Patents

Literature

31results about How to "Uniform hydrolysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method for high-purity alumina

InactiveCN102491391AUniform hydrolysisFully hydrolyzedAluminium oxide/hydroxide preparationMetallic aluminumSapphire

A preparation method for high-purity alumina powder includes: preparing aluminum alkoxide in liquid state at the room temperature by means of reaction of metallic aluminum with sec-butyl alcohol, using the reduced pressure distillation method for purifying, and preparing the high-purity alumina powder by means of hydrolyzing, reduced pressure distillation and calcinations. Using the method to prepare high-purity alumina powder has the advantages of simple preparation process, no pollution, low energy consumption, fine operating conditions, zero emission and the like. The alumina powder prepared by the method is applicable to the field of catalysts and can also be applied to the fields of laser crystals, sapphires, transparent alumina ceramics, sodium lamps, metal halides, high-grade abrasives and the like.

Owner:DALIAN JIAOTONG UNIVERSITY

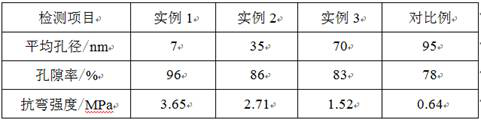

Method for preparing high-strength aluminum oxide foamed ceramic

The invention discloses a method for preparing a high-strength aluminum oxide foamed ceramic and belongs to the technical field of porous materials. The method comprises the following steps: mixing deionized water with polyvinyl alcohol solution in a mass ratio of (5:1)-(5:2), adding absolute ethyl alcohol which is 0.1-0.2 time of the mass of the deionized water, ammonium polyacrylate which is 0.1-0.2 time of the mass of the deionized water and alumina powder which is 0.3-0.4 times of the mass of the deionized water, carrying out ball milling and mixing so as to obtain a mixed blank material,mixing the mixed blank material with a hydroxymethyl cellulose solution according to a mass ratio of (8:1)-(10:1), adding an additive which is 0.3-0.5 time of the mass of the mixed blank material, stirring and mixing, injecting into a mold, carrying out heat-preservation curing, and calcining, thereby obtaining the high-strength aluminum oxide foamed ceramic. The high-strength aluminum oxide foamed ceramic prepared according to the technical scheme of the invention is uniform in pore size, has the characteristics of being high in strength under a high porosity condition, and has wide prospectsin development of the porous material technique industry.

Owner:郑州孚莱孚特性材料有限公司

Production process for extracting cystine by hair

InactiveCN103936639AHigh economic valueScientific and reasonable production process designOrganic compound preparationHydropoly/poly sulfide preparationHair streamsAnimal hair

The invention relates to a production process for extracting cystine by hair. The production process for extracting cystine by hair is characterized by comprising the following steps: step 1, preparing a cystine crude product by animal hair; step 2, treating the cystine crude product; and step 3, preparing a cystine finished product. The production process for extracting cystine by hair disclosed by the invention is scientific and reasonable in design, low in production cost, high in product purity and high in hair recovery rate. According to the production process for extracting cystine by hair disclosed by the invention, impurities are removed by neutralization and decolouration three times to purify the product, thus the quality of the product can achieve the standards of pharmacopoeia, AJI92 and USP (United States Pharmacopoeia), and economic value is greatly increased.

Owner:峨眉山市龙腾生物科技有限公司

Method for extracting leucine by utilizing corn protein powder

InactiveCN103922951ALow priceReduce manufacturing costOrganic compound preparationAmino-carboxyl compound preparationTert-leucineHydrolysis

The invention relates to a method for extracting leucine by utilizing corn protein powder. The method is characterized by comprising the steps of 1, hydrolysis stage of the corn protein powder; 2, preparation stage of leucine crude product I; 3, preparation stage of leucine crude product II; 4 preparation stage of leucine finished product. The method for extracting the leucine by the utilizing corn protein powder takes the corn protein powder as a production raw material, and the corn protein powder is lower in price, so that the production cost is greatly lowered. Furthermore, the product prepared by the method is high in purity, and the production technological conditions are simple, so that the method is more suitable for large-scale production and use.

Owner:鲁成宪

Preparation method for TiO2/WO3 composite powder

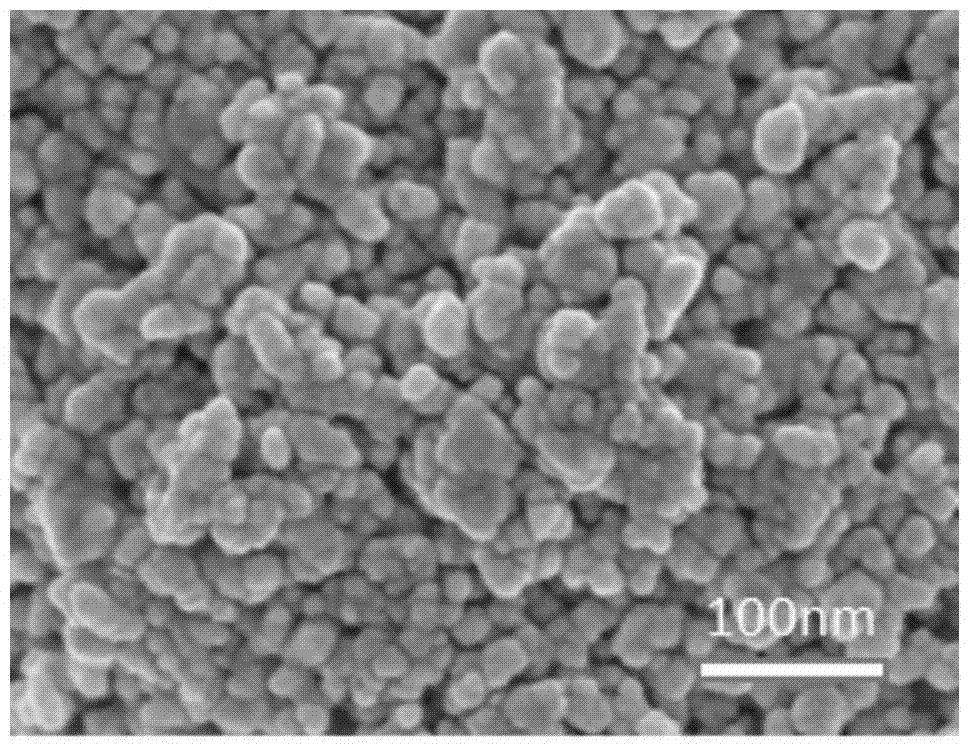

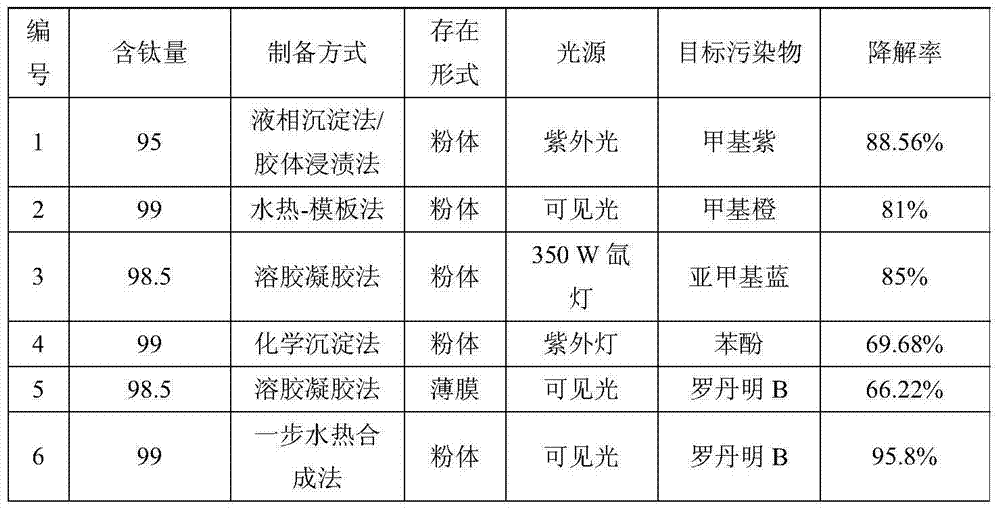

ActiveCN104741112AAvoid hydrolysisUniform hydrolysisWater/sewage treatment by irradiationOther chemical processesReaction temperatureSmall particle

The invention discloses a preparation method for TiO2 / WO3 composite powder. The preparation method comprises the following steps: uniformly mixing titanium sulfate, urea, alcohol and deionized water, adding acetylacetone, and uniformly stirring at the room temperature to obtain a solution A; dropwise adding concentrated nitric acid into the solution A to obtain a solution B; preparing a 0.1-0.3mol / L K2WO4 aqueous solution, and regulating the pH value to 1-3.5 to obtain a solution C; mixing the solution B with the solution C. performing hydrothermal reaction to obtain the TiO2 / WO3 composite powder. According to the preparation method disclosed by the invention, the titanium sulfate, K2WO4.2H2O and the like with low price are taken as raw materials, so that the preparation cost is low; a solution containing Ti and W is prepared and a product with the advantages of low reaction temperature and short period can be prepared by adopting a one-step hydrothermal method. By using the hydrothermal method is adopted, the TiO2 / WO3 composite powder with controllable morphology, high purity, small particles and a uniform particle size can be prepared.

Owner:广西自贸区见炬科技有限公司 +1

Preparation method of metal oxide/hollow microsphere composite filler

ActiveCN111995883AAvoid uneven crystallizationUniform hydrolysisPigment treatment with organosilicon compoundsReflecting/signal paintsMicrospherePhysical chemistry

The invention discloses a preparation method of a composite filler. According to the method, a metal oxide precursor is formed at first, hollow microspheres are introduced in the growth process of metal oxide crystal nucleuses, a silane coupling agent is added, metal oxide crystals and the hollow microspheres are combined in order through hydrolysis of the silane coupling agent, and agglomerationof metal oxide on the surfaces of the hollow microspheres is avoided; and metal oxide crystals in an ordered array are formed and then are rapidly hydrolyzed and crosslinked together with a metal oxide precursor, so rapid accumulation and growth of a metal oxide layer are realized, a tightly combined metal oxide wrapping layer is obtained by means of calcination and the like, and a flat reflectinglayer on the surface of the formed filler is effectively controlled. According to the method, the density and reflectance ratio of a surface reflection layer can be improved, and the heat insulationeffect of the obtained composite filler is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

