A method for modifying magnetic nano-ferric oxide based on wool fiber

A technology of ferroferric oxide and wool fiber, applied in chemical instruments and methods, alkali metal oxides/hydroxides, inorganic chemistry, etc., to achieve the effects of simple preparation method, anti-oxidation, and small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

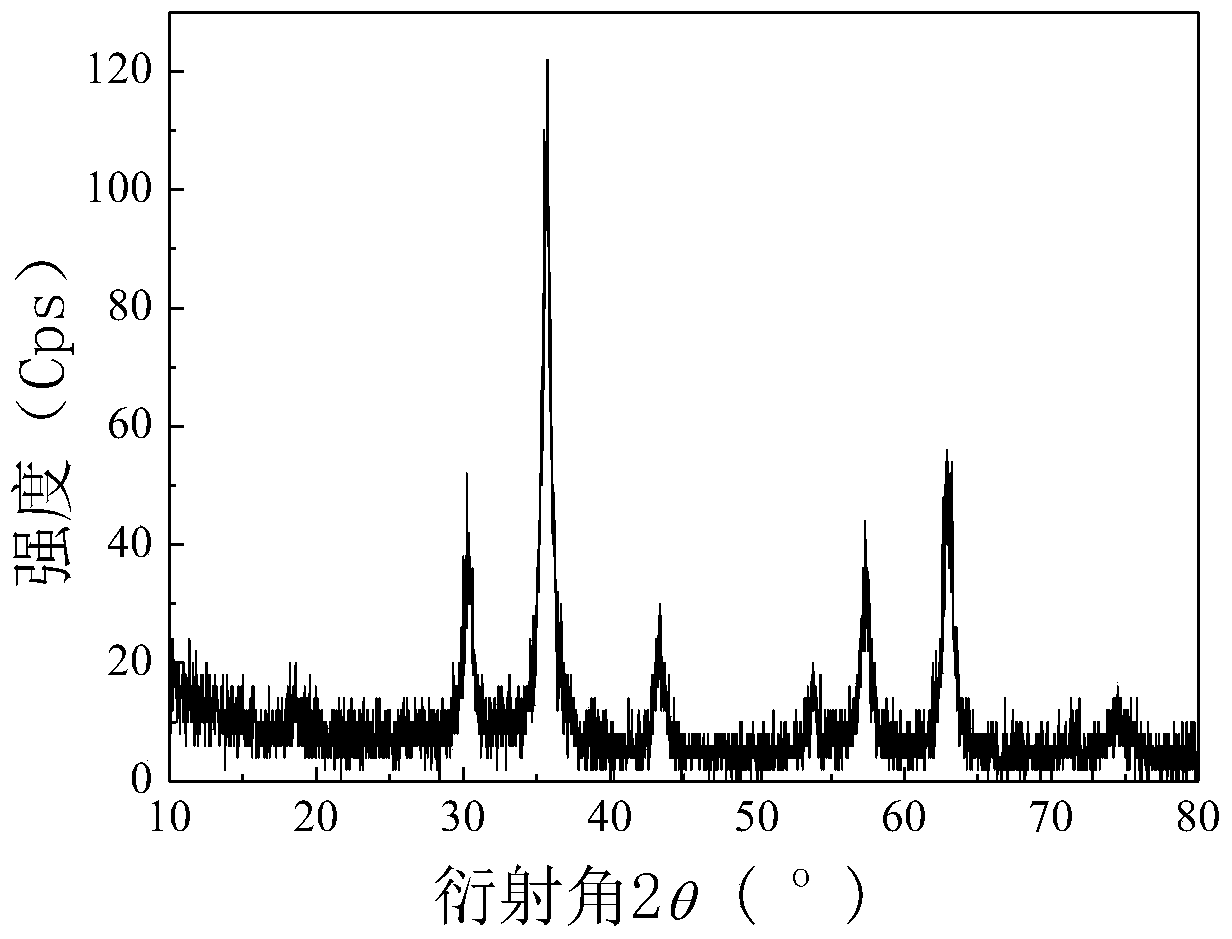

[0045] Fully dissolve 0.2g of sodium carbonate in 100mL of deionized water, weigh 2g of waste wool fiber according to the bath ratio of 1:50 and soak it in an aqueous solution of sodium carbonate at 40°C for 10min, then wash it with deionized water, and then Soak the wool fiber in an anhydrous ethanol solution at 40°C for 10 minutes, wash it once with deionized water, and dry it at 50°C. Fully dissolve 1g of sodium hydroxide in 50mL of deionized water, weigh 0.25g of washed wool fiber according to the bath ratio of 1:200, add it to the sodium hydroxide solution at 70°C, and speed stirring. After the wool fiber was completely dissolved, the sodium hydroxide solution was sealed with a plastic film, then kept at 70°C for 6 hours, and then ultrasonically oscillated for 20 minutes to obtain a wool fiber degradation solution rich in amino acids. Prepare a ferrous chloride solution with a volume of 1L and a concentration of 5% with deionized water, weigh ferric chloride according to...

Embodiment 2

[0048] Fully dissolve 1g of sodium carbonate in 100mL of deionized water, weigh 5g of waste wool fiber according to the bath ratio of 1:20 and soak it in an aqueous solution of sodium carbonate at 50°C for 30min, then wash it with deionized water, and then Wool fibers were soaked in absolute ethanol solution at 60°C for 30 minutes, washed with deionized water three times, and dried at 50°C. Fully dissolve 6g of sodium hydroxide in 100mL of deionized water, weigh 1g of washed wool fiber according to the bath ratio of 1:100, add it to the sodium hydroxide solution at 90°C, and turn it at a speed of 200 rpm Stir. After the wool fiber was completely dissolved, the sodium hydroxide solution was sealed with a plastic film, then kept at 90°C for 12 hours, and then ultrasonically oscillated for 40 minutes to obtain a wool fiber degradation solution rich in amino acids. Prepare a ferrous chloride solution with a volume of 200mL and a concentration of 10% with deionized water, weigh fe...

Embodiment 3

[0051] Fully dissolve 0.8g of sodium carbonate in 100mL of deionized water, weigh 2.5g of waste wool fiber according to the bath ratio of 1:40 and soak it in an aqueous solution of sodium carbonate at 45°C for 20min, then wash it with deionized water, Then soak the wool fiber in an anhydrous ethanol solution at 50°C for 20 minutes, wash it twice with deionized water, and dry it at 50°C. Fully dissolve 4g of sodium hydroxide in 100mL of deionized water, weigh 0.67g of washed wool fiber according to the bath ratio of 1:150, add it to the sodium hydroxide solution at 80°C, and speed stirring. After the wool fiber was completely dissolved, the sodium hydroxide solution was sealed with a plastic film, then kept at 80°C for 8 hours, and then ultrasonically oscillated for 30 minutes to obtain a wool fiber degradation solution rich in amino acids. Prepare a ferrous chloride solution with a volume of 1L and a concentration of 7% with deionized water, weigh ferric chloride according to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com