A kind of preparation method of porous ceramic membrane

A technology for porous ceramic membranes and preparation steps, which is applied in the field of preparation of porous ceramic membranes, and can solve problems such as poor bending strength and uneven pore size, and achieve the effects of increasing porosity, increasing porosity, and improving bending strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

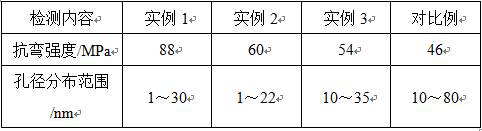

Examples

example 1

[0022]Mix sodium silicate solution with a mass fraction of 18% and polyethylene glycol in a beaker at a mass ratio of 5:1, and adjust the pH of the material in the beaker to 10.0 with a mass fraction of 20% sulfuric acid. After curing for 40 minutes, continue to adjust the pH of the material in the beaker to 8.0 with 20% sulfuric acid by mass fraction, age for 50 minutes at a temperature of 85°C, and filter with suction to obtain a pretreated silica blank. After the silica blank was washed with water for 12 times, and dried for 3 hours at a temperature of 80°C, pretreated silica was obtained; the pretreated silica and distilled water were mixed in a flask at a mass ratio of 1:55, and the frequency was After ultrasonic dispersion at 65kHz for 30min, add a 25% titanyl sulfate solution with a mass fraction three times the mass of pretreated silica to the flask, and stir and mix for 2h at a temperature of 80°C and a rotational speed of 360r / min. Finally, the pretreated silica mixt...

example 2

[0024] Mix sodium silicate solution with a mass fraction of 18% and polyethylene glycol in a beaker at a mass ratio of 5:1, and adjust the pH of the material in the beaker to 10.0 with a mass fraction of 20% sulfuric acid. After curing for 40 minutes, continue to adjust the pH of the material in the beaker to 8.0 with 20% sulfuric acid by mass fraction, age for 50 minutes at a temperature of 85°C, and filter with suction to obtain a pretreated silica blank. After the silica blank was washed with water for 12 times, and dried for 3 hours at a temperature of 80°C, pretreated silica was obtained; in parts by weight, weigh in sequence: 35 parts of alumina powder, 10 parts of polyvinyl alcohol Butyral, 12 parts plasticizer, 12 parts tetraethyl orthosilicate, 15 parts fatty acid, 8 parts dispersant, 5 parts pH regulator, 6 parts surfactant, 18 parts pretreated silica and 60 parts ethanol , mix alumina powder and pretreated silica in a mixer, and add orthosilicate ethyl ester, pH reg...

example 3

[0026] Mix sodium silicate solution with a mass fraction of 18% and polyethylene glycol in a beaker at a mass ratio of 5:1, and adjust the pH of the material in the beaker to 10.0 with a mass fraction of 20% sulfuric acid. After curing for 40 minutes, continue to adjust the pH of the material in the beaker to 8.0 with 20% sulfuric acid by mass fraction, age for 50 minutes at a temperature of 85°C, and filter with suction to obtain a pretreated silica blank. After the silica blank was washed with water for 12 times, and dried for 3 hours at a temperature of 80°C, pretreated silica was obtained; the pretreated silica and distilled water were mixed in a flask at a mass ratio of 1:55, and the frequency was After ultrasonic dispersion at 65kHz for 30min, add a 25% titanyl sulfate solution with a mass fraction three times the mass of pretreated silica to the flask, and stir and mix for 2h at a temperature of 80°C and a rotational speed of 360r / min. Finally, the pretreated silica mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com