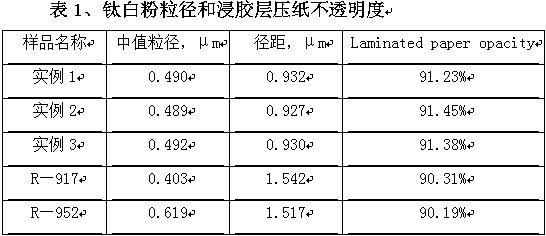

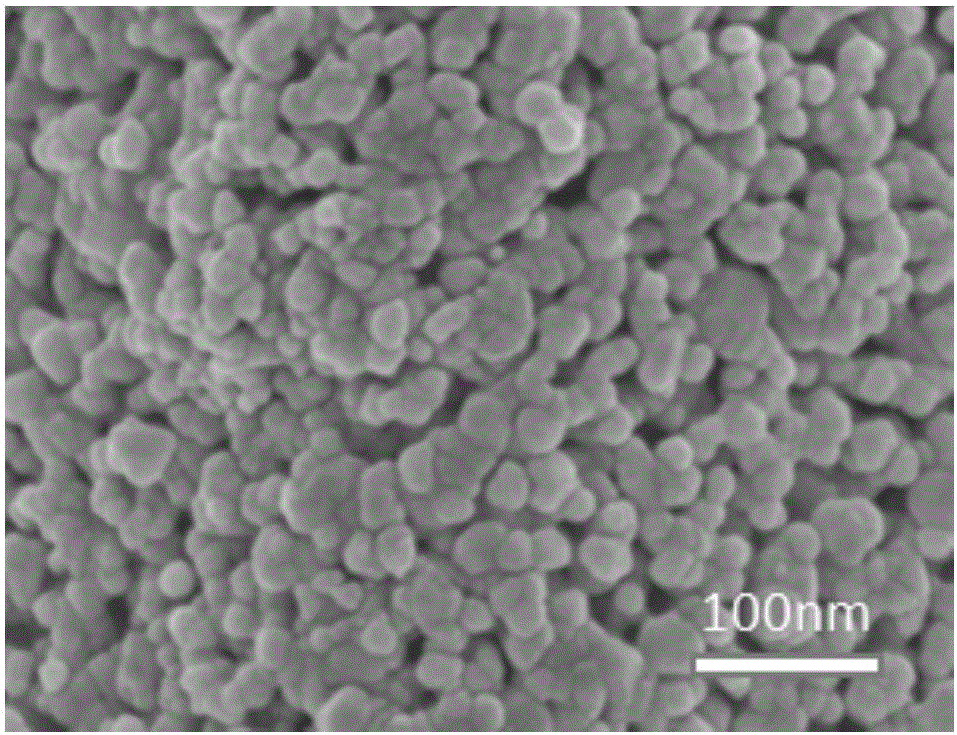

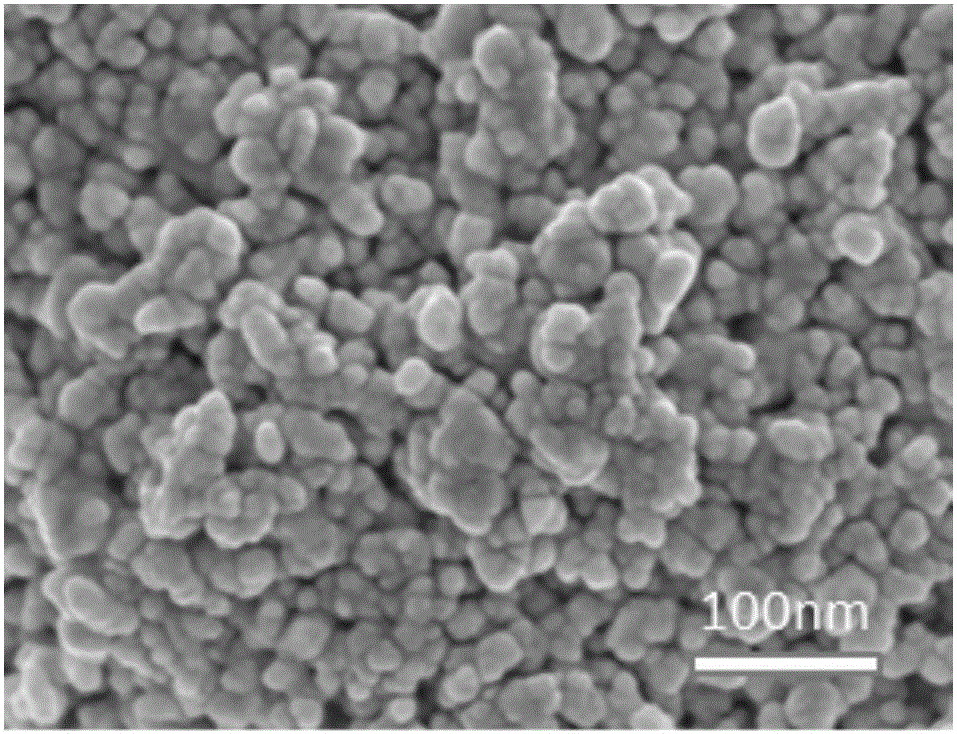

Method for controlling particle diameter of decorative body paper titanium dioxide

ActiveCN107500347AUniform sizeSleek sizeTitanium compoundsInorganic compound additionSaline waterSulfate

The invention discloses a method for controlling the particle diameter of decorative body paper titanium dioxide, and belongs to the technical field of decorative body paper titanium dioxide. Through the control of a hydrolysis working procedure, the method comprises the following steps: A: selecting titanium sulfate solution, preheating to 96-98 DEG C for standby use, and preheating desalted water to be boiling for standby use; B: firstly, adding the desalted water which is preheated to be boiling into a hydrolysis reactor to be stirred, then, adding the preheated titanium sulfate solution, stirring after the titanium sulfate solution finishes adding, and heating to raise temperature to slight boiling; C: after a hydrolysis rate of step B achieves 50-65%, stopping stirring and heating, and carrying out curing; D: after curing is carried out, stirring again, heating and raising temperature to slight boiling, and carrying out hydrolysis for 160-180min; E: adding the boiling desalted water, controlling total titanium concentration TiO2 in slurry to be 160-180g / L, keeping the slight boiling, and carrying out hydrolysis for 50-60min. According to the method disclosed by the invention, a titanium sulfate solution pyrohydrolysis technology is implemented by meeting body paper requirements, water and titanium dioxide particle diameter are even, and the method conforms to the hydrolysis technology specially designed for the particle diameter requirement of the decorative body paper titanium dioxide.

Owner:HEBEI MILSON TITANIUM DIOXIDE

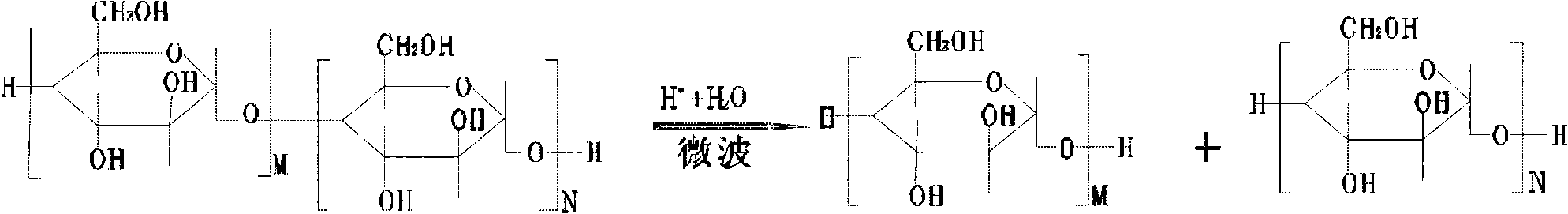

Dry method for preparing dextrin by microwave

The invention relates to a dry method for preparing dextrin by microwave. In the preparation method, starch and inorganic acid are used as raw materials; and by using special thermal effect and non-thermal effect of the microwave, the dextrin is prepared by hydrolyzing the starch with the acid in a microwave field. The preparation method comprises the following steps of: pouring the starch into an acid dosing machine, starting the acid dosing machine, spraying 1 to 30 percent acid in an amount which is 2 to 20 percent of the mass of the starch and uniformly mixing the starch and the acid; and putting the uniformly mixed starch which is added with the acid into a microwave reactor to perform microwave radiation for 2 to 20 minutes to obtain a finished product of the dextrin. Compared with the prior art, the dry method for preparing the dextrin by the microwave has the characteristics of simple and safe operation, low reaction temperature, short time, high efficiency, low energy consumption, no pollution, uniform starch hydrolysis, large-scale continuous production and the like, and is a simple, high-efficiency, energy-saving and environmental-friendly method for preparing the dextrin.

