Plastic melt PVT (pressure, volume and temperature) characteristic experimental device

An experimental device and melt technology, which is applied in the field of plastic melt PVT characteristic experimental devices, can solve the problems affecting the quality and appearance of plastics, warping and shrinkage of plastic products, and achieve the effects of low cost, uniform heating and high thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to be easier to understand the content, purpose and technical solutions of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings:

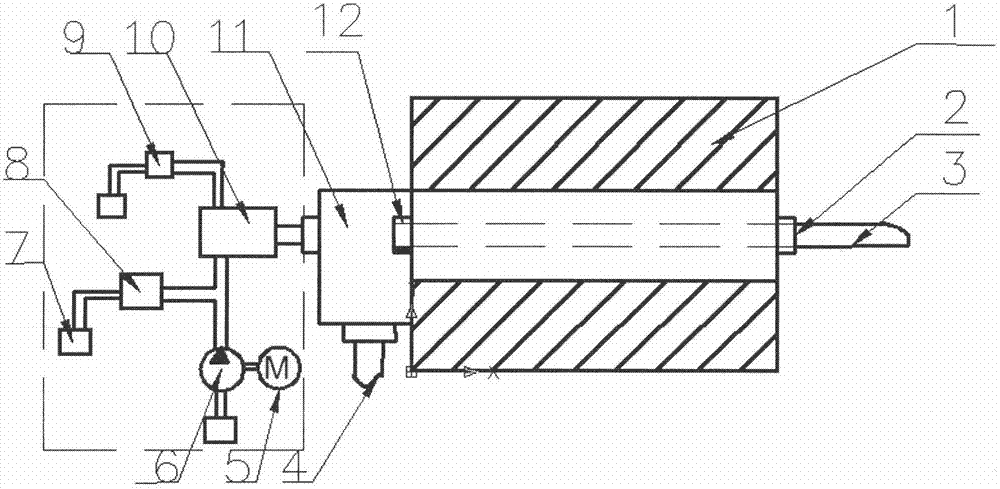

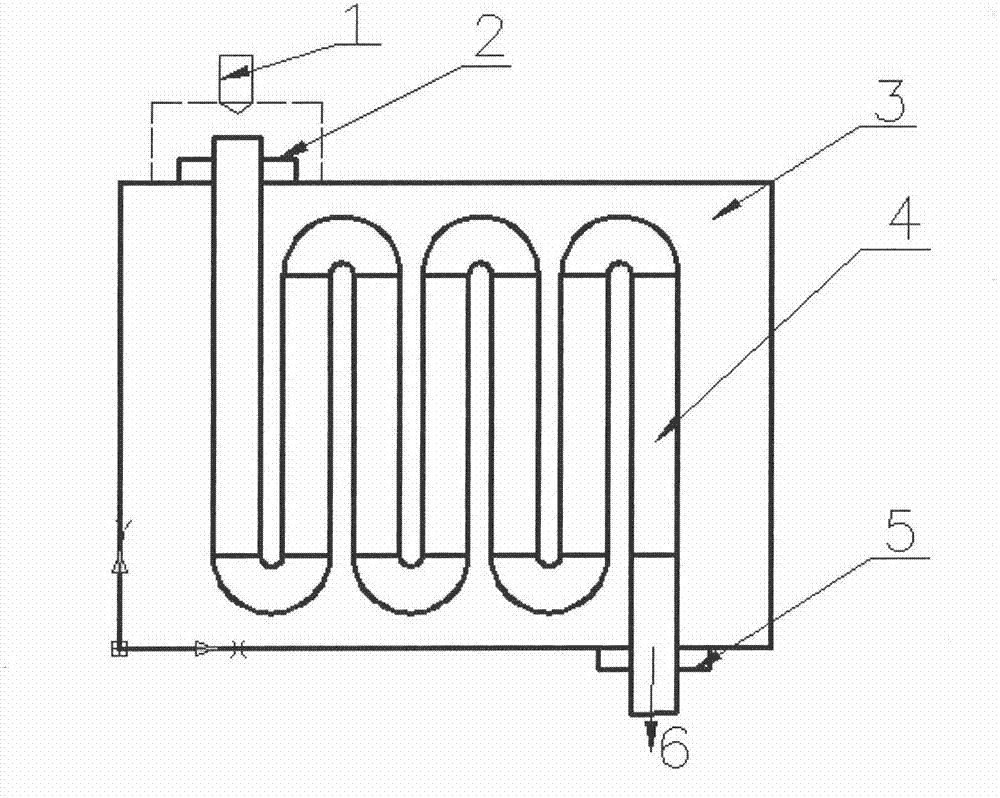

[0019] figure 1 A schematic diagram of the structure of the PVT characteristic experimental device is shown. The entire experimental device consists of four parts, namely a pressure device, a temperature device, a parameter acquisition device and an experimental platform. Before the experiment, prepare the selected experimental plastics in the melt state, and slowly flow into the incubator (14) from the melt inlet (4). The effect of the incubator is to ensure that the melt will not Because of the cooling of the time change, the phenomenon of melt crystallization in the early stage of the experiment is caused, which affects the progress of the experiment. And in order to be close to the real injection molding conditions, the melt flowing in from below wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com