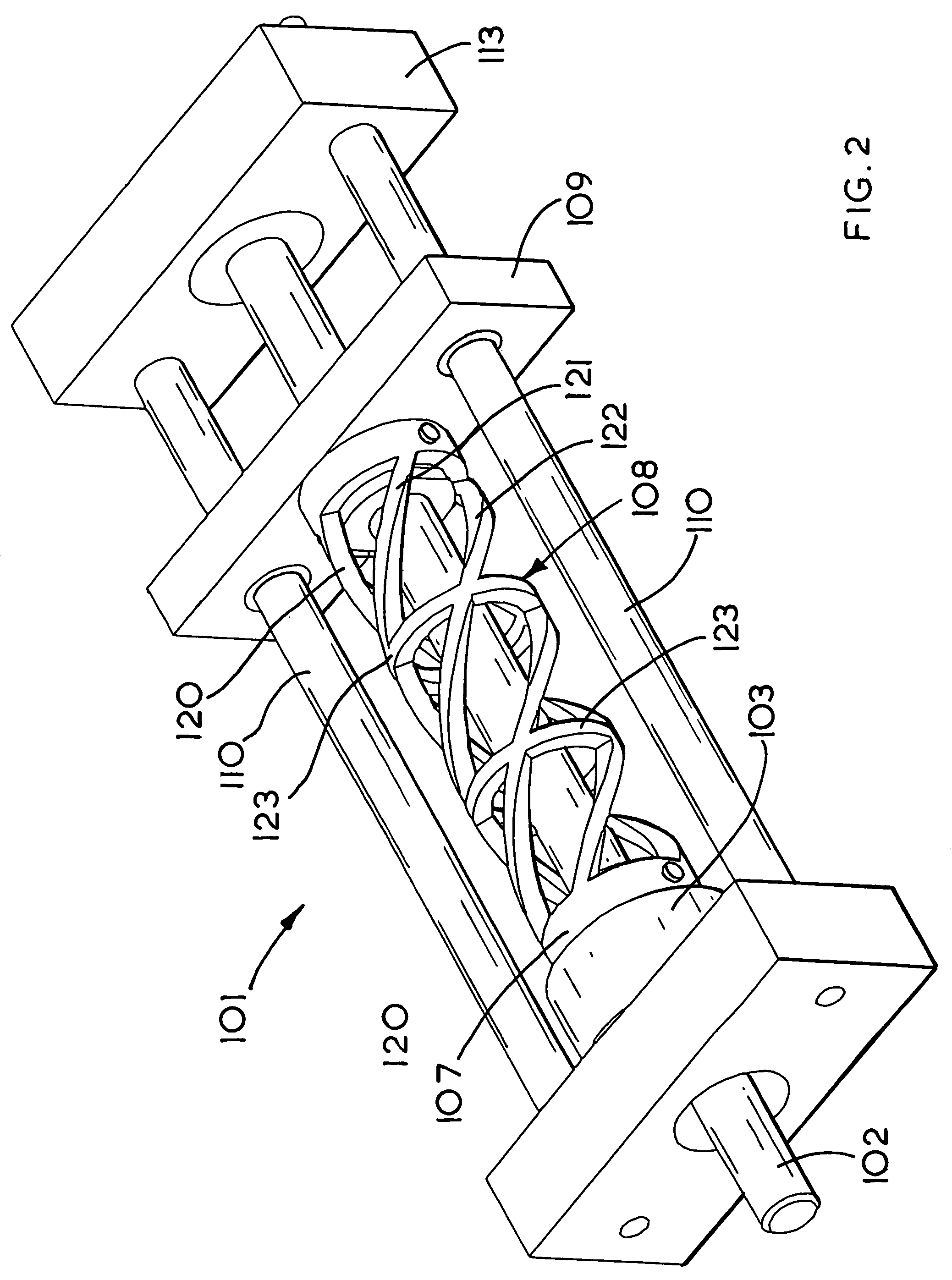

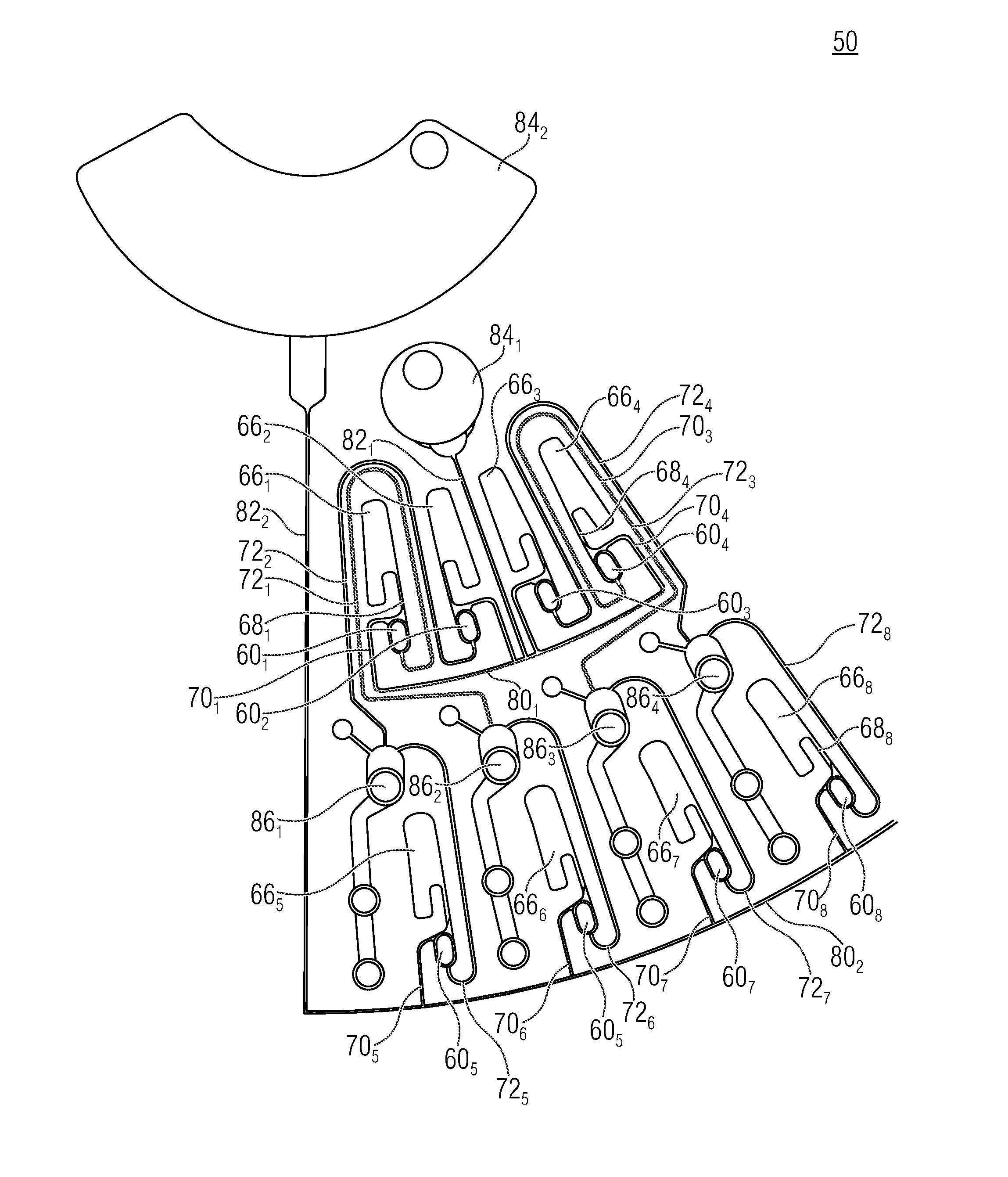

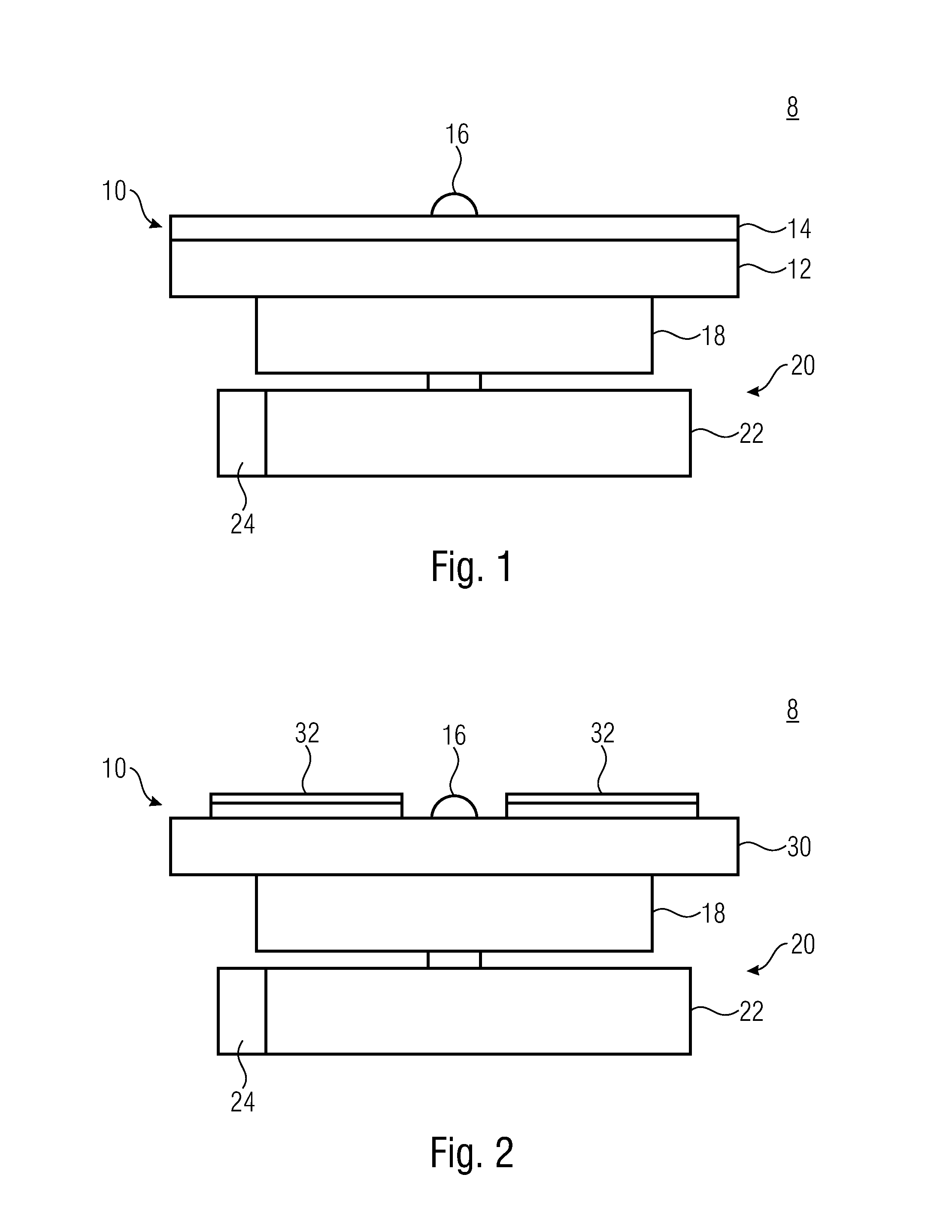

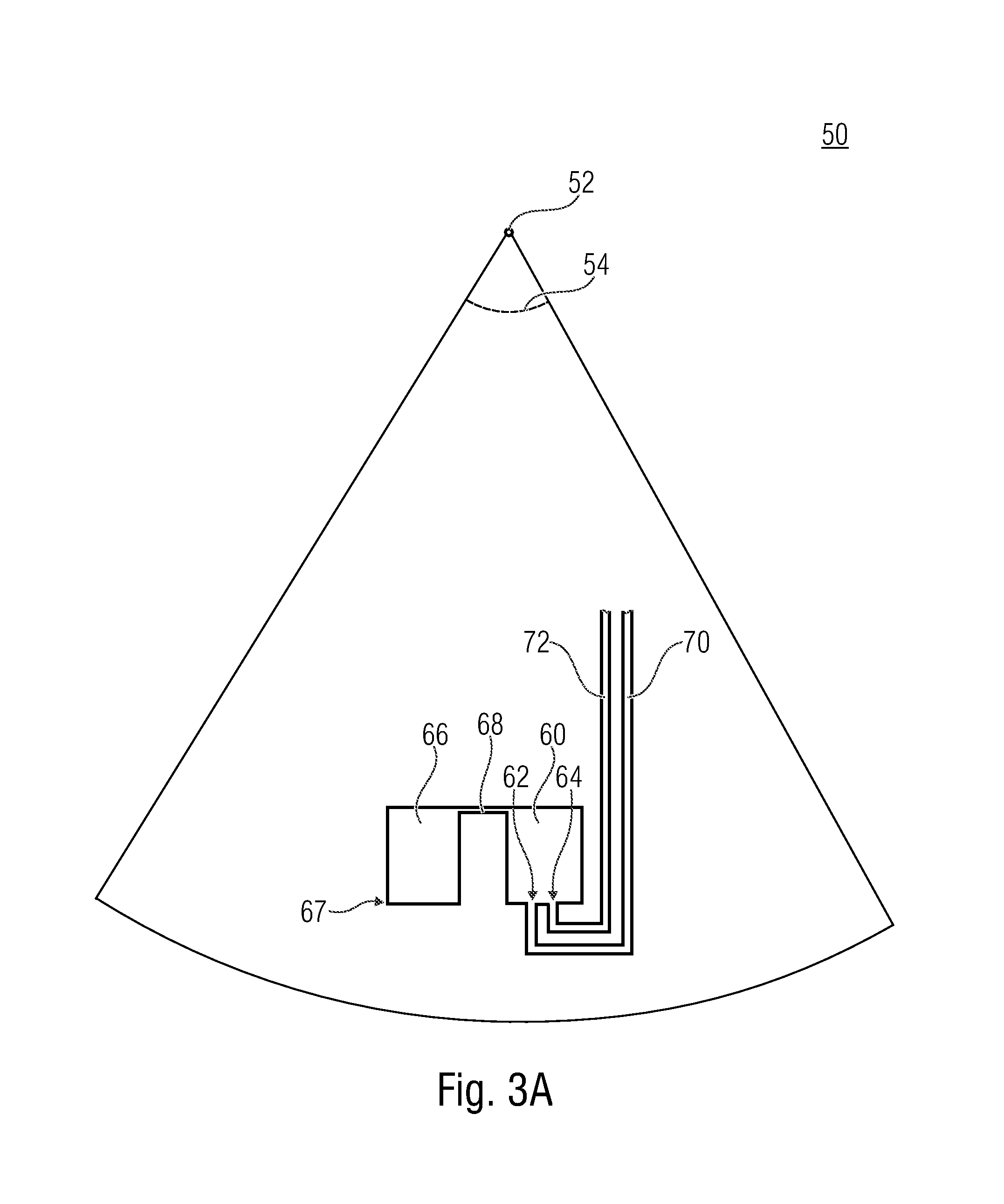

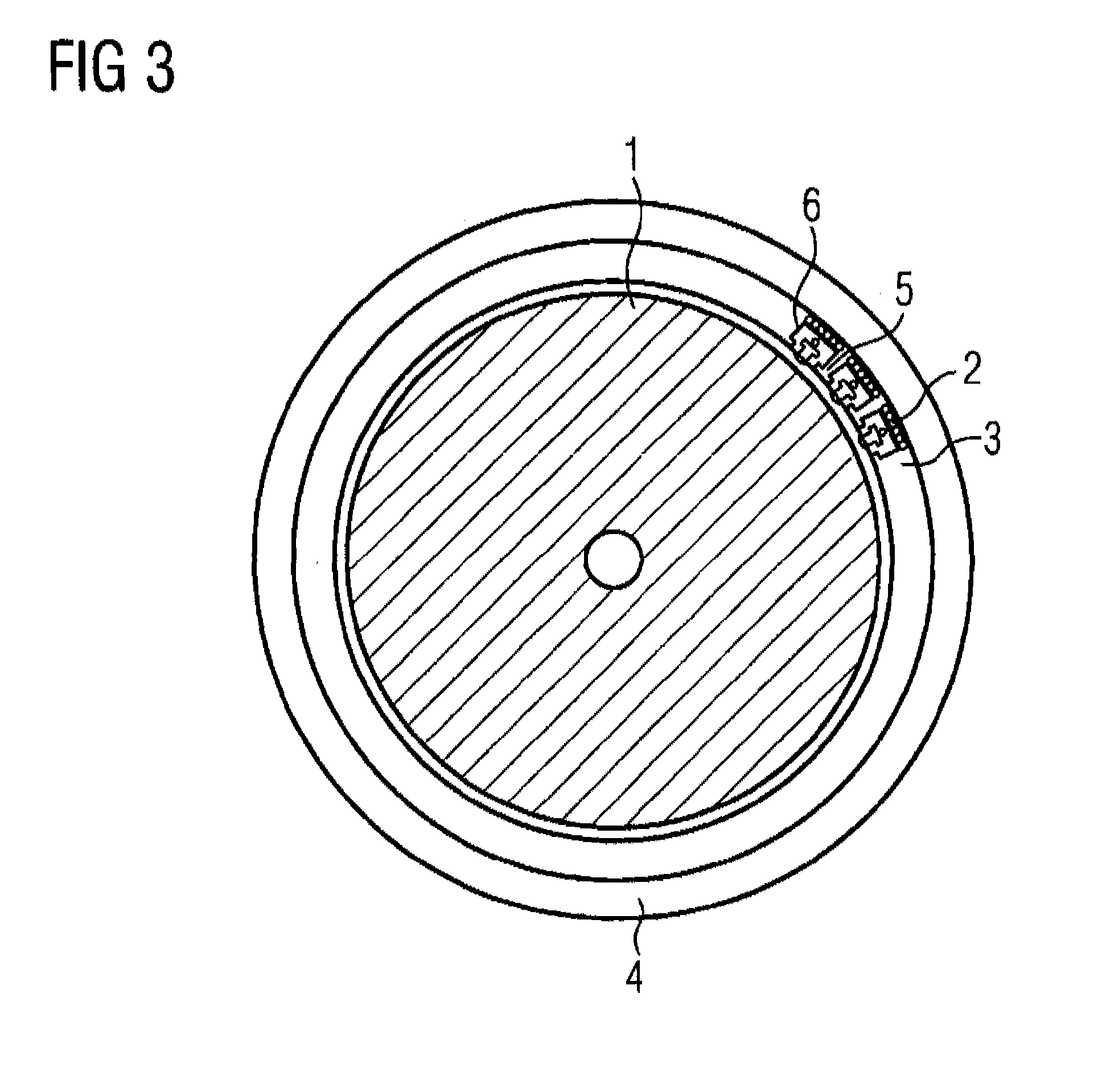

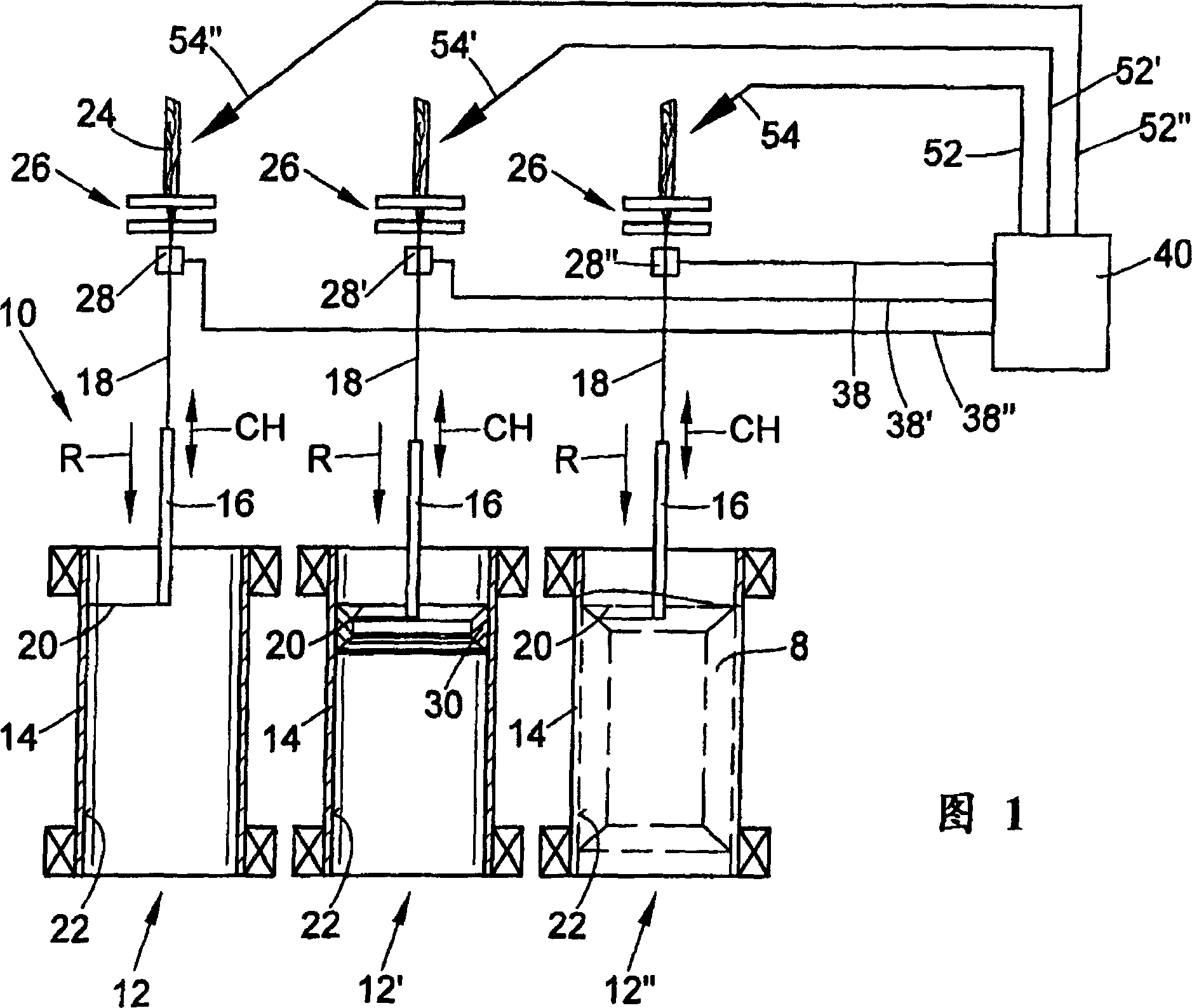

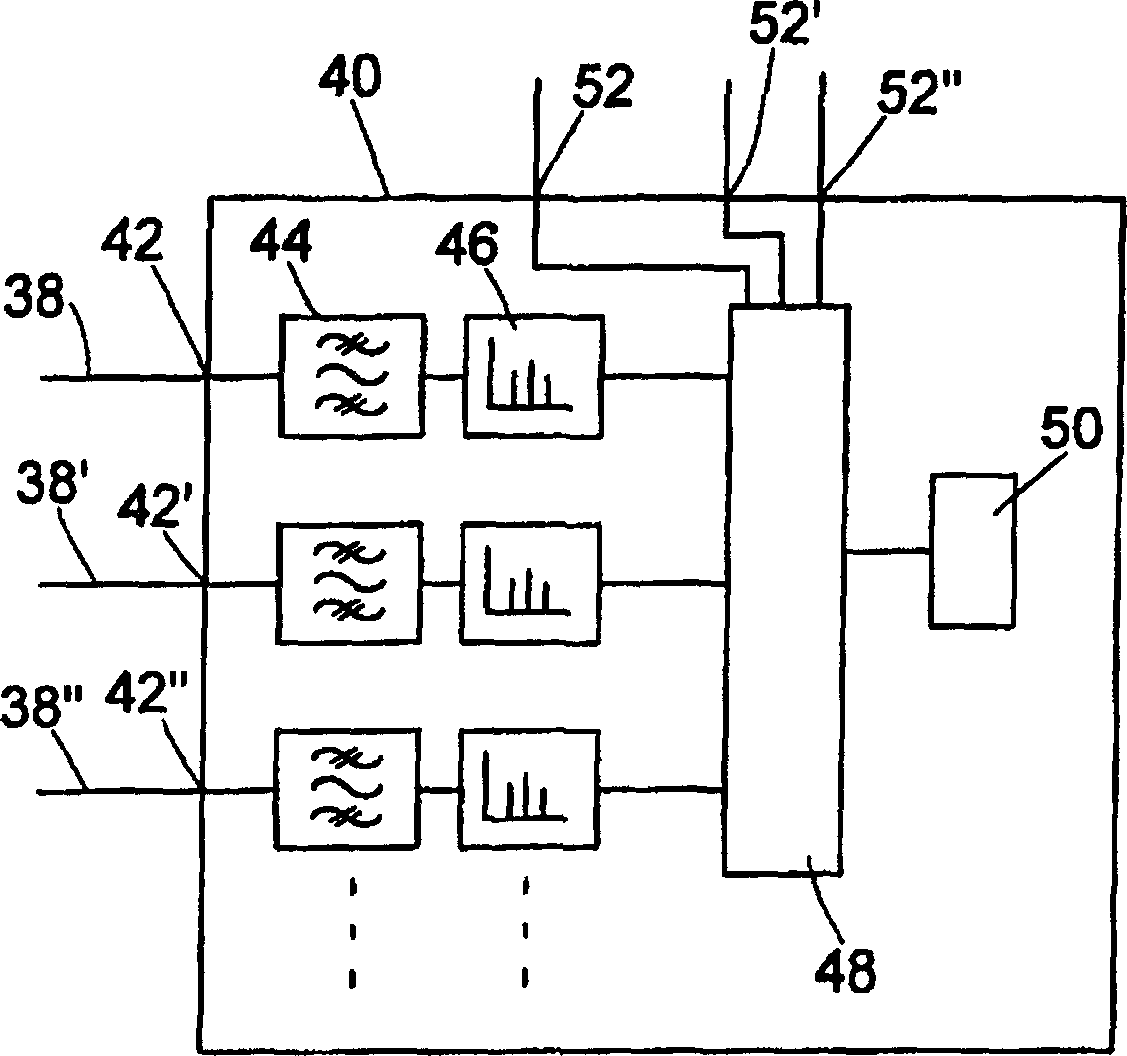

Fluidic Module, Device and Method for Aliquoting a Liquid

ActiveUS20160214104A1Reduce rotation frequencyLaboratory glasswaresFluid controllersInlet channelRotational frequency

A fluidic module includes first and second measuring chambers, first and second fluid inlet channels connected to the first and second measuring chambers, respectively, and first and second fluid outlet channels connected to the first and second measuring chambers, respectively. Upon rotation of the fluidic module about a center of rotation, liquids are centrifugally driven into the first and second measuring chambers via the first and second fluid inlet channels, respectively, so that compressible media previously present within the first and second measuring chambers are compressed by the liquids driven into the first and second measuring chambers, respectively. Upon a reduction of the rotational frequency and upon an expansion, resulting therefrom, of the compressible media, the liquids present within the first and second measuring chambers are driven out of same via the first and second fluid outlet channels, respectively.