Owner:罗代洪 +2

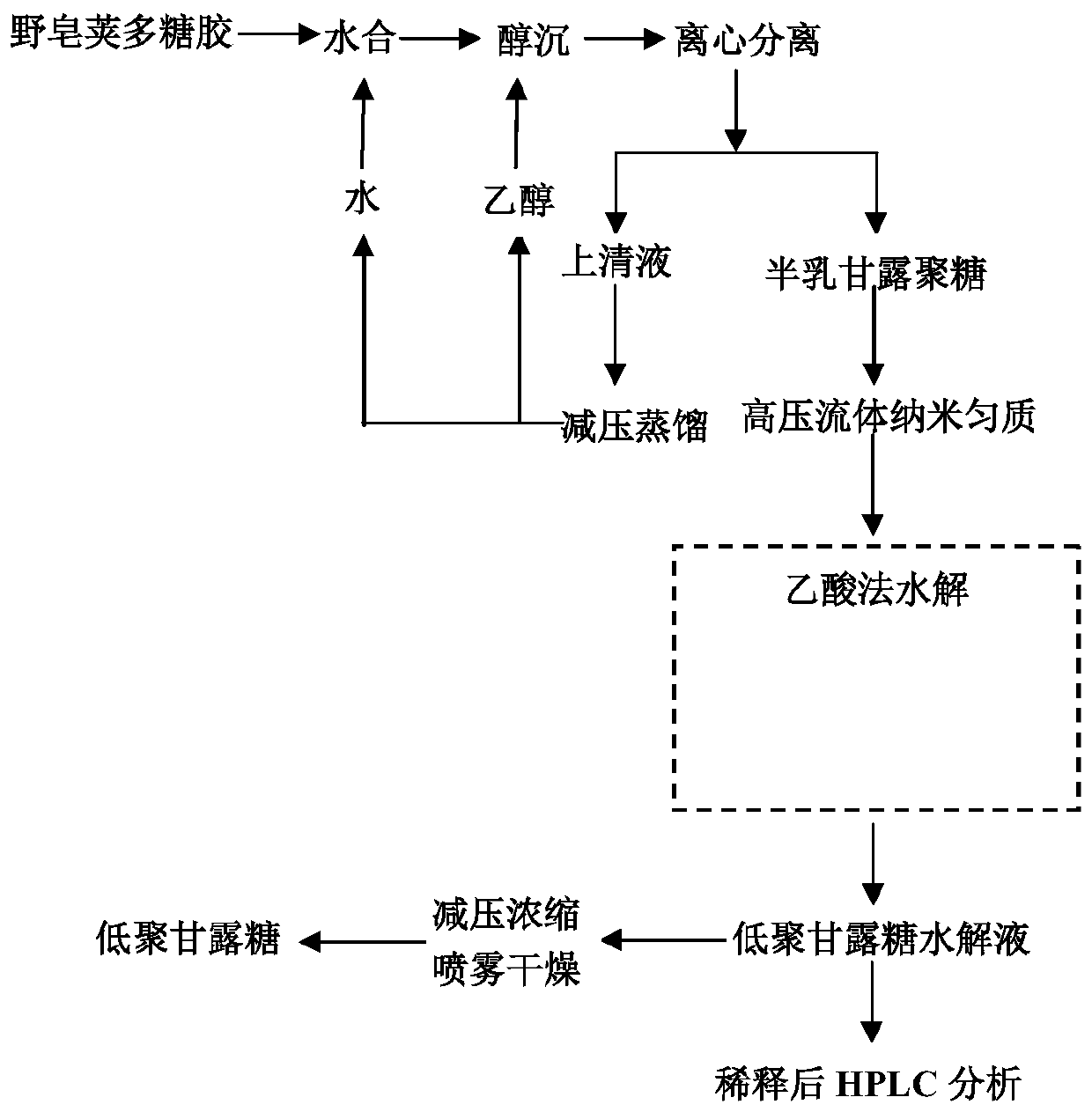

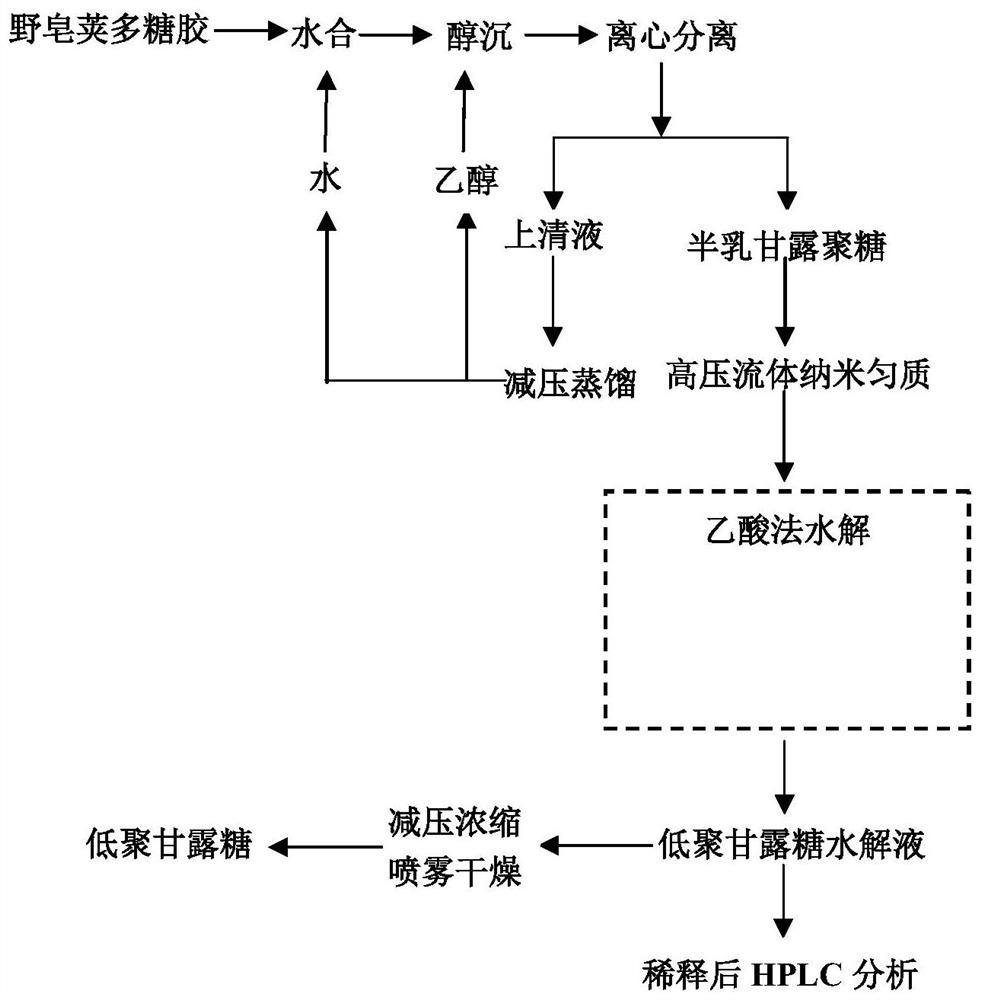

Preparation method of mannose oligosaccharides

ActiveCN109988872ASmall molecular weightEfficient removalSaccharides productionHigh pressureHydrolysis

The invention relates to a preparation method of mannose oligosaccharides. The method comprises the following steps: performing high-pressure fluid nano homogenization treatment on a galactomannan solution, adding acetic acid, and performing a degradation reaction; or, the method further comprises the steps of after the degradation reaction is completed, performing reduced-pressure concentration to recover the acetic acid, and performing spray drying on the concentrate to obtain the mannose oligosaccharides. According to the method provided by the invention, the galactomannan is subjected to homogenization by a high-pressure fluid nano homogenizer, the acetic acid is directly added for hydrolysis, so that the hydrolysis is uniform, and the hydrolysis speed is fast; compared with inorganicacids such as hydrochloric acid, sulfuric acid and trifluoroacetic acid, the acetic acid belongs to organic acids, has less corrosion to equipment and is easy to recycle; and the method can improve the production efficiency of the mannose oligosaccharides and improve the selectivity of the product, and has good industrial application prospects.

Owner:BEIJING FORESTRY UNIVERSITY

A kind of preparation method of alumina foam ceramics

The invention discloses a method for preparing a high-strength aluminum oxide foamed ceramic and belongs to the technical field of porous materials. The method comprises the following steps: mixing deionized water with polyvinyl alcohol solution in a mass ratio of (5:1)-(5:2), adding absolute ethyl alcohol which is 0.1-0.2 time of the mass of the deionized water, ammonium polyacrylate which is 0.1-0.2 time of the mass of the deionized water and alumina powder which is 0.3-0.4 times of the mass of the deionized water, carrying out ball milling and mixing so as to obtain a mixed blank material,mixing the mixed blank material with a hydroxymethyl cellulose solution according to a mass ratio of (8:1)-(10:1), adding an additive which is 0.3-0.5 time of the mass of the mixed blank material, stirring and mixing, injecting into a mold, carrying out heat-preservation curing, and calcining, thereby obtaining the high-strength aluminum oxide foamed ceramic. The high-strength aluminum oxide foamed ceramic prepared according to the technical scheme of the invention is uniform in pore size, has the characteristics of being high in strength under a high porosity condition, and has wide prospectsin development of the porous material technique industry.

