Patents

Literature

39 results about "Polymer ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In a given formulation or recipe of a polymer compound, the total amount/parts per hundred of polymer added to prepare certain compound is called polymer ratio. It basically refers to the aggregated amount of polymer content within the formulation that may undergo any physical or chemical change during the course of post polymerization or physical heat treatment.

Interpenetrating polymer network

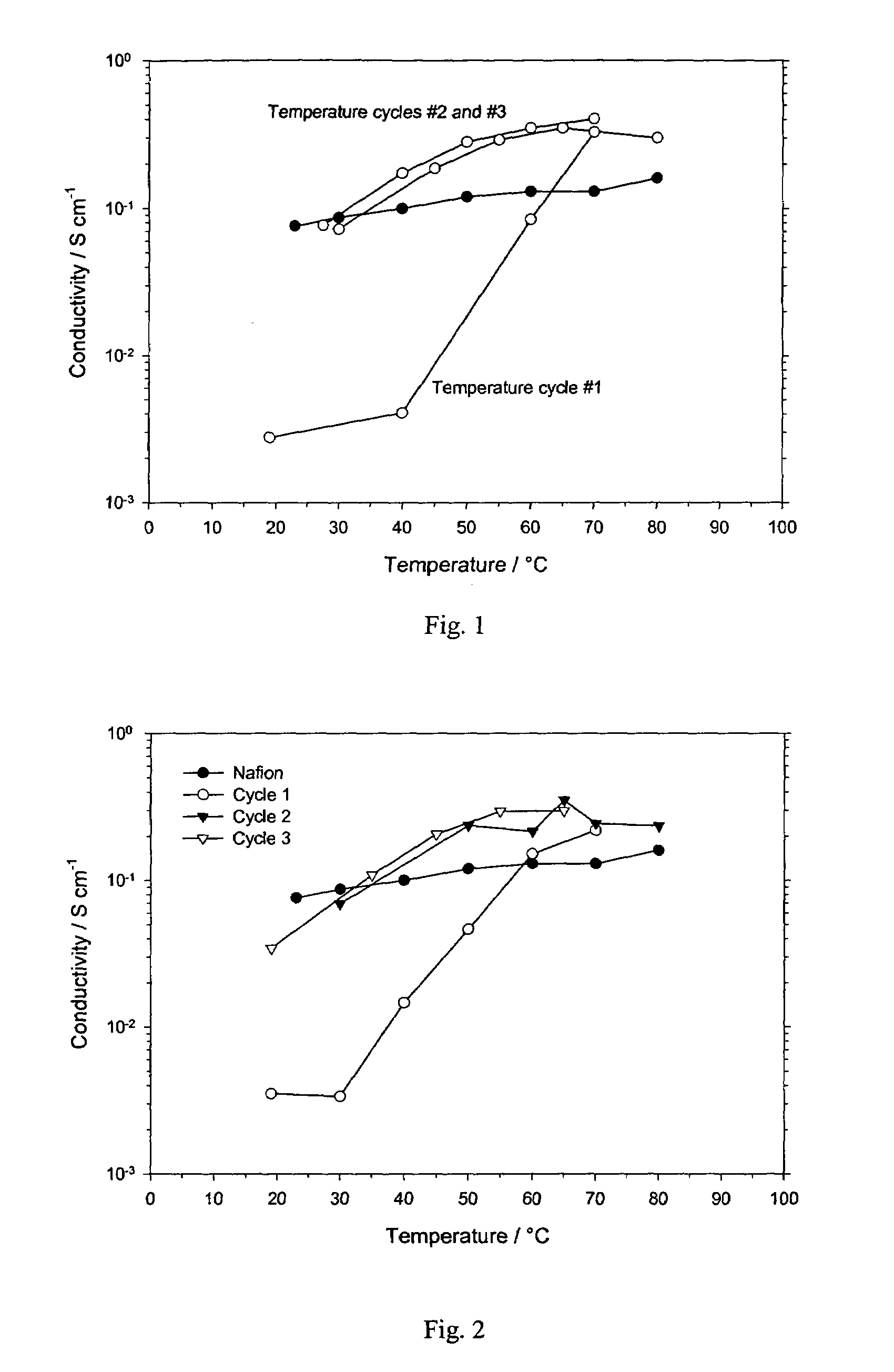

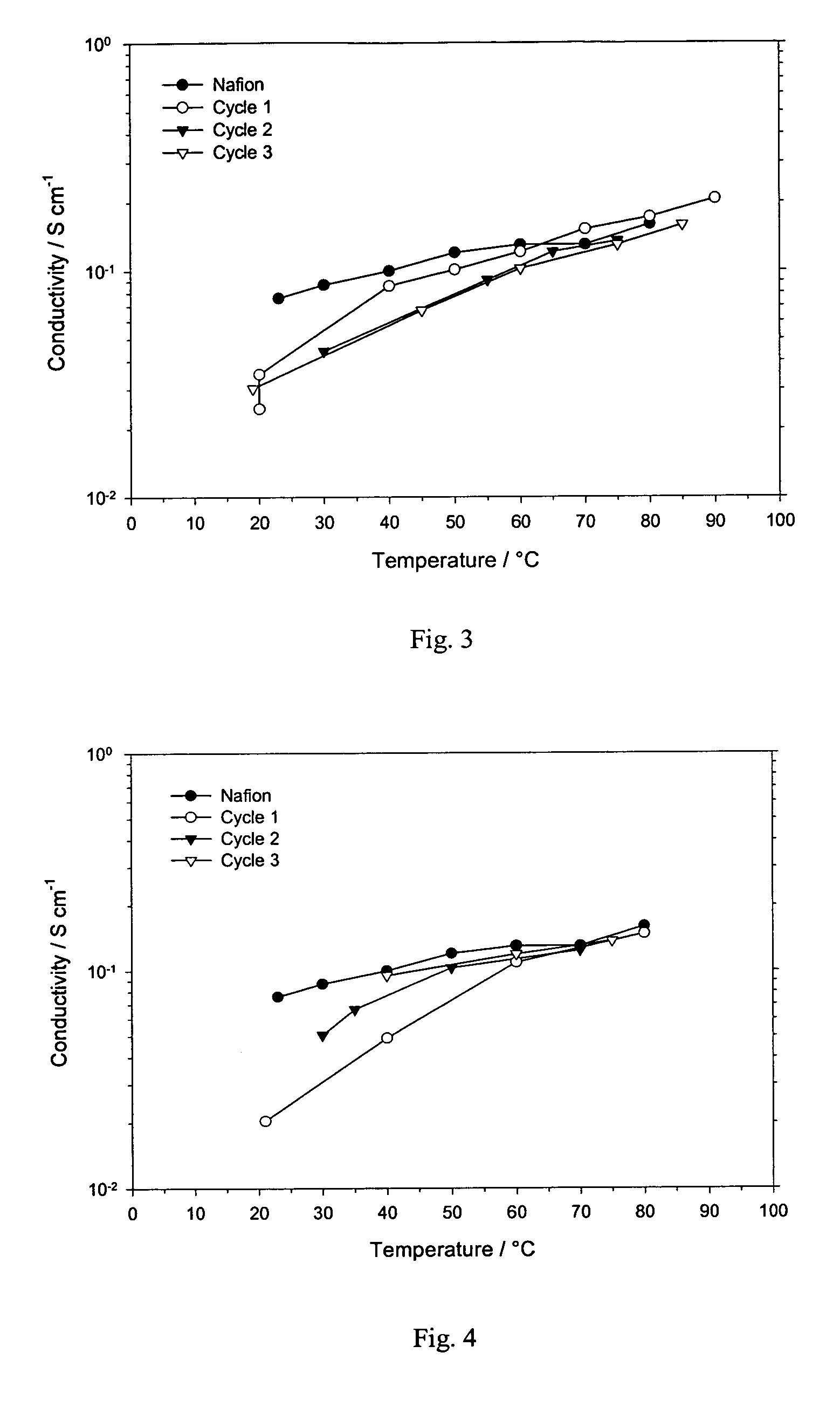

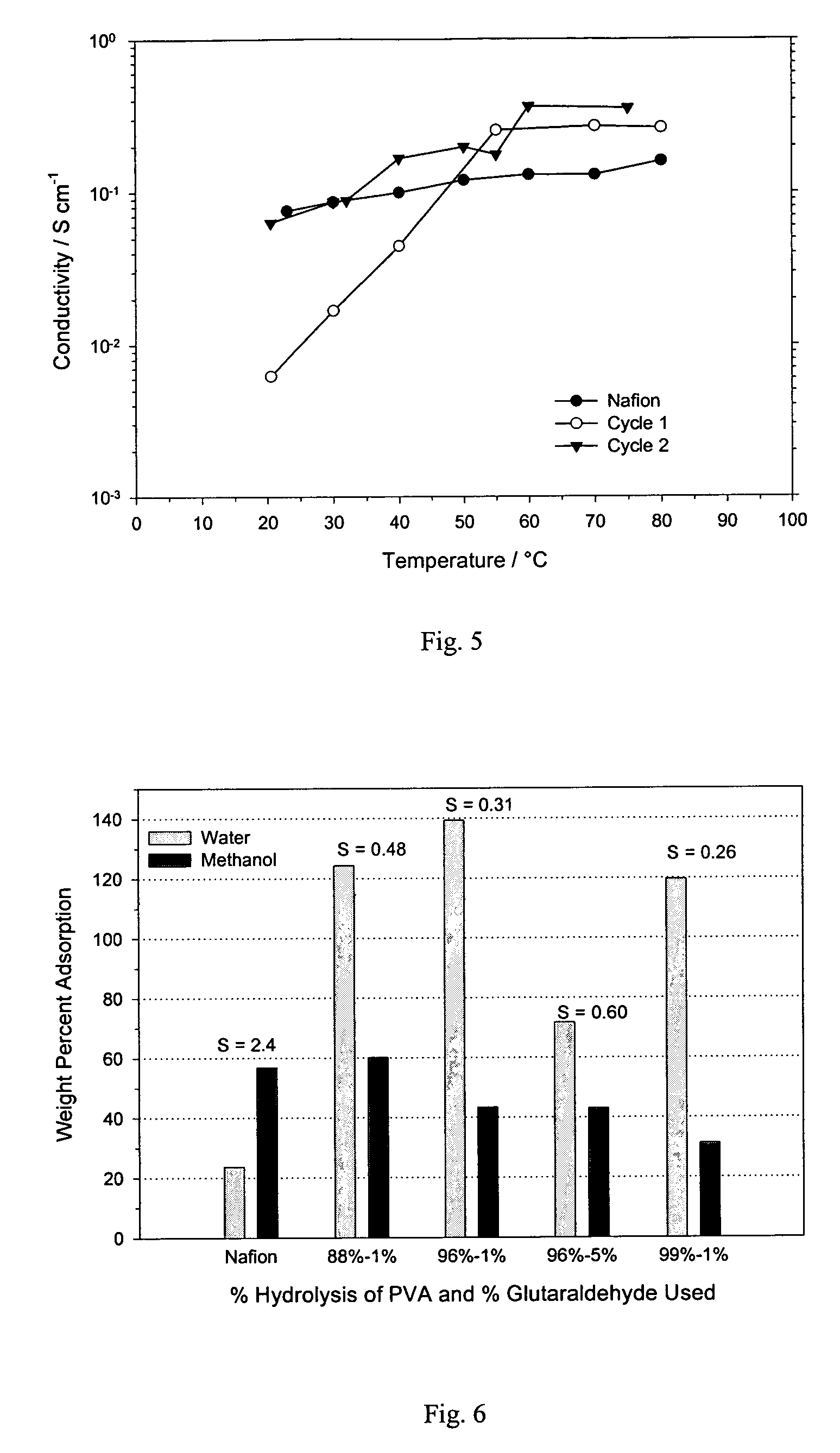

InactiveUS7176247B1Improve breathabilityFilm hydrationElectrolyte holding meansAbsorbent padsCross-linkPolymer science

A water insoluble interpenetrating polymer network is obtained by independently cross-linking a first polymer derived from a sulfonic acid or phosphonic acid group containing alkenyl monomer and a second polymer polymerized independently of the first polymer and interpenetrating the first polymer, where the second polymer is selectively permeable to water compared to methanol. Through adjustment of the degree of first polymer monomer acidification, polymer ratios and the extent of cross-linking in the at least two interpenetrating polymers, ion conductivity and solvent permeability are controlled. A film produced from such a water insoluble interpenetrating polymer network is well suited as a membrane in a direct methanol fuel cell. The relative degree and mechanism of cross-linking and interpenetrating the first polymer and second polymer are also adjustable parameters that impact on film properties.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

Heavy metal ion adsorbed film and preparation

InactiveCN101254457AImprove stabilityGood regeneration performanceOther chemical processesWater/sewage treatment by sorptionCross-linkPolymer science

The invention relates to a heavy metal ion adsorption film and a production method thereof. The heavy metal ion adsorption film is composed of polyvinyl alcohol and amido polymers at a polyvinyl alcohol / amido polymer ratio of (95:5) to (20:80). The amido polymers are polyvinyl amine, polyallylamine and branched polyethylene. The amido polymers are introduced into the aqueous solution of polyvinyl alcohol and then the resulting mixture undergoes crosslinking reaction with a cross-linking agent to form a three-dimensional polymer network. The method is simple, feasible and free of organic solvents. The introduction of amido groups can efficiently increase the water swellability of polyvinyl alcohol film and simultaneously enhance the adsorbability of the film to heavy metal ions.

