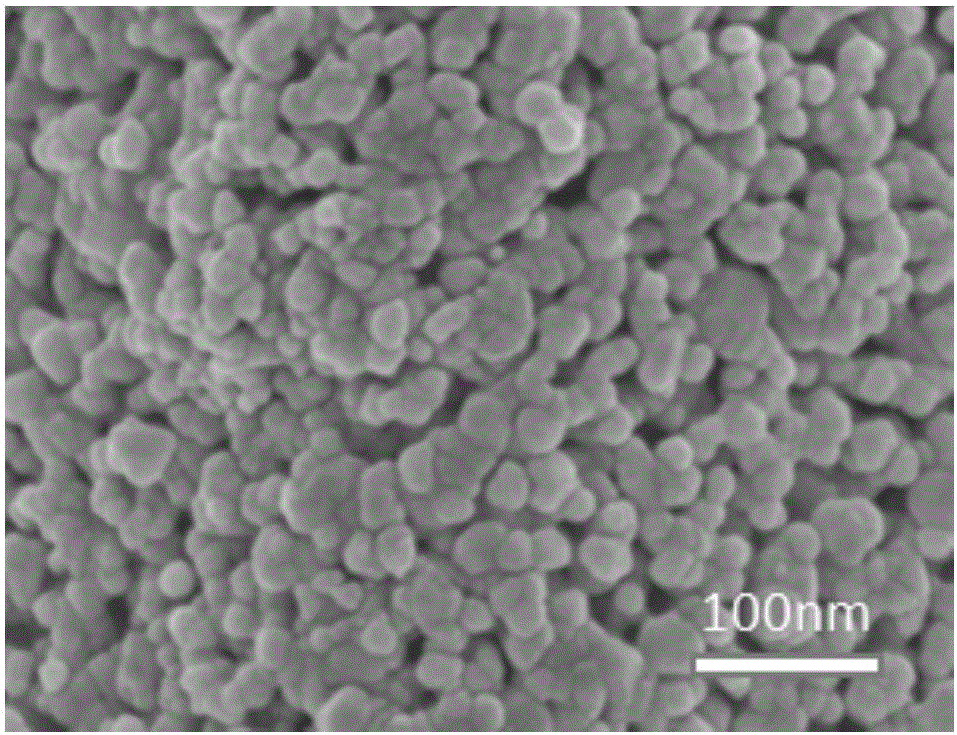

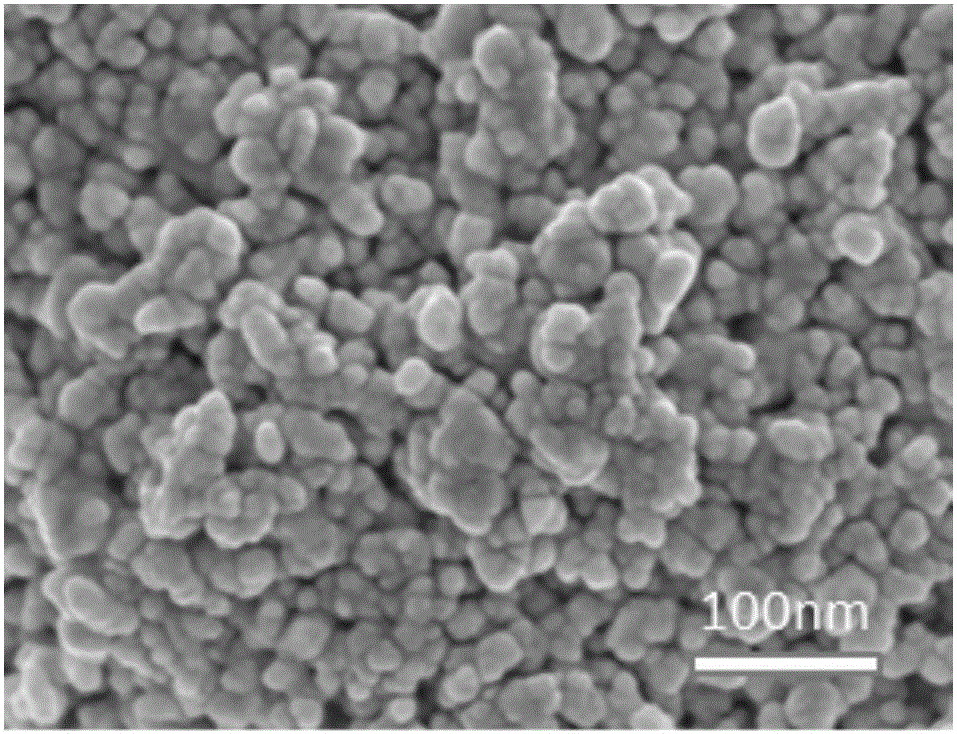

a tio 2 /wo 3 Preparation method of composite powder

A composite powder and uniform mixing technology, which is applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, chemical/physical processes, etc., can solve the long reaction cycle, complex preparation process, and reaction condition requirements Harsh and other problems, to achieve the effect of short cycle time, high photodegradability, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1) Mix titanium sulfate, urea, ethanol, and deionized water according to the mass ratio of titanium sulfate: urea: ethanol: deionized water = 2:0.8:8:60, and stir at 40°C for 2 hours, then add acetyl Acetone, solution A was obtained after stirring at room temperature for 0.4 h. Wherein, the addition of acetylacetone is 1.5% of the solution A quality.

[0029] 2) Add concentrated nitric acid with a mass fraction of 65% to solution A dropwise at 40°C, and fully react to obtain solution B after dropping and stirring for 2 hours. Wherein, the mass of concentrated nitric acid is 0.2% of solution B mass.

[0030] 3) At room temperature, the K 2 WO 4 2H 2 O was dissolved in deionized water to prepare K with a concentration of 0.2 mol / L 2 WO 4 aqueous solution, after magnetic stirring for 20 minutes, the pH value was adjusted to 3.0 with 3 mol / L hydrochloric acid to obtain solution C.

[0031] 4) According to the molar ratio of Ti and W elements n Ti :n W =x: (100-x), ...

Embodiment 2

[0038] 1) Mix titanium sulfate, urea, ethanol, and deionized water according to the mass ratio of titanium sulfate: urea: ethanol: deionized water = 2:0.8:8:60, stir at 40°C for 2 hours, and then add acetylacetone , solution A was obtained after stirring at room temperature for 0.4 h. Wherein, the addition of acetylacetone is 1.5% of the solution A quality.

