Patents

Literature

34results about How to "Does not destroy the crystal structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lithium ion battery high-nickel ternary positive electrode material and preparation method thereof, and lithium ion battery

ActiveCN108206279ADoes not destroy the crystal structureInhibition formationCell electrodesSecondary cellsState of artLithium carbonate

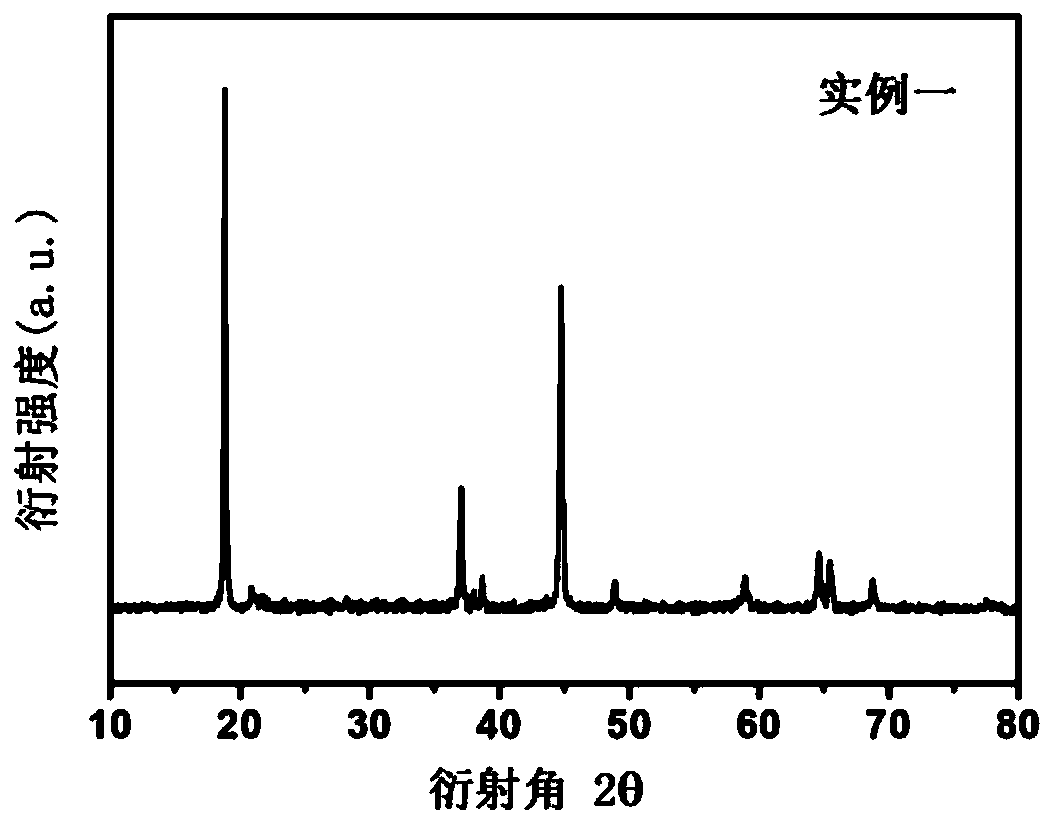

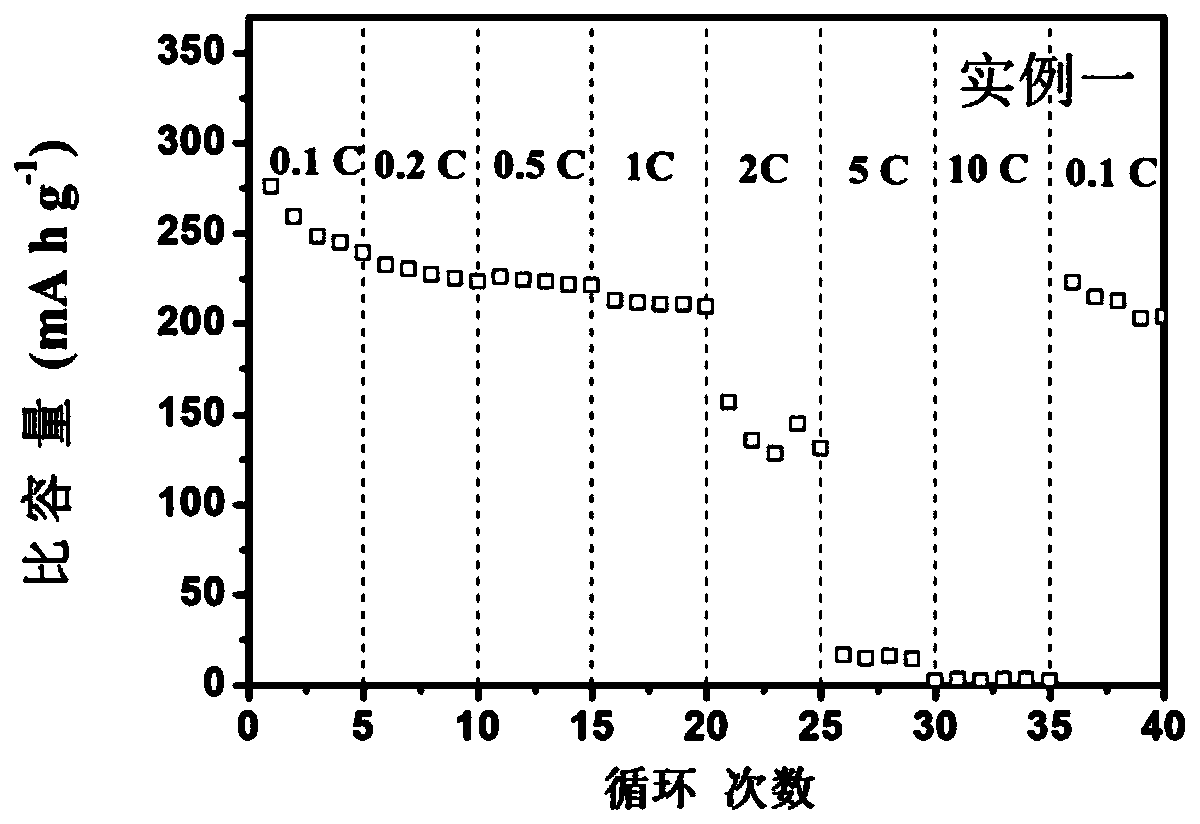

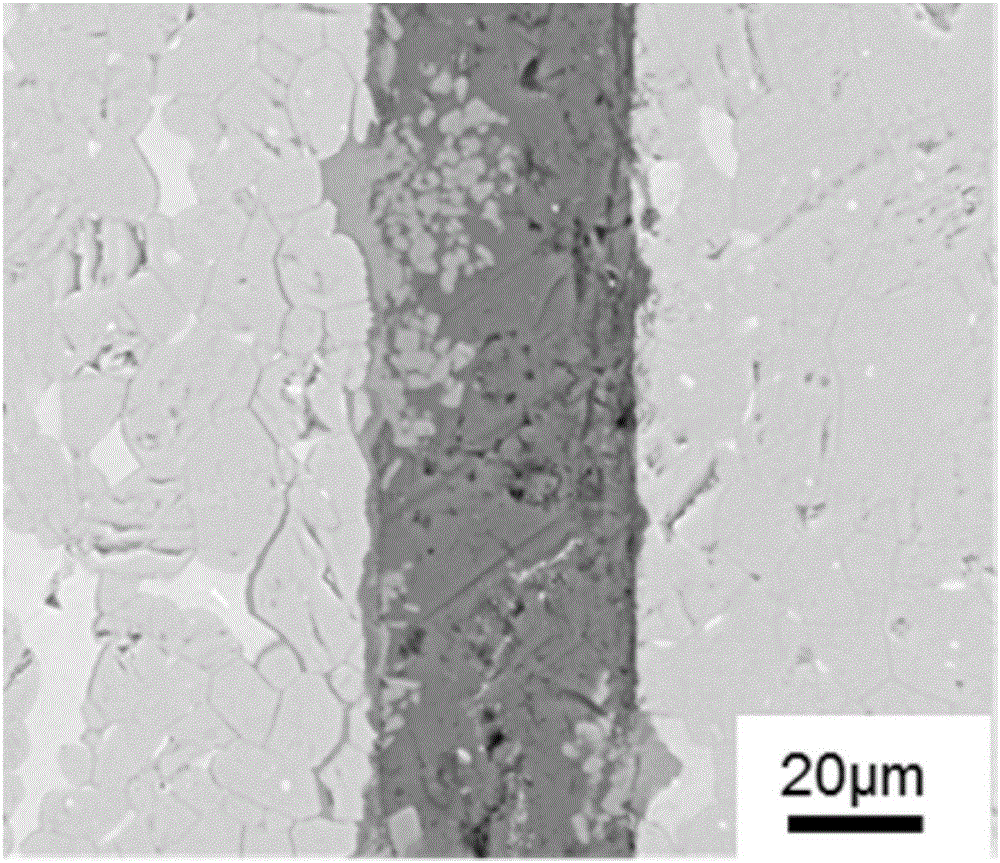

The invention discloses a lithium ion battery high-nickel ternary positive electrode material, which has a chemical general formula of LiNixM1-xO2, wherein x is more than or equal to 0.5 and is less than 1, M is one or a variety of materials selected from Co, Mn and Al, the surface of the ithium ion battery high-nickel ternary positive electrode material is coated with a lithium salt coating layer, and the lithium salt is a lithium salt containing a -COOLi functional group. Compared to the material in the prior art, the material of the present invention has the following characteristics that the residual lithium on the surface of the high-nickel material is modified to form the stable lithium salt coating layer, such that the residual lithium on the surface can be removed, the protection layer can cover the surface of the material, the generation of lithium carbonate can be inhibited, and the crystal structure of the material cannot be destroyed. According to the present invention, thelithium ion battery high-nickel ternary positive electrode material has advantages of good cycle stability and good storage performance, and the preparation method is simple, easy-performing, economical and environmentally friendly, and has good application prospect. The invention further discloses a lithium ion battery.

Owner:CONTEMPORARY AMPEREX TECH CO

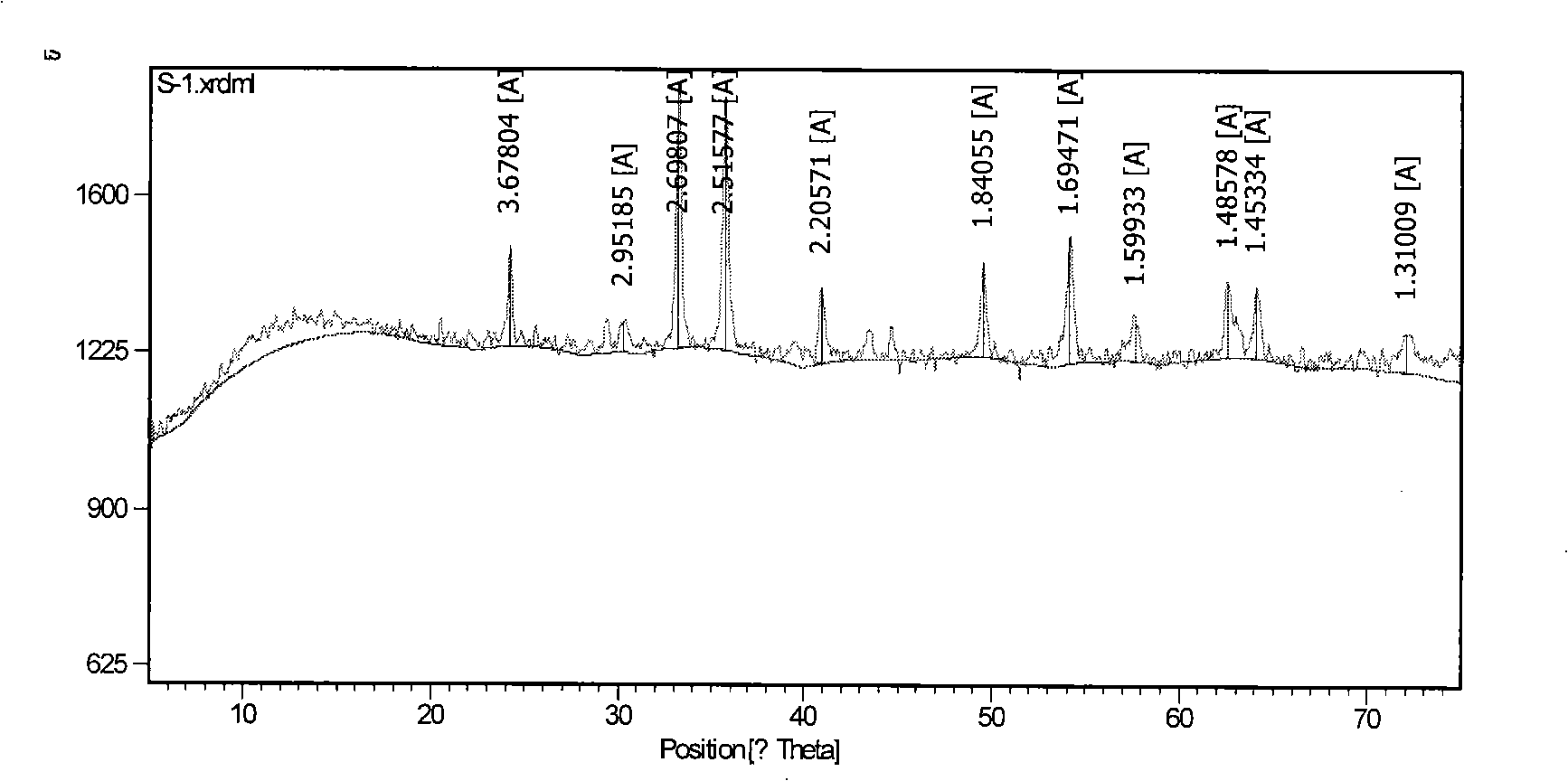

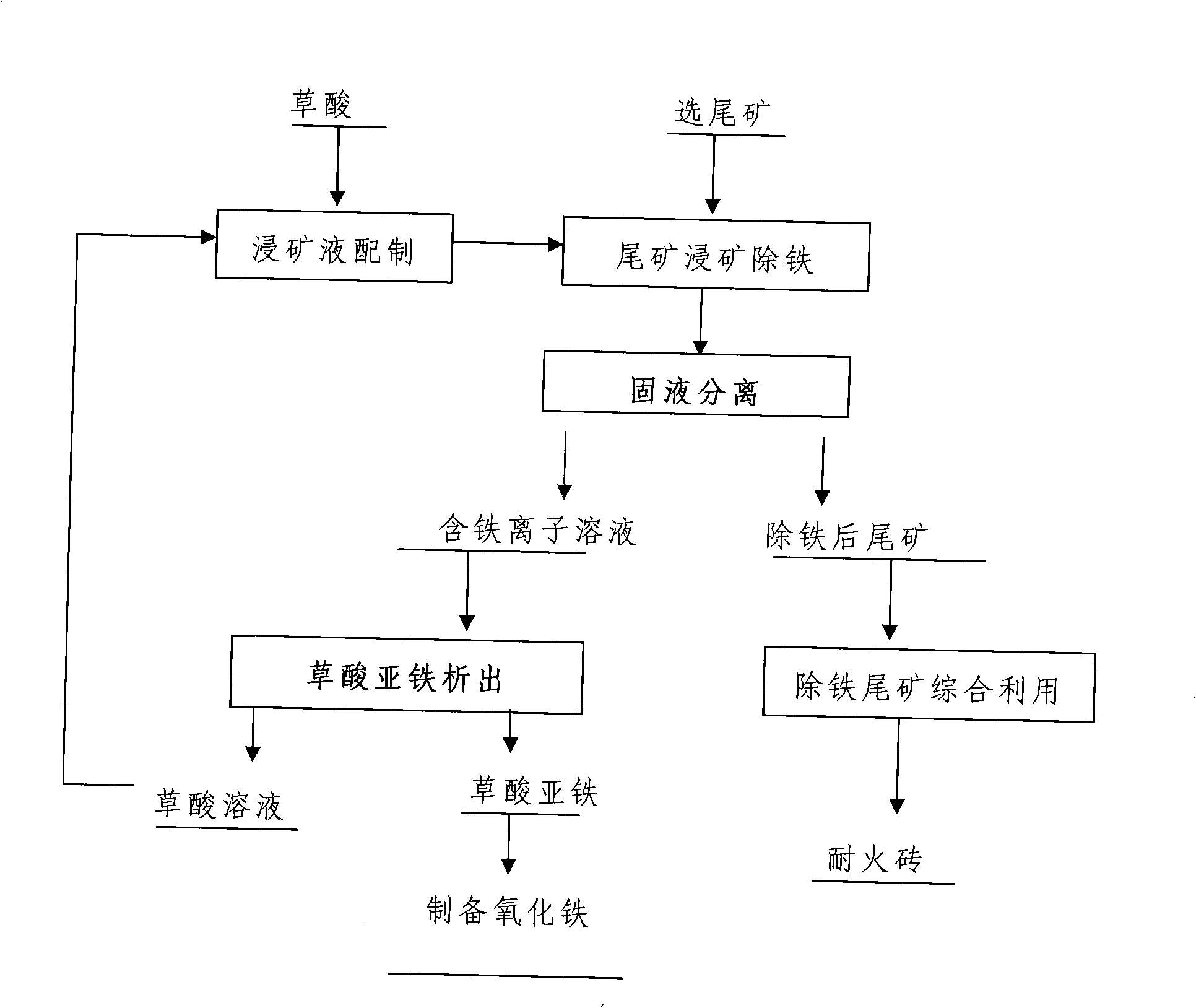

Process for preparing clay firebrick by flotation tailing of bauxite

InactiveCN101306953AReduce iron oxide contentDoes not destroy the crystal structureOxalateFire brick

A method for the treatment of bauxite flotation tailings relates to a method for making clay fire brick by means of bauxite flotation tailings and reclaiming the iron mineral in the tailings to make ferrous oxalate and ferric oxide. The method is characterized in that: firstly, the making process adopts oxalic acid leach bauxite cradling tailings iron mineral so as to remove iron; then, tailings is filtered and separated to make clay fire bricks. The method removes most impurity iron in the tailings at first so as to ensure that the content of ferric oxide in the tailings drops to less than 1.5 percent; meanwhile, only less than 1 percent of aluminum is leached out, and the crystal structure of the aluminum mineral in the tailings is not damaged basically; moreover, the flotation tailings with iron removed can be used to make qualified clay fire bricks.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