Owner:HAHN SCHICKARD GESELLSCHAFT FUER ANGEWANDTE FORSCHUNG EV

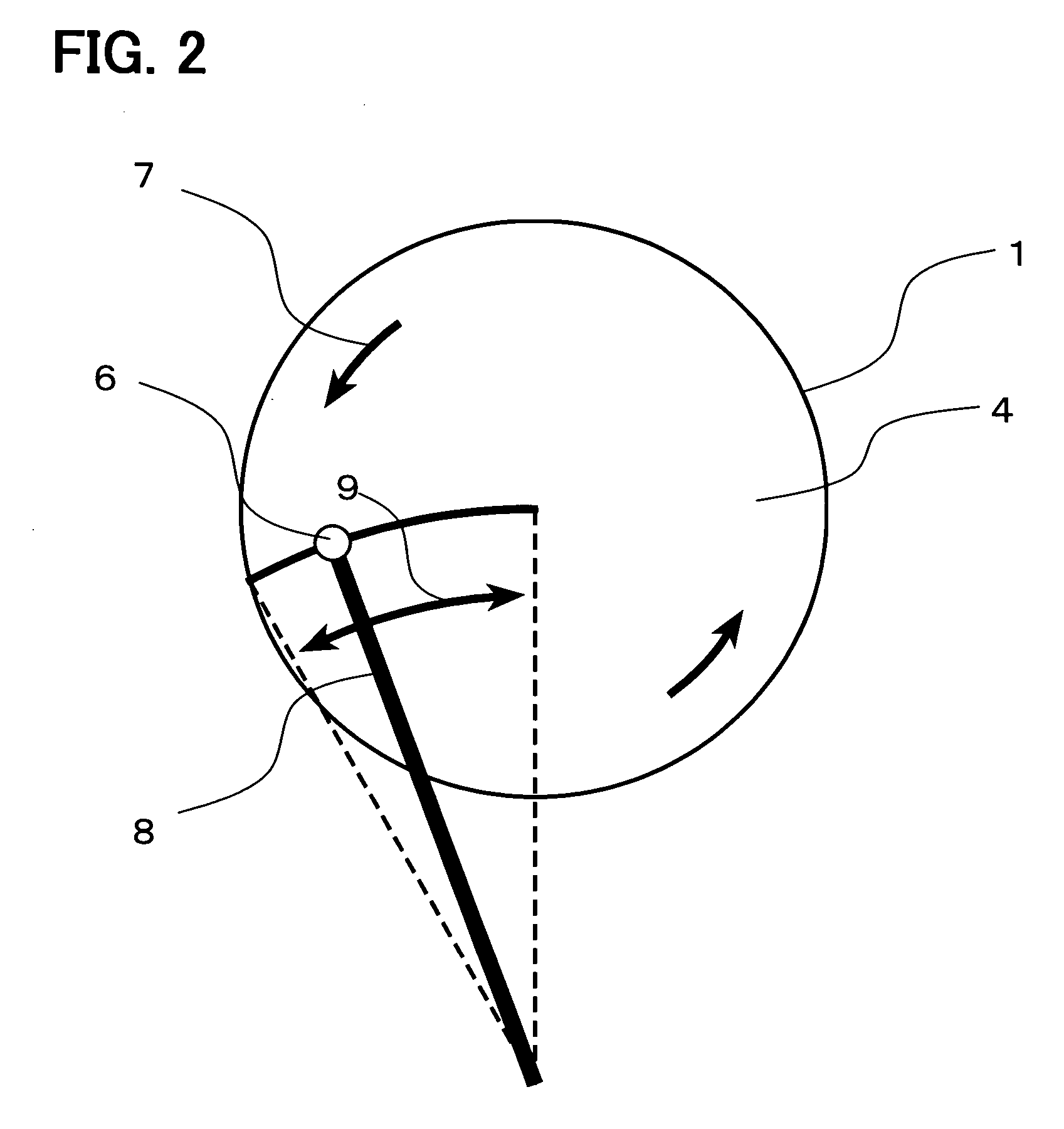

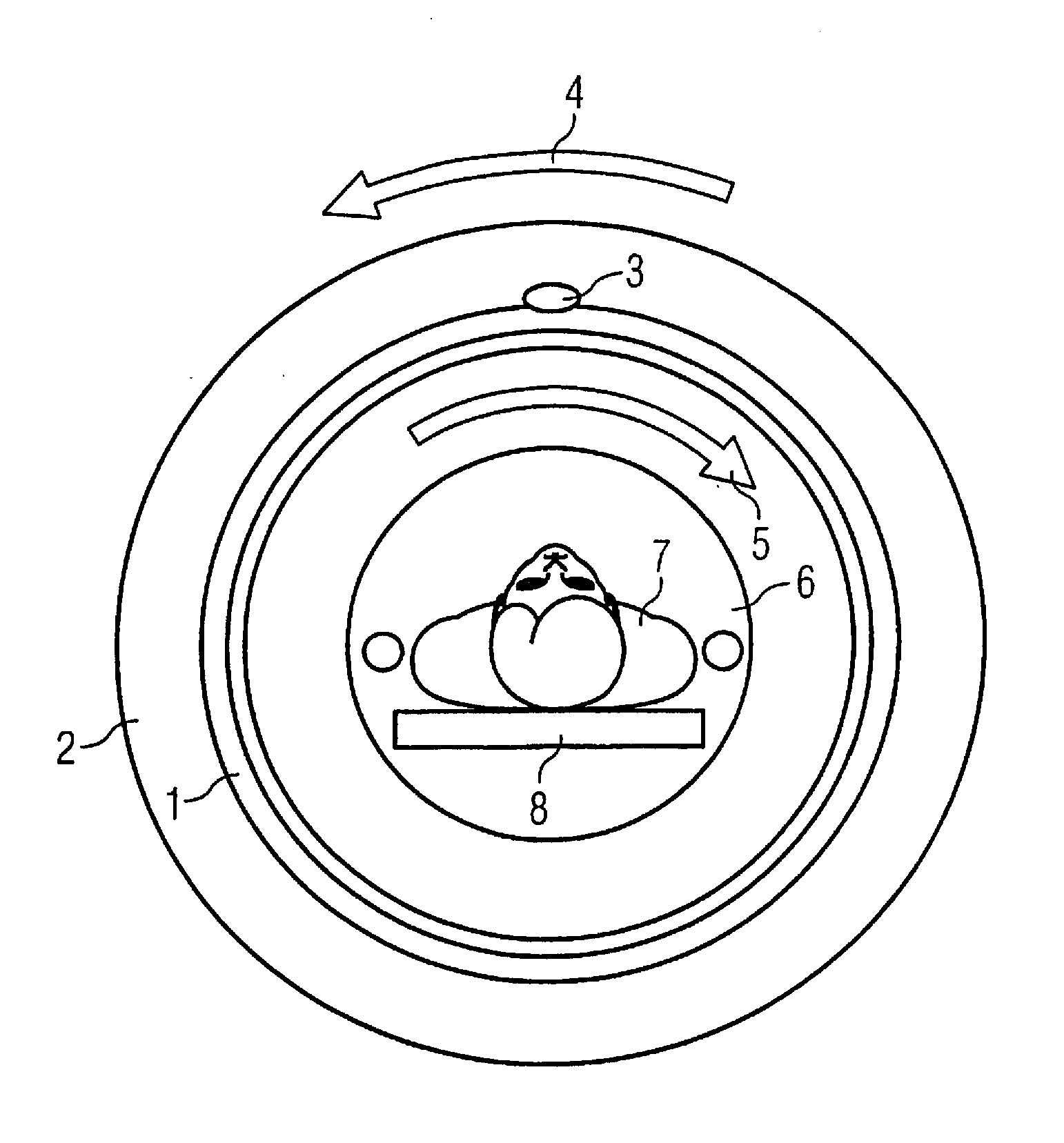

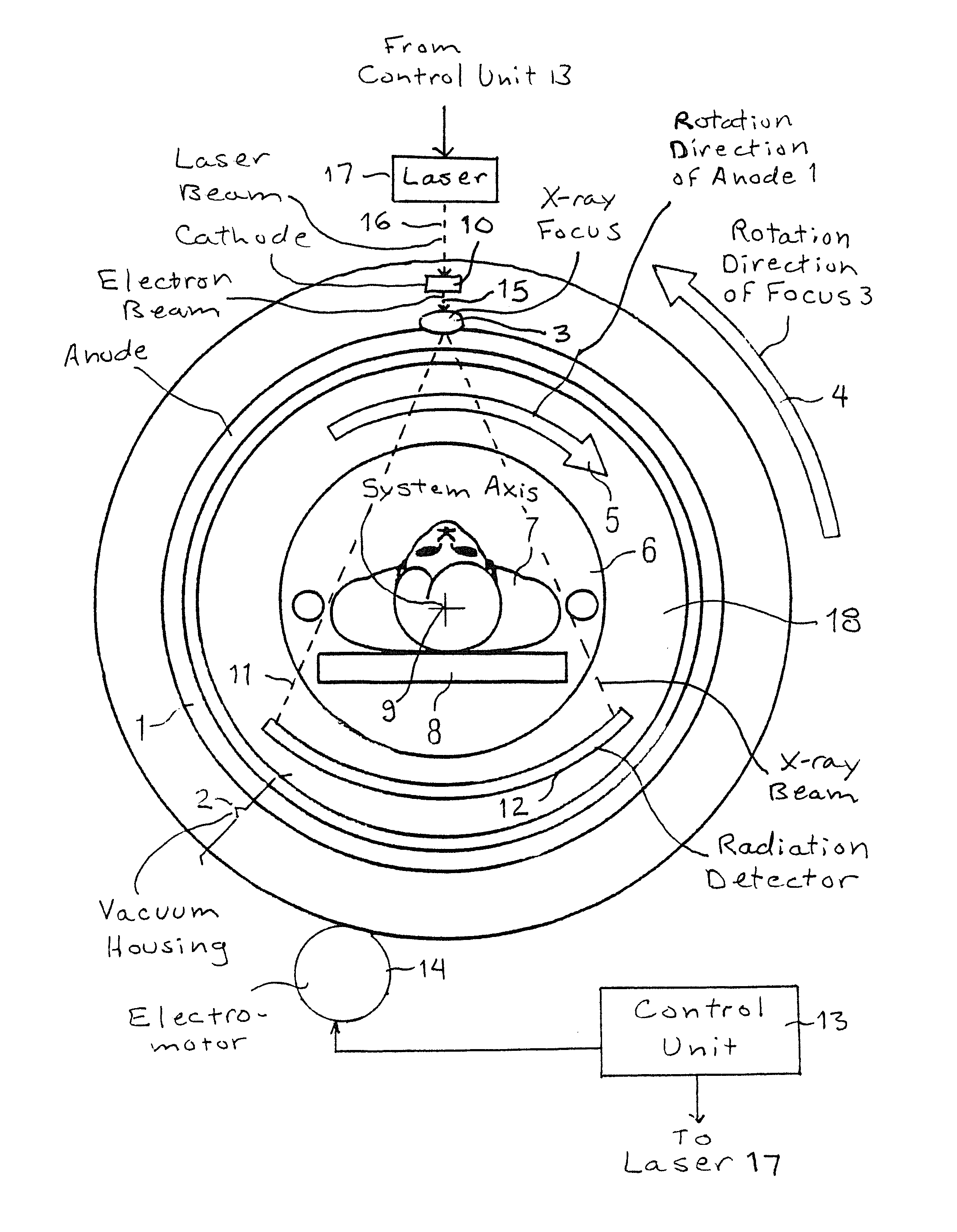

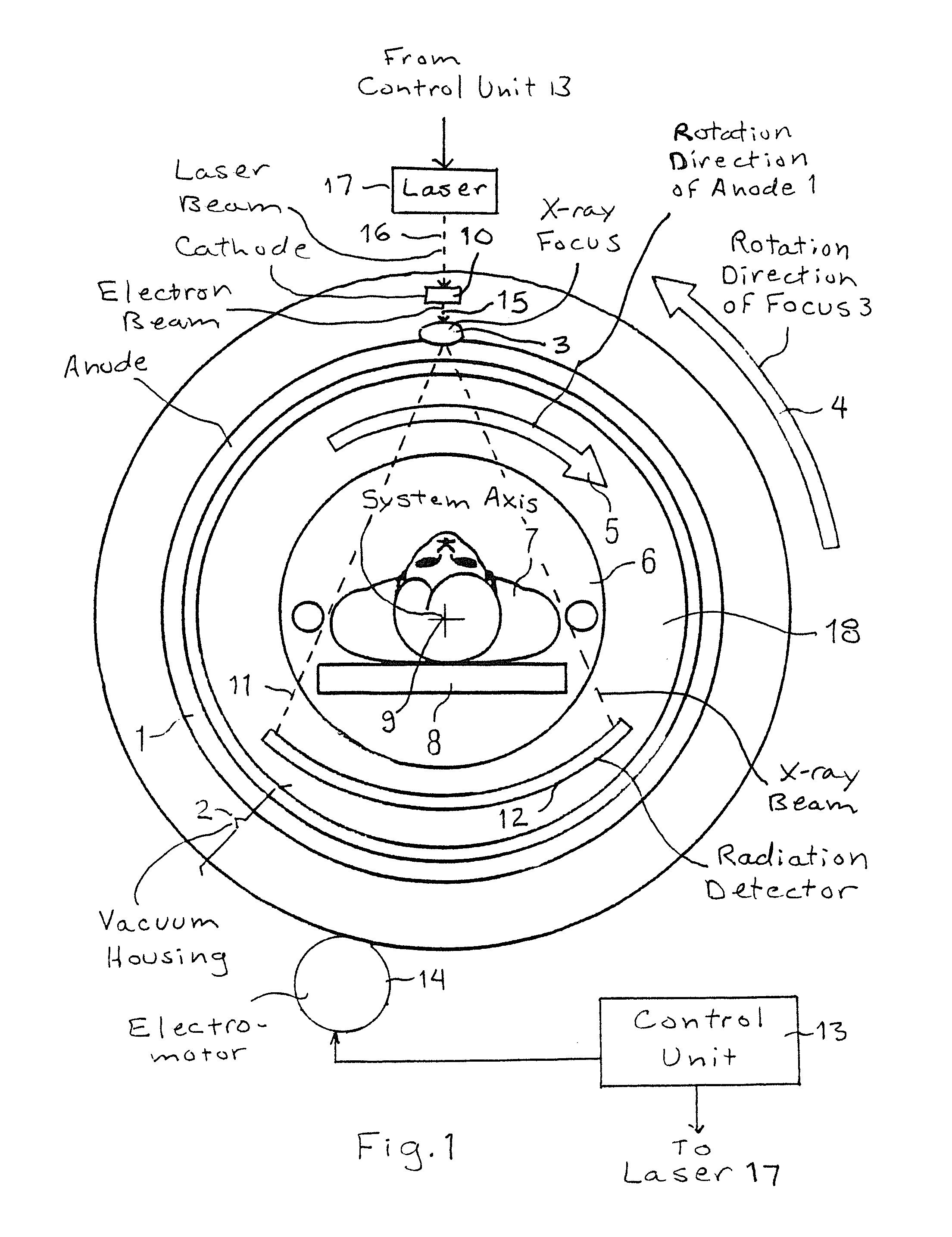

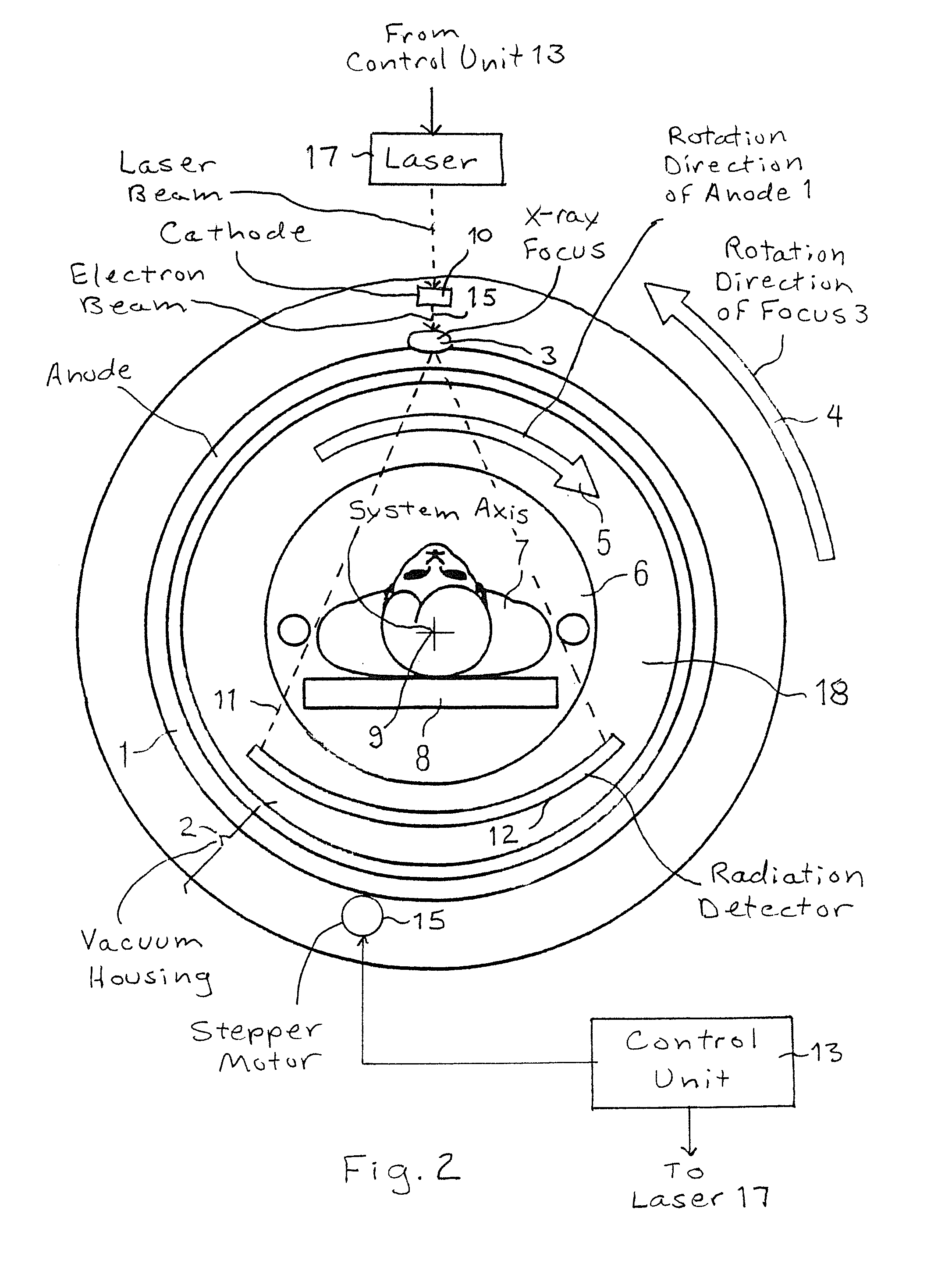

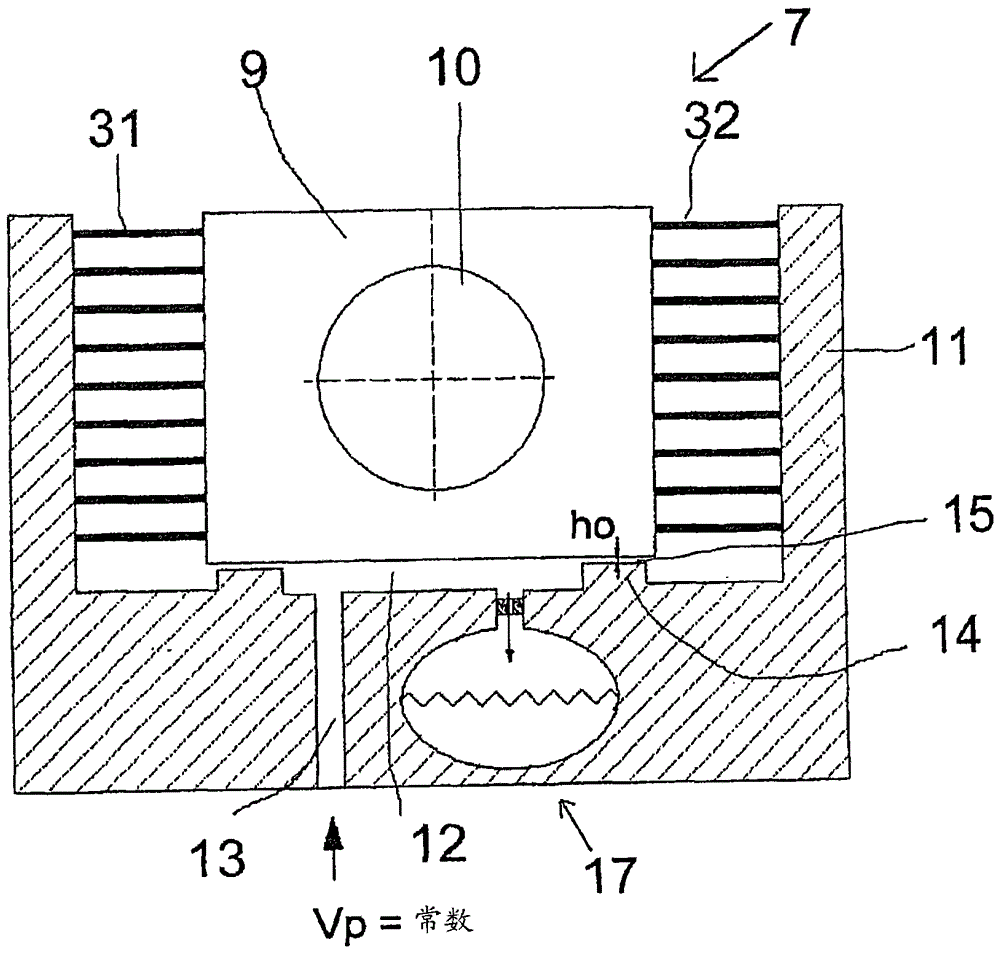

X-ray computed tomography apparatus

InactiveUS20100020918A1Increased x-ray powerReduce disadvantagesMaterial analysis using wave/particle radiationRadiation/particle handlingX-rayX ray computed

An x-ray computed tomography apparatus has one anode ring in a vacuum housing surrounding an examination volume, wherein a focus of an x-ray source revolves on the anode ring to expose the examination volume with an x-ray beam from different directions, and a detector system arranged on a rotating frame that can rotate around a system axis. The detector system serves to detect the x-ray radiation exiting from the examination volume, wherein the detector system and the focus can rotate around the system axis synchronously and in the same rotation direction with a rotation angle offset by 180°. The apparatus also includes a computer to process the measurement values acquired by the detector system. The anode ring can be driven such that it rotates around the system axis, and the rotation direction of the anode ring and the rotation direction of the focus around the system axis are opposite while a rotation of the focus around the system axis ensues.

Owner:SIEMENS AG

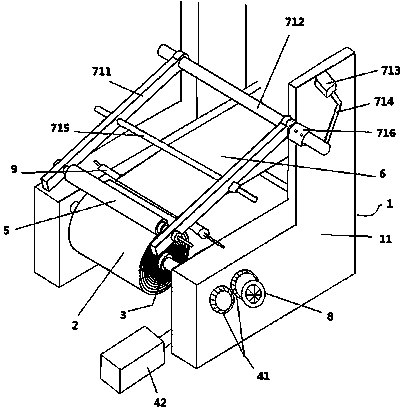

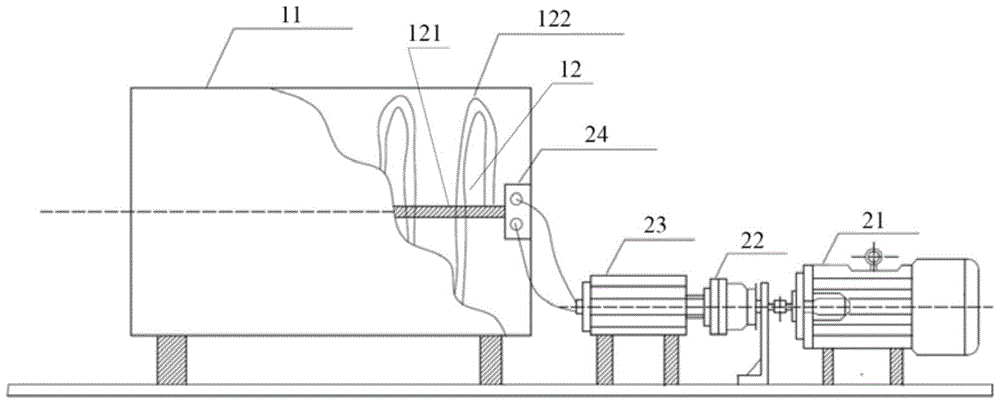

Thin film winding machine

PendingCN107628457AThere will be no problem of unevennessRewinding speed remains constantWebs handlingWinding machineThin membrane

The invention discloses a thin film winding machine which comprises a winding machine rack. The rack comprises a rack base and rack walls erected on the two sides of the rack base. The thin film winding machine further comprises a winding drum erected between the rack walls. The winding drum is rotationally connected to the rack walls on the two sides through a rotary shaft. The winding drum is connected with a winding drum drive device. The drive device comprises a chain wheel set connected with the rotary shaft and a motor used for driving the chain wheel set to rotate. A movable pressure roller is arranged on the outer side of the winding drum and is parallel to the winding drum. The pressure roller makes contact with thin film on the winding drum and is connected with an automatic regulating device used for keeping the pressure roller tightly pressing the thin film at constant pressure. The winding drum drive device and the automatic regulating device are electrically connected toa control cabinet at one side of the rack walls. The thin film winding machine provided by the invention is orderly in thin film winding and high in winding efficiency.

Owner:昆山御龙包装器材有限公司

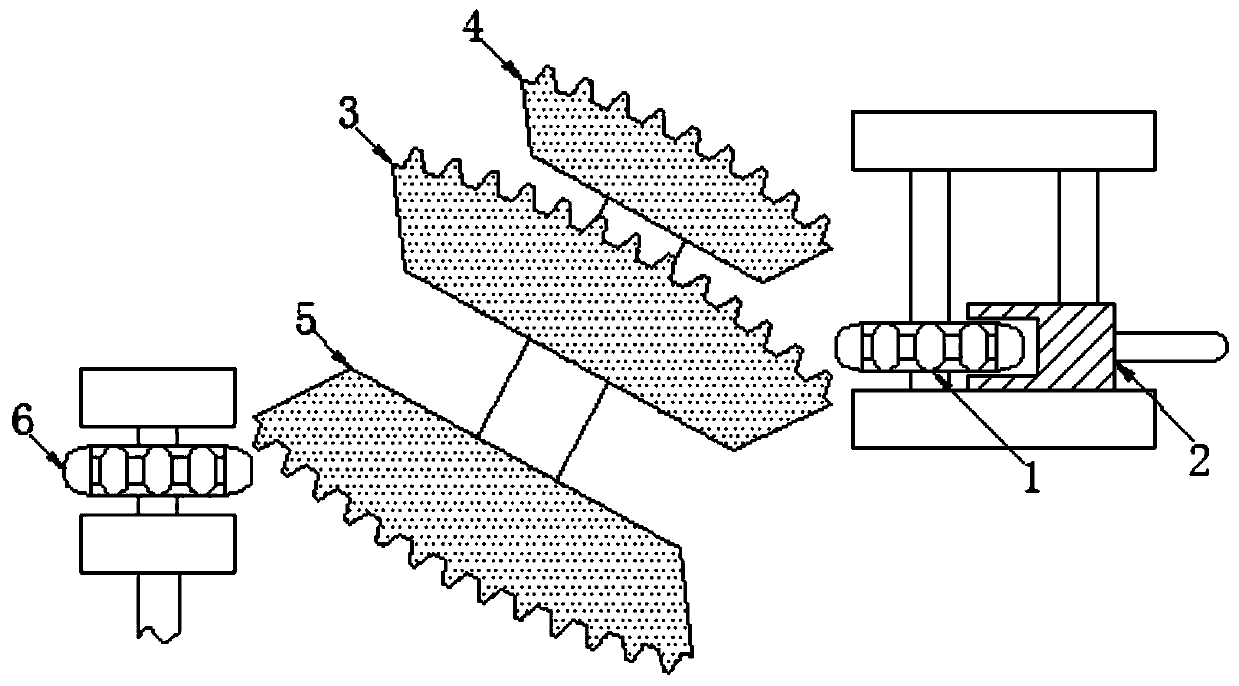

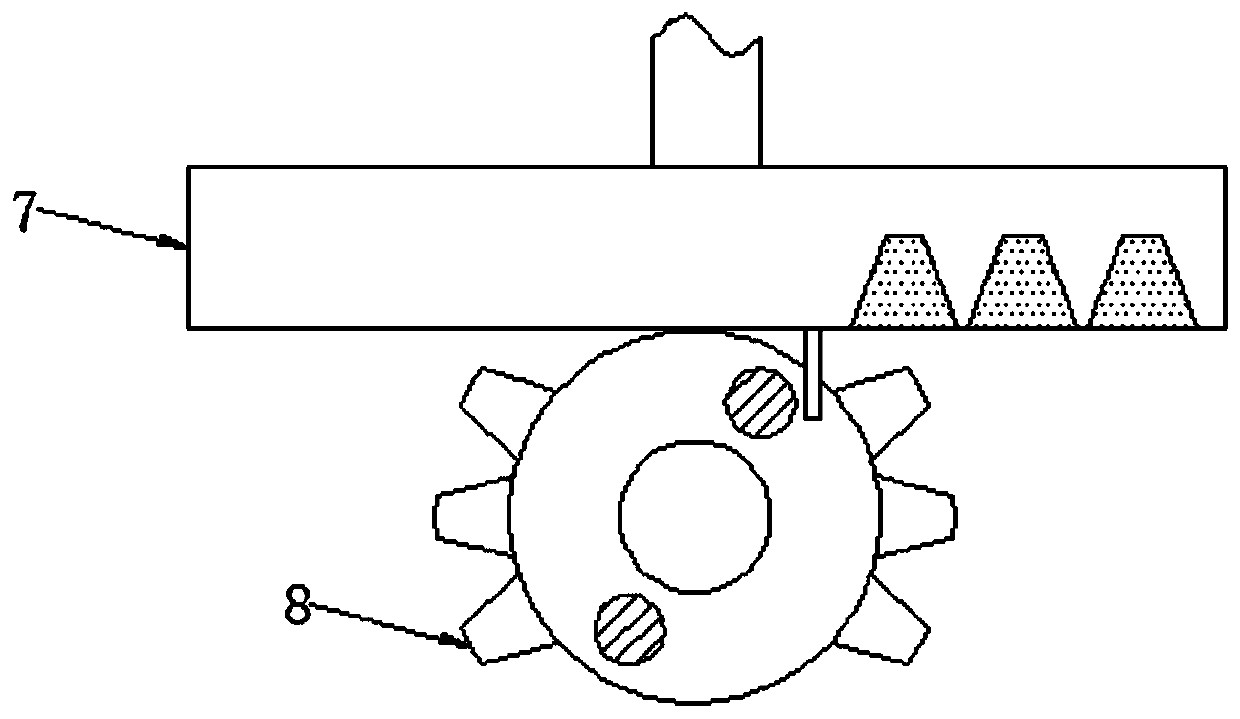

Crop fertilizing device capable of adjusting discharge amount by controlling opening and closing frequency

ActiveCN110663330AReduce rotation frequencyEasy to controlFertiliser distributersGear wheelAgricultural engineering

The invention relates to the technical field of agricultural equipment, and discloses a crop fertilizing device capable of adjusting the discharge amount by controlling the opening and closing frequency. The crop fertilizing device comprises a first gear. A clamping rod is movably connected to the outer side of the first gear. The first gear rotates to enable a second cone pulley to rotate intermittently by 180 degrees, and the clamping rod moves upwards to enable the first gear to be meshed with a second rotating plate. The rotating frequency of the second cone pulley is reduced as the sizesof a first rotating plate and the second rotating plate are different, and subsequent control of the fertilizer discharge amount is benefited, so that the discharge amount is regulated, and linkage between structures is improved. A fifth rotating plate rotates, a long shaft of the fifth rotating plate is close to a left protruded column of a moving rod, the fifth rotating plate pushes the moving rod to move leftwards, a stop plate is enabled to be away from a discharge outlet, the left protruded column, away from the moving rod, of the long shaft of the fifth rotating plate is close to a rightprotruded column of the fifth rotating plate, the moving rod is driven to move rightwards, and the stop plate moves rightwards and upwards to be close to the discharge outlet. The position of the stop plate is controlled to control discharge conditions, automatic discharge is achieved, and the crop fertilizing device is convenient and rapid to operate.

Owner:ANHUI HUATENG AGRI TECH CO LTD

X-ray CT system having a patient-surrounding, rotatable anode with an oppositely rotatable x-ray focus

InactiveUS8130897B2Increase powerReduce disadvantagesMaterial analysis using wave/particle radiationRadiation/particle handlingX-rayX ray computed

An x-ray computed tomography apparatus has one anode ring in a vacuum housing surrounding an examination volume, wherein a focus of an x-ray source revolves on the anode ring to expose the examination volume with an x-ray beam from different directions, and a detector system arranged on a rotating frame that can rotate around a system axis. The detector system serves to detect the x-ray radiation exiting from the examination volume, wherein the detector system and the focus can rotate around the system axis synchronously and in the same rotation direction with a rotation angle offset by 180°. The apparatus also includes a computer to process the measurement values acquired by the detector system. The anode ring can be driven such that it rotates around the system axis, and the rotation direction of the anode ring and the rotation direction of the focus around the system axis are opposite while a rotation of the focus around the system axis ensues.