[0039] 2) Add concentrated nitric acid with a mass fraction of 65% to solution A dropwise at 40°C, and fully react to obtain solution B after dropping and stirring for 2 hours. Wherein, the mass of concentrated nitric acid is 0.3% of solution B mass.

[0040] 3) At room temperature, the K 2 WO 4 2H 2 O was dissolved in deionized water to prepare K with a concentration of 0.2 mol / L 2 WO 4 aqueous solution, after magnetic stirring for 20 minutes, the pH value was adjusted to 3.0 with 3 mol / L hydrochloric acid to obtain solution C.

[0041] 4) By element molar ratio n Ti :n W =x: (100-x), where x=70, mix solution B ...

Embodiment 3

[0043] 1) Mix titanium sulfate, urea, ethanol, and deionized water according to the mass ratio of titanium sulfate: urea: ethanol: deionized water = 2:0.8:8:60, stir at 40°C for 2 hours, and then add acetylacetone , solution A was obtained after stirring at room temperature for 0.4 h. Wherein, the addition of acetylacetone is 1.5% of the solution A quality.

[0044] 2) Add concentrated nitric acid with a mass fraction of 65% to solution A dropwise at 40°C, stir for 2 hours and fully react to obtain solution B. Wherein, the mass of concentrated nitric acid is 0.3% of solution B mass.

[0045] 3) At room temperature, the K 2 WO 4 2H 2 O was dissolved in deionized water to prepare K with a concentration of 0.2 mol / L 2 WO 4 aqueous solution, after magnetic stirring for 20 minutes, the pH value was adjusted to 3.0 with 3 mol / L hydrochloric acid to obtain solution C.

[0046] 4) According to the molar ratio of Ti and W elements n Ti :n W =x: (100-x), where x=50, mix solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com