Owner:郑州孚莱孚特性材料有限公司

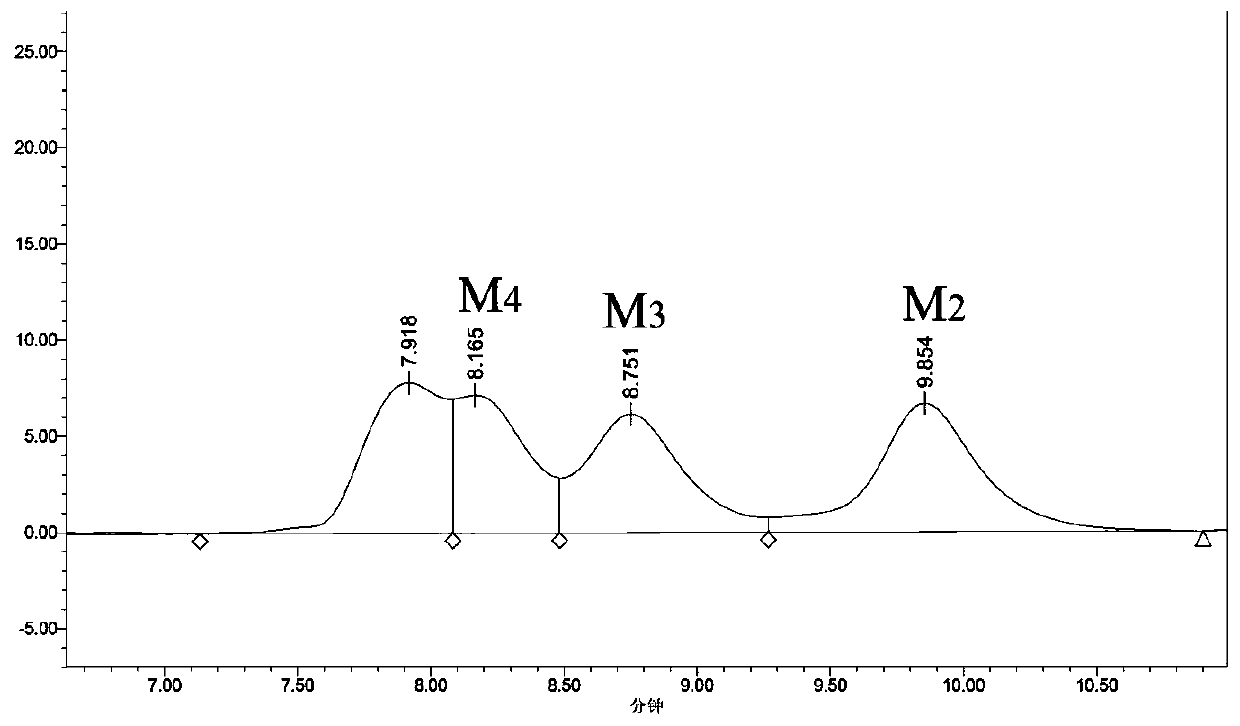

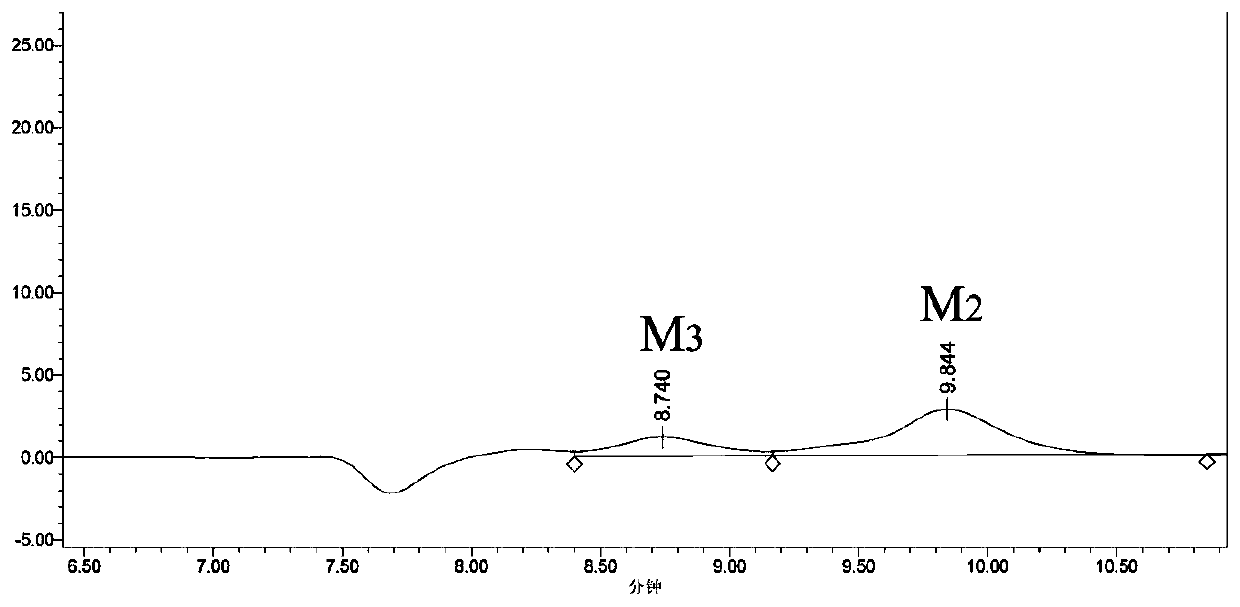

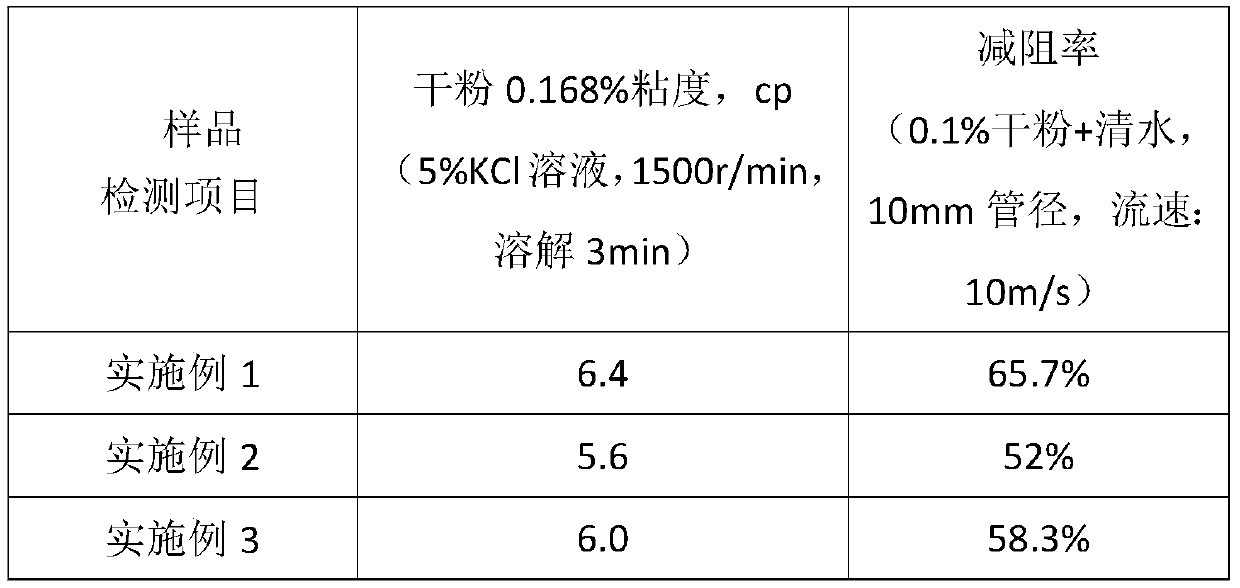

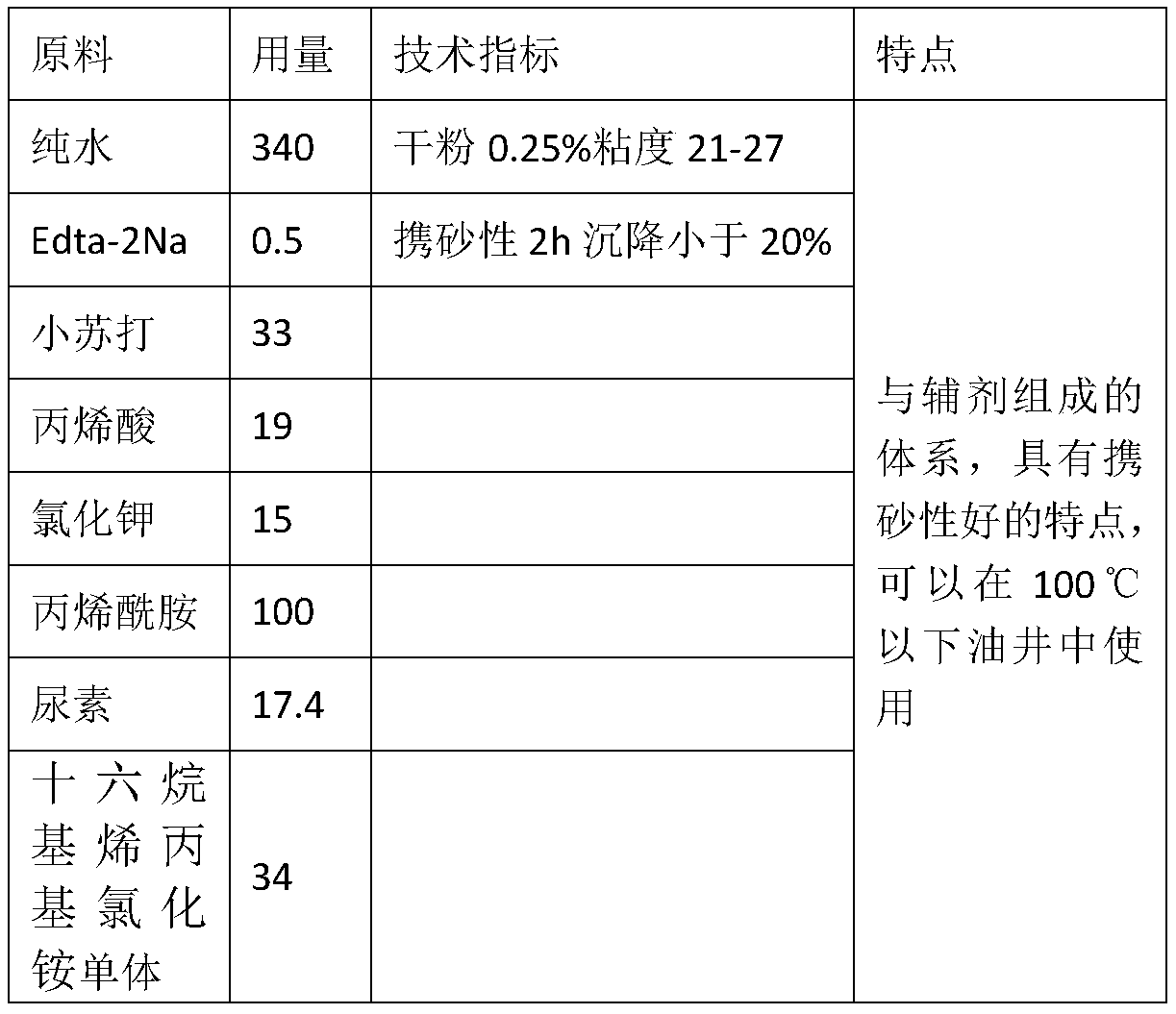

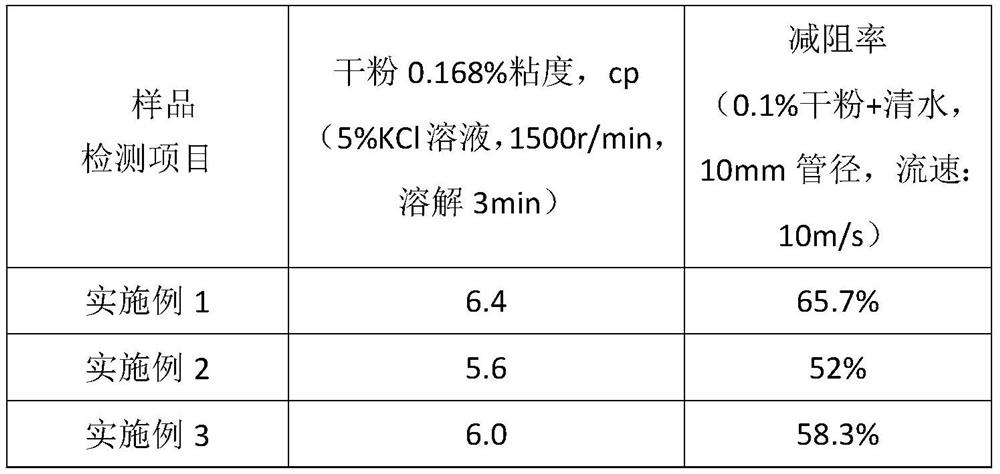

Salt-resistant drag-reduction agent polymer, and synthetic technology thereof

ActiveCN110194816AReduce pollution impactReduce conveying resistanceDrilling compositionSodium bicarbonatePolymer science

The invention discloses a salt-resistant drag-reduction agent polymer, and synthetic technology thereof. The salt-resistant drag-reduction agent polymer comprises, by weight, 320-360 parts of pure water, 0.1-0.3 part of Edta-2Na, 35-45 parts of sodium bicarbonate, 18-22 parts of acrylic acid, 8-12 parts of AMPS, 75-85 parts of acrylamide, and 14-18 parts of urea. The synthetic technology is simplein operation; product quality is stable; and environment pollution influence is extremely low. The salt-resistant drag-reduction agent polymer possesses advantages such as high dissolving speed, temperature resistance, salt resistance, shearing resistance, excellent compatibleness, and high drag reduction rate, is mainly used for reduction of conveying resistance force in shale hydrocarbon reservoir and compact sandstone hydrocarbon reservoir pressing crack construction and other fluid pipelines, enlarging discharge amount, and reducing power consumption.

Owner:江西富诚生态环境科技集团有限公司

Method for extracting leucine by utilizing corn protein powder

InactiveCN103922951BLow priceReduce manufacturing costOrganic compound preparationAmino-carboxyl compound preparationHydrolysisPreparation stage

The invention relates to a method for extracting leucine by utilizing corn protein powder. The method is characterized by comprising the steps of 1, hydrolysis stage of the corn protein powder; 2, preparation stage of leucine crude product I; 3, preparation stage of leucine crude product II; 4 preparation stage of leucine finished product. The method for extracting the leucine by the utilizing corn protein powder takes the corn protein powder as a production raw material, and the corn protein powder is lower in price, so that the production cost is greatly lowered. Furthermore, the product prepared by the method is high in purity, and the production technological conditions are simple, so that the method is more suitable for large-scale production and use.

