Method for preparing smectite inorganic gel by mechanochemical modification

A mechanochemical and inorganic gel technology, applied in chemical instruments and methods, inorganic chemistry, silicon compounds, etc., can solve the problems of slurry suspension, poor viscosity and particle size distribution, poor thickening and suspension, and cation exchange efficiency Low-level problems, to achieve the effect of superior suspension stability and thickening, uniformity and stability assurance, and accelerated ion exchange process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] (1) Zhejiang sodium montmorillonite, CEC is 85mmol / 100g, add water to make slurry, the slurry concentration is 5wt%, stir and disperse evenly, and then pretreat with hydrogen ion exchange resin to obtain hydrogen montmorillonite slurry, hydrogen montmorillonite The content of exchangeable divalent cations between stone layers is 18% of the total amount of cation exchange;

[0049] (2) Add sodium carbonate to the hydromontmorillonite slurry, so that the total amount of sodium ions is 1.2 times that of the montmorillonite CEC, stirring and dispersing evenly;

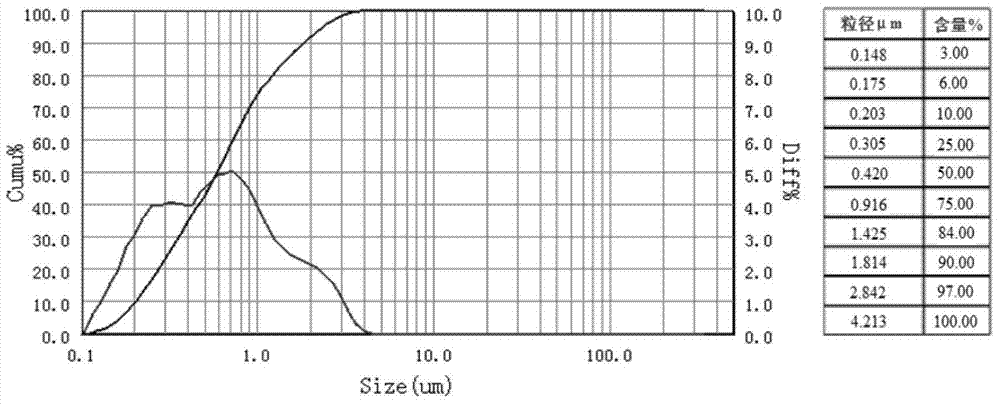

[0050] (3) The slurry is input into a nano sand mill for ultra-fine, the linear velocity is 15m / s, the selected grinding medium is a zirconia ball with a diameter of 5mm, and the particle size distribution of the obtained ultra-fine slurry is shown in the appendix figure 1 , it can be seen from the figure that D 50 0.420μm, D 90 It was 1.814 μm, and the target product was obtained. The suspension stability and vi...

Embodiment 2

[0056] (1) Sichuan calcium-based montmorillonite, CEC is 110mmol / 100g, add water to make slurry, the concentration of slurry is 20wt%, stir and disperse evenly, and then pretreat with hydrogen ion exchange resin to obtain hydrogen-based montmorillonite slurry, hydrogen-based montmorillonite The content of exchangeable divalent cations between stone layers is 10% of the total amount of cation exchange;

[0057] (2) lithium carbonate is added in the hydrogen-based montmorillonite slurry, so that the amount of lithium ion is 0.6 times that of montmorillonite CEC, stirring and dispersing evenly;

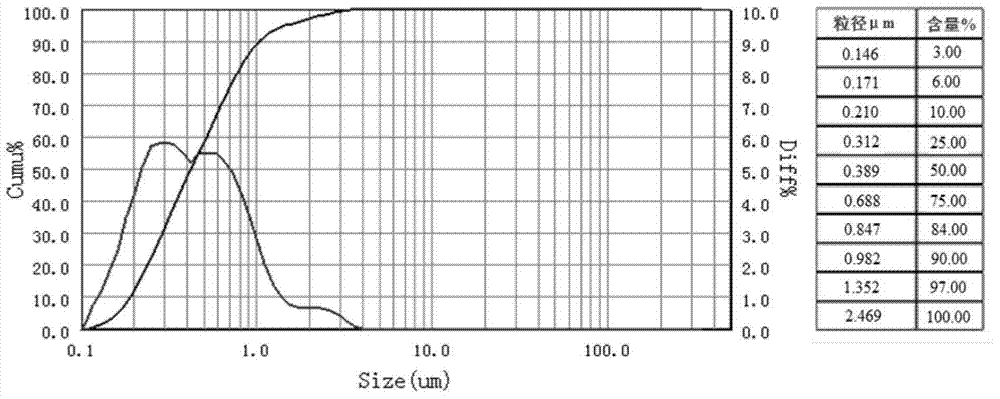

[0058] (3) Input the slurry into the nano ball mill for ultra-fine, the linear speed is 20m / s, the selected grinding medium is a zirconia ball with a diameter of 0.3mm, and the particle size distribution of the obtained ultra-fine slurry is shown in the appendix image 3 , it can be seen from the figure that D50 is 0.389 μm and D90 is 0.982 μm.

[0059] (4) Add sulfuric acid to the supe...

Embodiment 3

[0065] (1) Hebei calcium-based montmorillonite, CEC is 105mmol / 100g, add water to make slurry, the slurry concentration is 10wt%, stir and disperse evenly, then pretreat with sodium ion exchange resin to obtain sodium-based montmorillonite slurry, sodium-based montmorillonite The content of exchangeable divalent cations between stone layers is 8% of the total amount of cation exchange;

[0066] (2) Add sodium chloride to the sodium-based montmorillonite slurry, so that the total amount of sodium ions is 1 times that of the montmorillonite CEC, stirring and dispersing evenly;

[0067] (3) Input the slurry into the nano-impact mill for ultra-fine, the linear speed is 8m / s, the selected grinding medium is a zirconia ball with a diameter of 1mm, and the particle size distribution of the obtained ultra-fine slurry is shown in the appendix Figure 5 , it can be seen from the figure that D50 is 0.325μm, D 90 is 0.918 μm.

[0068] (4) Add magnesia to the superfine slurry, the amount...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com