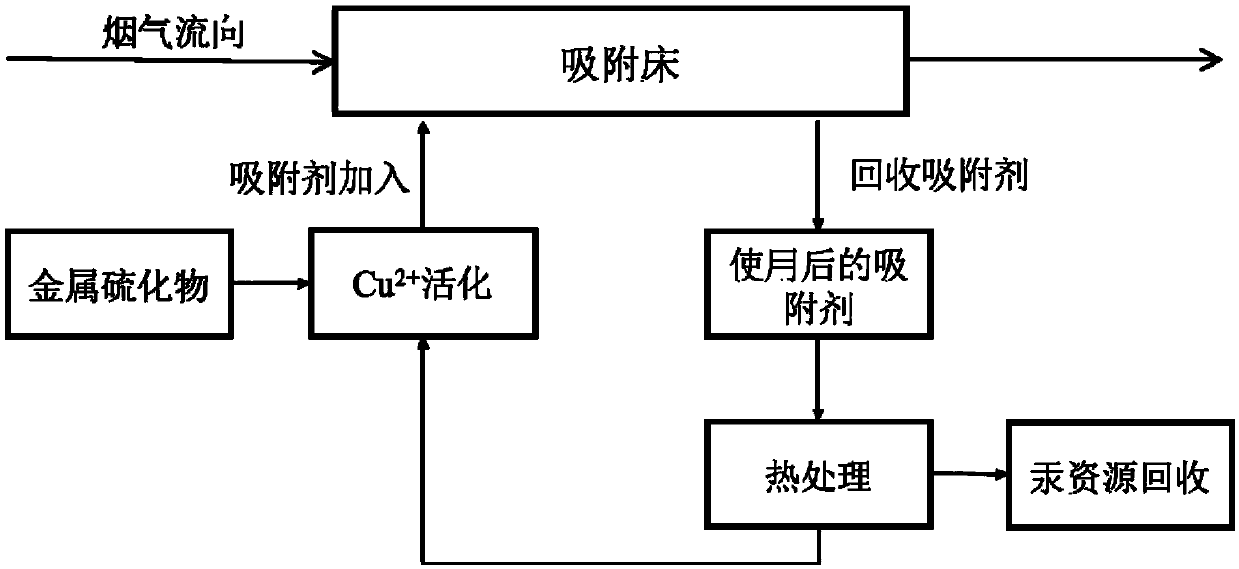

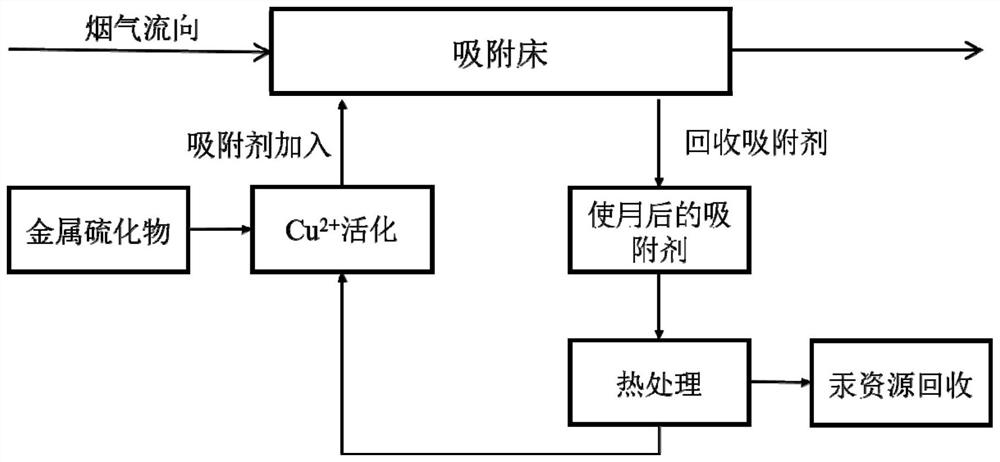

Activation and regeneration method for metal sulfide mercury removal adsorbing agent

The invention relates to an activation and regeneration method for a metal sulfide mercury removal adsorbing agent. The activation and regeneration method comprises the following steps: moderately soaking a metal sulfide main body inside an activate fluid consisting of a cupric salt solution, and then separating, washing and drying to complete the activation for the adsorbing agent, and then usingthe adsorbing agent to adsorb mercury inside an airflow. After the adsorbing agent is inactivated due to adsorption and saturation for mercury, and the adsorbed mercury is released through thermal treatment, and resource recovery is carried out on the mercury. The adsorbing agent after thermal treatment is put in the activate fluid again for soaking to complete the regeneration of a metal sulfide. Compared with the prior art, besides the synthetic metal sulfide, low-cost natural metal sulfide ores can be directly used as the adsorbing agent main body. The mercury adsorption property of the metal sulfide can be greatly strengthened through activation, and simultaneously, the regeneration of the metal sulfide after mercury adsorption can be realized. The using amount of the adsorbing agentis greatly reduced while efficient trapping of flue gas mercury is realized, so that the consumption cost of the adsorbing agent and the implementation difficulty of adsorption mercury removal technology are reduced.

Owner:SHANGHAI JIAO TONG UNIV

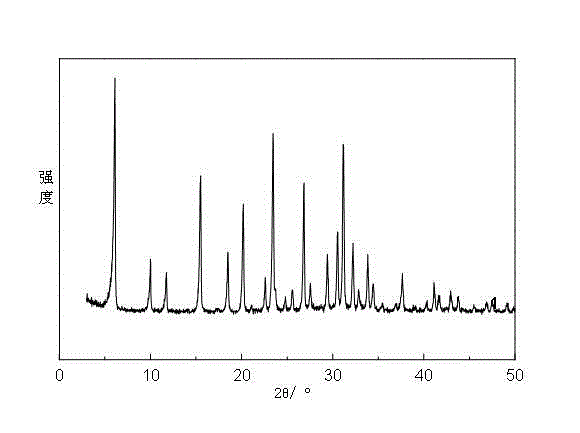

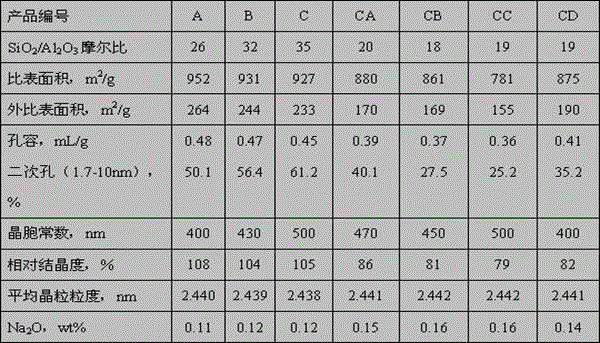

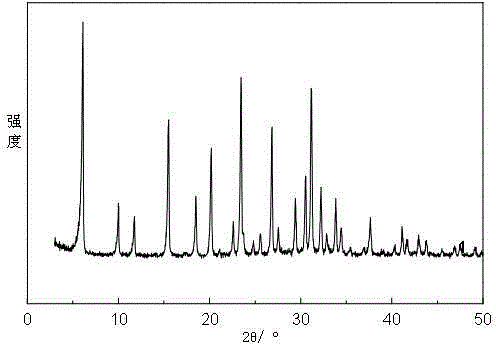

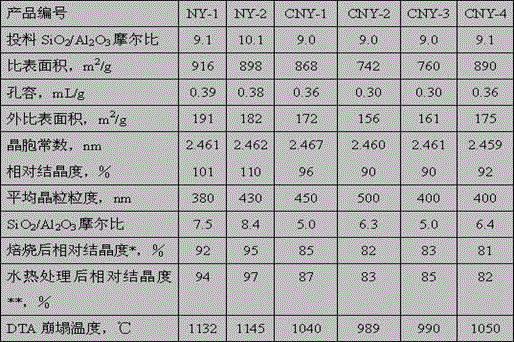

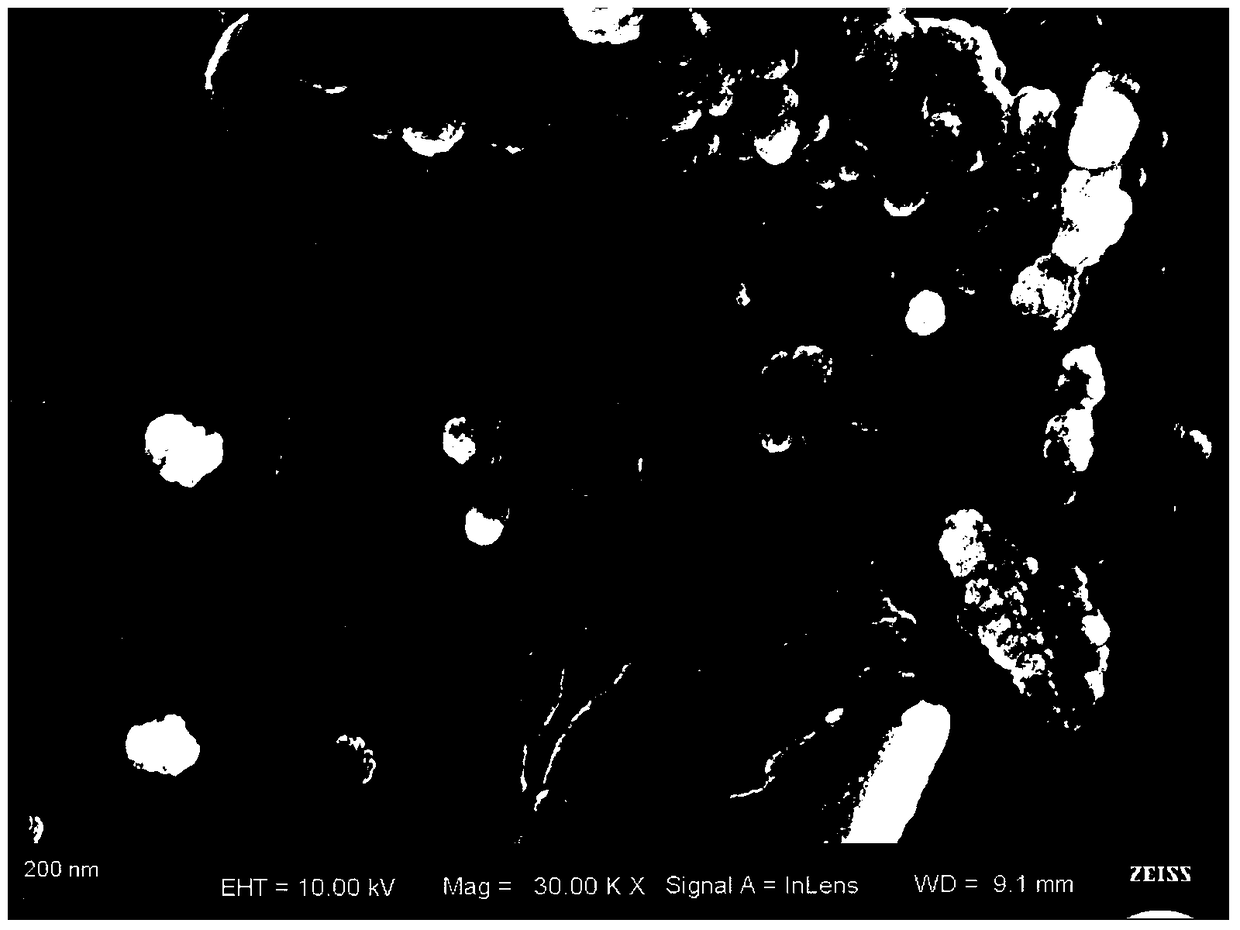

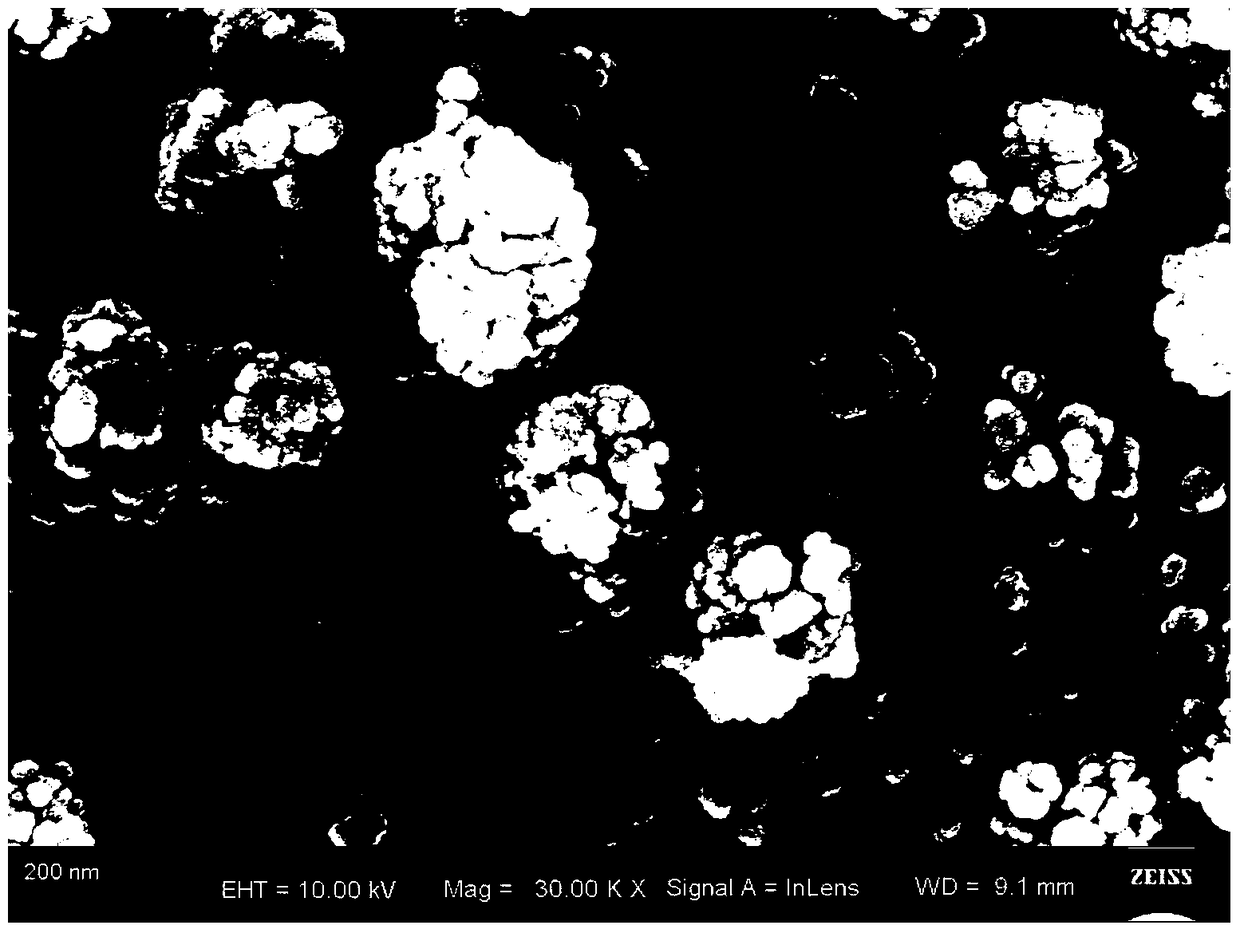

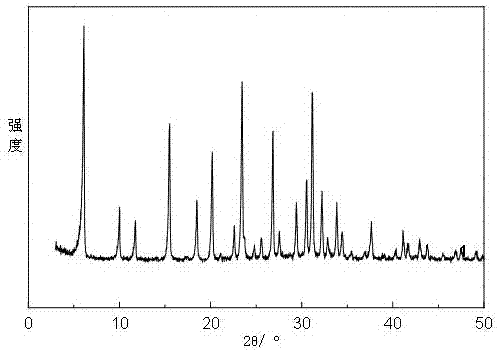

Modification method of small-grain NaY-type molecular sieve

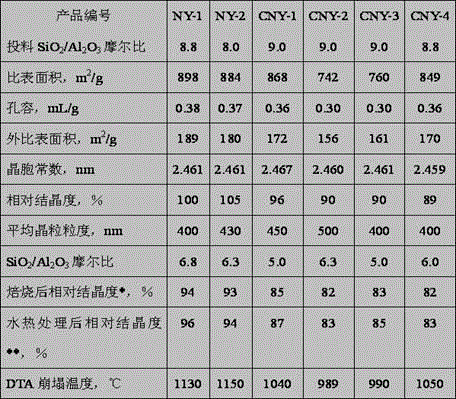

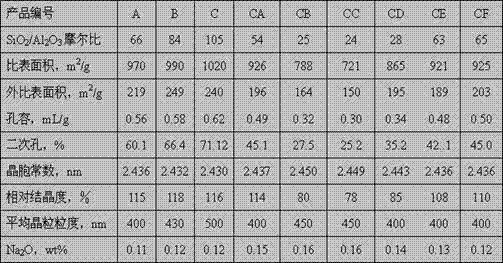

ActiveCN104591210AImprove stabilityStability is not affectedMolecular sieve catalystsFaujasite aluminosilicate zeoliteMolecular sieveNaphtha

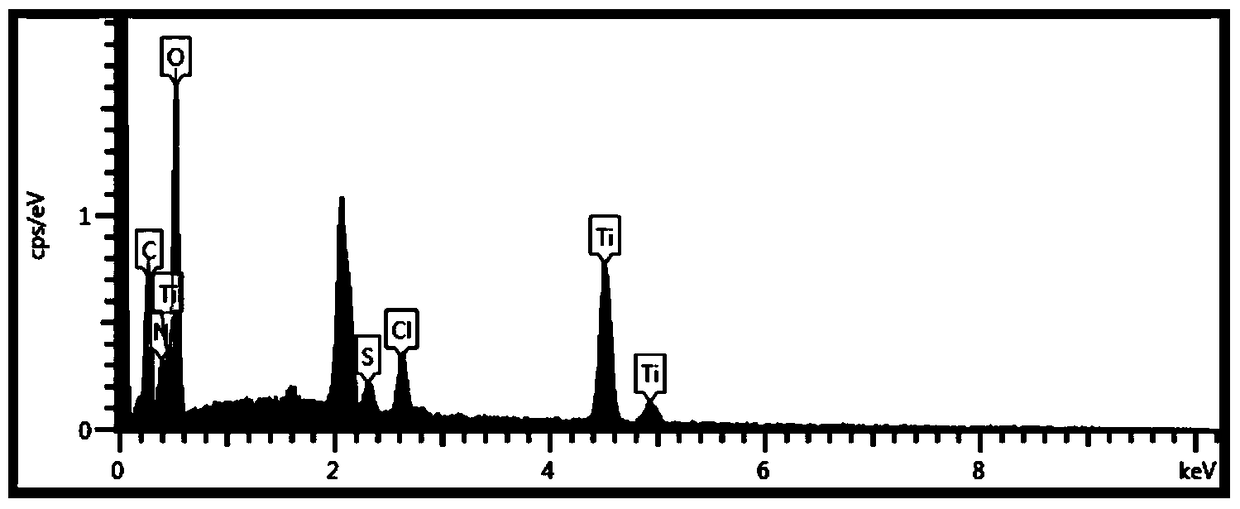

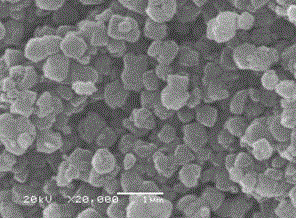

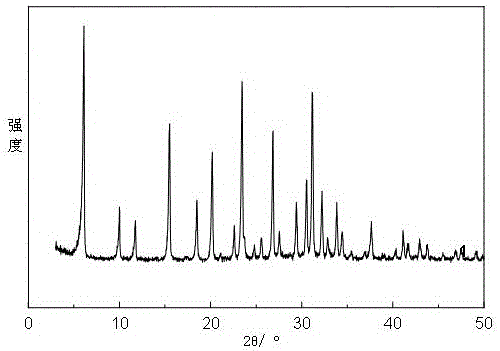

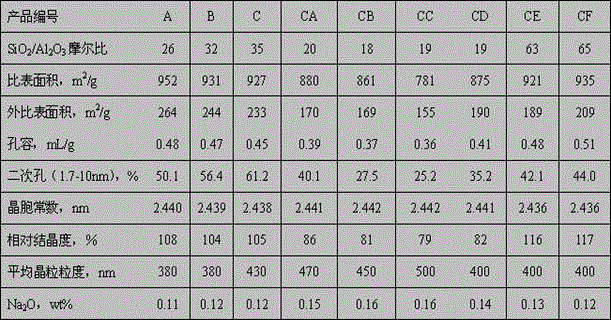

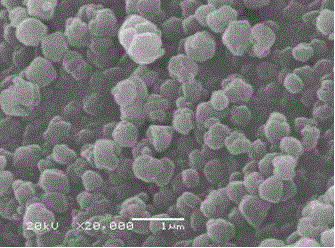

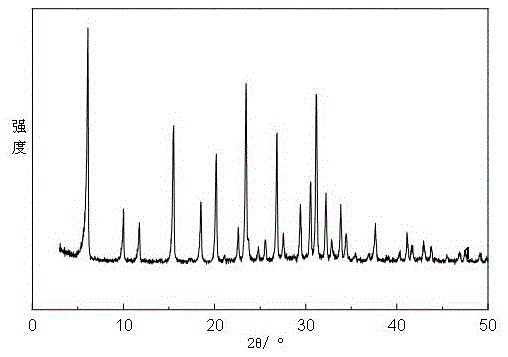

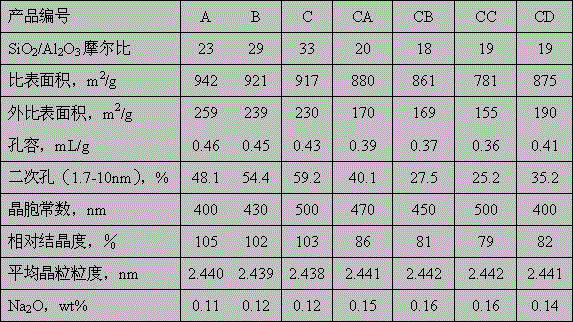

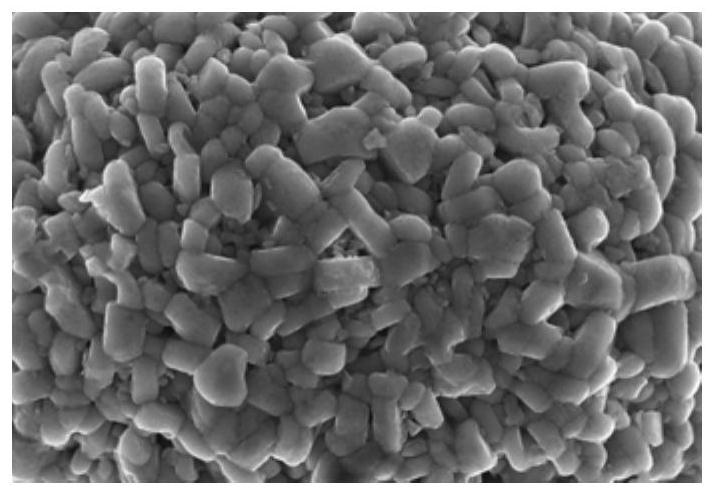

The invention discloses a modification method of a small-grain NaY-type molecular sieve. According to the invention, the NaY-type molecular sieve raw material with relatively high silica-to-alumina ratio, high crystallinity and good stability is adopted. Through sequential steps of alkali wash, ammonium exchange, hydrothermal treatment, and acid and ammonium salt mixed solution treatment, the obtained small-grain Y-type molecular sieve has relatively high SiO2 / A12O3 molar ratio as well as relatively high secondary pore proportion. Also, the stability of the Y-type molecular sieve is maintained. The molecular sieve has relatively high specific surface area and relatively high crystallinity. The Y-type molecular sieve provided by the invention is suitable to be used as a cracking component of a light oil hydrocracking catalyst. With the Y-type molecular sieve, the catalyst has the advantages of good activity, good heavy naphtha selectivity and excellent product quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