Owner:威海金钰环保科技有限公司

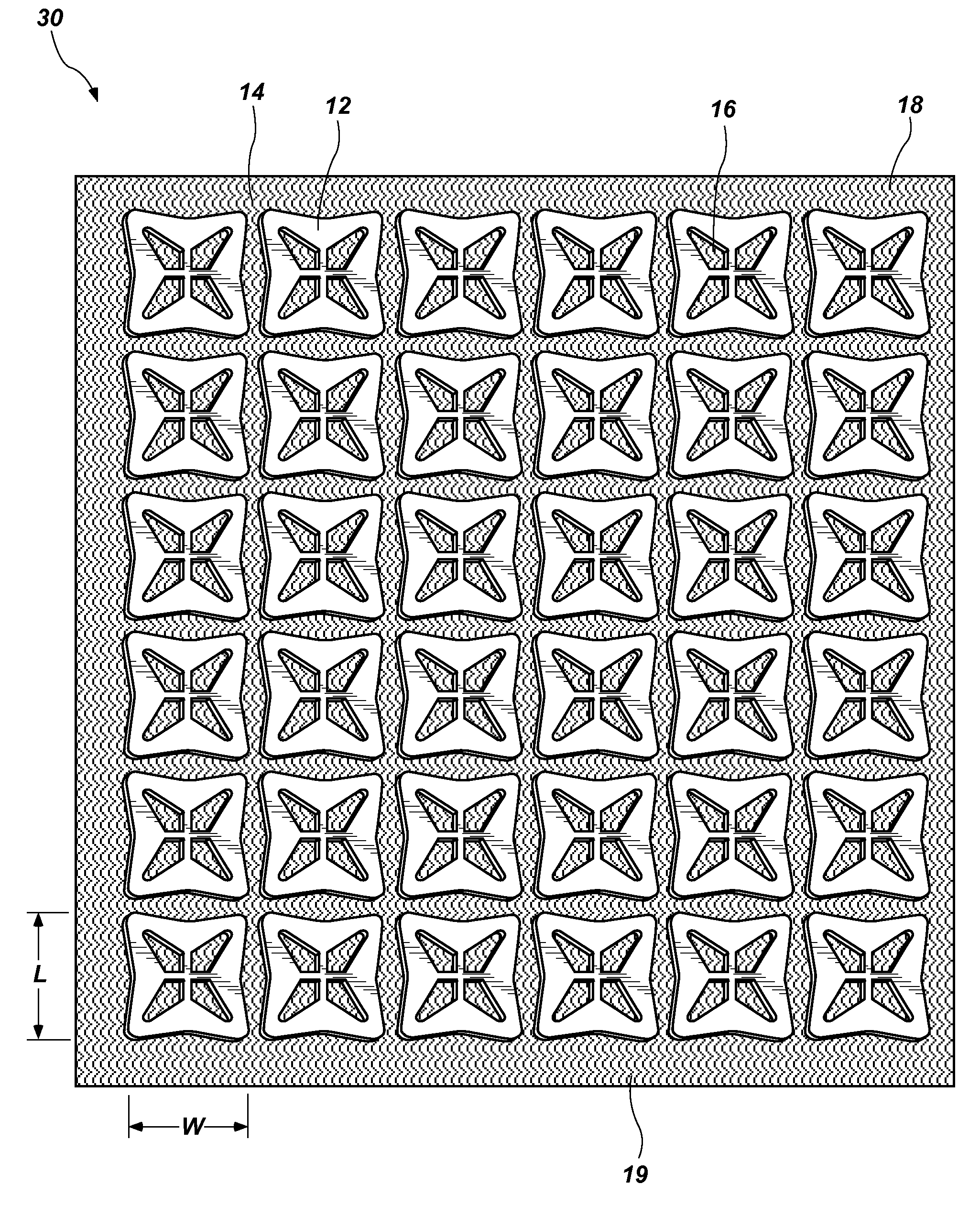

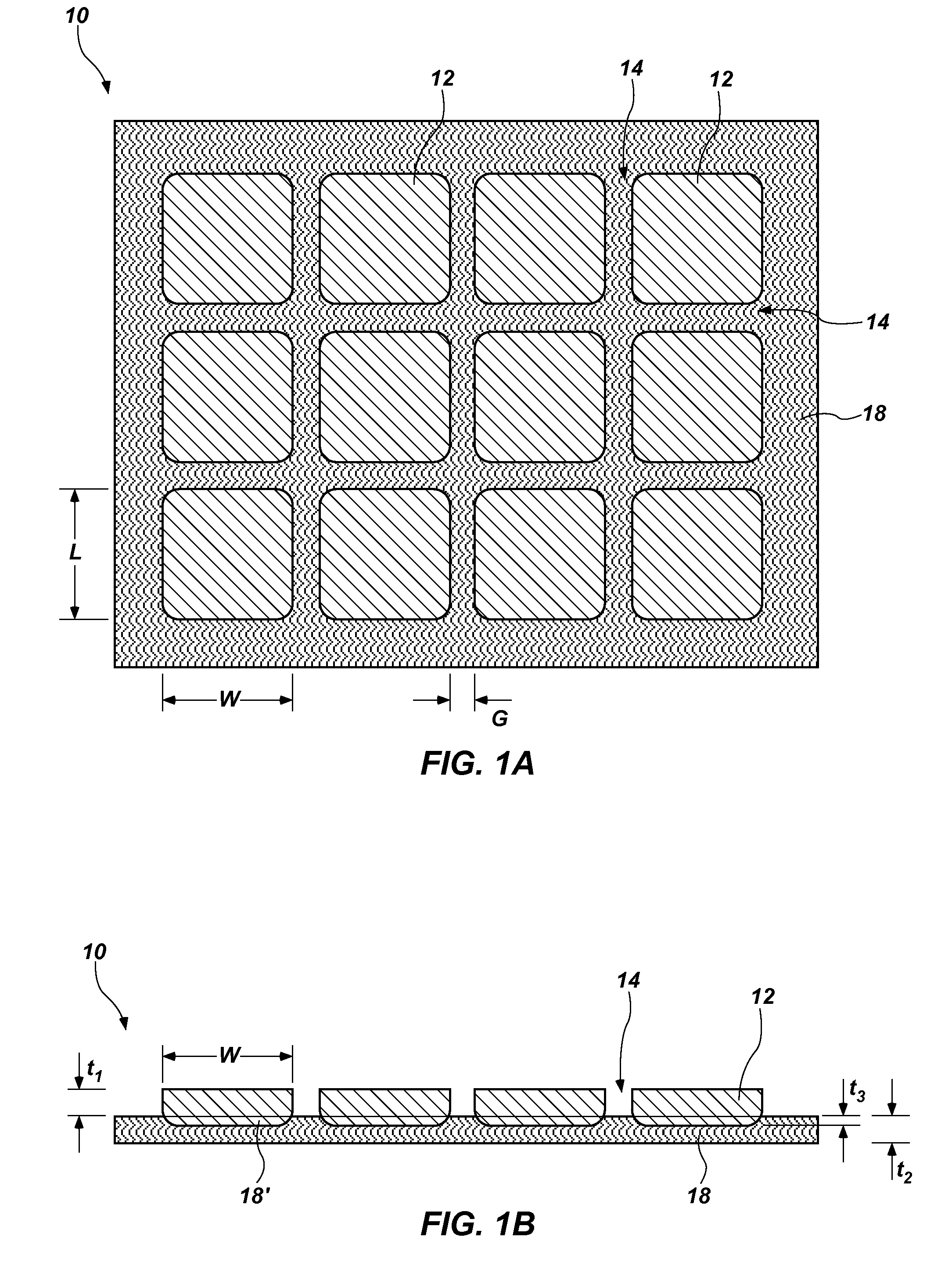

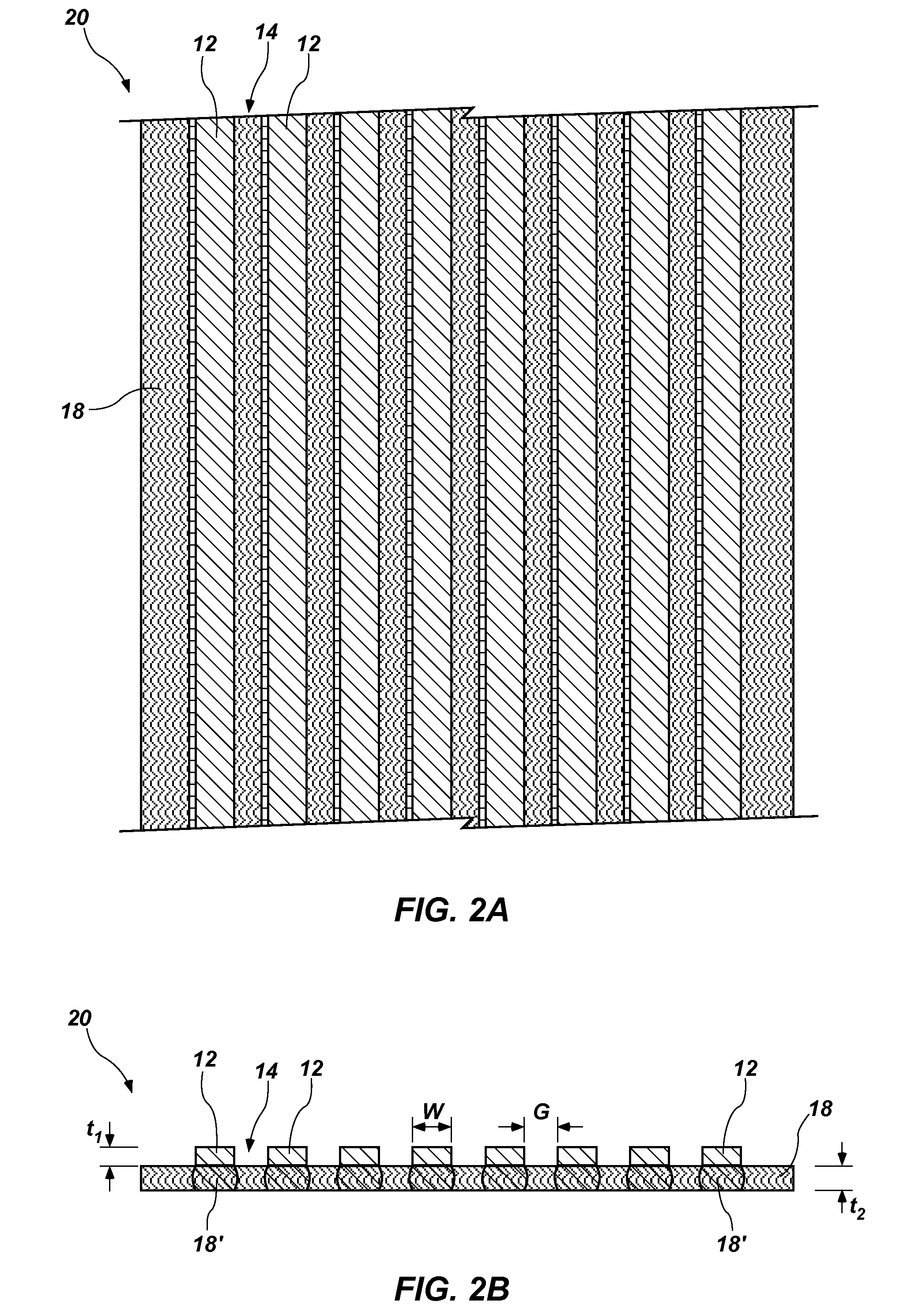

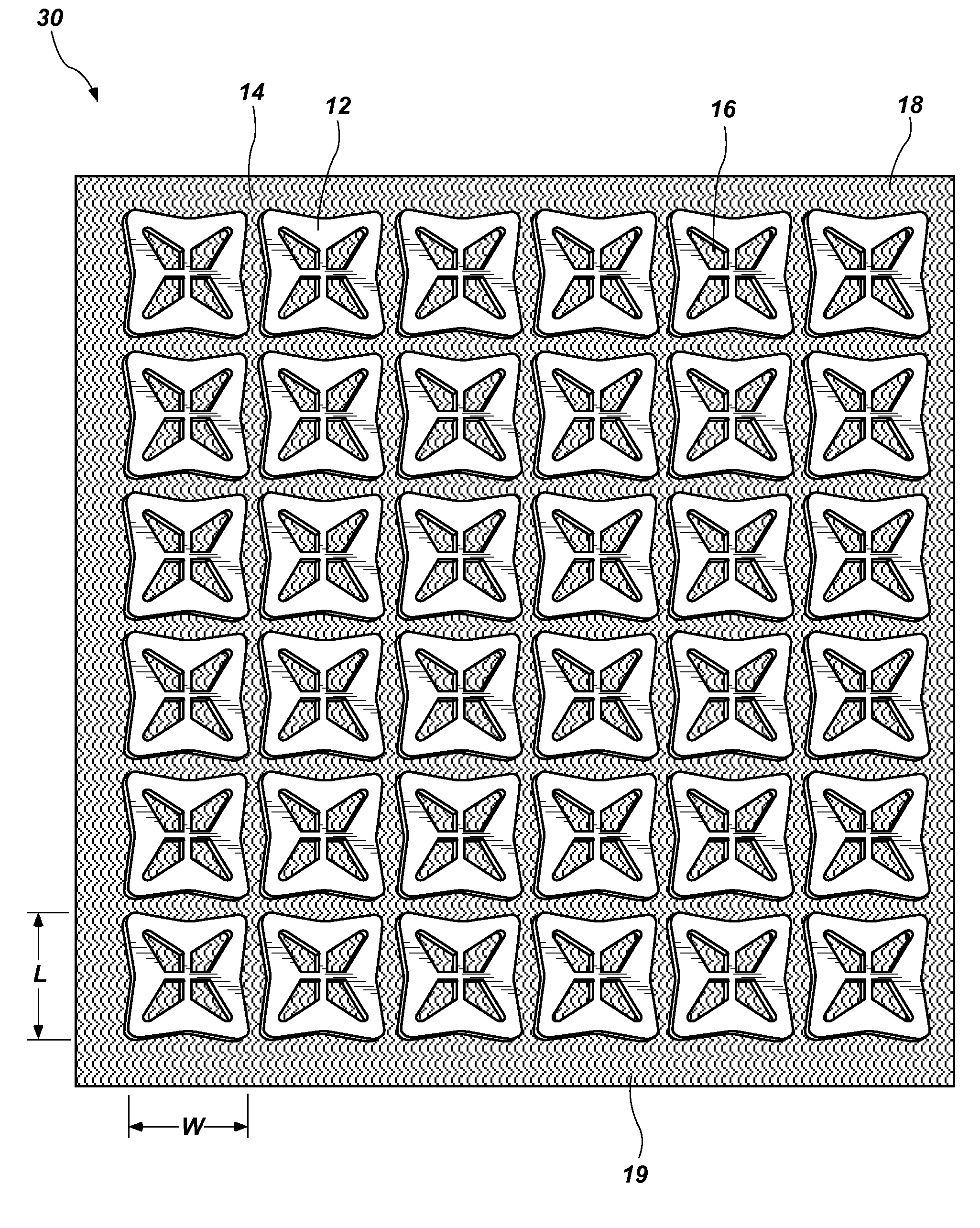

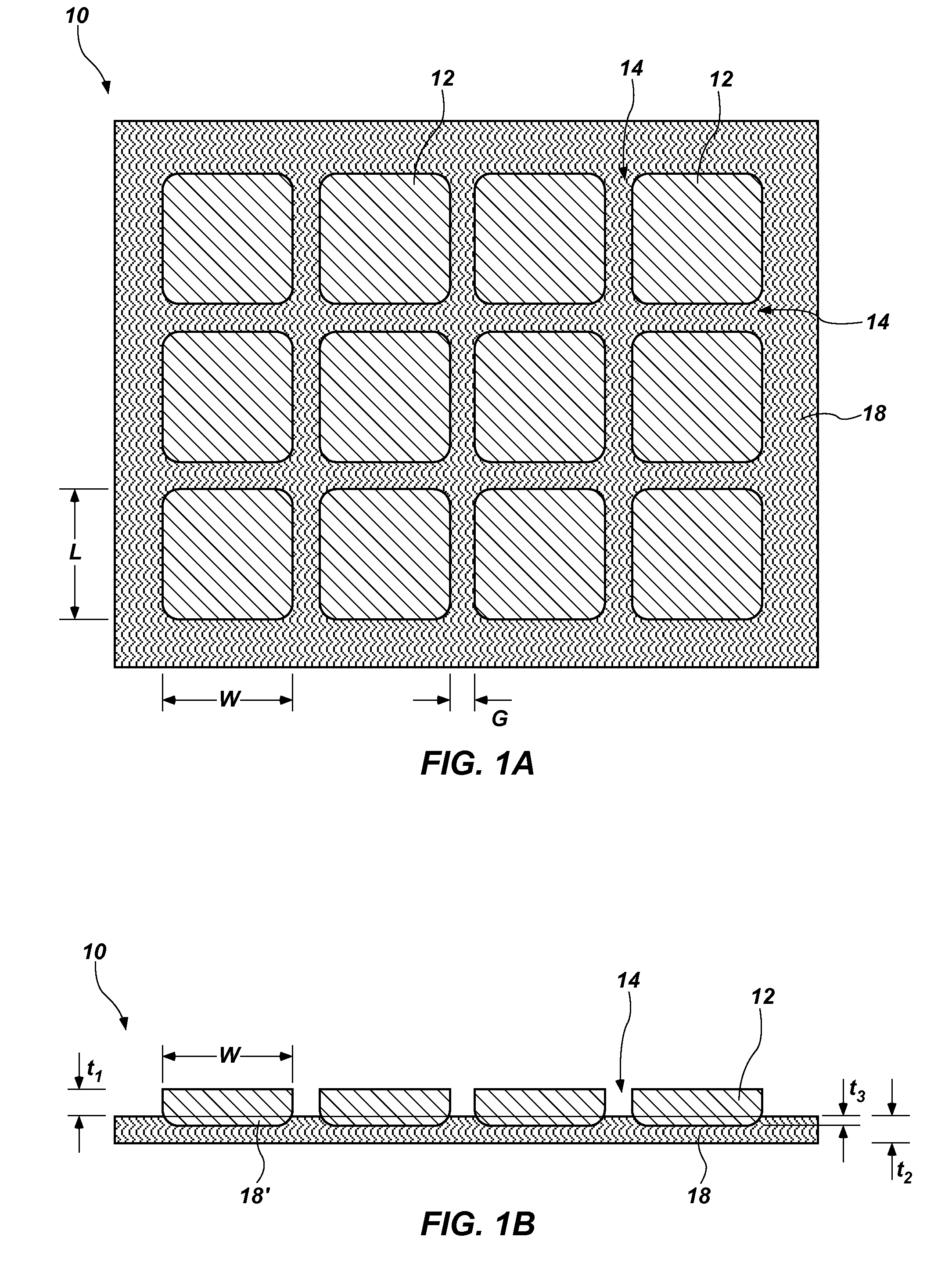

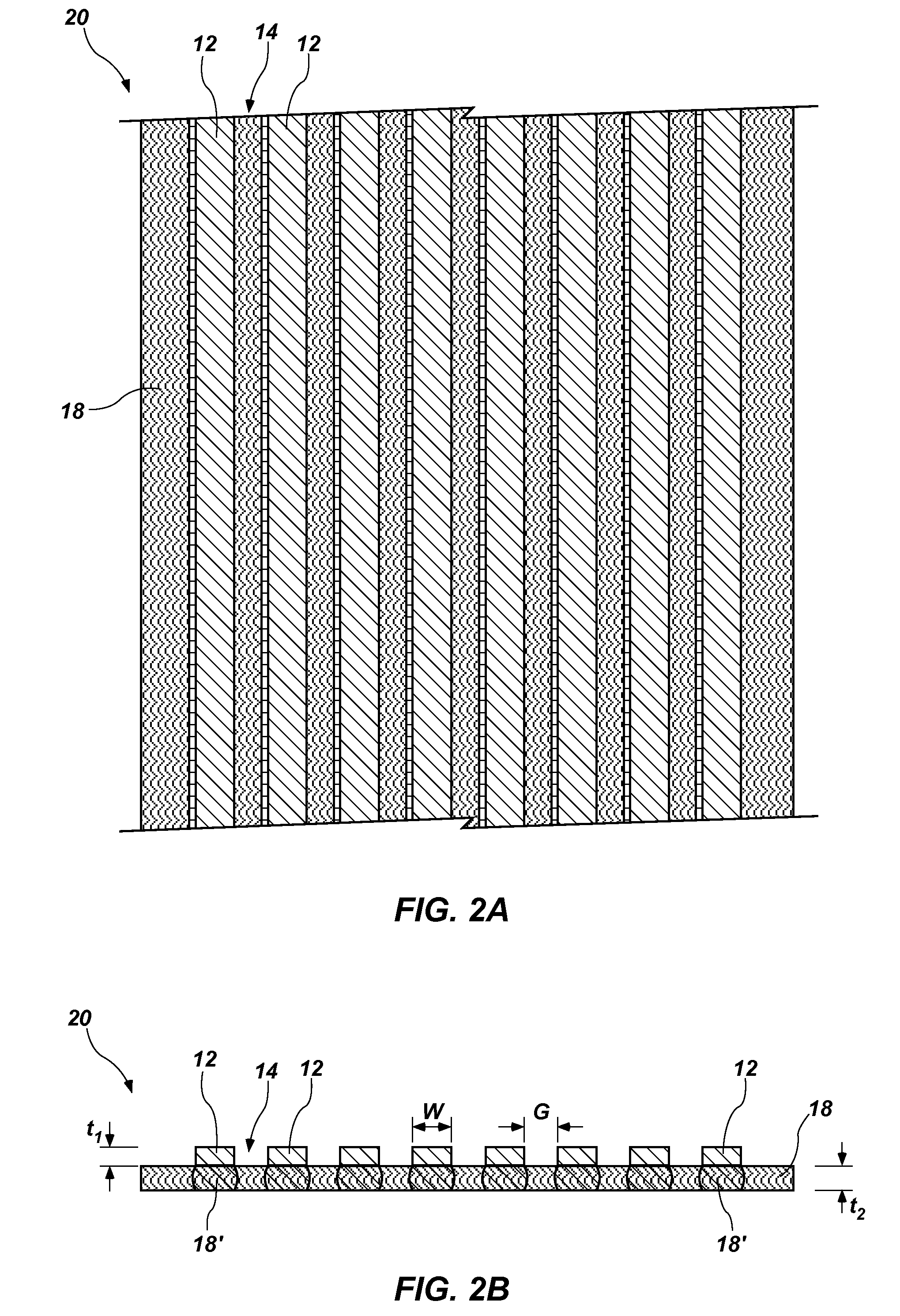

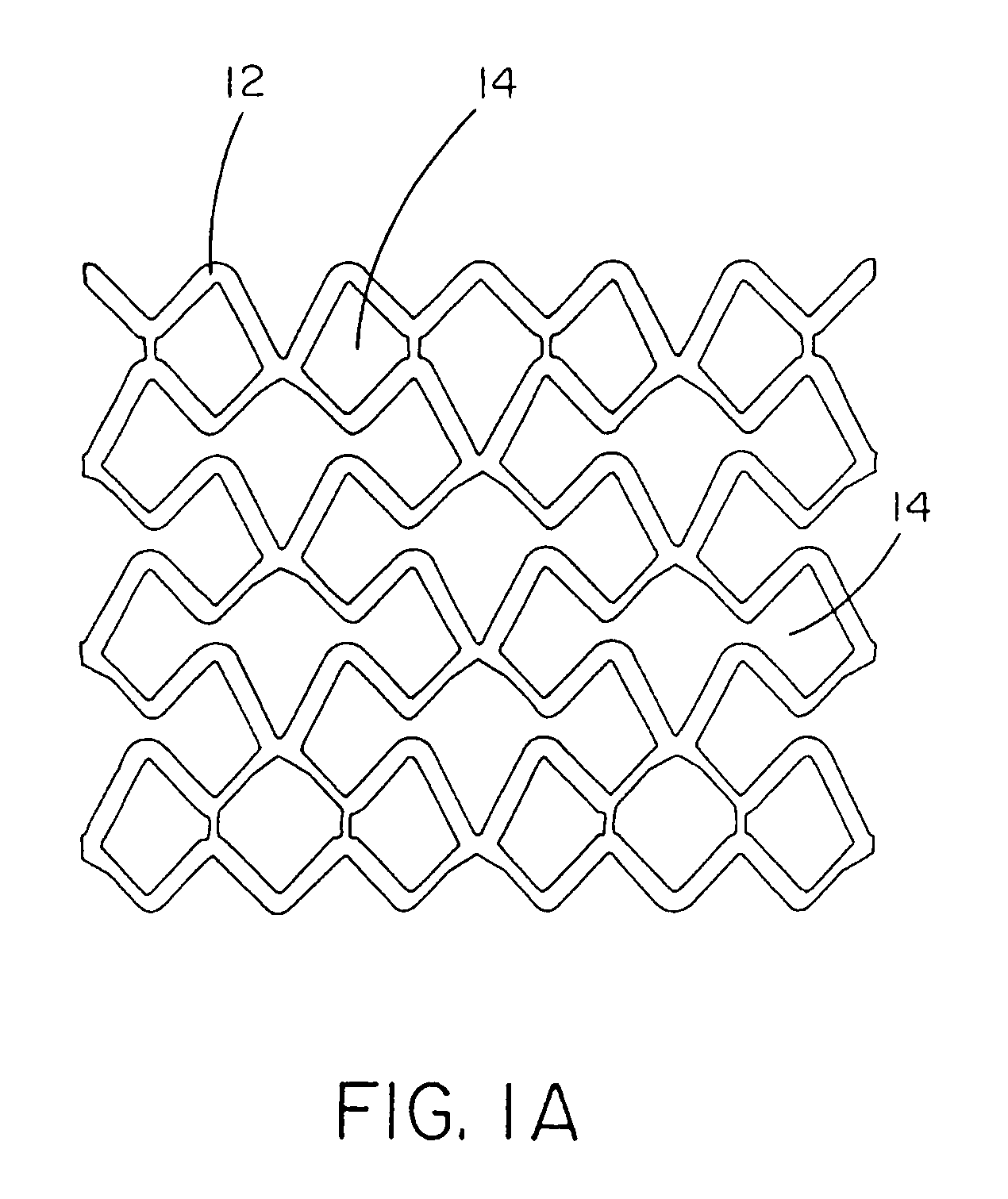

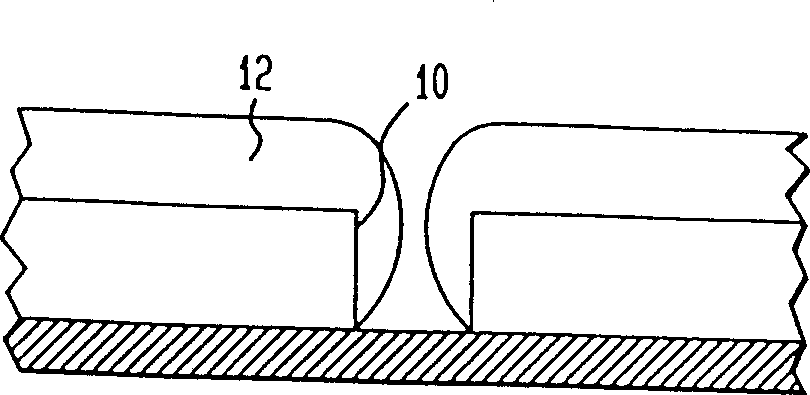

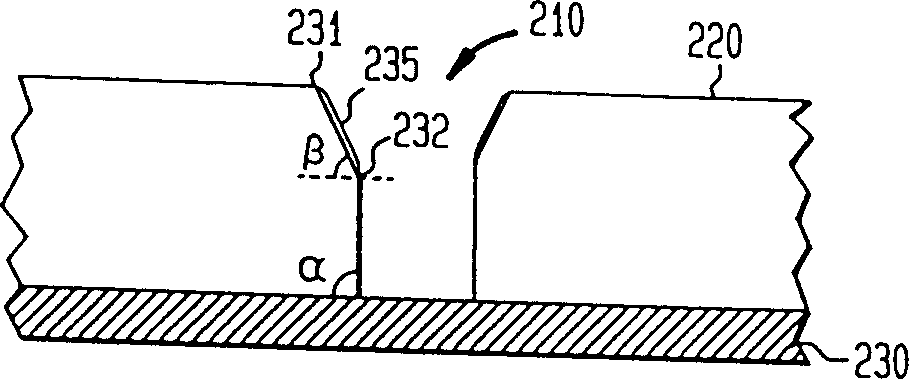

Breathable gel

Cushioning elements include a breathable material configured to allow gases to pass through at least a portion thereof, and a plurality of discrete segments of thermoplastic elastomeric gel (“gel”) heat-fused or otherwise attached to the breathable material. The gel comprises an elastomeric polymer and a plasticizer, with a plasticizer-to-polymer ratio of from about 0.3 to about 50. The plurality of discrete segments defines at least one breathable gap between adjacent discrete segments. Methods of forming cushioning elements include forming a plurality of discrete segments of gel, securing each segment to a breathable material, and providing a gas path through the breathable material and between adjacent segments. Another method includes providing molten gel within a mold, providing at least a second portion of the gel within a permeable material, and solidifying the gel to form discrete segments of gel.

Owner:PURPLE INNOVATION LLC

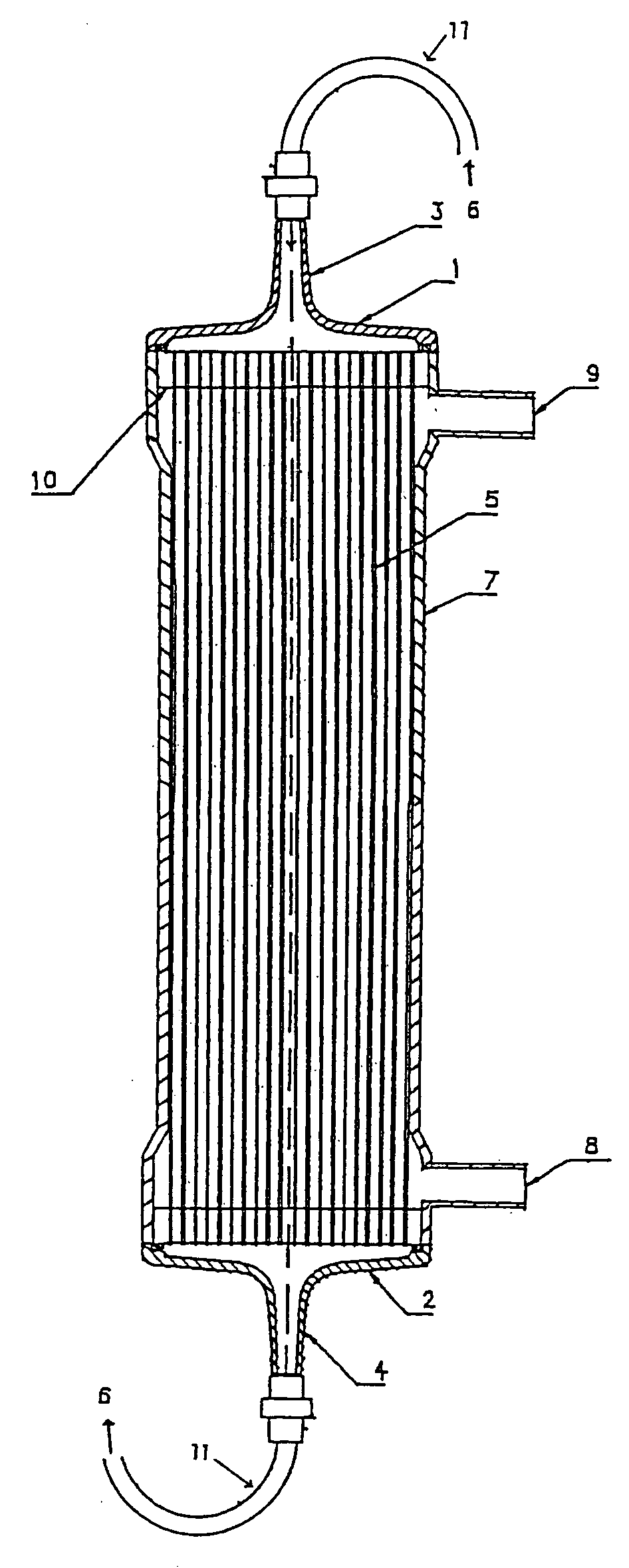

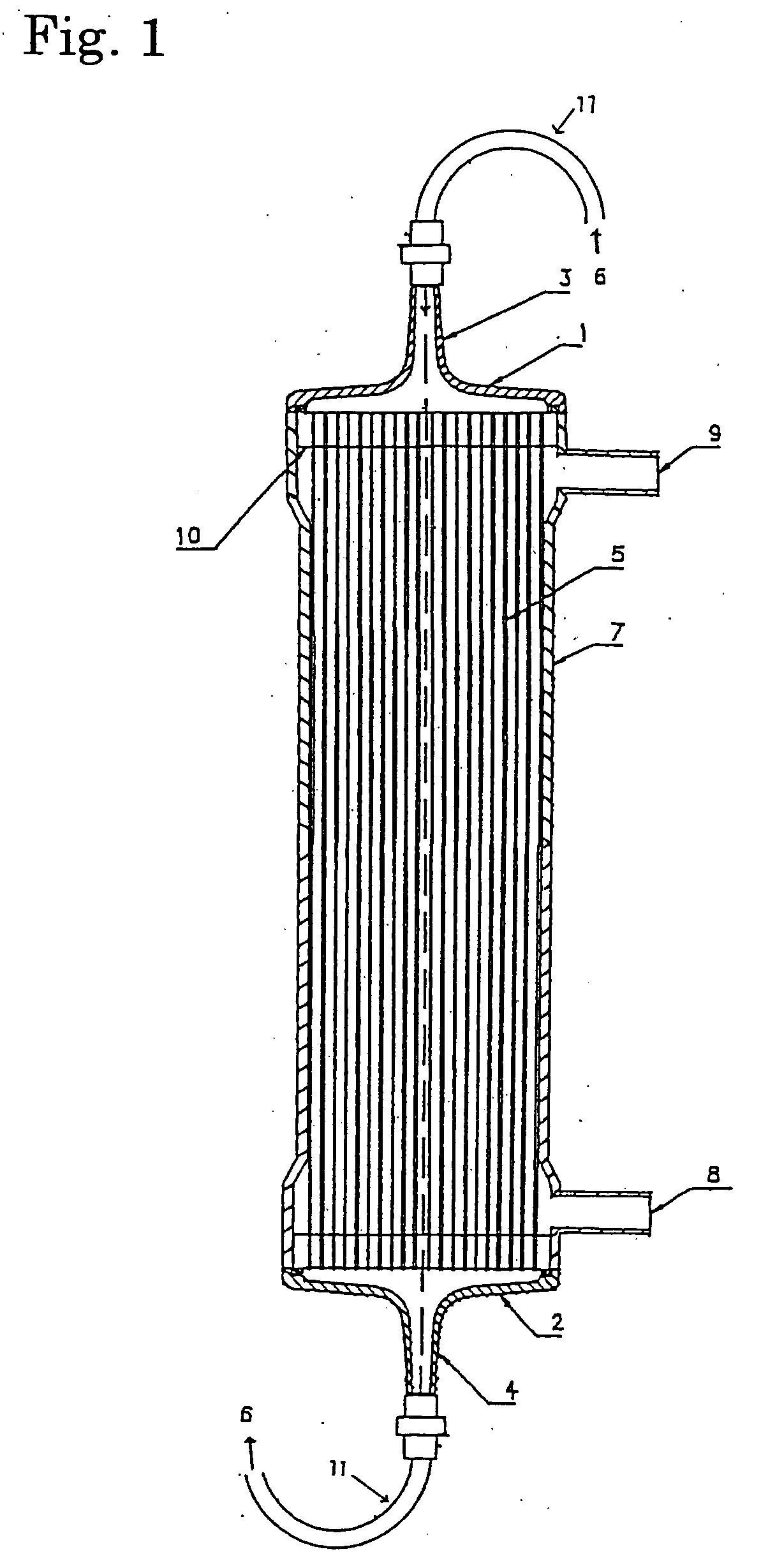

Modified substrate and process for producing modified substrate

InactiveUS20050273031A1Improve adsorption capacityImprove performanceGlovesMedical devicesAntioxidantAqueous solution

The present invention provides a modified substrate including a hydrophilic polymer wherein the soluble hydrophilic polymer ratio is 15 weight percent or less and the number of adhered human blood platelets is 10 / 4.3×103 μm2 or less. In addition, the present invention provides a method for producing a modified substrate including a step of irradiating the substrate with radiation while the substrate is brought into contact with an aqueous solution containing a hydrophilic polymer and an antioxidant. The present invention provides a modified substrate having high hematologic compatibility wherein the hydrophilic polymer is immobilized on the surface of the substrate, and a method for producing the same.

