A kind of anti-salt drag reducer polymer and its synthesis process

A technology of drag reducer and polymer, which is applied in the field of salt-resistant drag reducer polymer and synthesis technology, which can solve the problems of long production cycle and complicated process equipment, and achieve simple production operation, good solubility and high drag reduction rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

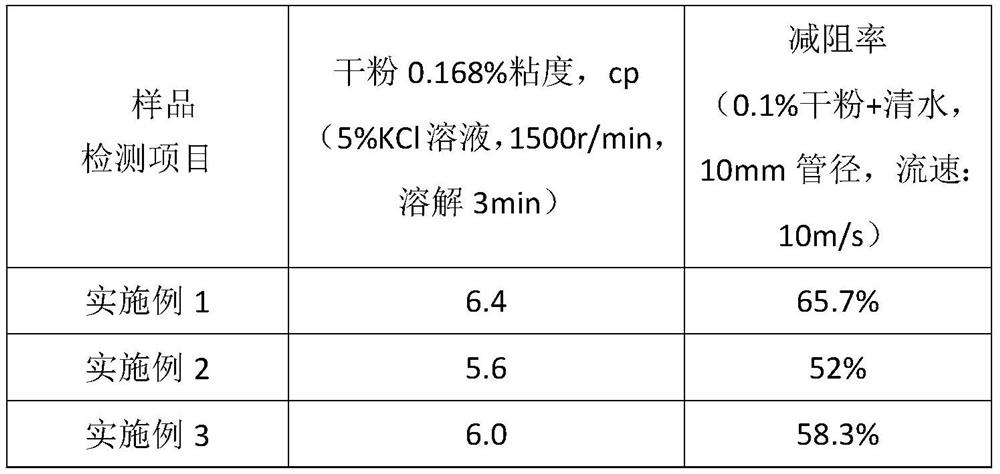

Examples

Embodiment 1

[0032] Salt resistance drag reducer polymer ratio

[0033] raw material Dosage technical indicators features pure water 340 Dissolving speed 2-3 minutes Fast dissolving, good resistance to salt Edta-2Na 0.2 Can resist 50,000 salinity salt water baking soda 40 acrylic acid 19 AMPS 10 Acrylamide 80 urea 16.8

[0034] The synthesis process is as follows:

[0035] 1. Add pure water to the reactor, turn on the stirring motor of the reactor, and adjust the speed to 18r / min.

[0036] 2. Join EDTA. Stirring time 5 minutes.

[0037] 3. Slowly add baking soda and stir for 30 minutes until the material liquid becomes clear.

[0038] 4. Adjust the speed to 8r / min. Add acrylic acid, add slowly, and the feeding time is 30 minutes, so as to prevent a large number of bubbles from being generated in the reaction kettle.

[0039] 5. After the bubbles in the reactor disappear, adjust the speed to 15r / mi...

Embodiment 2

[0048] Salt resistance drag reducer polymer ratio

[0049] raw material Dosage technical indicators features pure water 340 Dissolving speed 2-3 minutes Fast dissolving, good resistance to salt Edta-2Na 0.2 Can resist 50,000 salinity salt water baking soda 30 acrylic acid 19 AMPS 10 Acrylamide 80 urea 16.8

[0050] The synthesis process is as follows:

[0051] 1. Add pure water to the reactor, turn on the stirring motor of the reactor, and adjust the speed to 18r / min.

[0052] 2. Join EDTA. Stirring time 5 minutes.

[0053] 3. Slowly add baking soda and stir for 30 minutes until the material liquid becomes clear.

[0054] 4. Adjust the speed to 8r / min. Add acrylic acid, add slowly, and the feeding time is 30 minutes, so as to prevent a large number of bubbles from being generated in the reaction kettle.

[0055] 5. After the bubbles in the reactor disappear, adjust the speed to 15r / mi...

Embodiment 3

[0064] Salt resistance drag reducer polymer ratio

[0065] raw material Dosage technical indicators features pure water 340 Dissolving speed 2-3 minutes Fast dissolving, good resistance to salt Edta-2Na 0.2 Can resist 50,000 salinity salt water baking soda 48 acrylic acid 19 AMPS 10 Acrylamide 80 urea 16.8

[0066] The synthesis process is as follows:

[0067] 1. Add pure water to the reactor, turn on the stirring motor of the reactor, and adjust the speed to 18r / min.

[0068] 2. Join EDTA. Stirring time 5 minutes.

[0069] 3. Slowly add baking soda and stir for 30 minutes until the material liquid becomes clear.

[0070] 4. Adjust the speed to 8r / min. Add acrylic acid, add slowly, and the feeding time is 30 minutes, so as to prevent a large number of bubbles from being generated in the reaction kettle.

[0071] 5. After the bubbles in the reactor disappear, adjust the speed to 15r / mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com