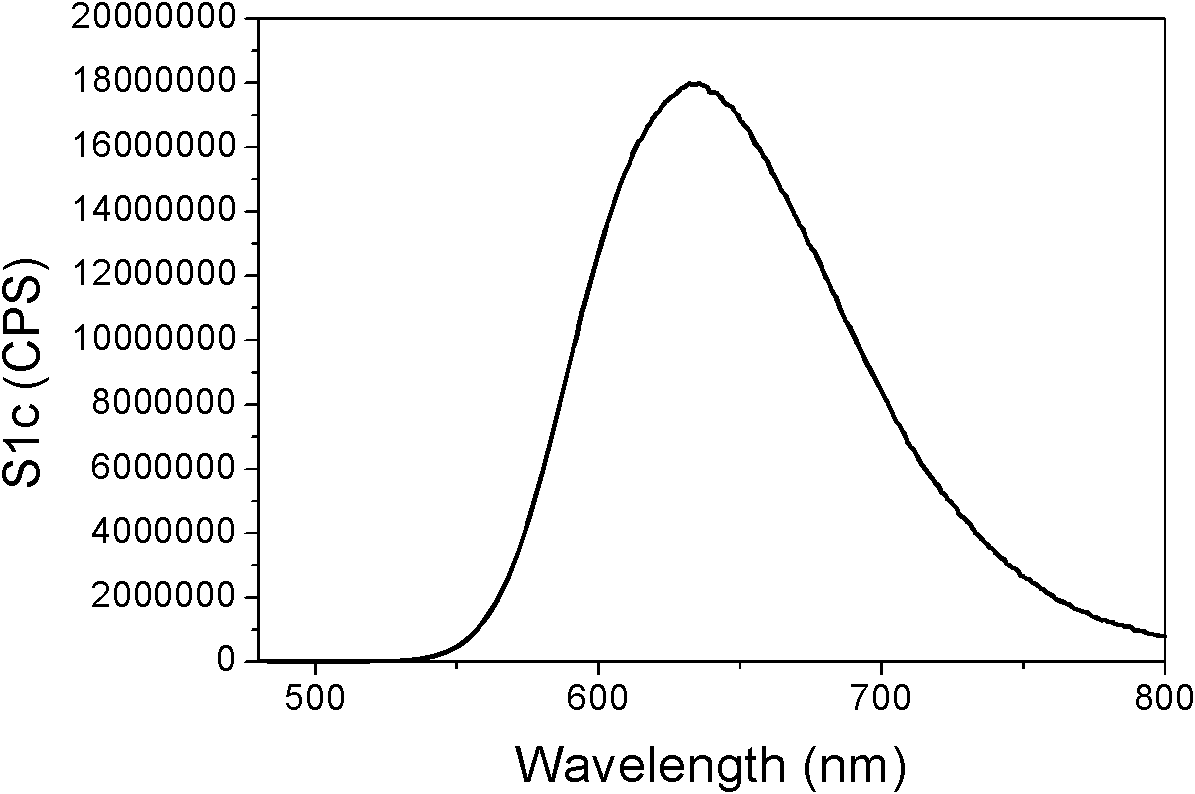

Preparation method of low-temperature cured nitride red phosphor paste

InactiveCN101942302AEasy to operateDo not destroy ingredientsLuminescent compositionsLow temperature curingSolvent

The invention provides a preparation method of low-temperature cured nitride red phosphor paste, comprising the following steps: 1) mixing the nitrides, europium nitride and silicon nitride of metal M according to the atom number ratio of M:Eu:Si being (2-x):x:5, after uniform mixing, calcining the mixture in nitrogen atmosphere and ball-milling the calcined mixture to obtain phosphor, wherein x is more than 0 and not more than 1.0; 2) dissolving vinyl chloride-vinyl acetate resins or polyester resins in solvents, then heating the mixture at constant temperature until the mixture is completely dissolved and filtering the dissolved substances to obtain an organic carrier; and 3) adding the phosphor prepared in the step 1), thickening agents and dispersing agents to the organic carrier prepared in the step 2) and stirring the mixture uniformly, thus preparing the low-temperature cured nitride red phosphor paste. The preparation method has the advantages of simple and easily operated adopted equipment and capability of realizing preparation of paste of the low-temperature cured nitride red phosphor M(2-x)EuxSi5N8 (M=Ca, Sr or Ba).

Owner:IRICO

Lithium-rich manganese-based/graphene composite cathode material, preparation method thereof and application thereof

InactiveCN110165181AImprove apparent conductivityAvoid polarizationSecondary cellsPositive electrodesHigh energyManganese

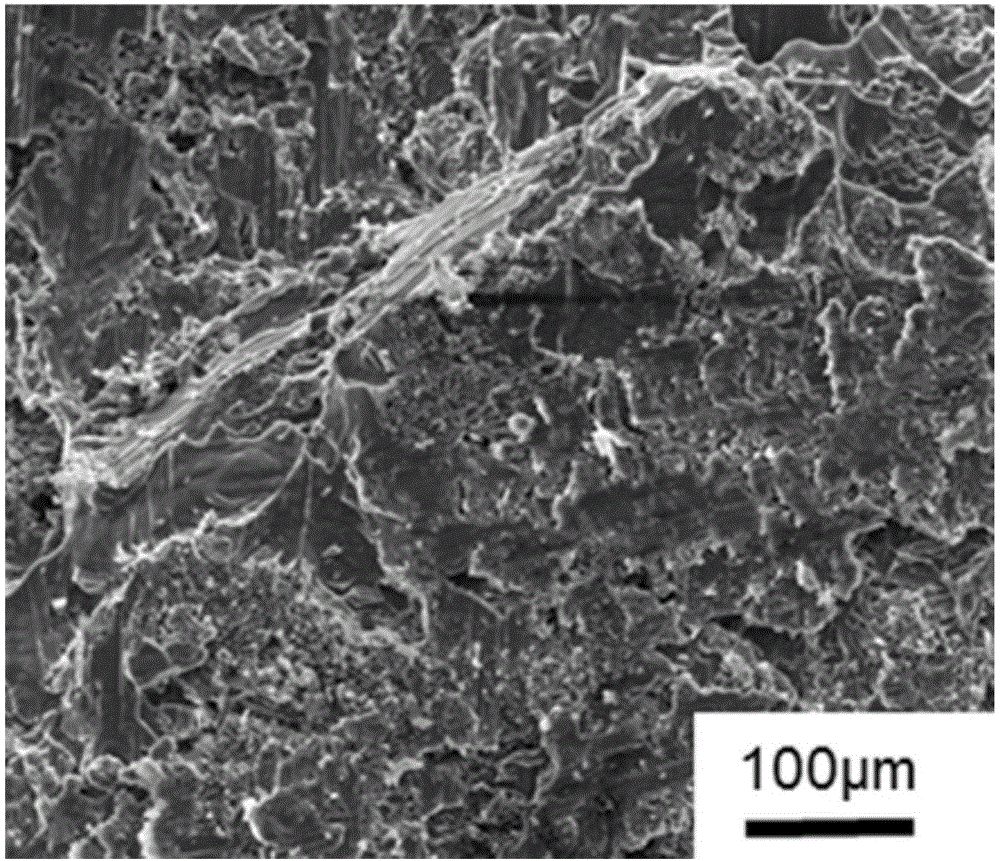

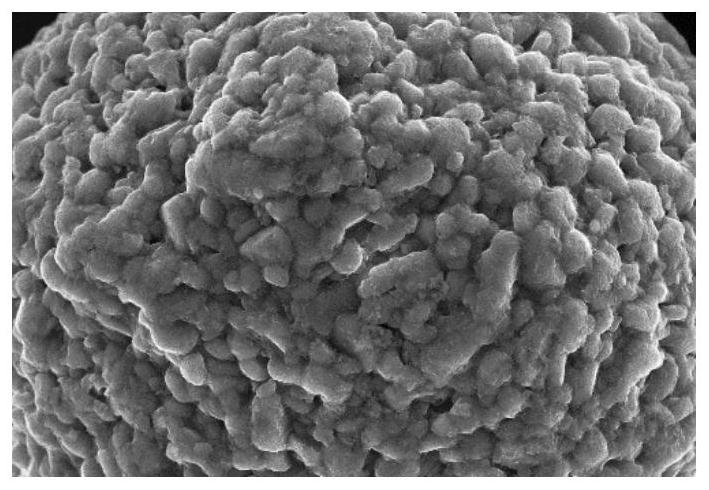

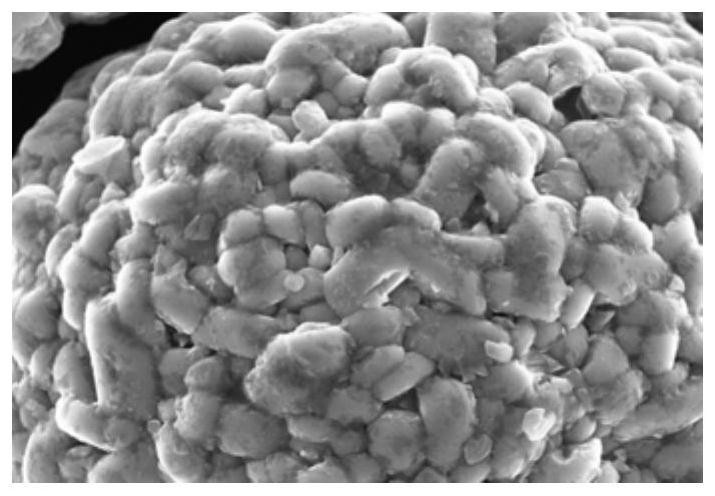

The invention discloses a lithium-rich manganese-based / graphene composite cathode material, a preparation method thereof and an application thereof. The method comprises the steps of: preparing precursor powders by a coprecipitation method and by using a manganese source, a nickel source, a cobalt source, a complexing agent and a precipitating agent as raw materials; subjecting the obtained precursor powders and a lithium source to two-stage calcination to obtain a lithium-rich manganese-based cathode material; then subjecting the obtained lithium-rich manganese-based cathode material and a graphene dispersion to high-energy ball milling; and obtaining the lithium-rich manganese-based / graphene composite cathode material by drying. In the product prepared by the method, the graphene sheet can be well compounded between the surface of the lithium-rich manganese-based material particle surfaces and the particles, and form a more perfect conductive network around the particles. The cathodematerial improves the charging and discharging process and the electrical conductivity of the lithium ion battery under the premise of maintaining the structural stability, and has a simple process and good repeatability.

Owner:EAST CHINA UNIV OF SCI & TECH

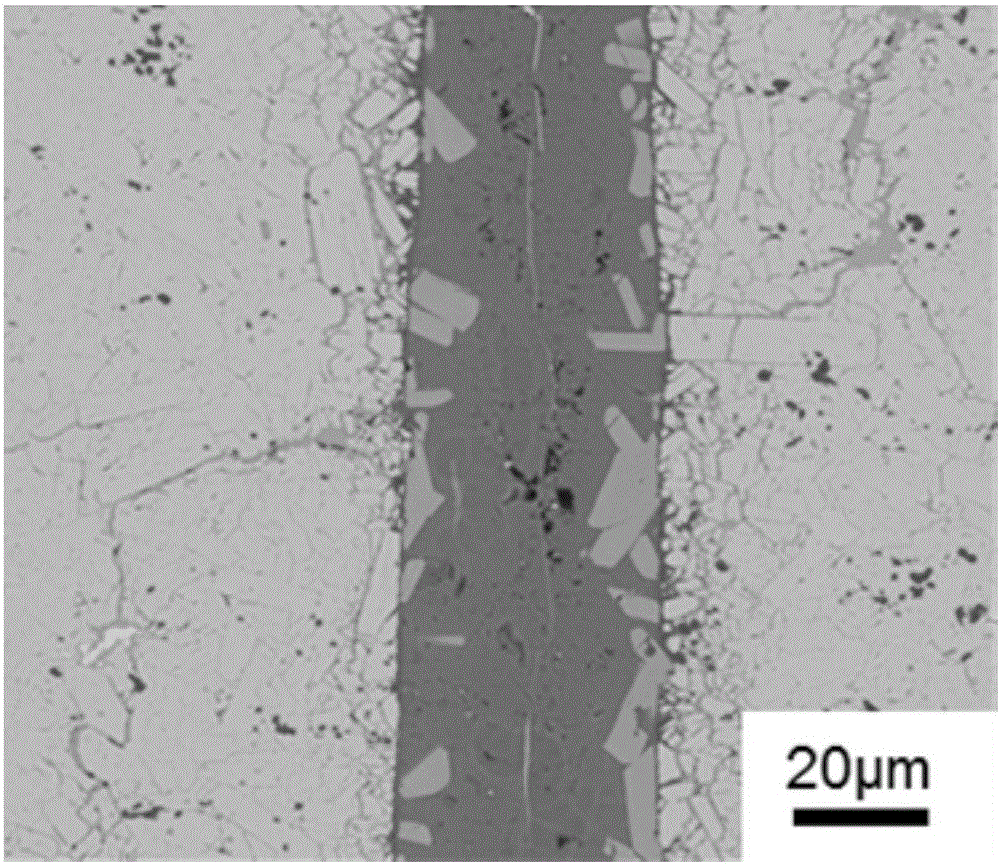

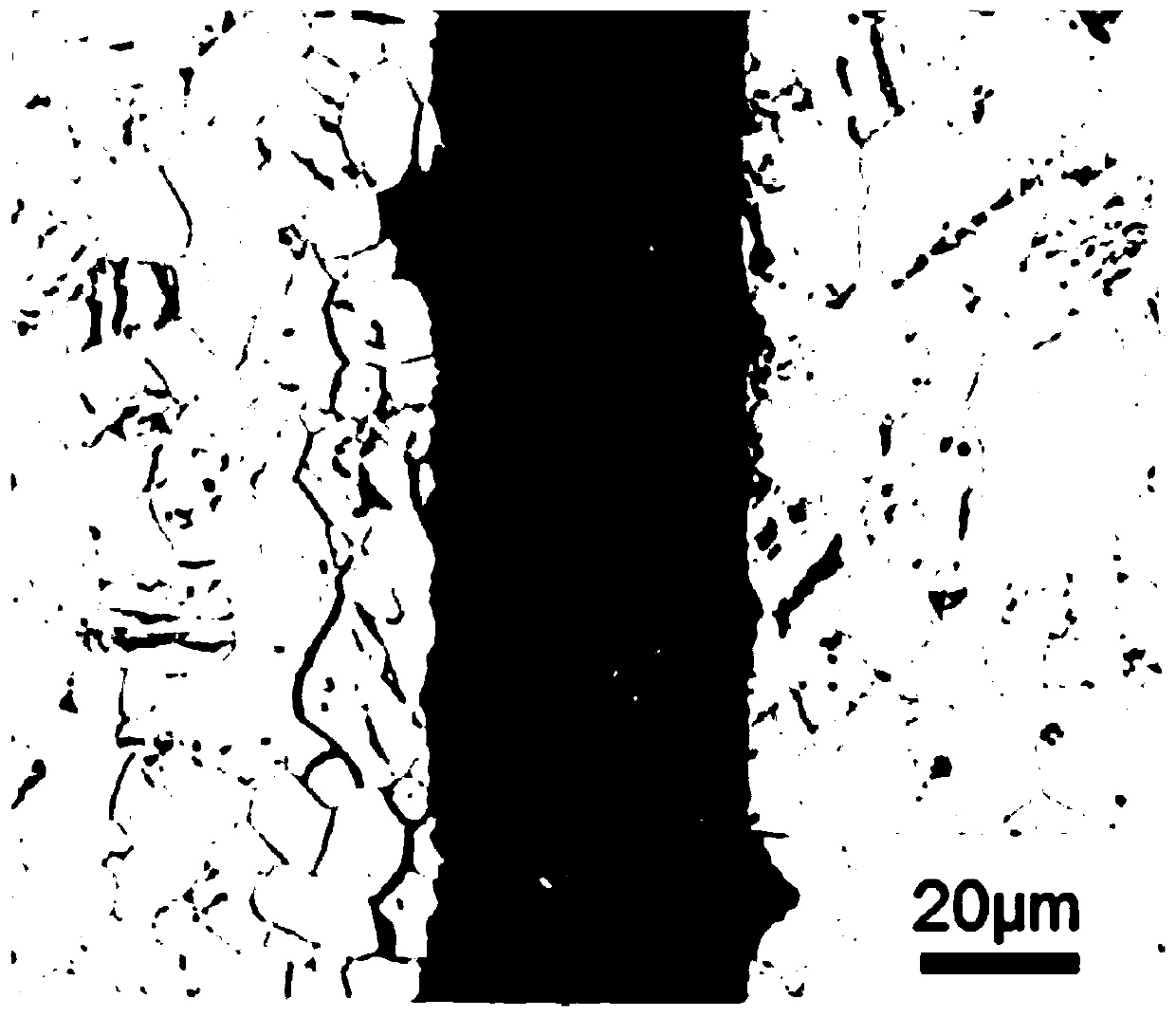

Method for brazing Ti2AlC ceramics by Al base brazing filler metal

InactiveCN107433401ALow melting pointLow costWelding/cutting media/materialsSoldering mediaVacuum pumpingUltimate tensile strength

The invention relates to a method for brazing Ti2AlC ceramics by Al base brazing filler metal, and aims to solve the technical problem of short service life of an existing electric contact component. The method includes the steps: first, preparing the brazing filler metal; second, assembling a Ti2AlC ceramic / brazing filler metal / Ti2AlC ceramic structural part, placing the structural part into a vacuum brazing furnace, performing vacuum pumping to reach 6.0*10<3>Pa, increasing temperature to 300 DEG C at the heating rate of 10 DEG C / min, keeping the temperature for 30min, increasing the temperature to 660-900 DEG C at the heating rate of 10 DEG C / min, keeping the temperature for 5-30min under the pressure of 0.2-1.0MPa, reducing the temperature to 300 DEG C at the cooling rate of 10 DEG C / min, performing furnace cooling and finishing brazing the Ti2AlC ceramics by the Al base brazing filler metal. By the method, a joint with an excellent mechanical property can be obtained, the shear strength of the joint is 70-120MPa, and electrical conductivity is 3.73-4.18*10<6>S / m and reaches 94% or more of the electrical conductivity of the Ti2AlC ceramics.

