The preparation method of high -nickel tripular positive materials for lithium -ion batteries covered with lithium salt covered layers and lithium ion batteries

A technology for lithium ion batteries and cathode materials, which is applied in battery electrodes, electrical components, secondary batteries, etc., can solve problems such as damage, uneven distribution of lithium precipitation, chemical delithiation, etc., and achieves simple operation, easy popularization and application, storage The effect of performance and loop performance improvements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

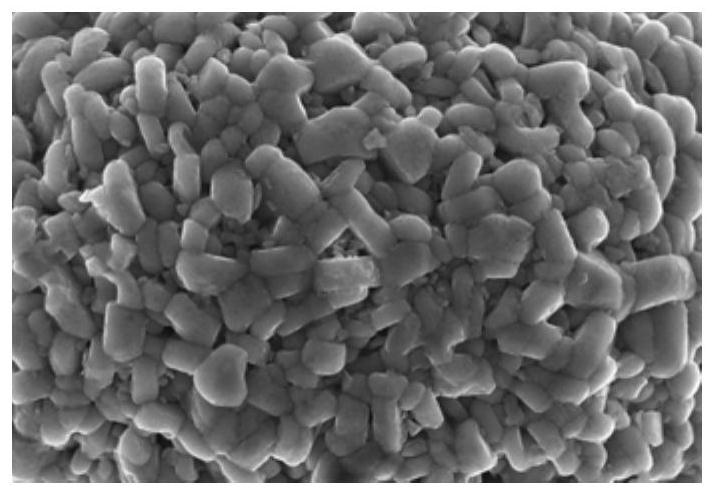

[0036] Select high nickel cathode material LiNi 0.65 Co0.15 Mn 0.15 O 2 , the ammonium salt is ammonium oxalate (NH 4 ) 2 C 2 O 4 . The residual lithium content (LiOH, Li 2 CO 3 ), according to the amount of residual lithium, the (NH) required for the complete reaction of residual lithium is calculated 4 ) 2 C 2 O 4 The theoretical amount of , where (NH 4 ) 2 C 2 O 4 The amount of addition and the amount of residual lithium on the surface (Li + ) in a molar ratio of 1:2, combining the high nickel cathode material with (NH 4 ) 2 C 2 O 4 Mix well by ball milling for 2h. Then carry out pre-reaction, pre-react at 100°C for 3h, wherein the heating rate is 5°C / min; then the temperature is raised to 300°C for sintering for 4h, the heating rate is 5°C / min, and the surface residual lithium is modified into Li 2 C 2 O 4 The high-nickel ternary cathode material for lithium-ion batteries, the thickness of the coating layer is about 100nm. Its SEM image is as figu...

Embodiment 2

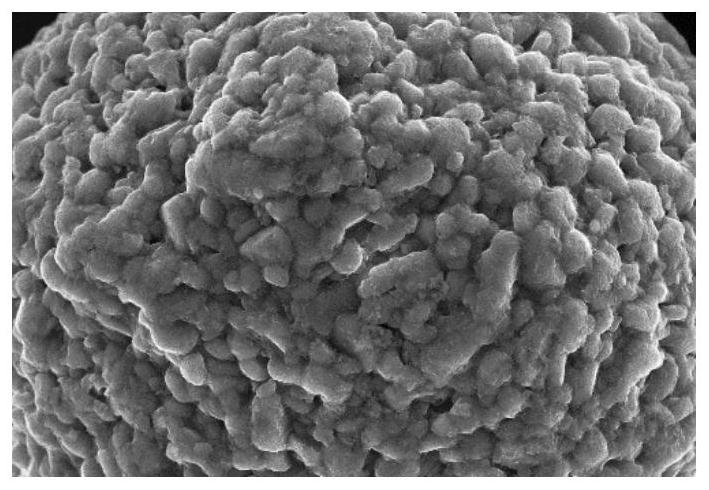

[0038] Select high nickel cathode material LiNi 0.8 Co 0.15 Al 0.05 O 2 , the ammonium salt is ammonium acetate CH 3 COONH 4 . The preparation method is the same as in Example 1, wherein CH 3 COONH 4 The amount of addition and the amount of residual lithium on the surface (Li + ) in a molar ratio of 1:1, changing the calcination parameters, pre-reacting at 90 °C for 2 h, where the heating rate is 5 °C / min; then heating to 250 °C for 2 hours, with a heating rate of 5 °C / min, to obtain Lithium modified to CH 3 COOLi's high-nickel ternary cathode material for lithium-ion batteries has a coating thickness of about 50nm.

Embodiment 3

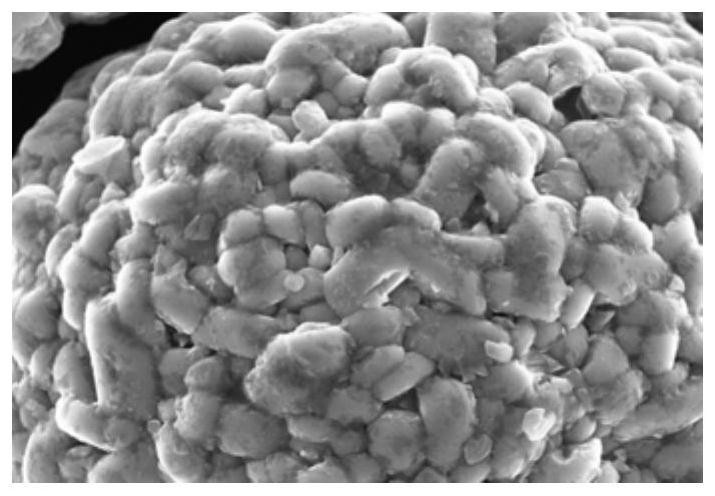

[0040] Select high nickel cathode material LiNi 0.8 Co 0.2 O 2 , the ammonium salt is ammonium citrate. The preparation method is the same as in Example 1, wherein the addition of ammonium citrate and the residual lithium amount on the surface (Li + ) in a molar ratio of 1:3, changing the calcination parameters, pre-reacting at 120 °C for 6 h, with a heating rate of 5 °C / min; then heating to 600 °C for 8 h, with a heating rate of 5 °C / min, to obtain surface residues. The thickness of the coating layer is about 300nm for the high-nickel ternary cathode material for lithium-ion batteries modified from lithium to lithium citrate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com