Patents

Literature

455results about How to "Good metallurgical bond" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

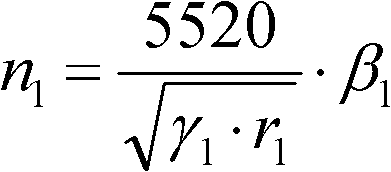

Centrifugal casting high-speed steel composite roll and manufacture method thereof

InactiveCN102615108AGood metallurgical bondHigh strengthRollsMetal rolling arrangementsNiobiumEconomic benefits

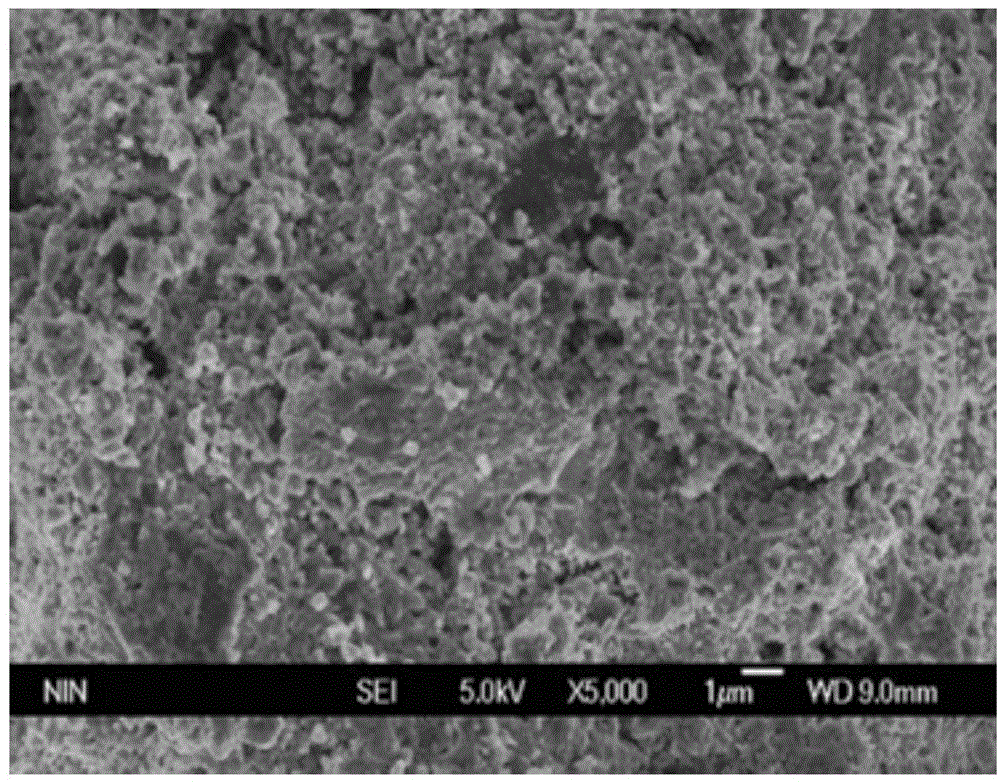

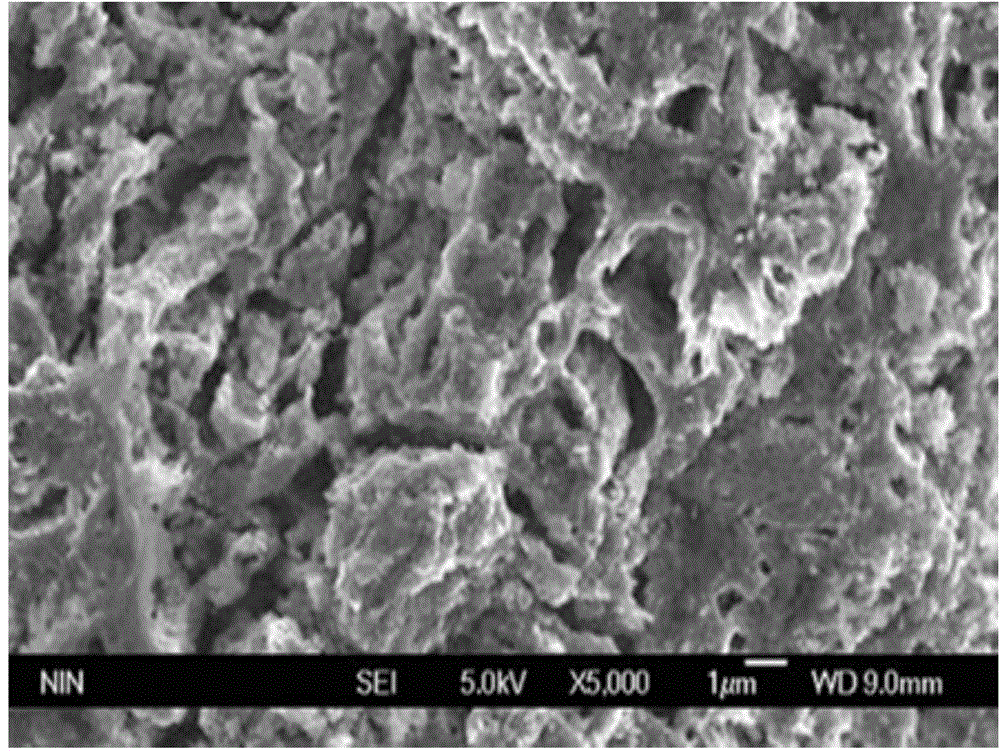

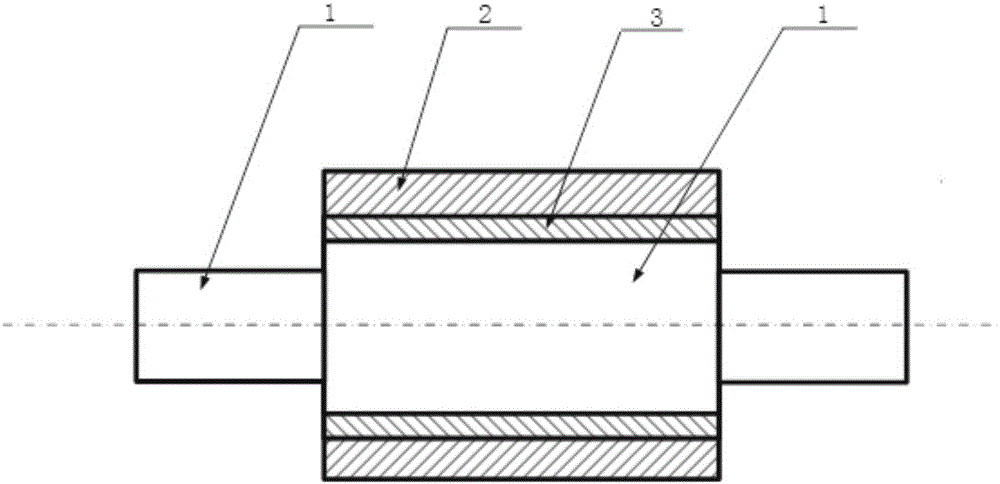

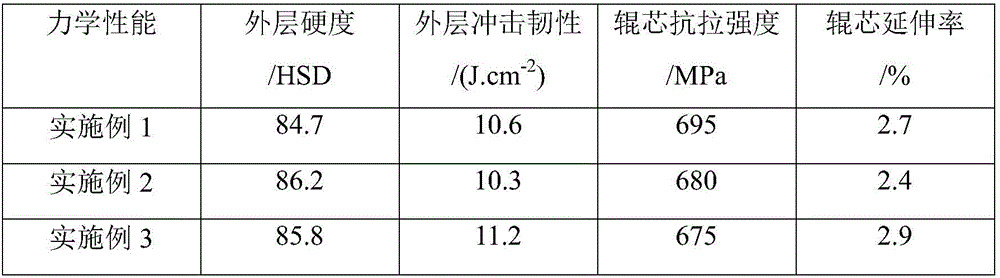

The invention relates to a centrifugal casting high-speed steel composite roll and a manufacture method thereof and belongs to the field of casting. The composite roll is composed of outer layer high-speed steel, middle layer graphitic steel and core high-strength nodular cast iron by centrifugal compounding. The centrifugal casting high-speed steel composite roll is based on the conventional high-carbon high-vanadium high-speed steel roll, the content of vanadium is appropriately reduced, niobium is added at the same time, and the Nb / V is controlled to be 0.3 to 0.5 so that Nb and V form complex carbide (V, Nb) C so as to avoid forming segregation under the action of centrifugal force. A roll core of the high-speed steel composite roll adopts high-strength nodular cast iron, and a multivariate graphite steel middle layer is poured between an outer layer and the roll core for preventing interfusing elements of Cr, B, and the like which cause embrittlement when the nodular cast iron is poured to be fused with the outer layer high-speed steel. Microalloying processing for refining the organization is carried out on a roll surface high-speed steel material and the middle layer graphitic steel so as to achieve the purpose of improving the thermal cracking capacity of the roll material. The centrifugal casting high-speed steel composite roll has high overall performance, long service life and good economic benefits.

Owner:BEIJING UNIV OF TECH

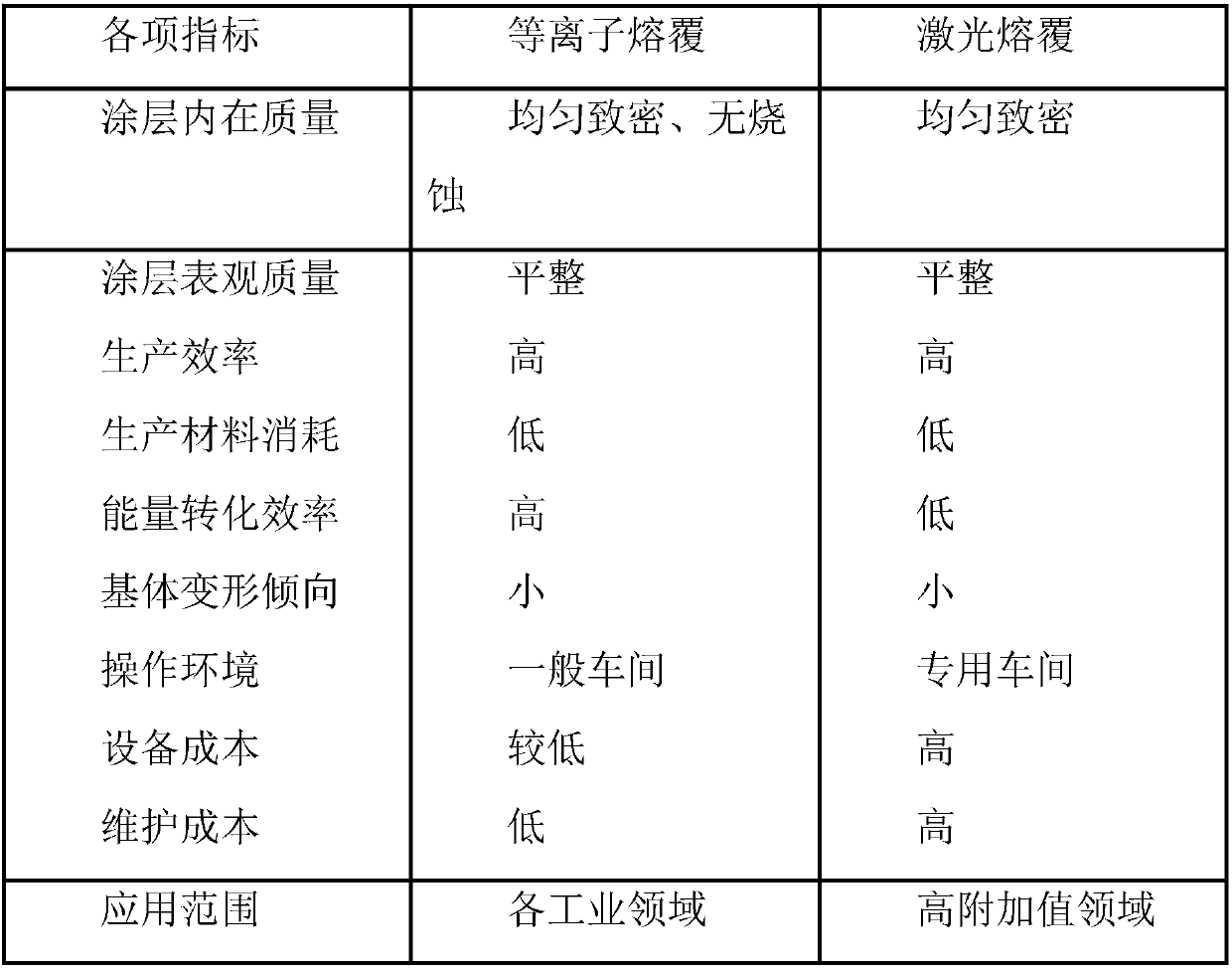

Laser fusing and coating process of wear resistant and anticorrosion alloy coatings at surface of slide plate of railroad turnout

InactiveCN101338425ANo pollution in the processImprove productivityMetallic material coating processesNumerical controlWear resistant

A laser cladding process of an exterior wear-resisting anti-corrosive alloy coating of a slide chair of a railway switch comprises processes as follows: firstly, the surface of the slide chair is pre-heated, which means the surface of the slide chair is degreased and de-rusted under room temperature; and the surface is cleaned up by alcohol; then alloy powder is prefabricated, which means iron-base, nickel-base or cobalt base alloy powders that are ready for cladding are preplaced on the processed surface of the slide chair, and a scraping straightedge provided with a rail is used for adjusting the pretreated metal powder so that the alloy powder can be distributed on the surface of the slide chair evenly and has proper thickness to meet the thick requirement of the coating after cladding; and finally, the slide chair is hardened by the laser cladding; the laser of CO2 gas is adopted; a numerical control machine is used as a working table and the surface of the slide chair is hardened by the laser cladding. The laser cladding process has the characteristics of no pollution, high production rate, low energy consumption, the little finishing allowance of cladding coating and low combined cost.

Owner:SHENYANG DALU LASER COMPLETE EQUIP

Composite reinforced wear-resistant part of metal-ceramic prefabricated member and manufacturing method of composite reinforced wear-resistant part

The invention discloses a composite reinforced wear-resistant part of a metal-ceramic prefabricated member and a manufacturing method of the composite reinforced wear-resistant part. The manufacturing method comprises the steps as follows: uniformly mixing ceramic particles with self-fluxing alloy powder to obtain a mixture; filling a mould cavity of a pressing machine with the mixture, pressing by pressure, forming and demoulding, and placing biscuits and gaskets into a drying box for drying; placing the dried biscuits and gaskets into a vacuum furnace for sintering, cooling and discharging to obtain the metal-ceramic composite prefabricated member; carrying out sand blasting on the prefabricated member, and spraying a layer of nickel-based self-fluxing alloy powder onto the surface of the prefabricated member; and placing the processed fabricated member onto the end surface of a cast cavity, and pouring metal liquid formed by smelting metal matrix materials into the bottom of the cast cavity to obtain the composite reinforced wear-resistant part of the metal-ceramic prefabricated member. According to the manufacturing method, the wear resistance and the impact resistance of the composite wear-resistant part are improved.

Owner:NANTONG GAOXIN ANTIWEAR MATERIALS TECH CO LTD

Composite roller for high vanadium high speed steel and its production process

The invention offers the high V super-speed steel complex roller and its producing craft. The roller includes roller heart and roller shell, the roller heart uses low metal alloy steel or middle carbon steel to produce, the shell uses high V super-speed steel, whose main element is : C: 1.8--3.5A%, V: 7--12%, Cr: 4--5%, Mo: 2--4%, Ni: 0.5--1.5%, other is Fe. The producing craft is: melt and cast the heart and shell by responding heat way. The roller in the invention has good whet feature, high rate of feature and price, using safely. Fine roller, high strength of combination, no crush in use; it can reduce the stop times. It efficiently increase the roller tenacity and whet feature, solve the problems in the heart leaving foundry, and solve the problems of complicated craft and high cost.

