A kind of brazing ti using al-based solder 2 alc ceramic method

A technology of brazing material and ceramics, applied in the direction of welding equipment, welding medium, welding/cutting medium/material, etc., can solve the problems of short life of electrical contact components, achieve the effects of reducing brazing temperature, improving joint strength, and low melting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

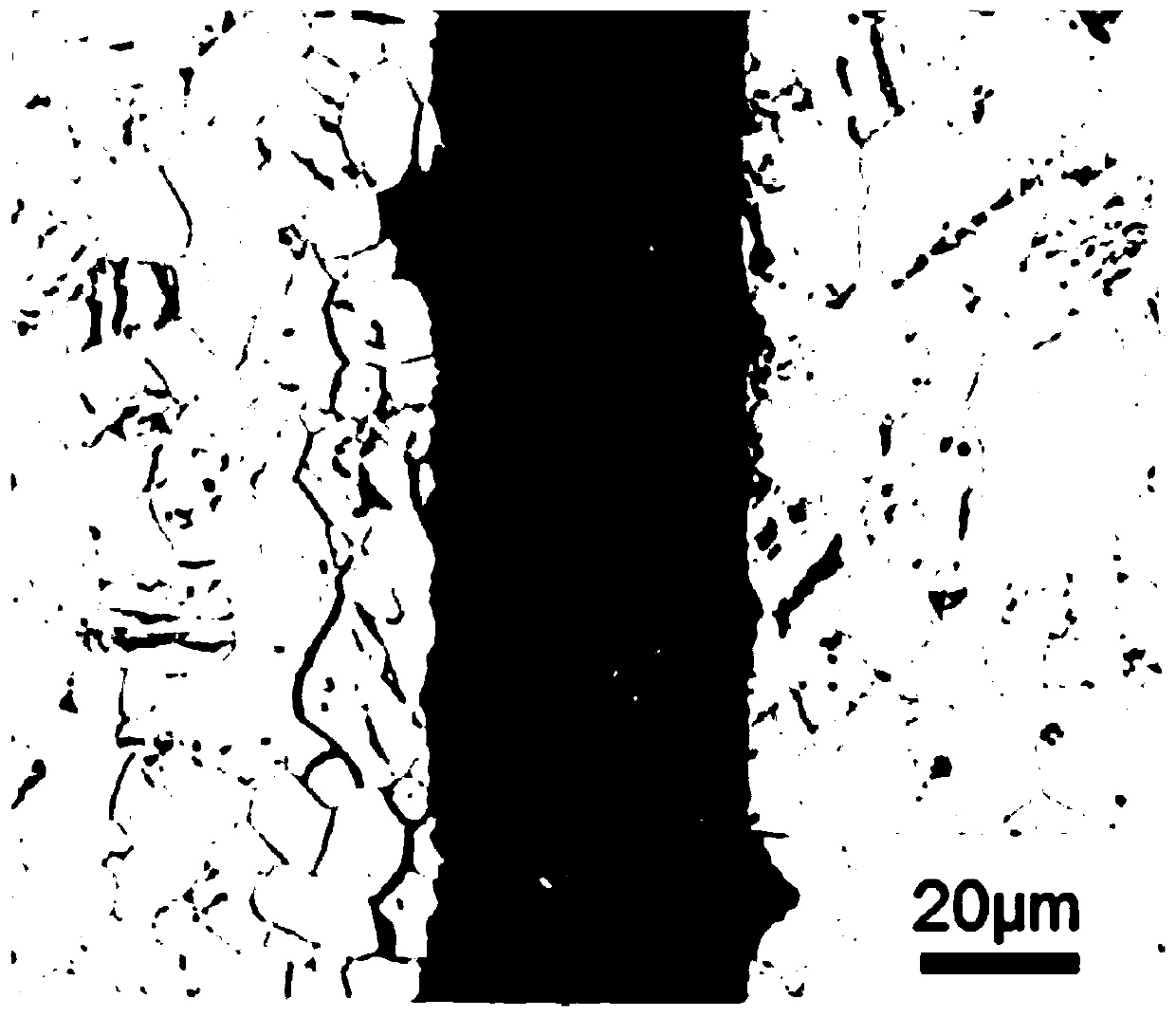

[0030] Specific implementation mode 1: In this implementation mode, a kind of Al-based solder is used to braze Ti 2 The method for AlC ceramics proceeds as follows:

[0031] 1. Preparation of solder:

[0032] Mix high-purity Al powder and Si powder into a crucible, then place it in a resistance furnace, raise the temperature to 750°C to 800°C, keep it warm for 3 hours, fully melt and homogenize, then cool to room temperature with the furnace to obtain brazing filler metal;

[0033] The mass fraction of Si in the solder is 0% to 12%, and the mass fraction of Al is 88% to 100%;

[0034] Second, the Ti 2 The surface of the AlC ceramic base material to be welded was polished and polished with 600#, 1200#, and 1500# water sandpaper in sequence, and the surface was polished with 0.5 μm diamond polishing agent until there were no obvious scratches. The polished Ti 2 The AlC ceramic base material is placed in absolute ethanol, and ultrasonically oscillated for 10min to 20min;

[0...

specific Embodiment approach 2

[0038] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that in step 1, the temperature is raised to 780° C. and kept for 3 hours. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0039] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the polished Ti in step two 2 The AlC ceramic base material was placed in absolute ethanol and ultrasonically oscillated for 15 min. Others are the same as those in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com