Owner:SIEMENS AG

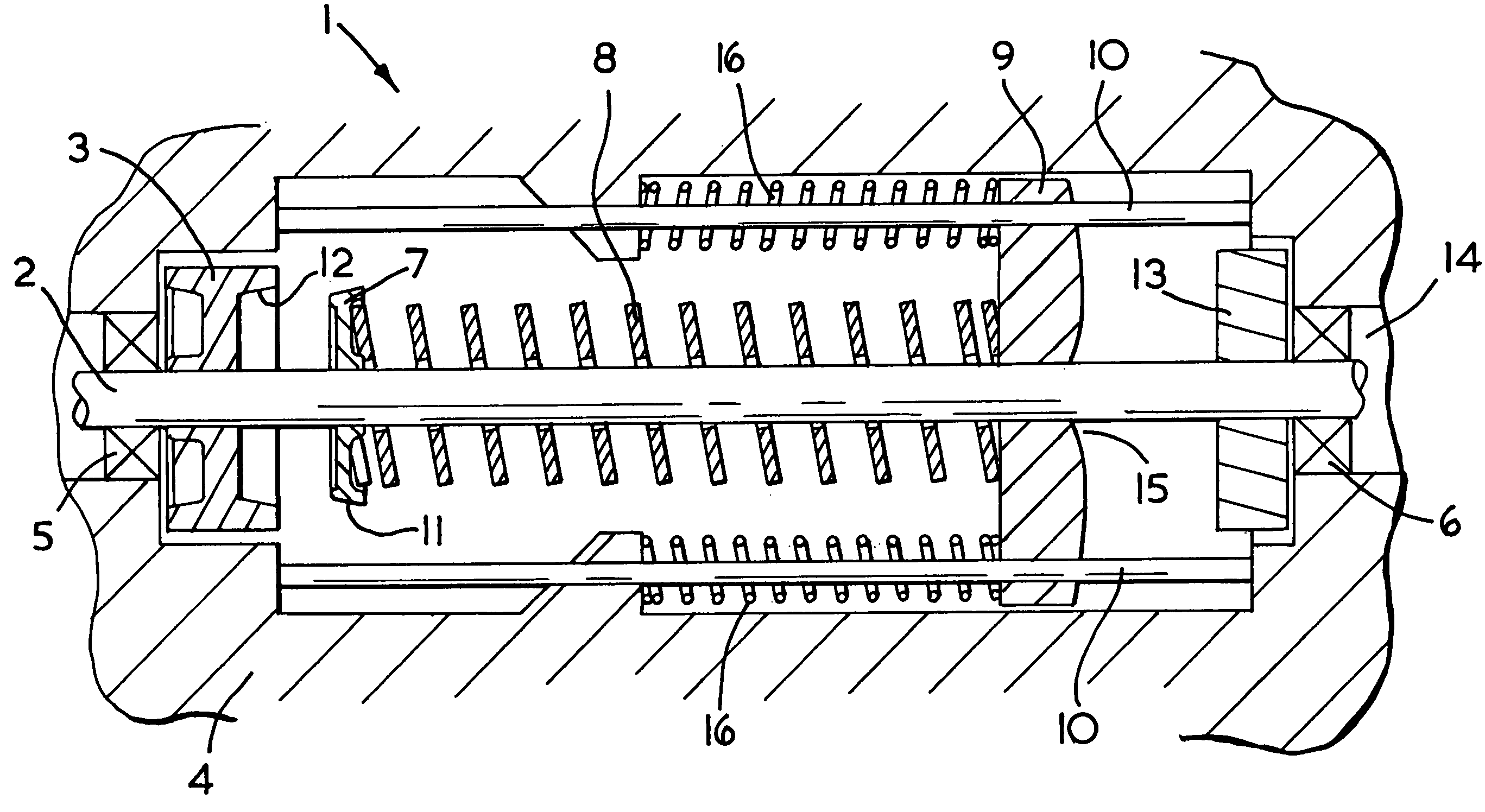

Vacuum turbomolecular pump

ActiveCN101253331AIntrinsic Magnetic DecreaseReduce induced voltageEfficient regulation technologiesPump controlElectric machineStator coil

A vacuum turbomolecular pump (10) is driven by a brushless direct current drive motor (16), which has stator coils and a permanent magnetic-exited motor rotor. When rotating, the motor rotor produces an electromotive force oriented counter to the direction of rotation. A motor controller (22) is provided, which is connected to the stator coils and which generates a current from the supply voltage, this current being impressed into the stator coils. In addition, a rotary frequency regulator (32) is provided that limits the rotary frequency (f) of the drive motor (16) to a nominal rotary frequency (fN). A power supply (20) is provided, which is connected to the motor controller (22) and which supplies a constant direct current voltage as a supply voltage for the motor controller (22).; The power supply (20) is designed so that the constant supply voltage (UV) is low enough that at a limit rotary frequency (fG), the electromotive force is equal to the drive force that can be maximally generated by the motor controller (22) and by the stator coils. The limit rotary frequency (fG) is less than 1.3 times the nominal rotary frequency (fN). As a result, the motor output is limited and the rotary frequency of the drive motor (16) is physically restricted to a limit rotary frequency (fG) in a reliable manner.

Owner:LEYBOLD HERAEUS GMBH & CO KG

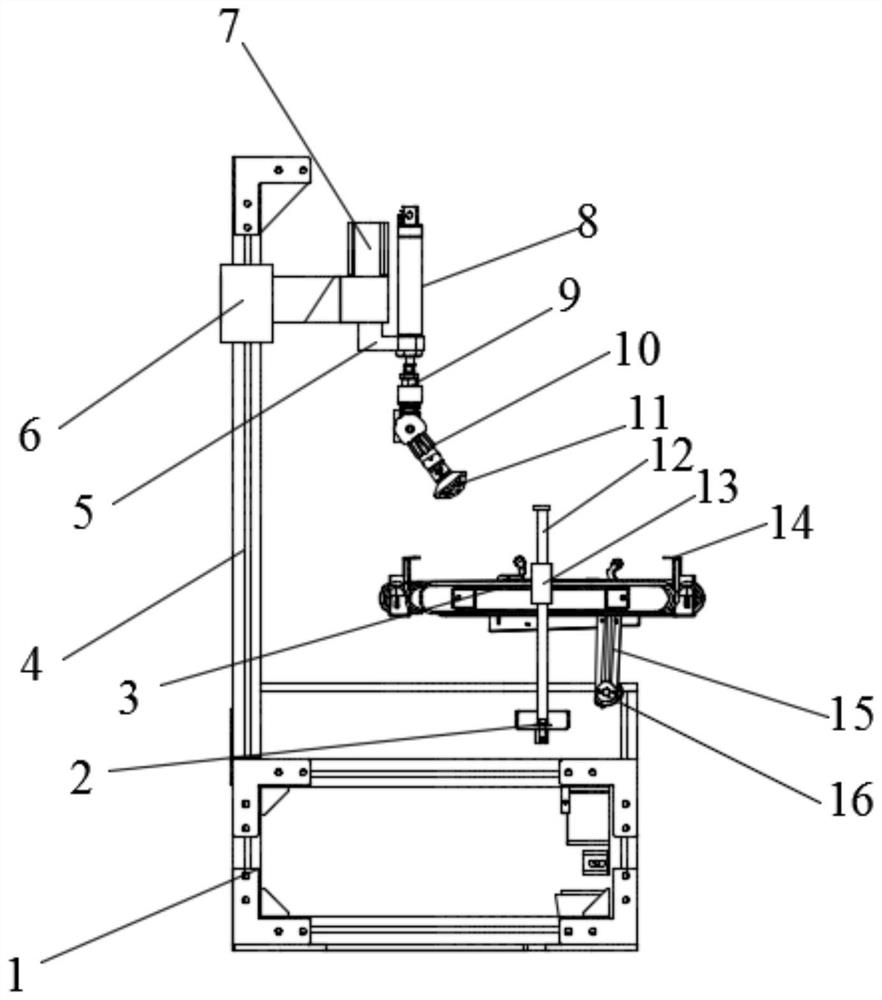

Abrasion resistance testing device for automobile tire

ActiveCN114136825AReal-time temperature monitoringReduce rotation frequencyVehicle tyre testingInvestigating abrasion/wear resistanceMechanical engineeringAutomotive engineering

The invention discloses an automobile tire abrasion resistance testing device, and belongs to the technical field of automobile tire testing, the automobile tire abrasion resistance testing device comprises a conveying device, a speed regulation device, a tire clamping device, an abrasion resistance testing device and a discharging table, the conveying device is arranged on the ground, and the speed regulation device is arranged on the ground and located over the conveying device; the tire clamping device is installed at the bottom of the speed adjusting device, the abrasion resistance testing device is installed on one side of the conveying device, and the discharging table is installed at one end of the conveying device. A batch of casual inspection tires are sequentially conveyed to the position below the tire clamping device through the conveying device, the tire clamping device fixes the to-be-detected tires, the wear resistance testing device moves to the two sides of the tires, then the tires are controlled by the speed adjusting device to rotate, and the wear resistance of the tires is detected. The rotating speed of the tires of different sizes is adjusted through the speed adjusting device, the tires are conveyed to the discharging table through the conveying device after testing is completed, and detection personnel measure the outer ring diameter change of the tires so as to judge whether the abrasion resistance is qualified or not.

Owner:廊坊易砚领创科技有限公司

A vertical force-measuring bridge bearing and its force-measuring method

ActiveCN106192739BReduce the influence of vertical forceReduce rotation frequencyBridge structural detailsApparatus for force/torque/work measurementSize increaseEngineering

A vertical force-measuring bridge bearing and its force-measuring method, through the measurement of local force and overall calibration, the overall force of the bearing is determined, the structure is simple, the increase in size and weight is small, the force measurement is reliable, and the bridge support can be realized The vertical force measurement function of the support can solve the problem of vertical force measurement of the support and provide technical support for bridge monitoring.