Owner:HARBIN INST OF TECH

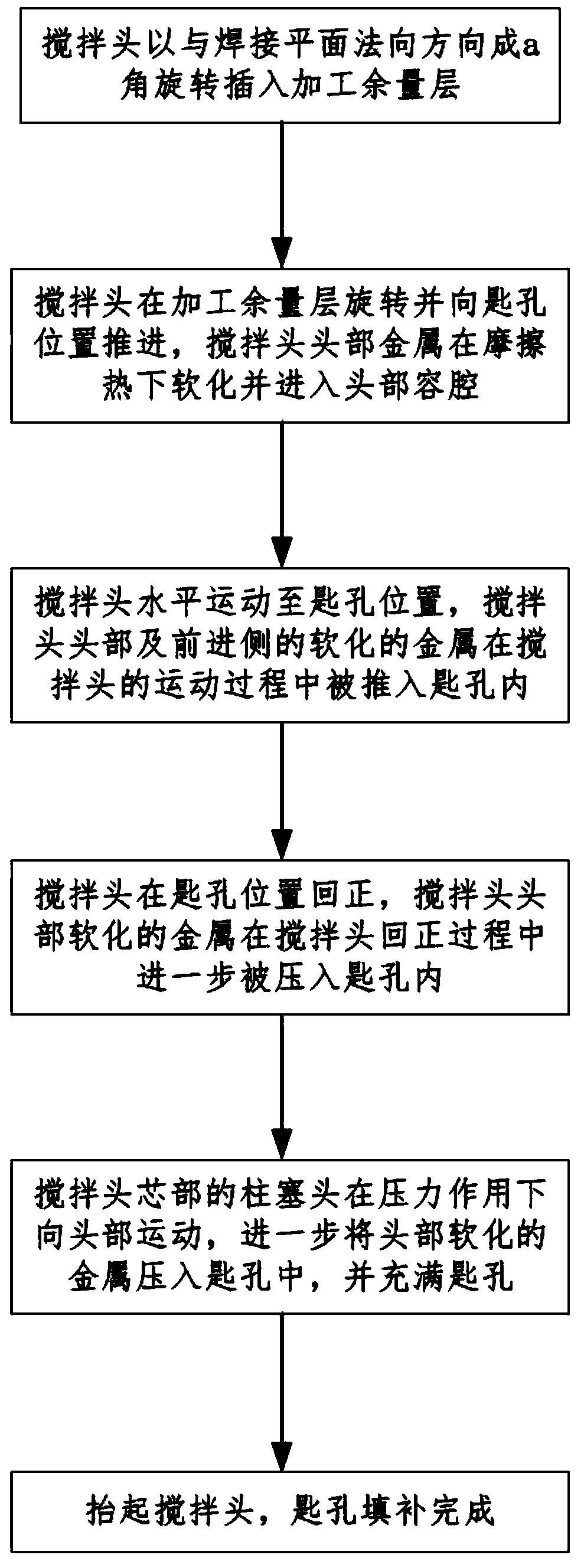

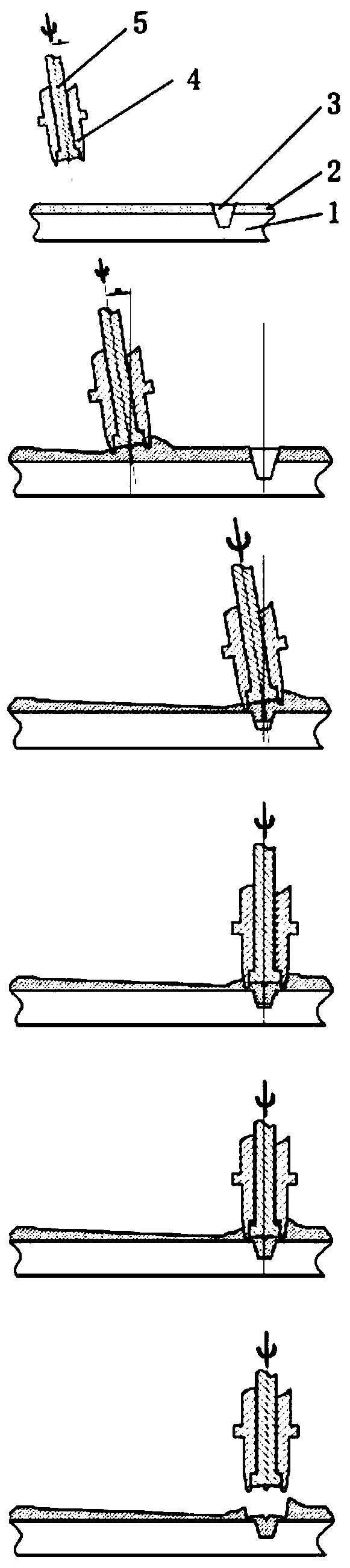

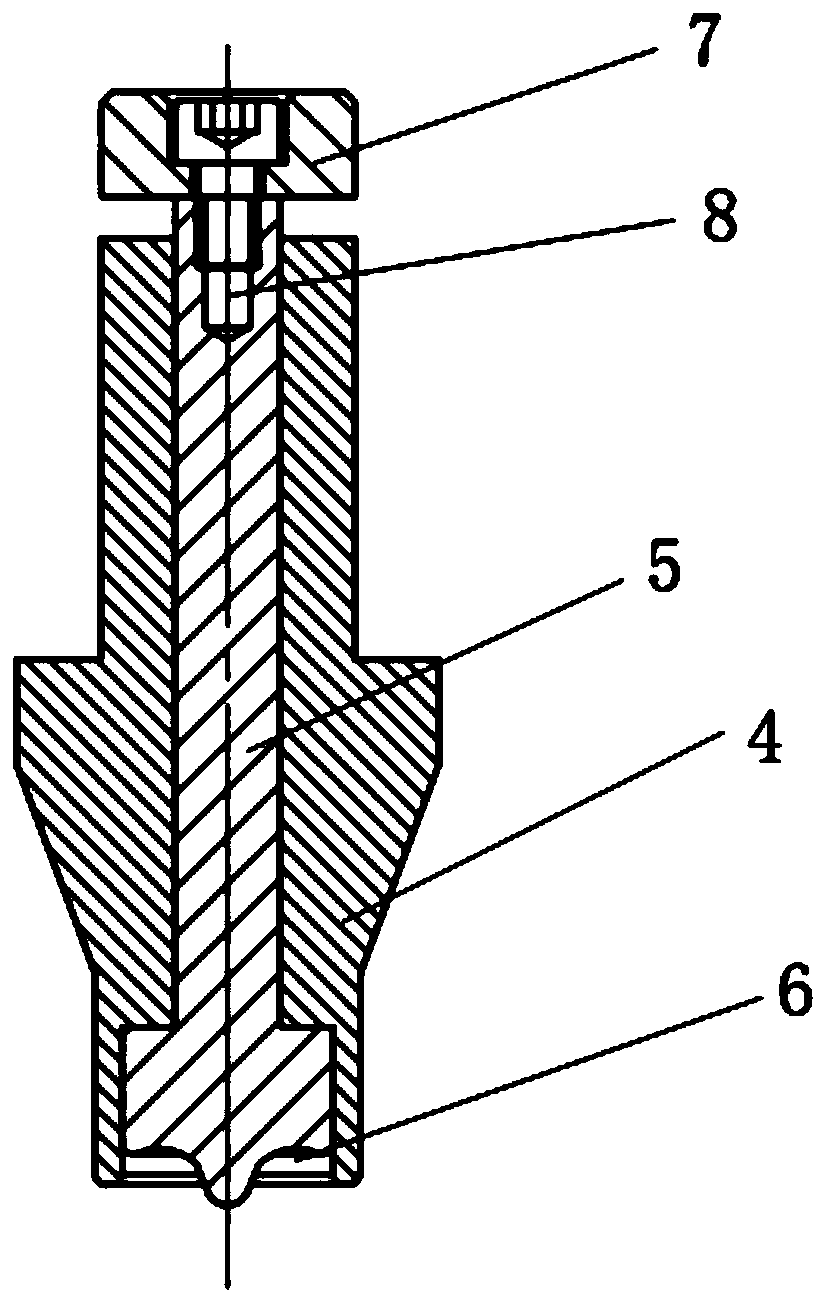

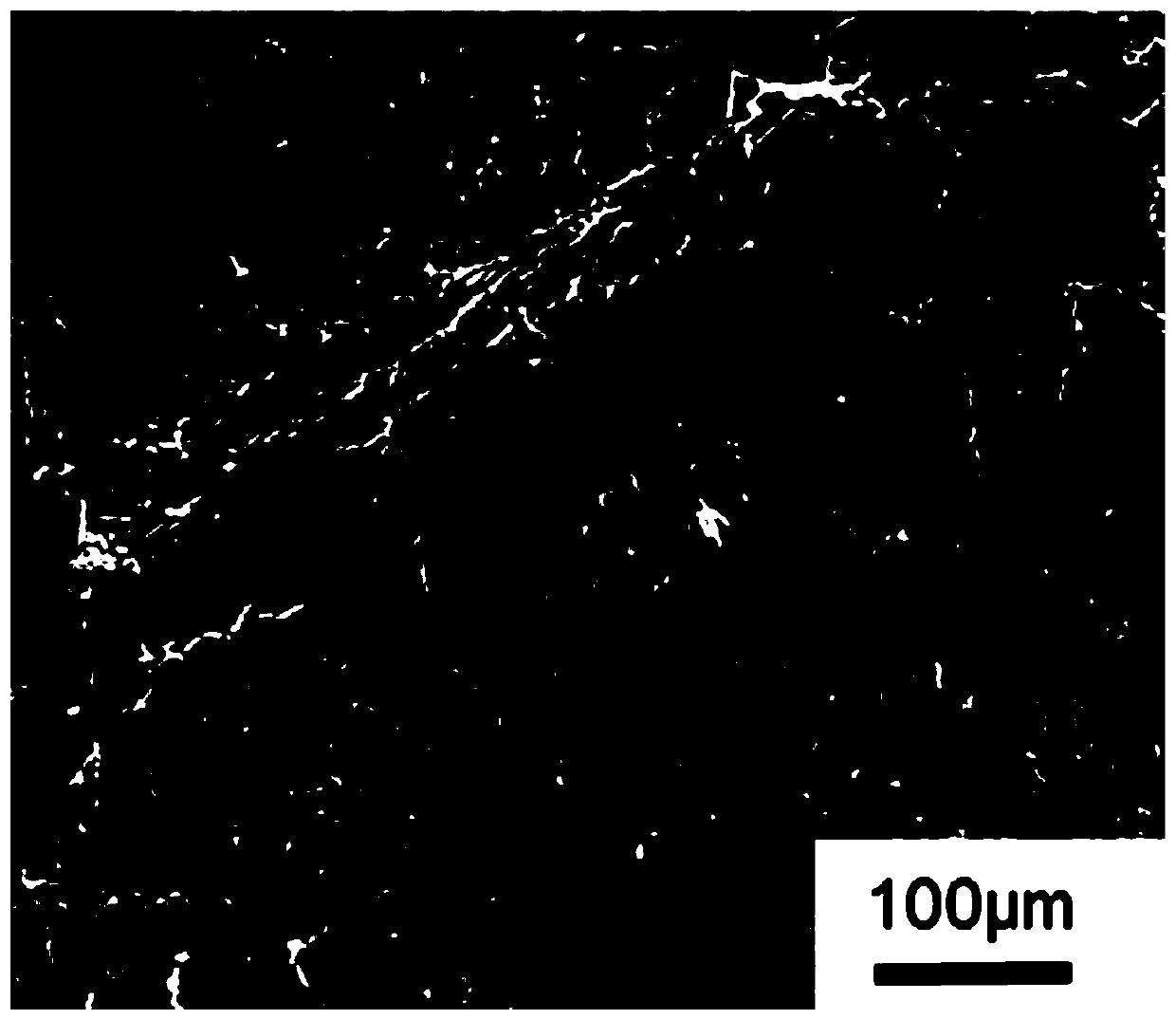

Method for filling welding key hole by utilizing friction stir

ActiveCN110576254AEnsure consistencyDoes not damage mechanicsNon-electric welding apparatusEngineeringMechanical engineering

The invention discloses a method for filling a welding key hole by utilizing friction stir. The method comprises the following steps that (1) a stirring head is obliquely inserted into a machining allowance layer relative to a welding surface normal of a workpiece; (2) the end part of the stirring head located in the machining allowance layer is pushed to a key hole position in a machining allowance layer; (3) the stirring head is turned back, and the axis of the stirring head coincides with the center of the key hole; and (4) the stirring head is lifted, and the key hole filling is finished.According to the filling method, the characteristic that the friction heat can soften the workpiece material when the stirring head rotates in the workpiece is utilized, the softening machining allowance material on the surface of the workpiece is migrated to the key hole through the motion of rotating the stirring head, and the softened material fills the key hole through the combined motion of the rotating head.

Owner:武汉尚田工业科技有限公司

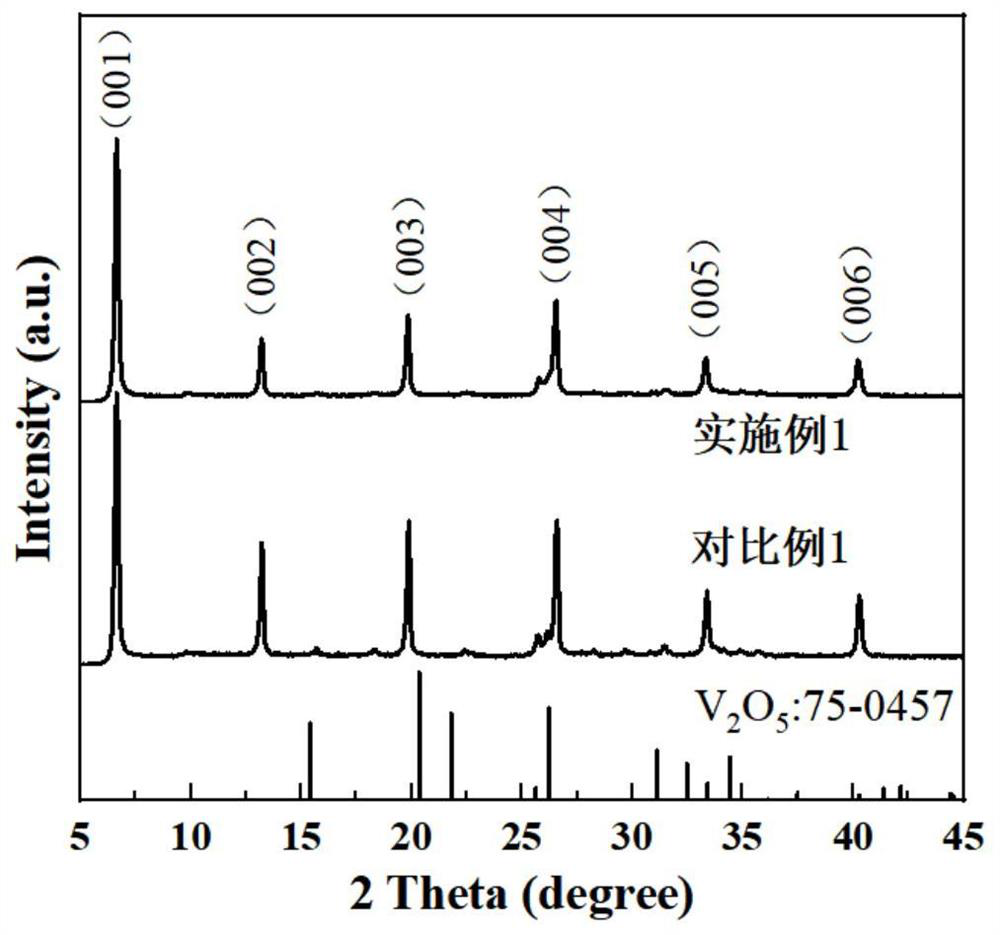

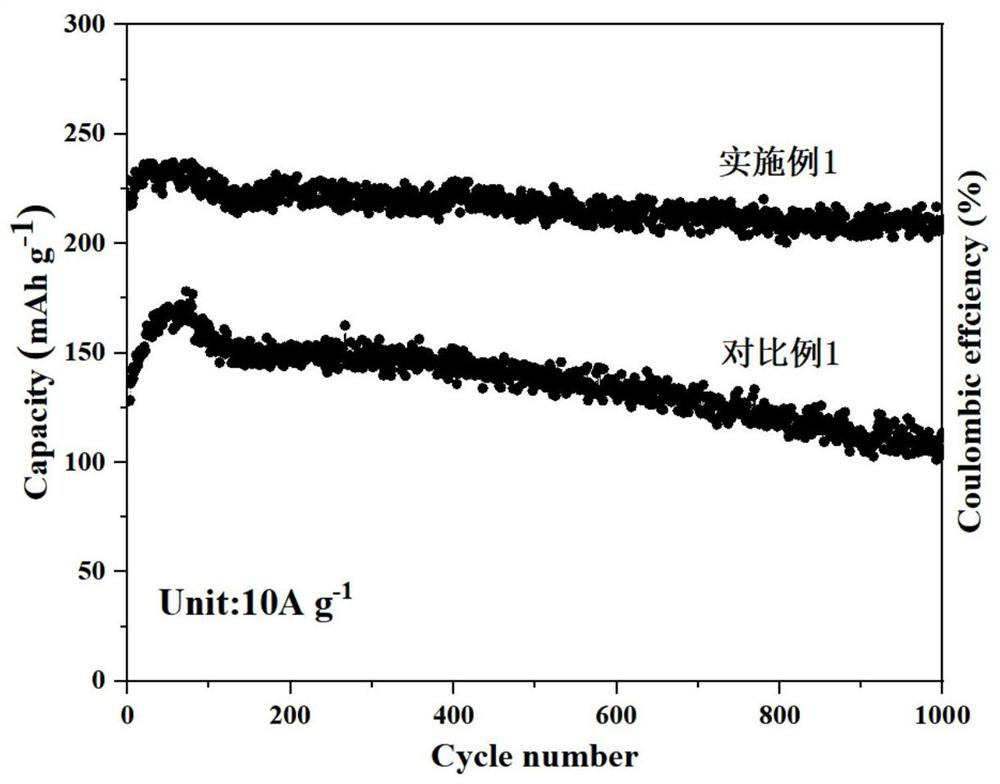

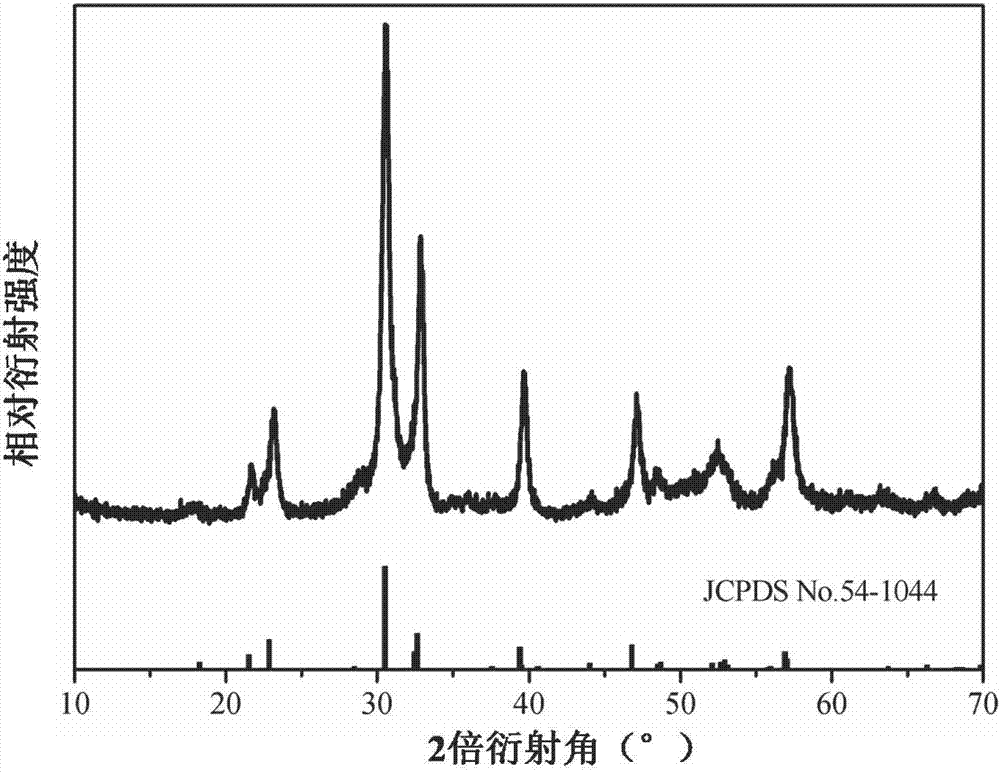

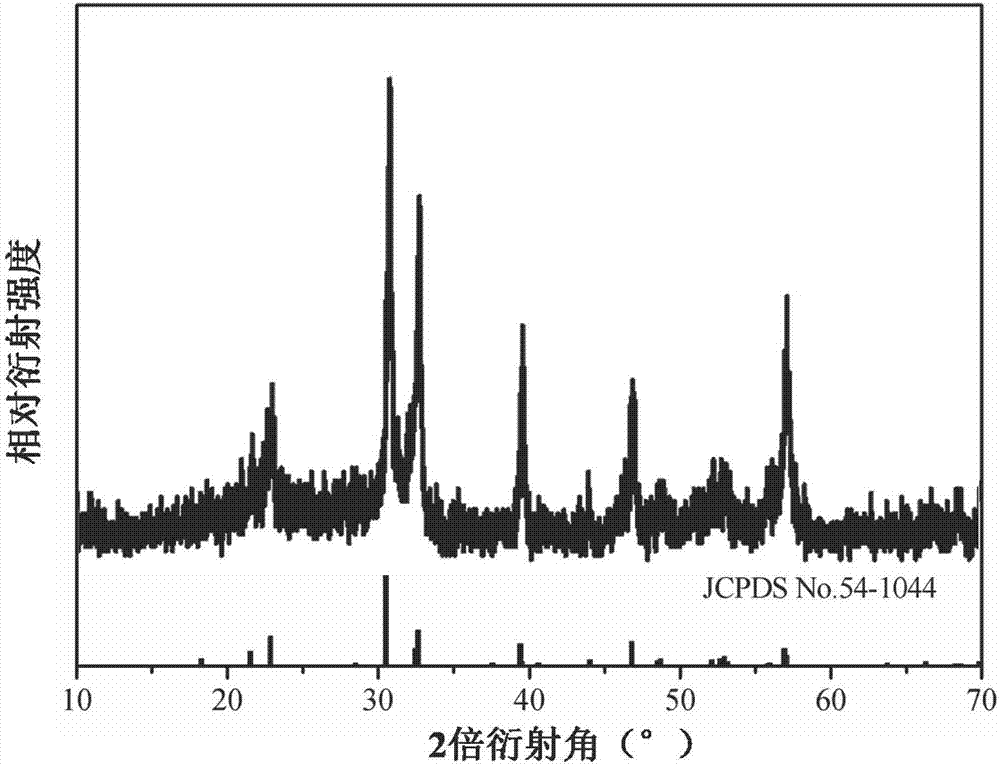

Preparation method of positive electrode material, water-based zinc ion battery positive electrode and application