Owner:TORAY IND INC

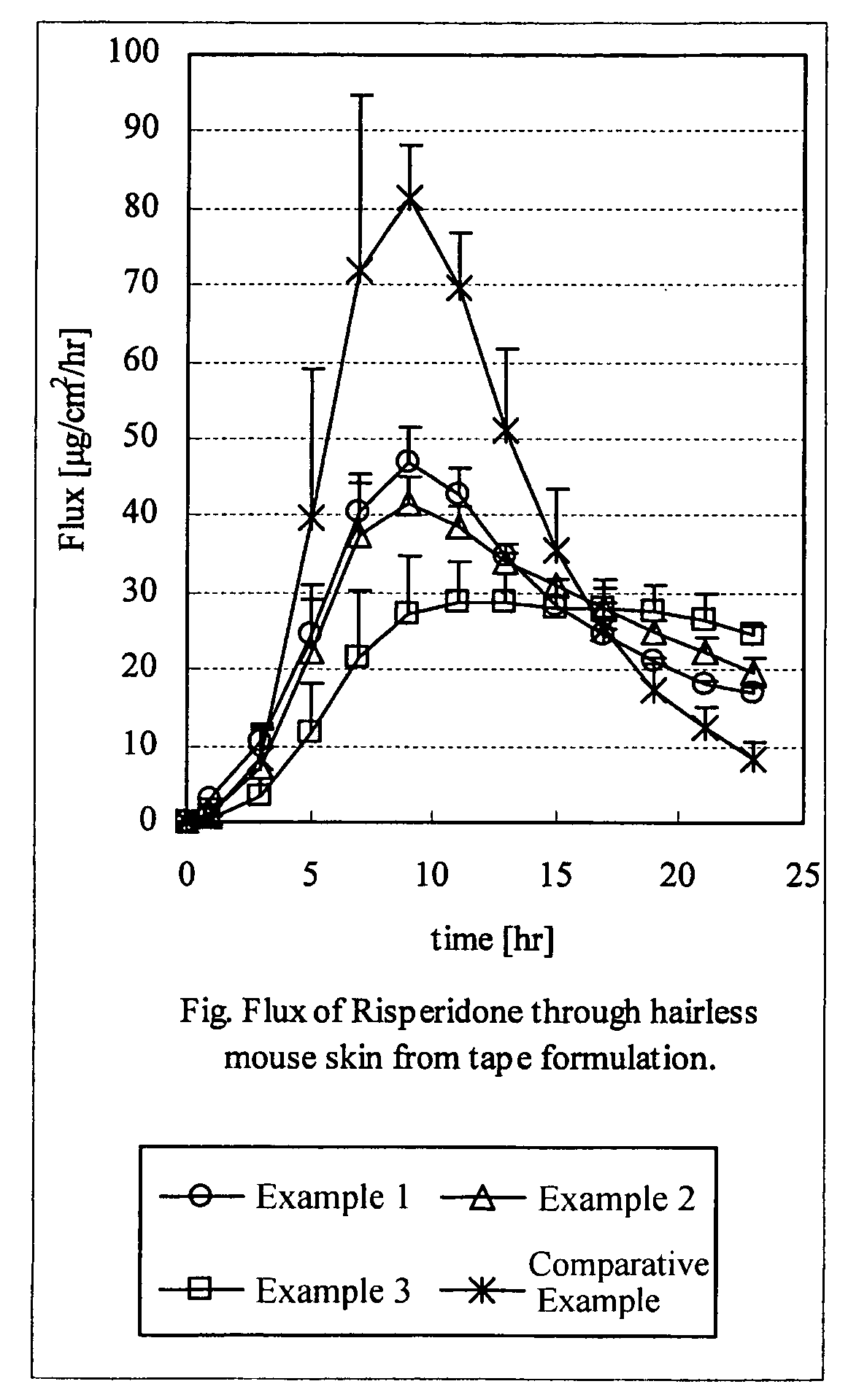

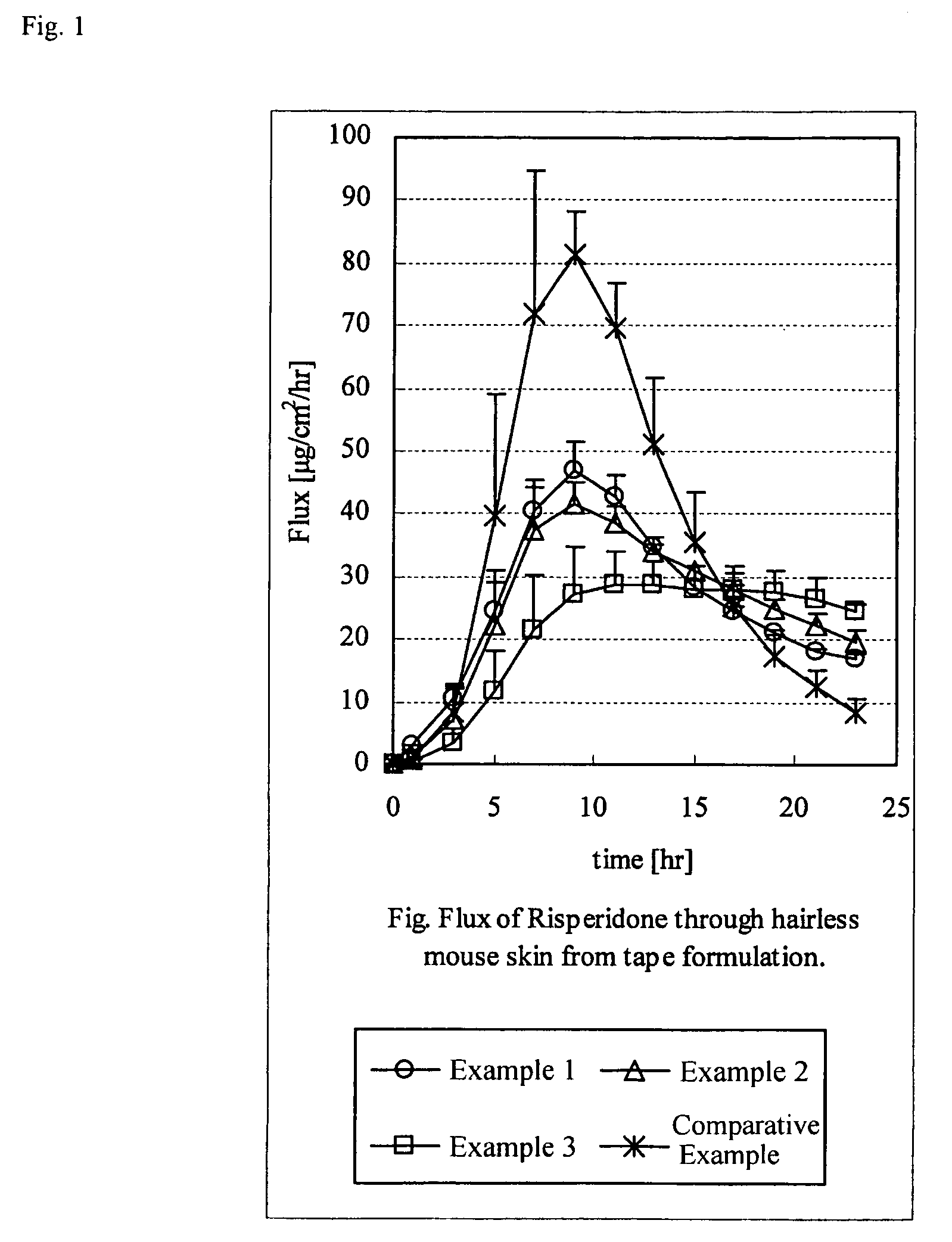

Adhesive patch for external use with improved cohesive force and sustained-release characteristics

InactiveUS20090004255A1Good drug skin permeabilityMaintain good propertiesBiocideNervous disorderMeth-Additive ingredient

The amount of penetration into the skin in adhesive patches generally tends to show a certain peak and trough. An adhesive patch is provided in which the drug shows satisfactory penetrability because of a polymer proportion and drug penetration is constant over a certain period. The adhesive patch for external use has a pressure-sensitive adhesive layer containing a drug. It is characterized in that the pressure-sensitive adhesive layer comprises: polyvinylpyrrolidone and / or a copolymer of monomers including vinylpyrrolidone as the main ingredient; and a (meth)acrylic ester copolymer having a basic nitrogen atom and / or cationic nitrogen atom.

Owner:HISAMITSU PHARM CO INC

A highly filled oxidatively degradable polymer packaging material and its preparation method

A highly filled oxidatively degradable polymer packaging material and its preparation method, which are mixed and extruded from the following components, the components are calculated by weight: inorganic filler 70-90, polyolefin polymer 10-30, optical function Auxiliary 0.01-0.2, thermal functional additive 0.01-0.2, coupling agent 0.05-5, lubricant 0.01-5. Drying the powder of the inorganic filler, adding a coupling agent to a mixer to mix and activate it; then mixing it with a polymer and an oxidative degradation additive according to the ratio, melting and mixing it in an extruder and granulating it to obtain a packaging material. After use, the packaging material of the present invention can be absorbed into fragments or powder under the action of oxygen and sunlight in the natural environment, and further degrade into carbon dioxide, water and inorganic minerals, which solves the problem of "white pollution". The packaging material adopts non-toxic and harmless raw materials, has abundant sources, is low in cost, and can be widely used in fields such as food packaging and industrial product packaging.

Owner:宋旭

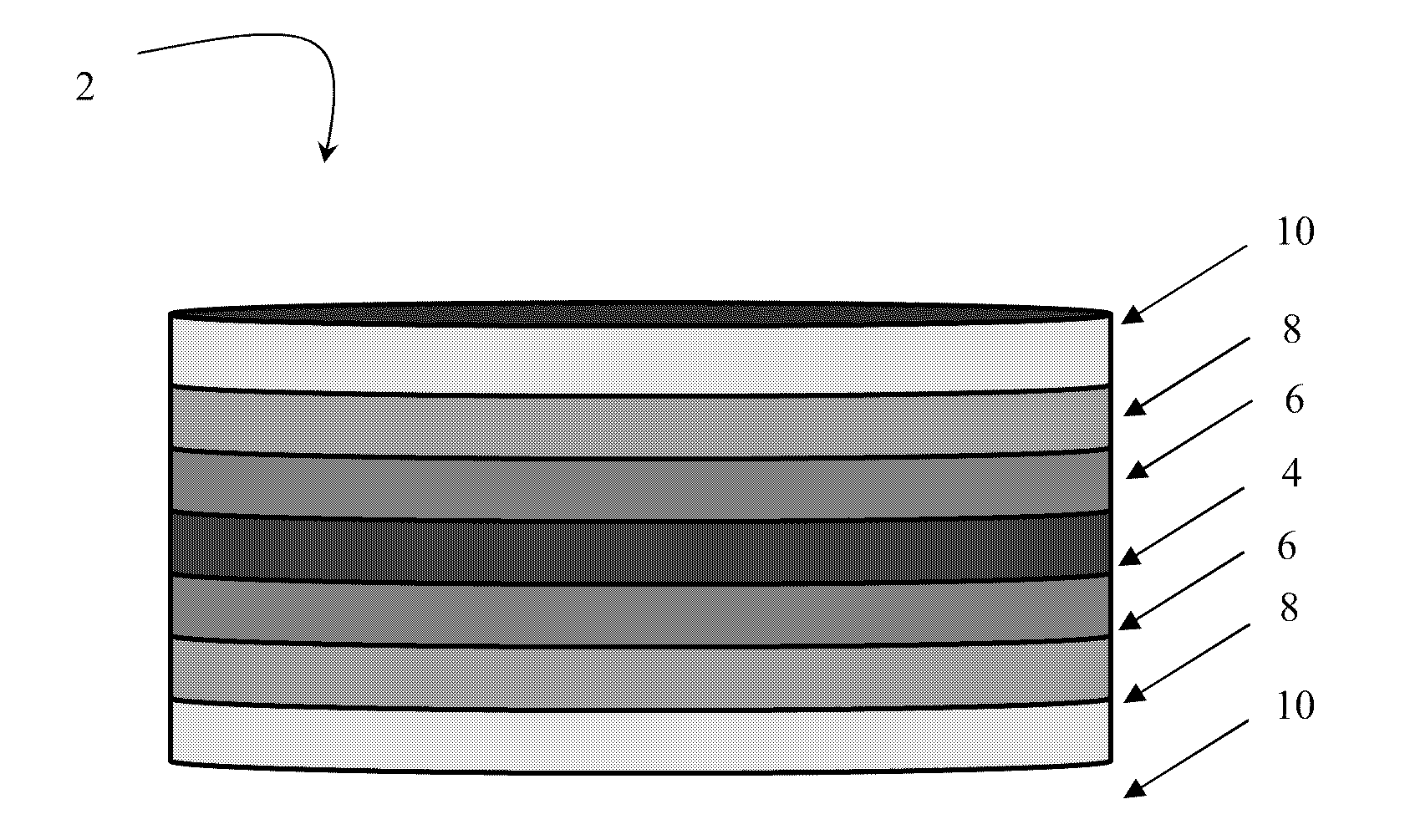

Composition and method of preparation of release systems for constant (zero-order) release of active agents

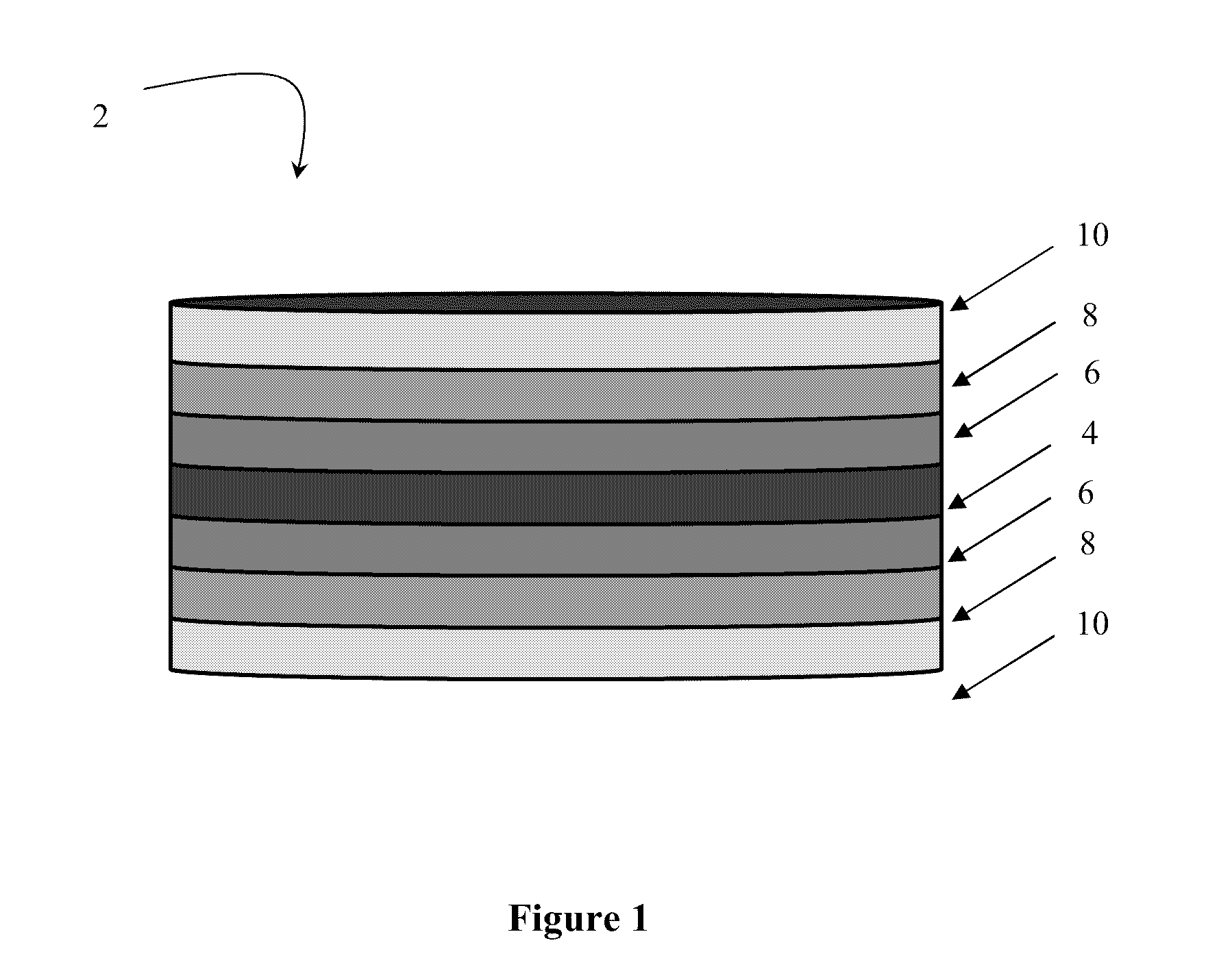

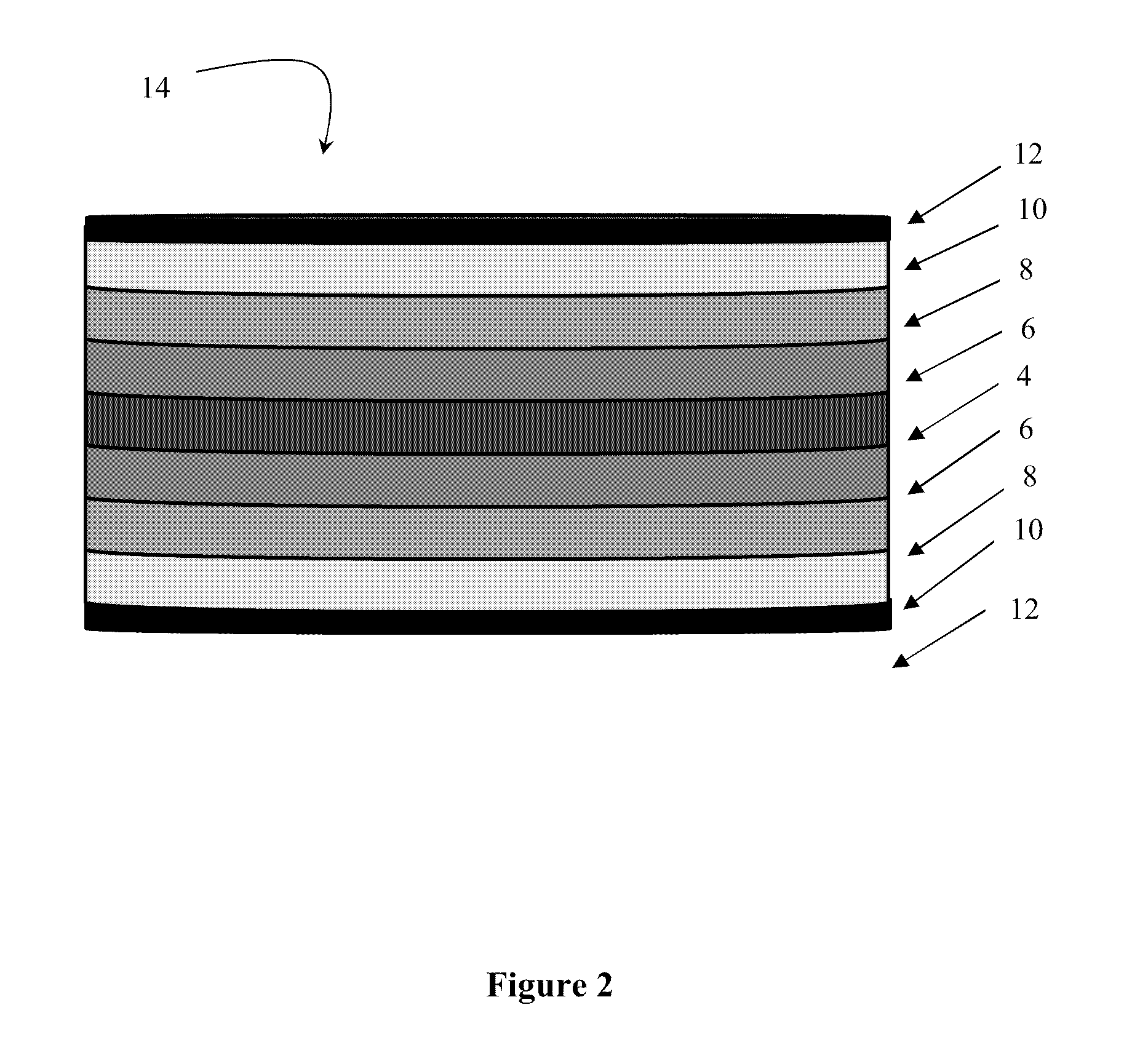

The present invention includes methods and compositions for pharmaceutical compositions that exhibit substantially constant release profile. The composition includes at least two layers with different drug to polymer ratios. The layers can be arranged in any order to achieve desirable pharmaceutical effects.

Owner:APPIAN LABS

Gunnable adhesive composition for use in construction membrane applications

A gunnable adhesive composition includes a silicone resin and an organopolysiloxane, or a reaction product thereof; as well as a filler and a solvent. The silicone resin and the organopolysiloxane are present in amounts to provide a resin / polymer ratio ranging from 58% to 64%. The gunnable adhesive composition may be applied to low surface energy substrates at ambient temperatures without primer or other surface treatment. The gunnable adhesive composition and adhesive product thereof are useful in weather barrier applications, such as building wraps.