Owner:LUOYANG SUNRUI SPECIAL EQUIP

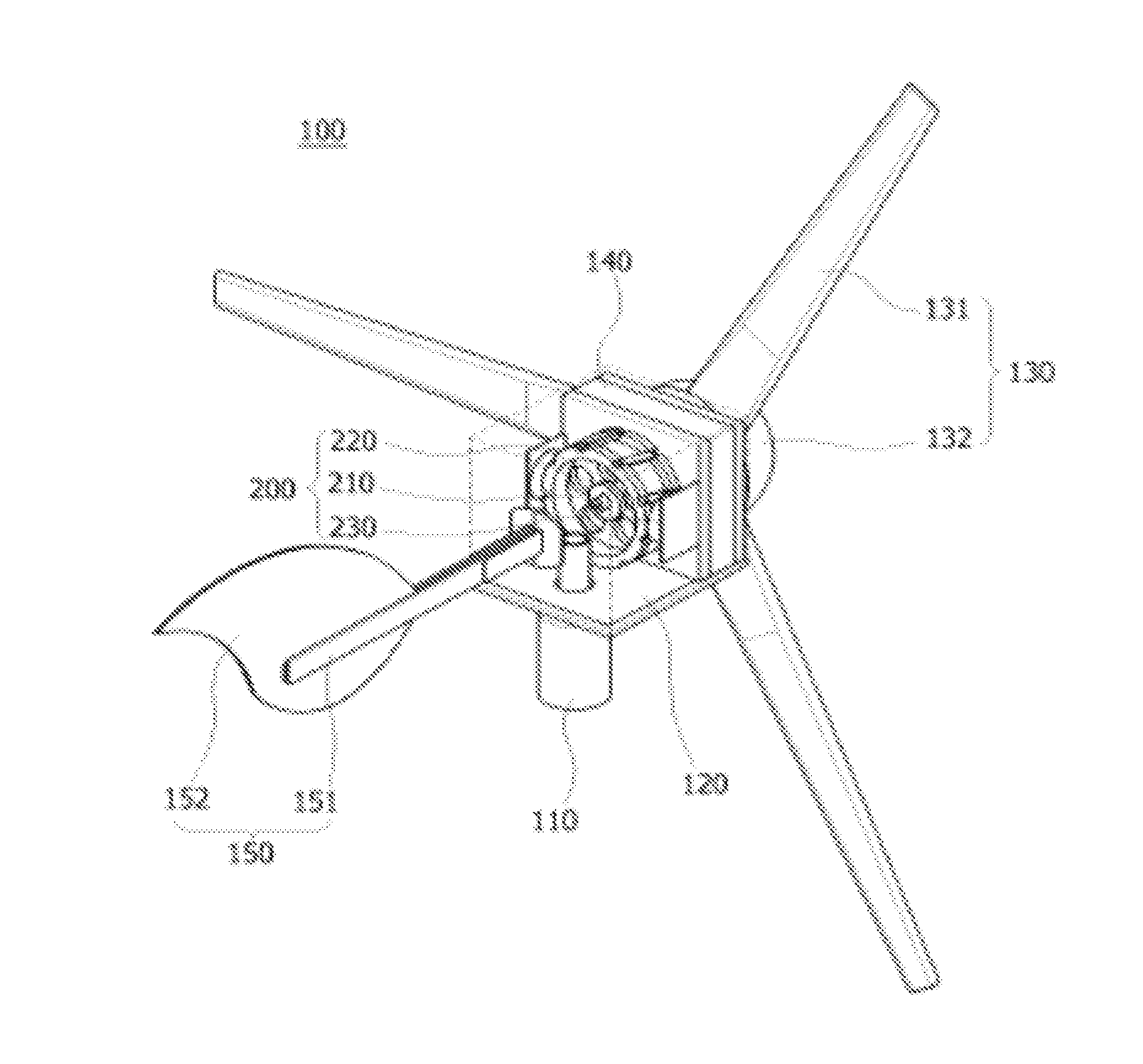

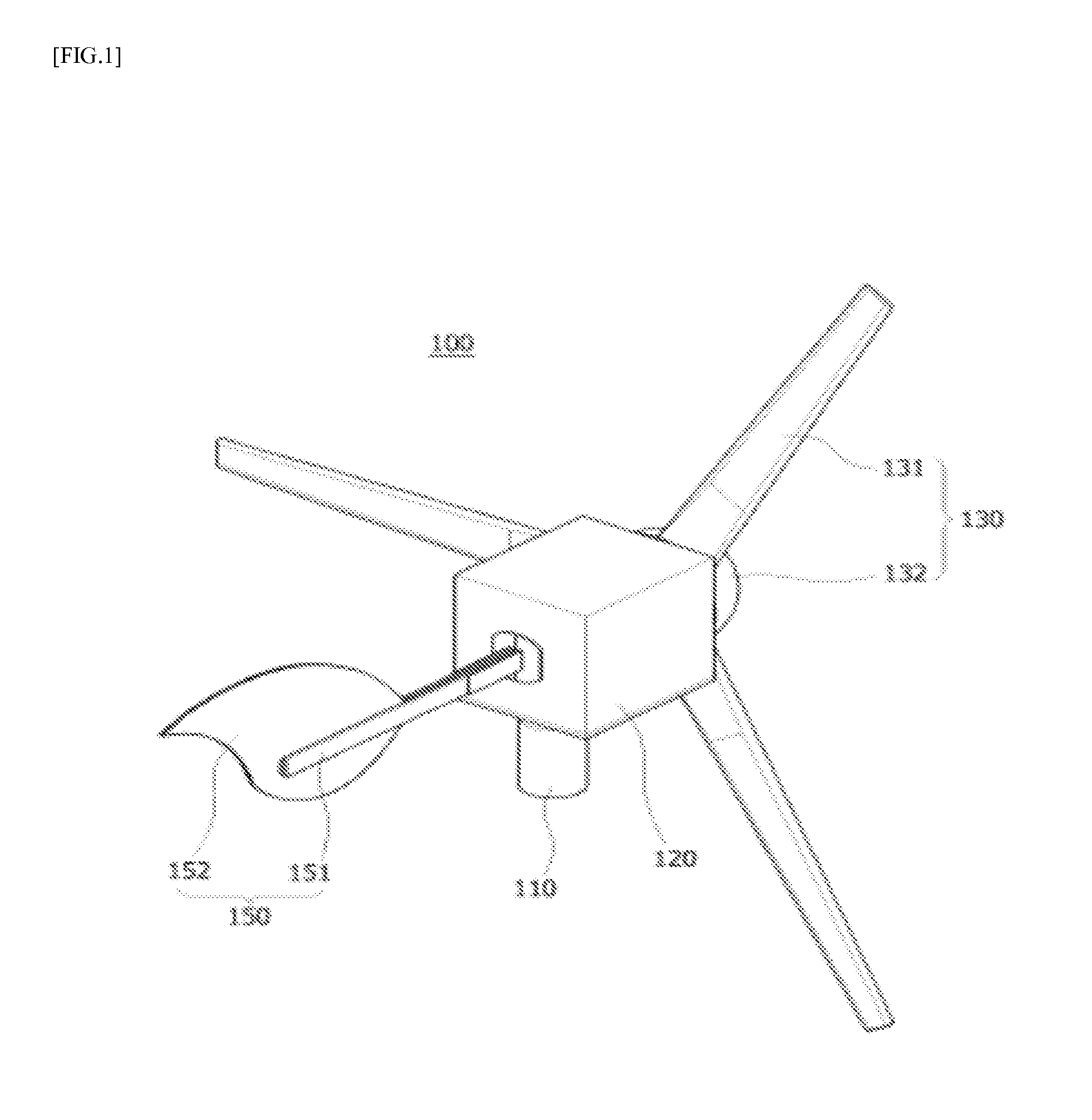

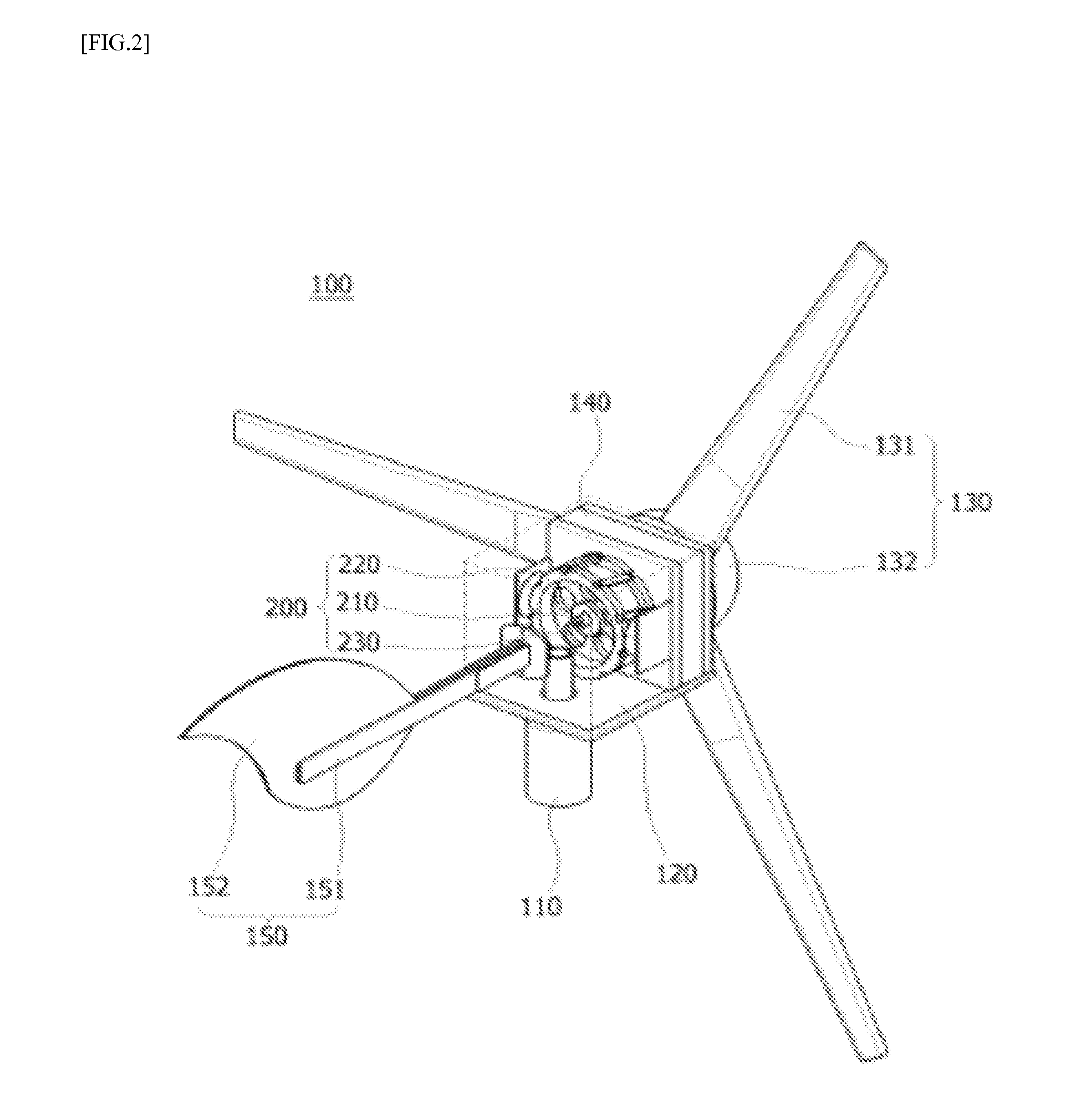

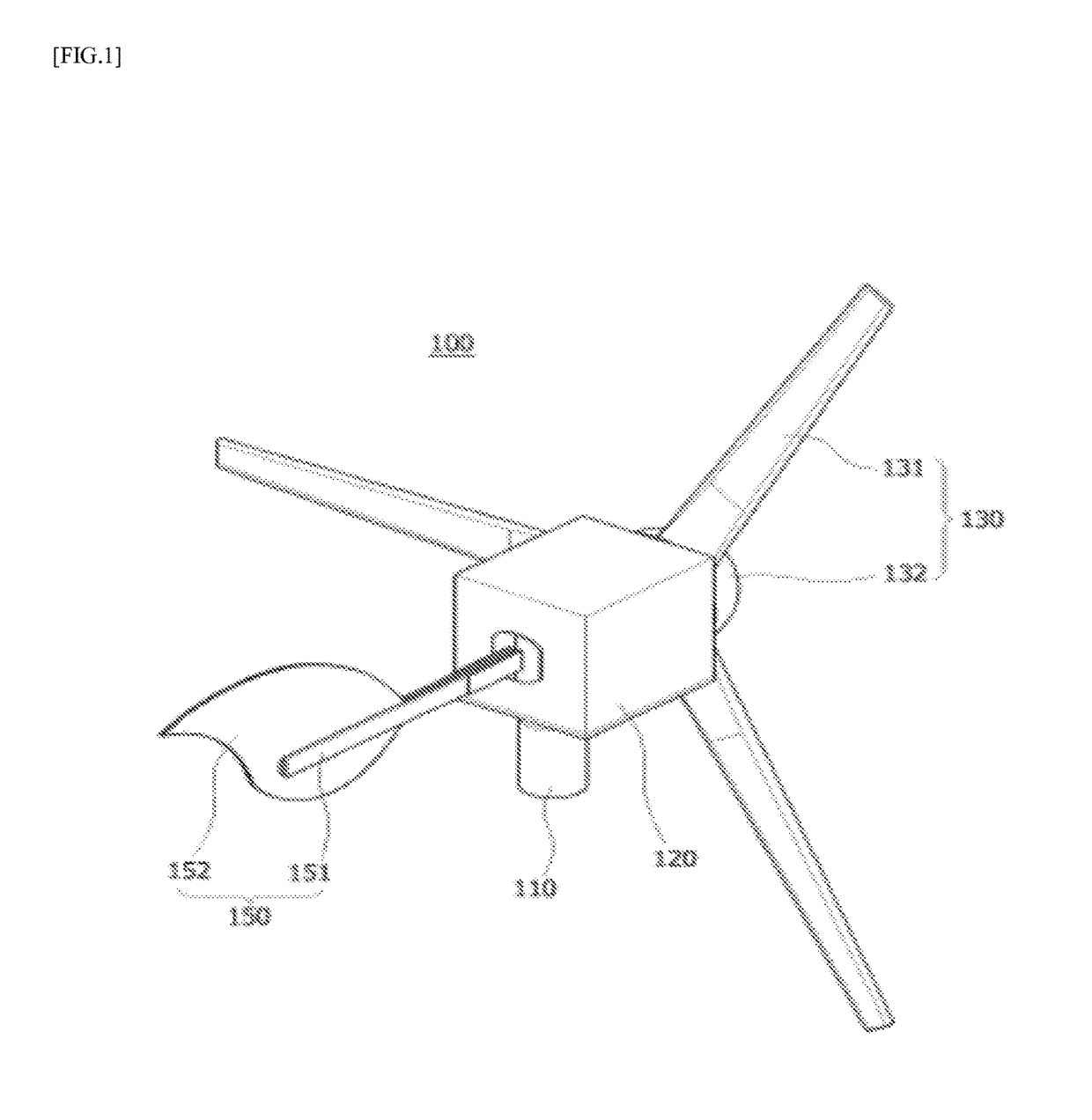

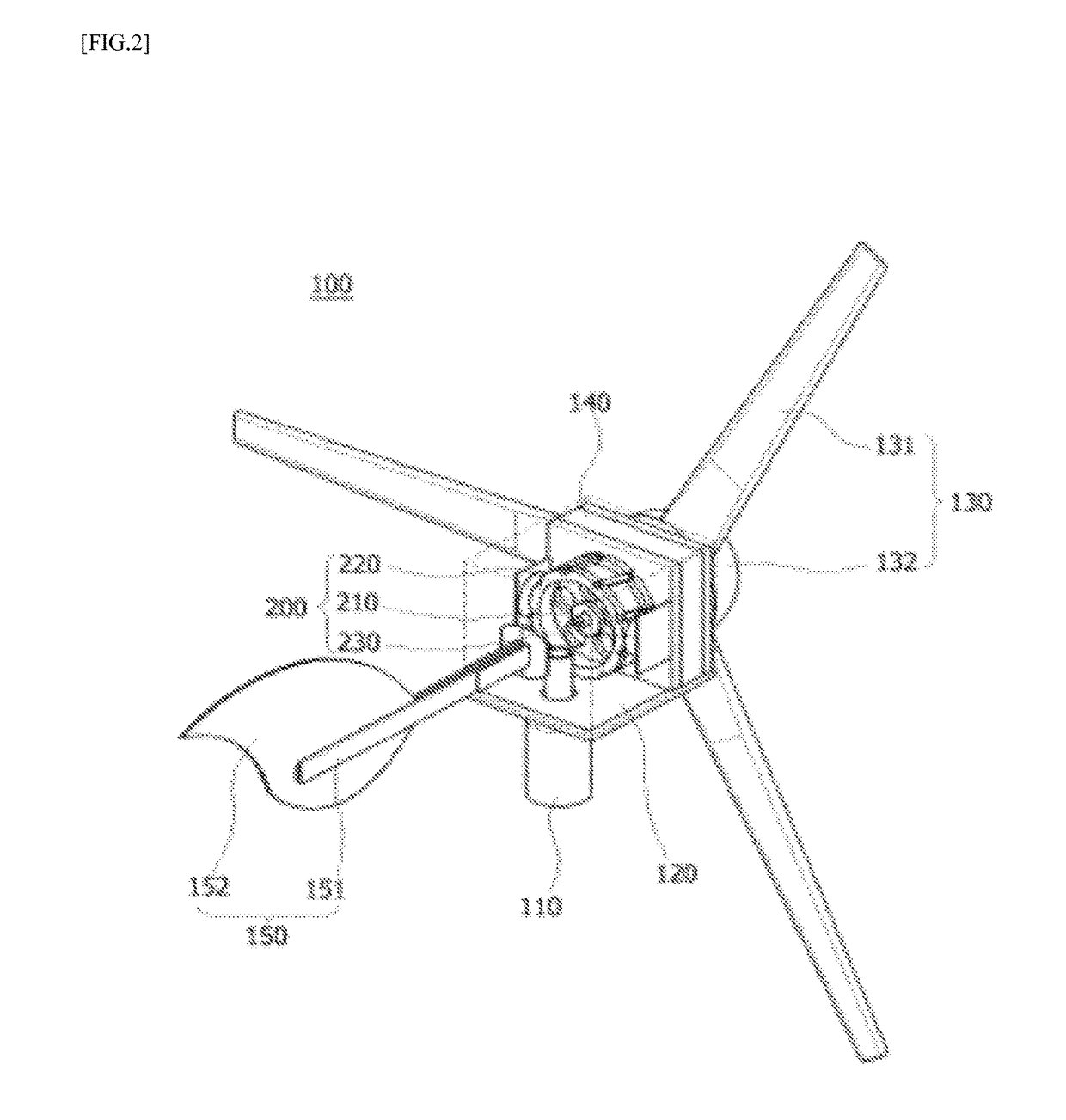

Wind turbine

ActiveUS20170009742A1Smooth power fluctuationsImprove power generation efficiencyEngine fuctionsMachines/enginesElectricityEngineering

The wind generator includes a support part, a housing connected to an upper portion of the support part, the housing having an inner space, a blade part connected to one side of the housing, the blade part, an electricity generating part seated in the inner space of the housing, a flywheel, and a tail part. The flywheel includes a shaft rotating together with the blade part, a rotor coupled to the shaft, the rotor including at least one permanent magnet along an outer circumferential surface thereof, at least one coil part disposed outside in a radial direction of the rotor and around which a trigger coil is wound, the at least one coil generating magnetic fields when current is supplied to the trigger coil, and a circuit part supplying pulse-type current to trigger coil when the permanent magnet passes through a center of the trigger coil.

Owner:NURIELECOM CO LTD

Arrangement having an electric machine and method for operating an electric machine

InactiveUS8358094B2Reduce the overall diameterImprove thermal conductivityTemperature control without auxillary powerDC motor speed/torque controlElectricityThermal state

The invention relates to a method and arrangement having an electric machine, comprising a stator (4) and a rotor (1) and an infrared temperature sensor, wherein the detection field of the infrared temperature sensor is directed at an outer surface of the rotor (1). The infrared temperature sensor is a thermopile (6) for radiometrically contactlessly detecting a temperature of the rotor (1), the thermopile being arranged in a slot of the stator (4) and being compatible with standard slot-sealing-wedge components of the electric machine with regard to assembly, and thus enables the operational monitoring of the thermal state of an electric machine in a novel manner, such that adapted power states can be achieved.

Owner:SIEMENS AG

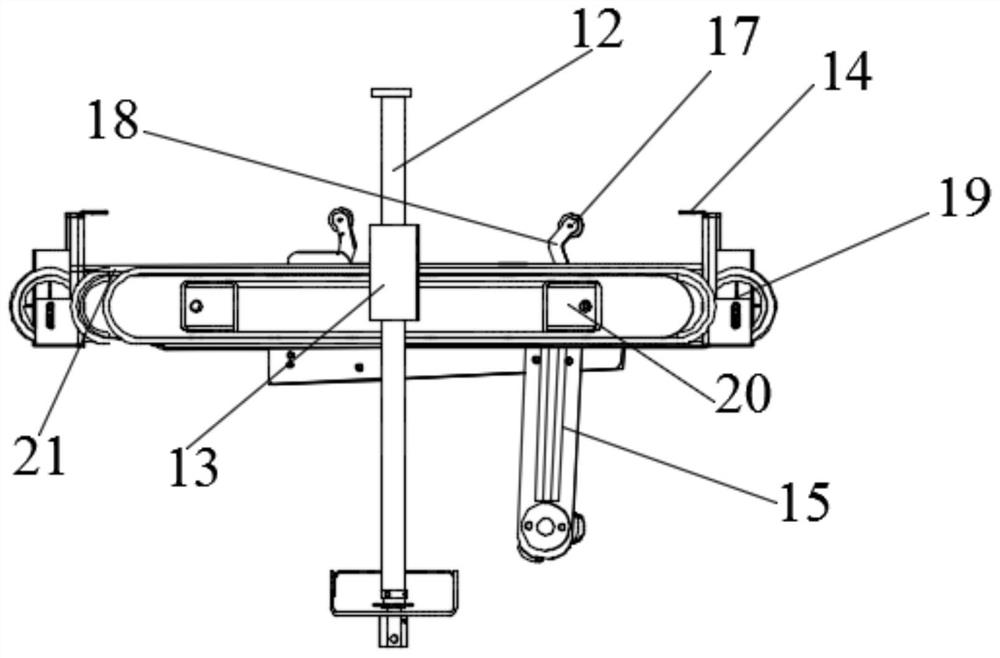

Coating equipment for machining part of new energy automobile

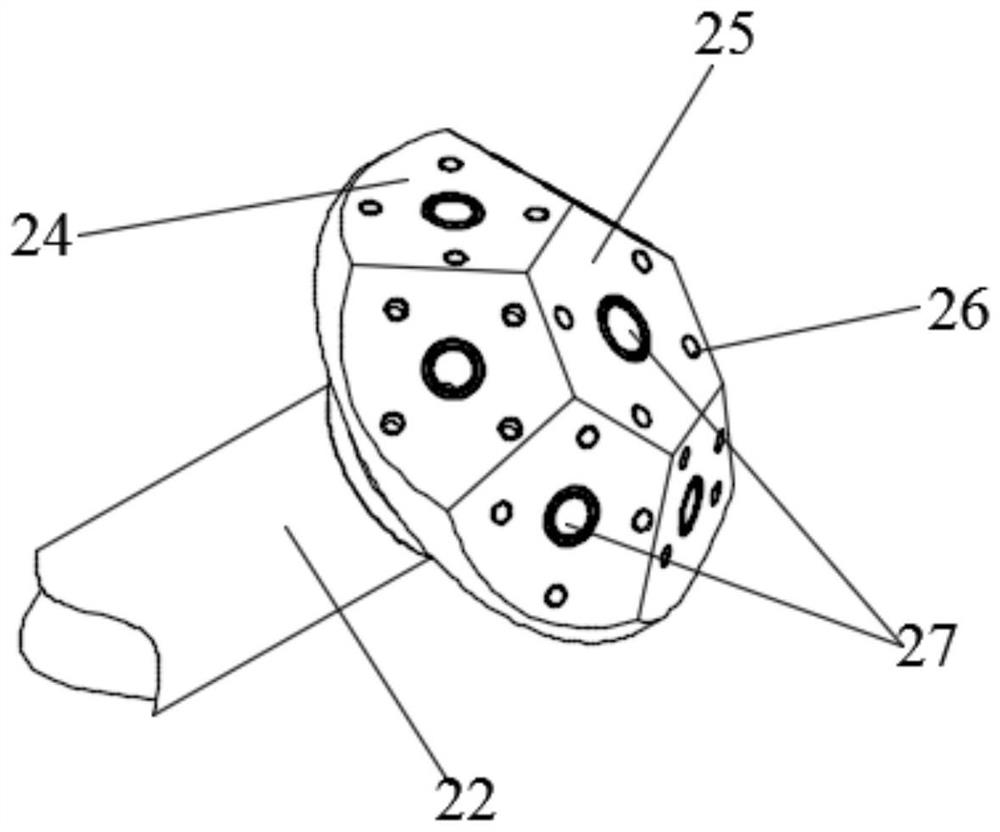

ActiveCN113578588AFor automatic positioningReduce rotation frequencySpraying apparatusMachine partsNew energy

