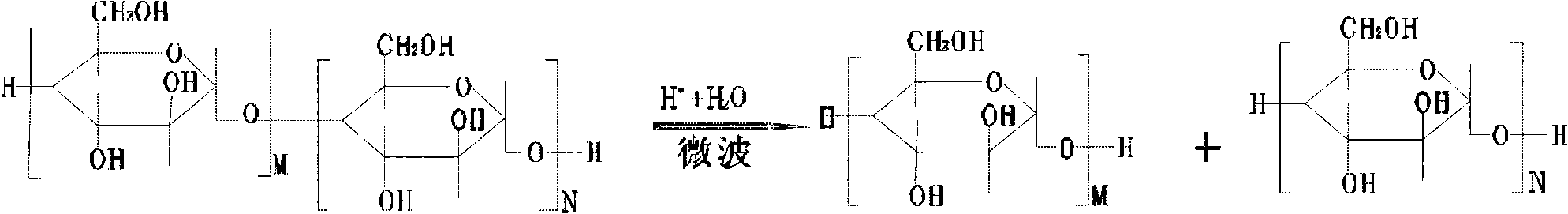

Dry method for preparing dextrin by microwave

A technology of dextrin preparation and microwave method, which is applied in the field of microwave dry method preparation of dextrin, can solve the problems of long time, uneven starch hydrolysis, high reaction temperature, etc., and achieve the effect of short time, environmentally friendly preparation method and low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Add 100kg of starch into the acid adding machine, start the mixer, add 2kg of 8% dilute nitric acid by spraying, mix for 20 minutes until uniform, transfer the acid-added starch into the microwave continuous transmission box reactor, and control the transmission speed so that The starch is irradiated in the microwave field for about 10 minutes, and then cooled to obtain the finished product.

Embodiment 2

[0014] Add 100kg of starch into the acid adding machine, start the mixer, add 10kg of 10% dilute hydrochloric acid by spraying, mix for 20 minutes until uniform, transfer the acid-added starch into the microwave continuous transmission box reactor, and control the transmission speed so that The starch is irradiated in the microwave field for about 15 minutes, and the finished product is obtained after cooling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com