PendingCN113979473AIncrease layer spacingImprove electrochemical performanceSecondary cellsPositive electrodesElectrolytic agentElectrical battery

The invention discloses a preparation method of a positive electrode material, a water-based zinc ion battery positive electrode and application. The preparation method comprises the following steps: dissolving soluble doped metal salt in water, and uniformly stirring; meanwhile, uniformly stirring with a V2O5 aqueous solution added with an H2O2 solution, carrying out heat preservation treatment on the stirred liquid, cooling to room temperature, and then centrifugally washing and drying; and mixing a dried solid with a conductive agent and a binder to form positive electrode slurry, coating the positive electrode slurry to form a pole piece, drying the pole piece, and finally assembling high-purity zinc foil, 3mol L <-1 > Zn (CF3SO3) 2 or ZnSO4 aqueous electrolyte and a glass microfiber diaphragm or chemical analysis filter paper into the water-based zinc ion battery. The positive electrode material prepared on the basis of the preparation method shows excellent stability and relatively high reversible capacity in an electrochemical testing process, and has relatively great application potential.

Owner:XI AN JIAOTONG UNIV

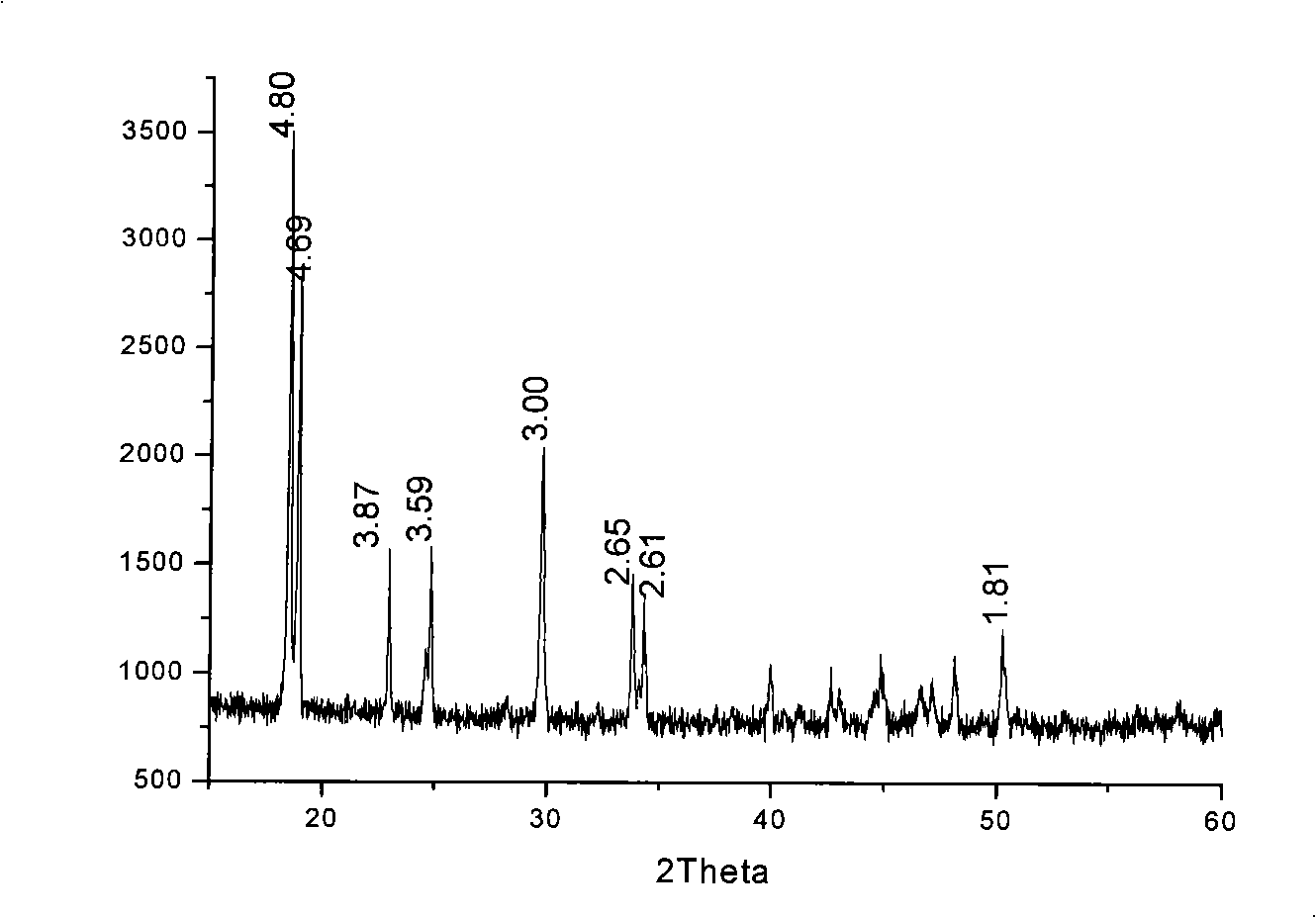

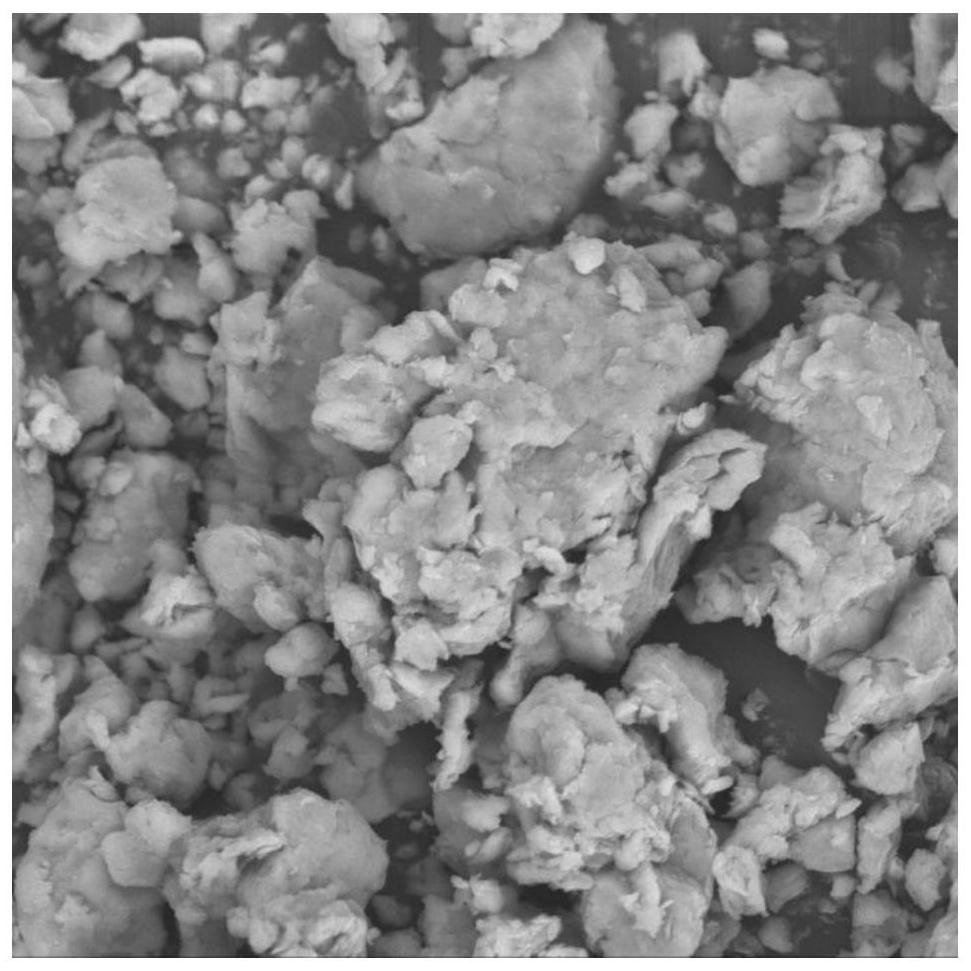

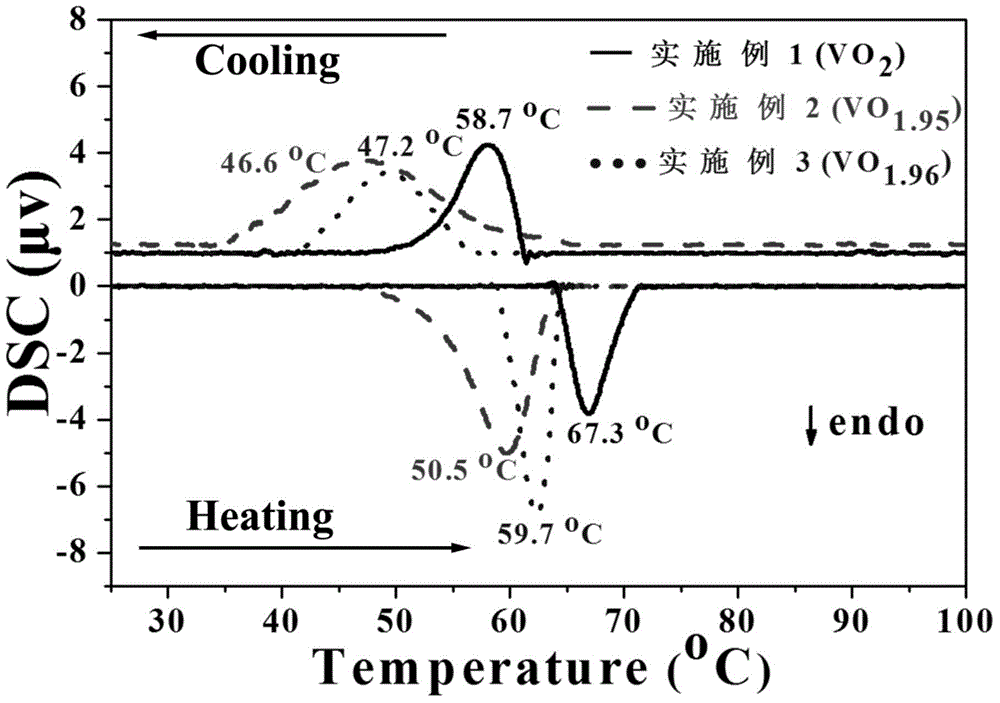

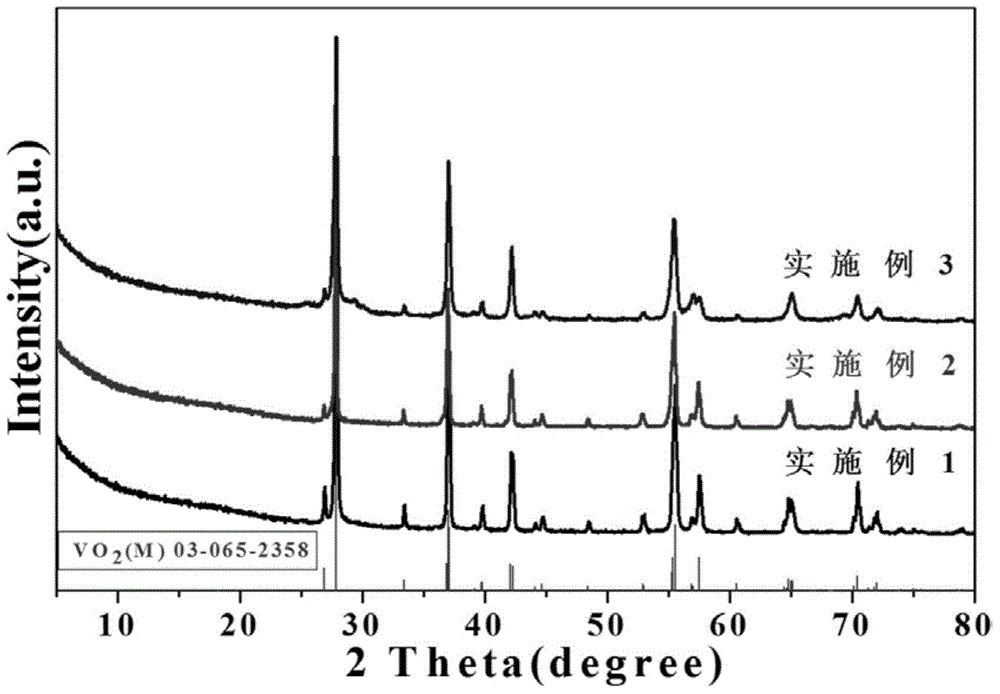

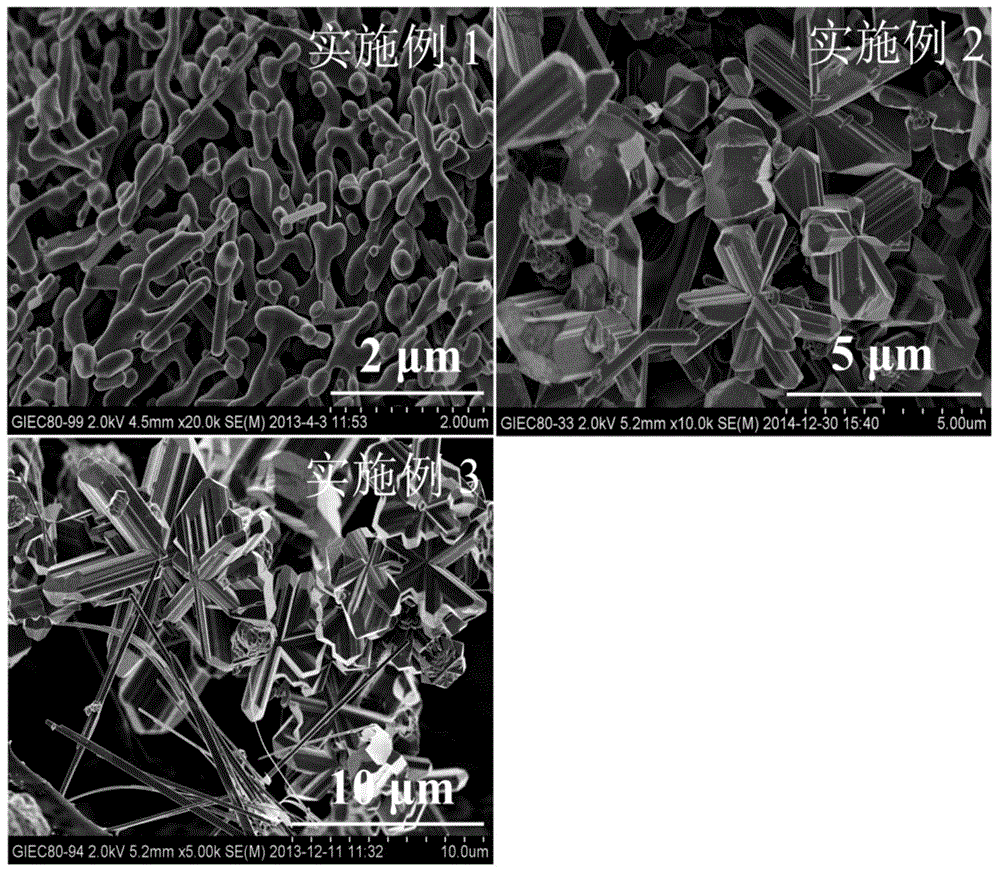

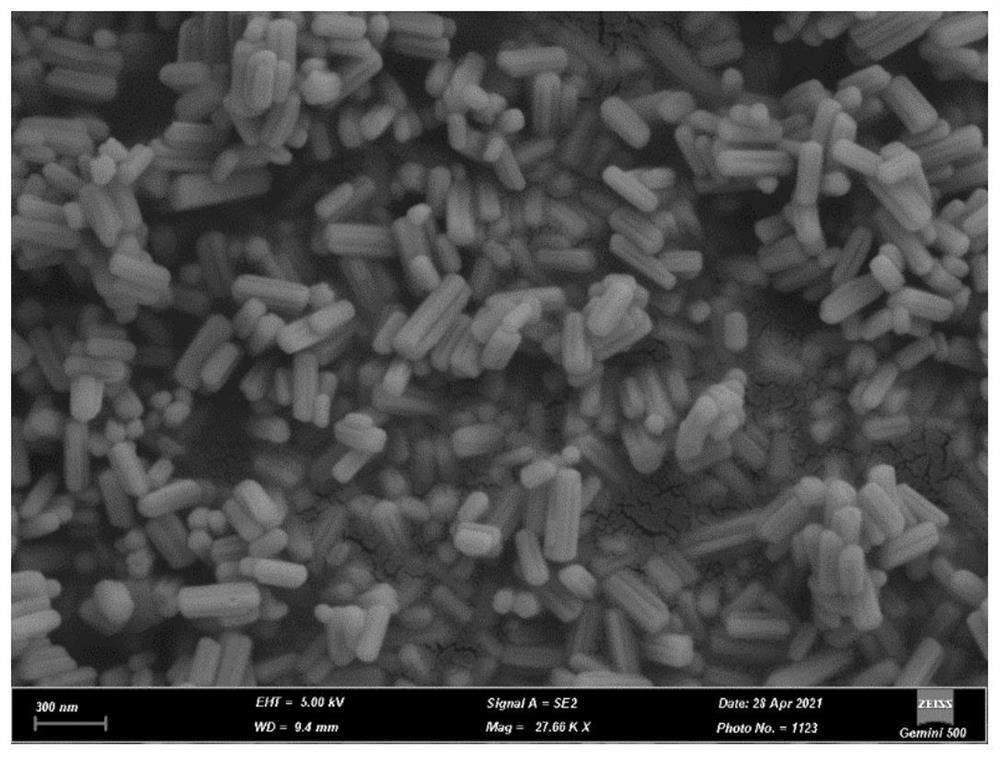

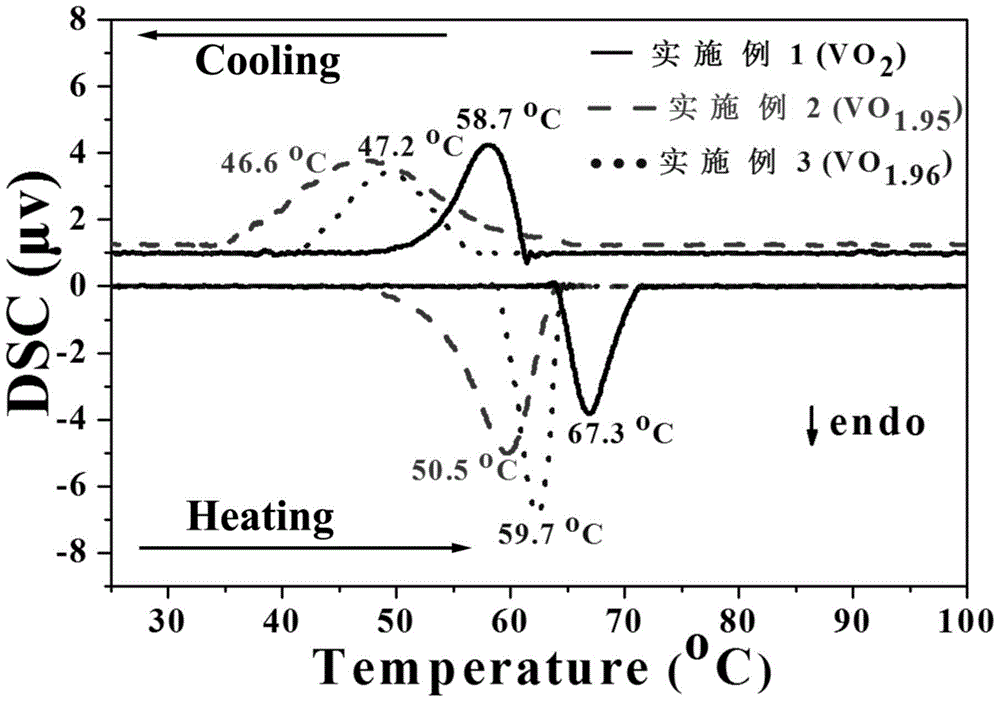

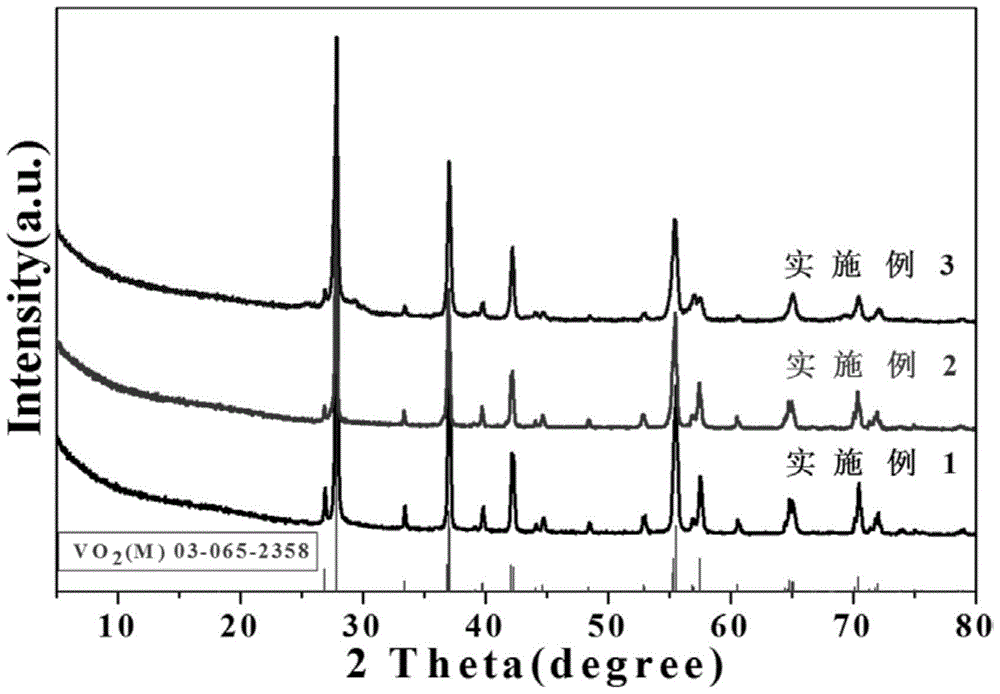

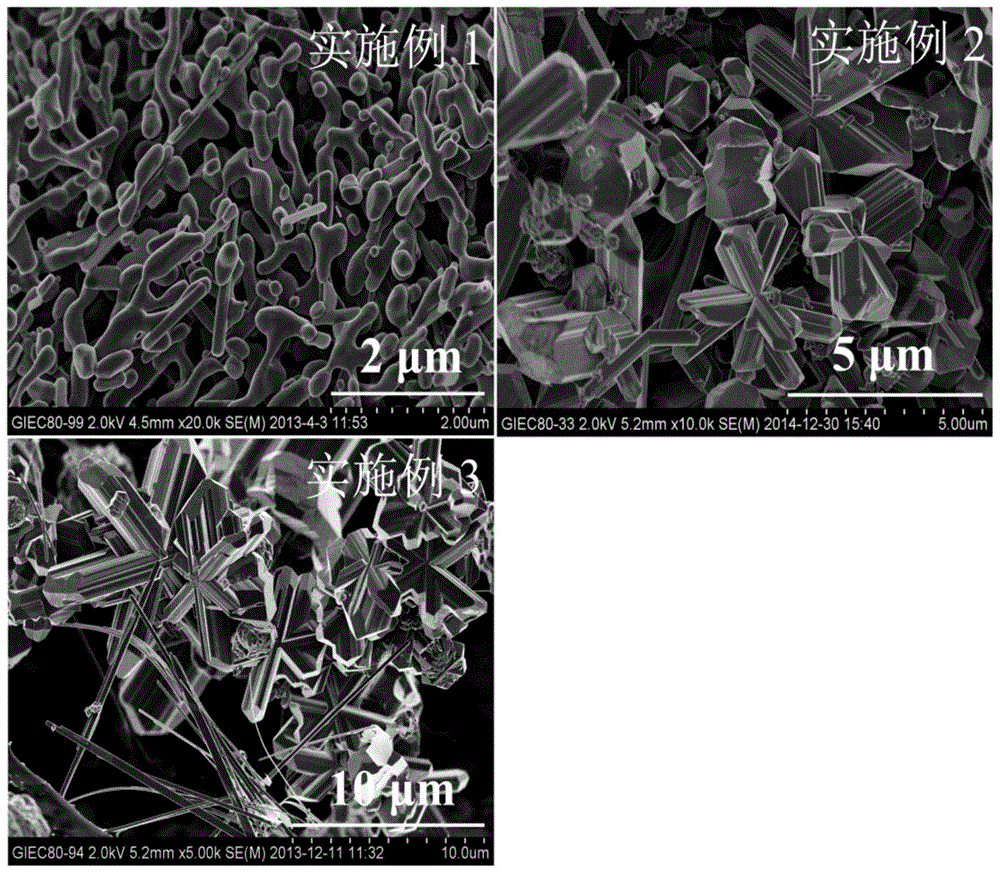

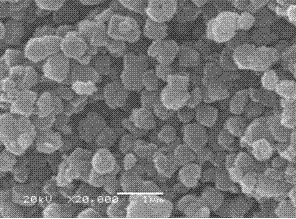

Preparation method for non-stoichiometric ratio type nanometer VO2-x powder for regulating and controlling phase transition temperature

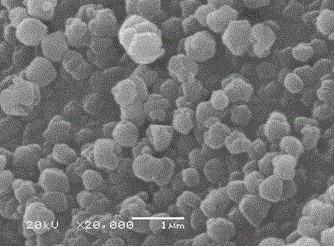

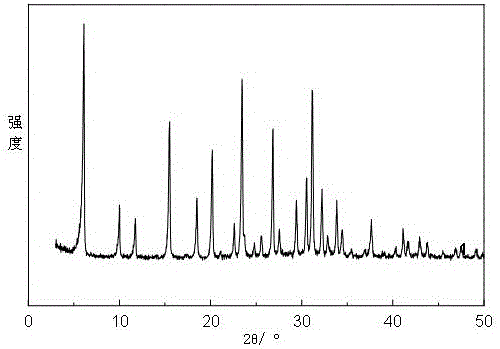

InactiveCN104817113AGood phase change performanceDoes not destroy the crystal structureMaterial nanotechnologyVanadium oxidesIonVanadium dioxide