The invention discloses coating equipment for machining a part of a new energy automobile. The equipment can realize automatic positioning of a workpiece, can realize automatic adjustment of the position and posture of the workpiece, and realizes automatic clamping and positioning, and a spraying end of a spraying head at least comprises a plurality of spraying surfaces, the spraying surfaces are arranged in a non-parallel mode, and each spraying surface is at least provided with one independently controlled spraying nozzle. By arranging the spraying nozzles on the spraying surfaces, the corresponding spraying nozzles can be controlled to conduct spraying according to the positions of the spraying nozzles and the positions of spraying workpieces, so that the spraying efficiency is effectively improved; and therefore, the rotating frequency of the nozzle is reduced, and the spraying effect is improved.

Owner:SHANDONG VOCATIONAL COLLEGE OF IND

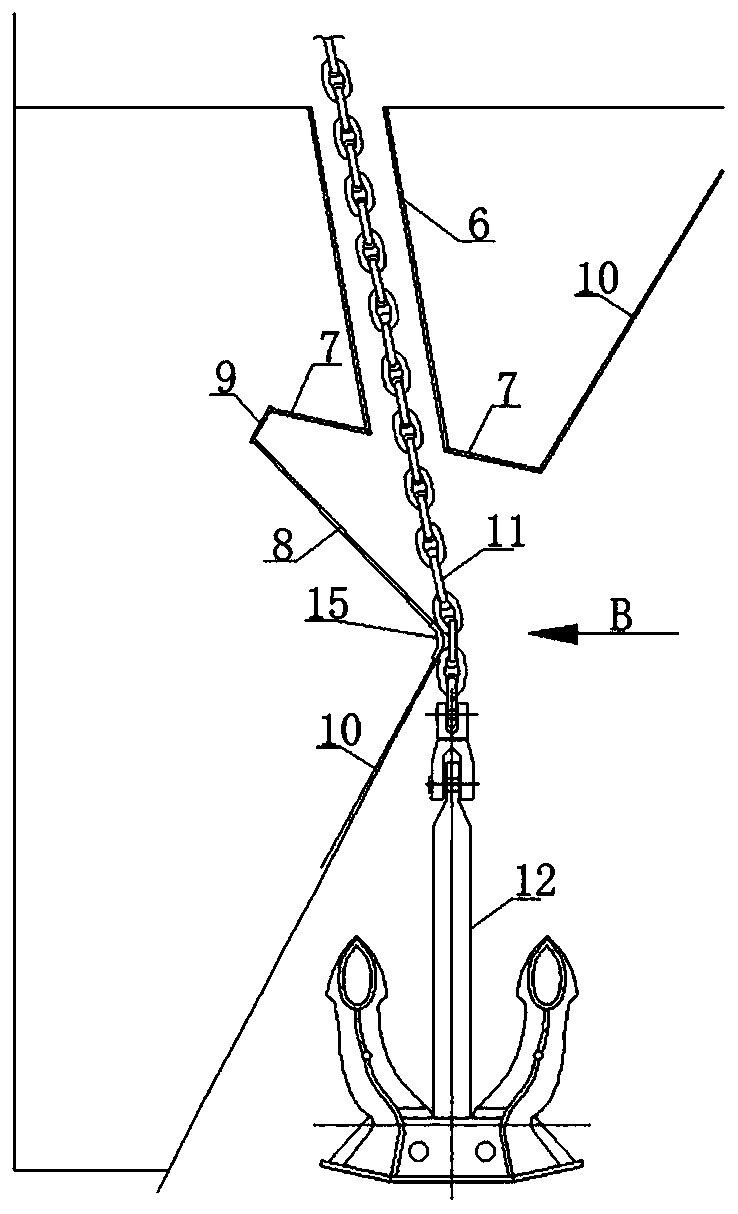

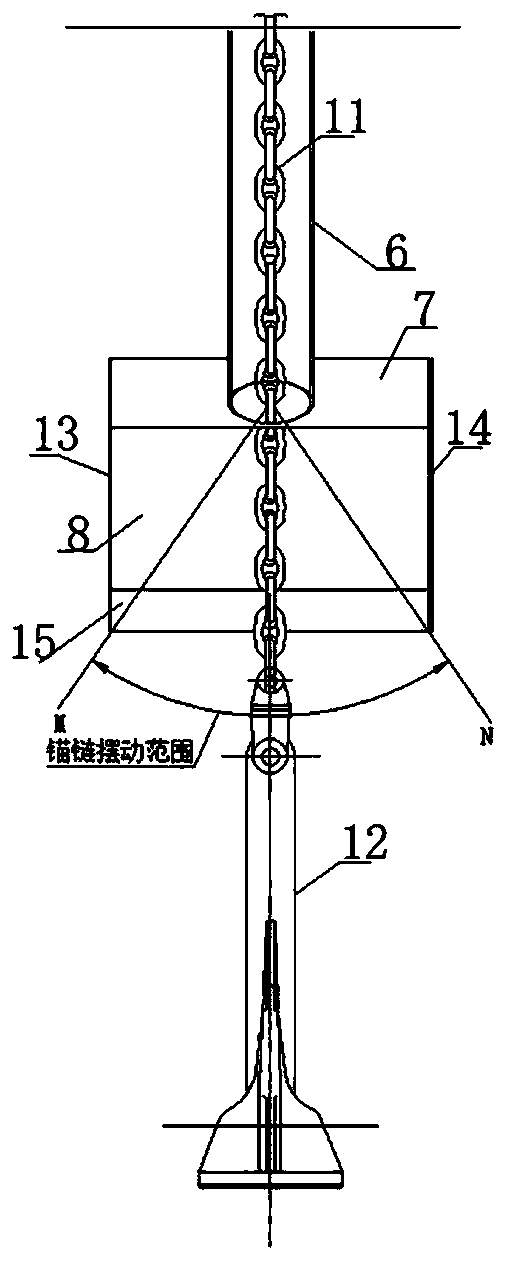

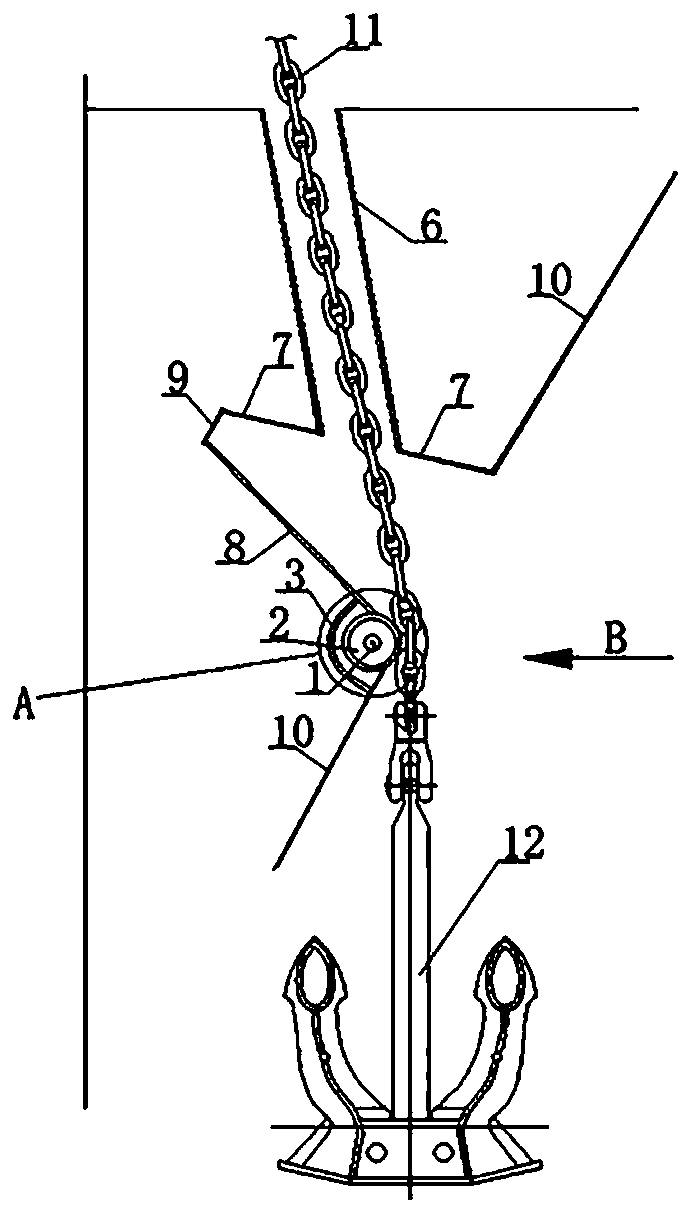

Ship and hidden type anchor hole structure

InactiveCN110254632ASmooth rotationEasy to retractWaterborne vesselsMarine engineeringConical surface

The invention relates to the technical field of anchor hole structures, in particular to a ship and a hidden type anchor hole structure. The hidden anchor hole structure comprises an anchor hole bottom plate and a rolling unit arranged at the transition position of the anchor hole bottom plate and a ship body outer plate; the rolling unit comprises a rolling cover and a rolling shaft assembly; the rolling cover comprises two sealing plates which are connected at the included angle between the anchor hole bottom plate and the outer plate of the ship body; and the rolling cover further comprises a wrapped plate connected between the anchor hole bottom plate, the hull outer plate and the two sealing plates, the two ends of a roller assembly are respectively assembled on the corresponding sealing plates, the roller assembly is provided with a rolling surface which rolls along with sliding anchor chains, the rolling surface comprises a first conical surface and a second conical surface, and the vertex sides of the first conical surface and the second conical surface face the inner side of the roller assembly. According to the hidden type anchor hole structure, the friction acting force is greatly reduced in the anchor receiving and anchoring process, and the service life of the transition position of the hull outer plate and the anchor hole bottom plate is prolonged.