Owner:HENAN UNIV OF SCI & TECH +1

Abrasive particles with metallurgically bonded metal coatings

InactiveUS20020069592A1Improve solubilityGood metallurgical bondPigmenting treatmentOther chemical processesBorideRhenium

An abrasive composite particle comprising a cubic abrasive core particle encapsulated within a deposit of hexagonal metallurgical bond forming material comprising at least about 50 volume percent rhenium, ruthenium, osmium or mixtures thereof. The metallurgical bonds serve to retain the core particle in a matrix / binder very strongly. Metallurgical bonds are formed by the encapsulating material taking into solution, at the interface with the cubic abrasive core particle, some element or compound from the abrasive particle such as, for example, carbon or cubic boron nitride, from the core particle. Chemical bonds are not formed between the abrasive particle and the deposit. Suitable abrasive core particles include diamond, cubic carbides, cubic borides, cubic nitrides, cubic oxides, and the like. Conventional fabrication procedures such as chemical vapor deposition are employed to form the metallurgical bond forming deposit on the core particle. The composite abrasive particles are useful in forming articles according to conventional powdered metal processing operations. The articles so formed are useful for their hardness as well as their abrasiveness.

Owner:POWDERMET

Abrasive particles with metallurgically bonded metal coatings

InactiveUS6540800B2Improve solubilityGood metallurgical bondPigmenting treatmentOther chemical processesBorideRhenium

Owner:POWDERMET

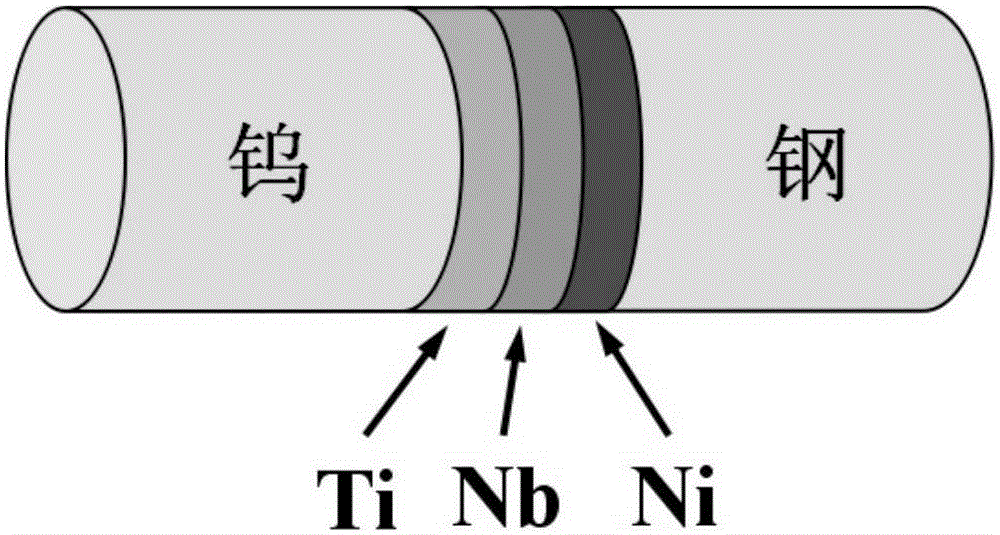

High-performance tungsten/steel composite material based on high-temperature application and preparation method thereof

ActiveCN105216394AHigh tensile strength at room temperatureImprove high temperature mechanical propertiesLaminationLamination apparatusNiobiumJoint stress

The invention relates to a high-performance tungsten / steel composite material based on high-temperature application and a preparation method thereof and belongs to the technical field of preparation of composite materials. By adoption of the high-performance tungsten / steel composite material, the problems of large residual joint stress, low strength, poor heat resistance and high connection temperature in an existing tungsten / steel connector are solved. The high-performance tungsten / steel composite material is prepared from a tungsten-based layer, a titanium layer, a niobium layer, a nickle layer and a steel-based layer which are arranged in sequence and prepared by adopting a welding method. The high-performance tungsten / steel composite material is obtained by superposing the tungsten-based layer, the titanium layer, the niobium layer, the nickle layer and the steel-based layer in sequence according to the superposition mode of the tungsten-based layer, the titanium layer, the niobium layer, the nickle layer and the steel-based layer and carrying out vacuum diffusion bonding. The high-performance tungsten / steel composite material has the advantages that the room-temperature tensile strength is larger than or equal to 352MPa, and the tensile strength at the temperature of 650DEG C is larger than or equal to 338MPa; the structure design is reasonable, the process is simple, the large-scale application is convenient, and simultaneously, the high-performance tungsten / steel composite material can be widely applied in diffusion bonding of refractory metal and other dissimilar metal materials.

Owner:CENT SOUTH UNIV

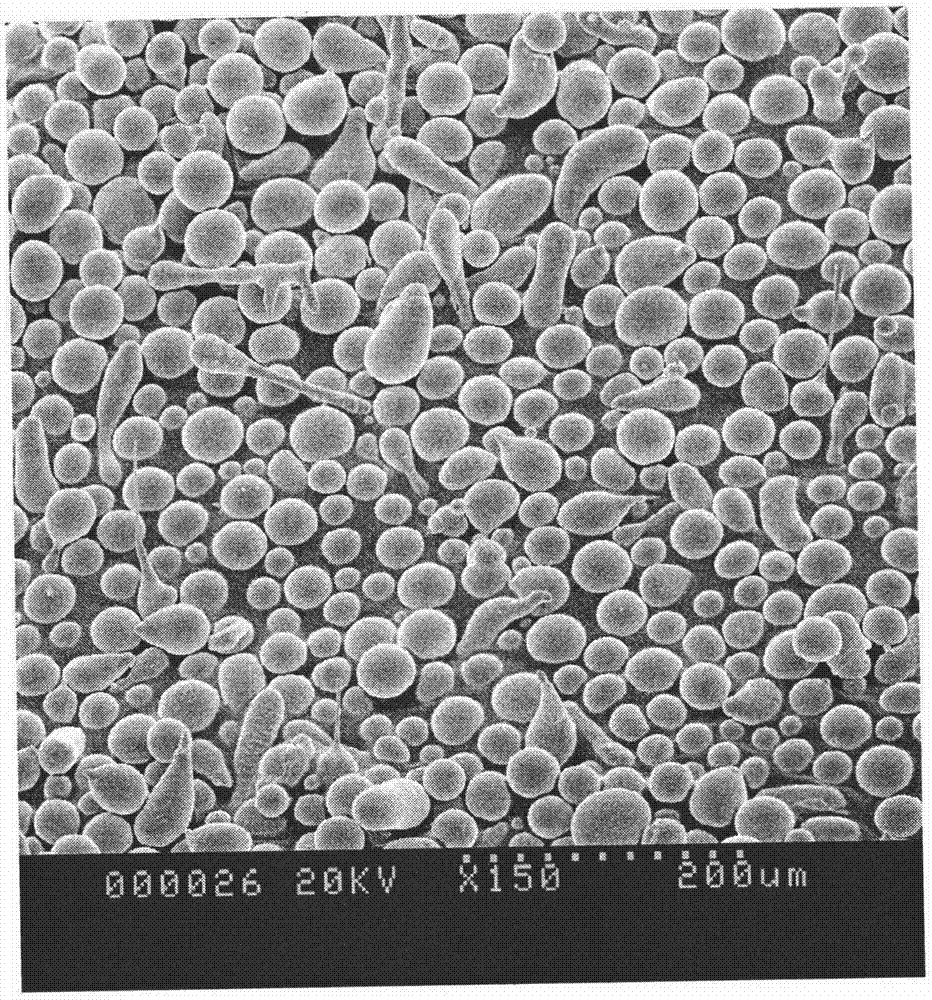

Laser cladding repairing method for aircraft end-journal part surface

InactiveCN105256249AShorten maintenance timeReduce maintenance costsMetallic material coating processesHeat-affected zoneSlag

The invention belongs to the technical field of laser cladding, relates to a laser cladding repairing method for aircraft end-journal part surface, particularly to a method for repairing the mechanical wear and scrape malfunction of an aircraft end-journal part after long-time service by adopting the laser fused deposition technology. The method aims at mechanical wear, scrape and other defects on the surface of the part, selects spherical precipitation to harden stainless steel metal dust, adopts reasonable laser cladding technological parameters, and removes residual stress of the part after cladding through the specific heat treatment technology to recover the performance of the aircraft end-journal and realize repairing of lengthening the service life. The repaired end-journal part hardly deforms, and the depth of a heat affected area is no more than 0.5mm; the repairing area does not have the defects of cracks, incomplete fusion and slag inclusion; the serviceability of the repaired end-journal is recovered.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

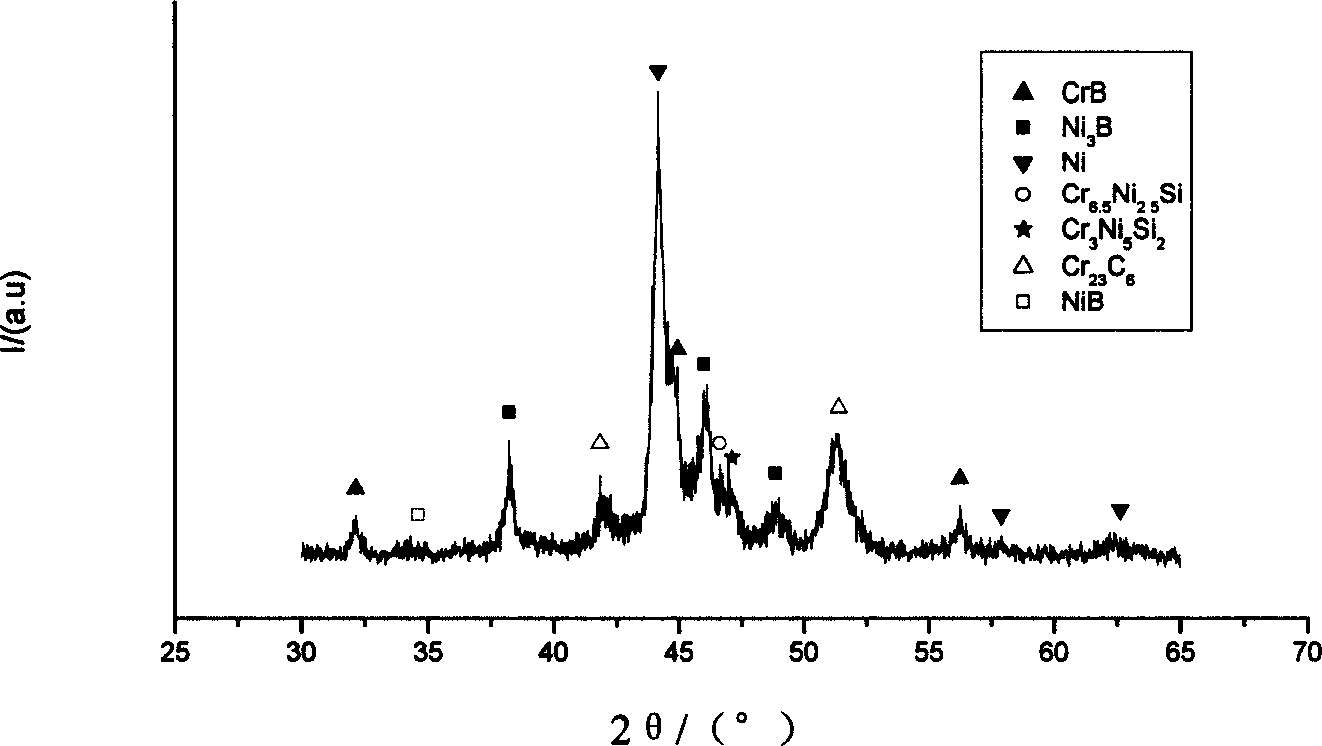

Nickel base self-fusible alloy-rare earth composite coating material and its preparing method

InactiveCN1580324AEasy to modifyImprove performanceMetallic material coating processesParticulatesSilanes

The invention is a nano-particulate demulsifying agent used in demulsification of trinary oil recovery produced fluid. The application of new technique of trinary oil recovery enhances the crude oil recovery, where the polymer injection oil-recovery technique increases the oil, obviously, but also causes the difficulty in demulsifying the produced fluid at the same time. Its character lies in that: the nano-particulate demulsifying agent is composed of particle nucleating material which processes the surface of nano silicon oxide material by silane coupler and fluorine compound and reacting solvent containing arenes as dimethylbenzene, as well as polyether demulsifying agent as multicomponent polyether, amine polyether and resin polyether. It effectively solve the problem about the demulsification of trinary oil recovery polymer injection produced fluid, field used quantity little, demulsifying speed rapid, dehydrating efficiency high and oil-water interface regular.