The invention discloses a preparation method for non-stoichiometric ratio type nanometer VO2-x powder for regulating and controlling phase transition temperature. A target product is obtained through carrying out hydrothermal reaction and annealing treatment on a precursor made of oxalic acid, de-ionized water and vanadium source, the stoichiometric ratio of the product is controllable (x=0-0.05), the phase change temperature can be regulated in the range of Tc=63.0-53.5 degrees centigrade, and the material is more excellent in phase change performance and better for manufacturing a thermochromic smart window, a field effect transistor and the like. The preparation method for the non-stoichiometric ratio type nanometer VO2-x powder for regulating and controlling the phase transition temperature is short in production period, simple in technique, moderate in reaction condition, environmental friendly, low in cost and suitable for large-scale production; the prepared powder can be prepared into a piece of large VO2-x film with adjustable phase change temperature through combining with a powder film forming technology; the preparation method is good for breaking through the application bottleneck of a vanadium dioxide smart window.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

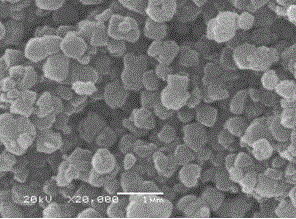

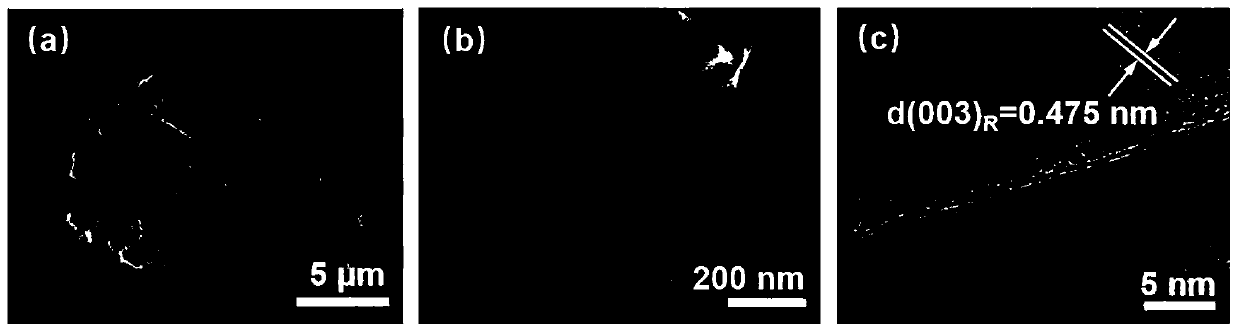

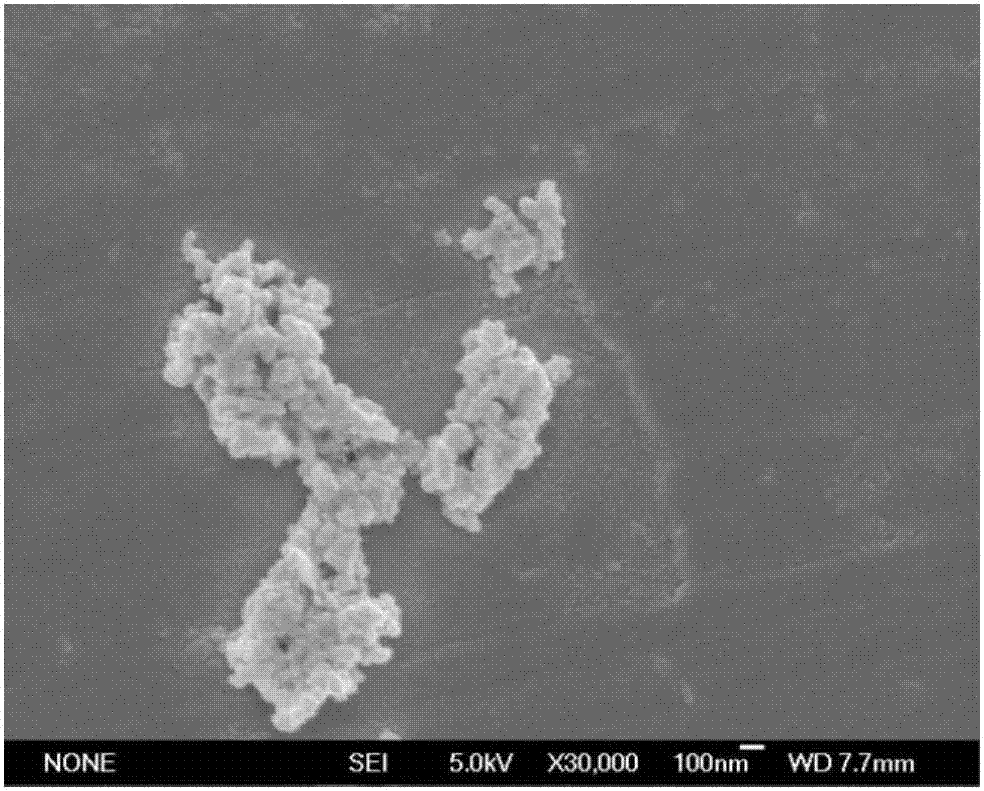

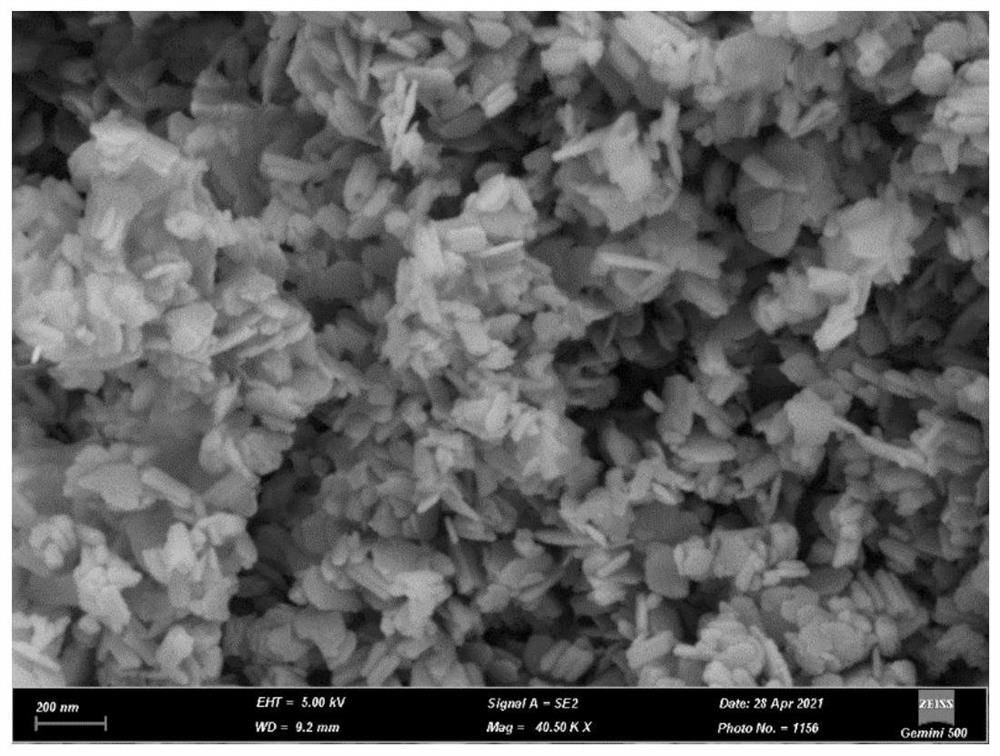

Method for improving bismuth ferrotitanium oxide nano-powder aggregation

ActiveCN107140690AEasy reunionDoes not destroy the crystal structureMaterial nanotechnologyIron compoundsFreeze-dryingCentrifugation

The invention provides a method for improving bismuth ferrotitanium oxide nano-powder aggregation. The method comprises the steps that 1, bismuth ferrotitanium oxide nano-powder and acid liquor are mixed, and suspension is obtained; 2, the suspension is subjected to sealing standing or sealing stirring, and mixed liquor is obtained; 3, the mixed liquor is subjected to ultrasonic dispersion, and dispersion liquid is obtained; 4, the dispersion liquid is subjected to centrifugation, washing and freeze drying, and a dispersed product is obtained. By means of the method, the bismuth ferrotitanium oxide powder aggregation problem can be effectively solved, the crystal structure and morphology of bismuth ferrotitanium oxide particles cannot be destroyed, and the bismuth ferrotitanium oxide nano particles good in monodispersity can be obtained.

