A method of controlling the particle size of titanium dioxide for decorative base paper

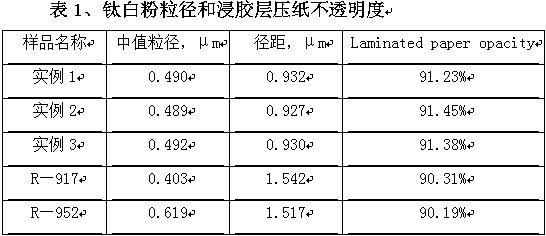

A technology for decorating base paper and titanium dioxide, applied in chemical instruments and methods, papermaking, titanium compounds, etc., can solve the problems of insufficient attention to titanium dioxide particle size control, serious industry homogeneity, and poor application effect, and achieve good achromatic power. , good consistency, uniform size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Titanium sulfate solution preheating: Take 1000ml of titanium sulfate liquid in a 2000ml beaker, heat in a resistance furnace, control the heating rate at 1°C / min, and heat to 98°C. Titanium sulfate solution quality index: total titanium concentration TiO 2 225.21g / L; Ti 3+ Concentration 1.89g / L; acid ratio 1.81; Fe 2+ / TiO 2 0.29; stability 530ml, stability is also known as stability, in the production of titanium dioxide, titanium liquid has a tendency to undergo early hydrolysis and precipitate white metatitanic acid (or orthotitanic acid) colloidal particles under the condition of changing conditions. The strength of this tendency is called the stability of the titanium solution, and the characteristic that indicates the strength of this tendency is called the stability. The stability of the titanium solution is calculated by distilling each ml of titanium solution with distilled water at 25°C until it becomes white and turbid. It is indicated by the number of m...

Embodiment 2

[0035] Preheating of titanium sulfate solution: Take 1000ml of titanium sulfate liquid in a 2000ml beaker, heat in a resistance furnace, control the heating rate at 1°C / min, and heat to 96°C. Titanium sulfate solution quality index: total titanium concentration TiO 2 231.45g / L; Ti 3+ Concentration 2.45g / L; acid ratio 1.76; Fe 2+ / TiO 2 0.27; stability 500ml; solid phase 10.4mg / L.

[0036] Desalinated water is preheated to boiling 99°C.

[0037] Adding bottom water: Add 250ml of boiled desalted water into a 2000ml beaker with stirring, and stir.

[0038] Add titanium sulfate solution: Add the preheated titanium sulfate solution into the beaker in the step, and add it for 17 minutes.

[0039] Heating and boiling: After adding the titanium sulfate solution, stir for 5 minutes, raise the temperature to a slight boiling, the temperature is 114°C, the heating time is 17 minutes, the temperature is controlled at 114-118°C, hydrolyzed for 41 minutes, the slurry turns into a helm...

Embodiment 3

[0045] Titanium sulfate solution preheating: Take 1000ml of titanium sulfate liquid in a 2000ml beaker, heat in a resistance furnace, control the heating rate at 1°C / min, and heat to 98°C. Titanium sulfate liquid quality index: Total titanium concentration TiO 2 233.18g / L; Ti 3+ Concentration 2.57g / L; Acid ratio 1.72; Fe 2+ / TiO 2 0.27; Stability 515ml; The solid phase is 21.3mg / L.

[0046] Desalinated water is preheated to boiling 101°C.

[0047] Adding bottom water: Add 250ml of boiled desalted water into a 2000ml beaker with stirring, and stir.

[0048] Add titanium sulfate solution: add the preheated titanium sulfate solution to the step In the beaker, the addition time was 18 minutes.

[0049] Heating and boiling: After adding the titanium sulfate solution, stir for 5 minutes, raise the temperature to slight boiling, the temperature is 118°C, the heating time is 18 minutes, the temperature is controlled at 112-118°C, hydrolyzed for 43 minutes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com