Owner:DOW SILICONES CORP

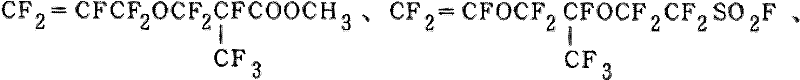

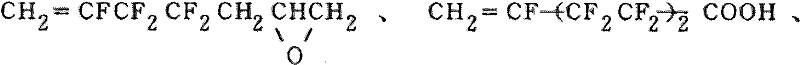

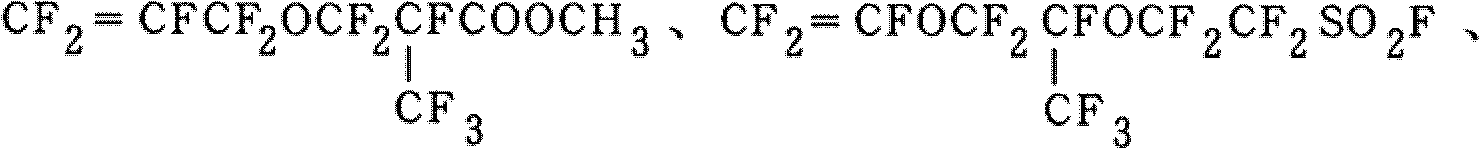

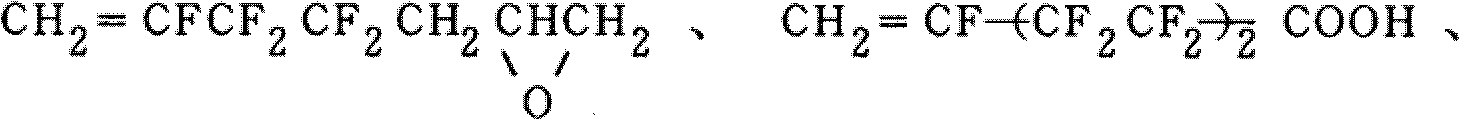

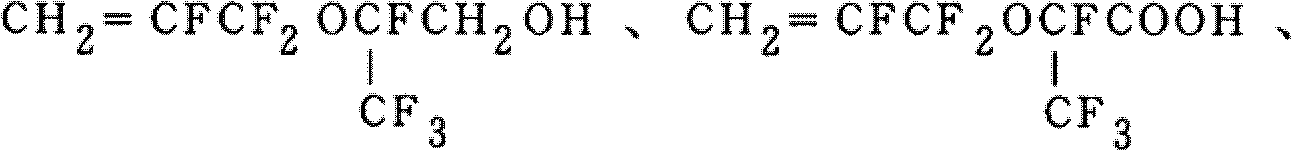

Aqueous dispersoid of fluorine-containing seed polymer particles and aqueous coating combination

The invention provides an aqueous dispersoid of fluorine-containing seed polymer particles serving as a film formation component for an aqueous coating combination. Although the ratio of acrylic acid ester polymers during seed polymerization is high, the acrylic acid ester polymers are highly compatible with the fluorine-containing polymer serving as seed particles, and can provide transparent films. The invention relates to an aqueous dispersoid of fluorine-containing seed polymer particles and an aqueous coating combination containing the aqueous dispersoid. A fluorine-containing polymer containing at least one fluoro-alkene unit is served as a seed particle and is obtained by polymerization of monomer mixtures containing acrylic acid ester monomers and ethylene monomer containing hydrolyzed monosilane, wherein the content of the acrylic acid ester monomer unit is, by mass, 40-400 parts relative to 100 parts of the fluorine-containing polymer particles, and the content of the ethylene monomer containing hydrolyzed monosilane is by mass, 0.1-2 parts relative to 100 parts of the acrylic acid ester monomer unit.

Owner:DAIKIN IND LTD

Binder for Electric Double Layer Capacitor Electrode

InactiveUS20070274023A1Large electrode densityImprove bindingHybrid capacitor electrodesElectrolytic capacitorsInternal resistanceSlurry

Provided are a binder for an electric double layer capacitor electrode which gives an electrode having a high electrode density and a high binding force and which comprises a polymer that can give a polymer film having a tensile stress of 2 MPa or less when the film is elongated at the ratio of 100% and having the elongation at break of 450% or more; a binder composition for an electric double layer capacitor electrode and a slurry composition for an electric double layer capacitor electrode which each comprises the binder; an electrode produced by use of the slurry composition; and an electric double layer capacitor which has the electrode so as to exhibit a large electrostatic capacity and a small internal resistance.

Owner:ZEON CORP

Pressure sensitive adhesives and methods for their preparation

InactiveCN101223257AGood lookingThin material handlingPressure sensitive film/foil adhesivesSolventPolymer ratio

A pressure sensitive adhesive composition includes (A) a bodied MQ resin containing (i) a resinous core and (ii) a nonresinous polyorganosiloxane group, where the nonresinous polyorganosiloxane group is terminated with a silicon-bonded hydroxyl group; (B) a treated MQ resin, where (B) / (A) ratio has a value of 0.3 to 5.0, and (C) a polydiorganosiloxane terminated with a condensation reactable group; where resin / polymer ratio has a value of 2.0 to 3.0; optionally (D) a crosslinker; optionally (E) a catalyst; and optionally (F) a solvent. A pressure sensitive adhesive product prepared by curing the pressure sensitive adhesive composition is useful in structural attachment applications such as structural glazing applications.