Owner:UNIV OF SCI & TECH OF CHINA

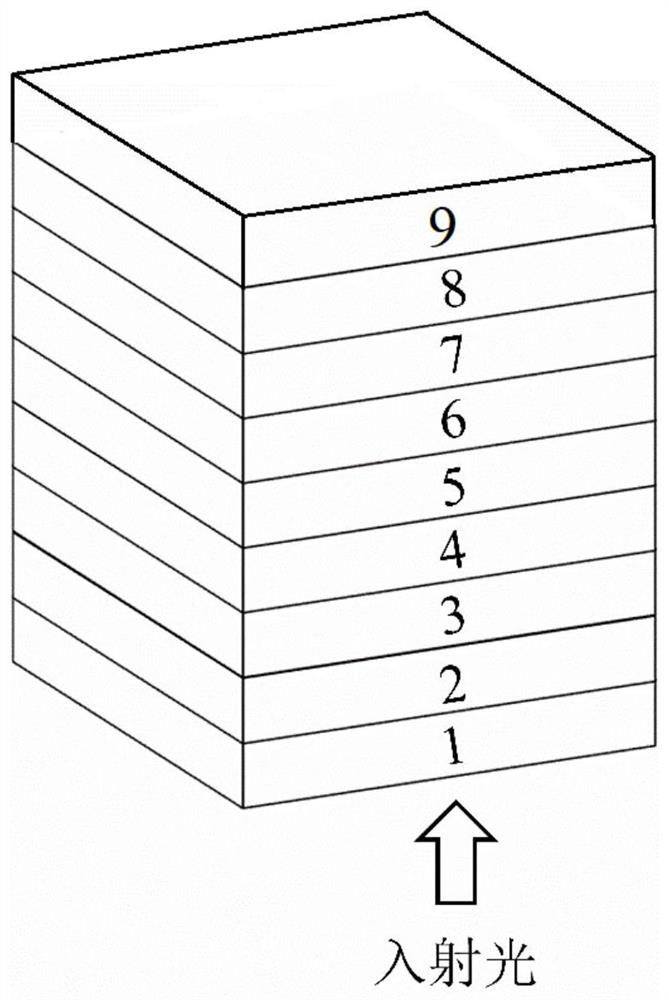

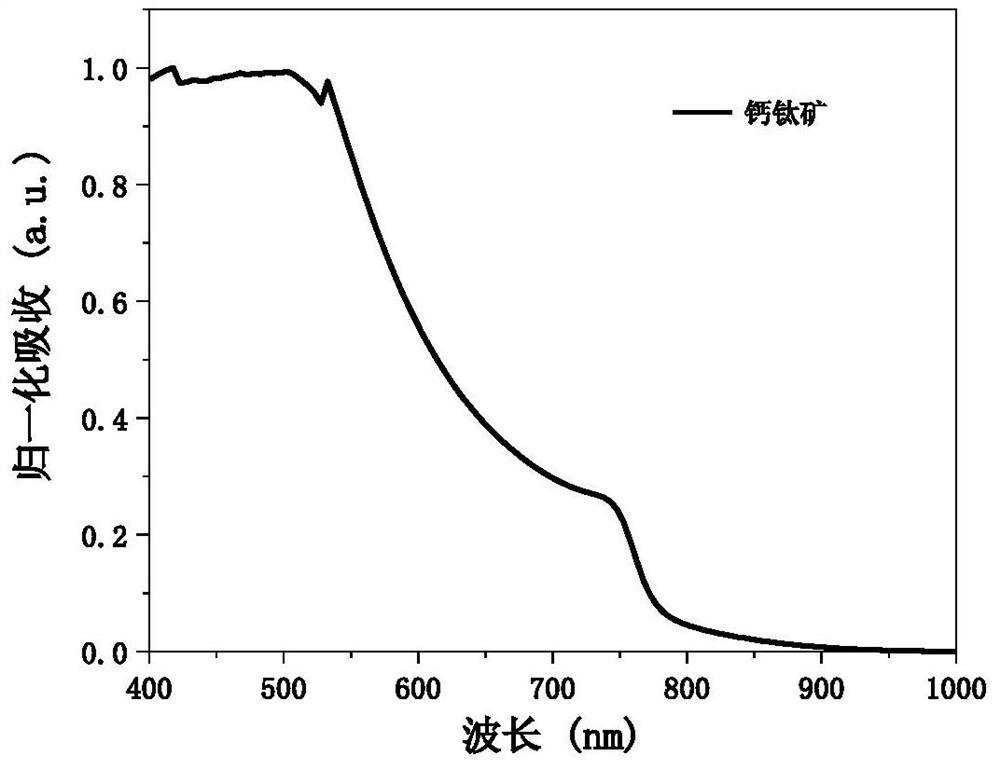

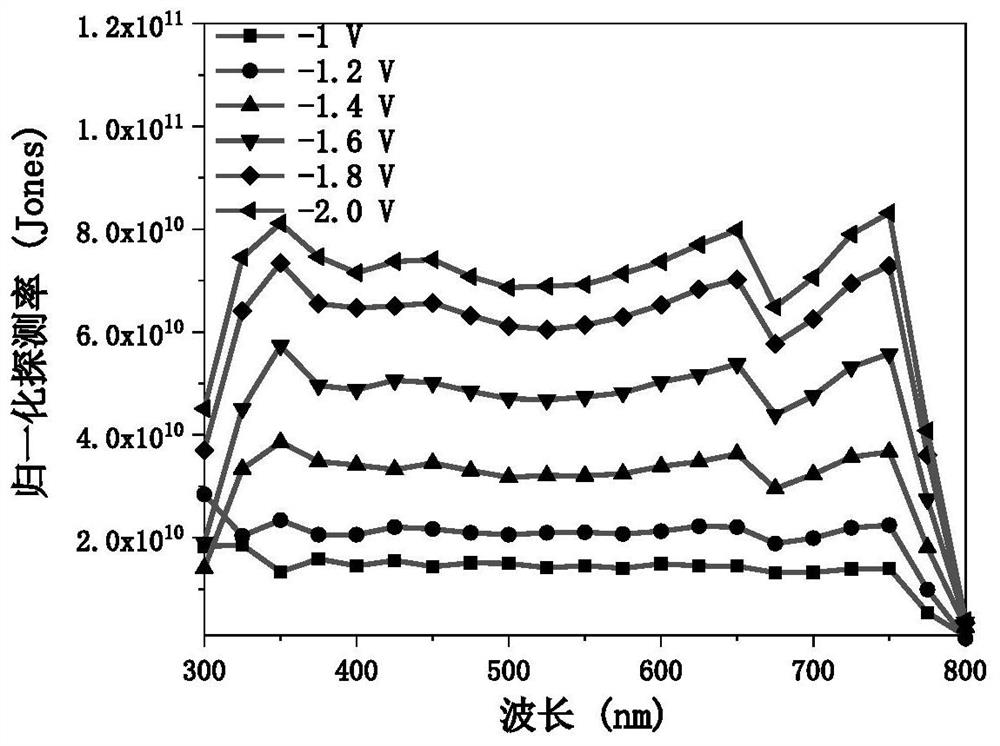

Multiplying perovskite-organic composite photoelectric detector and preparation method thereof

InactiveCN112670413AImprove detection rateSimplify environmental conditions and processesSolid-state devicesSemiconductor/solid-state device manufacturingPhysicsElectron capture

The invention discloses a multiplication type perovskite organic composite photoelectric detector and a preparation method thereof. The device structurally comprises a transparent substrate, an anode, a hole transport layer, a perovskite layer, a spacer layer, an electron transport layer, an electron capture layer, a hole transport side and a metal cathode in sequence, wherein the perovskite layer is a perovskite thin film prepared by a spin-coating soaking dynamic spin-coating method, the spacer layer is a blending layer of TAPC and C60 or C70, and the electron capture layer is a blending layer of MoO3 and C60 or C70. According to the invention, the electron capture layer is evaporated on the perovskite layer, the damage to the perovskite film is reduced while the photomultiplication effect is obtained by using the electron capture induced hole tunneling injection mechanism, and the perovskite material does not need to be prepared in a glove box, so the application of the perovskite material in the direction of a photoelectric detector is expanded.

Owner:SOUTH CHINA UNIV OF TECH

Treatment method for regulating and controlling morphology and particle size of oxysulfide fluorescent powder through laser irradiation

ActiveCN113528139AGuaranteed contentImprove luminosityNanoopticsLuminescent compositionsSuspended particlesFluorescence

The invention discloses a treatment method for regulating and controlling morphology and particle size of oxysulfide fluorescent powder through laser irradiation, and belongs to the field of photoelectric materials. A precursor is prepared by adopting a solvothermal method, and the magneton-shaped Gd2O2S: Tb single crystal fluorescent powder with high fluorescence property is prepared by calcining the precursor in a sulfur-containing atmosphere, and then irradiating suspended particles of the fluorescent powder by using laser, thereby regulating and controlling the morphology and the particle size of the fluorescent powder on the basis of ensuring the crystallization property. The method is characterized in that (1) the magneton-shaped Gd2O2S: Tb single crystal fluorescent powder is obtained through a solvothermal method and a calcination mode in a sulfur-containing atmosphere; and (2) non-focused laser is introduced, and laser irradiation is performed on the fluorescent powder suspended particles under a stirring condition. The fluorescent powder is irradiated by laser, the regulation and control process is efficient, rapid, green and environment-friendly, other impurities are not introduced, the size and morphology of the fluorescent powder are controllable, and the surface is free of ligand and high in modifiability.

Owner:UNIV OF SCI & TECH BEIJING

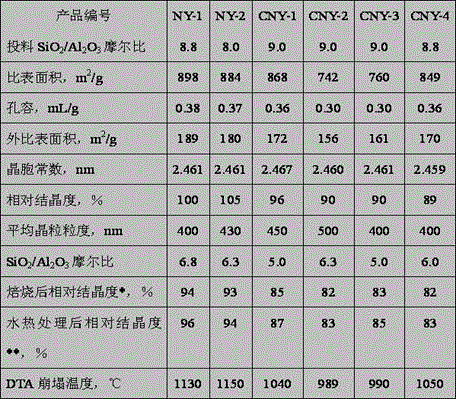

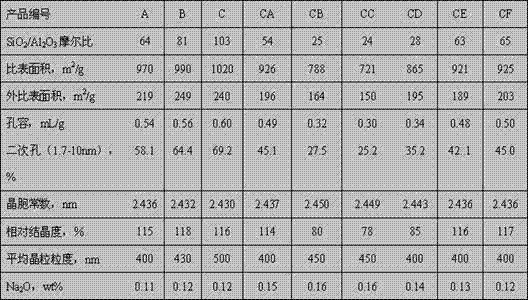

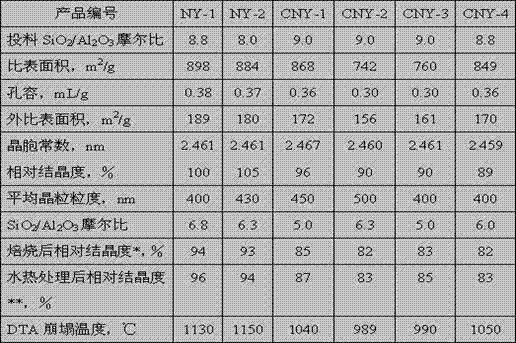

Modification method for small-grain NaY type molecular sieve

ActiveCN104828840AImprove stabilityStability is not affectedFaujasite aluminosilicate zeoliteMolecular sieveCrystallinity

The invention discloses a modification method for a small-grain NaY type molecular sieve. According to the method, a NaY type molecular sieve raw material with a high silica-alumina ratio, a high degree of crystallization and good stability is employed and successively undergoes alkali washing, ammonium exchange, aluminum removal and silicon supplement, hydro-thermal treatment and treatment with a mixed solution of acid and an ammonium salt; and the obtained small-grain Y type molecular sieve has a high SiO2 / Al2O3 mol ratio and a high proportion of secondary pores, retains the stability of a Y type molecular sieve and has a high specific surface area and a high degree of crystallization. The small-grain Y type molecular sieve prepared in the invention is applicable as a cracking component for a hydrocracking catalyst used for high and medium oil and enables the hydrocracking catalyst to have good activity, medium oil selectivity and product properties.

Owner:CHINA PETROLEUM & CHEM CORP +1

A method for preparing nano-titanium dioxide with high photocatalytic activity by using waste wool

ActiveCN105728052BCause secondary pollutionSimple preparation processOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationActive agentSurface-active agents

Owner:XI'AN POLYTECHNIC UNIVERSITY

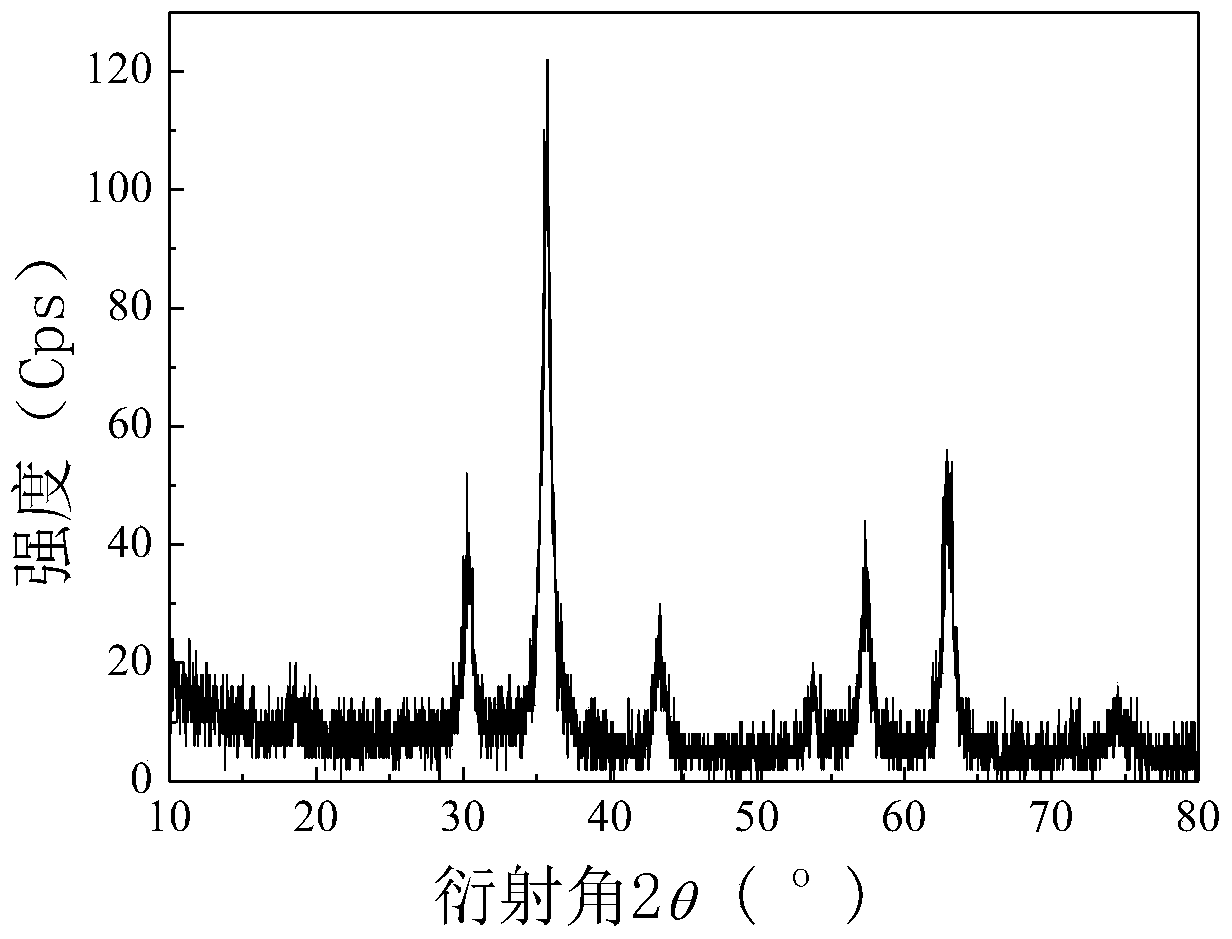

Small-grain Y-type molecular sieve and preparation method thereof

ActiveCN104591209BImprove stabilityStability is not affectedFaujasite aluminosilicate zeoliteMolecular sieveNaphtha

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of small-grain Y-type molecular sieve

ActiveCN104828838BImprove stabilityStability is not affectedMolecular sieve catalystsFaujasite aluminosilicate zeoliteMolecular sieveCrystallinity

The invention discloses a preparation method for a small-grain Y type molecular sieve. According to the method, a NaY type molecular sieve raw material with a high silica-alumina ratio, a high degree of crystallization and good stability is employed and successively undergoes ammonium exchange, primary hydro-thermal treatment, treatment with an alkali-containing solution, secondary hydro-thermal treatment and treatment with a mixed solution of acid and an ammonium salt; and the obtained small-grain Y type molecular sieve has a high SiO2 / Al2O3 mol ratio and a high proportion of secondary pores, retains the stability of a Y type molecular sieve and has a high specific surface area and a high degree of crystallization. The small-grain Y type molecular sieve prepared in the invention is applicable as a cracking component for a hydrocracking catalyst used for high and medium oil and enables the hydrocracking catalyst to have good activity, medium oil selectivity and product properties.

Owner:CHINA PETROLEUM & CHEM CORP +1

A non-stoichiometric nanovo for controlling phase transition temperature 2-x Preparation method of powder

InactiveCN104817113BGood phase change performanceDoes not destroy the crystal structureMaterial nanotechnologyVanadium oxidesVanadium dioxideField-effect transistor

The invention discloses a preparation method for non-stoichiometric ratio type nanometer VO2-x powder for regulating and controlling phase transition temperature. A target product is obtained through carrying out hydrothermal reaction and annealing treatment on a precursor made of oxalic acid, de-ionized water and vanadium source, the stoichiometric ratio of the product is controllable (x=0-0.05), the phase change temperature can be regulated in the range of Tc=63.0-53.5 degrees centigrade, and the material is more excellent in phase change performance and better for manufacturing a thermochromic smart window, a field effect transistor and the like. The preparation method for the non-stoichiometric ratio type nanometer VO2-x powder for regulating and controlling the phase transition temperature is short in production period, simple in technique, moderate in reaction condition, environmental friendly, low in cost and suitable for large-scale production; the prepared powder can be prepared into a piece of large VO2-x film with adjustable phase change temperature through combining with a powder film forming technology; the preparation method is good for breaking through the application bottleneck of a vanadium dioxide smart window.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Hydrocracking catalyst carrier and preparation method thereof

ActiveCN104588121AHigh ratio of silicon to aluminumHigh crystallinityCatalyst carriersMolecular sieve catalystsMolecular sieveNaphtha

The invention discloses a hydrocracking catalyst carrier and a preparation method thereof. The catalyst carrier is composed of a small-grain Y type molecular sieve, amorphous silica-alumina and alumina. According to the preparation method, the small-grain Y type molecular sieve with the characteristics of proper dealumination degree, good crystallinity retentivity and well-developed secondary pores is used as an acid component; and when the small-grain Y type molecular sieve and the amorphous silica-alumina are cooperatively used for preparing a hydrocracking catalyst, the hydrocracking catalyst has the advantages of good activity, heavy naphtha selectivity and superior product quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method for small-grain Y type molecular sieve

ActiveCN104828838AImprove stabilityStability is not affectedMolecular sieve catalystsFaujasite aluminosilicate zeoliteMolecular sieveCrystallinity

The invention discloses a preparation method for a small-grain Y type molecular sieve. According to the method, a NaY type molecular sieve raw material with a high silica-alumina ratio, a high degree of crystallization and good stability is employed and successively undergoes ammonium exchange, primary hydro-thermal treatment, treatment with an alkali-containing solution, secondary hydro-thermal treatment and treatment with a mixed solution of acid and an ammonium salt; and the obtained small-grain Y type molecular sieve has a high SiO2 / Al2O3 mol ratio and a high proportion of secondary pores, retains the stability of a Y type molecular sieve and has a high specific surface area and a high degree of crystallization. The small-grain Y type molecular sieve prepared in the invention is applicable as a cracking component for a hydrocracking catalyst used for high and medium oil and enables the hydrocracking catalyst to have good activity, medium oil selectivity and product properties.

Owner:CHINA PETROLEUM & CHEM CORP +1

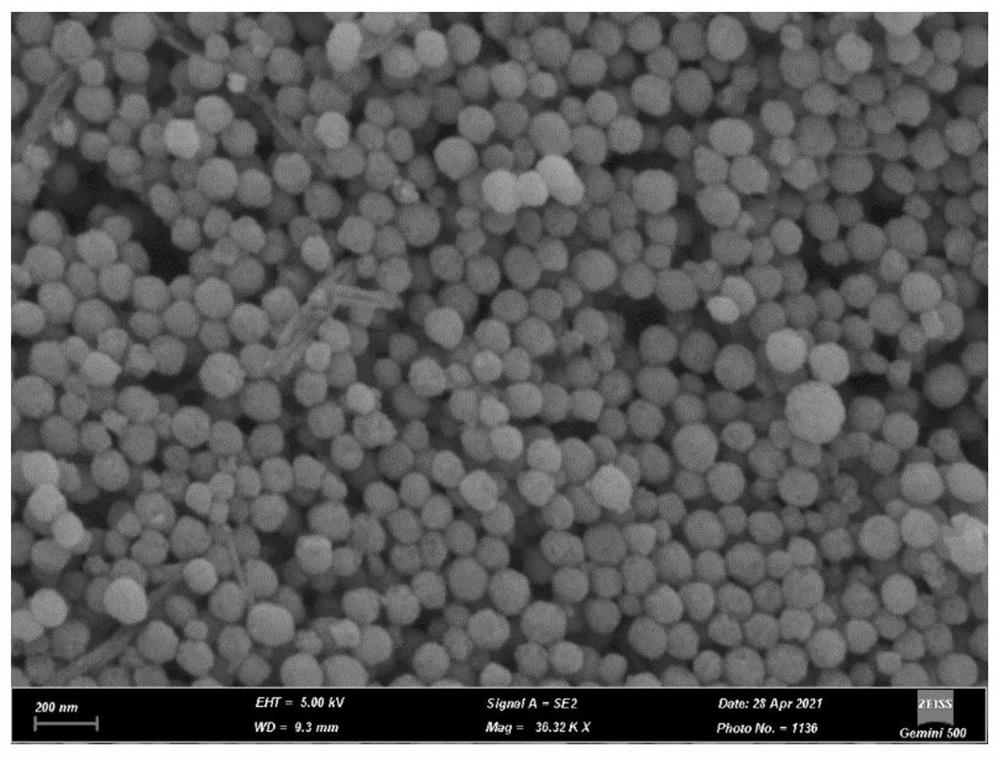

A method for modifying magnetic nano-ferric oxide based on wool fiber

ActiveCN105498717BFully hydrolyzedUniform hydrolysisOther chemical processesWater contaminantsOrganic filmCrystal structure

The invention discloses a method for carrying out magnetic nano ferroferric oxide modification based on wool fibers. Organic degradation liquid containing rich amino acid is prepared and then added into a ferroferric oxide precursor solution, nano ferroferric oxide crystallization and settling are carried out, and finally modified nano ferroferric oxide is obtained through filtering, washing and drying. By adding a certain amount of wool fiber degradation liquid, hematite ferroferric oxide nanopaticles for wrapping organic ingredients can be prepared, the clustering phenomenon of generated magnetic nano ferroferric oxide can be avoided, the particle size is small, the ferroferric oxide is uniformly distributed, damage to the crystal structure of ferroferric oxide can be avoided, an organic film wrapped by magnetic nanopaticles on the surface can achieve certain thickness, and combination is firm; meanwhile, ferroferric oxide can be prevented from being oxidized, the adsorption performance on heavy metal ions is good, and ferroferric oxide can be repeatedly used. The preparing method is simple, efficient and free of pollution to the environment.

