Method for producing vias having variable sidewall profile

A plasma etching, semiconductor technology, used in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as reducing productivity and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

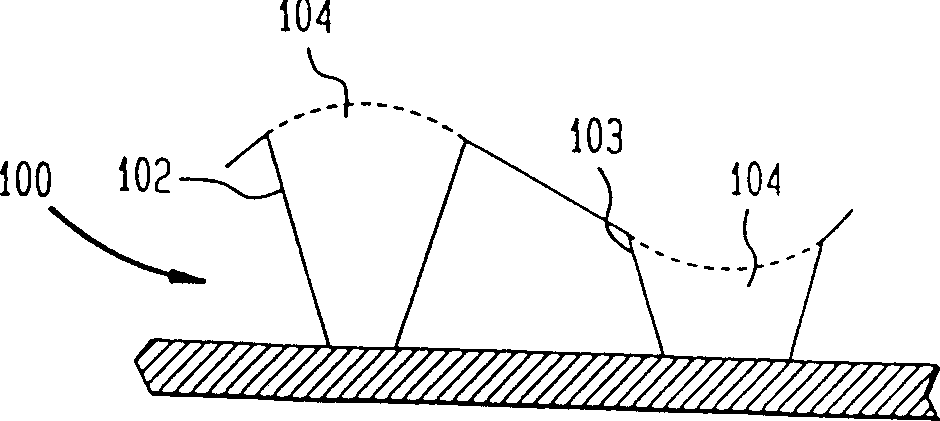

[0045] Using a commercially available plasma etch chamber with a wall temperature of 35°C and a cathode support temperature of 20°C, vias were created in a silicon dioxide layer deposited on a titanium nitride (TiN) layer ,Such as image 3 shown, under the following conditions:

[0046] Pressure 300 millitorr (mTorr)

[0047] Nitrogen substrate pressure 8 Torr

[0048] Power 900 watts

[0049] Magnetic induction 80 gauss

[0050] The first step in creating a sloped opening in the silica layer is to pass 100 standard cubic centimeters (sscm) of CHF through the chamber for 90 seconds 3 and 20 sccm of argon. The result was a sidewall slope of about 69° and an opening diameter of about 980 microns.

[0051] Second stage gas flow changed to 30sccm CHF 3 and 100 seem argon and continue for 90 seconds. As a result, the inclination angle of the sidewall is about 80°, and the diameter of the opening at the bottom of the via hole is about 610 microns. image 3 is a photomicrogr...

example 2

[0052] Using the process conditions of Example 1, the duration of the first stage is 120 seconds, the diameter of the formed opening is about 1000 microns, and the inclination angle of the side wall is about 67°. The chamber pressure of the second etching phase was changed from 100 mTorr to 300 mTorr, and the duration was 60 seconds. The second stage forms a via bottom opening with a diameter of approximately 600 microns and a sidewall inclination angle of approximately 81°. Figure 4 is the micrograph of the result. Additionally, a smooth transition is formed between the initial etched corner and the second etched corner. No obvious incision exists.

[0053] In this way, only by changing two parameters, the etching time and the proportion of etching gas, the shape of the sidewall of the opening can be changed at will to form openings of different sizes with different inclination angles. Smoother sidewall slopes can be obtained by gradually changing the etch gas ratio. In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com