Synergistic high-tower urea-based fertilizer and preparation method thereof

A urine-based and fertilizer technology, applied in the directions of organic fertilizers, inorganic fertilizers, urea compound fertilizers, etc., can solve the problems of improving crop quality, unable to effectively improve the utilization rate of fertilizer nutrients, and unable to add them, so as to improve crop quality and yield, improve Soil physicochemical properties, effects on improving quality and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

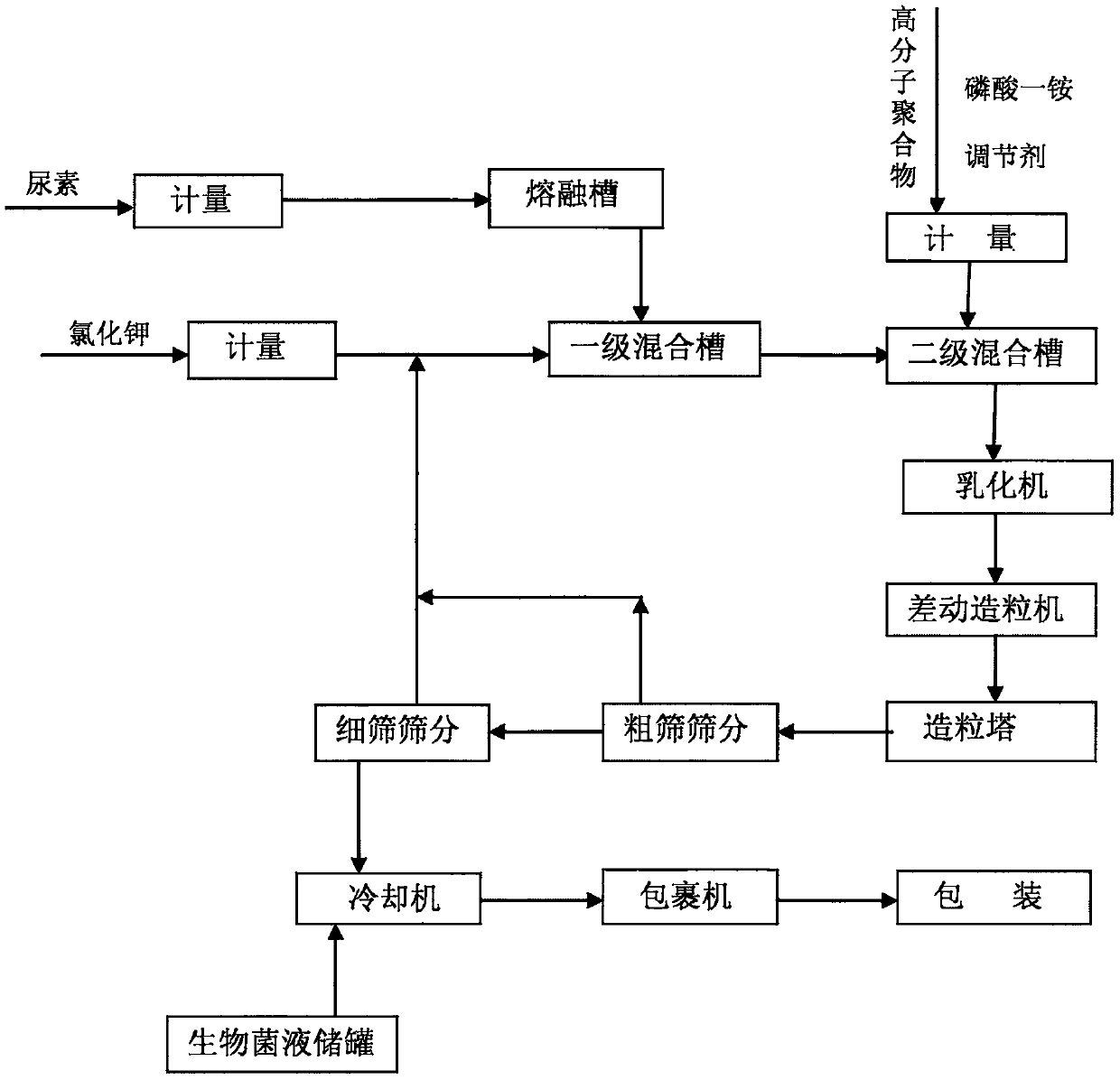

[0023] A method for preparing a synergistic high tower urea-based fertilizer comprises the following steps:

[0024] (1) Add the metered urea into the melting tank, the temperature of the melting tank is controlled at 120°C-125°C, and the melted urea solution overflows to the primary mixing tank;

[0025] (2) Add the measured potassium chloride into the primary mixing tank and mix it evenly with the urea solution. The temperature of the primary mixing tank is controlled at 110°C-115°C, and the mixed molten material overflows to the secondary mixing tank ;

[0026] (3) In the secondary mixing tank, add monoammonium phosphate, high molecular polymer and regulator by metering, and mix with the molten material for less than 5 minutes to obtain a mixed molten slurry. The temperature of the secondary mixing tank is controlled at 100°C-105 ℃;

[0027] (4) After the mixed molten slurry is emulsified by the emulsifier, the differential granulator is used to complete the spray granula...

Embodiment 1

[0032] Embodiment 1: Product proportioning 24-10-16, taking 1 ton of product raw material consumption quota as example:

[0033] raw material name Input amount (kg) N% P2O5% K2O% illustrate urea 478 22.08 potassium chloride 260 16.12 Monoammonium Phosphate 186 2.05 10.04 Naphthaleneacetic acid 6 polyacrylamide 50 Bacillus megaterium 12 Bacillus subtilis 8 total 1000 24.13 10.04 16.12

[0034] Specific production process:

[0035] (1) 478 kilograms of metered urea (containing N 46.2%) are added in the melting tank, the temperature of the melting tank is controlled at 120 ° C, and the urea solution after melting overflows to the primary mixing tank;

[0036] (2) 260 kilograms of metered potassium chloride (containing K2O 62%) are added in the primary mixing tank, uniformly mixed with the urea solution by stirring, the temperature of the primary mixing t...

Embodiment 2

[0042] Embodiment 2: The product ratio is 22-12-18, taking the raw material consumption quota of 1 ton product as an example:

[0043] raw material name Input amount (kg) N% P2O5% K2O% illustrate urea 426 19.68 potassium chloride 291 18.04 Monoammonium Phosphate 223 2.45 12.04 paclobutrazol 5 Polyacrylate 40 Bacillus megaterium 10 Bacillus subtilis 5 total 1000 22.13 12.04 18.04

[0044] Specific production process:

[0045] (1) 426 kilograms of metered urea (containing N 46.2%) are added in the melting tank, the temperature of the melting tank is controlled at 125° C., and the urea solution after melting overflows to the primary mixing tank;

[0046] (2) 291 kilograms of potassium chloride (containing K2O 62%) through metering are added in the primary mixing tank, uniformly mixed with the urea solution by stirring, the primary mixing tank temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com