Owner:XI'AN POLYTECHNIC UNIVERSITY

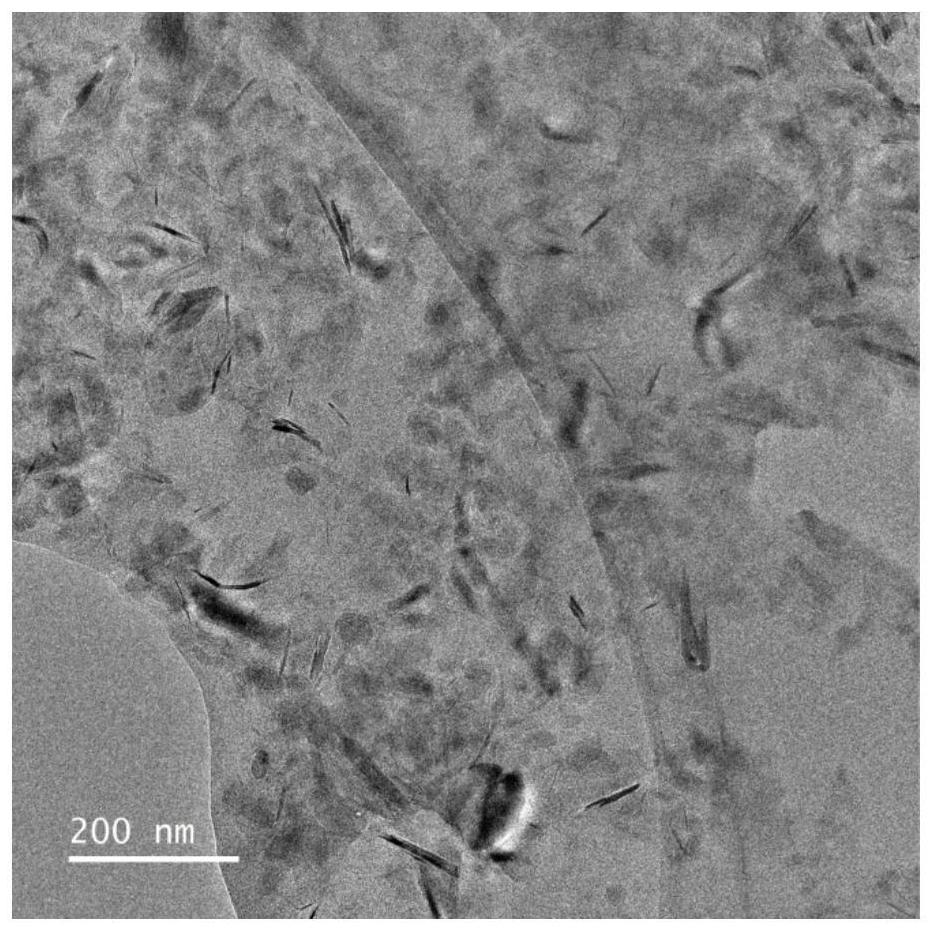

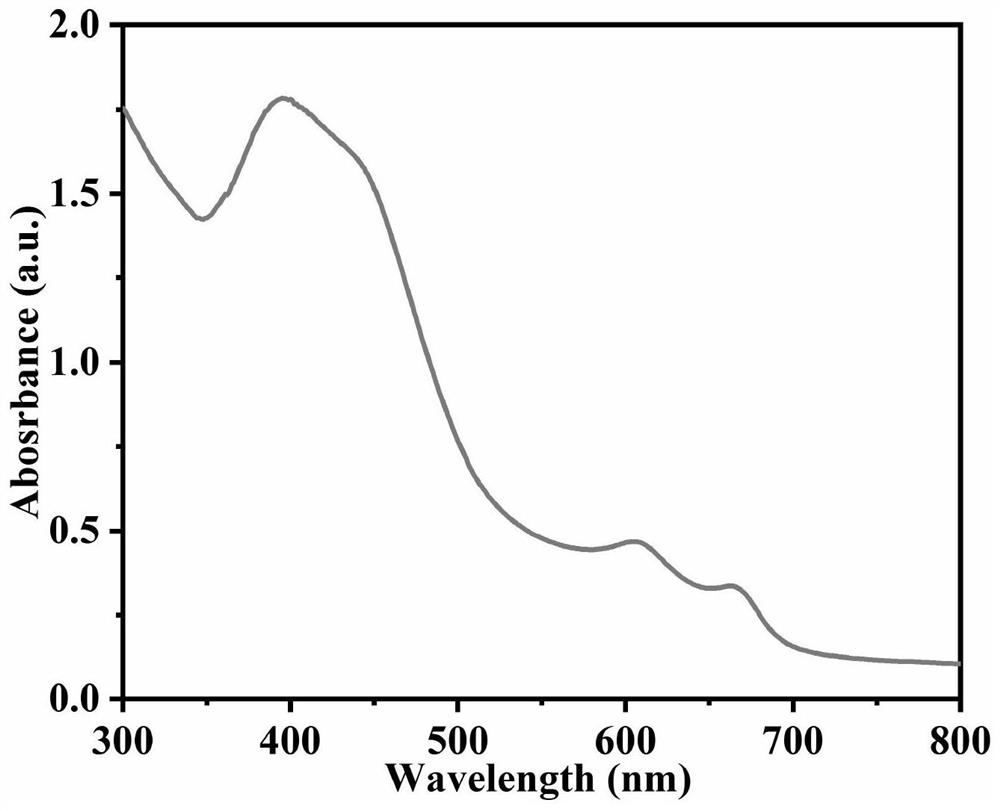

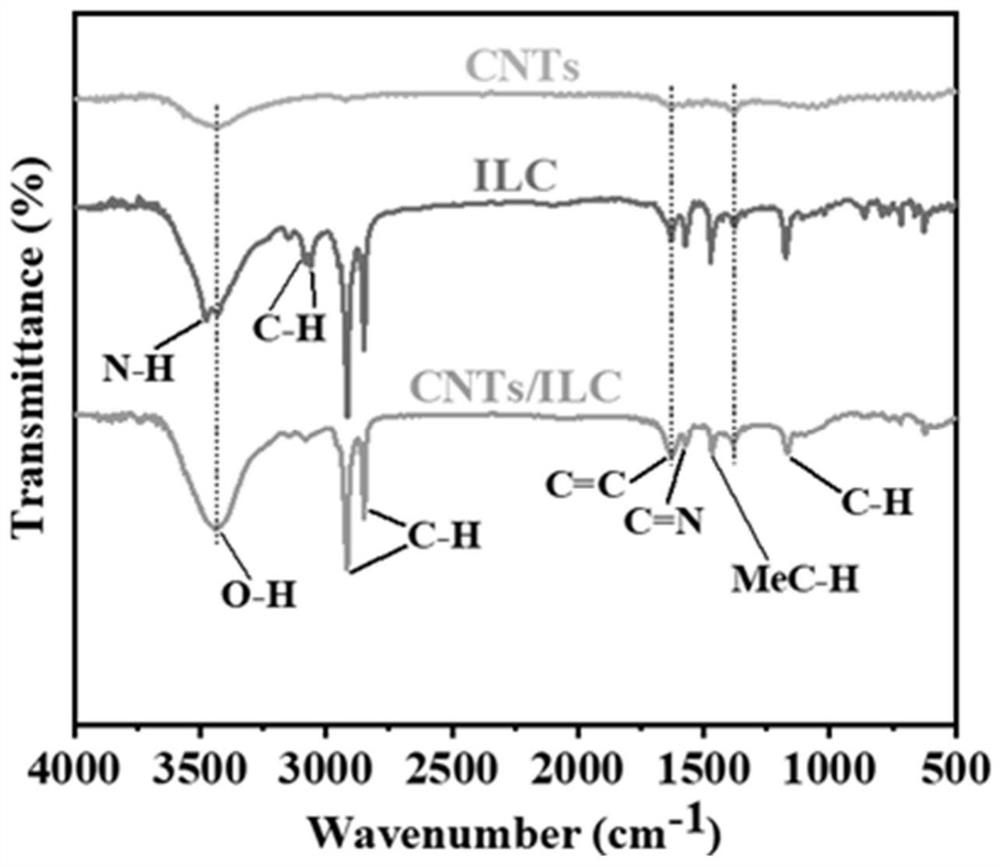

High-concentration high-dispersity ultrathin molybdenum disulfide dispersion liquid and preparation method thereof

PendingCN112591797AGood dispersionDisperse thoroughlyMolybdenum sulfidesHigh concentrationCrystal structure

The invention discloses a high-concentration high-dispersity ultrathin molybdenum disulfide dispersion liquid and a preparation method thereof. Molybdenum disulfide is used as a raw material, ionic liquid crystal is used as an auxiliary agent, the raw material and the auxiliary agent are dispersed in deionized water according to a specific proportion, and a water-based high-concentration high-dispersity ultrathin molybdenum disulfide dispersion liquid is prepared by adopting an ultrasonic mode. The prepared molybdenum disulfide dispersion liquid can be stably stored for a long time at normal temperature, the preparation process is simple and efficient, the production period is short, and the method is suitable for large-scale production; and the molybdenum disulfide prepared by adopting water as a solvent has no residual organic matters on the surface, is low in production cost, environment-friendly and high in safety coefficient, does not destroy the crystal structure of molybdenum disulfide, and has a very high application value.

Owner:SHAANXI UNIV OF SCI & TECH

Method for preparing small-grain Y-type molecular sieve

ActiveCN104828839BImprove stabilityStability is not affectedMolecular sieve catalystsMolecular sieveCrystallinity

The invention discloses a preparation method of a small-grain Y-type molecular sieve. The method adopts NaY type molecular sieve raw material with high silicon-aluminum ratio, high crystallinity and good stability, and sequentially undergoes alkali washing, ammonium exchange, dealumination of silicon, hydrothermal treatment, and treatment with a mixed solution of acid and ammonium salt to obtain The small-grain Y-type molecular sieves obtained higher SiO 2 / A1 2 o 3 While the molar ratio is high, the proportion of secondary pores is high, and the stability of the Y-type molecular sieve is maintained. The molecular sieve has a high specific surface area and a high crystallinity. The Y-type molecular sieve obtained by the invention is suitable as a cracking component of a hydrocracking catalyst for medium oil, and can make the catalyst have good activity, medium oil selectivity and excellent product properties.

Owner:CHINA PETROLEUM & CHEM CORP +1

Modification method of small grain nay type molecular sieve

ActiveCN104591211BImprove stabilityStability is not affectedFaujasite aluminosilicate zeoliteMolecular sieveNaphtha

The invention discloses a modification method for a small-grain NaY molecular sieve. According to the method, an NaY molecular sieve with a high Si / Al ratio, high crystallinity and good stability is used as a raw material, caustic washing, ammonium exchange, hydrothermal treatment and treatment with a mixed solution of acid and ammonium salt are successively carried out, so the obtained small-grain NaY molecular sieve has a higher SiO2 / Al2O3 molar ratio and higher proportion of secondary pores, maintains the stability of the NaY molecular sieve, and has a great specific surface area and higher crystallinity. The small-grain NaY molecular sieve prepared in the invention is applicable as a cracking component of a light oil type hydrocracking catalyst and enables the catalyst to have good activity, heavy naphtha selectivity and excellent product nature.

Owner:CHINA PETROLEUM & CHEM CORP +1

The preparation method of high -nickel tripular positive materials for lithium -ion batteries covered with lithium salt covered layers and lithium ion batteries

ActiveCN108206279BDoes not destroy the crystal structureInhibition formationCell electrodesSecondary cellsLithium carbonatePhysical chemistry

The present invention discloses a preparation method for the surface covered with lithium -salt overwriting on the surface of lithium -ion batteries. The steps are: (1) the ‑COONH 4 The ammonium salt and the surface of the high -nickel ternary urban material with residual lithium are mixed with solid phase, and the particle size D of ammonium salt meets 0.1 μm ≤D <2 μm;React with the lithium lithium on the surface of the high nickel ternary positive material to obtain the high nickel ternary ivory material covered with lithium salt overwrite; the chemical general formula of high nickel tripular positive materials is lini x M 1‑x O 2 Among them, 0.5 ≤ x <1, M are several types of CO, Mn, Al, and the lithium salt covered layer covered with high nickel tripular positive pole material surface is the lithium salt of the lithium salt sample containing ‑cooli functional group.The residual lithium on the surface of the ternary orthopedic material is modified to form a stable lithium salt cover layer, which can remove the surface residual lithium and cover it on the surface of the material to form a protective layer.The crystal structure of the material.

Owner:CONTEMPORARY AMPEREX TECH CO

A kind of brazing ti using al-based solder 2 alc ceramic method

InactiveCN107433401BLow melting pointLow costWelding/cutting media/materialsSoldering mediaVacuum pumpingUltimate tensile strength

The invention relates to a method for brazing Ti2AlC ceramics by Al base brazing filler metal, and aims to solve the technical problem of short service life of an existing electric contact component. The method includes the steps: first, preparing the brazing filler metal; second, assembling a Ti2AlC ceramic / brazing filler metal / Ti2AlC ceramic structural part, placing the structural part into a vacuum brazing furnace, performing vacuum pumping to reach 6.0*10<3>Pa, increasing temperature to 300 DEG C at the heating rate of 10 DEG C / min, keeping the temperature for 30min, increasing the temperature to 660-900 DEG C at the heating rate of 10 DEG C / min, keeping the temperature for 5-30min under the pressure of 0.2-1.0MPa, reducing the temperature to 300 DEG C at the cooling rate of 10 DEG C / min, performing furnace cooling and finishing brazing the Ti2AlC ceramics by the Al base brazing filler metal. By the method, a joint with an excellent mechanical property can be obtained, the shear strength of the joint is 70-120MPa, and electrical conductivity is 3.73-4.18*10<6>S / m and reaches 94% or more of the electrical conductivity of the Ti2AlC ceramics.

Owner:HARBIN INST OF TECH

High-concentration carbon nanotube slurry and preparation method thereof

PendingCN112694081AImprove securityReduce manufacturing costCarbon compoundsHigh concentrationPhysical chemistry

The invention discloses a high-concentration carbon nanotube slurry and a preparation method thereof, and solves the technical problem of poor stability of the carbon nanotube slurry in a water environment, the preparation method comprises the following steps: 1) mixing carbon nanotube powder and ionic liquid crystal in a mass ratio of (1: 1)-(5: 1), adding the mixture into deionized water, and fully stirring and uniformly mixing to obtain a mixed solution; 2) putting the mixed solution into a reaction kettle, and carrying out hydrothermal reaction at 150-250 DEG C; 3) taking out a product after the hydrothermal reaction to obtain high-concentration carbon nanotube slurry; the prepared high-concentration carbon nanotube slurry is high in concentration and good in dispersity, can be stably stored for more than 6 months for a long time under the condition of normal temperature, and has relatively high application value.

Owner:SHAANXI UNIV OF SCI & TECH

A method for modifying small-grain nay-type molecular sieves

ActiveCN104828840BImprove stabilityStability is not affectedMolecular sieve catalystsMolecular sieveCrystallinity

Owner:CHINA PETROLEUM & CHEM CORP +1

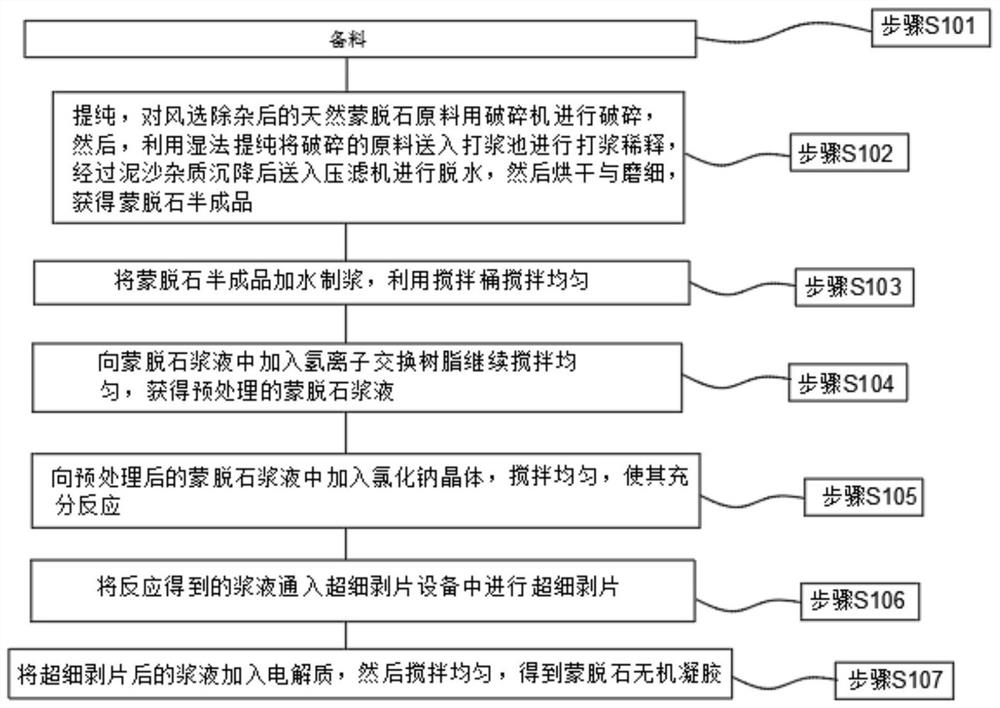

Preparation method of natural montmorillonite mineral inorganic gel

PendingCN111807381AReduce the impact of suspension stabilityDoes not destroy the crystal structureGel preparationSilicon compoundsPhysical chemistryMontmorillonite

The invention discloses a preparation method of natural montmorillonite mineral inorganic gel. The preparation method comprises the following steps: S101: material preparation: taking a natural montmorillonite raw material, water, hydrogen ion exchange resin, sodium chloride crystal and electrolyte for later use; S102, purification: crushing the natural montmorillonite raw material subjected to winnowing and impurity removal by using a crusher, then feeding the crushed raw material into a pulping tank for pulping and dilution by using wet purification, and feeding the raw material into a filter press for dehydration after sediment impurity sedimentation so as to obtain a montmorillonite semi-finished product; S103, adding water into the montmorillonite semi-finished product for pulping; S104, adding hydrogen ion exchange resin into the montmorillonite slurry; S105, adding sodium chloride crystals into the montmorillonite slurry; S106, introducing the slurry obtained by the reaction into ultrafine stripping equipment for ultrafine stripping; and S107, adding electrolyte into the slurry subjected to superfine stripping, and uniformly stirring to obtain the montmorillonite inorganic gel. The water dispersibility, the suspension stability and the thickening property of montmorillonite are effectively improved, the cost is low, and the preparation method is suitable for popularization.

Owner:内蒙古蒙兴粘土科技有限责任公司

Activation and regeneration method for metal sulfide mercury removal adsorbent

ActiveCN109092277BLow costOptimizationGas treatmentDispersed particle separationSorbentMercury adsorption

The invention relates to a method for activating and regenerating a mercury-removing adsorbent for metal sulfides. The main body of metal sulfides is moderately soaked in an activation solution composed of a divalent copper salt solution, followed by separation, cleaning and drying to complete the process. Activation of the sorbent, which is then used to adsorb mercury from the gas stream. When the adsorbent is deactivated due to adsorption saturation of mercury, the adsorbed mercury is released through heat treatment, and mercury is recovered as a resource. The heat-treated adsorbent is immersed in the activation solution again to complete the regeneration of metal sulfides. Compared with the prior art, in addition to the synthesized metal sulfide, the present invention can also directly use cheap natural metal sulfide ore as the main body of the adsorbent. The mercury adsorption performance of metal sulfides can be greatly enhanced by activation, and at the same time, the regeneration of metal sulfides after mercury adsorption can be realized. While achieving high-efficiency capture of flue gas mercury, the amount of adsorbent is greatly reduced, thereby reducing the consumption cost of adsorbent and the implementation difficulty of adsorption and mercury removal technology.

Owner:SHANGHAI JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com