Owner:CSSC HUANGPU WENCHONG SHIPBUILDING COMPANY

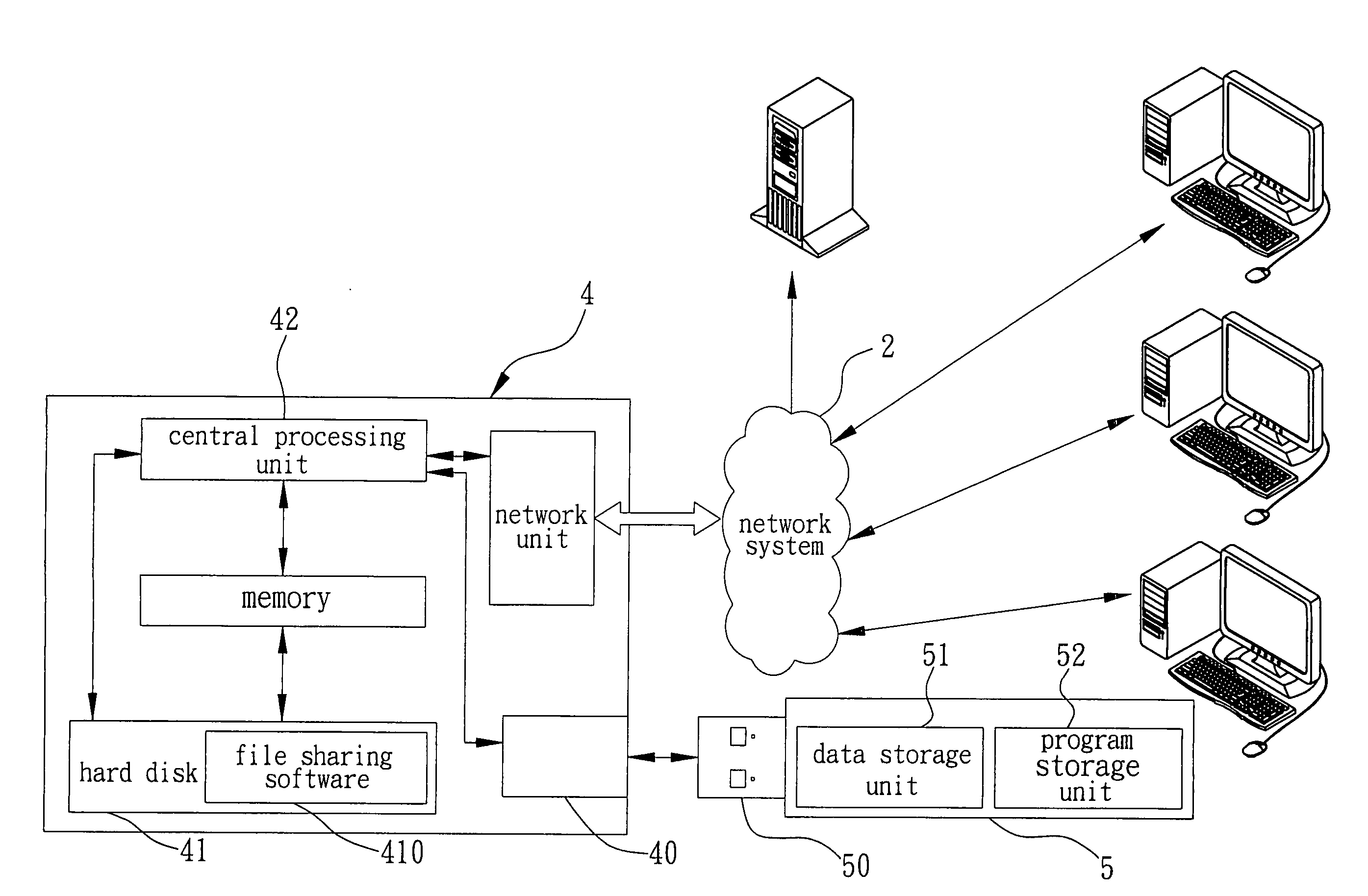

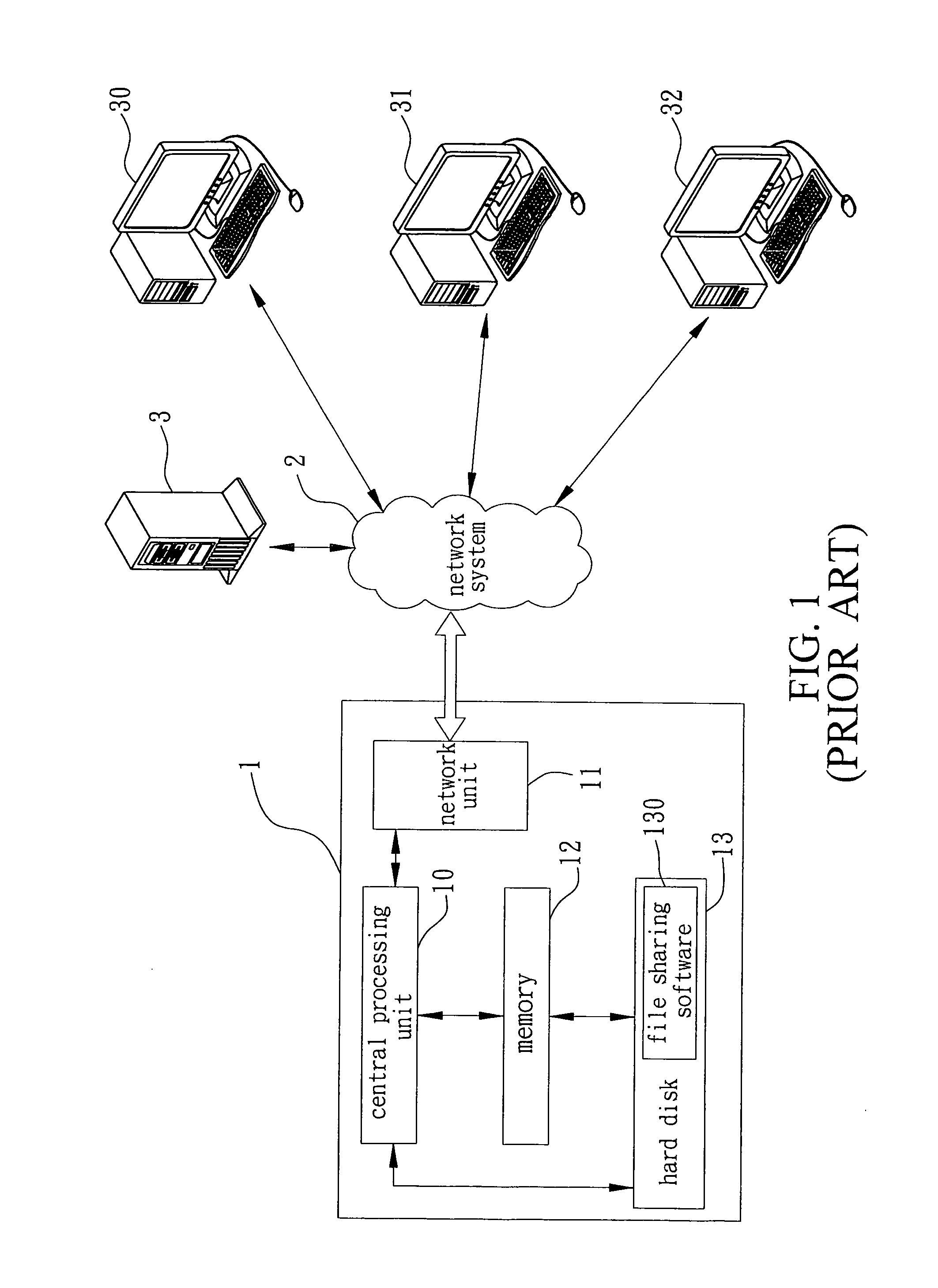

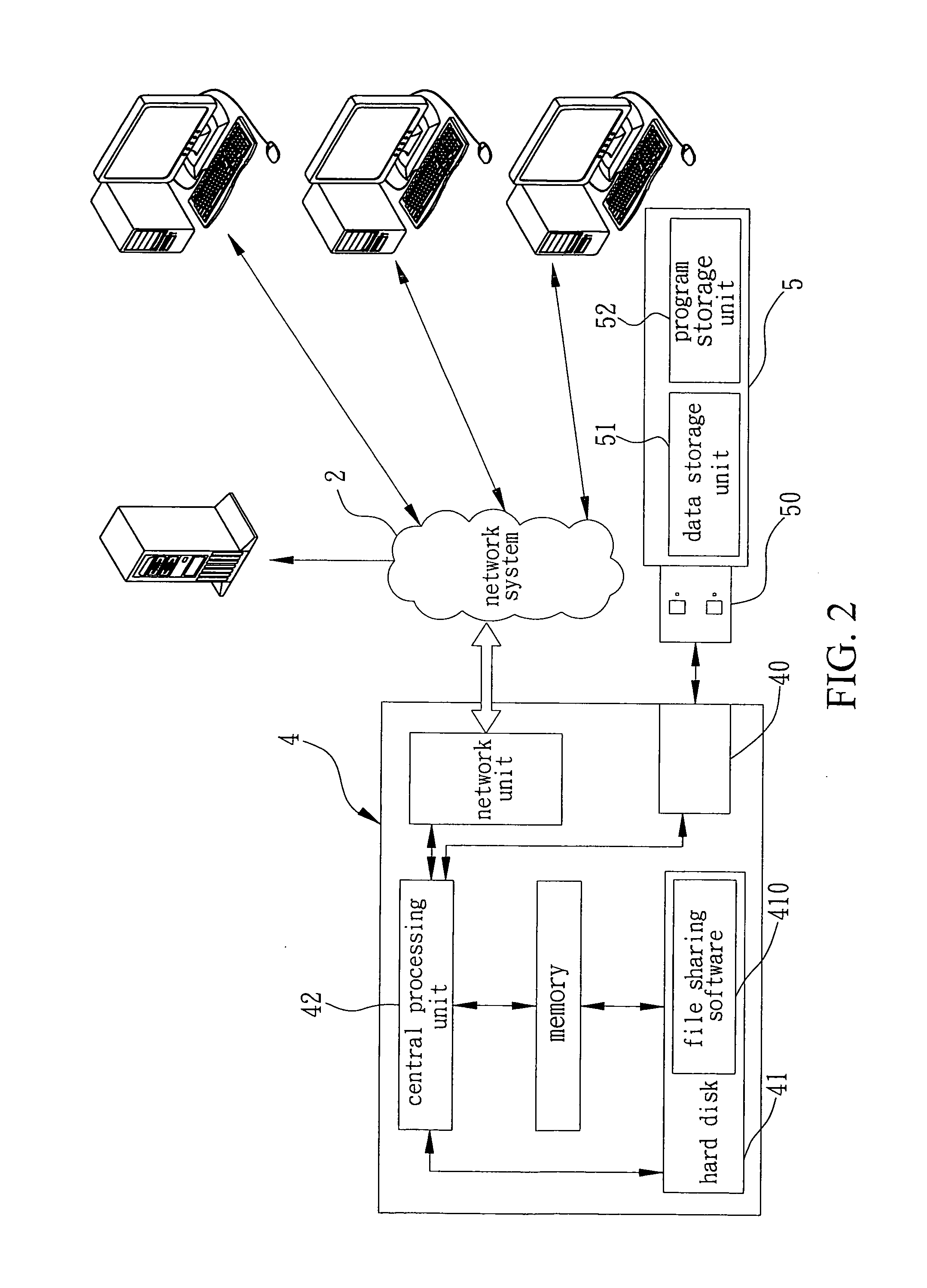

Data write/read auxiliary device and method for writing/reading data

InactiveUS20090019236A1Not easy to rotateReducing access frequency to hard disk sectorsMemory systemsInput/output processes for data processingData storeFile sharing

A data write / read auxiliary device and method for writing / reading data are provided. A data storage unit and a program storage unit are installed in the data write / read auxiliary device, wherein the program storage unit is for storing automatic execution program and protection program. When the data write / read auxiliary device is connected to a data processing device, the automatic execution program is executed for automatically executing programs stored in the program storage unit. The protection program is executed for executing an access process on data storage unit to judge whether driving a write / read head or not based on outcome of the access process when a file sharing software is executed for data downloading and uploading. Through the data storage unit as a buffer area of data before writing / reading data on a hard disk, the data write / read auxiliary device and method for writing / reading data can protect the hard disk.

Owner:HSU WEI CHIANG +5

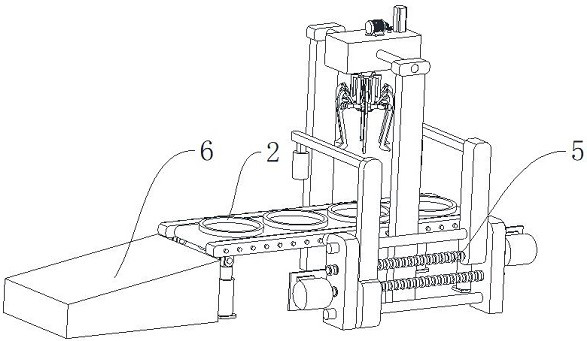

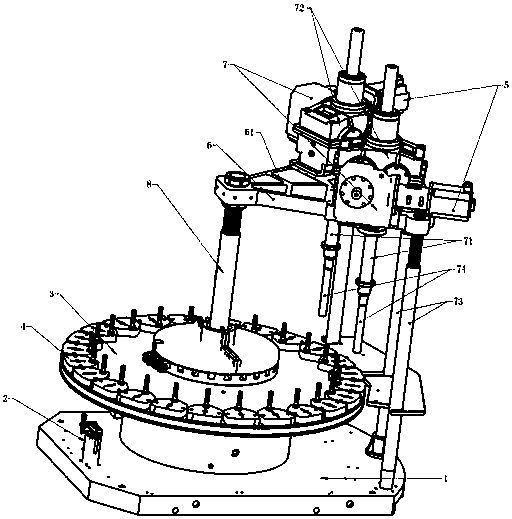

Multi-workstation stamping glassware pressing machine

PendingCN108275868AEasy to controlImprove product qualityGlass pressing apparatusGlass productionControl systemMicrocomputer control

The invention provides a multi-workstation stamping glassware pressing machine, which belongs to the field of glass production devices. The multi-workstation stamping glassware pressing machine comprises a base, an apical cup apparatus, a turntable, a lower mold, a middle column, a stander, a control system and a plurality of servo stamping apparatuses, wherein by improving the stander and the servo stamping apparatus, the plurality of sets of motor gear servo stamping apparatuses are installed on the same stander, each servo stamping apparatus is accurately and independently controlled or synchronously controlled by virtue of a micro computer control system, when large-sized glassware is produced, any one of the servo stamping apparatuses can be used, and when the servo stamping apparatushas mechanical malfunction or is maintained, the normal production can still be ensured; and when small-sized glassware is produced, two servo stamping apparatuses can work simultaneously, so that one product obtained from one machine can be changed to multiple products from one machine, the production efficiency is increased, and the production cost is decreased.

Owner:FOSHAN SENTAI MACHINERY MOLD CO LTD

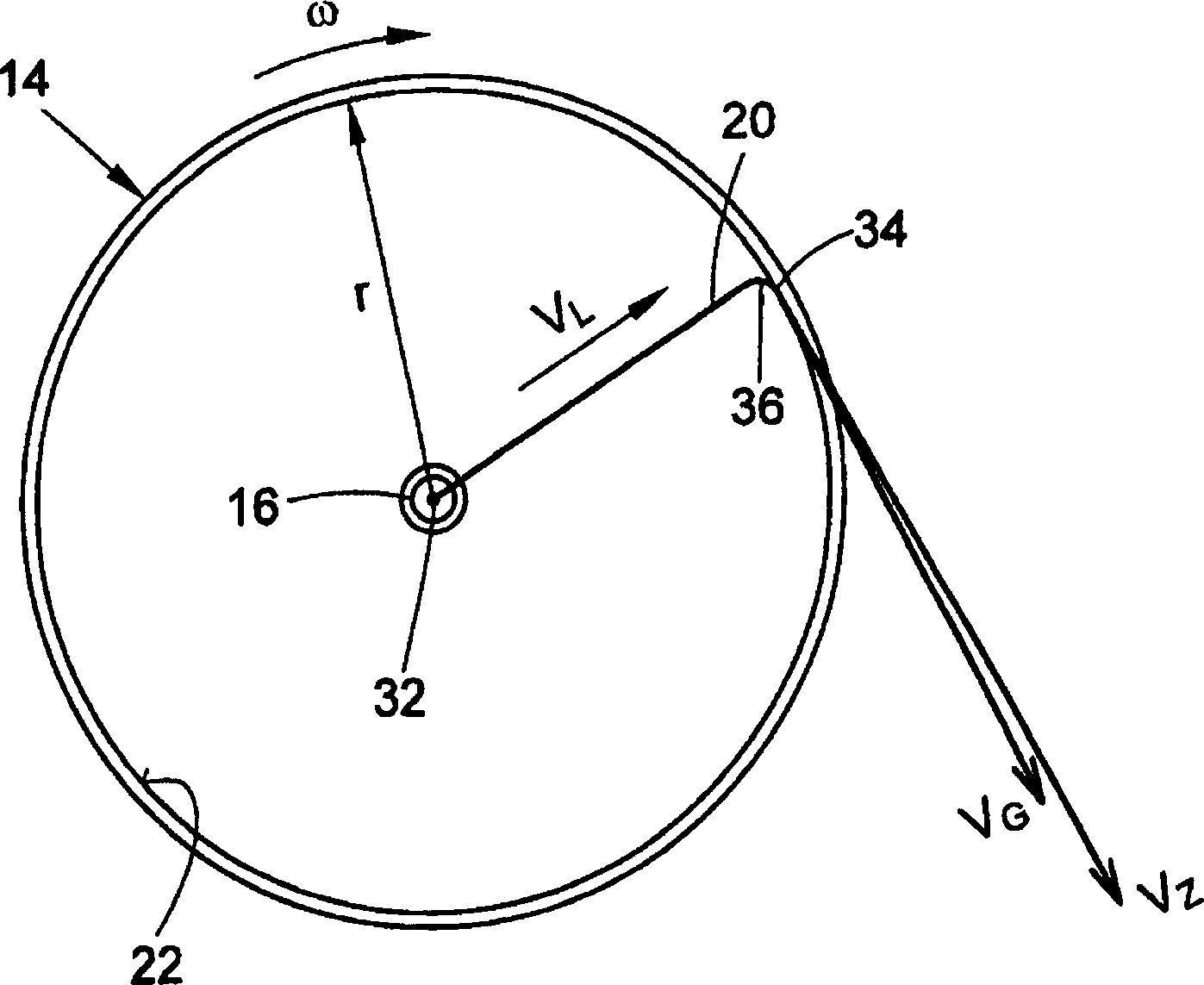

Method and device for box spinning

InactiveCN1225576CAvoid the Consequences of Poor CopsReduce rotation frequencyContinuous wound-up machinesOpen-end spinning machinesYarnStops device

The invention relates to a method and device for operating a pot spinning machine which has a plurality of identical work stations each having a drafting device with a slubbing stop device, a spinning centrifuge rotating at high speed around an axis, and a tubular reciprocable guide. A slubbing emerging from the yarn guide mouth forms a rotating yarn leg which is deposited on the inner wall of the spinning centrifuge in the form of a spinning cake. At the start of a spinning cycle of the spinning machine (10), the individual spinning centrifuges (14) of the spinning machine are checked for the presence (30) of yarn cake remnants.

