Preparation method of natural montmorillonite mineral inorganic gel

A technology of inorganic gel and montmorillonite, which is applied in the directions of gel preparation, inorganic chemistry, chemical instruments and methods, etc., can solve the problems of high cost, insufficiency and low benefit, and achieves low cost, simple process and improved product quality. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

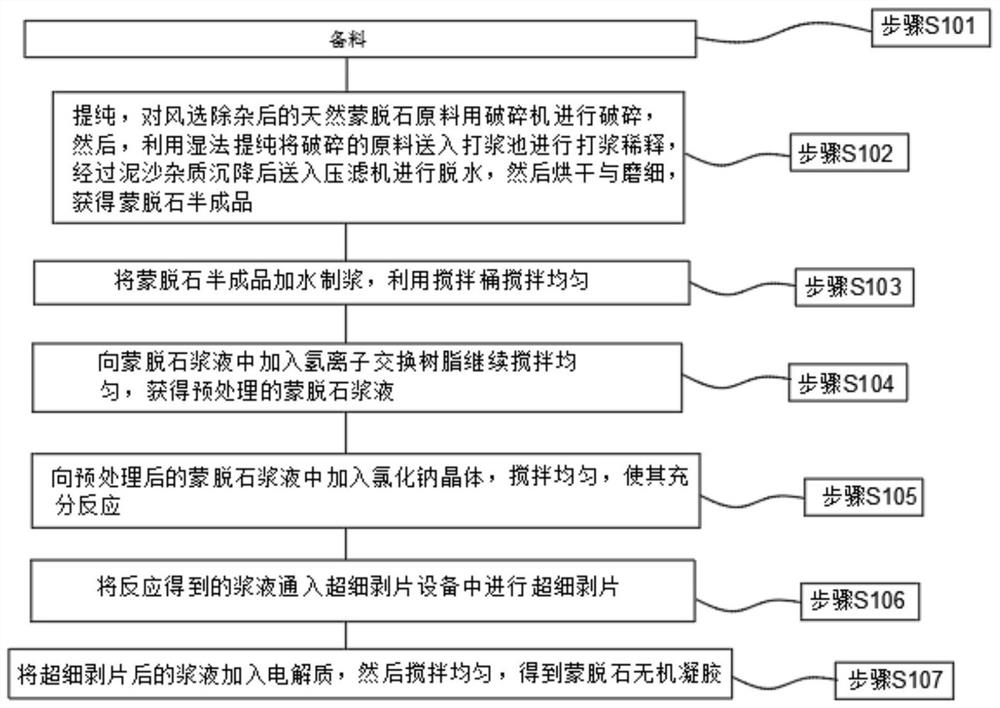

[0028] see figure 1 , the present invention provides a kind of technical scheme: a kind of preparation method of natural montmorillonite mineral inorganic gel, comprises the following steps:

[0029] Step S101: Prepare materials, take natural montmorillonite raw materials, water, hydrogen ion exchange resin, sodium chloride crystals, and electrolyte for standby;

[0030] Step S102: Purify, crush the natural montmorillonite raw material after winnowing and removing impurities with a crusher, and then use wet purification to send the crushed raw material to the beating tank for beating and dilution, and send it to the crushing tank after sedimentation and impurity settlement. Filter for dehydration, then dry and grind to obtain semi-finished montmorillonite;

[0031] Step S103: Add water to the semi-finished montmorillonite to make slurry, and stir evenly with a mixing bucket;

[0032] Step S104: adding hydrogen ion exchange resin to the montmorillonite slurry and continuing t...

Embodiment 2

[0037] see figure 1 , the present invention provides a kind of technical scheme: a kind of preparation method of natural montmorillonite mineral inorganic gel, comprises the following steps:

[0038] Step S101: Prepare materials, take natural montmorillonite raw materials, water, hydrogen ion exchange resin, sodium chloride crystals, and electrolyte for standby;

[0039] Step S102: Purify, crush the natural montmorillonite raw material after winnowing and removing impurities with a crusher, and then use wet purification to send the crushed raw material to the beating tank for beating and dilution, and send it to the crushing tank after sedimentation and impurity settlement. Filter for dehydration, then dry and grind to obtain semi-finished montmorillonite;

[0040] Step S103: Add water to the semi-finished montmorillonite to make slurry, and stir evenly with a mixing bucket;

[0041] Step S104: adding hydrogen ion exchange resin to the montmorillonite slurry and continuing t...

Embodiment 3

[0046] see figure 1 , the present invention provides a kind of technical scheme: a kind of preparation method of natural montmorillonite mineral inorganic gel, comprises the following steps:

[0047] Step S101: Prepare materials, take natural montmorillonite raw materials, water, hydrogen ion exchange resin, sodium chloride crystals, and electrolyte for standby;

[0048]Step S102: Purify, crush the natural montmorillonite raw material after winnowing and removing impurities with a crusher, and then use wet purification to send the crushed raw material to the beating tank for beating and dilution, and send it to the crushing tank after sedimentation and impurity settlement. Filter for dehydration, then dry and grind to obtain semi-finished montmorillonite;

[0049] Step S103: Add water to the semi-finished montmorillonite to make slurry, and stir evenly with a mixing bucket;

[0050] Step S104: adding hydrogen ion exchange resin to the montmorillonite slurry and continuing to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com