Multi-workstation stamping glassware pressing machine

A glassware and multi-station technology, applied in glass pressing, glass production, glass molding, etc., to improve product quality, reduce production costs, and increase production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

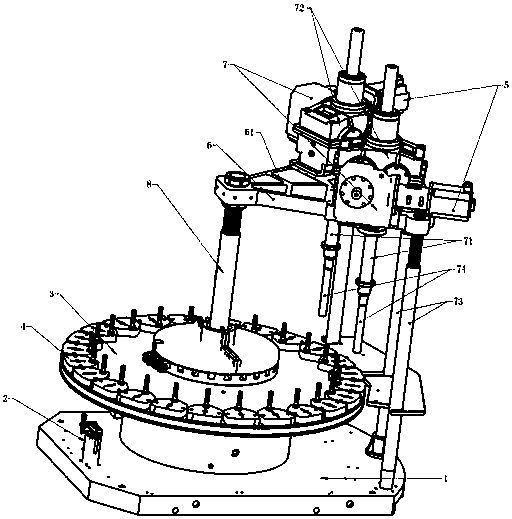

[0022] Such as Figure 1-2 Shown is a multi-station stamping glassware press, which includes a base 1, a cup top device 2, a turntable 3, a lower mold 4, a center column 8, a frame 6, a control system and two sets of servo stamping devices 7;

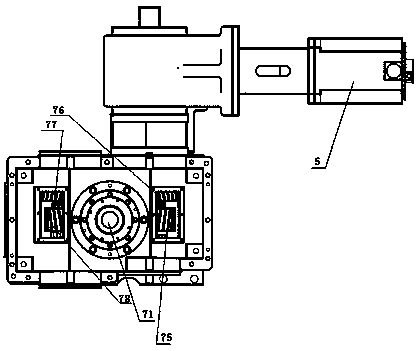

[0023] The servo stamping device 7 includes a support column 73, a servo motor 5, a mechanical transmission assembly 72, a pressing rod 71 and an upper mold 74; one end of the support column 73 is fixedly connected to the base 1, and the other end is fixedly connected to the frame 6 , cooperate with the center column 8 to support the frame 6; the servo motor 5 is fixedly installed on the frame 6, and the power output end of the servo motor 5 is connected to the pressing rod 71 slidingly connected to the frame 6 through a mechanical transmission assembly 72 The radial ends of the cross-section control the pressing rod 71 to move up and down, and the servo motor 5 is electrically connected to the control system; the upper die 74 is fixedl...

Embodiment 2

[0031] The difference between the second embodiment and the first embodiment is that there are three sets of servo stamping devices 7 installed on the pressing machine, and three pieces of glassware can be pressed simultaneously when pressing small pieces of glassware.

Embodiment 3

[0033] The difference between embodiment three and embodiment one and two is that there are six sets of servo stamping devices 7 installed in the pressing machine. When pressing small pieces of glassware, six pieces of glassware can be pressed at the same time, and some parts can be slightly pressed. Larger glassware are pressed simultaneously.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com