Owner:OERLIKON TEXTILE GMBH & CO KG

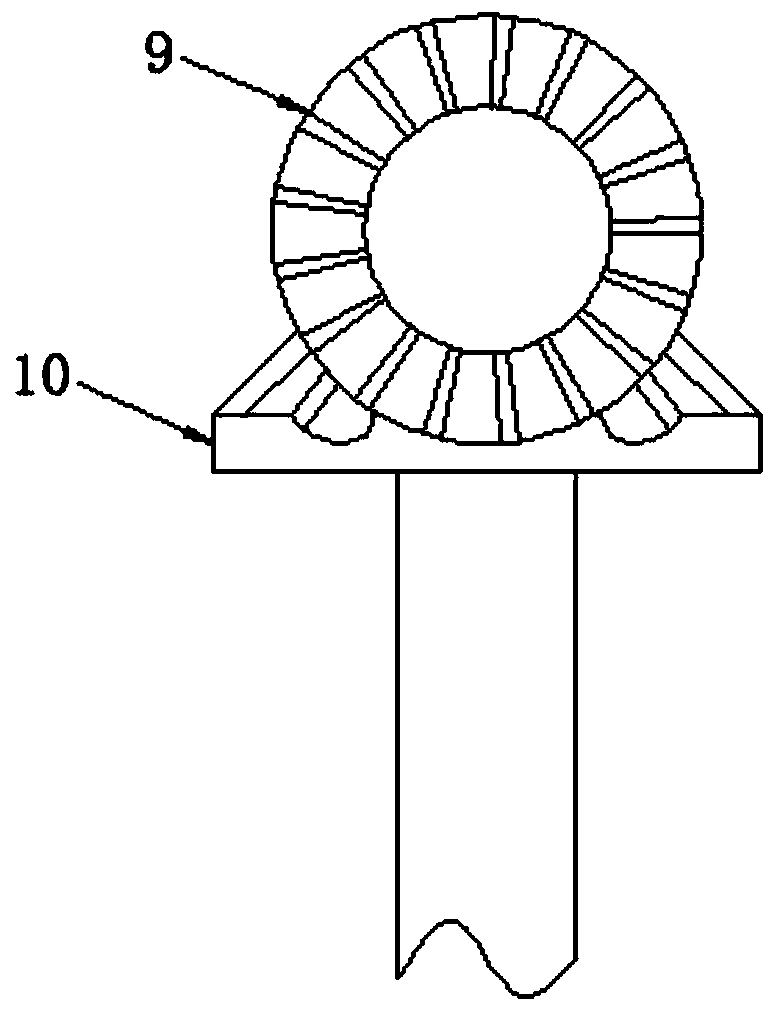

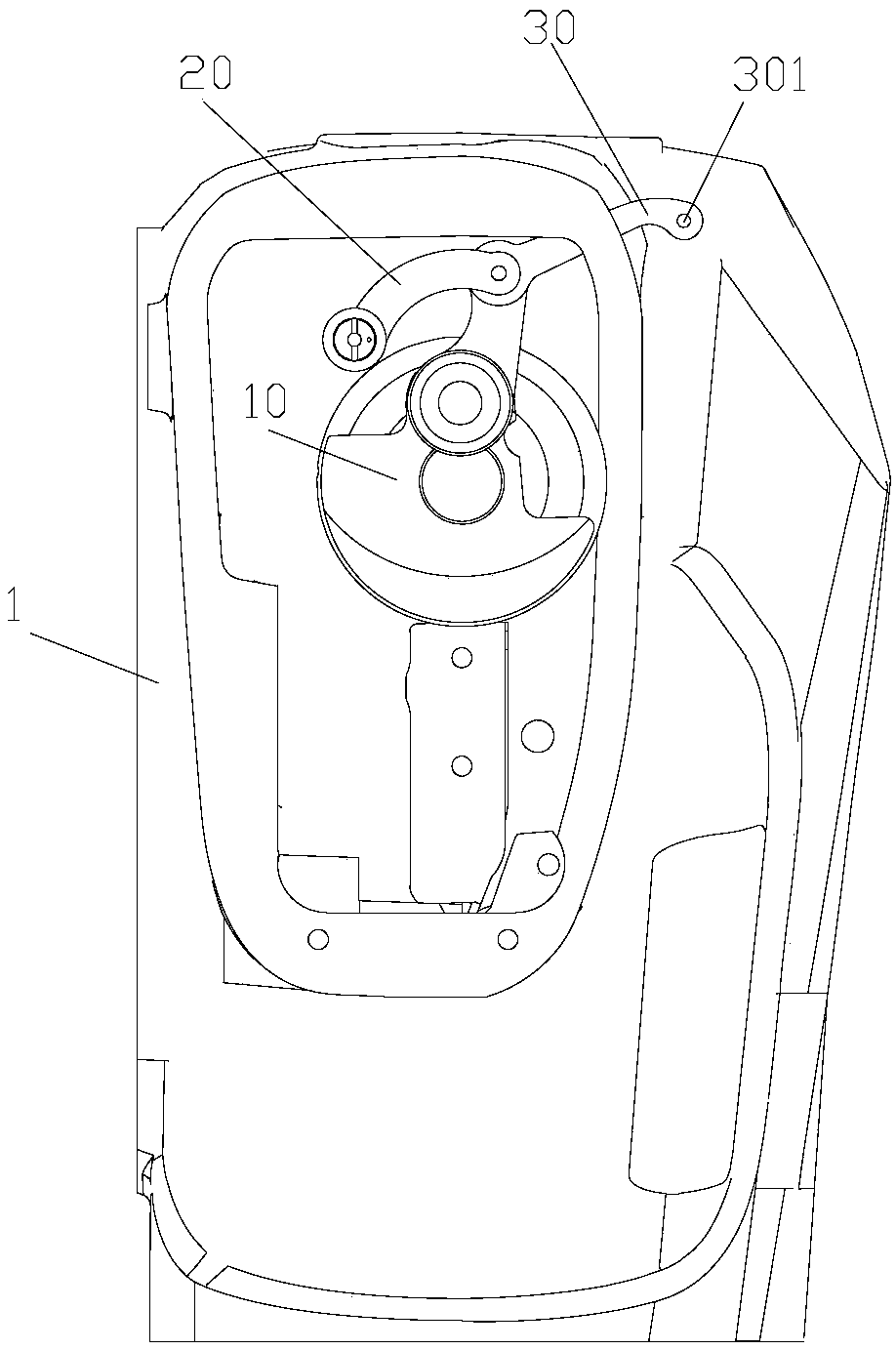

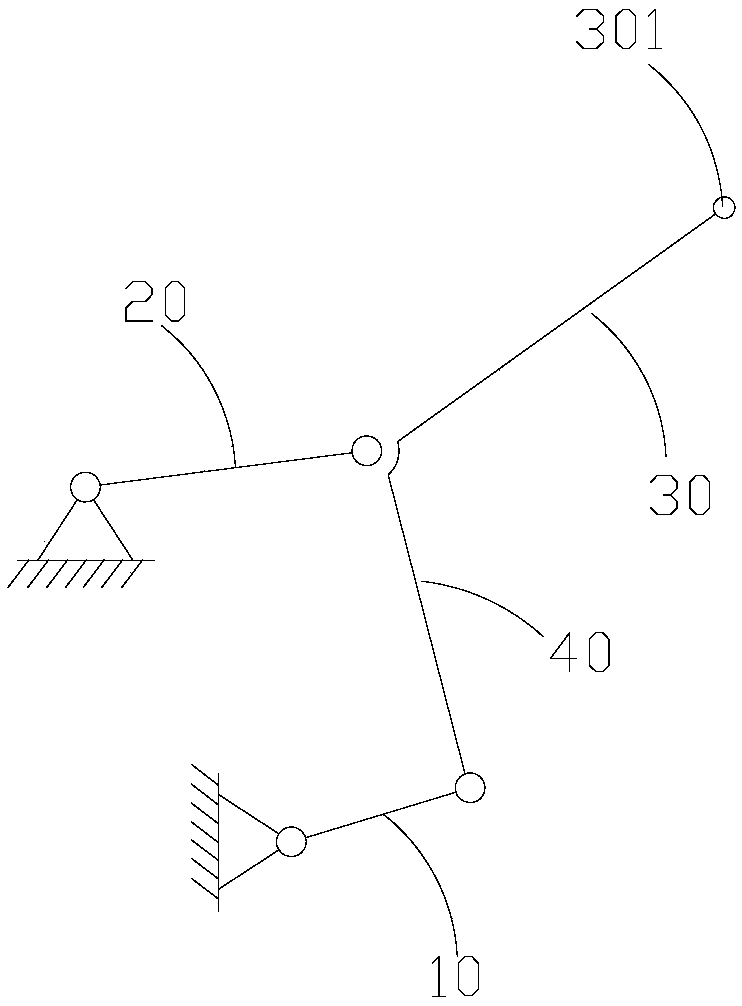

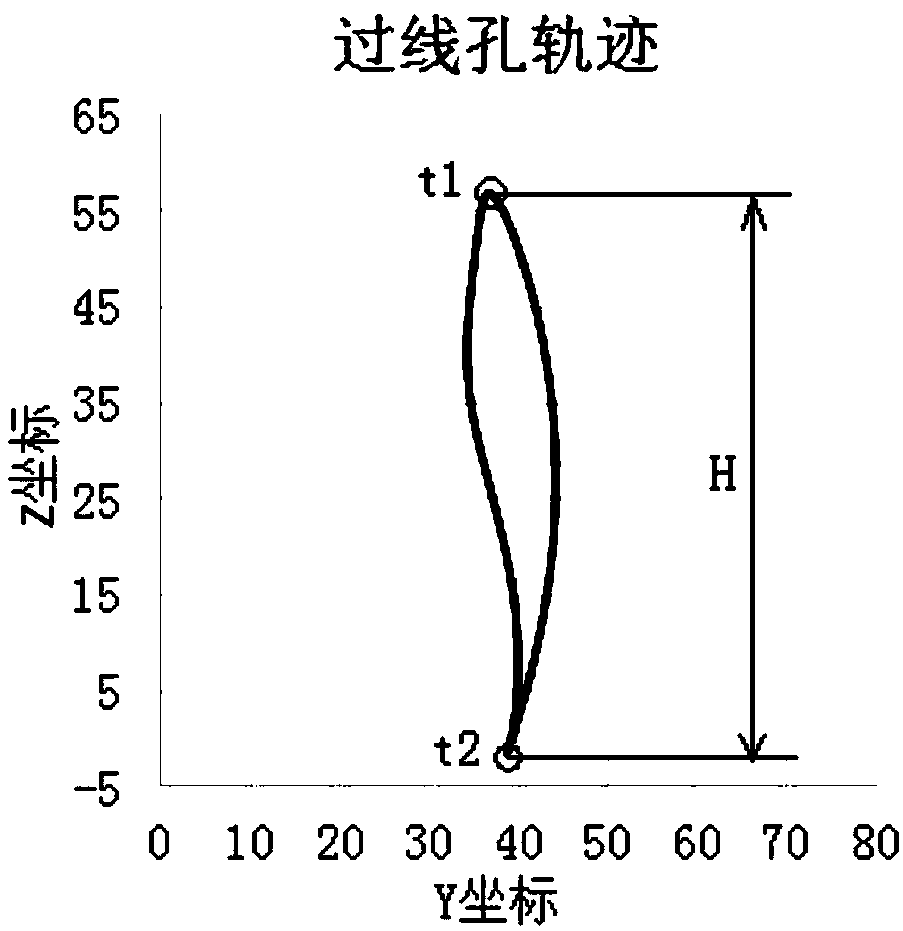

Thread take-up mechanism used for sewing machine and sewing machine

InactiveCN109457409AReduce rotation frequencySewing-machine control devicesTake-up devicesEngineeringSewing machine

The invention provides a thread take-up mechanism used for a sewing machine and the sewing machine. The thread take-up mechanism includes a thread take-up rod, a connecting rod assembly and a fixedlyarranged driving part; one end of the thread take-up rod is rotatably arranged, the other end of the thread take-up rod is provided with a thread through hole, one end of the connecting rod assembly is connected with the driving part, the other end of the connecting rod assembly is connected with the thread take-up rod, and the driving part drives the connecting rod assembly to swing in a reciprocating mode. The connecting rod assembly has three states, the connecting rod assembly in the first state and the connecting rod assembly in the second state are symmetrically arranged on the two sidesof the connecting rod assembly in the third state, the connecting rod assembly is in a straight line state in the third state, the thread through hole of the thread take-up rod is located at the highest point in the first state and the second state, and the thread through hole of the thread take-up rod is located at the lowest point in the third state. According to the mechanism and the sewing machine, the driving part rotates once, the thread through hole of the thread take-up rod can be at the highest point twice, and the rotation frequency of the driving part is reduced.

Owner:JACK SEWING MASCH CO LTD

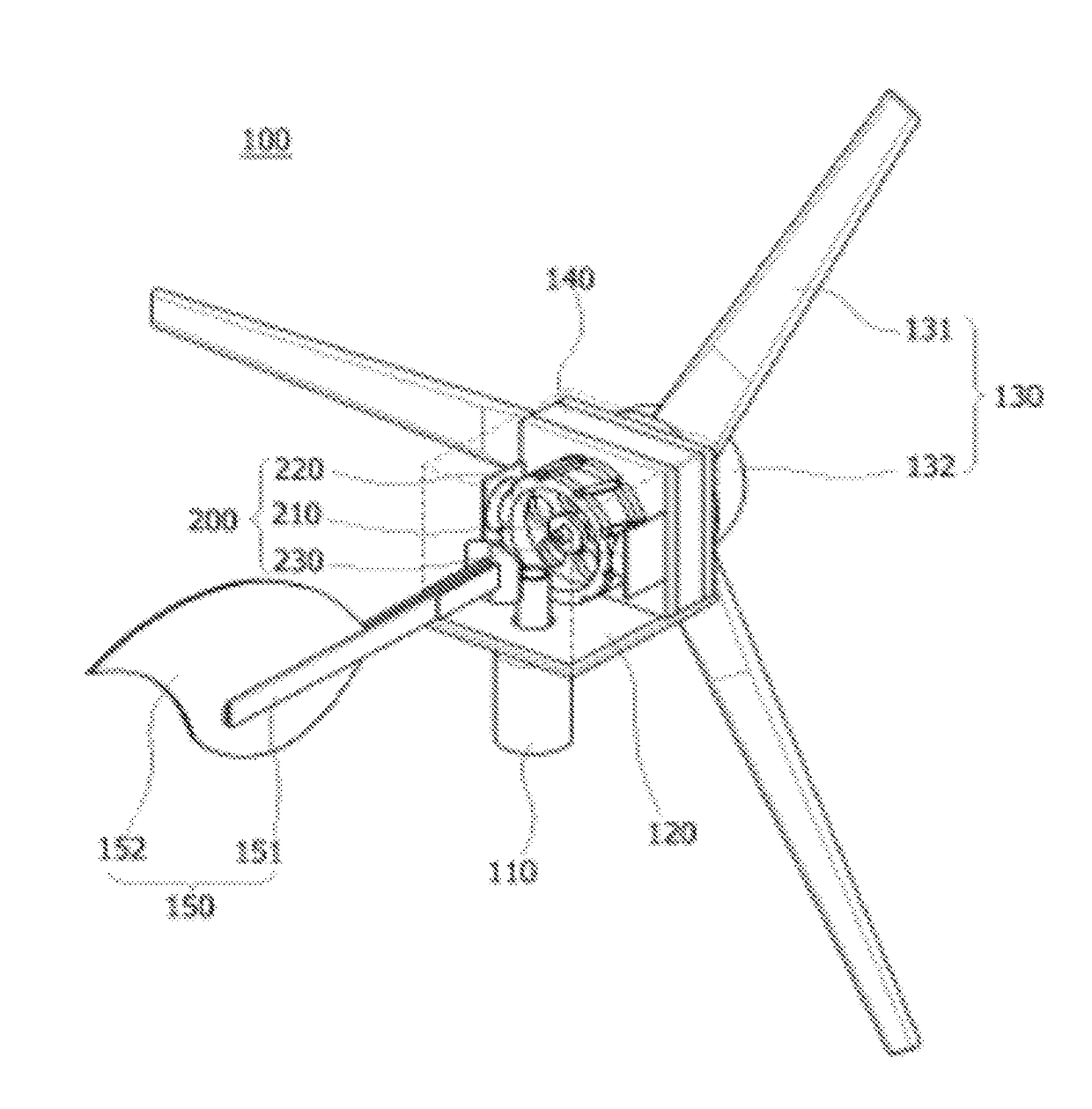

Wind turbine

ActiveUS9759195B2Improve power generation efficiencyIncreases a rotational inertiaEngine fuctionsMachines/enginesInterior spaceElectricity

The wind generator includes a support part, a housing connected to an upper portion of the support part, the housing having an inner space, a blade part connected to one side of the housing, the blade part, an electricity generating part seated in the inner space of the housing, a flywheel, and a tail part. The flywheel includes a shaft rotating together with the blade part, a rotor coupled to the shaft, the rotor including at least one permanent magnet along an outer circumferential surface thereof, at least one coil part disposed outside in a radial direction of the rotor and around which a trigger coil is wound, the at least one coil generating magnetic fields when current is supplied to the trigger coil, and a circuit part supplying pulse-type current to trigger coil when the permanent magnet passes through a center of the trigger coil.

Owner:NURIELECOM CO LTD

A car flower machine for chain jewelry

ActiveCN110732684BImprove machining accuracyCorrect twistJewelleryTurning machinesEngineeringMechanical engineering

The invention relates to a pattern lathing machine, in particular to a pattern lathing machine of chain-shaped jewelry. The pattern lathing machine comprises a machine frame, a supporting base assembly and a tool. The machine frame is placed on the ground. The supporting base assembly comprises a supporting plate, a positioning wheel and a first driving piece. The supporting plate is connected tothe upper side of the machine frame. The positioning wheel is rotationally connected with the supporting plate through a horizontal shaft. The first driving piece is used for driving the positioning wheel to rotate. A positioning groove is formed in the wheel surface of the positioning wheel. The pattern lathing machine is characterized in that the positioning groove is annular, the bottom edge ofthe positioning groove is provided with a plurality of continuous containing grooves, a tilt angle is formed between the bottom sides of every two adjacent containing grooves, and the bottom sides ofevery other two containing grooves are parallel. Each chain section of the chain-shaped jewelry can be clamped in the corresponding containing groove, the stability of the chain-shaped jewelry in thepositioning groove is ensured, the tool can stably press the chain sections in the containing grooves in the pattern lathing process, the machining precision is quite high, fine patterns can be machined, and the effect of improving the machining precision of the surface of the chain-shaped jewelry is realized.

Owner:深圳盛大首饰有限公司

Organic fertilizer for livestock leftovers fermented by biological carbon

PendingCN110922273ABalanced ratioPromote growthBio-organic fraction processingMicroorganism based treatmentBiotechnologyMicroorganism

The invention belongs to the technical field of fertilizers with special fertilizer efficiency, and discloses an organic fertilizer for livestock leftovers fermented by biological carbon. The weight and mass parts of the raw materials of the organic fertilizer include 50-80 parts of livestock leftovers, 20-30 parts of biochar, 3-6 parts of microbial agents and 30-40 parts of water. The livestock leftovers are firstly crushed during production and microbial agents, water and crushed livestock leftovers are placed in a fermentation barrel for fermentation; the biochar is added into the fermentation barrel after 3 days of fermentation for continuing fermentation; after 2 days, the materials in the fermentation barrel are stirred by using a stirring rod to realize uniform mixing and decomposition of the raw materials; a crushing rod is arranged on the stirring rod to crush the biochar; after 2 days, the residue in the fermentation barrel is filtered and the liquid is taken out to form a liquid organic fertilizer. The problems that the existing liquid organic fertilizer has less carbon content and microorganisms and has limited promotion effect on plant growth and soil improvement effect can be solved.

Owner:重庆酷熊科技有限公司

Energy-saving hydrolyzer and method for preparing polyacrylamide polymer by post-hydrolysis method

The invention provides an energy-saving hydrolyzer and method for preparing polyacrylamide polymers by a post-hydrolysis method. The hydrolyzer includes a stirring device, and the direct power of the stirring device of the hydrolyzer is provided by a hydraulic device. The invention also provides a method for producing polyacrylamide polymers by using the energy-saving hydrolyzer. Utilizing the hydrolyzer of the invention to produce polyacrylamide polymers can save energy and reduce consumption, and reduce production costs.