Owner:HEFEI UNIV OF TECH +1

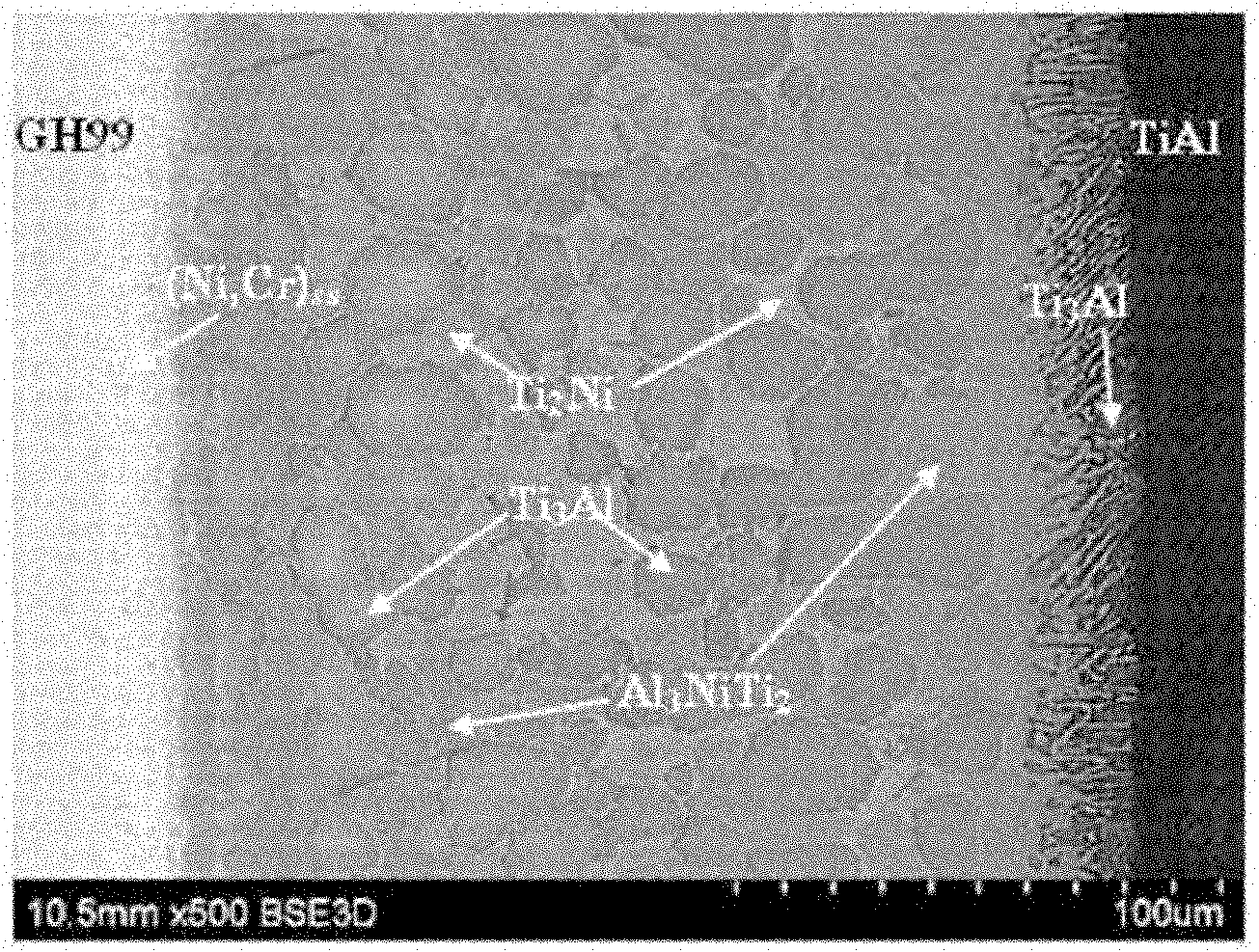

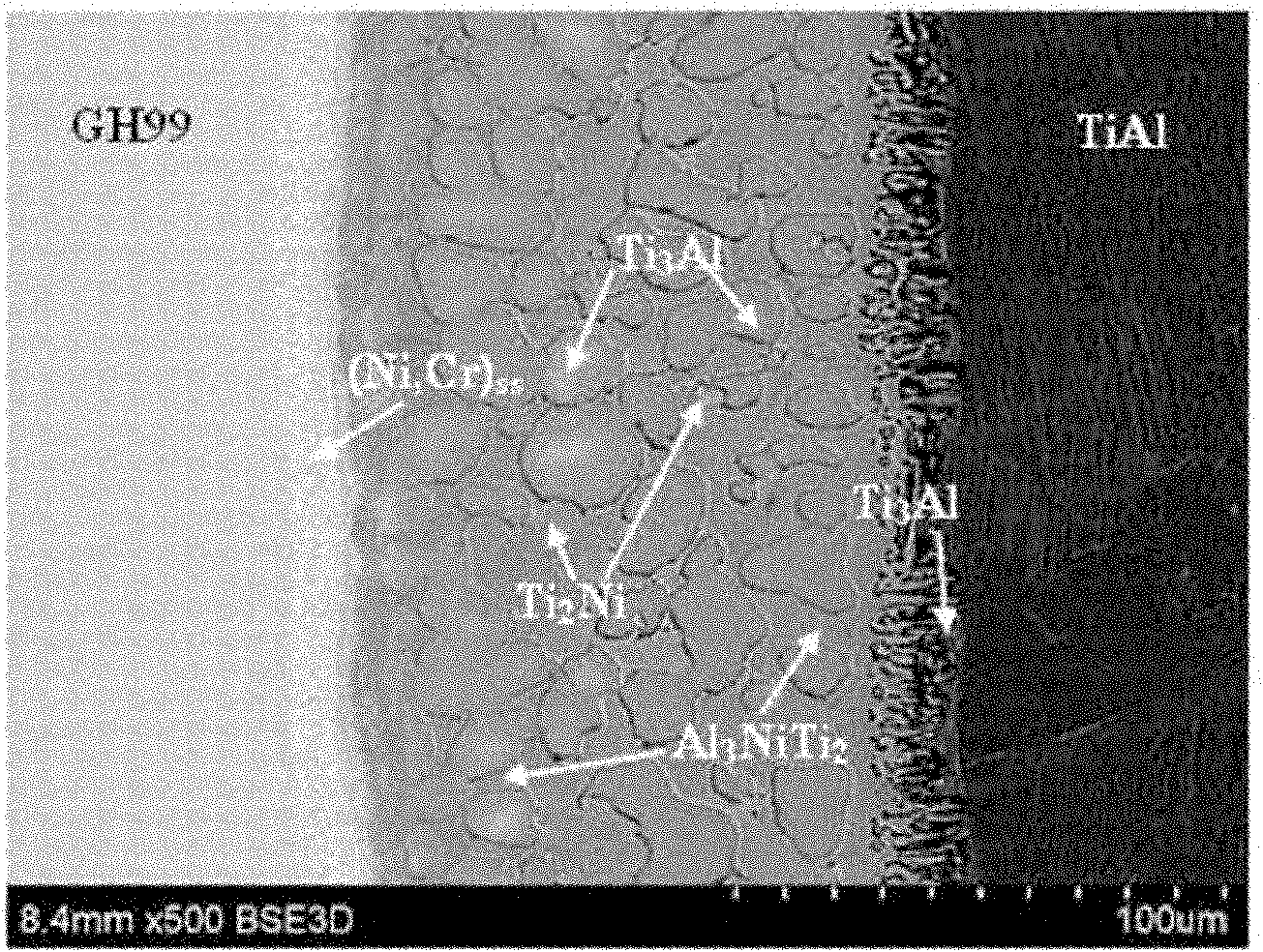

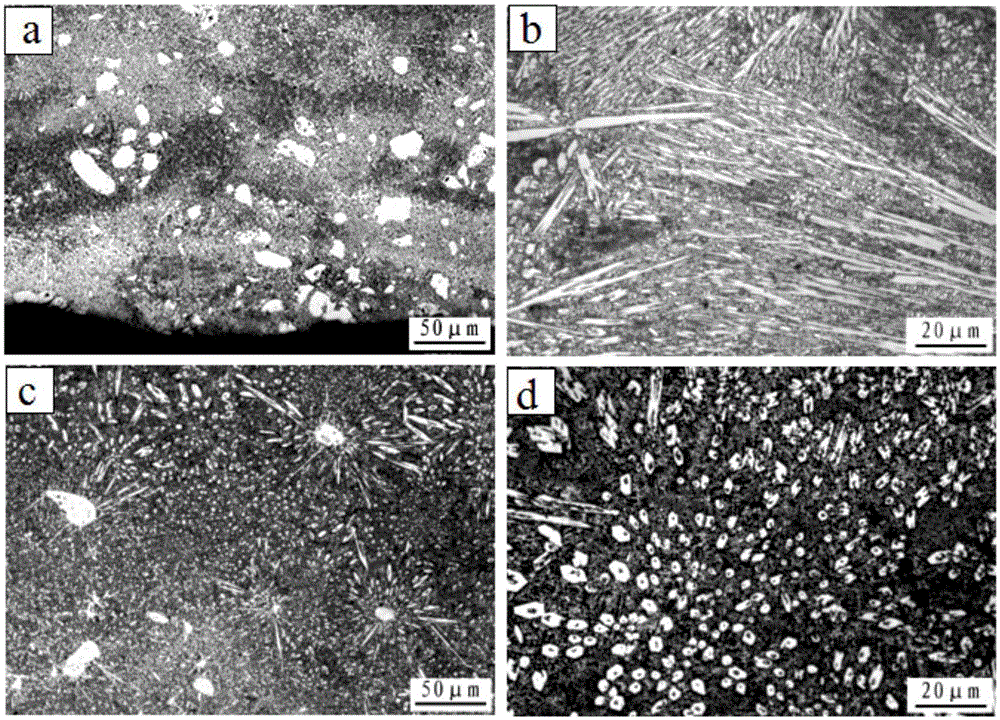

Contact reaction brazing connection method for TiAl based alloy and Ni based high-temperature alloy

ActiveCN101972877AAchieving a soldered connectionSimple processSoldering apparatusContact reactionsSuperalloy

The invention discloses a contact reaction brazing connection method for TiAl based alloy and Ni based high-temperature alloy, relating to a welding method for the TiAl based alloy and the Ni based high-temperature alloy and solving the problems of the traditional diffusion connection method for the TiAl based alloy and the Ni based high-temperature alloy that the process is complicated, the cost is high, the connection thermal cycle period is long, the efficiency is low, the requirement on the to-be-welded surface of a weldment is high, a silver brazing joint is not resistant to high temperature, and the brittle phase of high-temperature brazing is easy to aggregate and grow. The method comprises the steps of: treating the to-be- surface of a Ti foil, the TiAl based alloy and the Ni based high-temperature alloy, placing the Ti foil between the TiAl based alloy and the Ni based high-temperature alloy to form a weldment to be welded, and welding the weldment to be welded in a vacuum brazing furnace. The joint obtained in the invention has high shear strength up to 240-300MPa, and the shear strength is 180-210MPa at the high temperature of 800 DEG C, and the joint can be used as a hot end part for aerospace under high-temperature environment.

Owner:HARBIN INST OF TECH

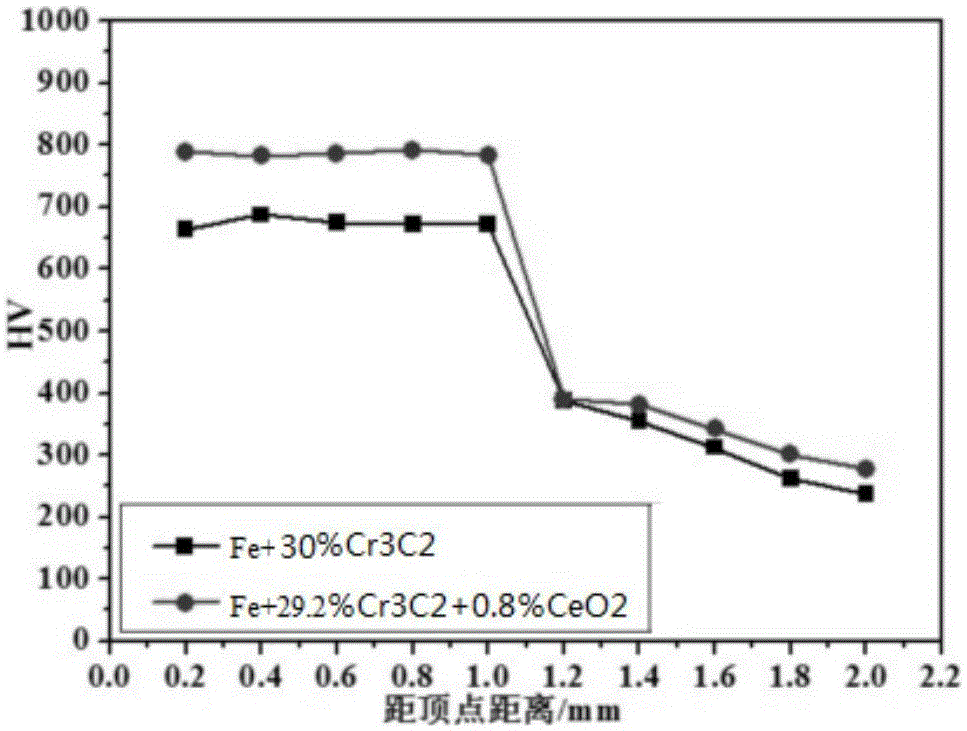

Iron-based Cr3C2 laser-cladding coating added with CeO2 and preparation method of coating

ActiveCN105112909AHigh hardnessImprove wear resistanceMetallic material coating processesAlloyHardness

The invention discloses an iron-based Cr3C2 laser-cladding coating added with CeO2 and a preparation method of the coating, and belongs to the technical field of surface modification. The coating is prepared by uniformly mixing the following components in percentage by mass for laser-cladding: 65-73% of iron-based self-fluxing alloy powder, 26.5-34% of Cr3C2 alloy powder and 0.5-1% of CeO2 powder. The preparation method comprises the following steps: powder preparation; uniform mixing and drying; preparation and post-treatment of the coating. Through adoption the technical scheme, the rigidity, abrasion resistance and high-temperature oxidation resistance of the coating can be improved; besides, the forming quality and cladding property of the coating can be remarkably improved to inhibit and eliminate bubbles and cracks.

