Method and device for box spinning

A technology of centrifugal spinning and spinning machines, which is applied to spinning machines, textiles, papermaking, and open-end spinning machines, etc., and can solve problems such as the generation and existence of yarn package residues that cannot be found, and can only be found at a later date

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

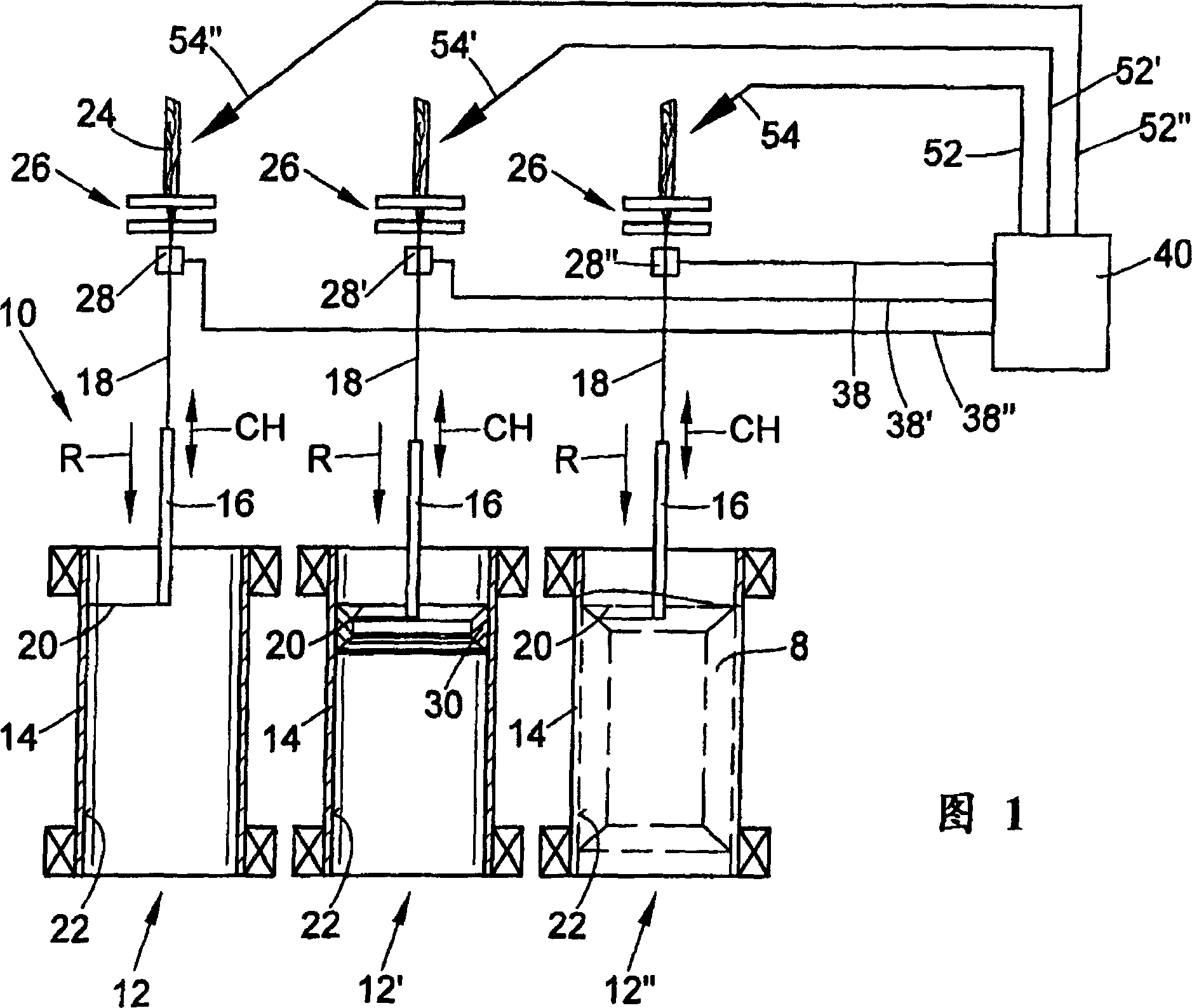

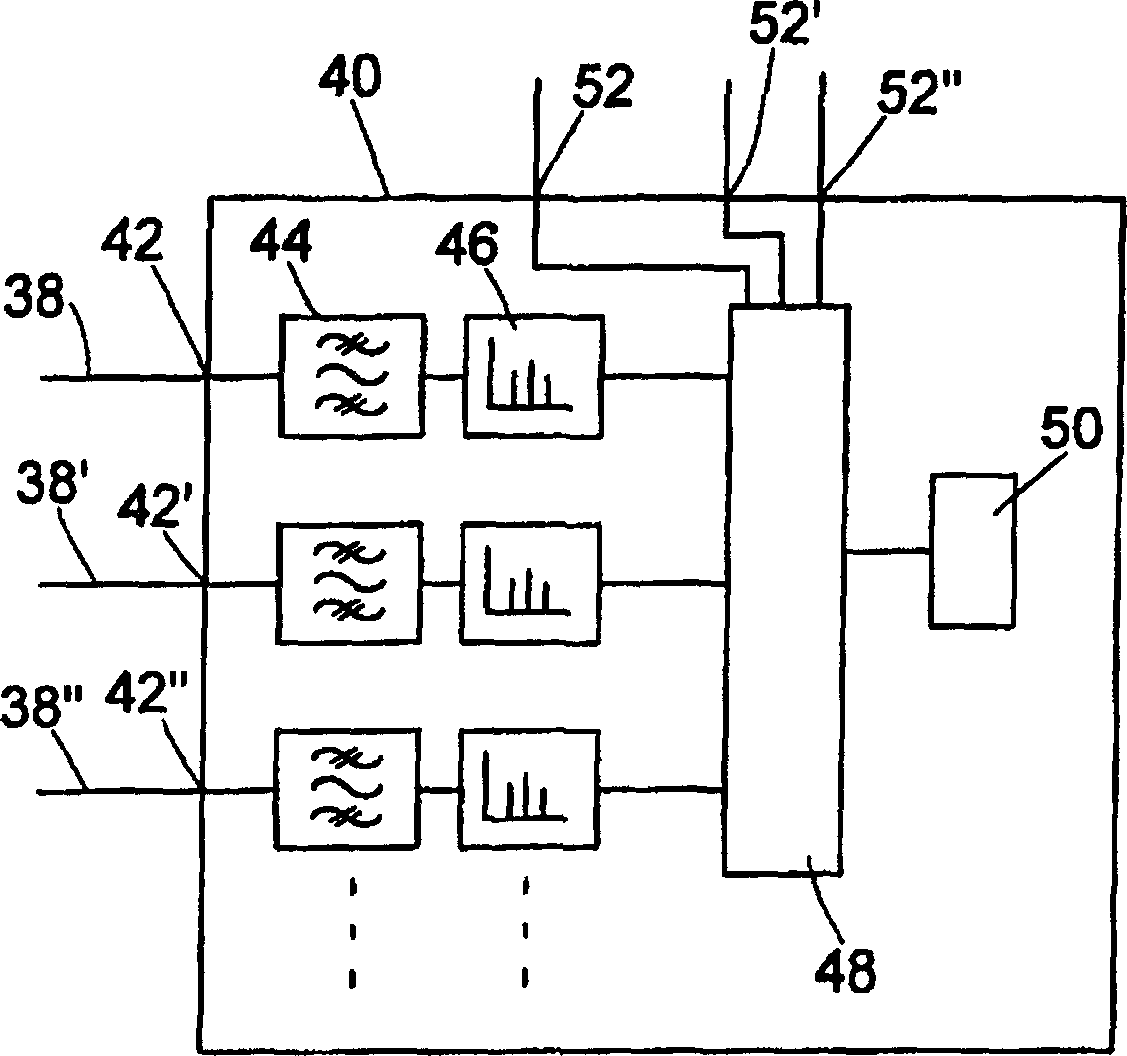

[0040]Fig. 1 shows schematically a centrifugal spinning machine 10 with many working positions 12, and three such working positions 12, 12' and 12 " are shown in sectional view in Fig. 1 .

