Efficient, environment-friendly and safe powder body combustion system of industrial kiln

A combustion system and powder technology, applied in the direction of combustion method, combustion type, combustion using block fuel and liquid fuel, etc., can solve the problem of insufficient release of fuel calorific value, inability to control the air flow angle, and inability to provide powder Solve the problems of body fuel and other issues, and achieve the effect of sufficient and easy combustion, low emission and high environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following is a detailed description of the high-efficiency, environment-friendly and safe powder combustion system for industrial kilns of the present invention in conjunction with the accompanying drawings.

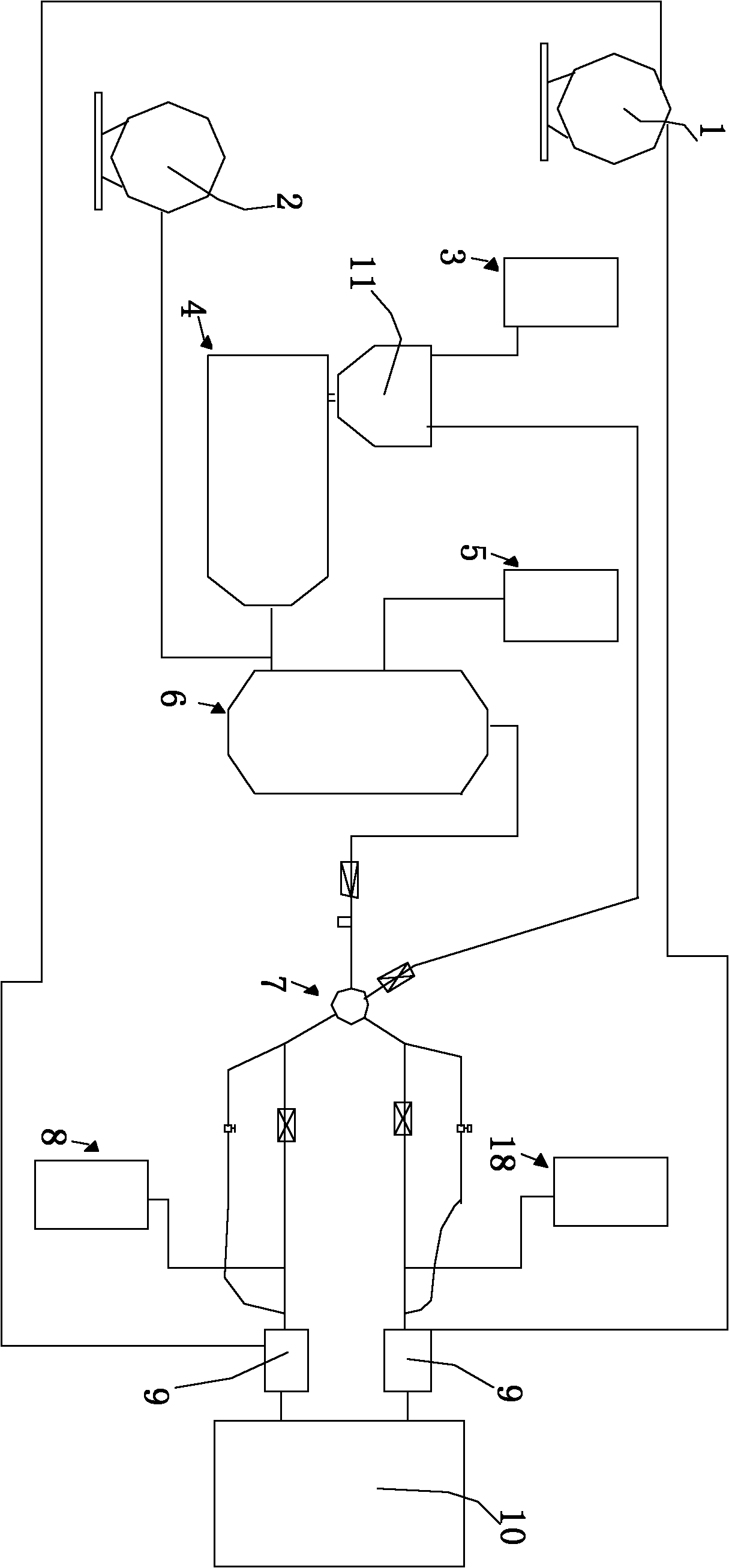

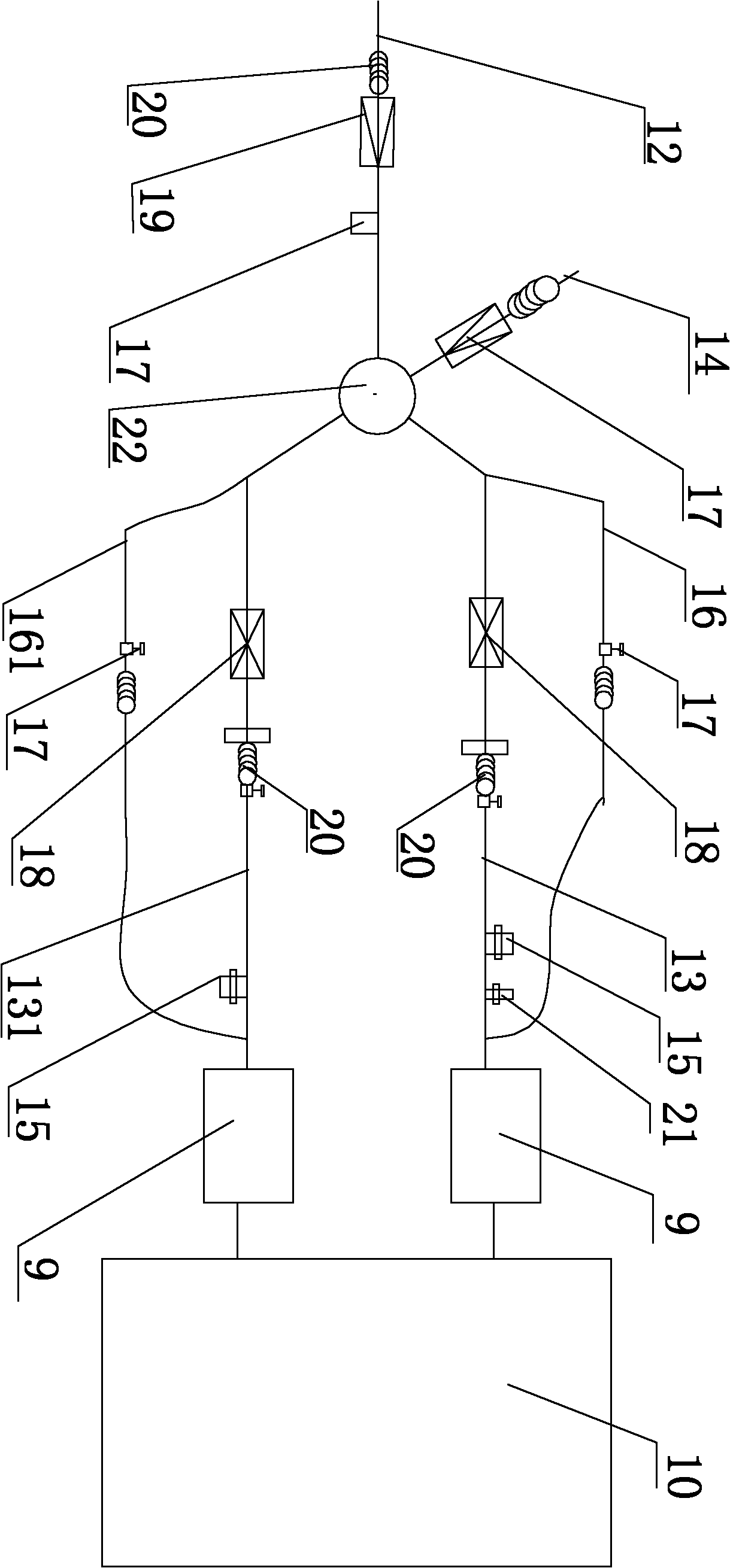

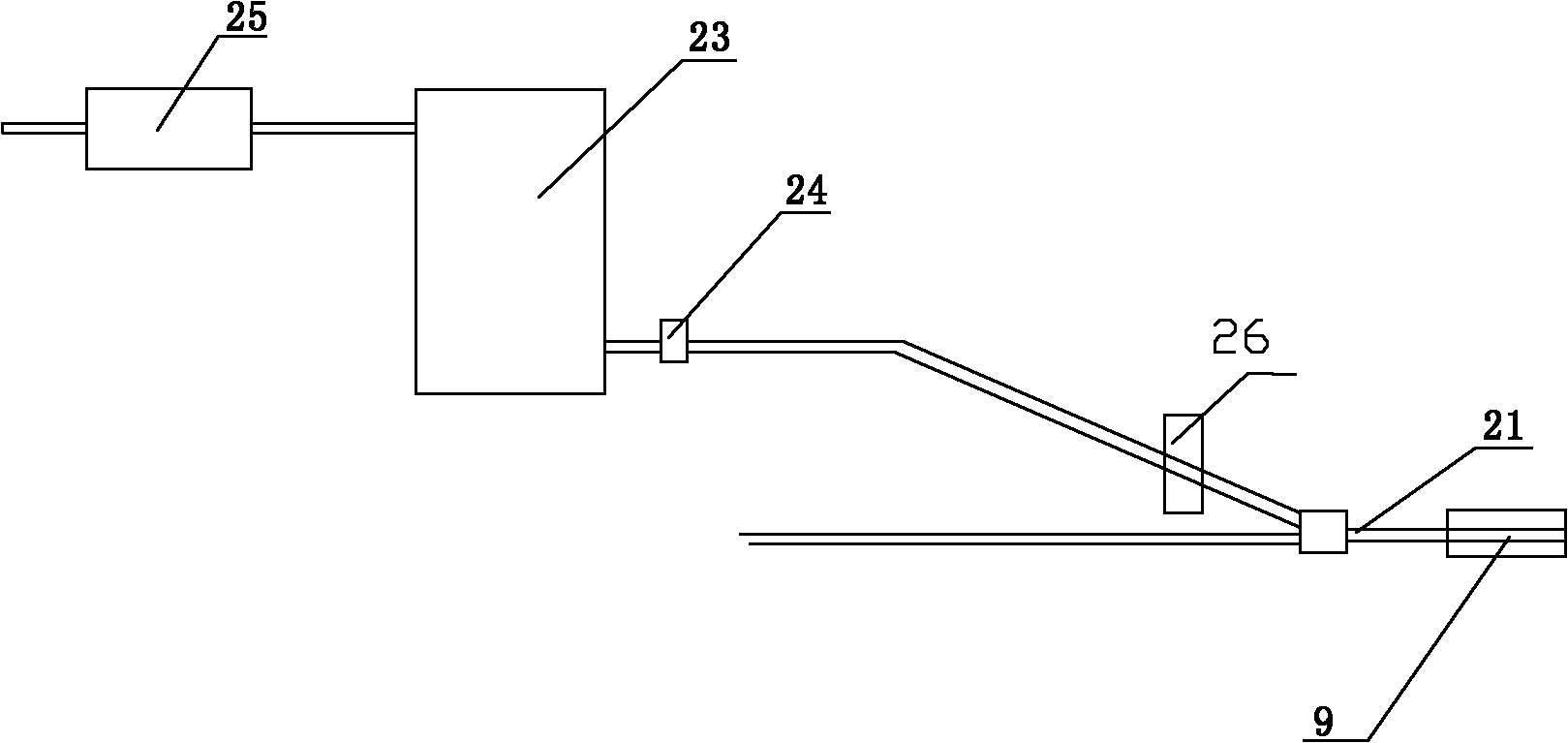

[0039] Such as figure 1 As shown, the high-efficiency, environment-friendly and safe powder combustion system of an industrial kiln includes a solid fuel superfine device 3, a feeding device 11, a micro-powder modification device 6, a powder conveying control distribution safety device 7, a burner 9 and a furnace 10, The solid fuel superfine device 3 is connected to the powder inlet of the feeding device 4, the powder outlet of the feeding device 4 is connected to the material inlet of the micropowder modification device 6, and the micropowder modification The device 6 is connected to the burner 9 through the powder delivery control distribution safety device 7, and the burner 9 is installed in the furnace 10; the burner 9 is connected to the high-pressure fan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com