Owner:ANHUI MA STEEL SURFACE TECH CO LTD

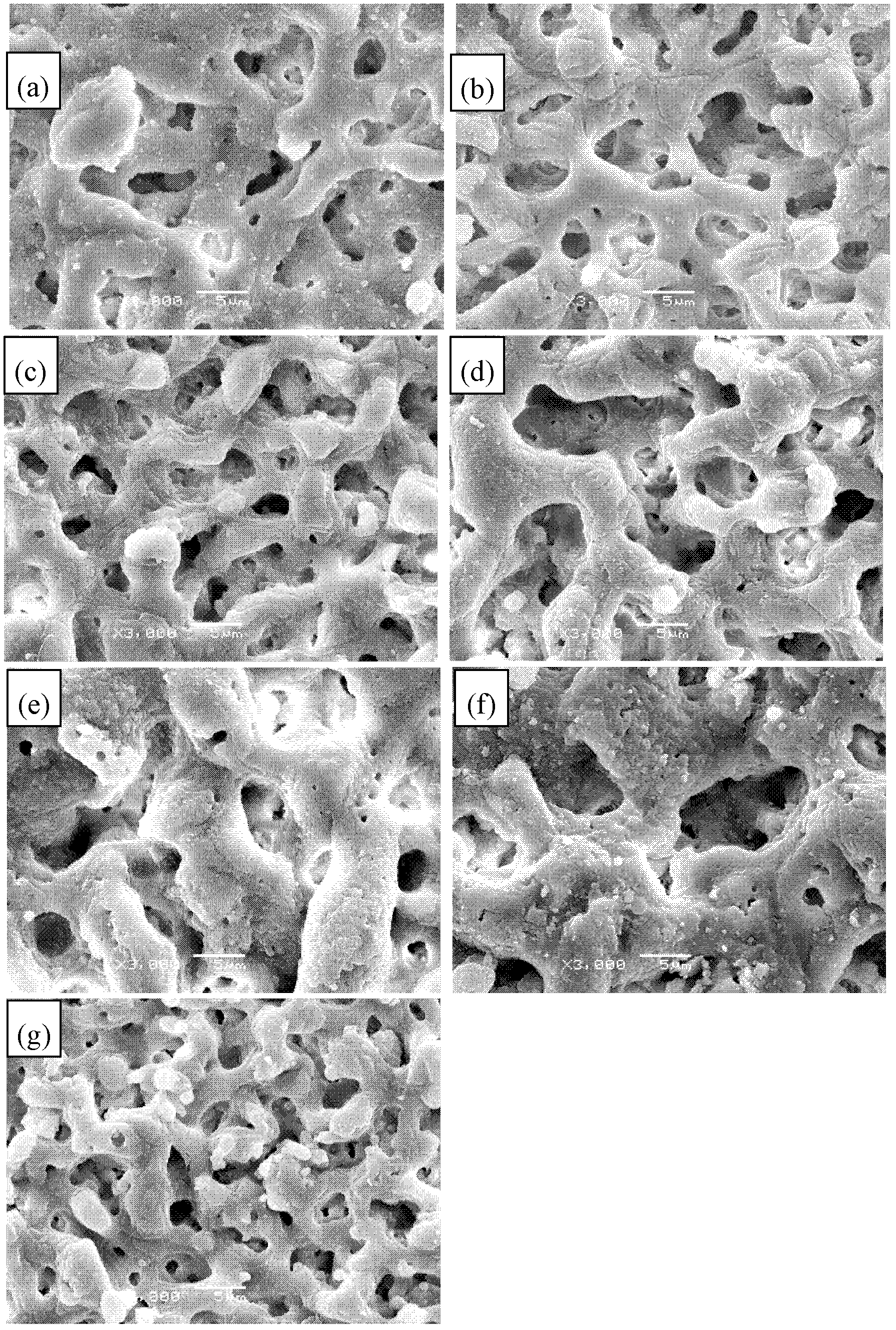

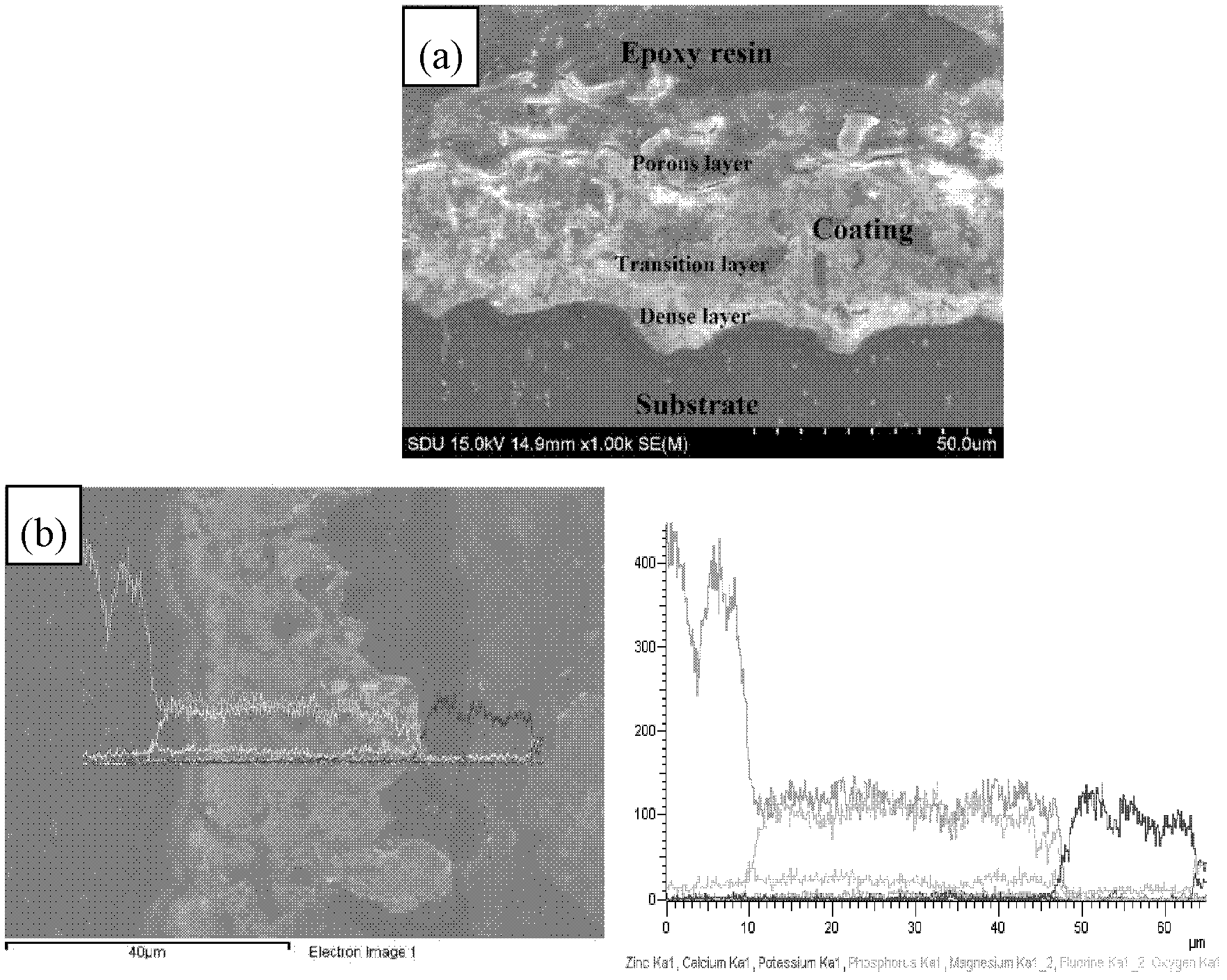

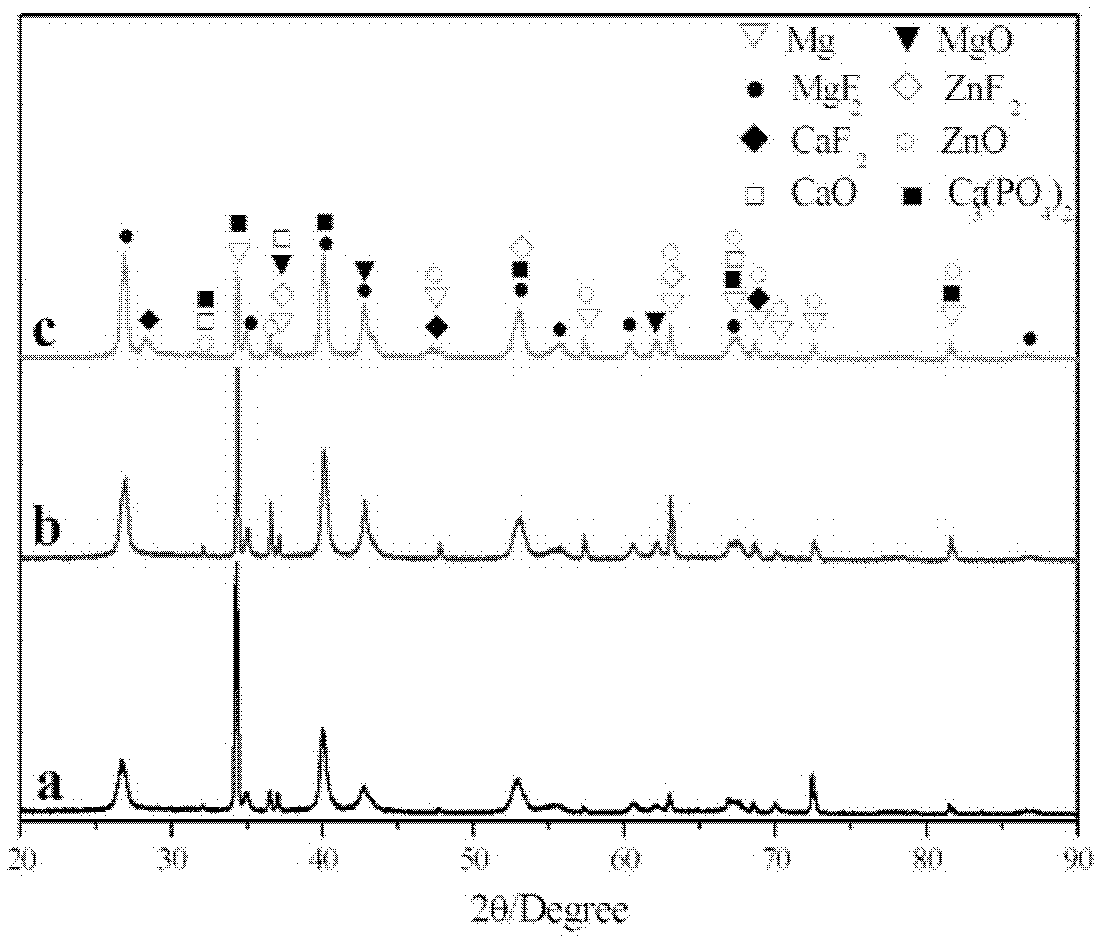

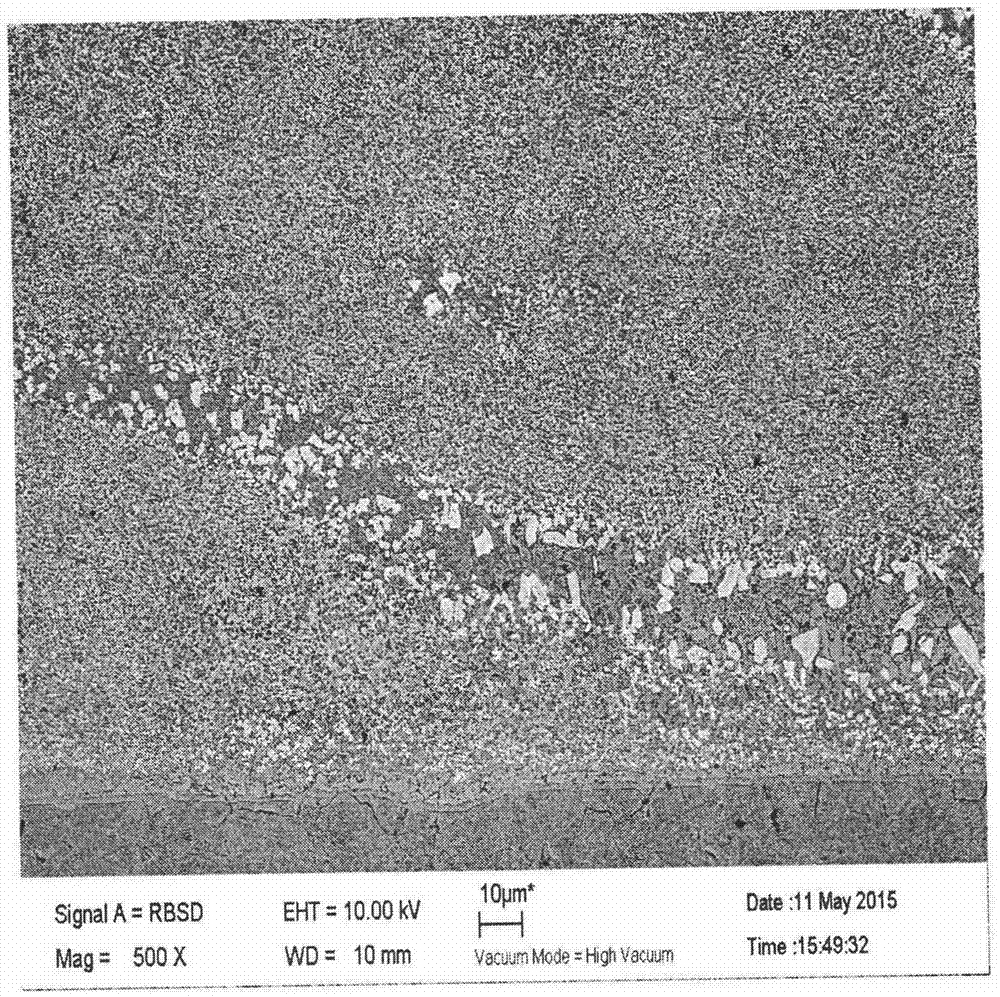

Preparation method of biological ceramic coating rich in calcium and phosphate phases on surface of magnesium alloy

ActiveCN102220620AHigh hardnessHigh densityAnodisationPhosphatisationPlasma electrolytic oxidationMicro arc oxidation

The invention relates to a preparation method of a biological ceramic coating rich in calcium and phosphate phases on the surface of magnesium alloy, comprising the following steps of: adding (C6H5O7)2Ca3.4H2O and Na3PO4 to deionized water, and simultaneously adding KOH, NH4HF2, N(CH2CH2OH)3, C3H8O3 and H2O2 to prepare an electrolyte with a certain concentration ratio of calcium and phosphate; disposing the magnesium alloy in the electrolyte as an anode which is prepared through micro arc oxidation energization reaction. The calcium-phosphate ceramic coating obtained by the preparation methodconsists of three layers of a loose layer, a transition layer and a compact layer, wherein the surface of the loose layer consists of a plurality of uniformly distributed micropores, the transition layer is between the loose layer and the compact layer, and the compact layer and a substrate body form good metallurgical bonding; therefore, the coating has high rigidity, high density, high bonding force and good corrosion resistance and abrasion resistance; simultaneously, the mouse acute systemic toxicity test indicates that the coating has good biocompatibility, and the simulated body fluid soaking test indicates that the coating has good biological activity.

Owner:SHANDONG UNIV

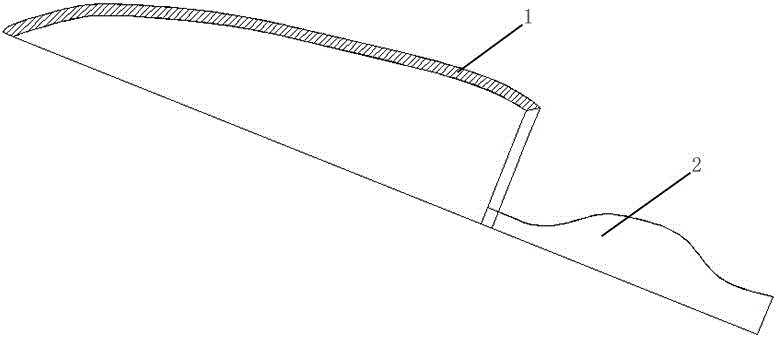

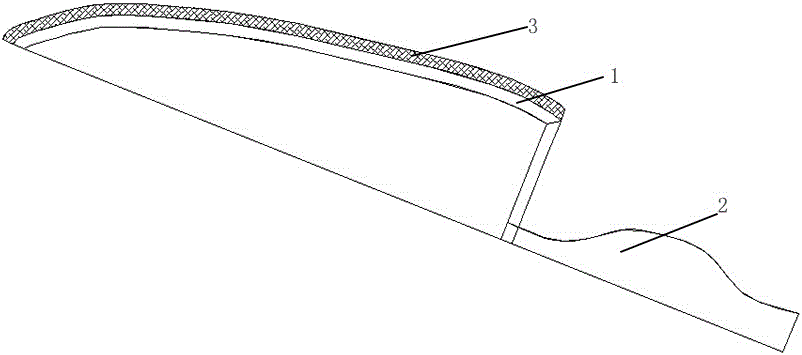

Tool for strengthening blade through laser cladding technology

ActiveCN106119838ASmall and uniform tissueLow dilution rateMetallic material coating processesMetal working apparatusAlloyLaser

The invention discloses a tool for strengthening a blade through the laser cladding technology. The tool comprises a tool body and a handle. The position of a cutting edge line of the tool body is provided with a cladding layer in a cladding manner, wherein the cladding layer is formed by abrasion-resisting hard alloy mixed powder. The hard alloy mixed powder is formed by mixing nickel-base alloy powder and tungsten carbide powder according to the proportion. By mass percent, the nickel-base alloy powder accounts for 40%-70%, and the tungsten carbide powder accounts for 30%-60%. The nickel-base alloy powder comprises, by mass percent, 18%-23% of Cr, 4%-7% of Fe, 2%-4.5% of Nb, 8%-11.5% of Mo, 0.2%-0.4% of Al, 1%-2.5% of Ti, 0.1%-0.6% of C, 0.2%-0.5% of Si, 0.2%-0.6% of Mn, 1.5%-2.5% of V and the balance Ni. The tool has the beneficial effects that the cladding layer and the tool body are in well metallurgy combination, the structure of the cladding layer is fine and uniform, and the dilution rate is low; after the tool body is sharpened, the hardness, sharpness, abrasion resistance and corrosion resistance of a blade part are greatly improved, cost is low, the hardness of the blade part is improved, and meanwhile tenacity cannot be reduced.