Owner:DOW CORNING CORP

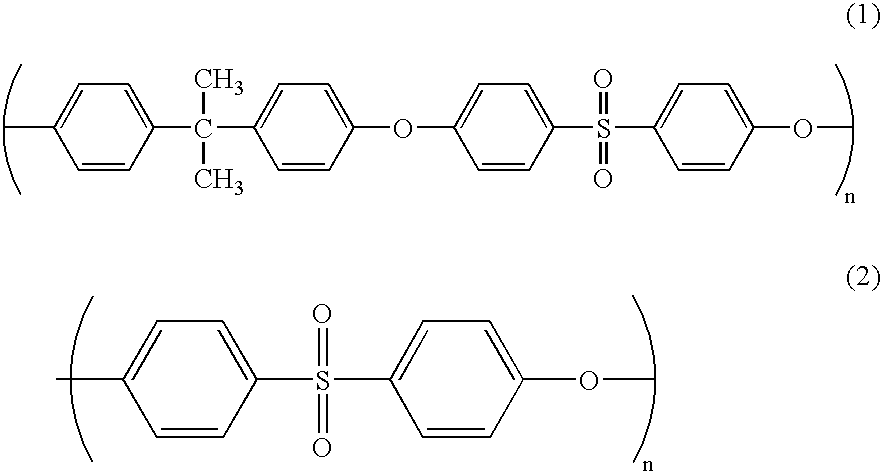

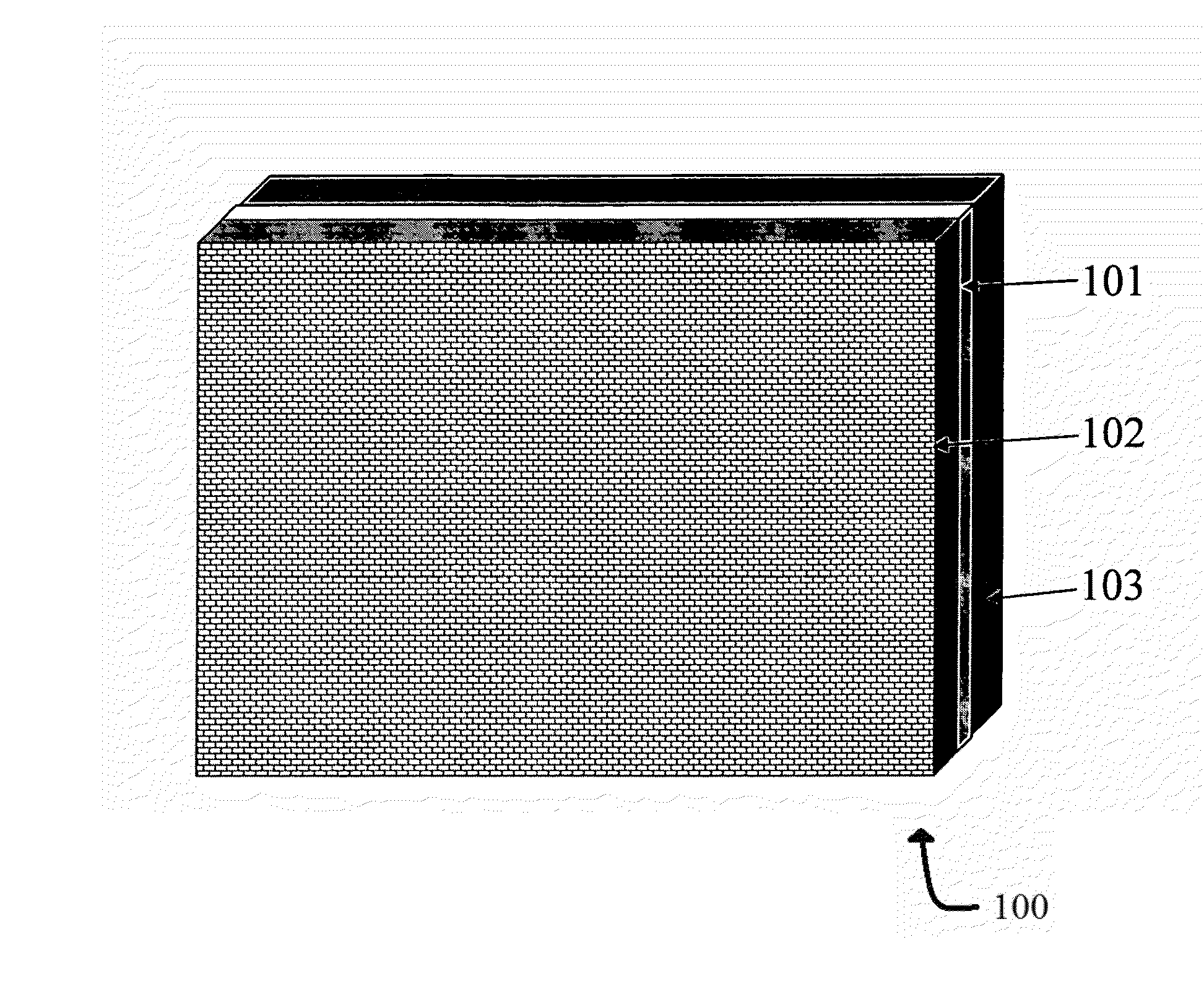

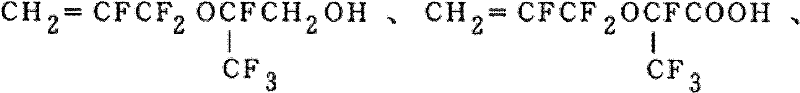

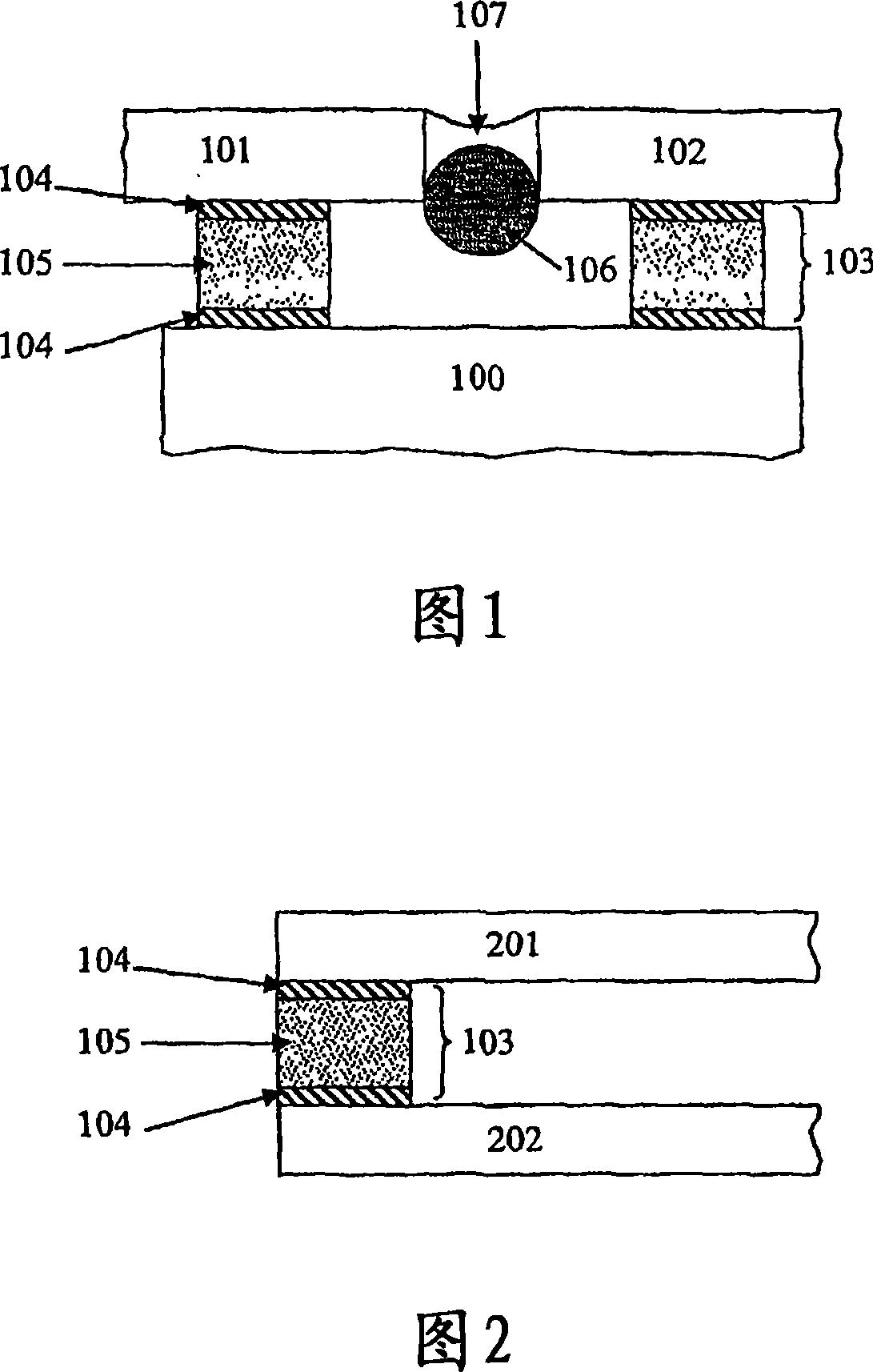

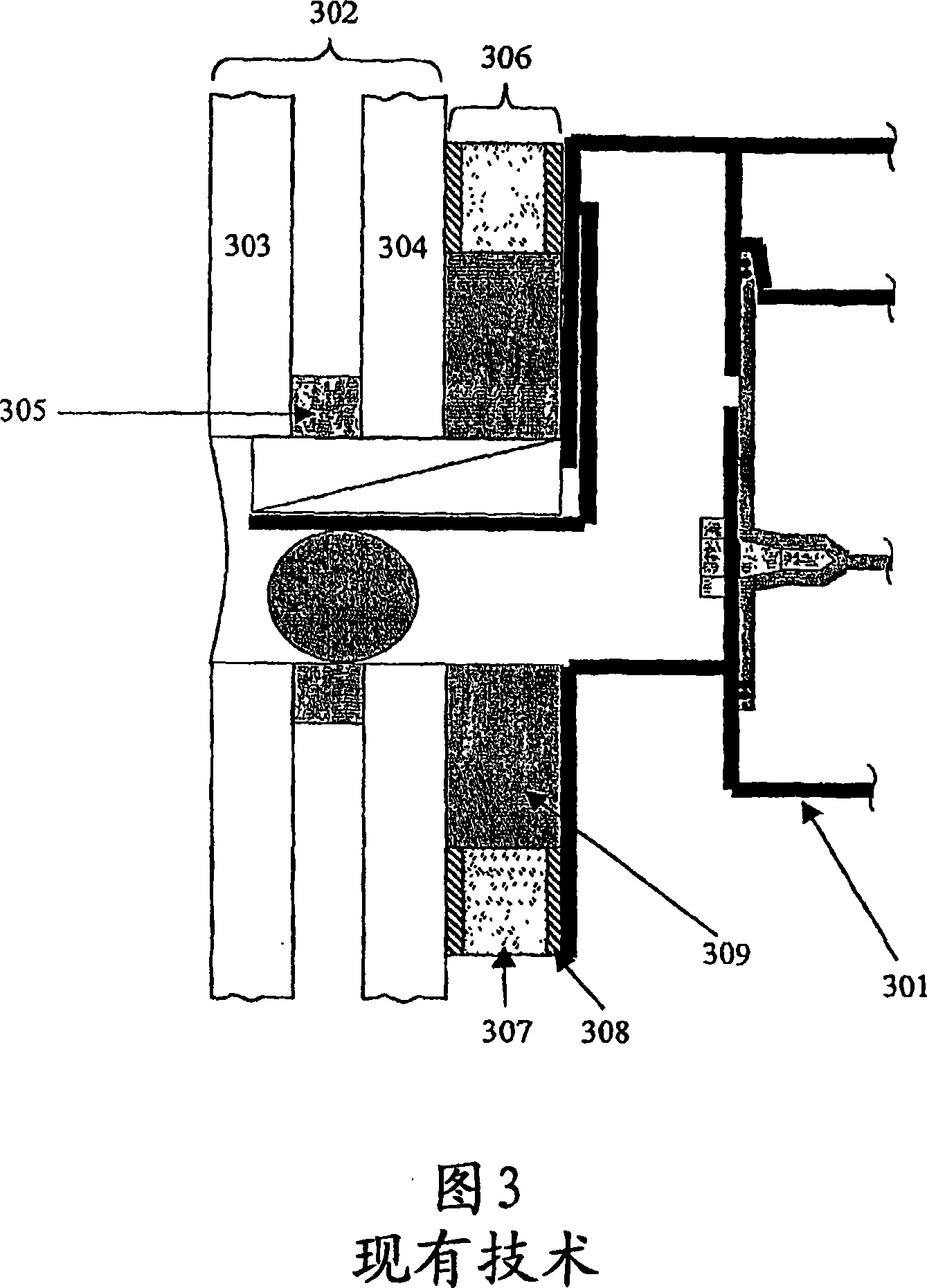

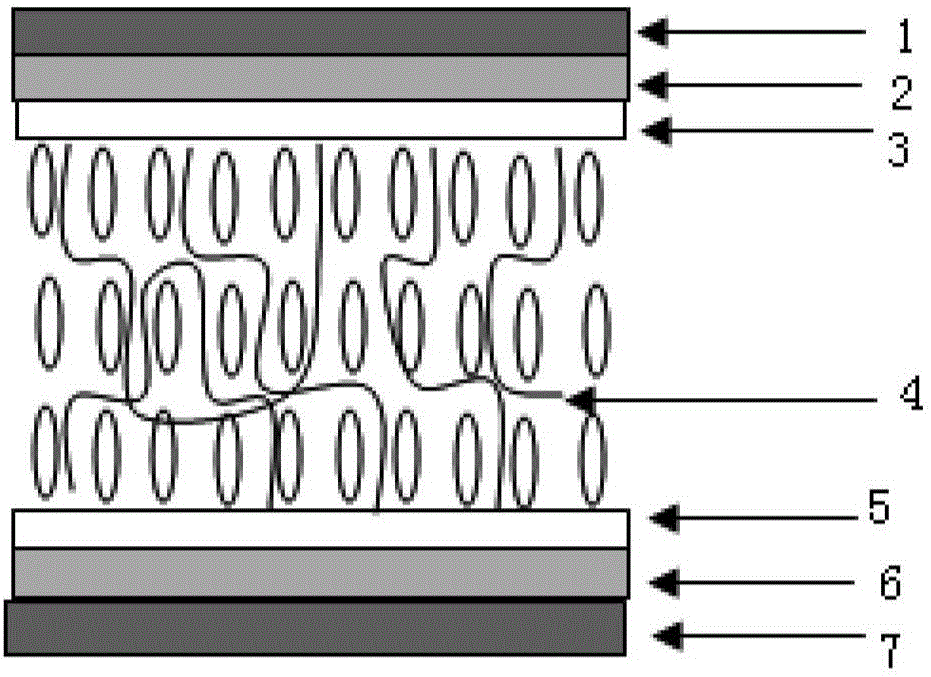

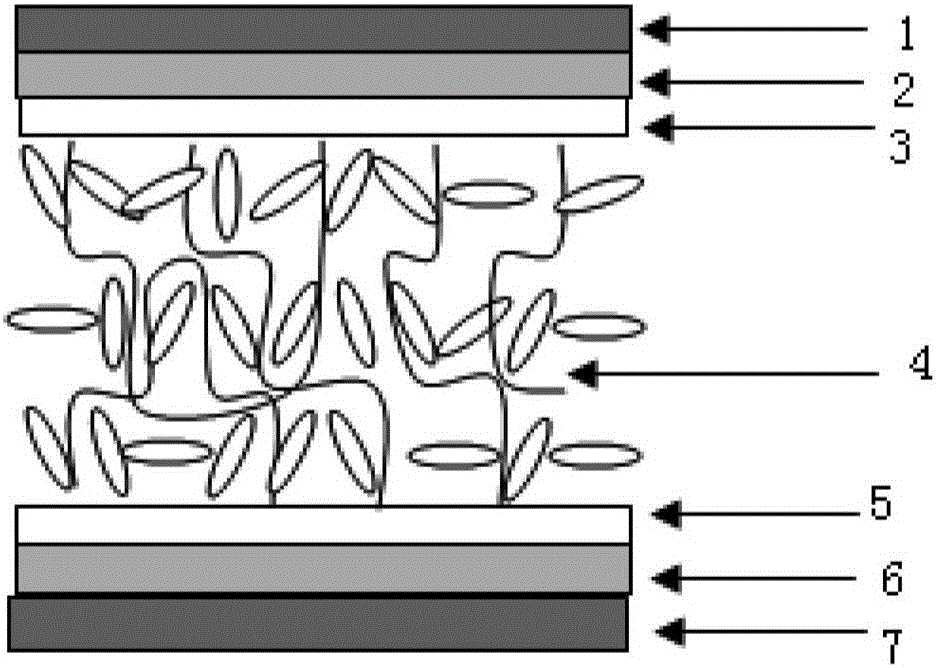

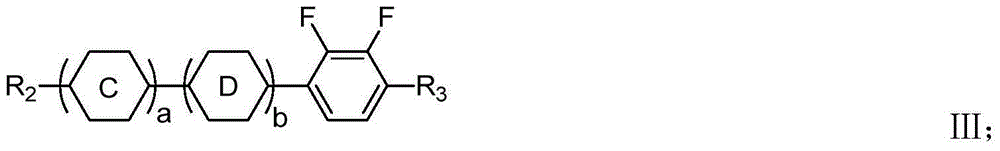

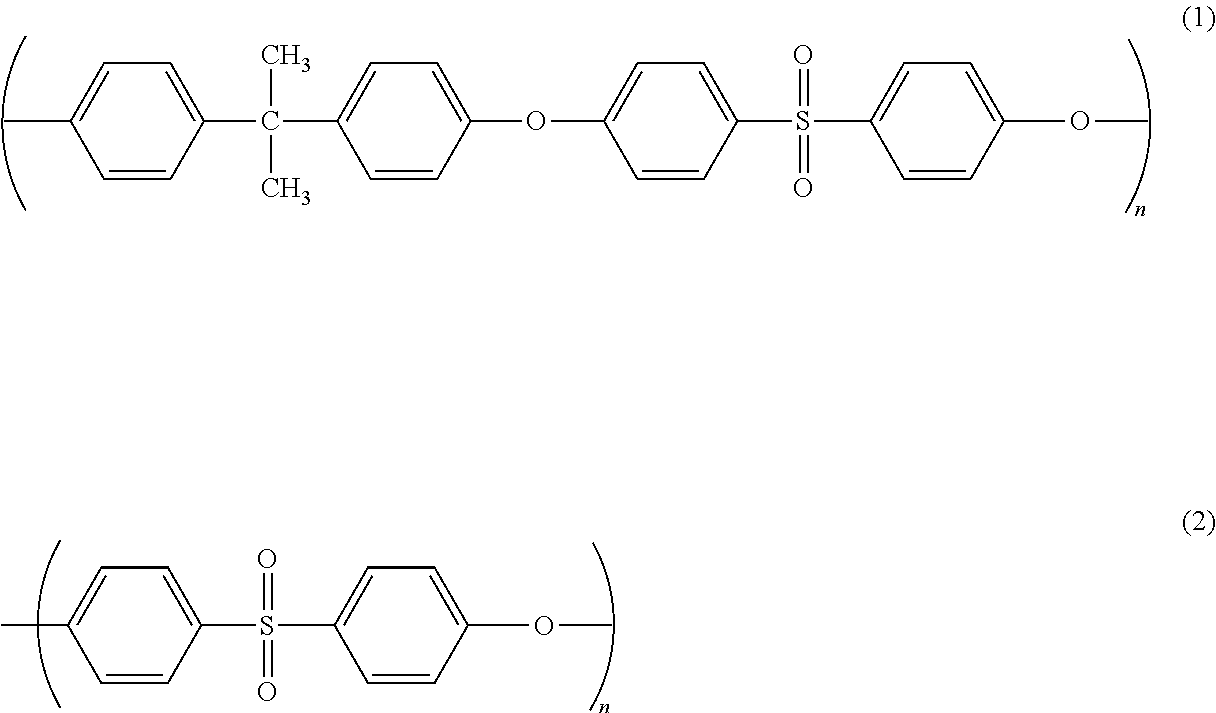

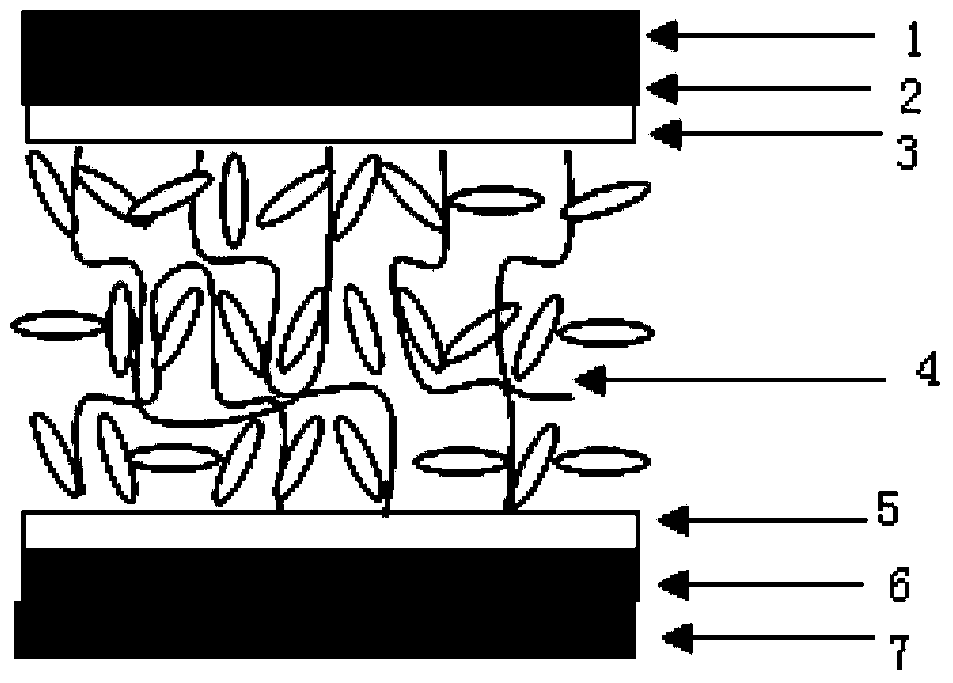

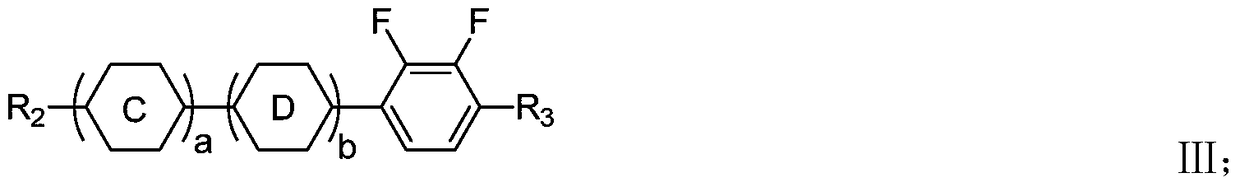

Polymer network liquid crystal display

The invention provides a polymer network liquid crystal display. The polymer network liquid crystal display comprises a first matrix layer, a first conducting layer, a first orientation layer, a liquid crystal dielectric layer, a second orientation layer, a second conducting layer and a second matrix layer, wherein the liquid crystal dielectric comprises a first component accounting for 1-15% of the total weight of the liquid crystal dielectric and a second component accounting for 85-99% of the total weight of the liquid crystal dielectric; a group composed of one or more polymerizable compounds having structures in general formula I and / or general formula II is used as the first component; and a nematic phase liquid crystal composition is used as the second component. The polymer network liquid crystal display is in a transparent state in case of zero electric field, and the light transmittance is higher than 85%; after voltage application, the polymer network liquid crystal display is in a scattering state; no visual angle problem exists in the transparent state; and in case of a 120-degree visual angle, the light transmittance is still higher than 80%. Therefore, the polymer network liquid crystal display provided by the invention has better off-state light transmittance and a bigger visual angle; and meanwhile, due to the small proportion of polymers, the polymer network liquid crystal display has lower drive voltage and can realize the reverse mode PDLC (polymer dispersed liquid crystal) effect of low-voltage driving. The general formula I and the general formula II are shown in the specification.

Owner:JIANGSU HECHENG DISPLAY TECHCO

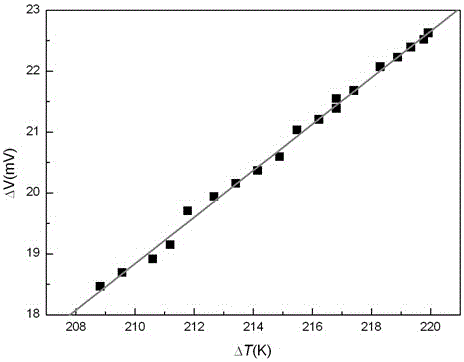

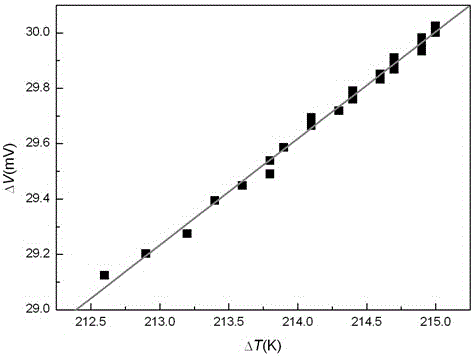

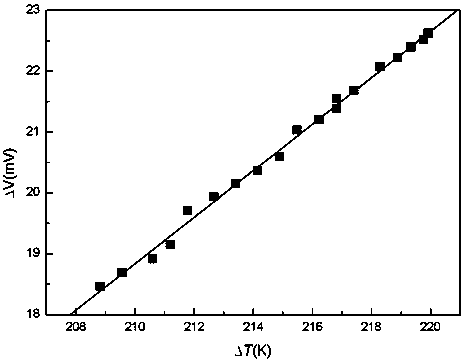

Thermoelectric thick film preparation method

ActiveCN105024007AImprove performanceNot easily oxidizedThermoelectric device manufacture/treatmentOrganic solventRoom temperature

The invention relates to a thermoelectric thick film preparation method. Thermoelectric thick film slurry is composed of thermoelectric material particles, polymers and an organic solvent. Due to the polymer ratio, the thermoelectric thick film slurry printed on a flexible substrate does not fall automatically after being dried, after the thermoelectric thick film slurry is fully dried, one face with viscose of a high temperature-resisting thin film is used for tight covering, and a thermoelectric thick film with excellent performance is acquired through cold isostatic pressing processing. As the polymer ratio is the lowest ratio which can only enable the thermoelectric thick film slurry printed on the flexible substrate not to fall automatically after being dried, attachment and molding of the thermoelectric thick film on the flexible substrate are acquired through the tightly-covered high temperature-resisting thin film and cold isostatic pressing processing, the thermoelectric particles are fully and tightly contacted, conductivity s close to that of a bulk can be acquired, the thermoelectric performance is improved, and due to protection of the high temperature-resisting thin film, the thermoelectric thick film is not likely to oxidize even if working for a long time at a temperature between room temperature and 230 DEG C.

Owner:SUN YAT SEN UNIV

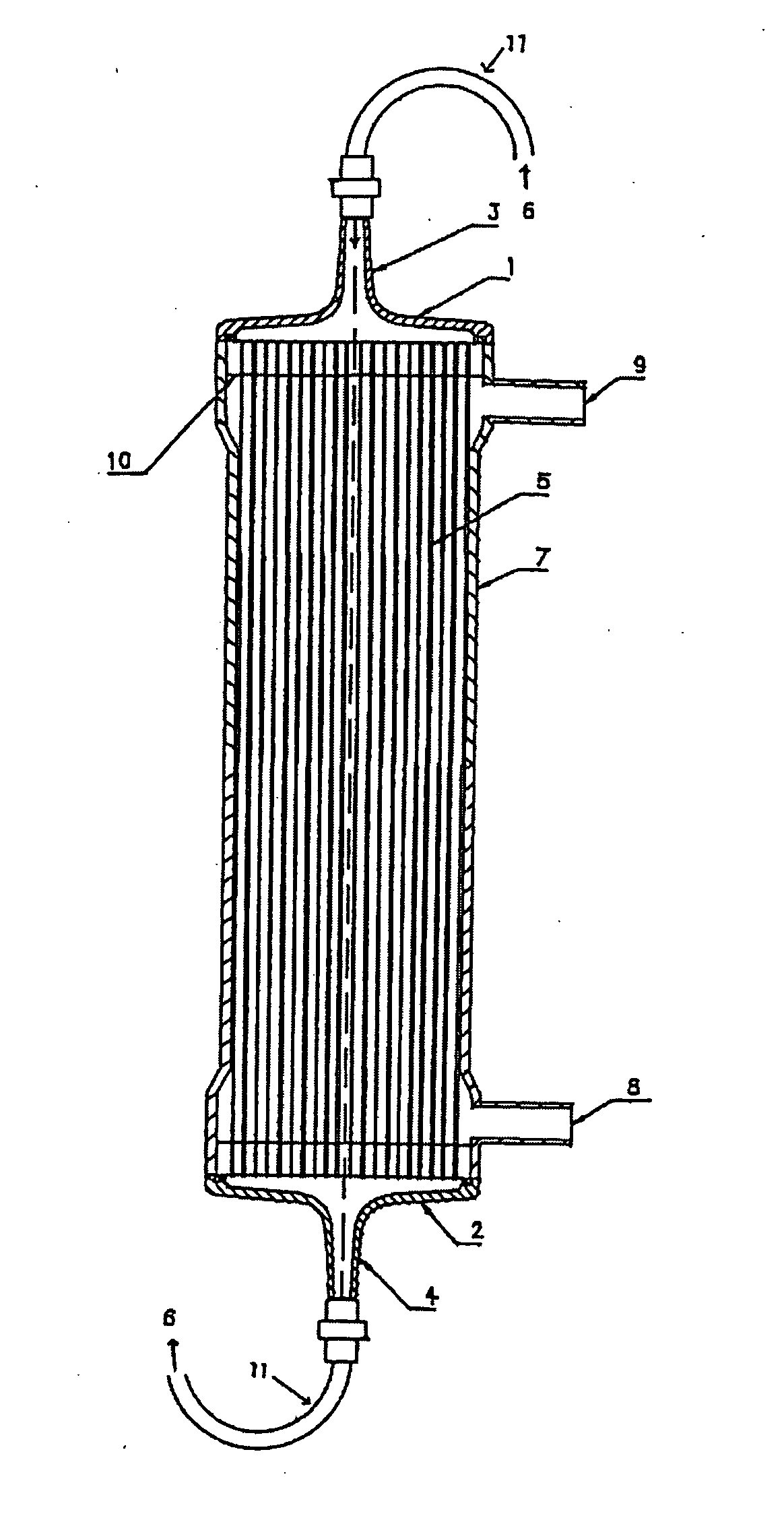

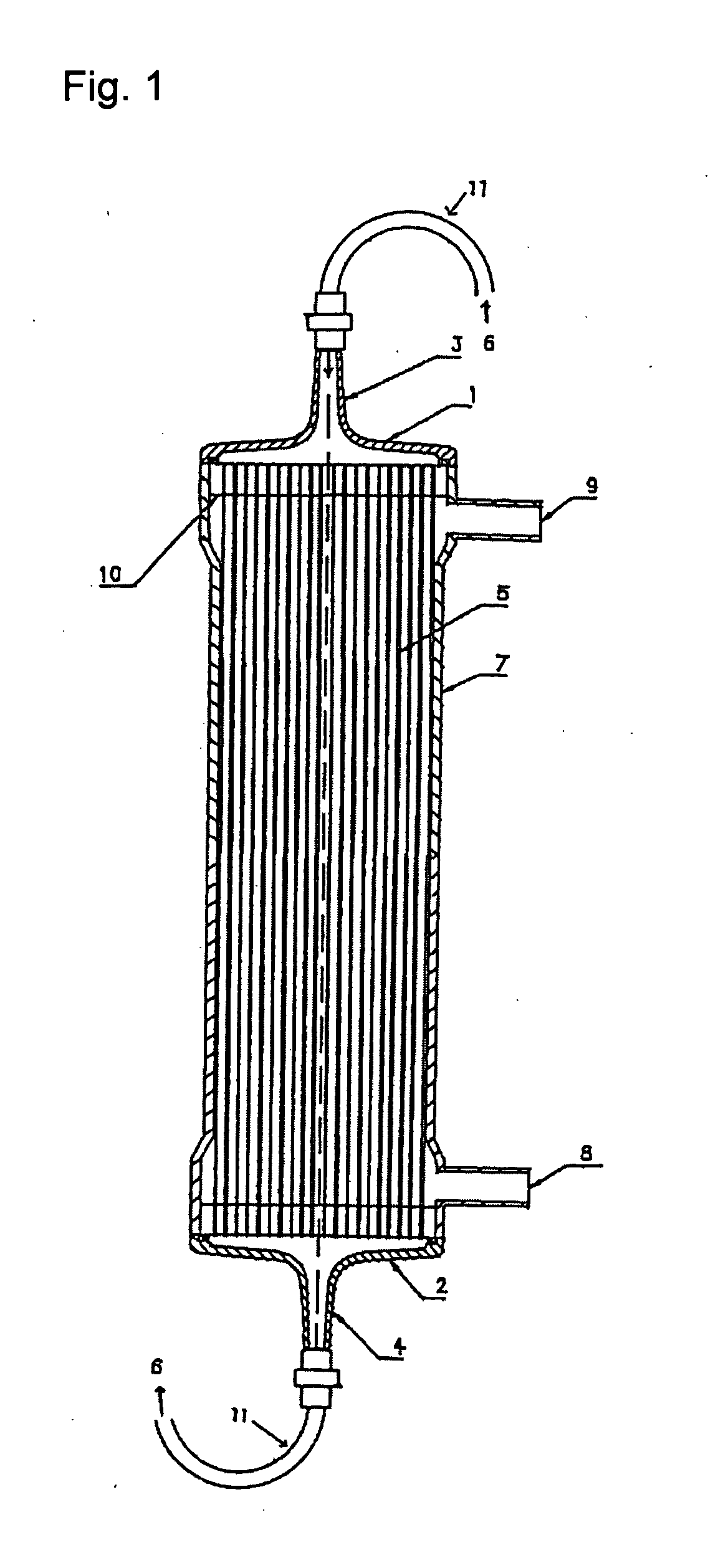

Porous Non-Asbestos Separator and Method of Making Same

The present invention relates to an inert, non-asbestos separator and method of making same, the separator comprising an inorganic / polymer fibrid and agglomeration composite material containing from about 5 weight percent to about 70 weight percent of organic halocarbon polymer fibers together with from about 30 wt percent to about 95 weight percent of a finely divided non-organic particulate, which non-organic particulate is firmly bound in said composite fibrids and agglomerates; a natural gum thickening agent in an amount to provide a viscosity of about 6270 to about 590 cP at 0.22 sec−1; and an inert inorganic particulate powder whereby the inert inorganic particulate remains unbound from the inorganic / polymer fibrid and agglomeration composite, the inorganic particulate powder having a mean particle size of not greater than 1.0 μm and being present in an amount to provide a ratio of polymer fiber composite to unbound inorganic particulate in a range from about 1 to 25.

Owner:IND DE NORA SPA

Breathable gel

Cushioning elements include a breathable material configured to allow gases to pass through at least a portion thereof, and a plurality of discrete segments of thermoplastic elastomeric gel (“gel”) heat-fused or otherwise attached to the breathable material. The gel comprises an elastomeric polymer and a plasticizer, with a plasticizer-to-polymer ratio of from about 0.3 to about 50. The plurality of discrete segments defines at least one breathable gap between adjacent discrete segments. Methods of forming cushioning elements include forming a plurality of discrete segments of gel, securing each segment to a breathable material, and providing a gas path through the breathable material and between adjacent segments. Another method includes providing molten gel within a mold, providing at least a second portion of the gel within a permeable material, and solidifying the gel to form discrete segments of gel.

Owner:PURPLE INNOVATION LLC

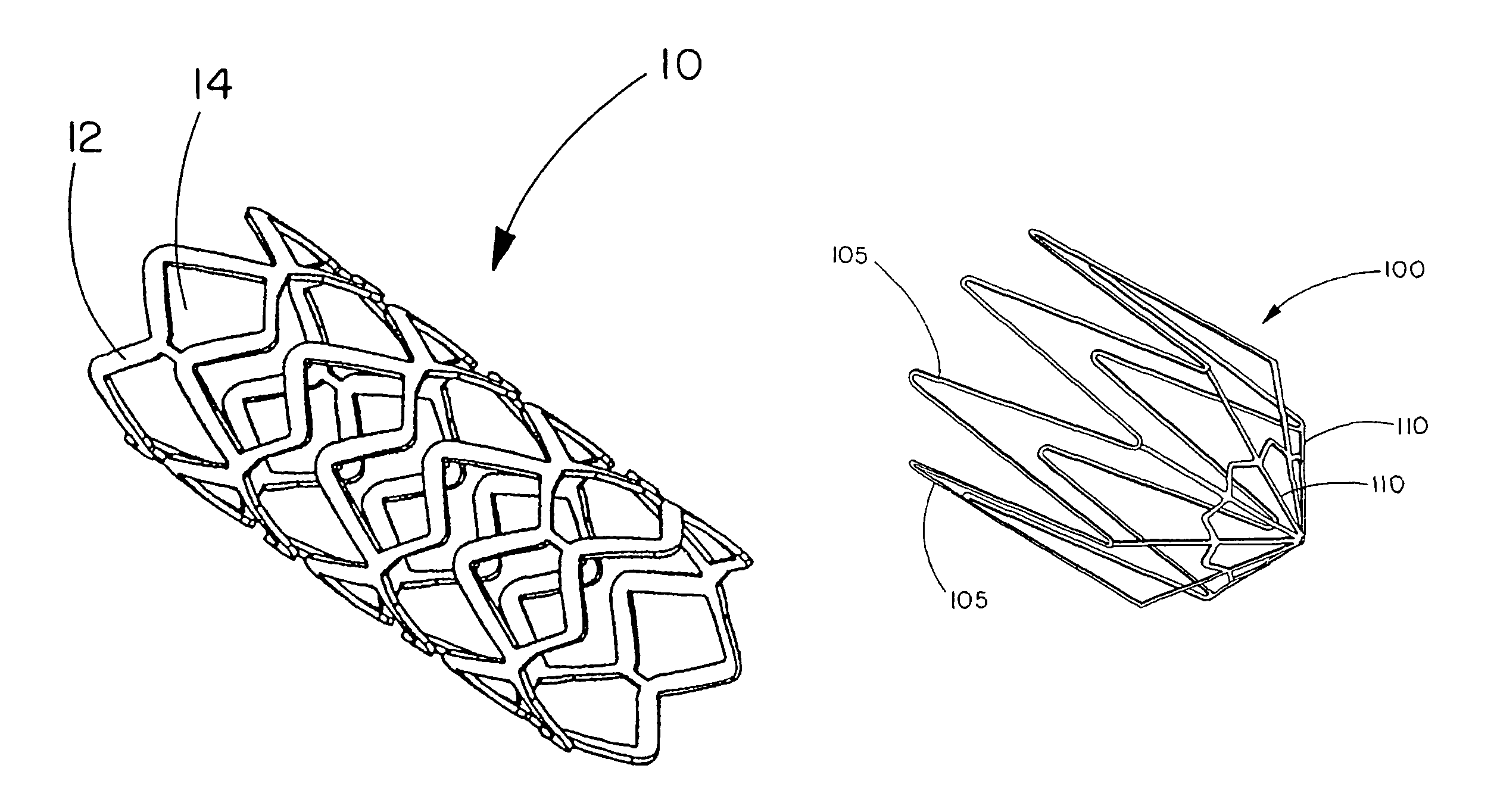

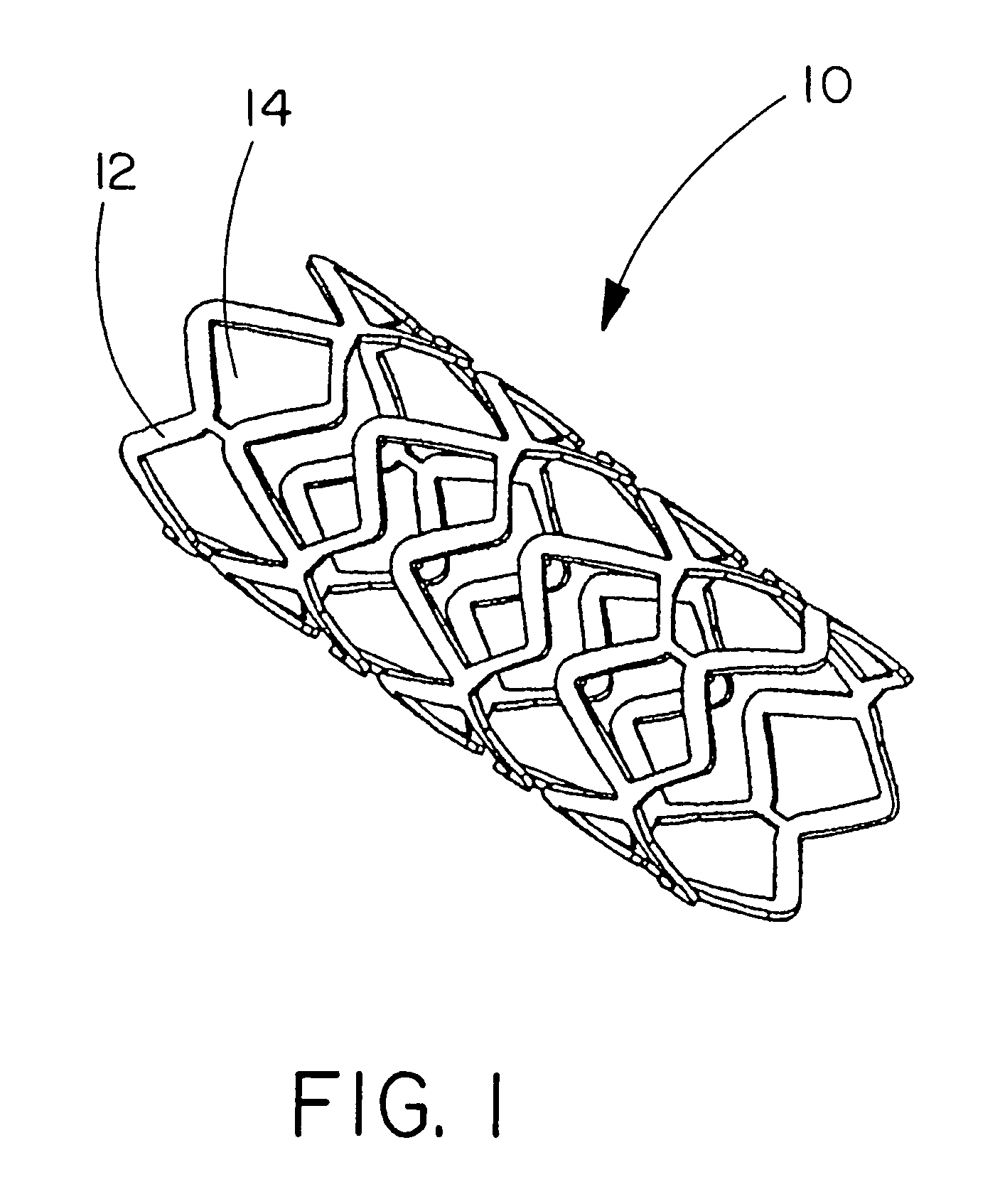

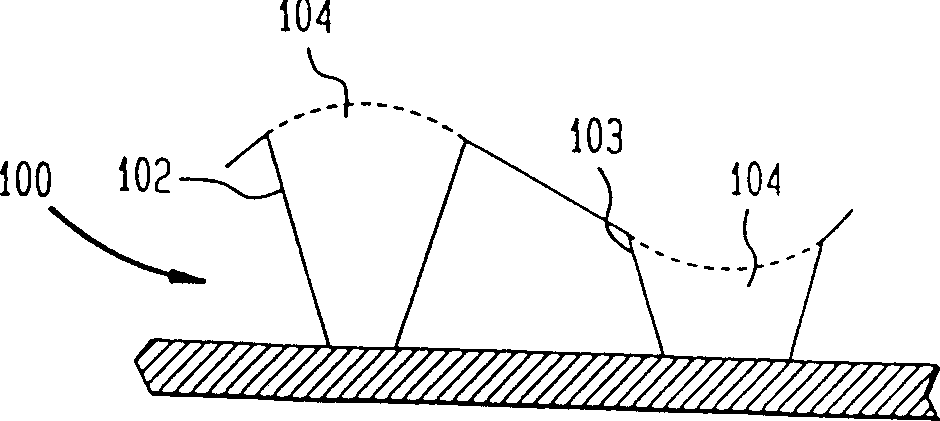

Bioabsorbable self-expanding endolumenal devices

InactiveUS9005269B2Increase elasticityImprove complianceStentsDilatorsGlass transitionBioabsorbable polymer

Bioabsorbable self-expanding medical devices formed of an integral framework with a multiplicity of fenestrations are provided. The framework is continuous, non-filamentous, non-braided, and non-interlaced. The devices includes a non-blended hydrolysable co-polymeric material comprising an amorphous component with a glass transition temperature that is below ambient body temperature and a crystallizable component that possesses a crystalline melting point in excess of ambient body temperature. The devices radially expand from a compressed first diameter to an uncompressed second diameter equal to or greater than 1.5 times the first diameter within two minutes in an aqueous medium at 37° C. following release of a compressive force placed on the devices. Additionally, the medical device does not change axial length significantly as the radial dimensions of the devices are changed. Further, the medical devices may be constructed of different bioabsorbable polymers, polymer ratios, and / or different geometries and portions may bioabsorb at different rates.