Owner:鲁成宪

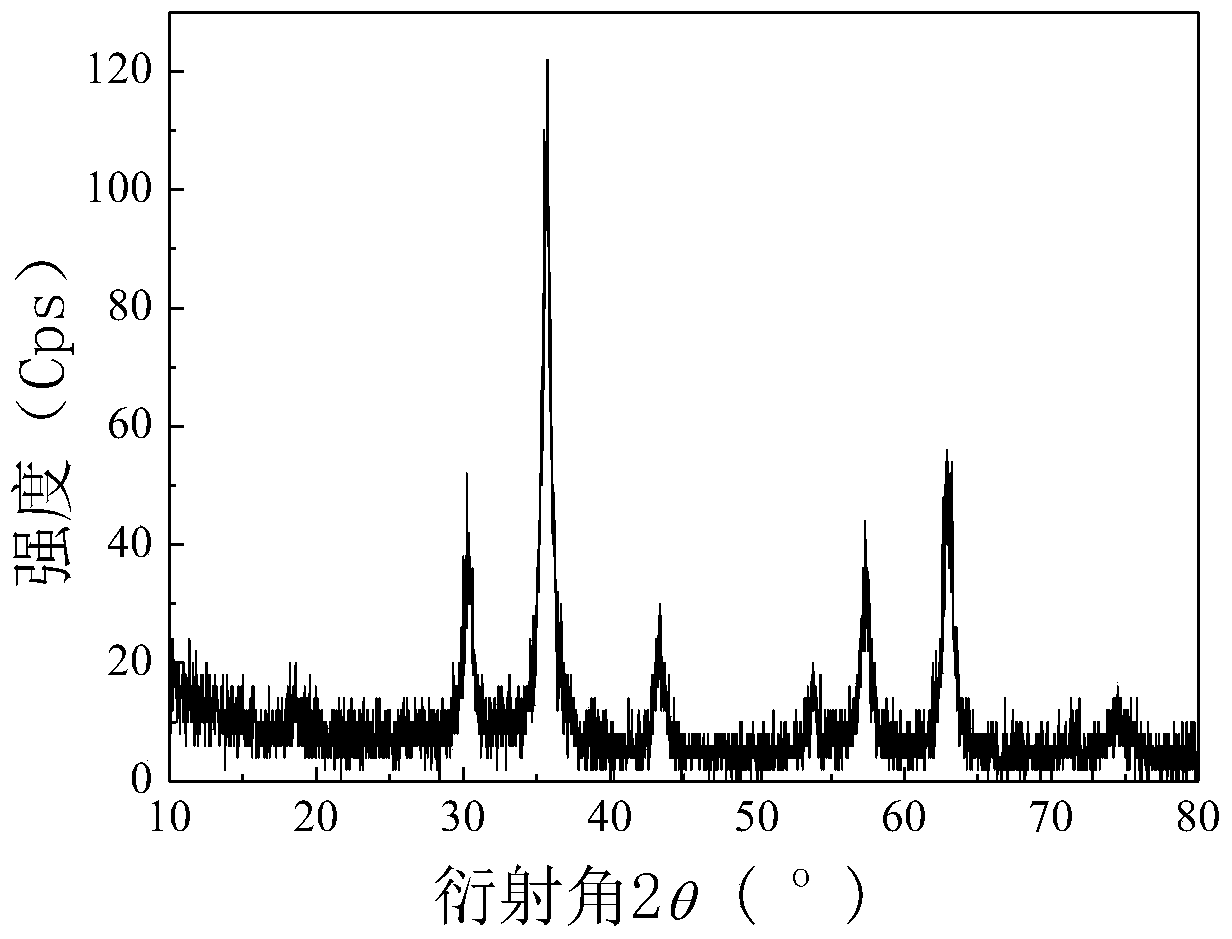

Preparation method of nanometer zirconium dioxide

ActiveCN108862379AFine particle sizeImprove regularityNanotechnologyZirconium oxidesChemistrySulfuric acid

The invention discloses a preparation method of nanometer zirconium dioxide, and belongs to the technical field of preparation of nanometer materials. The preparation method comprises the following steps of mixing zirconium alcohol salt mixture and ethylene glycol according to a mass ratio of 1:1 to 2:1, adding a modified nanometer fiber film and concentrated sulfuric acid, stirring to react, filtering, washing, and drying, so as to obtain a blank of the nanometer zirconium dioxide, wherein the mass of modified nanometer fiber film is equal to 0.2 to 0.4 time of mass of the zirconium alcohol salt mixture, and the mass of concentrated sulfuric acid is equal to 0.01 to 0.02 time of mass of the zirconium alcohol salt mixture; calcining the blank of the nanometer zirconium dioxide to obtain the pretreated nanometer zirconium dioxide, mixing the pretreated nanometer zirconium dioxide and a sodium hydroxide solution according to a mass ratio of 1:5 to 1:10, filtering, washing until the washing solution is neutral, and drying, so as to obtain the nanometer zirconium dioxide. The prepared nanometer zirconium dioxide has the advantages that the particle size distribution range is narrower,the size is smaller, the dispersing property is excellent, and the easiness in agglomeration in the preparation process is avoided.

Owner:乐昌东锆新材料有限公司

Method for extracting leucine by using corn gluten meal

InactiveCN109422661ALow priceReduce manufacturing costOrganic compound preparationAmino-carboxyl compound preparationProcess conditionsHydrolysis

The invention relates to a method for extracting leucine by using corn gluten meal. The method is characterized by comprising the following steps: step 1: a hydrolysis stage of corn gluten meal; step2: a preparation stage of a leucine crude product I; step 3: a preparation stage of a leucine crude product II; and step 4: a preparation stage of a leucine finished product. The method for extractingleucine from corn gluten meal utilizes corn gluten meal as a raw material for production, the price is lower, and the production cost is greatly reduced. At the same time, the product obtained by themethod of the invention has high purity, the production process conditions are relatively simple, and the method is more suitable for large-scale production and use.