Owner:YANGJIANG KNIFESCISSOR HARDWARE RES INSTITUTION OF IND TECH +1

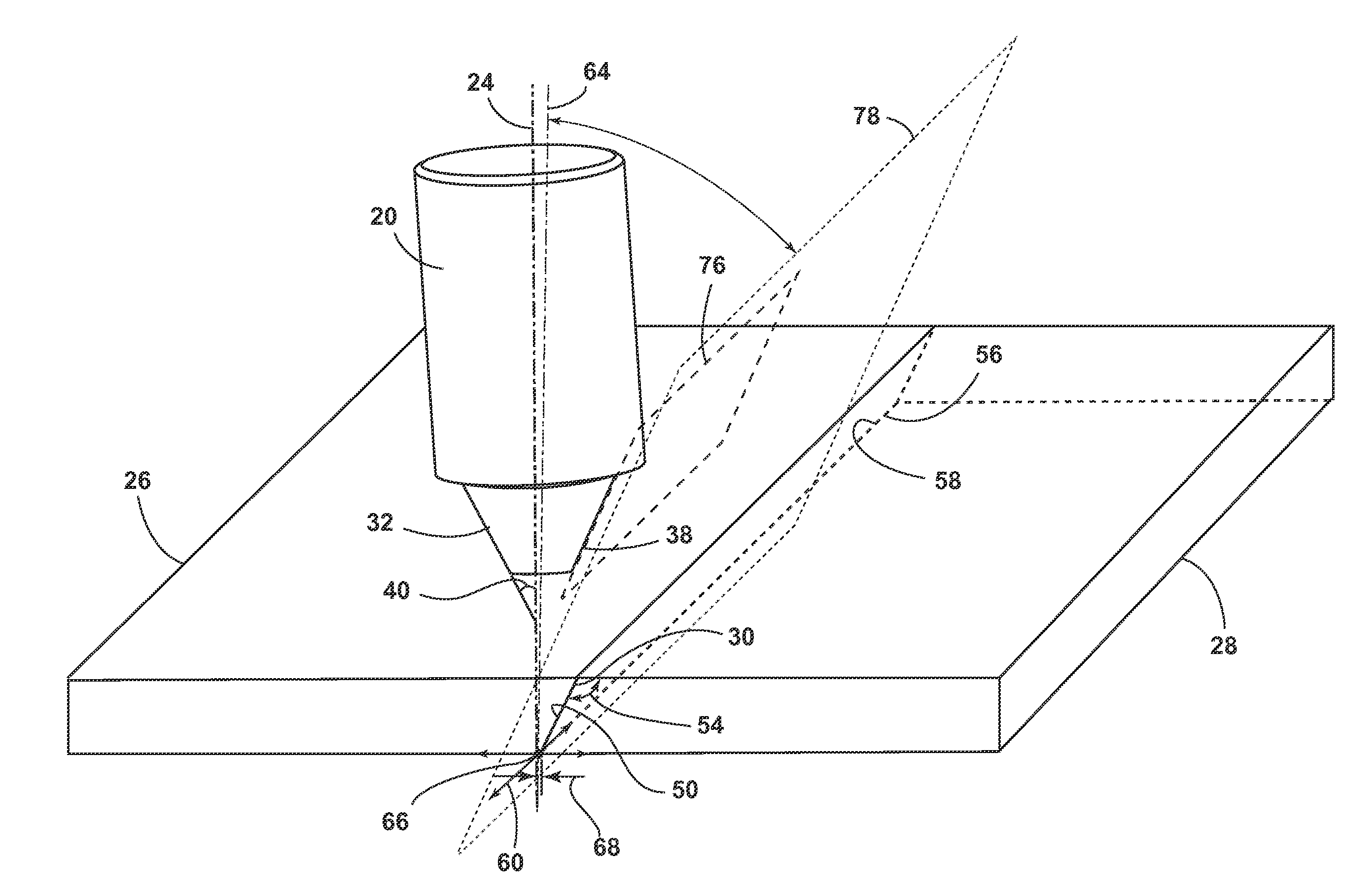

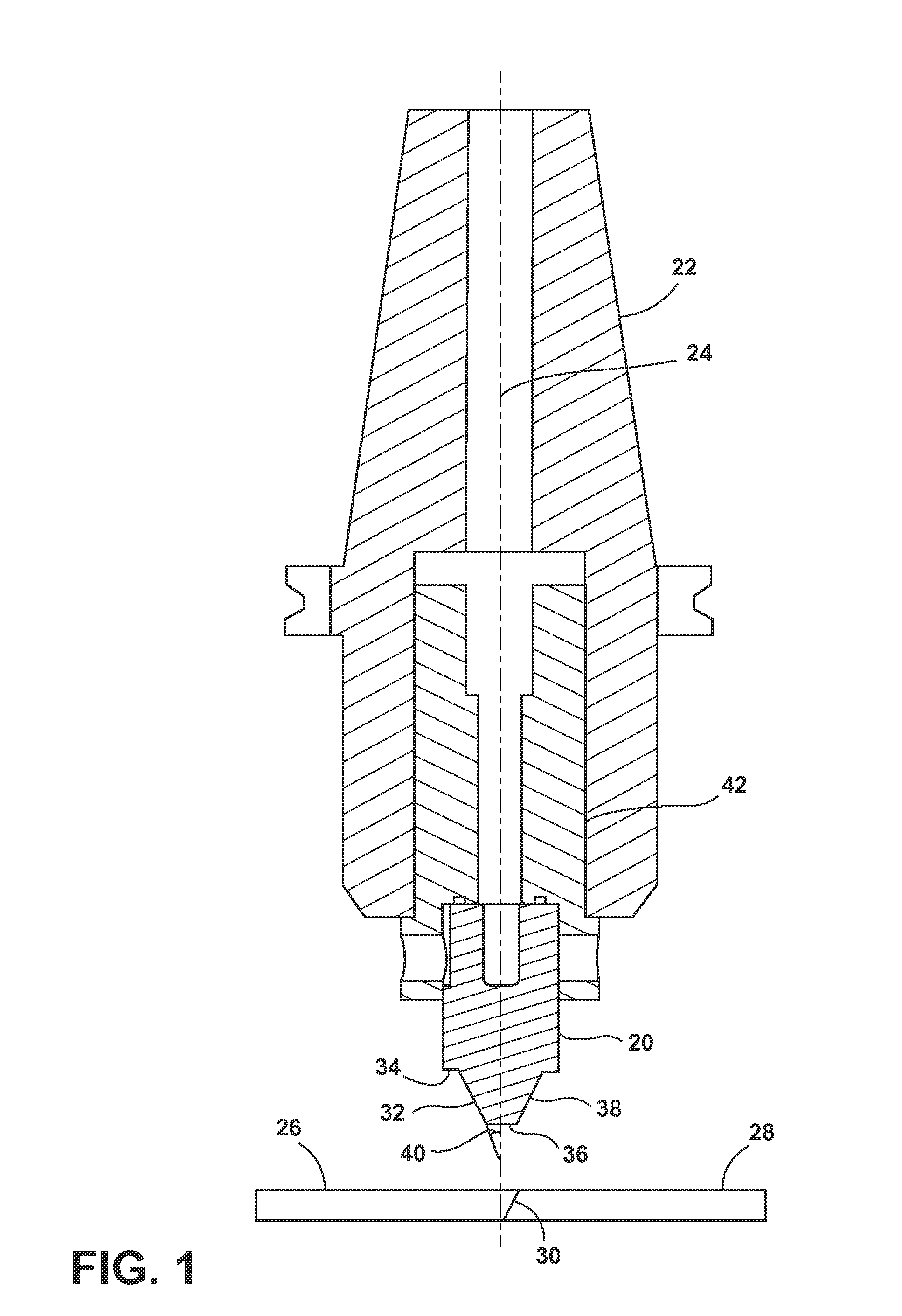

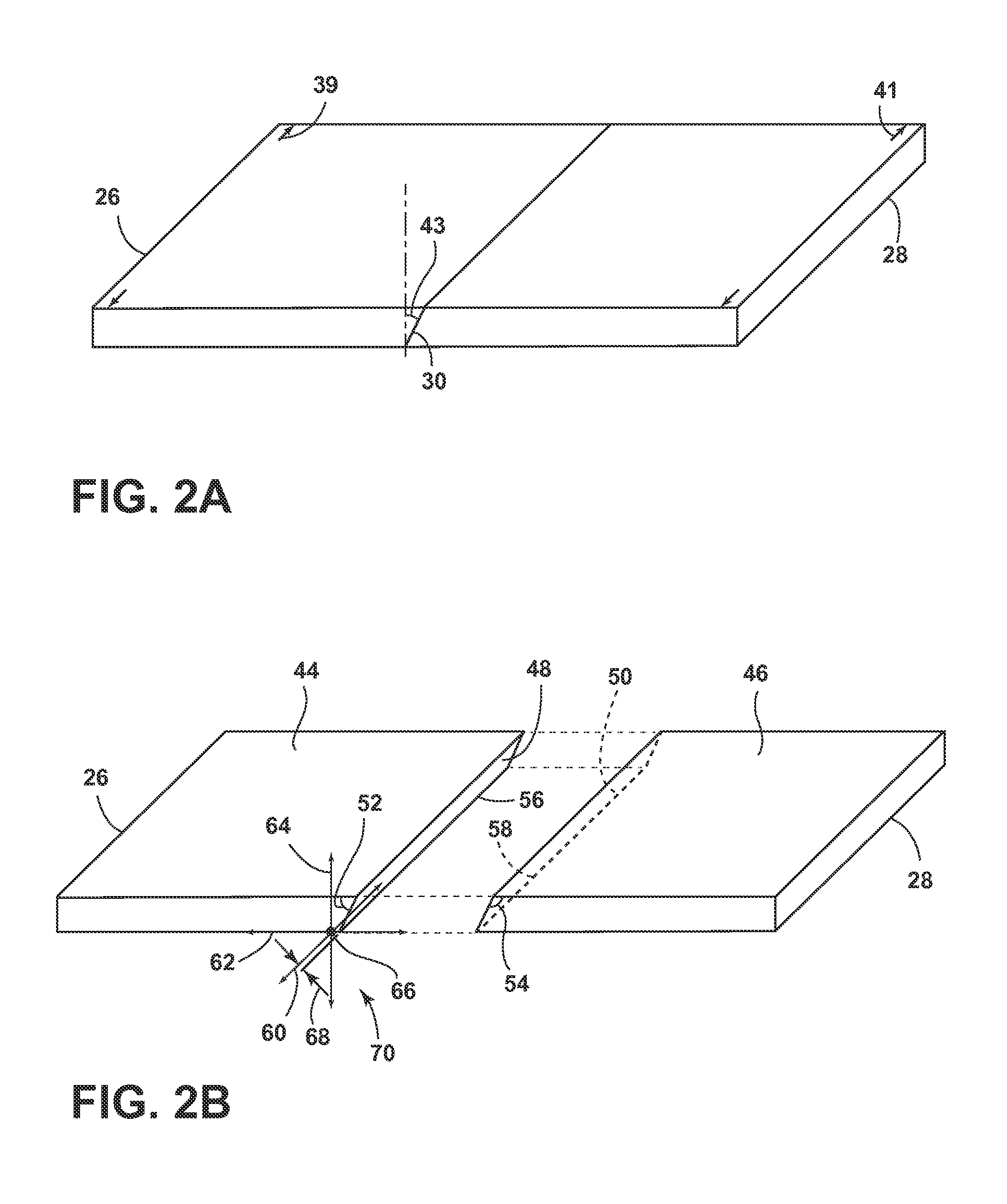

Method of friction stir welding

InactiveUS20140367452A1Avoid excessive wearStronger weld jointWelding/soldering/cutting articlesNon-electric welding apparatusEngineeringMechanical engineering

A method of friction stir welding is provided. The method includes providing a stir tool configured to rotate about and move along a stir tool axis and includes a pin with a pin axial end surface and a pin tapered surface that extends radially outwardly from the pin axial end surface. The method further includes providing the first member with a first member faying surface and defining a normal line that is normal to the first member top surface, is perpendicular to a longitudinal axis, and extends through a reference point. The method further includes providing the second member with a second member faying surface and forming a joint interface between the first and second members. The method further comprises contacting the rotating pin with the second member faying surface, the stir tool axis being disposed at a side tilt angle upon contact.

Owner:FOCUS HOPE

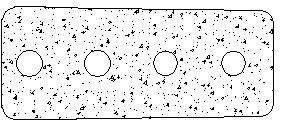

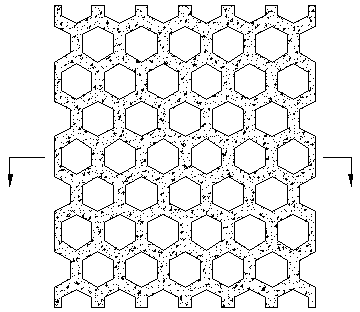

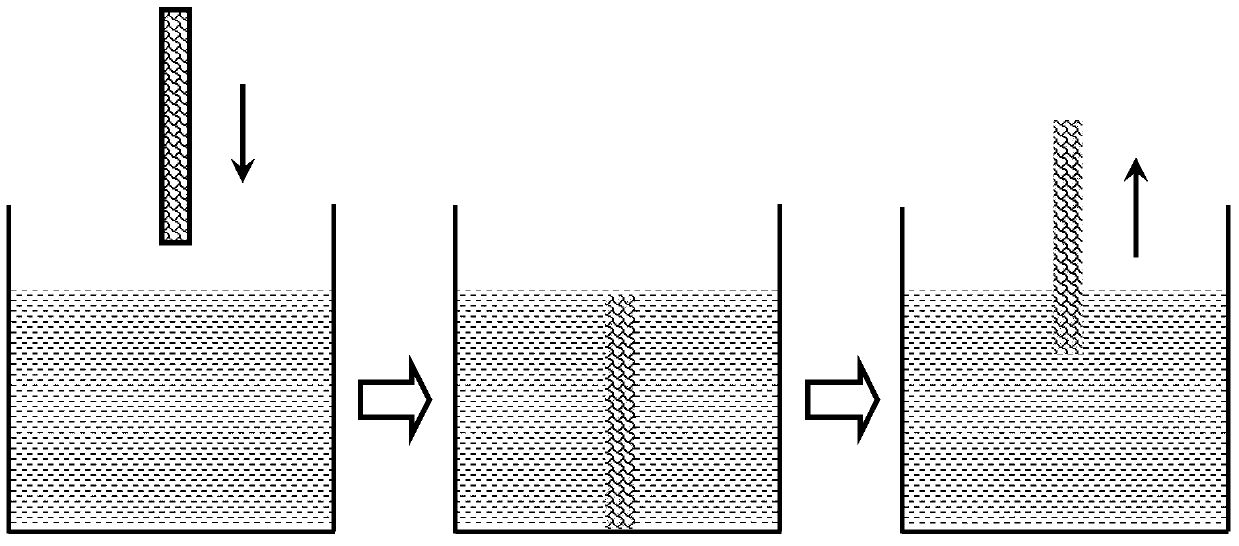

Preparation method of ceramic-metal compound wear-resistant material

The invention discloses a preparation method of a ceramic-metal compound wear-resistant material. The material is characterized by comprising the steps as follows: a ceramic prefabricated member provided with holes is prepared with ceramic powder firstly; then the ceramic prefabricated member is plated with nickel in a chemical nickel-plating manner, and the thickness of a nickel-plating layer is 10 mu m-200 mu m; the ceramic prefabricated member plated with the nickel is fixed in a casting mold, and a basic molten metal is casted at negative pressure, so that the ceramic-metal compound wear-resistant material is obtained. According to the method, the manufacture is simple; the method is particularly suitable for production of large plate pieces; the yield is high, and the performance is stable; a substrate is combined with the prefabricated member, so that good metallurgical bonding can be formed; and the preparation method can be used widely in wear-resistant fields of cement, thermal power, metallurgy and mines and suitable for mass production.

Owner:CHONGQING LUOMAN WEAR RESISTANT MATERIALS

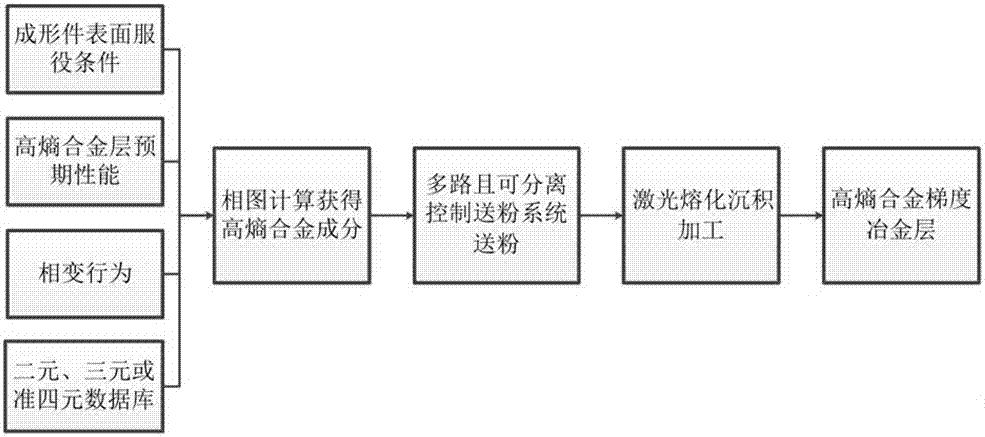

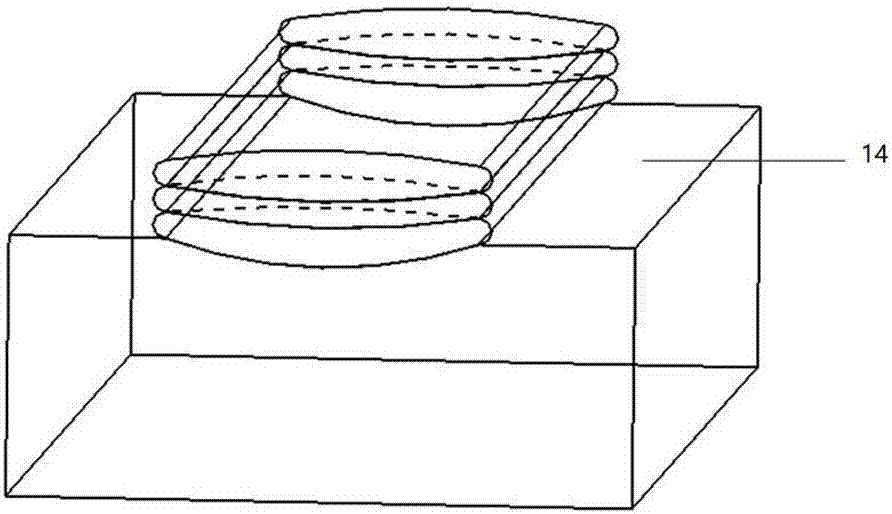

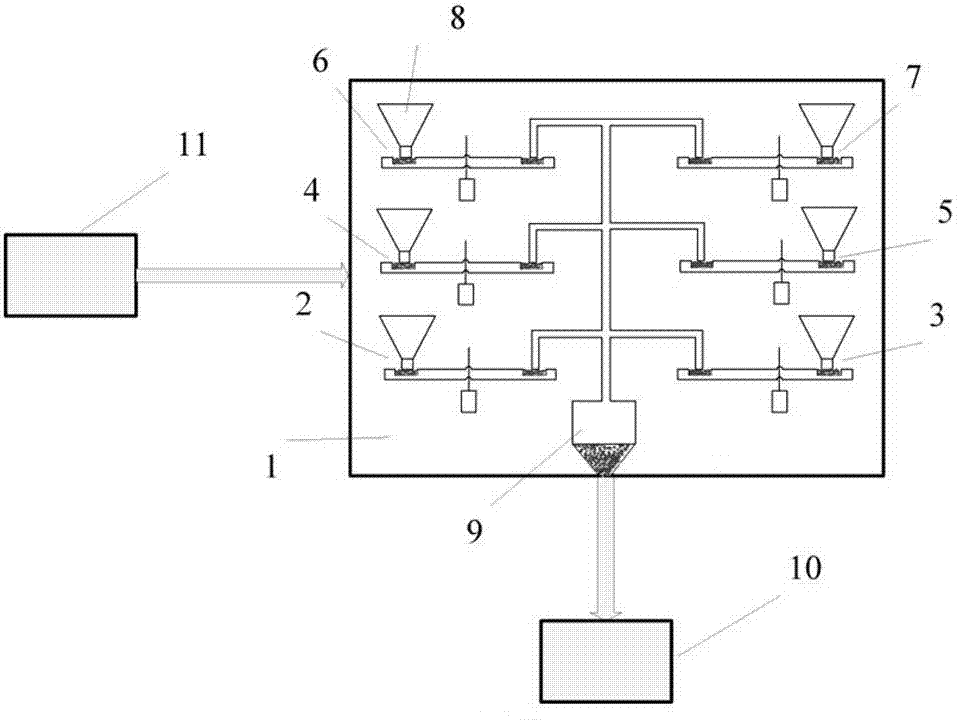

Additive manufacturing method of surface high-entropy alloying gradient metallurgy layer