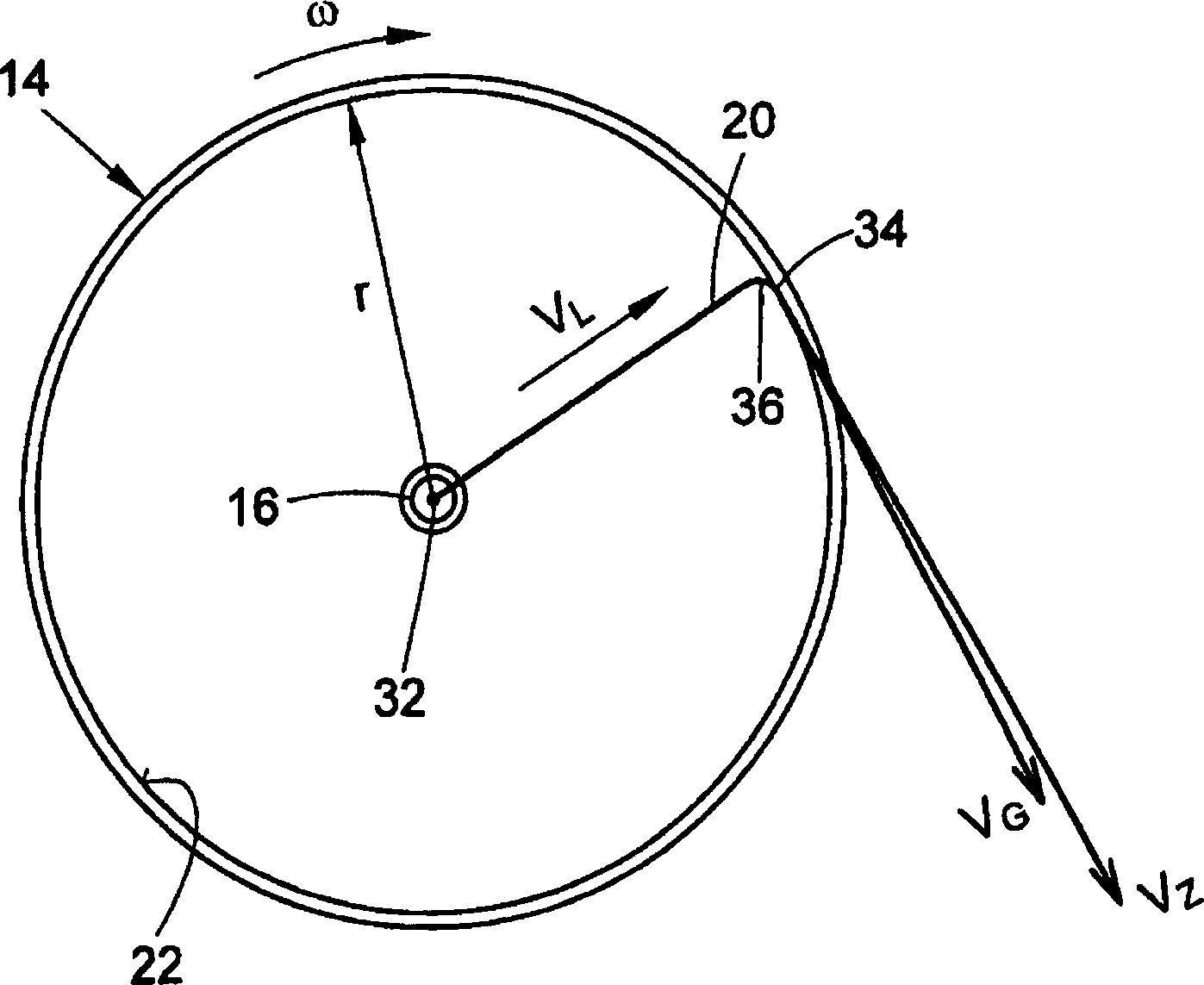

[0041] Each working station 12 comprises a centrifugal spinning pot 14 rotating at high speed supported, for example, by magnetic bearings not shown.

[0042] The centrifugal spinning tanks 14 are each associated with a tubular yarn guide 16 capable of traversing and descending in the direction R, the longitudinal axis of which is located on the axis of rotation of the centrifugal spinning tank 14 .

[0043] The individual rovings 24 are fed into the centrifugal spinning tank 14 via the yarn feeder 16 and are placed as yarn cake 8 on the inner wall 22 of the spinning centrifugal tank 14 with the formation of a yarn strand 20 . A spun yarn 18 can thus be produced from the roving by the rotation of the centrifuge pot 14 .

[0044] The roving 24 is drafted in a drafting device 26, which is o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com