Owner:张坤

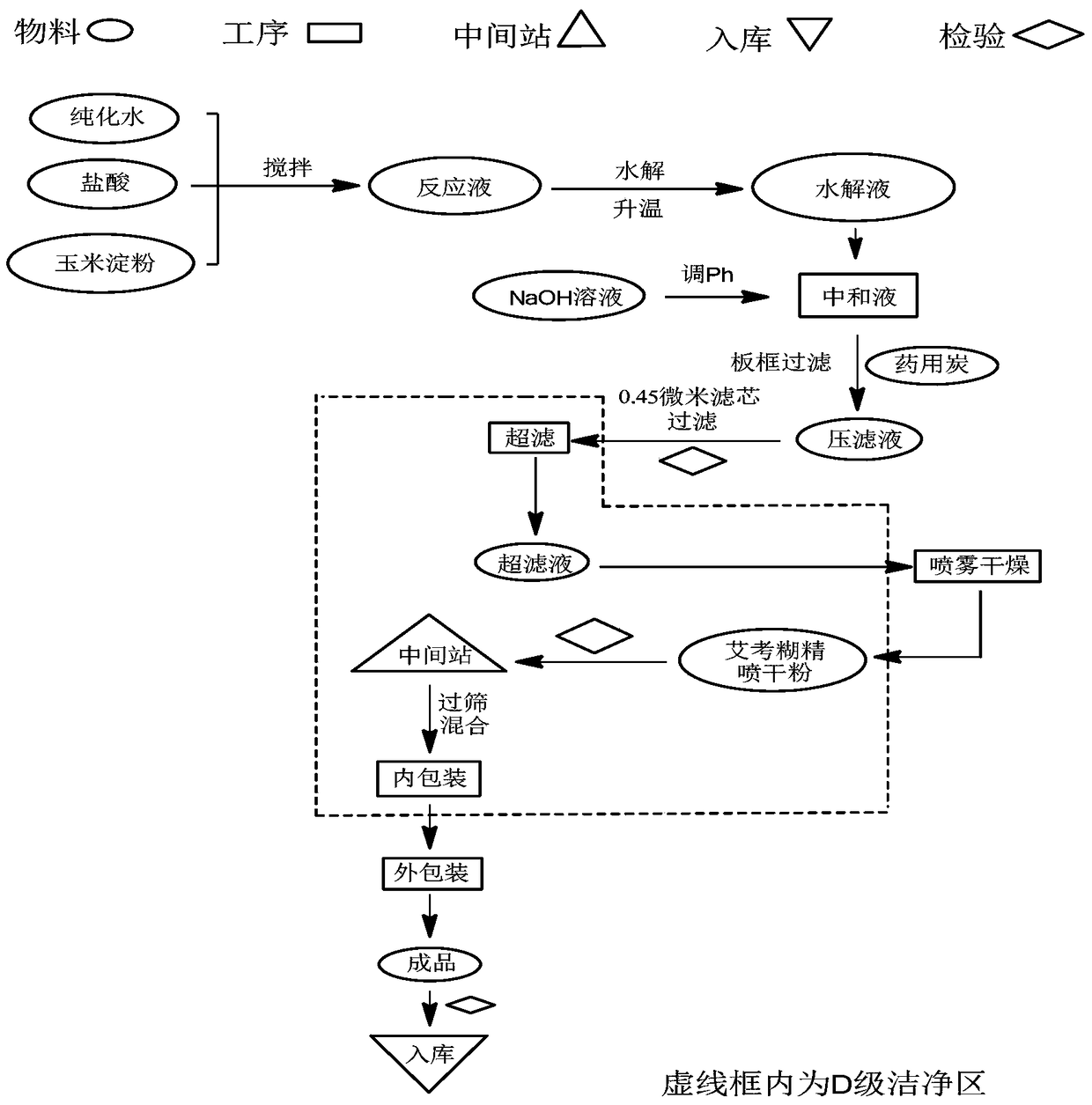

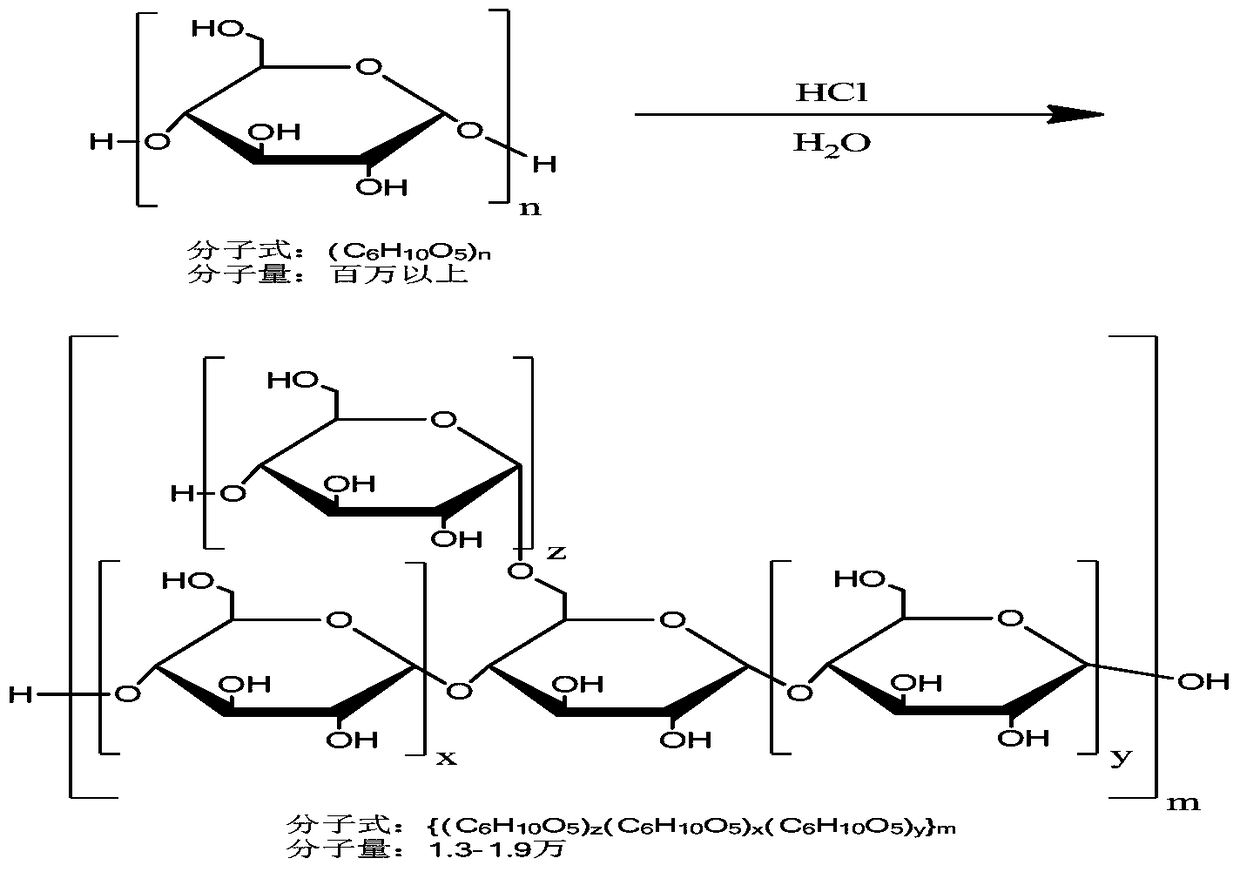

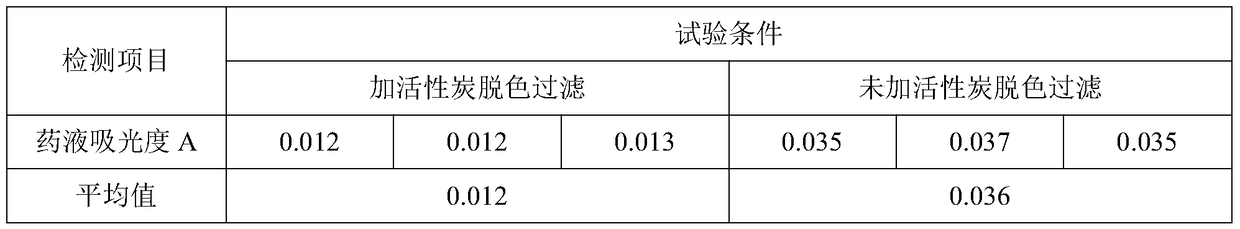

Industrial production method of icodextrin

Owner:四川博佳制药有限公司

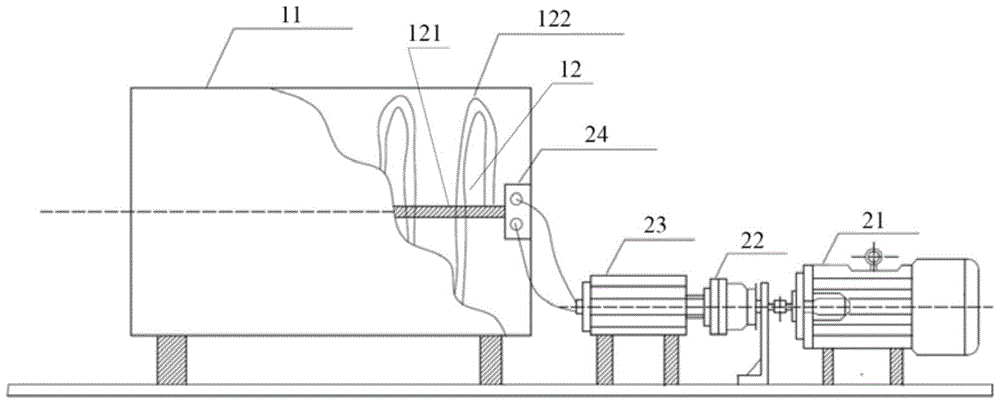

Energy-saving hydrolyzer and method for preparing polyacrylamide polymer by post-hydrolysis method

The invention provides an energy-saving hydrolyzer and method for preparing polyacrylamide polymers by a post-hydrolysis method. The hydrolyzer includes a stirring device, and the direct power of the stirring device of the hydrolyzer is provided by a hydraulic device. The invention also provides a method for producing polyacrylamide polymers by using the energy-saving hydrolyzer. Utilizing the hydrolyzer of the invention to produce polyacrylamide polymers can save energy and reduce consumption, and reduce production costs.

Owner:PETROCHINA CO LTD

A method for modifying magnetic nano-ferric oxide based on wool fiber

ActiveCN105498717BFully hydrolyzedUniform hydrolysisOther chemical processesWater contaminantsOrganic filmCrystal structure

The invention discloses a method for carrying out magnetic nano ferroferric oxide modification based on wool fibers. Organic degradation liquid containing rich amino acid is prepared and then added into a ferroferric oxide precursor solution, nano ferroferric oxide crystallization and settling are carried out, and finally modified nano ferroferric oxide is obtained through filtering, washing and drying. By adding a certain amount of wool fiber degradation liquid, hematite ferroferric oxide nanopaticles for wrapping organic ingredients can be prepared, the clustering phenomenon of generated magnetic nano ferroferric oxide can be avoided, the particle size is small, the ferroferric oxide is uniformly distributed, damage to the crystal structure of ferroferric oxide can be avoided, an organic film wrapped by magnetic nanopaticles on the surface can achieve certain thickness, and combination is firm; meanwhile, ferroferric oxide can be prevented from being oxidized, the adsorption performance on heavy metal ions is good, and ferroferric oxide can be repeatedly used. The preparing method is simple, efficient and free of pollution to the environment.

Owner:XI'AN POLYTECHNIC UNIVERSITY

A method for preparing titanium dioxide/hollow microsphere composite reflective heat insulation filler

ActiveCN109988449BUniform hydrolysisImprove the wrapping effectReflecting/signal paintsPolymer scienceHydrolysis

The invention discloses a preparation method of titanium dioxide / hollow microsphere composite particles. In this method, a hydrophilic alkaline ionic liquid is used to replace the water+alkali system, so that the reaction has a more stable hydrolysis rate. Bead dispersion and surface titania adsorption film formation. The composite particle filler prepared by the above method has good titanium dioxide dispersion and film-forming properties, improves coating uniformity, and has obvious heat insulation effect.

Owner:CHINA PETROLEUM & CHEM CORP +1

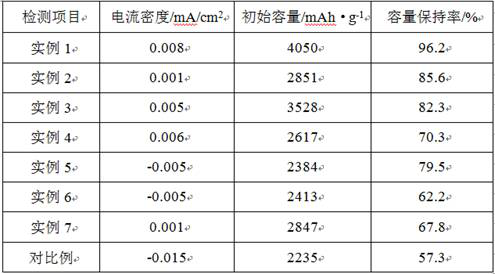

A kind of preparation method of structure-stable lithium battery composite electrode powder material

ActiveCN109860554BEasy reunionAvoid reunionCell electrodesLi-accumulatorsComposite electrodeNew energy

The present invention discloses a preparation method of a lithium battery composite powder body material with a stable structure, belonging to the technical field of new energy materials. The method comprises the steps of: performing reaction of a pretreated oxidized graphene dispersion liquid, a melamine solution and a modified gelatin dispersion liquid to prepare xerogel, performing smashing andscreening of the xerogel to obtain hydrogel crushed aggregates, and performing heating reflux reaction of the hydrogel crushed aggregates, the silicate ester diluent, trimethylaluminum and oleic acidto prepare ordered load hydrogel crushed aggregates, and performing mixed reaction of the ordered load hydrogel crushed aggregates and an ammine silver solution, performing hydrazine hydrate reduction to prepare a reduction material, and finally controlling different temperature rise rates and processing rates to perform high-temperature reaction of the reduction material to prepare a lithium battery composite powder body material with a stable structure. The product prepared in the invention is stable in structure in the use process, effectively avoids decreasing of the performances due to volume expansion, effectively improves the service life, the use safety and the cycle stability of the product and forms a push effect on development of the new energy field.