InactiveCN107971490AReduce distortionImprove work efficiencyAdditive manufacturing apparatusIncreasing energy efficiencyHigh entropy alloysUltimate tensile strength

The invention discloses an additive manufacturing method of a surface high-entropy alloying gradient metallurgy layer, and belongs to the field of surface alloying. The additive manufacturing method comprises the following steps that step one, high-entropy alloying components are obtained through calculation based on a phase diagram; step two, an LMD technological strategy is designed, wherein anLMD technology is designed to carry out laser multilayer melting and sedimentation and increase the content of alloy powder in mixed powder layer by layer from the bottom up, and powder delivering schemes of different gradient coatings are formulated to design a multichannel and separable control powder delivering system; and step three, laser melting and sedimentation machining is carried out, thus the high-entropy alloying gradient metallurgy layer is obtained. The additive manufacturing method achieves the effects that the high-entropy alloying gradient layer excellent in properties is prepared on the surface of a cheap base material, the requirement that the surface properties of a formed part are outstanding is met, the production cost is lowered substantially, the bonding strength between the material surface metallurgy layer and a base is improved, and cracking of the metallurgy layer is inhibited effectively.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

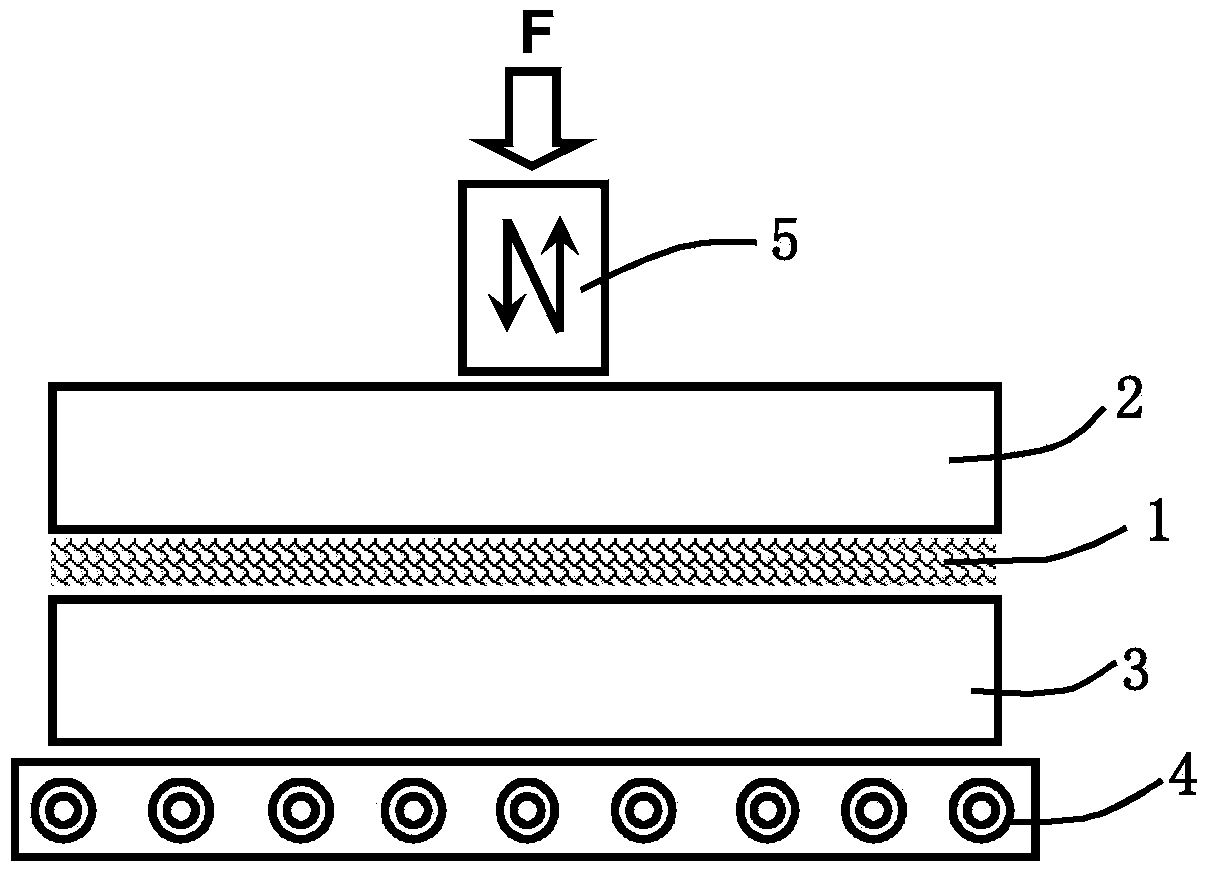

Preparing method for porous metal matrix compound brazing filler metal alloy soldering head

ActiveCN104191057ASuitable for brazingHigh strengthSoldering apparatusThermal dilatationUltrasonic vibration

The invention discloses a preparing method for a porous metal matrix compound brazing filler metal alloy soldering head. The method adopts porous metal matrix compound brazing filler metal alloy filled up with brazing filler metal alloy, a compound brazing filler metal layer is prefabricated between hard base metal, then the brazing filler metal alloy filled into the porous metal layer is heated to melt, and a tool head of an ultrasonic vibrating device acts on the surface of the base metal and exerts certain-pressure certain-time ultrasonic vibration on the surface of the base metal to finish a brazing process. When the method is used for preparing the brazing soldering head, the porous metal with high melting point can have a supporting function to a soldering seam layer in a brazing soldering process, the liquid-phase brazing filler metal alloy is prevented from being extruded out excessively in the ultrasonic vibration action. Thus, the preparation of the brazing soldering head with a large fuse face is achieved. In addition, the porous metal layer in the brazing seam layer can reduce the thermal expansion coefficients of the brazing seam layer, and the strength of the brazing seam layer and the strength of the connection interface between the brazing seam layer and the base metal are improved.