Owner:WL GORE & ASSOC INC

Method for producing vias having variable sidewall profile

A via opening having a varying sidewall taper can be made by varying the proportion of polymers deposited on the sidewalls during the etch. For example, the proportion of a fluorine-containing etch gas and an inert carrier gas can be changed to etch smooth variably tapered vias in silicon oxide to ensure complete filling of the vias by a subsequently deposited layer of material.

Owner:SIEMENS AG

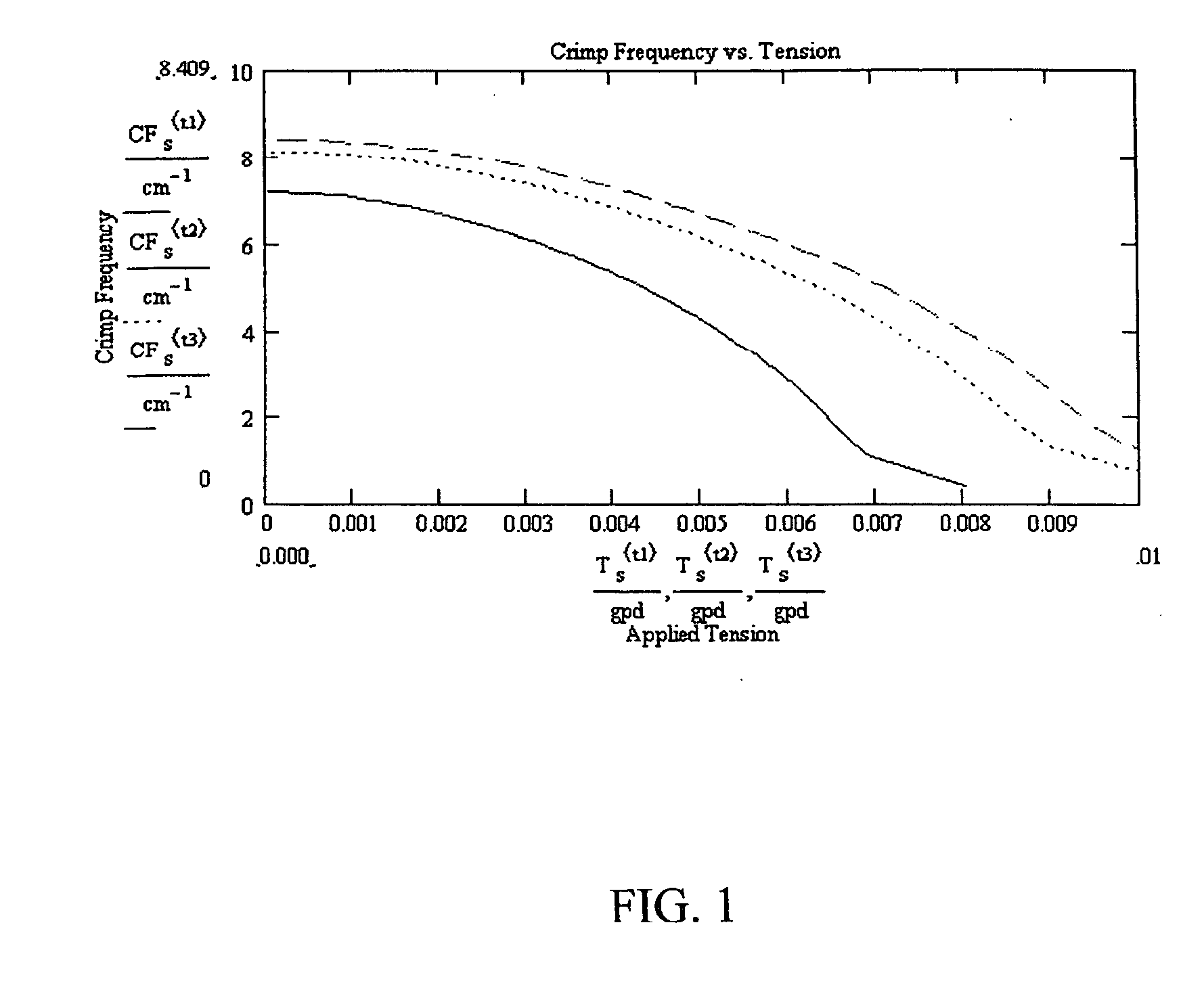

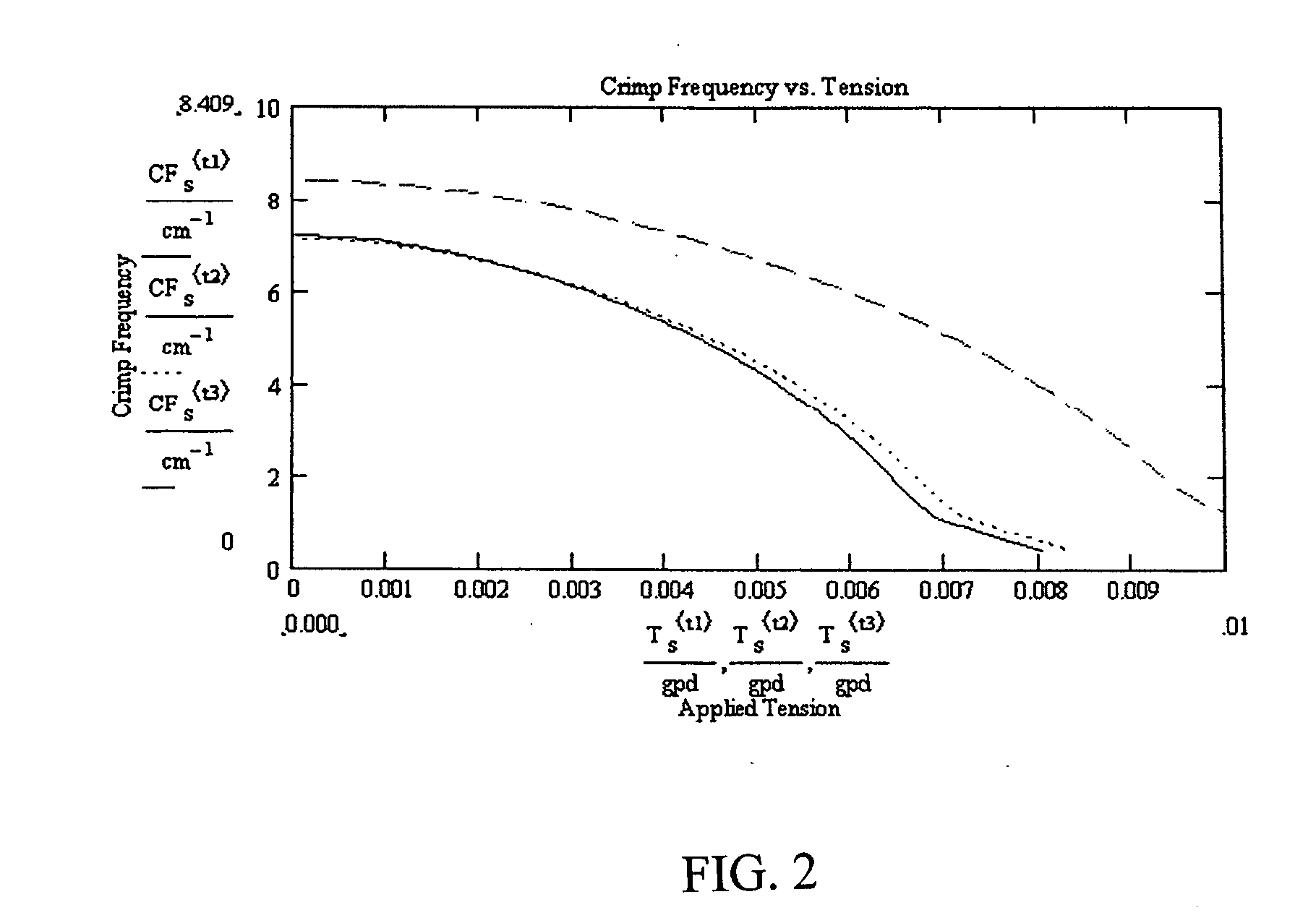

Fabrics of mixed-polyester-ratio bi-component fibers

Yarns of mixed ratios of bi-component fibers are disclosed, in which some filaments of a yarn produced during the spinning process are of different polymer ratios than other filaments in the same yarn. The yarns are preferably spun with the desired mixture of polymer ratios and the difference in polymer ratios are preferably at least about 10% absolute. The net overall ratio of the yarn is between about a 55 / 45 and a 75 / 25 mixture of PET / PTT by weight. Knit and woven fabrics can be prepared that include these mixed ratio yarns.

Owner:INVISTA NORTH AMERICA R L

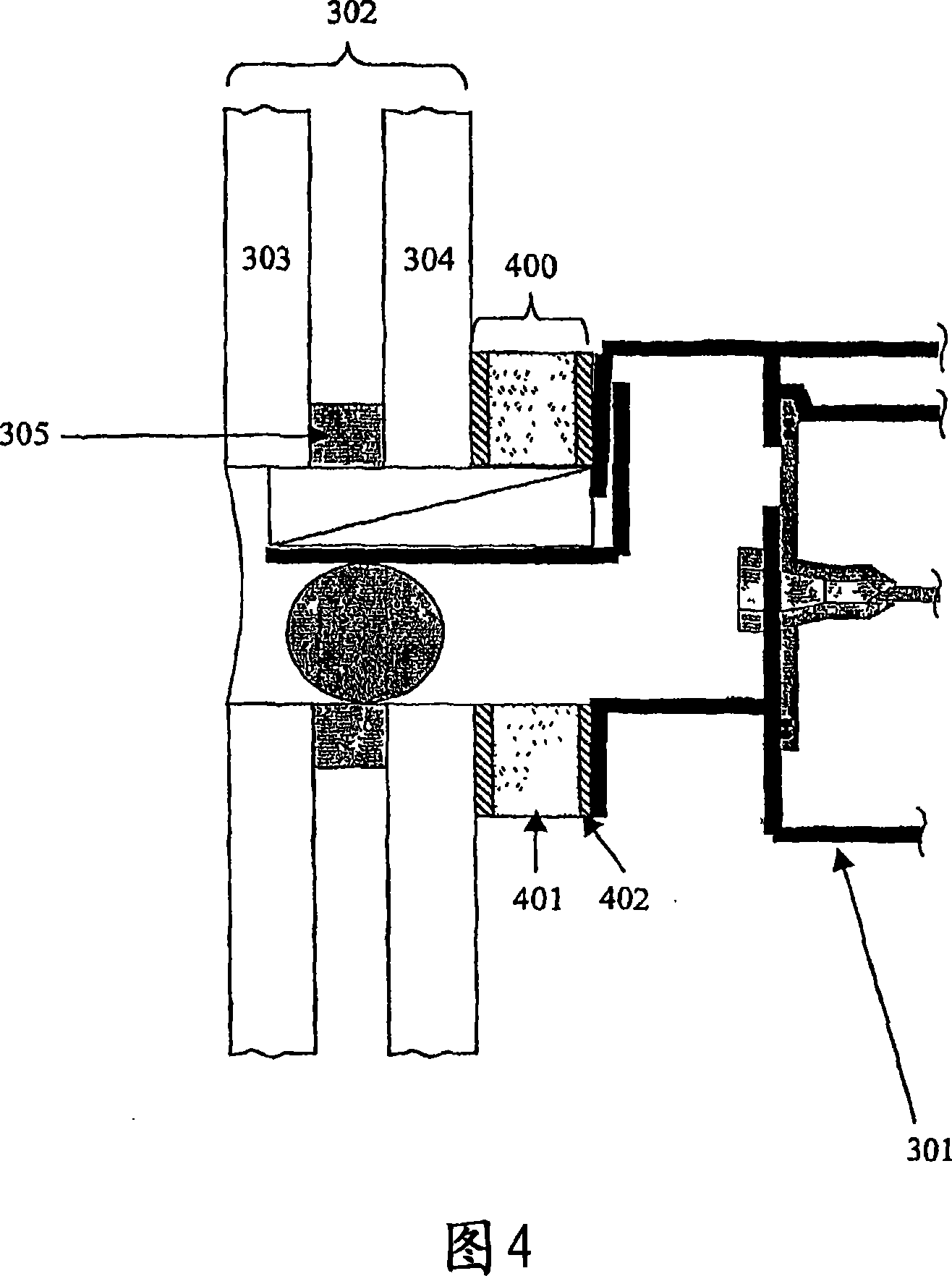

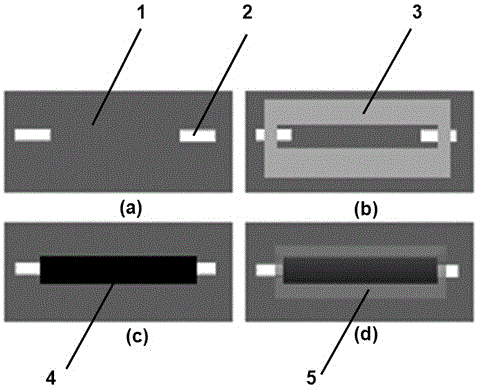

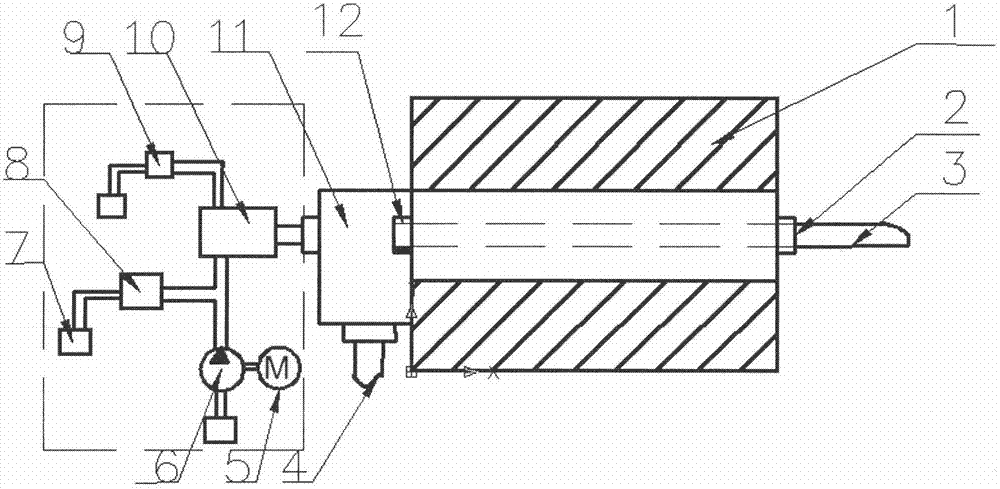

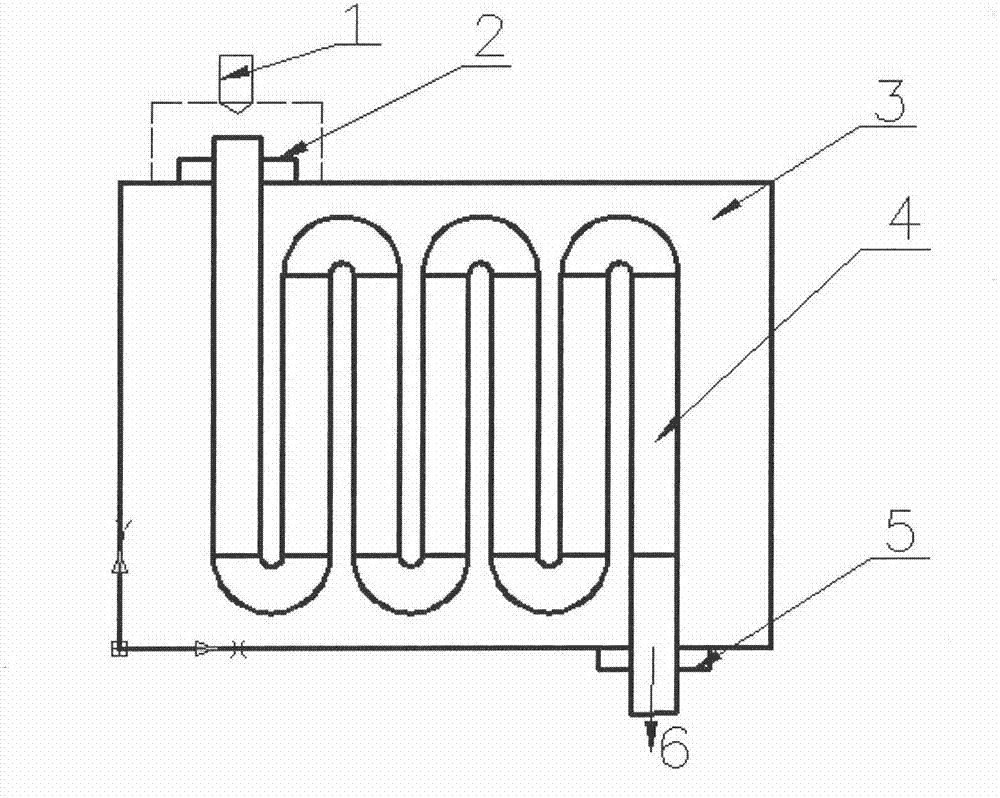

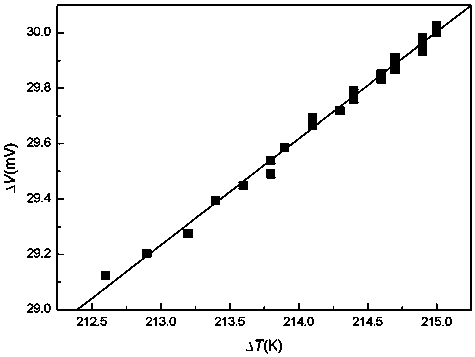

Plastic melt PVT (pressure, volume and temperature) characteristic experimental device

InactiveCN104267177AImprove thermal efficiencyEvenly heatedMaterial testing goodsMolecular materialsEngineering

The invention discloses a plastic melt PVT (pressure, volume and temperature) characteristic experimental device. The plastic melt PVT characteristic experimental device comprises a pressure device, a temperature device, a parameter acquisition device and an experimental platform. As a high-molecular polymer, plastic is complicated in characteristics which can be influenced by different ratios of polymers in plastic; meanwhile, in the injection molding production, the quality of a plastic piece is severely influenced by pressure and temperature. The plastic melt PVT characteristic experimental device is simple in structure and capable of conveniently and rapidly acquiring various parameters needed in the experiment and simulating the flow situation of a melt in a runner. The plastic melt PVT characteristic experimental device is mainly used for researching the PVT characteristics of different plastic or high-molecular materials, so that theoretical basis can be provided for selection of plastic in the injection molding production and selection of the temperature and pressure, optimal production parameters can be acquired, the production efficiency can be improved, the quality of the plastic piece can be improved, the cost is reduced, and the significance is great.