Owner:江苏全锂智能科技有限公司

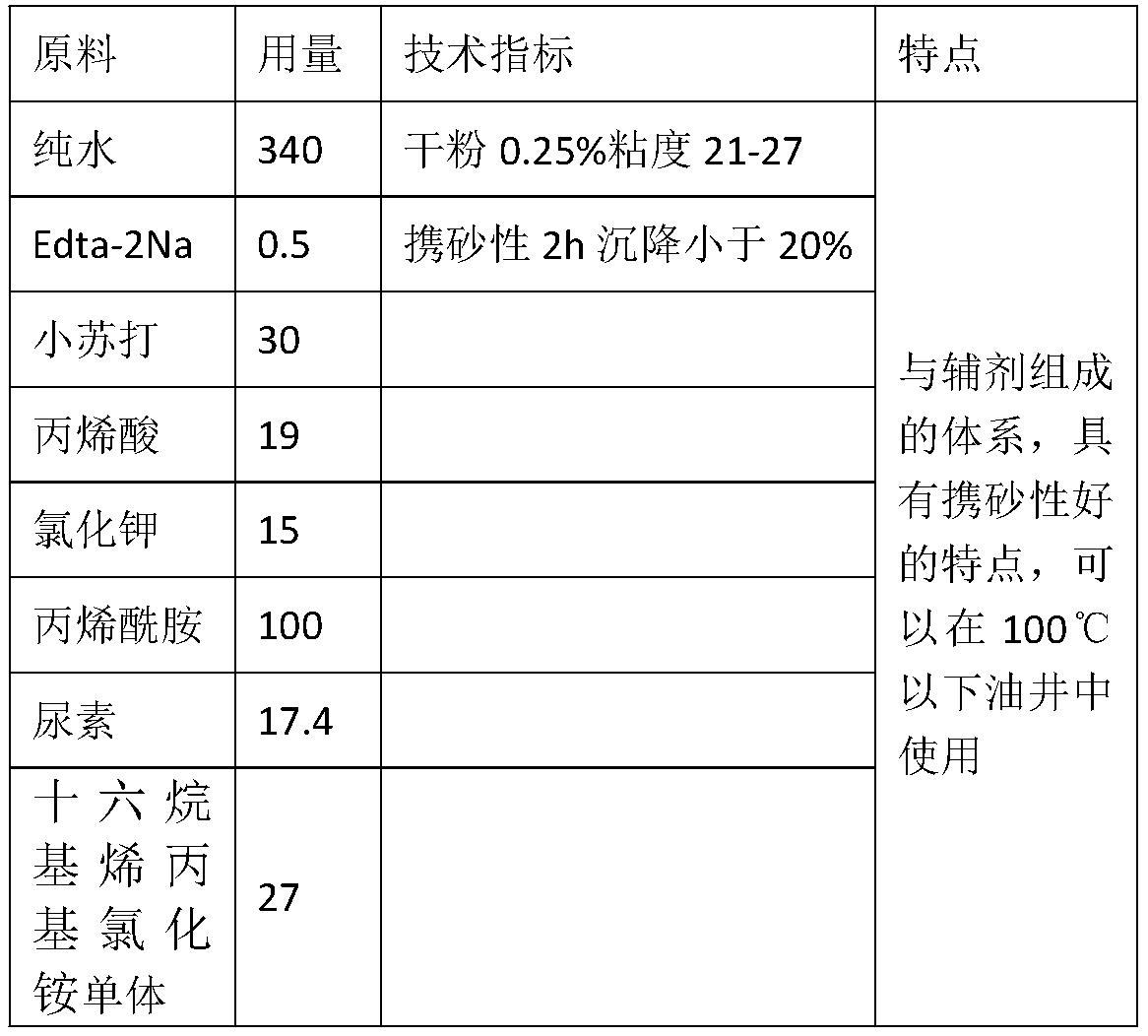

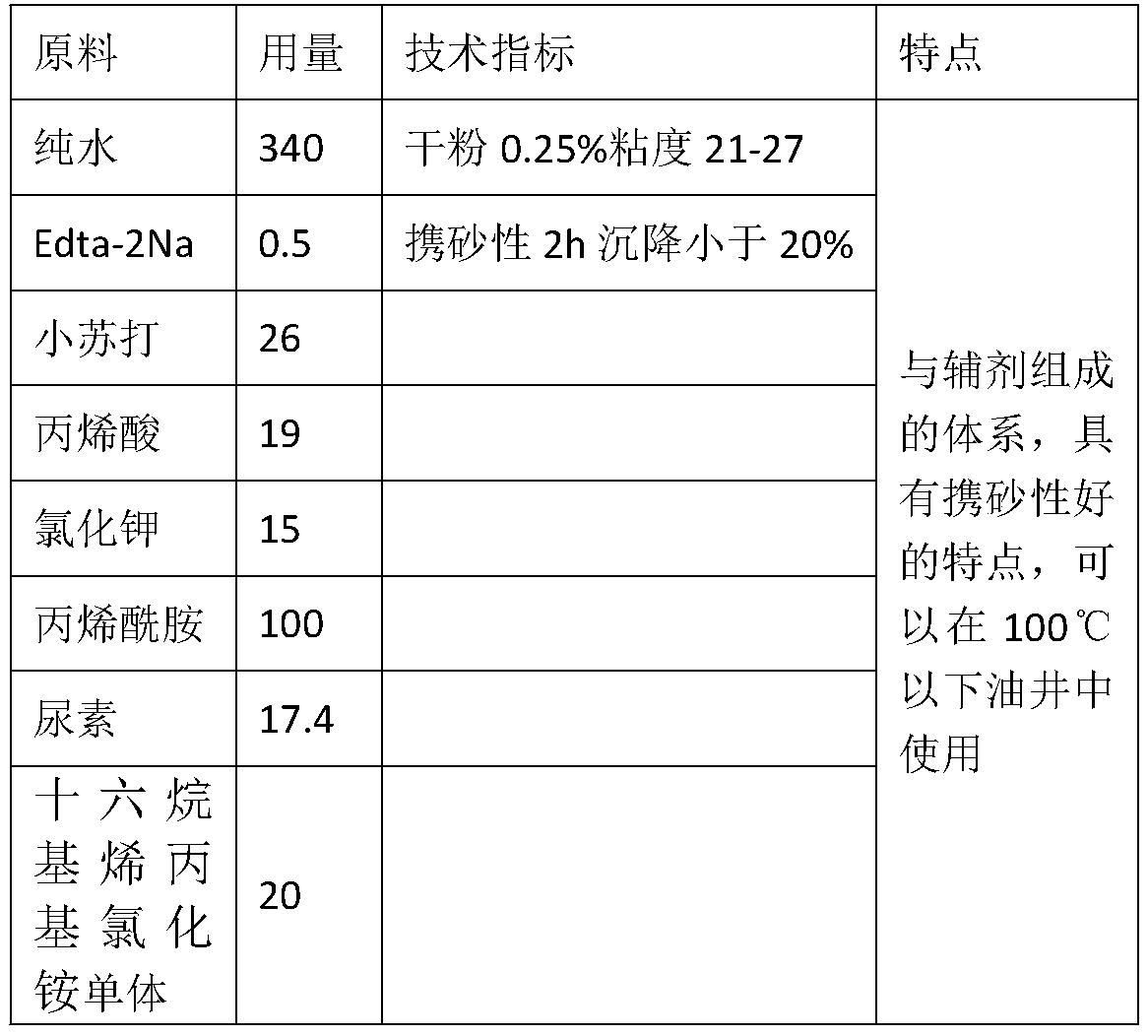

Hydrophobic associated polymer and synthesis process

ActiveCN110204651AReduce pollution impactEasy to operateDrilling compositionSolubilityPolymer science