Owner:CHINA NAT ELECTRIC APP RES INST +1

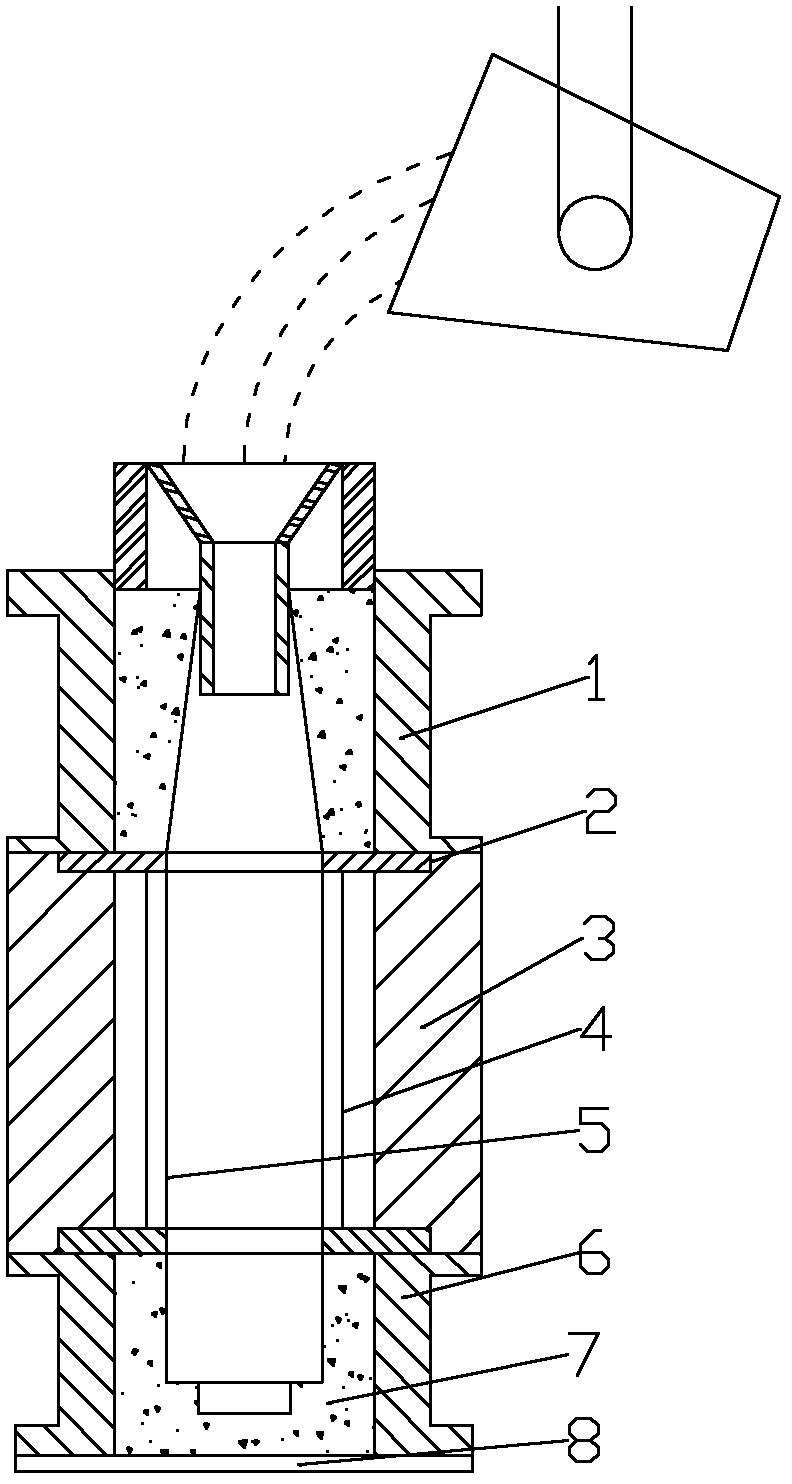

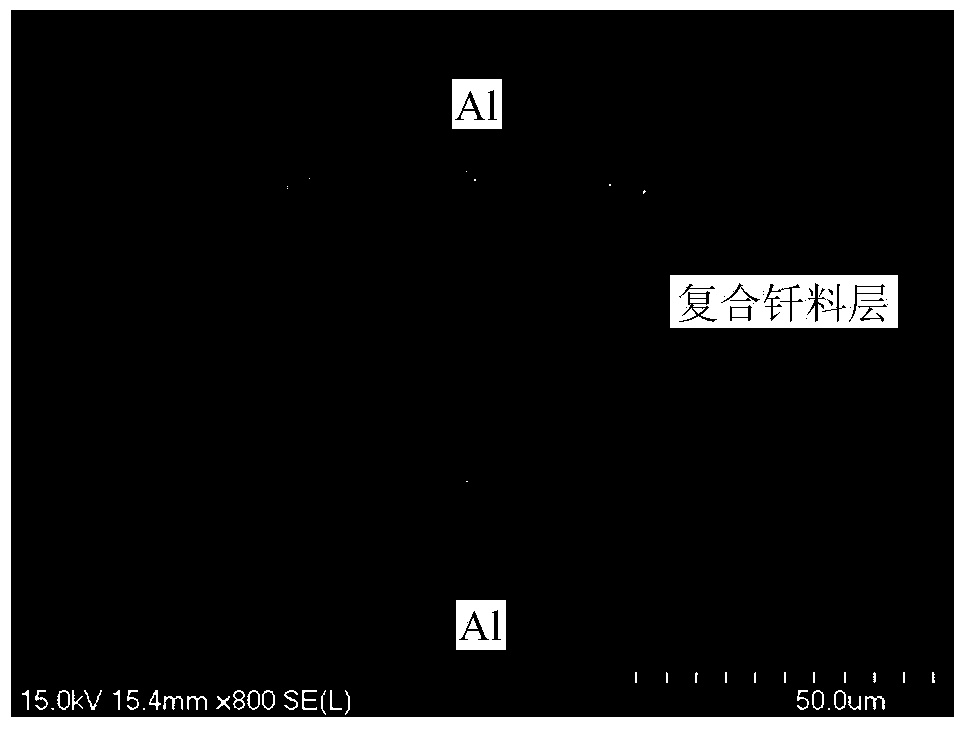

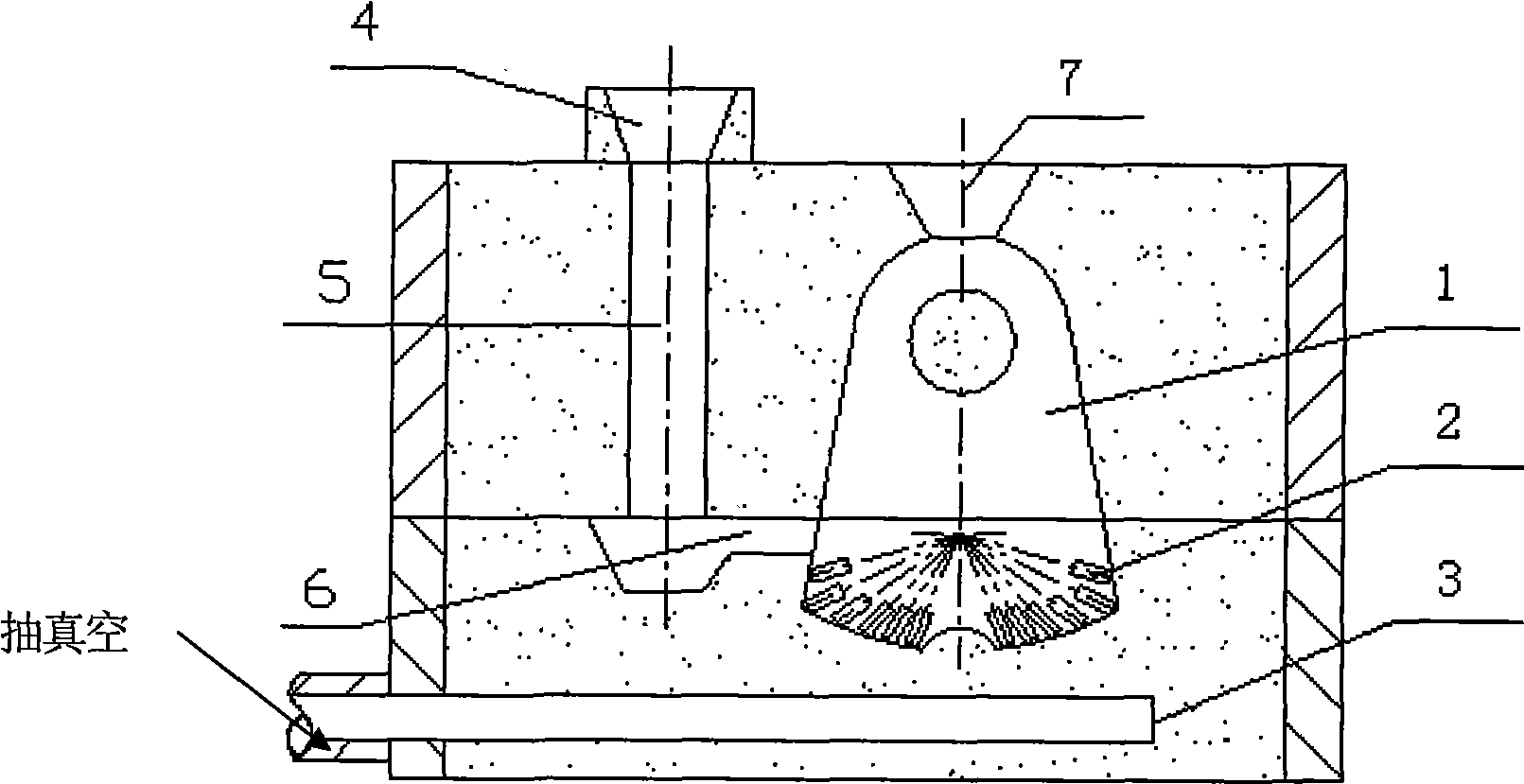

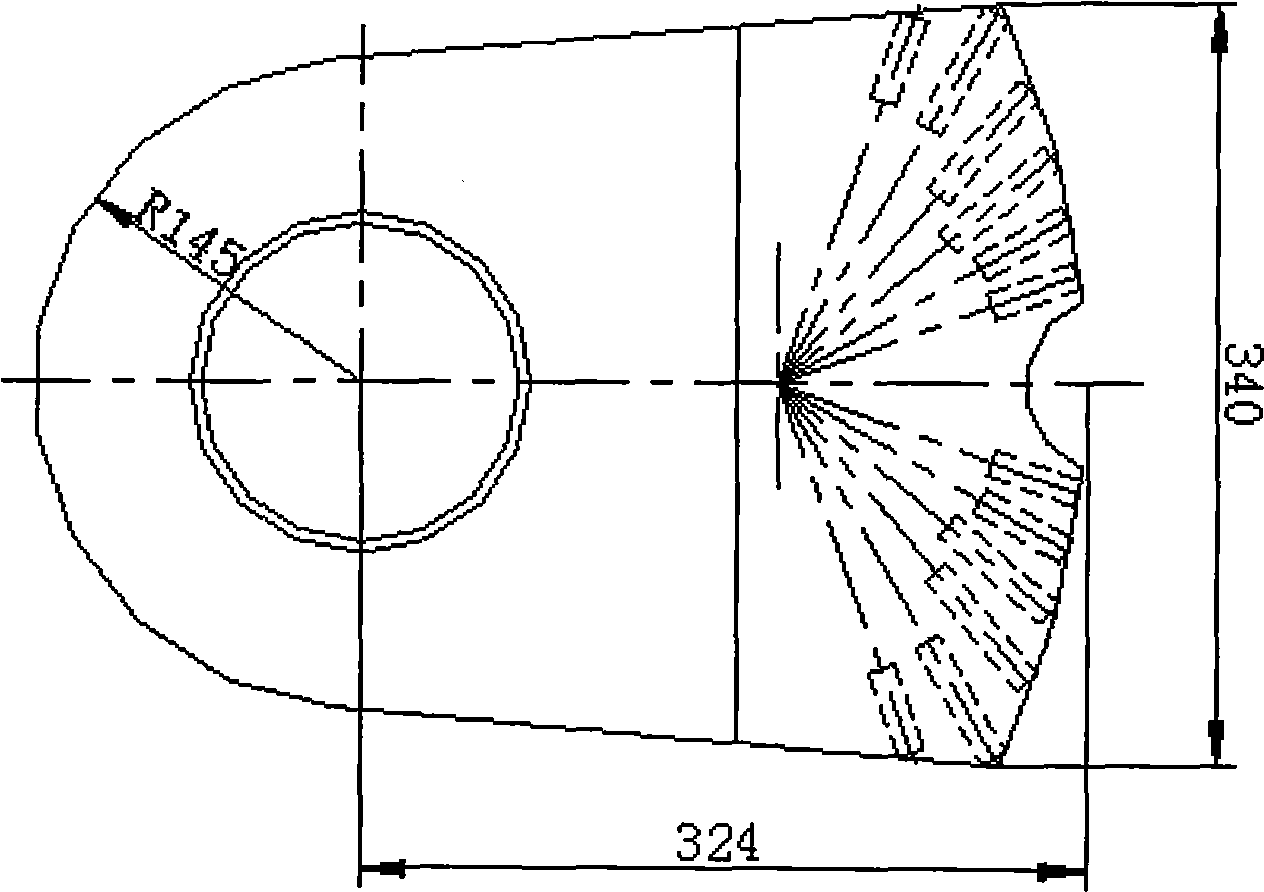

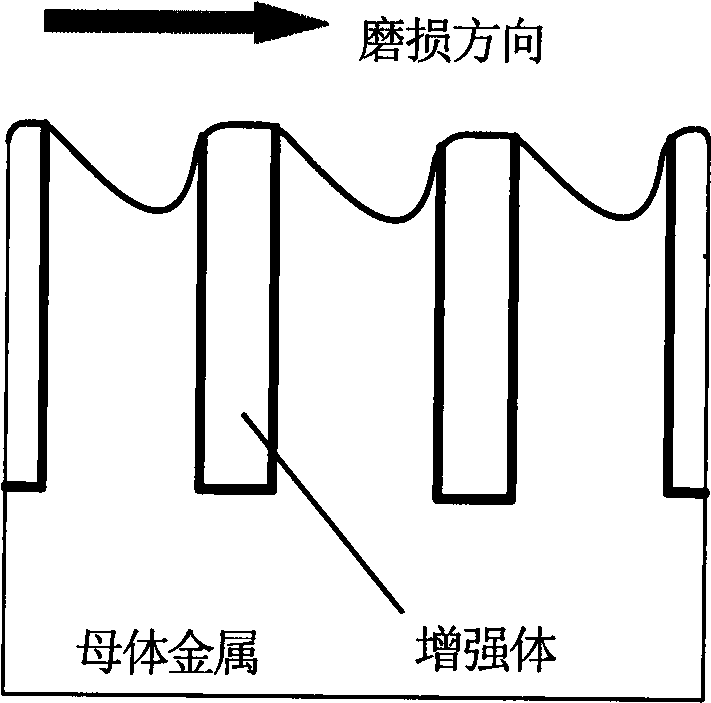

Composite material hammerhead of crusher and negative pressure casting method thereof

The invention discloses a composite material hammerhead of a crusher and a negative pressure casting method thereof. The negative pressure casting method comprises that: firstly, a metal parent material is subjected to electric smelting to form molten metal; WC particles and a bonding agent are mixed and prepared into paste, the paste is filled in a columnar metal screen which is then baked in a sealed mode to form a prefabricated body, and the prefabricated body is placed on the end face side of a mould cavity; a vacuum pump is started 5 minutes earlier than the tapping of the molten metal, and then the molten metal is tapped off for casting; and the vacuum pump is switched off after 4 minutes of the casting completion. The composite material hammerhead hammer body obtained by the preparation method is made of high manganese steel, alloy steel or common carbon steel; a hammer end, namely a working face or a striking face consists of a metal matrix and columnar reinforcers uniformly distributed in the metal matrix, wherein the columnar reinforcers are made of a composite material formed through infiltration of a ceramic particle prefabricated body and mother liquor metal, and have the hardness of HRC55-67 and excellent impact abrasion resistance; and the interface of the columnar reinforcers and the metal matrix, and the interface of the WC particles in the reinforcers and a substrate have good metallurgical bonding and high bonding strength.

Owner:XI AN JIAOTONG UNIV

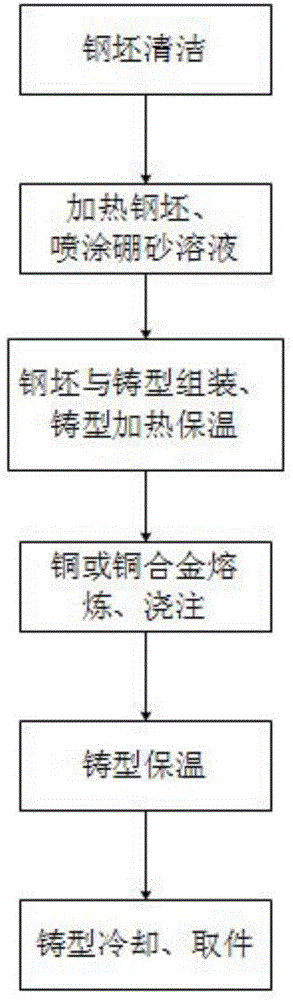

Copper and steel bimetallic casting application technology

The invention provides a copper and steel bimetallic casting application technology. Copper or copper alloy with certain thickness is directly cast on a steel base body by a static casting mold casting method. The technology mainly comprises the following steps of cleaning a steel billet, heating the steel billet, spraying a borax solution, combining a casting mold, heating and insulating heat, melting and casting the copper or the copper alloy, and insulating the heat of the casting mold at high temperature. The copper and steel bimetallic casting application technology has the advantages that a copper or copper alloy layer with certain thickness and without segregation can be cast on various shapes and various sizes of steel billets, and the good metallurgical combination between the copper or copper alloy layer of a casting and the steel billets is realized.

Owner:GUIZHOU ANJI AVIATION PRECISION CASTING

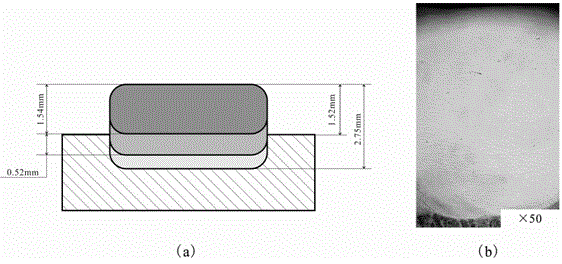

Iron-base alloy gradient cladding layer and preparation method thereof

InactiveCN105420724AObvious gradient changeLow priceMetallic material coating processesStop timeLaser scanning

The invention relates to a metal surface cladding layer and a preparation method thereof, in particular to an iron-base alloy gradient cladding layer and a preparation method thereof. The cladding layer is composed of a bottom cladding layer, a sandwiched cladding layer and a top cladding layer sequentially arranged on a base body, the three cladding layers are obtained by cladding of three kinds of different iron-base alloy powder layer by layer, and the three kinds of iron-base alloy powder comprise FJ-1 powder, first iron-base alloy powder and high-ferrochromium-base alloy powder; when the cladding layer is prepared, each kind of powder undergoes laser cladding according to specific process parameters, the inter-layer laser stopping time is 10 minutes, inter-layer laser scanning paths are perpendicular, and finally the gradient cladding layer with the cladding thickness being 2.75 mm and the surface hardness being 60 HRC can be formed. The cladding layer is mainly characterized in that the microhardness values of the three layers are not uniform. The gradient cladding layer technology is applied to the wear area of steel work-pieces H13 for repair and is wide in application prospect of fast forming components on the steel work-pieces H13.

Owner:LIAONING UNIVERSITY OF TECHNOLOGY

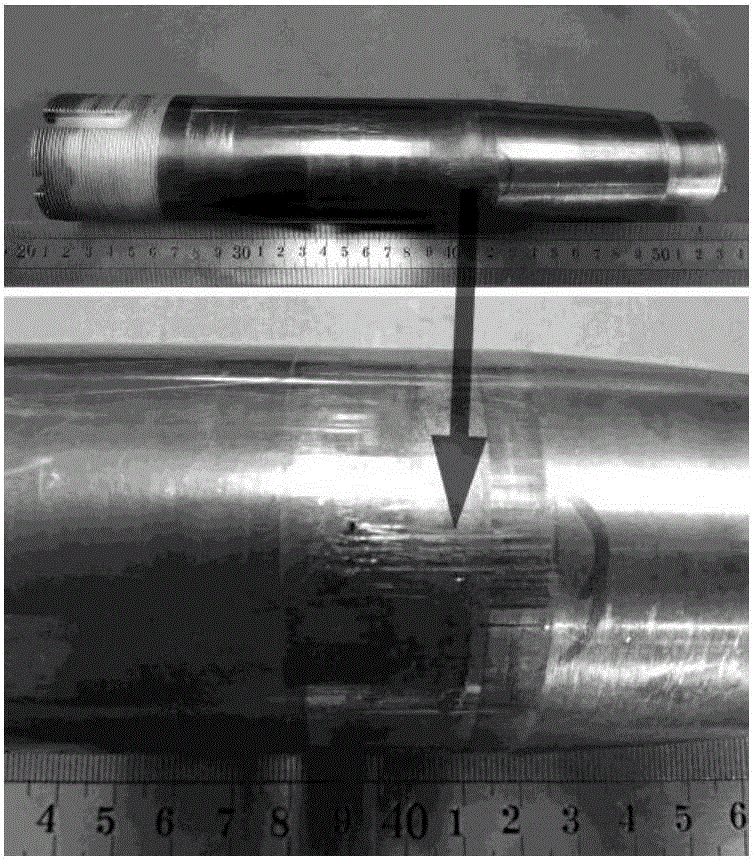

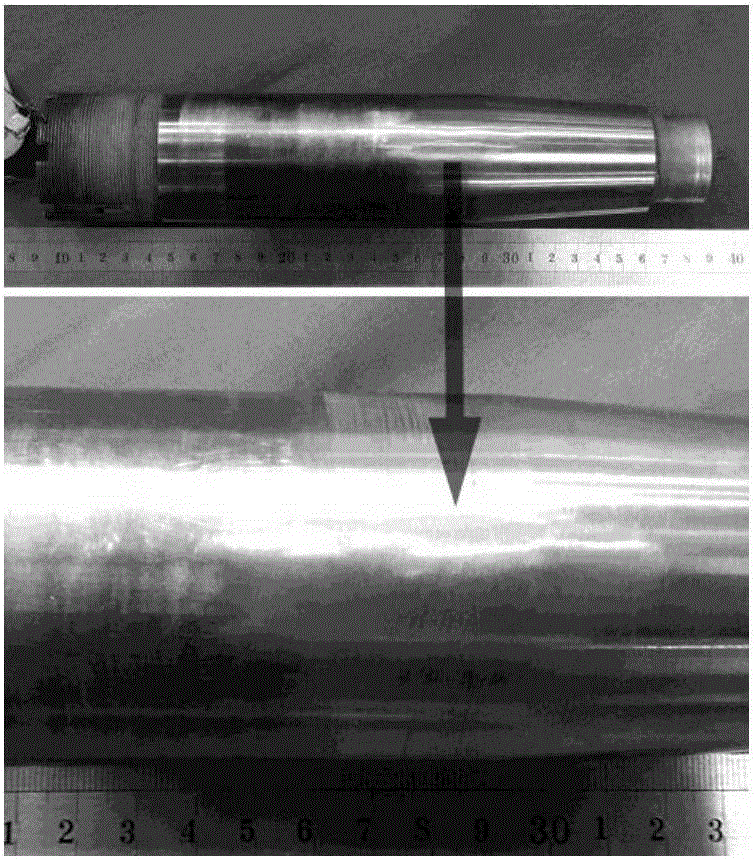

Railway vehicle axle repair process

InactiveCN104480466AGood metallurgical bondRelief of residual stressMetallic material coating processesSlagAutomotive engineering

The invention discloses a railway vehicle axle repair process. The process comprises the steps of pretreatment, laser cladding, residual stress relaxation and machining, wherein in the laser cladding step, the adopted metal powder comprises, by mass, 0.1-0.25% of carbon, 17.5-28% of chromium, 10.5-16% of nickel, 0-0.65% of boron, 0.12-1.0% silicon, 0-4.5% of molybdenum, 0-0.8% of manganese and the balance being iron. A vehicle axle repaired through the process is small in microstructure, free of the defects such as air holes, slag inclusion and cracks and capable of meeting the requirement for use performance; the service life of the repaired vehicle axle reaches or exceeds that of a new axle. The railway vehicle axle repair process has the advantages that operation is easy, the controllability is good, the damaged vehicle axle can be repaired quickly in a short time, the cost for replacement of the damaged axle with the new axle is lowered, the use cost of the vehicle axle is lowered, harm of the discarded vehicle axle to the environment is reduced, and environmental friendliness is achieved.