Owner:CHANGZHOU UNIV

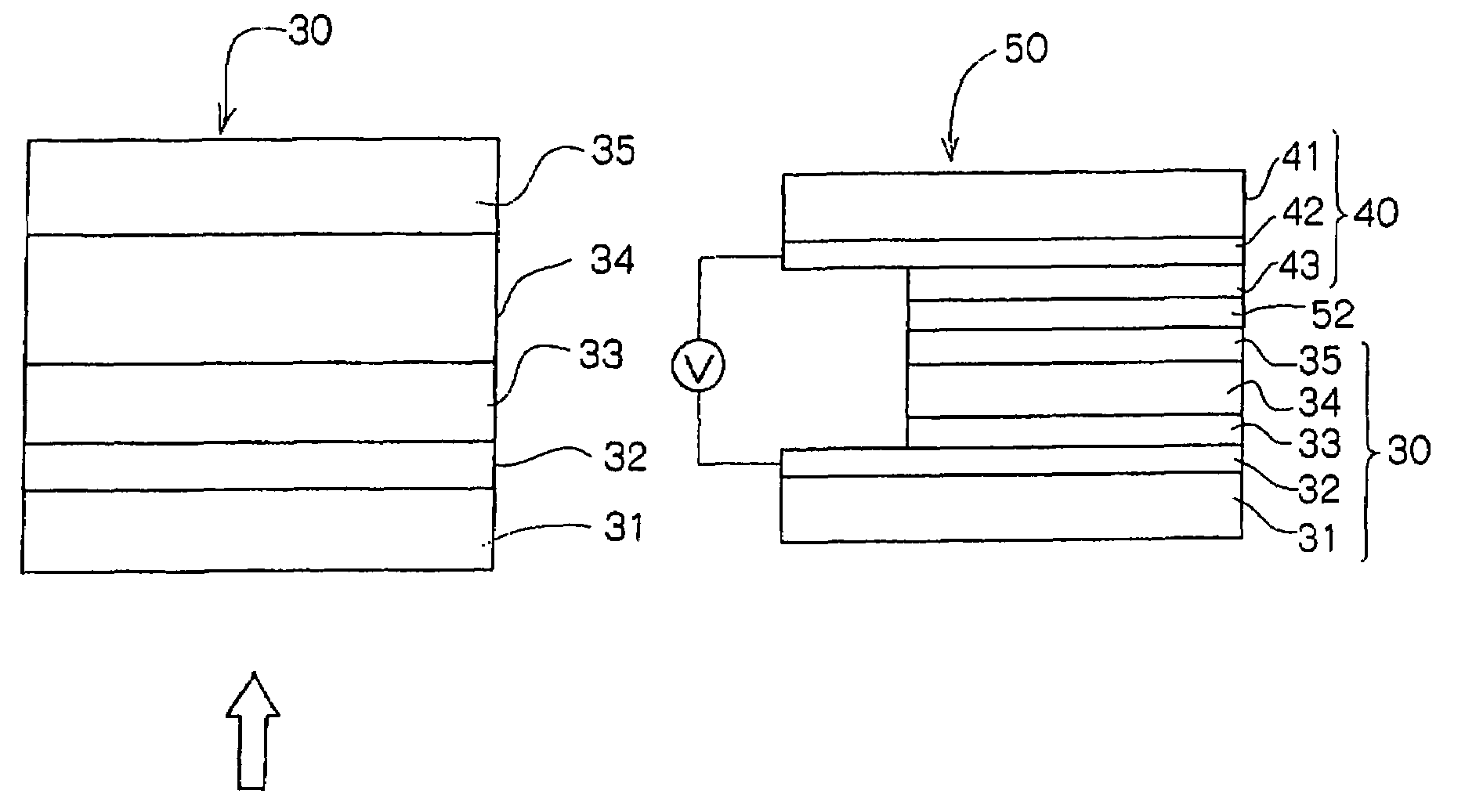

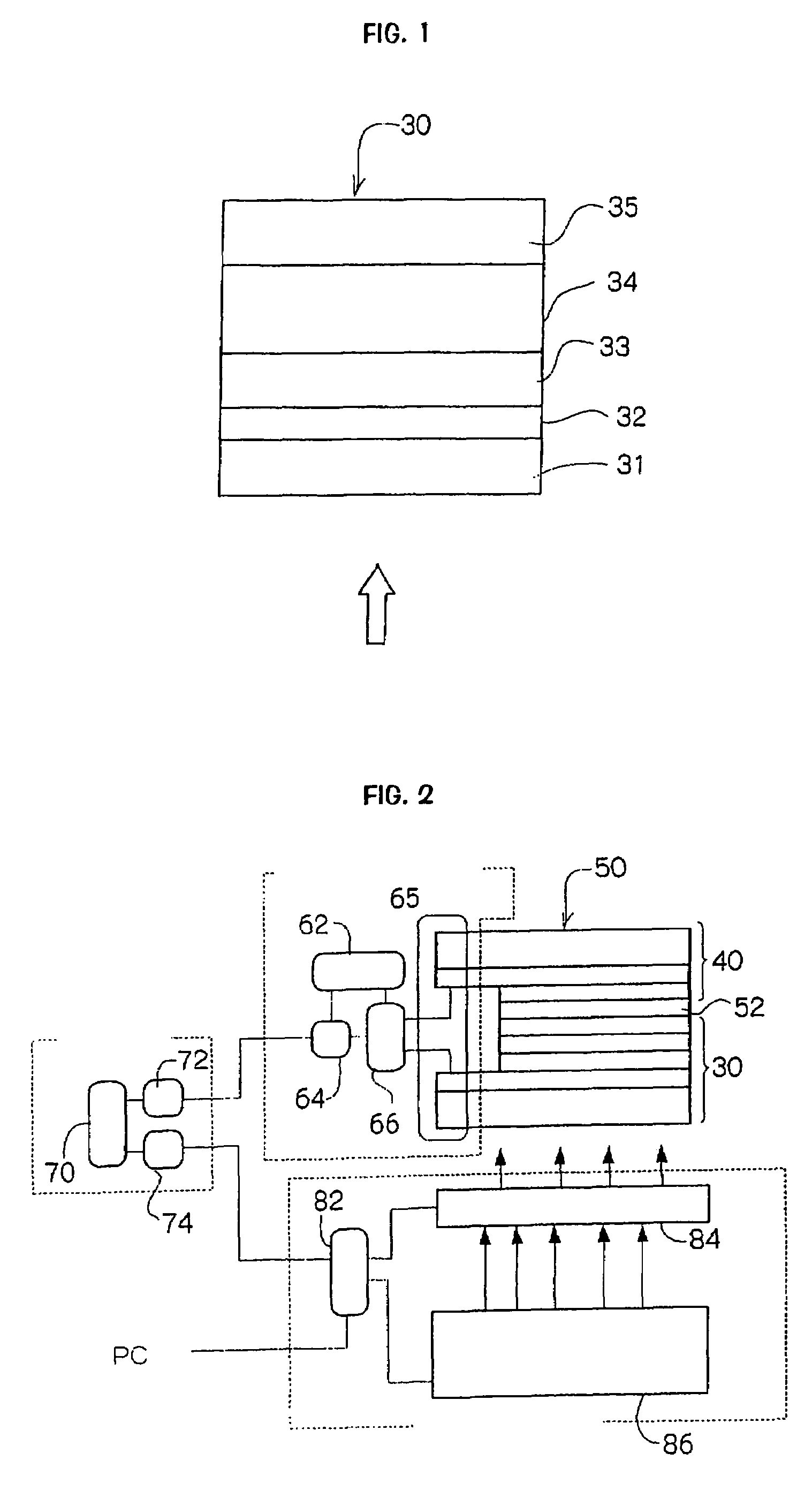

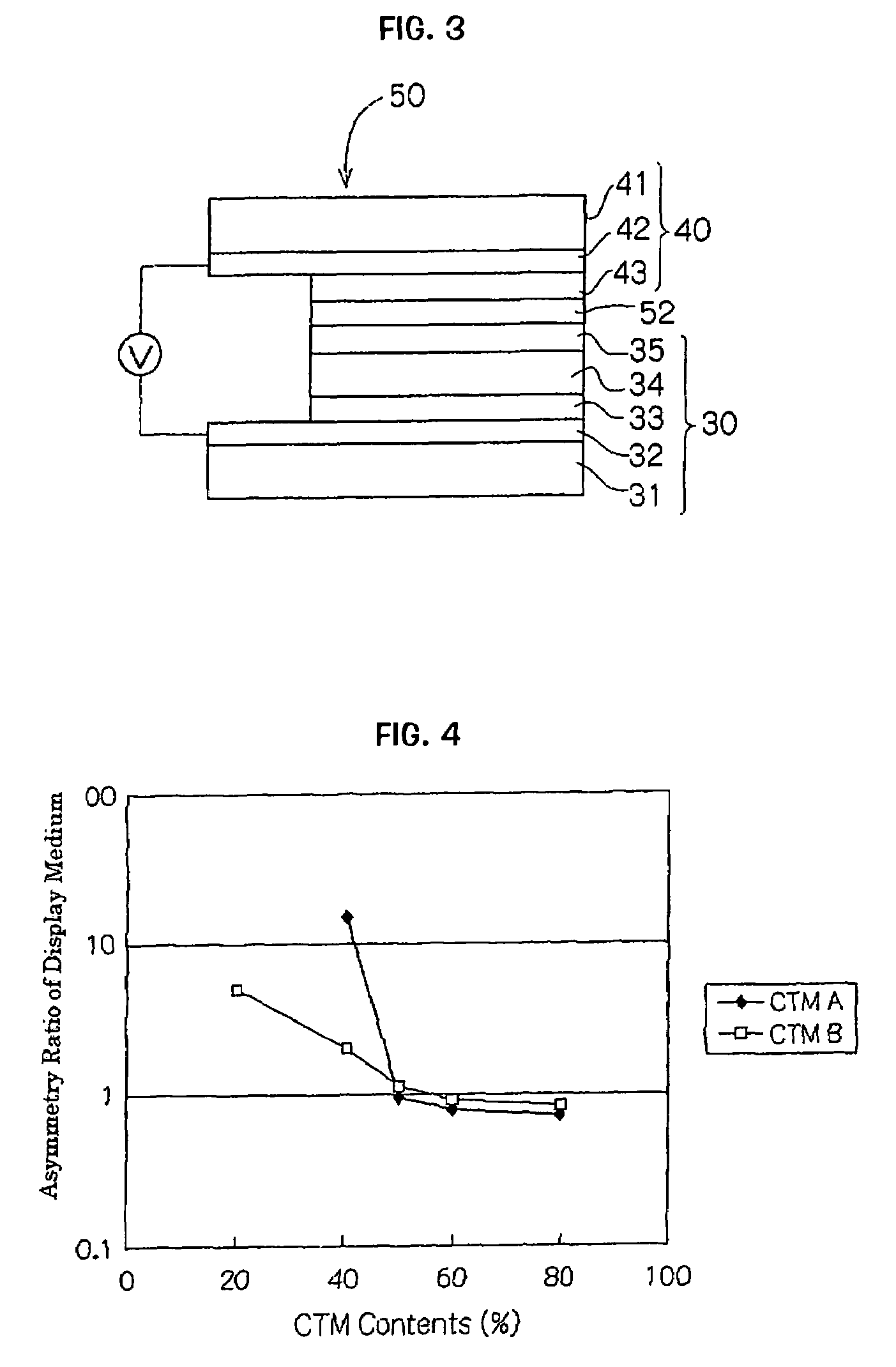

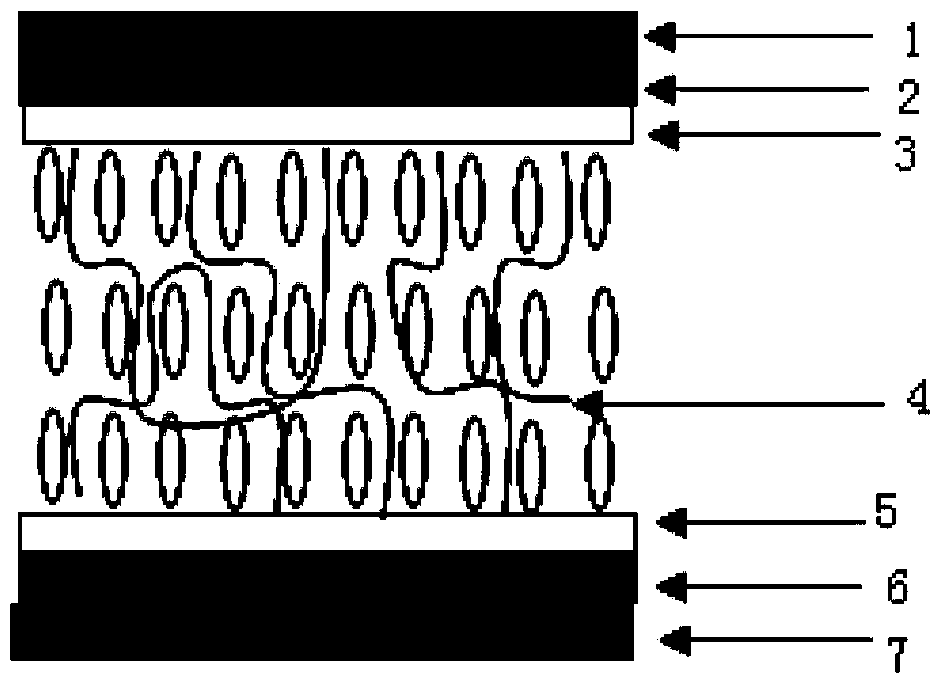

Optical switching element, and device, optically addressed type display medium and display each using the optical switching element

InactiveUS7206115B2Excellent characteristicsImprove performanceStatic indicating devicesElectrographic process apparatusTransport layerDisplay device

The invention provides an optical switching element and a device, an optically addressed type display medium and a display each including such an optical switching element. The optical switching element comprising an optical switching layer including lower and upper charge generating layers and a charge transporting layer sandwiched therebetween, wherein the optical switching element has at least one of the following characteristics. (1) In the charge transporting layer, a charge transporting material to binder polymer ratio calculated according to the formula: [charge transporting material / (charge transporting material+binder polymer)]×100 (% by weight) is 50% by weight or more; (2) a polymer compound is used as the charge transporting material; and (3) the charge generating layer on the light incident side (the lower charge generating layer) has a lower light absorptance than that of the other charge generating layer (the upper charge generating layer).

Owner:FUJIFILM BUSINESS INNOVATION CORP

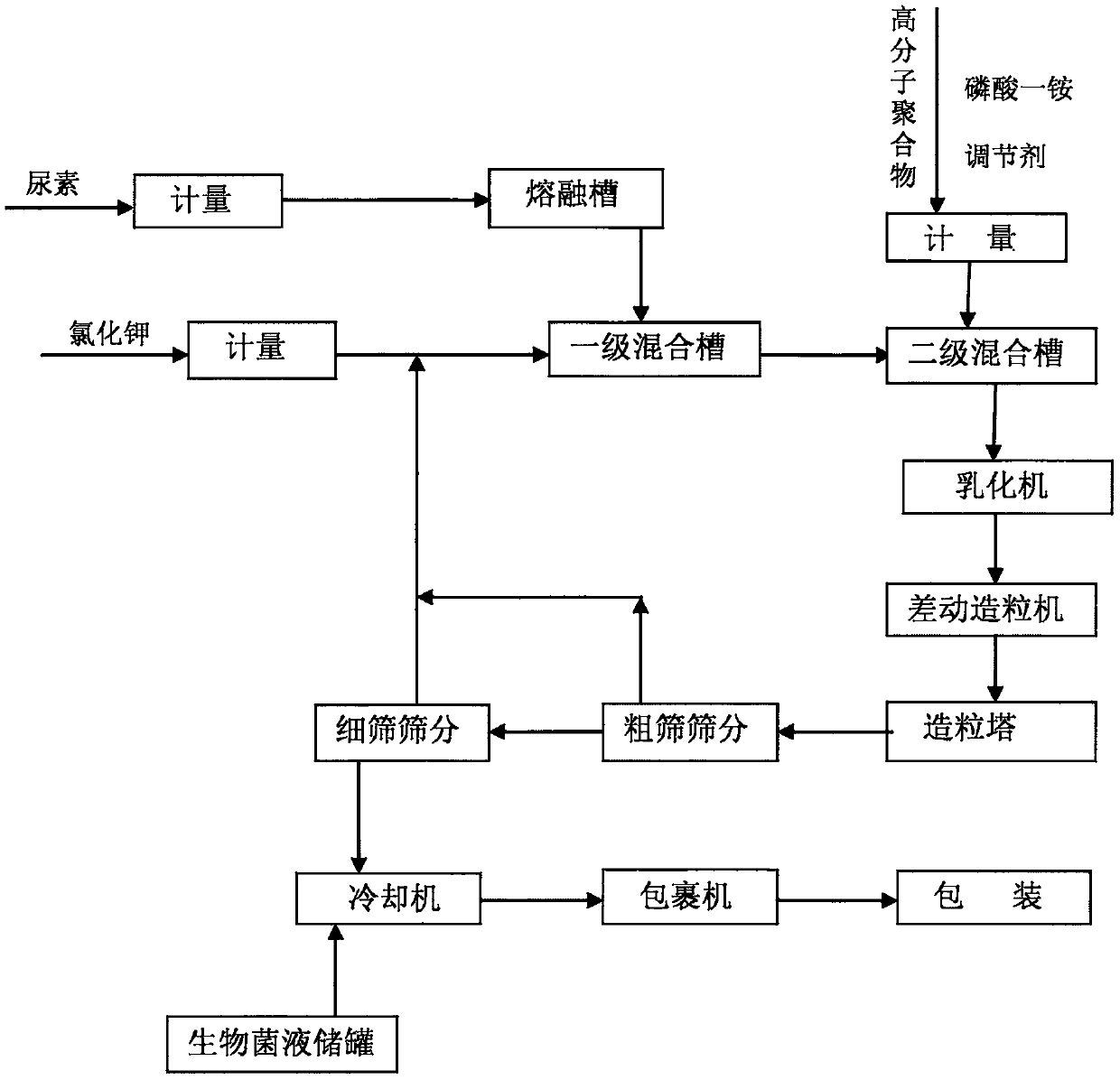

Synergistic high-tower urea-based fertilizer and preparation method thereof

InactiveCN111574275APromote rootingPromote tilleringAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersBiotechnologyNutrition

The invention discloses a synergistic high-tower urea-based fertilizer and a preparation method thereof. The synergistic high-tower urea-based fertilizer comprises the following components in percentage by mass: 40%-50% of urea, 25%-32% of potassium chloride, 15%-25% of monoammonium phosphate, 0.4%-0.8% of a regulator, 3%-6% of a high-molecular polymer and 1%-3% of biological bacteria. According to the preparation method, a high-tower granulation technology is adopted, and the plant growth regulator, the high-molecular polymer and the biological bacteria are added so that the product is more comprehensive in nutrition, and has the effects of improving the product quality, promoting fertilizer synergy, improving the physical and chemical properties of soil, improving the crop quality and yield and enhancing the disease resistance of crops.

Owner:孟宪英

Process for producing modified substrate

InactiveUS20110117287A1Improve adsorption capacityImprove performanceMembranesSemi-permeable membranesAntioxidantFluence

The present invention provides a modified substrate including a hydrophilic polymer wherein the soluble hydrophilic polymer ratio is 15 weight percent or less and the number of adhered human blood platelets is 10 / 4.3×103 μm2 or less. In addition, the present invention provides a method for producing a modified substrate including a step of irradiating the substrate with radiation while the substrate is brought into contact with an aqueous solution containing a hydrophilic polymer and an antioxidant. The present invention provides a modified substrate having high hematologic compatibility wherein the hydrophilic polymer is immobilized on the surface of the substrate, and a method for producing the same.

Owner:UENO YOSHIYUKI +2

polymer network liquid crystal display

The invention provides a polymer network liquid crystal display. The polymer network liquid crystal display comprises a first matrix layer, a first conducting layer, a first orientation layer, a liquid crystal dielectric layer, a second orientation layer, a second conducting layer and a second matrix layer, wherein the liquid crystal dielectric comprises a first component accounting for 1-15% of the total weight of the liquid crystal dielectric and a second component accounting for 85-99% of the total weight of the liquid crystal dielectric; a group composed of one or more polymerizable compounds having structures in general formula I and / or general formula II is used as the first component; and a nematic phase liquid crystal composition is used as the second component. The polymer network liquid crystal display is in a transparent state in case of zero electric field, and the light transmittance is higher than 85%; after voltage application, the polymer network liquid crystal display is in a scattering state; no visual angle problem exists in the transparent state; and in case of a 120-degree visual angle, the light transmittance is still higher than 80%. Therefore, the polymer network liquid crystal display provided by the invention has better off-state light transmittance and a bigger visual angle; and meanwhile, due to the small proportion of polymers, the polymer network liquid crystal display has lower drive voltage and can realize the reverse mode PDLC (polymer dispersed liquid crystal) effect of low-voltage driving. The general formula I and the general formula II are shown in the specification.

Owner:JIANGSU HECHENG DISPLAY TECHCO

Porous non-asbestos separator and method of making same

The present invention relates to an inert, non-asbestos separator and method of making same, the separator comprising an inorganic / polymer fibrid and agglomeration composite material containing from about 5 weight percent to about 70 weight percent of organic halocarbon polymer fibers together with from about 30 wt percent to about 95 weight percent of a finely divided non-organic particulate, which non-organic particulate is firmly bound in said composite fibrids and agglomerates; a natural gum thickening agent in an amount to provide a viscosity of about 6270 to about 590 cP at 0.22 sec−1; and an inert inorganic particulate powder whereby the inert inorganic particulate remains unbound from the inorganic / polymer fibrid and agglomeration composite, the inorganic particulate powder having a mean particle size of not greater than 1.0 μm and being present in an amount to provide a ratio of polymer fiber composite to unbound inorganic particulate in a range from about 1 to 25.