Owner:PETROCHINA CO LTD

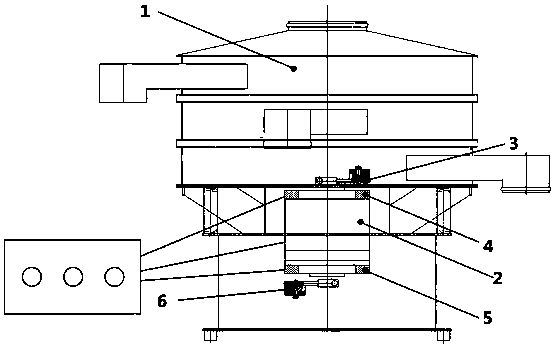

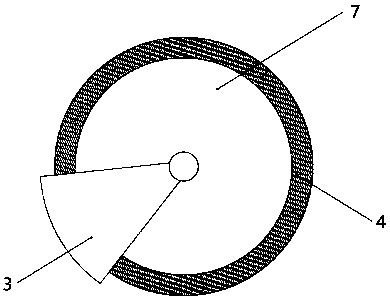

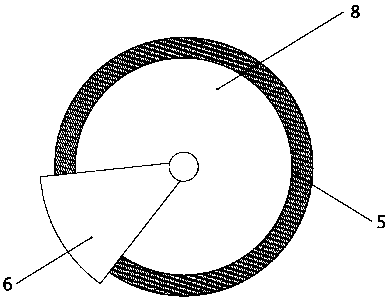

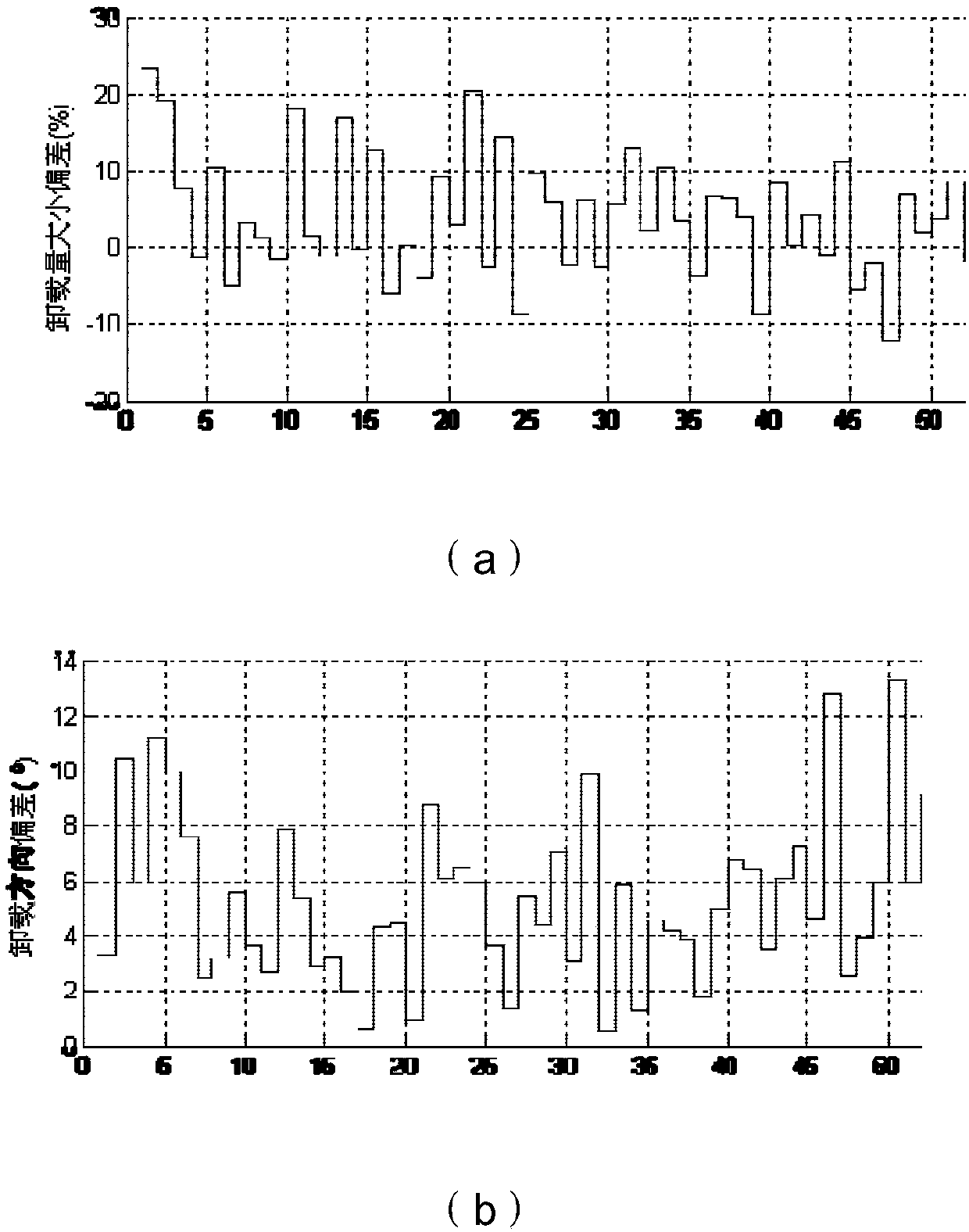

A vibration buffer device for rotary vibrating screen

ActiveCN106391455BExtended service lifeReduce rotation frequencySievingScreeningResonanceEngineering

The invention discloses a rotary vibration screen resonance buffer device. A protection cover is arranged on the upper portion of a screen machine main body and provided with a material inlet. A screen frame is arranged in the screen machine main body. A discharging outlet is formed in the side wall of the screen machine main body. A vibration motor fixedly connected with the screen frame is arranged in a screen machine bottom frame at the bottom of the screen machine main body. An upper annular electromagnet is fixedly and additionally arranged in the position, close to an upper flail block, of the outer edge of an upper end cover of the vibration motor. A lower annular electromagnet is fixedly and additionally arranged in the position, close to a lower flail block, of the outer edge of a lower end cover of the vibration motor. The vibration motor, the upper annular electromagnet and the lower annular electromagnet are electrically connected with a controller through circuits. According to the rotary vibration screen resonance buffer device, severe resonance shaking generated by the vibration motor after the device is stopped can be effectively avoided, the process of gradual decrease of the motor rotation speed when a screen machine is stopped is shortened, the machine body resonance generation time is shortened, and the service life of a rotary vibration screen is prolonged.

Owner:XINXIANG ZHEN YING MACHINERY EQUIP CO LTD

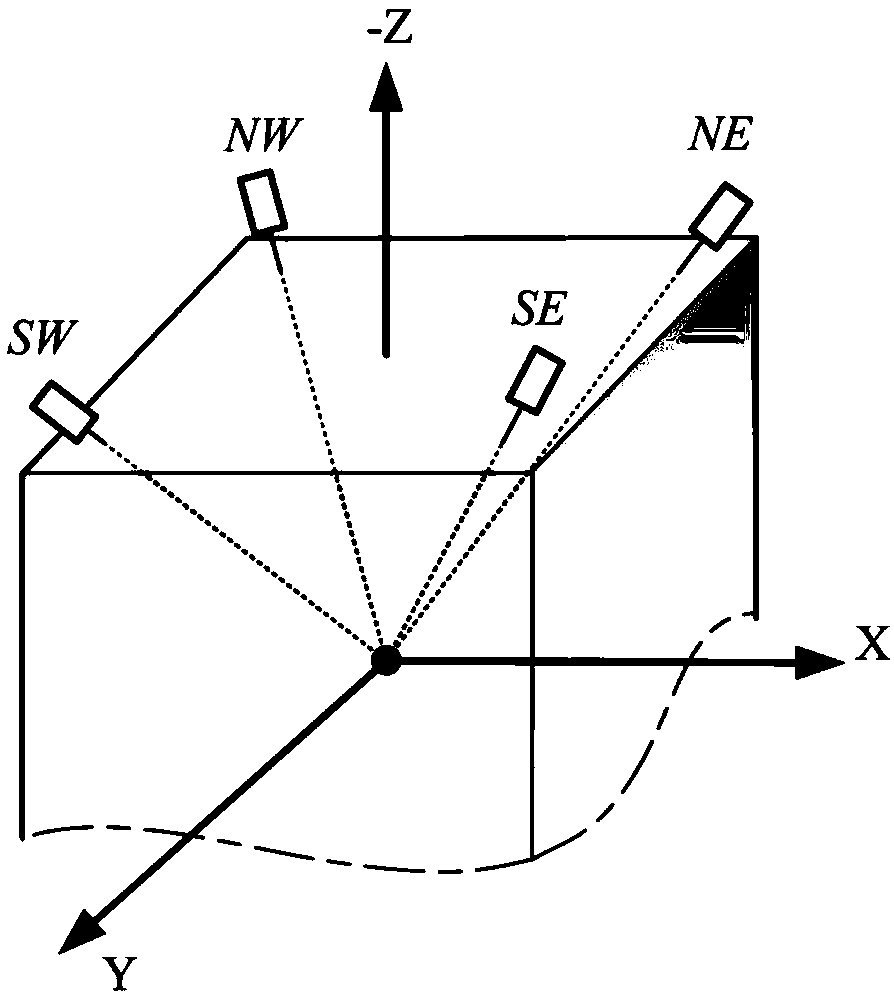

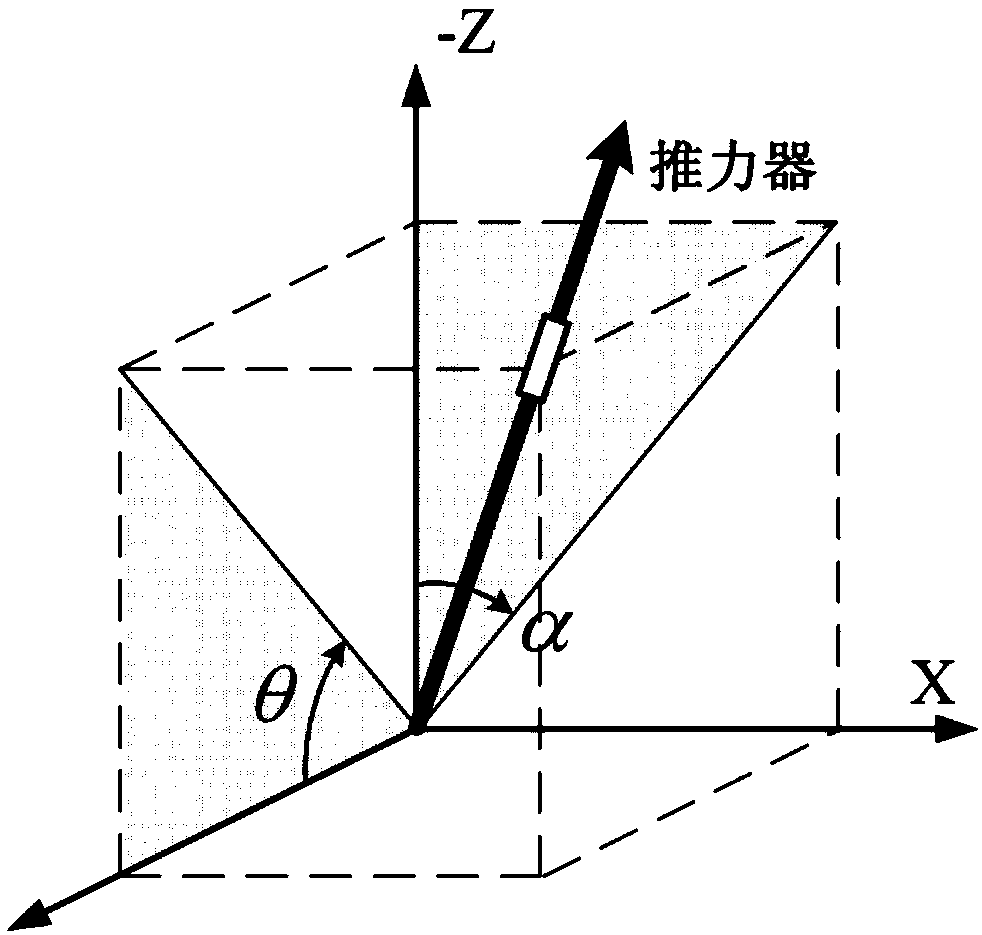

A Angular Momentum Unloading Method for Electric Propulsion Considering Thruster Arc Loss

ActiveCN106394935BRaise unloading longitudeEasy to implementCosmonautic propulsion system apparatusSpacecraft guiding apparatusElectricityDeflection angle

The invention discloses an electric propulsion angular momentum unloading method taking thruster arc section losses into consideration. The method is suitable for earth synchronous orbit electric propulsion satellites conically arranged, a vector adjusting mechanism adjusting electric thrusters is used for generating the moment of momentum, and angular momentum unloading of an on-satellite angular momentum exchange executing mechanism is achieved. Firstly, under the situation that any unloading number of days is given, and ignition combinations (a normal or fault mode) are kept at any positions of the electric thrusters on the diagonal line, a common and simplified electric propulsion angular momentum unloading dynamics model taking the arc section losses into consideration is established; then, method establishing conditions and an electric thruster deflection angle obtaining method are given; and finally, a treatment manner under the situation of the overload of angular momentum unloading is given. According to the method, through proper simplification on the dynamics model, the calculated amount of the unloading method is reduced, the arc section losses of electric thruster ignition are taken into consideration, the angular momentum unloading precision is improved, and an effective method is provided for in-orbit angular momentum unloading of the electric thrusters.

Owner:BEIJING INST OF CONTROL ENG

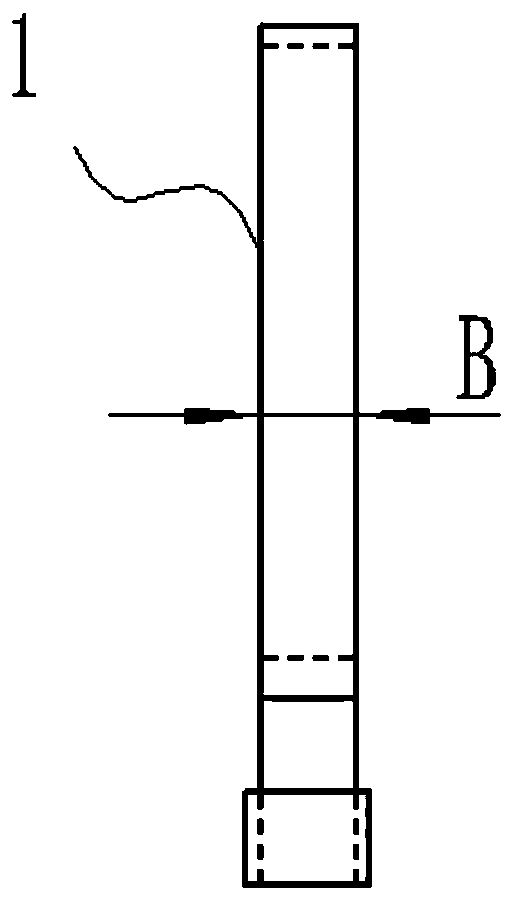

Device and method for winding a web of material

The invention relates to a device for winding a material web on a mandrel (5), said device having at least one roller (2, 3), on which the reel is supported during winding and which Rotates at a maximum rotational frequency, wherein the rollers are mounted in bearing arrangements via a bearing (7, 8) at each roller end, and the rollers (2, 3) and their bearing arrangements have a first natural frequency. It is also desirable to be able to wind vibration-critical material webs with as few problems as possible. For this purpose, the first natural frequency can be set to be lower than the maximum rotational frequency of the roller.

Owner:VOITH PATENT GMBH

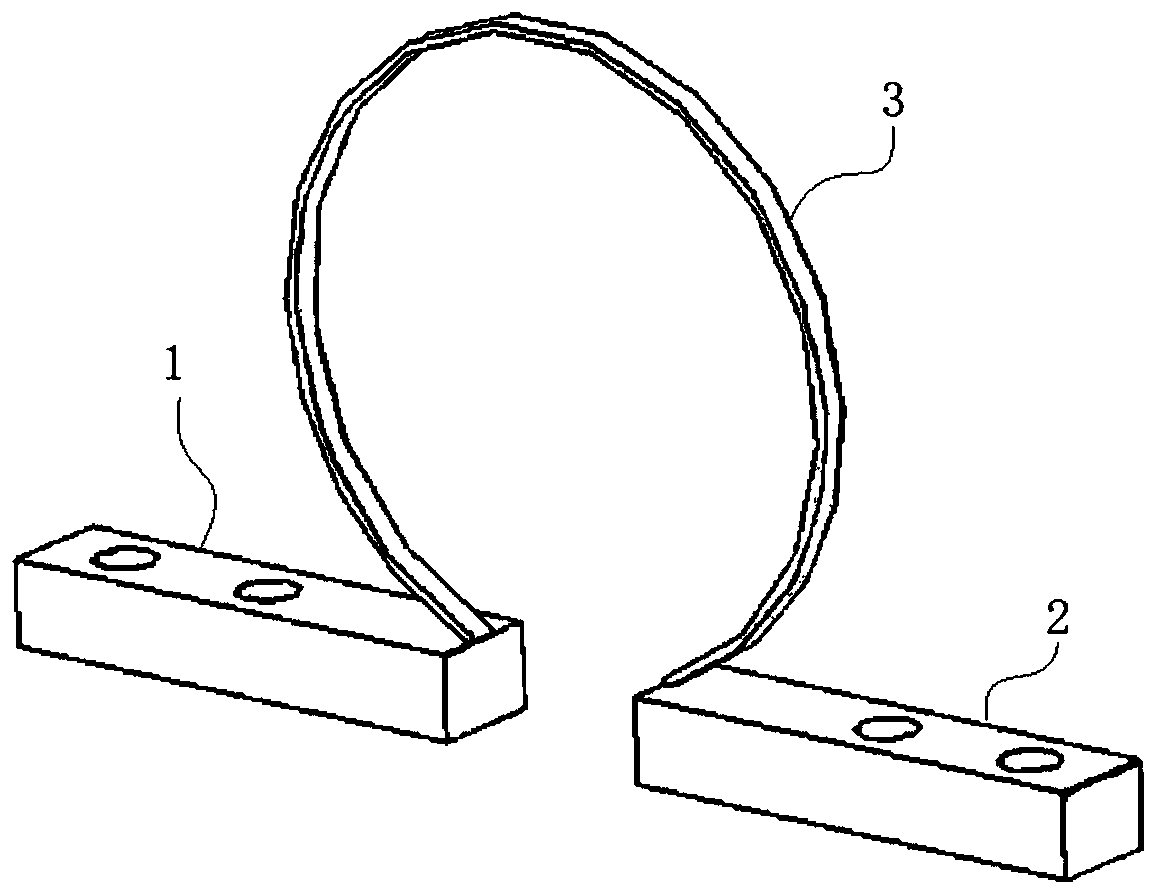

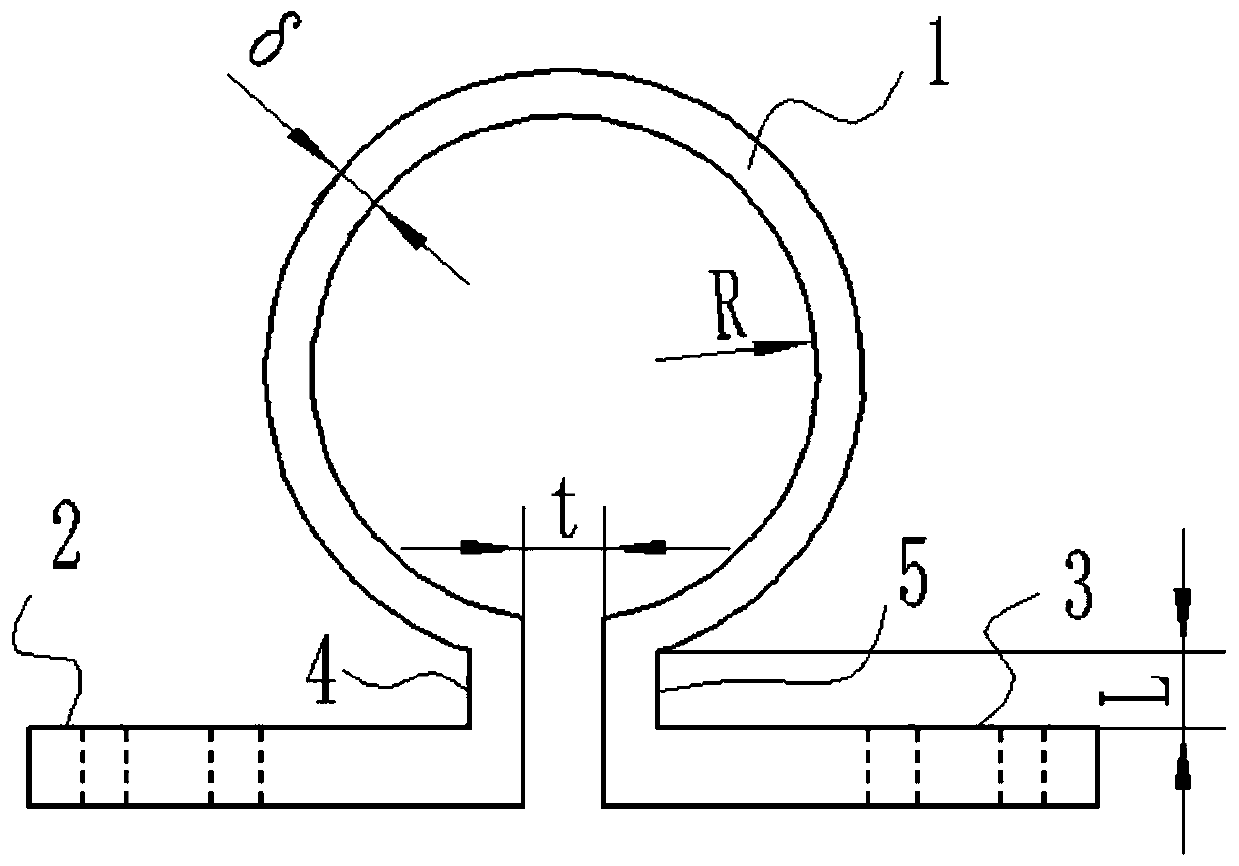

Elastic supports for flutter wind tunnel models

ActiveCN107631851BReduce difficultyReduce rotation frequencyAerodynamic testingIntegrated designTest requirements

Owner:SHENYANG AIRCRAFT DESIGN INST AVIATION IND CORP OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com