High-concentration carbon nanotube slurry and preparation method thereof

A carbon nanotube, high-concentration technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve problems such as poor stability of carbon nanotube slurry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The invention provides a kind of preparation method of high-concentration carbon nanotube slurry, comprising the following steps:

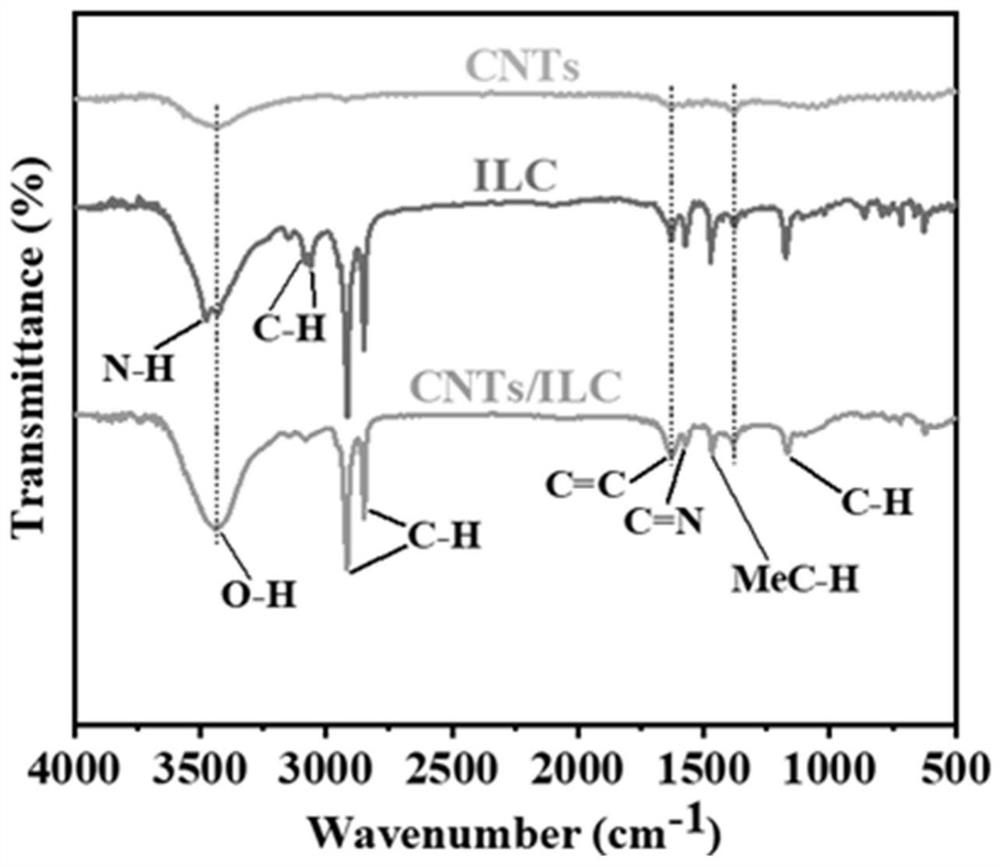

[0023] 1) Mix carbon nanotube powder and ionic liquid crystal with a mass ratio of (1:1) to (5:1) and add them into deionized water, stir and mix well to obtain a mixed solution; preferably, the particle size of the carbon nanotube powder 2-5nm; ionic liquid crystals include imidazole ionic liquid crystals; further preferably, ionic liquid crystals include 1-hexadecyl-3-methylimidazole bromide, 1-hexadecyl-3-methylimidazolium tetrafluoroboron salt, 1-hexadecyl-3-methylimidazole hexafluorophosphate, 1-dodecyl-3-methylimidazole chloride and 1-dodecyl-3-methylimidazole bromide One or more of them; the concentration of ionic liquid crystal is 2.5-20mg / mL; the amount of deionized water is 10-30ml, and the mass ratio of deionized water to carbon nanotube powder is (10:1)~(30:1 );

[0024] 2) Put the mixed solution in a reaction kettle, and cond...

Embodiment 1

[0029] (1) Weigh 1-hexadecyl-3-methylimidazole bromide and carbon nanotube powder with a mass ratio of 1:2 and add them into 30ml deionized water, stir vigorously until fully dissolved in deionized water, and obtain Mixed solution of carbon nanotube powder and ionic liquid crystal;

[0030] (2) Add the homogeneously mixed mixed solution into a polytetrafluoroethylene-lined reaction kettle, and perform a high-temperature hydrothermal reaction at 180° C. for 12 hours;

[0031] (3) Pour out the product after the hydrothermal reaction to obtain a high-concentration carbon nanotube slurry.

Embodiment 2

[0033] (1) Weigh 1-hexadecyl-3-methylimidazolium tetrafluoroborate and carbon nanotube powder with a mass ratio of 1:3 and add them to 30mL deionized water, stir vigorously until fully dissolved in deionized water, Obtain a mixed solution for carbon nanotube powder and ionic liquid crystal;

[0034] (2) Add the homogeneously mixed mixed solution into a polytetrafluoroethylene-lined reaction kettle, and perform a high-temperature hydrothermal reaction at 180° C. for 15 hours;

[0035] (3) Pour out the product after the hydrothermal reaction to obtain a high-concentration carbon nanotube slurry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com