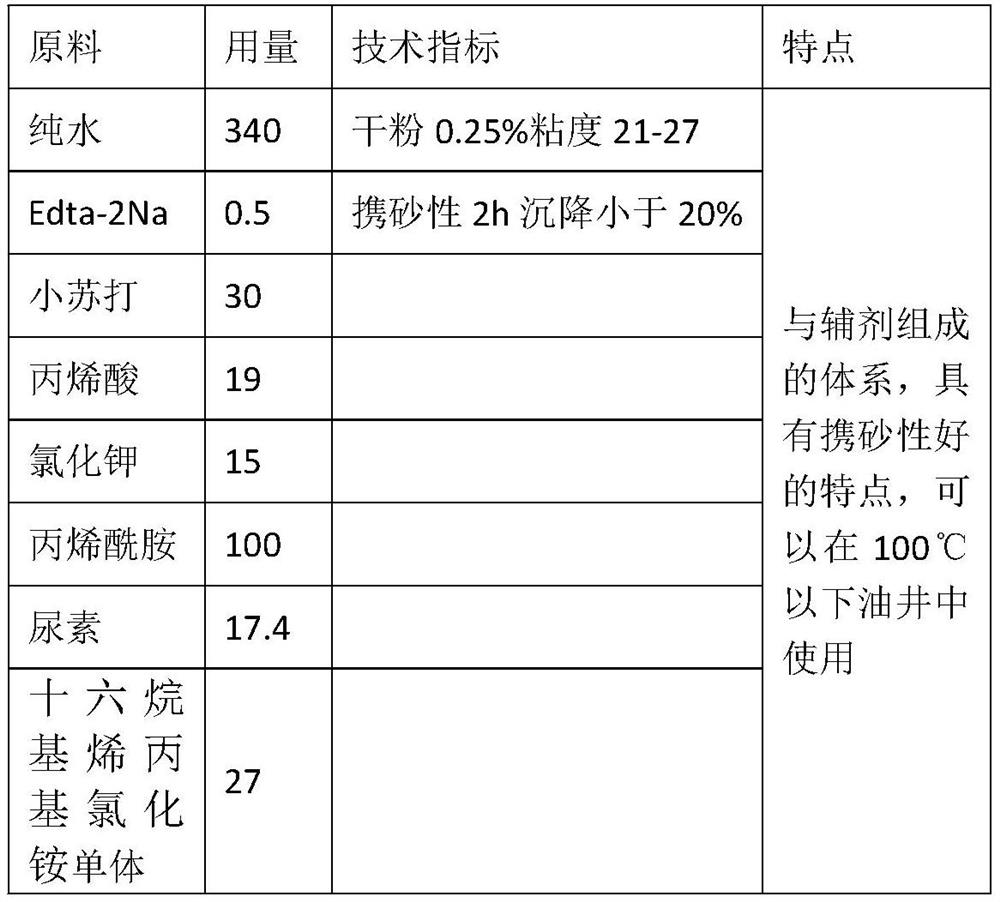

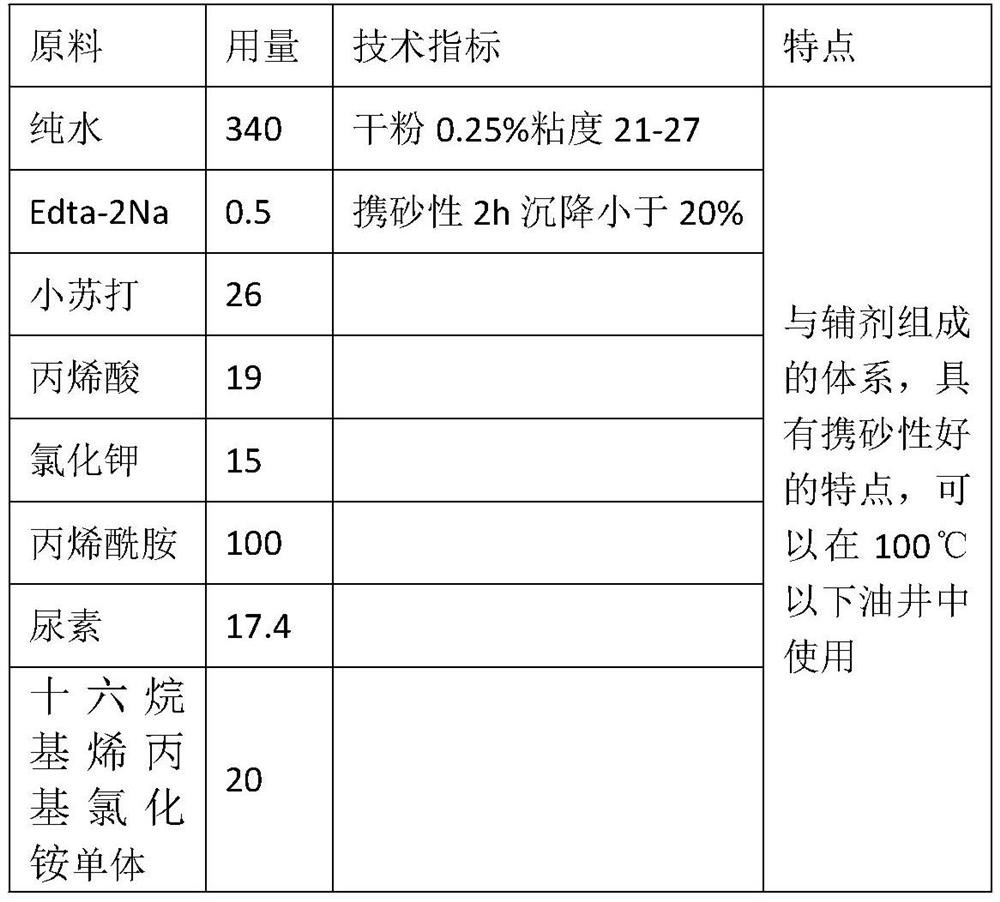

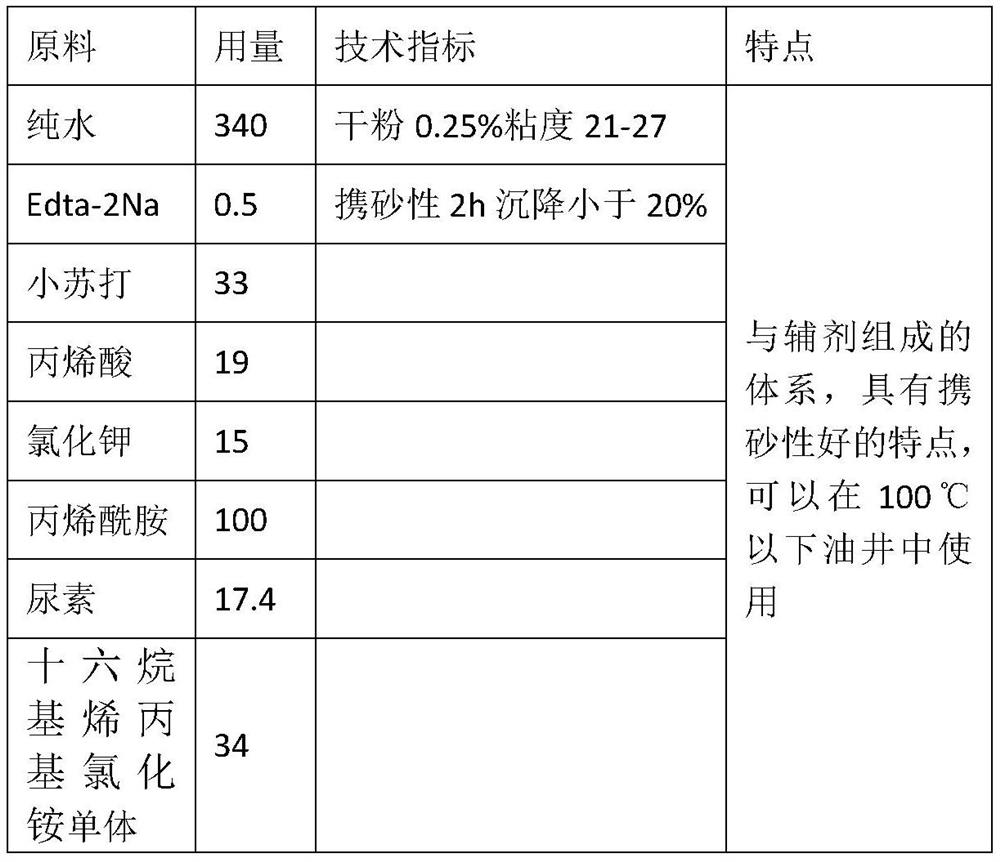

The invention discloses a hydrophobic associated polymer and a synthesis process. The hydrophobic associated polymer is characterized by including, by weight, 320-360 parts of pure water, 0.25-0.75 part of ethylene diamine tetraacetic acid (EDTA-2Na), 25-35 parts of baking soda, 18-22 parts of acrylic acid, 12-18 parts of potassium chloride, 95-105 parts of acrylamide, 15-20 parts of urea and 25-30 parts of a monomer, wherein the EDTA-2Na has the sand carrying property of 2+ / -0.1 hours, the sedimentation smaller than 20%, the dry powder content of 0.25% and the viscosity of 21-27. Compared with the prior art, the hydrophobic associated polymer is simple in operation, low in production cost, stable in product quality and extremely low in environmental pollution effect. Meanwhile, the hydrophobic associated polymer has the advantages of being wide in raw material source, simple in production and operation, low in cost, small in influences on the environment, stable in product quality, high in dissolubility, resistant to temperature and salt, resistant to shearing, high in viscosity and the like and can be suitable for medium-and-low-temperature oil and gas reservoir fracturing construction and three-time oil production.

Owner:江西富诚生态环境科技集团有限公司

A method of controlling the particle size of titanium dioxide for decorative base paper

ActiveCN107500347BUniform sizeSleek sizeTitanium compoundsInorganic compound additionSaline waterSulfate

The invention discloses a method for controlling the particle diameter of decorative body paper titanium dioxide, and belongs to the technical field of decorative body paper titanium dioxide. Through the control of a hydrolysis working procedure, the method comprises the following steps: A: selecting titanium sulfate solution, preheating to 96-98 DEG C for standby use, and preheating desalted water to be boiling for standby use; B: firstly, adding the desalted water which is preheated to be boiling into a hydrolysis reactor to be stirred, then, adding the preheated titanium sulfate solution, stirring after the titanium sulfate solution finishes adding, and heating to raise temperature to slight boiling; C: after a hydrolysis rate of step B achieves 50-65%, stopping stirring and heating, and carrying out curing; D: after curing is carried out, stirring again, heating and raising temperature to slight boiling, and carrying out hydrolysis for 160-180min; E: adding the boiling desalted water, controlling total titanium concentration TiO2 in slurry to be 160-180g / L, keeping the slight boiling, and carrying out hydrolysis for 50-60min. According to the method disclosed by the invention, a titanium sulfate solution pyrohydrolysis technology is implemented by meeting body paper requirements, water and titanium dioxide particle diameter are even, and the method conforms to the hydrolysis technology specially designed for the particle diameter requirement of the decorative body paper titanium dioxide.

Owner:HEBEI MILSON TITANIUM DIOXIDE

a tio 2 /wo 3 Preparation method of composite powder

ActiveCN104741112BAvoid hydrolysisUniform hydrolysisWater/sewage treatment by irradiationOther chemical processesReaction temperatureTitanium sulfate

Owner:广西自贸区见炬科技有限公司 +1

A kind of hydrophobic association polymer and synthesis process

ActiveCN110204651BReduce pollution impactEasy to operateDrilling compositionEthylenediamineSolubility

Owner:江西富诚生态环境科技集团有限公司

A kind of preparation method of mannose oligosaccharide

ActiveCN109988872BSmall molecular weightEfficient removalSaccharides productionAcetic acidOrganic acid

The invention relates to a preparation method of mannose oligosaccharides, which comprises: performing high-pressure fluid nano-homogeneous treatment on a galactomannan solution, and then adding acetic acid to perform a degradation reaction; or further comprising concentrating under reduced pressure after the degradation reaction is completed Acetic acid is recovered, and the concentrated solution is spray-dried to obtain mannose oligosaccharides. In the invention, the galactomannan is homogenized by a high-pressure fluid nanometer homogenizer, and then directly hydrolyzed by adding acetic acid, so that the hydrolysis is uniform and the hydrolysis speed is fast. Compared with inorganic acids such as hydrochloric acid, sulfuric acid, and trifluoroacetic acid, acetic acid is an organic acid, which is less corrosive to equipment and easy to recycle. The method of the invention can improve the production efficiency of the mannose oligosaccharide and product selectivity, and has good industrial application prospects.

Owner:BEIJING FORESTRY UNIVERSITY

Method for preparing (Zn,Cd)S quantum dot

The invention relates to a method for preparing a (Zn,Cd)S quantum dot, which comprises the following steps of: (1) dissolving soluble salt of zinc or / and and cadmium and thioacetamide raw materials into water or water-ethanol mixed liquor and adjusting a pH value to weak acidity with weak acid to obtain homogeneous reaction system mother liquor; and (2) transferring the homogeneous reaction system mother liquor obtained in the step (1) into a hydrothermal reactor for automatically generating pressure for sealing, heating to 70-100 DEG C and reacting for 30minutes to 24 hours to obtain the (Zn,Cd)S quantum dot. Compared with the prior art, the invention has the advantages of low cost, controllable process and product property, high uniformity, energy saving, high efficiency, pure water phase preparation and environmental protection.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Method of preparing protein polypeptide retanning agent

The invention provides a method for preparing a protein polypeptide re-tanning agent. The method comprises the following steps: chrome leather waste is placed into an aqueous solution dissolved with calcium lignosulphonate and sodium hydroxide, subjected to hydrolysis reaction at a temperature of between 100 and 110 DEG C, and subjected to temperature reduction after hydrolysis reaction; and the pH value of the mixture is adjusted to between 6.5 and 7.5, and the protein polypeptide re-tanning agent is obtained, wherein the mass ratio of the chrome leather waste to the calcium lignosulphonate to the sodium hydroxide is 3.5-4.0 to 1.6-1.9 to 1. The method has the advantages that the adequate hydrolysis technology is adopted, and products obtained by hydrolysis of collagen are more stable and more simple and convenient to use, and are difficult to delaminate; and due to addition of the calcium lignosulphonate, the method is favorable for dispersing the chrome leather waste into a sodium hydroxide aqueous solution, promoting hydrolysis of the chrome leather waste, making the hydrolysis reaction tend to be consistent, causing the molecular weight of hydrolysis products to be controlledwithin a small range between 5,000 and 10,000, realizing uniform hydrolysis of the collagen of the chrome leather waste, and making the final products stable, difficult to delaminate and having better re-tanning function.

Owner:CHINA JILIANG UNIV

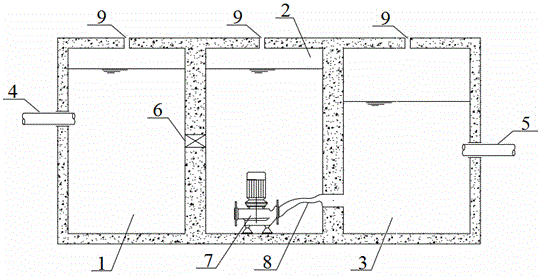

Buffer tanks for hydrolysis of small particulate organic waste

ActiveCN104550191BFully hydrolyzedUniform hydrolysisSolid waste disposalSedimentation settling tanksThree levelWater source

The invention relates to a buffer pool for the hydrolysis of small-granular organic wastes. The buffer pool comprises a first-level buffer pool, a second-level buffer pool and a third-level buffer pool, wherein the first-level buffer pool and the second-level buffer pool are used for storing organic wastewater, the third-level buffer pool is used for carrying out the hydrolysis on the organic wastewater, the first-level buffer pool and the second-level buffer pool are connected by a separating wall, an electric gate valve is arranged on the separating wall, the bottom of the second-level buffer pool is provided with a submersible sewage pump, the submersible sewage pump is connected with the third-level buffer pool by a pipeline, and a heat supply device is arranged in the third-level buffer pool; and the volume of the second-level buffer pool is greater than the wastewater quantity produced by an organic wastewater source in the hydrolysis cycle of the organic wastewater. According to the buffer pool, due to the arrangement of the three levels of buffer pools, the first-level buffer pool and the second-level buffer pool can be used for storing and accommodating the newly produced wastewater, and the third-level buffer pool can be used for carrying out the hydrolysis on the organic wastewater, so that the newly produced wastewater can be separated from the wastewater which is being hydrolyzed, so that the sufficient hydrolysis of the organic wastewater is ensured, and the effect of late anaerobic digestion is ensured.

Owner:WISDRI ENG & RES INC LTD

A kind of anti-salt drag reducer polymer and its synthesis process

ActiveCN110194816BReduce pollution impactReduce conveying resistanceDrilling compositionSalt resistanceProcess engineering

The invention discloses a salt-resistant drag reducer polymer and a synthesis process, which is characterized in that the parts by weight of each raw material are: 320-360 parts of pure water, 0.1-0.3 parts of Edta-2Na, 35-45 parts of baking soda, and 18 parts of acrylic acid —22 parts, AMPS 8-12 parts, acrylamide 75-85 parts, urea 14-18 parts. The invention has the outstanding advantages of simple production operation, stable product quality and extremely low impact on environmental pollution. At the same time, the product technical indicators have the advantages of fast dissolution, temperature and salt resistance, shear resistance, good compatibility, high drag reduction rate, etc., and are mainly used to reduce fracturing construction and other fluid pipeline transportation in shale oil and gas reservoirs and tight sandstone oil and gas reservoirs Resistance, play the role of increasing displacement and reducing power consumption.

Owner:江西富诚生态环境科技集团有限公司

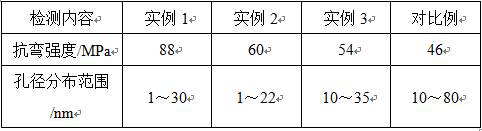

A kind of preparation method of porous ceramic membrane

The invention discloses a preparation method of a porous ceramic membrane, which belongs to the technical field of inorganic non-metallic materials. In parts by weight, weigh in order: 15-35 parts of alumina powder, 4-10 parts of polyvinyl butyral, 5-12 parts of plasticizer, 8-12 parts of ethyl orthosilicate, 10-10 parts 15 parts of fatty acid, 5-8 parts of dispersant, 3-6 parts of surfactant, 8-18 parts of modified silica and 40-60 parts of ethanol, mix alumina powder with modified silica, and add Ethyl orthosilicate, fatty acid, surfactant and dispersant are used to obtain a pretreatment film-forming liquid, which is mixed with polyvinyl butyral, and a plasticizer is added to obtain a film-forming liquid. The membrane solution is cast into a membrane and sintered to obtain a pretreated porous ceramic membrane; the pretreated porous ceramic membrane is pickled, filtered, washed, and dried to obtain a porous ceramic membrane. The porous ceramic filter membrane provided by the invention has excellent bending strength, and the uniformity of pore size distribution is improved.

Owner:江苏新时膜科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com