Owner:IND DE NORA SPA

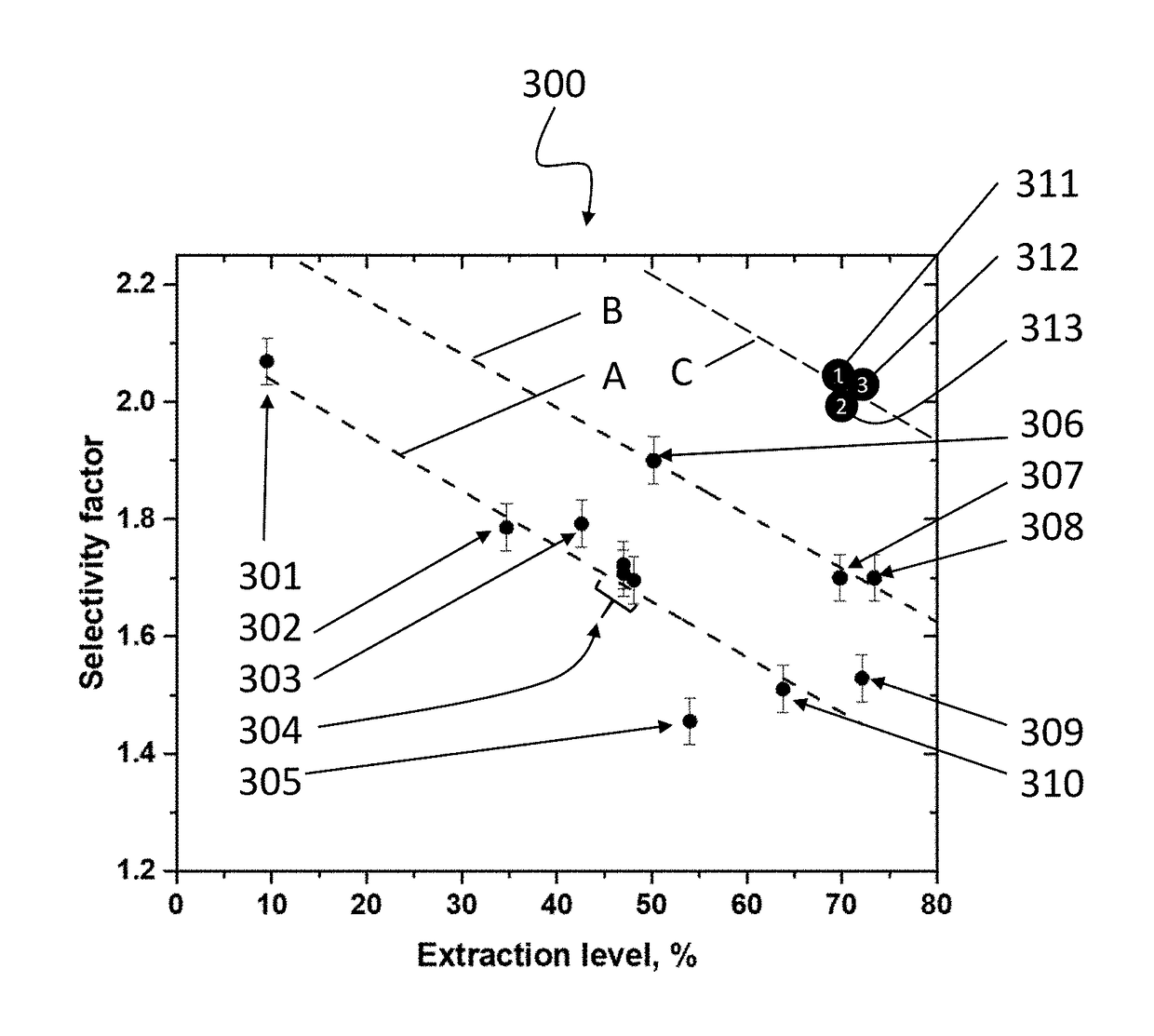

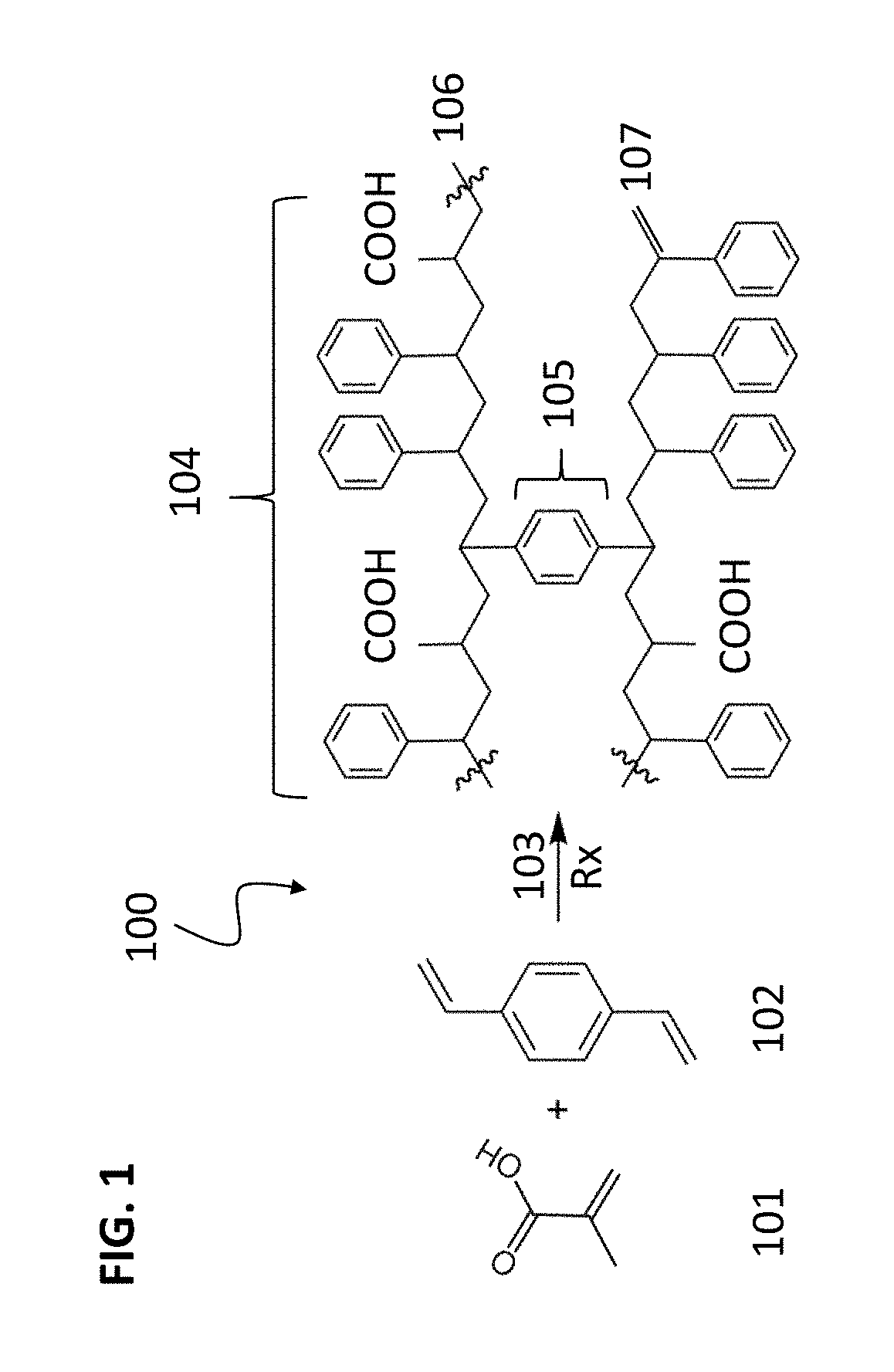

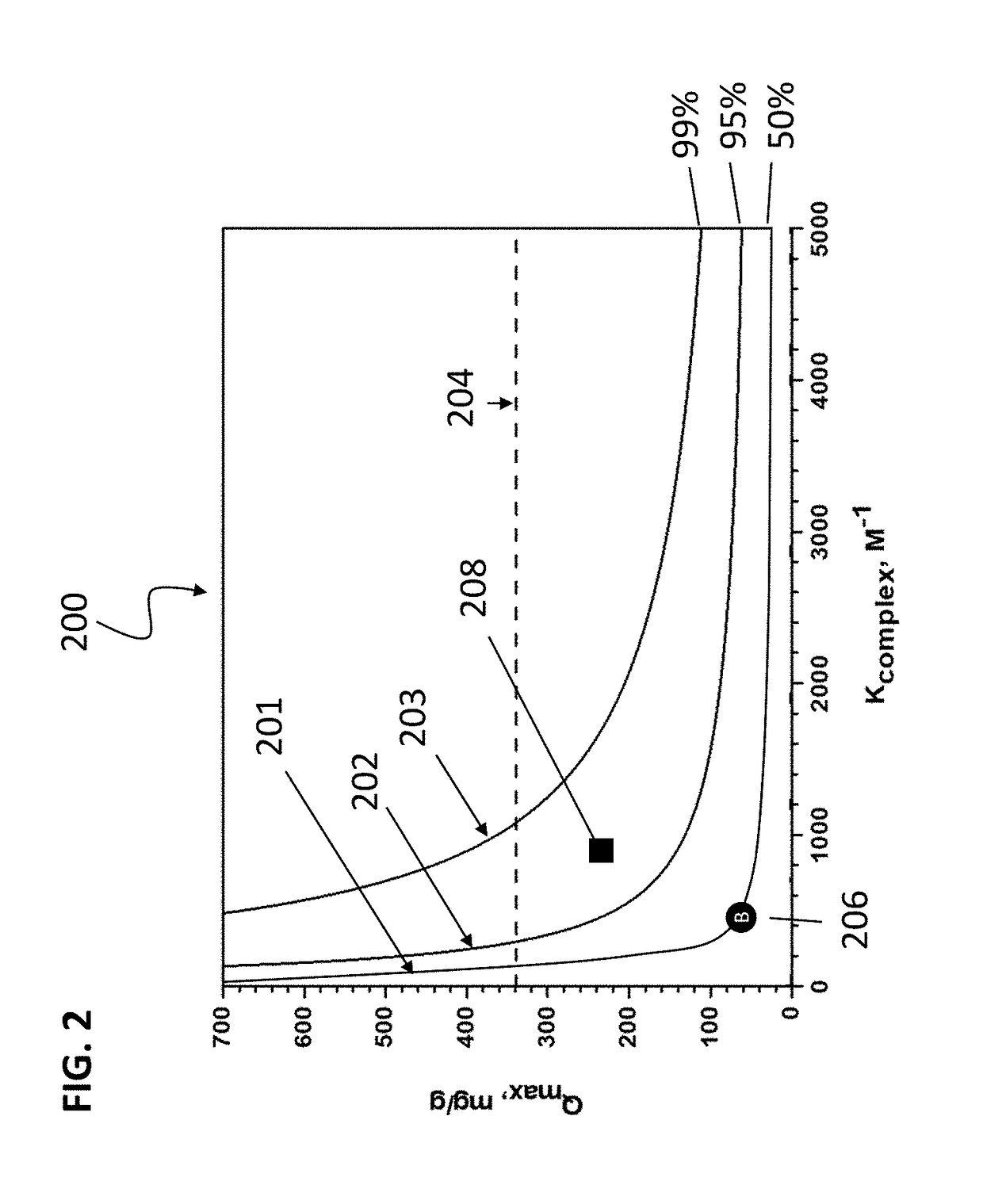

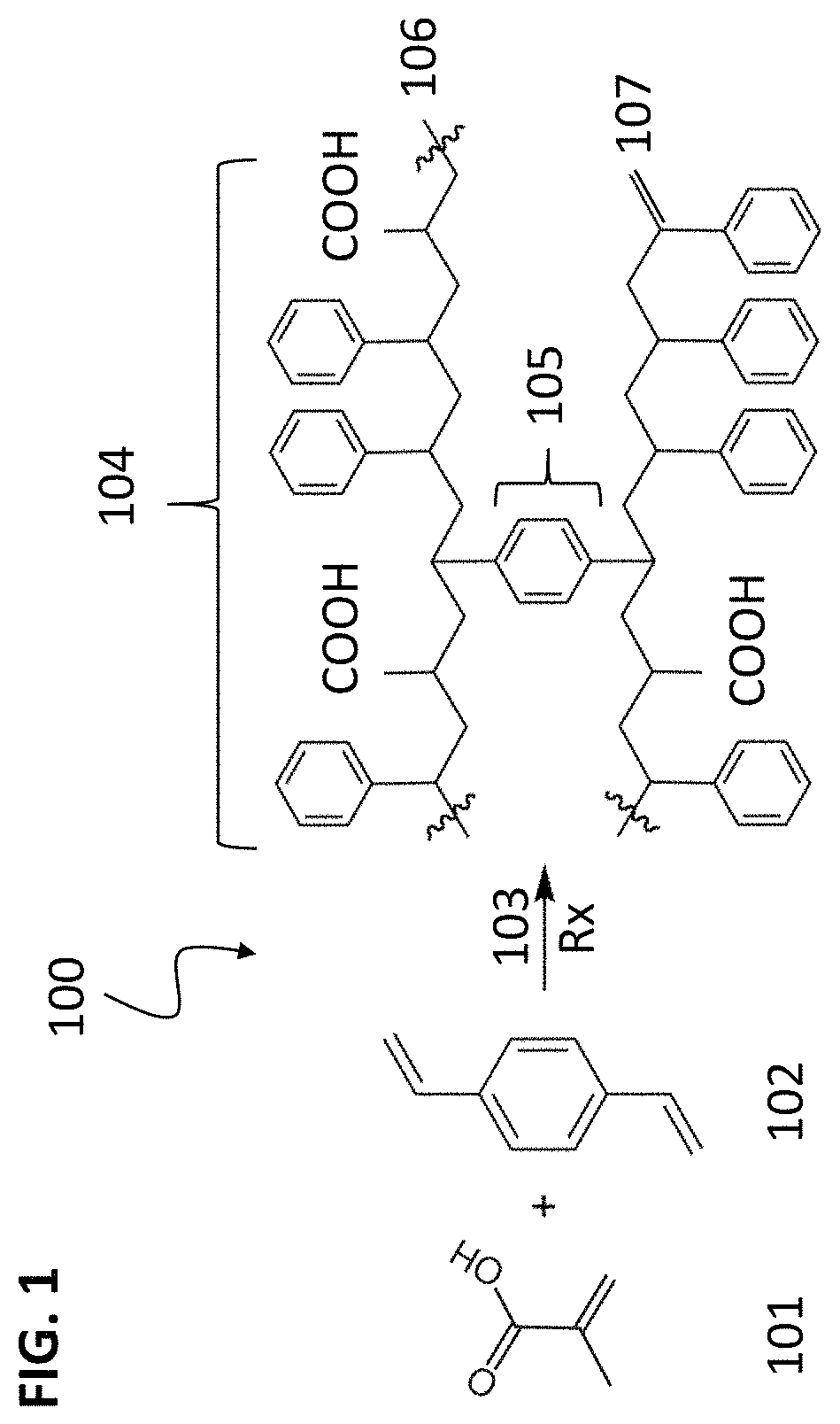

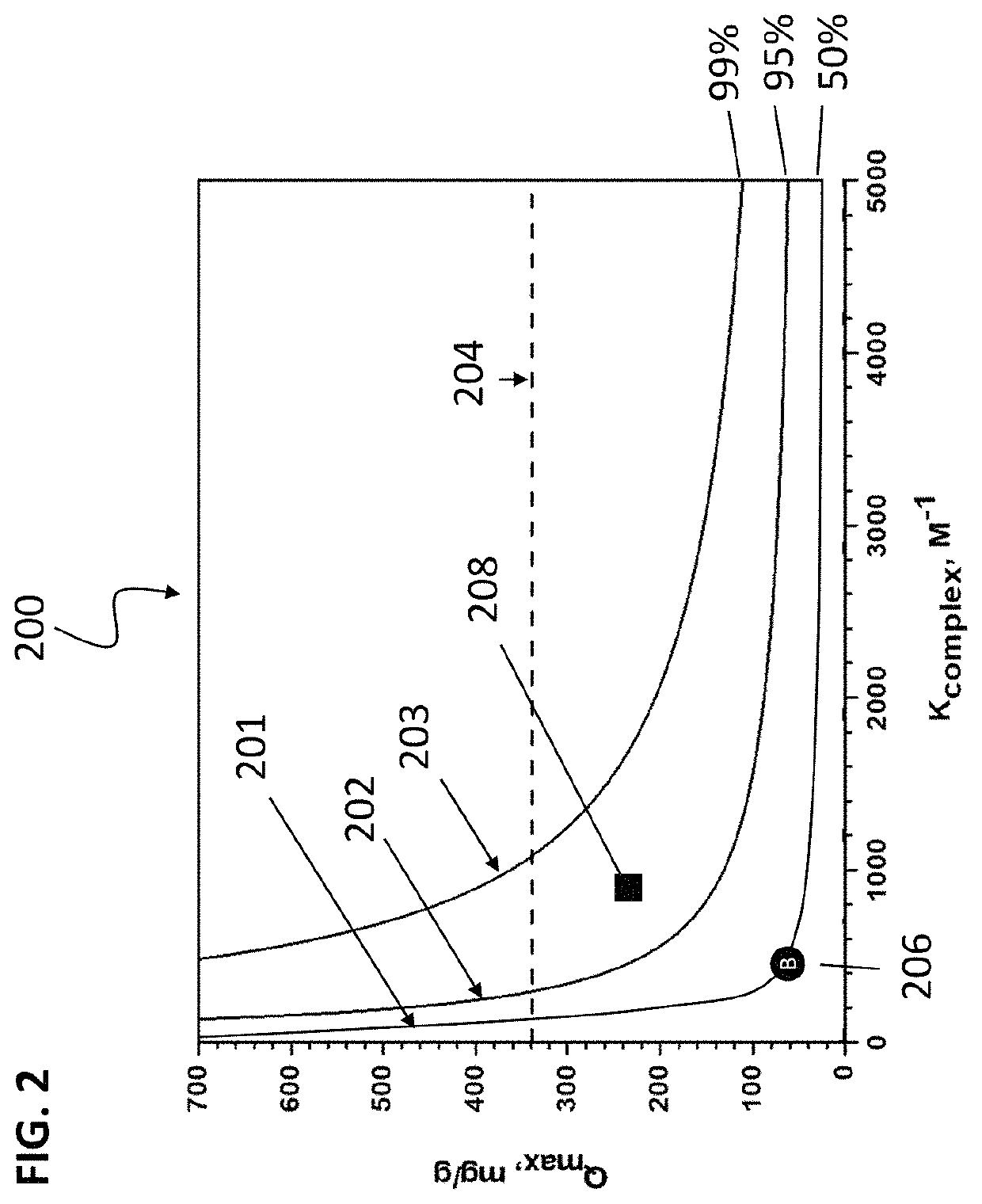

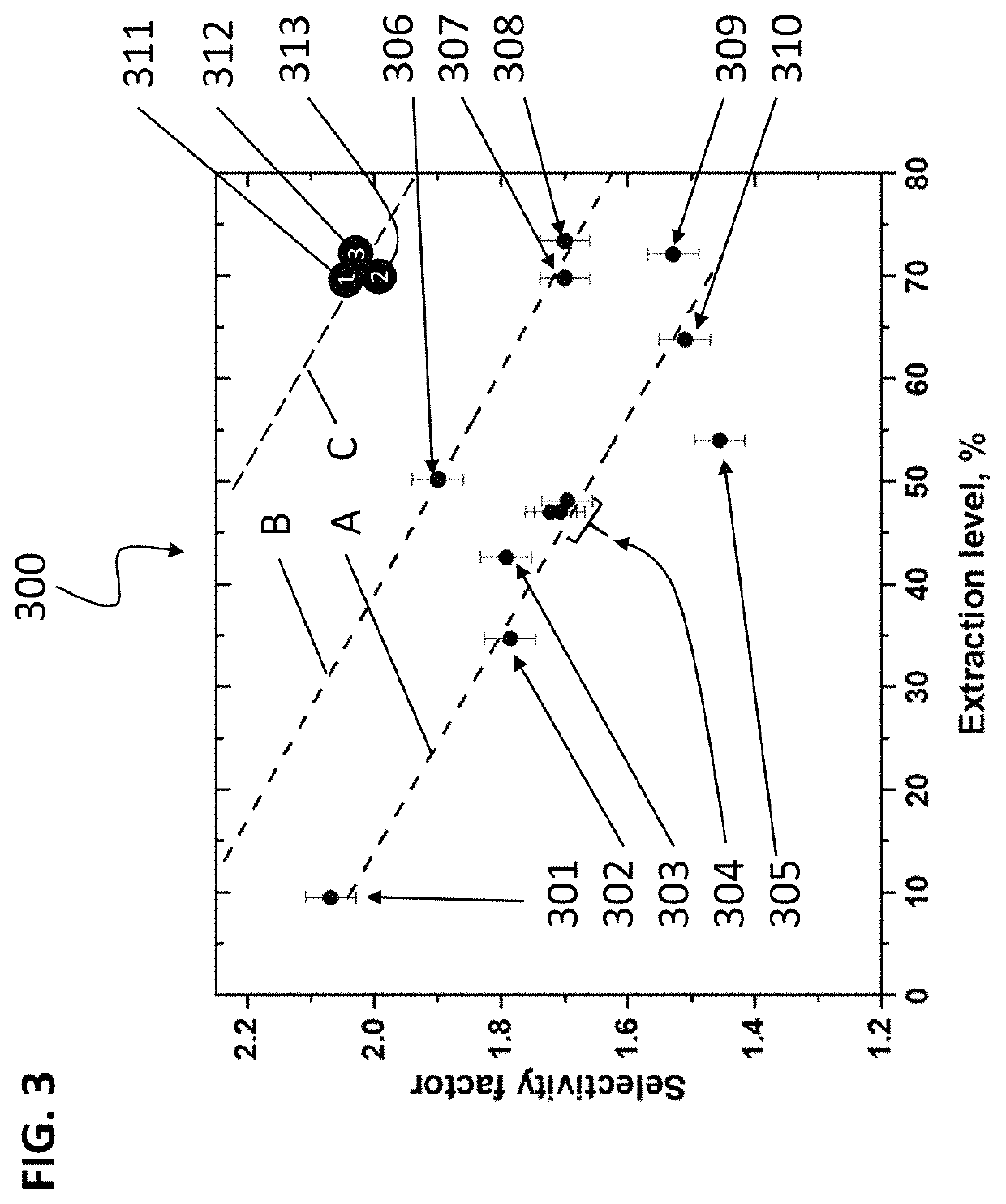

Programmable polymer caffeine extraction

ActiveUS20180325138A1Increase capacityHigh selectivityOther chemical processesSolid sorbent liquid separationCross linkerAbsorbance

The invention relates to a caffeine-templated MIP copolymer matrix and devices employing these polymers that exhibit high absorbance or binding capacity for caffeine while retaining rapid caffeine uptake kinetics, and which function in both cold and hot aqueous environments to selectively remove caffeine from a beverage with a high selectivity factor in order to better preserve the sensory aspects of the decaffeinated beverage, and which can easily be used by a typical consumer to treat their beverage within a short time frame of less than about one minute. More specifically, the invention relates to copolymeric MIP matrices produced according to methods wherein the template to polymer ratio is dramatically increased in order to raise the affinity of the resulting MIP materials, and hyper-crosslinked MIP matrices produced using higher amounts of crosslinking agents to produce high affinity copolymer matrices that better maintain a high degree of selectivity towards caffeine while minimizing the uptake of congeners to better maintain the sensory characteristics of the decaffeinated beverages. The invention further relates to manual and mechanical devices employing the inventive MIP matrices in a variety of physical forms and configurations that enable a user to decaffeinate a beverage manually or automatically within one minute or less, or select a level of decaffeination by controlling the exposure time to said devices.

Owner:STUCKEY MARION MELVIN +1

Pressure sensitive adhesives and methods for their preparation

InactiveCN101223257BGood lookingThin material handlingPressure sensitive film/foil adhesivesSolventPolymer ratio

A pressure sensitive adhesive composition includes (A) a bodied MQ resin containing (i) a resinous core and (ii) a nonresinous polyorganosiloxane group, where the nonresinous polyorganosiloxane group is terminated with a silicon-bonded hydroxyl group; (B) a treated MQ resin, where (B) / (A) ratio has a value of 0.3 to 5.0, and (C) a polydiorganosiloxane terminated with a condensation reactable group; where resin / polymer ratio has a value of 2.0 to 3.0; optionally (D) a crosslinker; optionally (E) a catalyst; and optionally (F) a solvent. A pressure sensitive adhesive product prepared by curing the pressure sensitive adhesive composition is useful in structural attachment applications such as structural glazing applications.

Owner:DOW CORNING CORP

A kind of preparation method of nano-iron powder material with continuous controllable activity

ActiveCN110216280BActivity persistence is controllableSolve reunionMaterial nanotechnologyTransportation and packagingCelluloseButadiene Dioxide

The invention discloses a preparation method of a nano-iron powder material with controllable activity continuity, which uses acrylonitrile-butadiene-styrene terpolymer and ethyl cellulose to achieve embedding of nano-iron powder through phase separation , and then impregnated with ethyl cellulose solvent to realize the pore transformation of the embedded nano-iron powder particles, endowing the embedded nano-iron powder particles with the continuity of activity, and the activity can be achieved by the ratio of the two polymers Sustainability is controllable. The method of the invention can not only solve the problem of agglomeration of the nano-iron powder particles, but also realize the controllability of the activity continuity of the nano-iron powder.

Owner:TSINGHUA UNIV

A method for preparing thermoelectric thick film

ActiveCN105024007BImprove performanceNot easily oxidizedThermoelectric device manufacture/treatmentOrganic solventRoom temperature

Owner:SUN YAT SEN UNIV

Aqueous dispersoid of fluorine-containing seed polymer particles and aqueous coating combination

The invention provides an aqueous dispersoid of fluorine-containing seed polymer particles serving as a film formation component for an aqueous coating combination. Although the ratio of acrylic acid ester polymers during seed polymerization is high, the acrylic acid ester polymers are highly compatible with the fluorine-containing polymer serving as seed particles, and can provide transparent films. The invention relates to an aqueous dispersoid of fluorine-containing seed polymer particles and an aqueous coating combination containing the aqueous dispersoid. A fluorine-containing polymer containing at least one fluoro-alkene unit is served as a seed particle and is obtained by polymerization of monomer mixtures containing acrylic acid ester monomers and ethylene monomer containing hydrolyzed monosilane, wherein the content of the acrylic acid ester monomer unit is, by mass, 40-400 parts relative to 100 parts of the fluorine-containing polymer particles, and the content of the ethylene monomer containing hydrolyzed monosilane is by mass, 0.1-2 parts relative to 100 parts of the acrylic acid ester monomer unit.

Owner:DAIKIN IND LTD

Programmable polymer caffeine extraction

ActiveUS11051529B2Increase capacityHigh selectivityOther chemical processesSolid sorbent liquid separationDecaffeinationBiochemical engineering

The invention relates to a caffeine-templated MIP copolymer matrix and devices employing these polymers that exhibit high absorbance or binding capacity for caffeine while retaining rapid caffeine uptake kinetics, and which function in both cold and hot aqueous environments to selectively remove caffeine from a beverage with a high selectivity factor in order to better preserve the sensory aspects of the decaffeinated beverage, and which can easily be used by a typical consumer to treat their beverage within a short time frame of less than about one minute. More specifically, the invention relates to copolymeric MIP matrices produced according to methods wherein the template to polymer ratio is dramatically increased in order to raise the affinity of the resulting MIP materials, and hyper-crosslinked MIP matrices produced using higher amounts of crosslinking agents to produce high affinity copolymer matrices that better maintain a high degree of selectivity towards caffeine while minimizing the uptake of congeners to better maintain the sensory characteristics of the decaffeinated beverages. The invention further relates to manual and mechanical devices employing the inventive MIP matrices in a variety of physical forms and configurations that enable a user to decaffeinate a beverage manually or automatically within one minute or less, or select a level of decaffeination by controlling the exposure time to said devices.

Owner:STUCKEY MARION MELVIN +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com