Owner:SOUTHWEST JIAOTONG UNIV

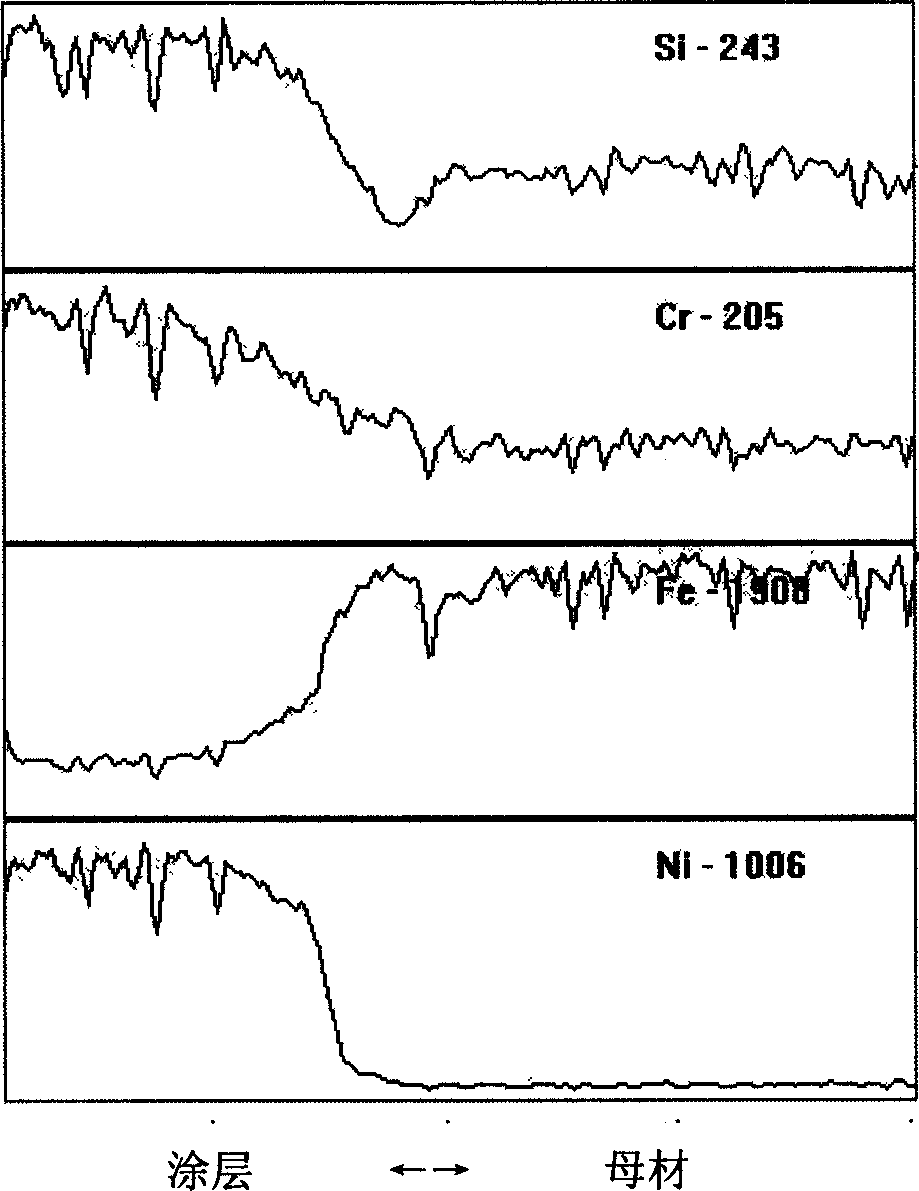

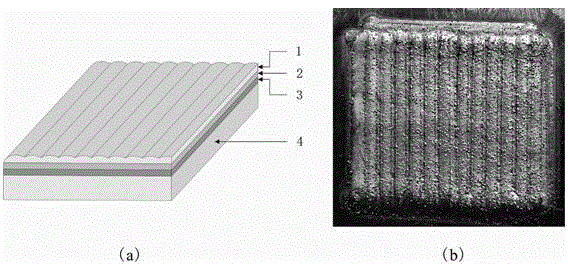

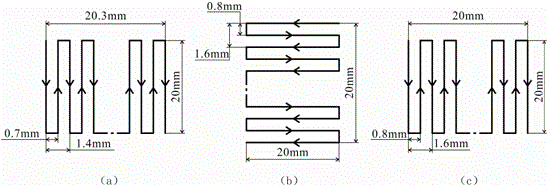

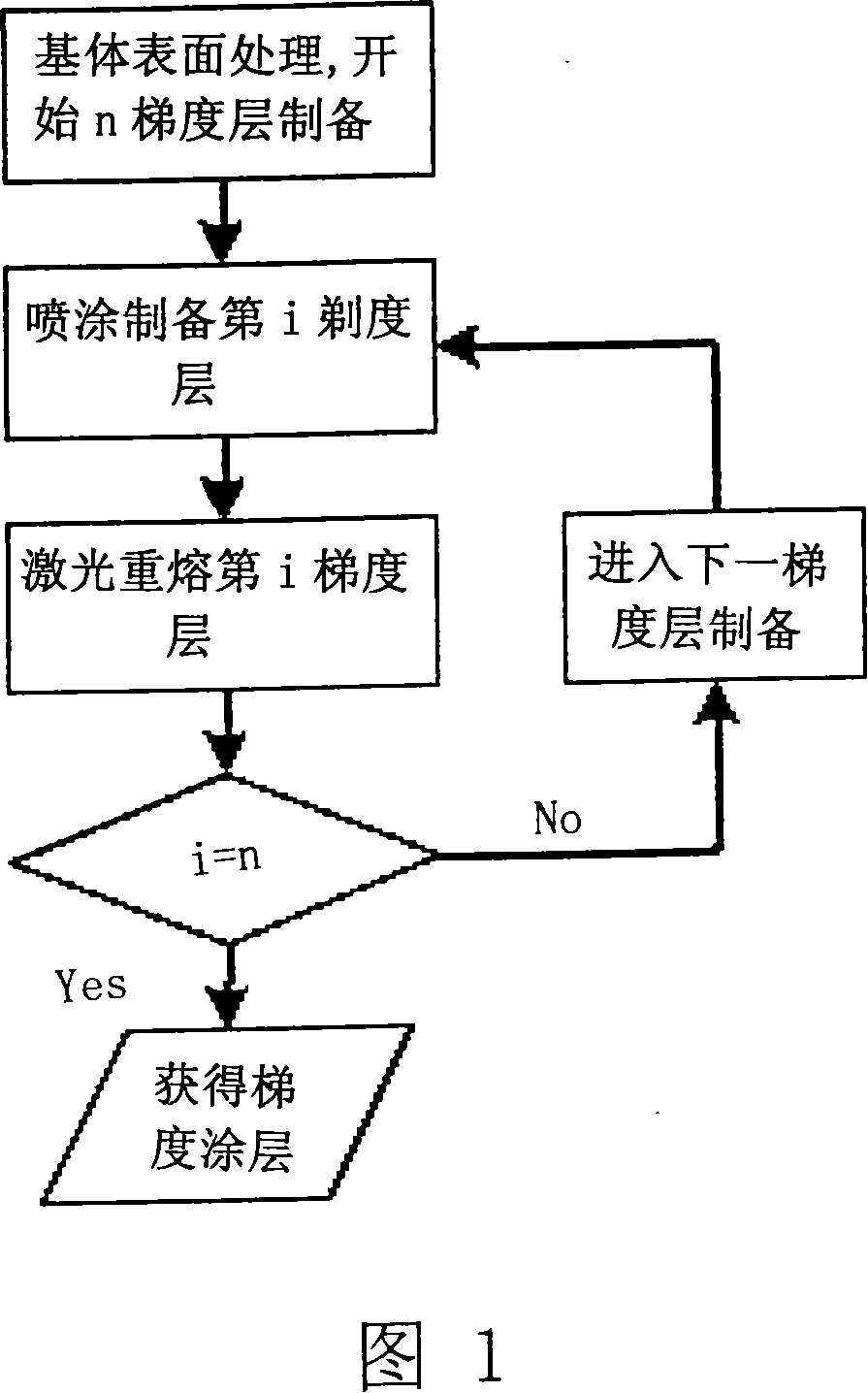

Processing method of hot sprayed gradient coatings based on time after time laser refusing

InactiveCN101112701AImprove bindingGood metallurgical bondPretreated surfacesCoatingsThermal sprayingOptoelectronics

A hot spray grads coat processing method based on multi-time laser remelting belongs to a novel material processing method. The method has a main innovative point that the multi-time laser remelting method is adopted for the composite process of the hot spraying grads coats, and the defects that not all sub-coat reaches the metallurgy combination, the grads structure in the coats is damaged and the hot spraying laminated organization can not be eliminated, etc. on the conditions of remelting without laser or one-time laser remelting are overcome. The detailed process is that the purification and activation disposal are firstly disposed to the base metal material, the first grads material is sprayed on the surface of the base and one-time laser remelting is sequentially carried out for the first grads layer, causing the first grads layer to form the metallurgy combination with the base; after that, the second grads material is sprayed on the surface of the first grads layer after remelting of laser and the secondary laser remelting is carried out, causing the metallurgy combination to be formed between the two grads oats; sequentially adopting the method, the hot spraying and laser remelting process are respectively carried out to all grads coats. The invention has the advantages of simple and reliable processing method and meeting the comprehensive performance requirements of coats.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

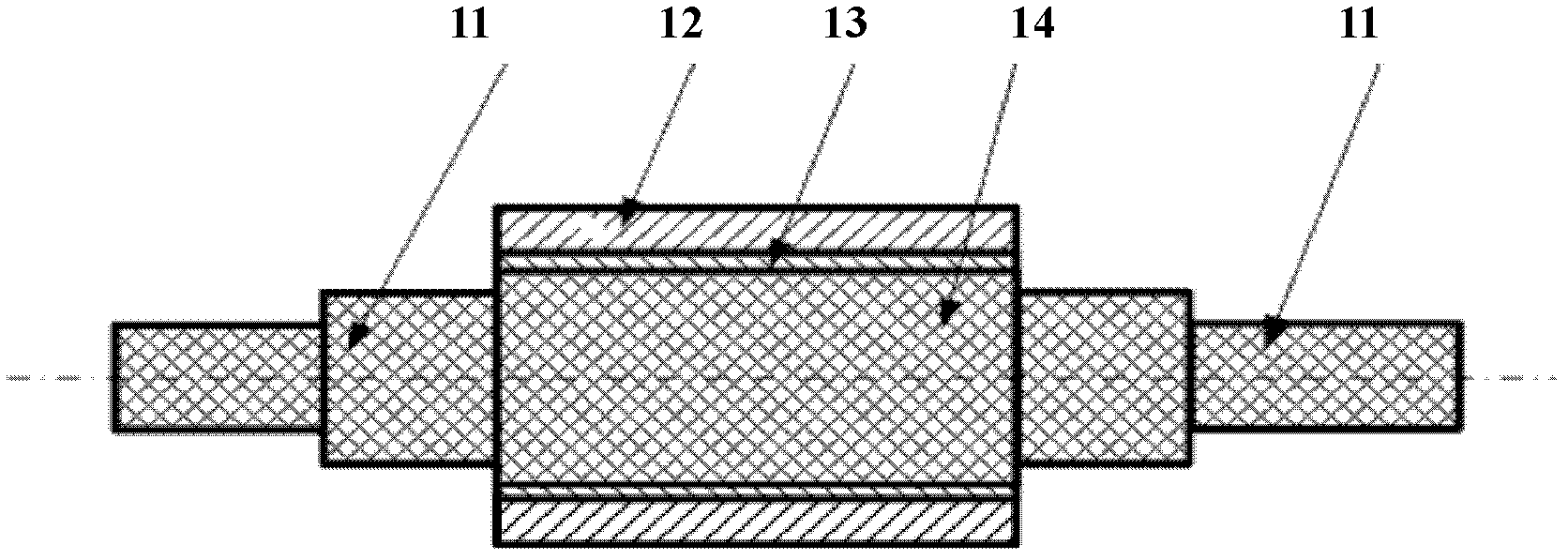

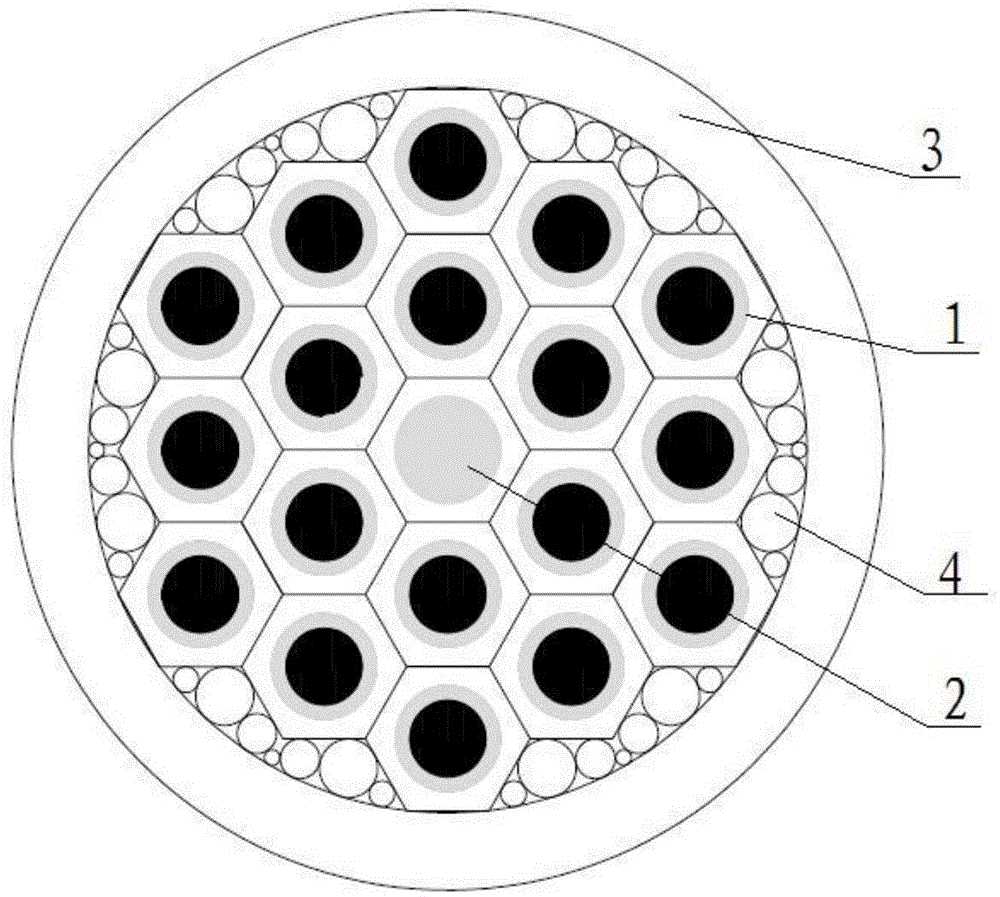

Method for manufacturing multi-core MgB2 superconductive wires through extrusion technology

ActiveCN104091651AImprove compactnessHigh yield strengthCable/conductor manufactureComposite strengthMachining deformation

The invention discloses a method for manufacturing multi-core MgB2 superconductive wires through the extrusion technology. The method includes the steps that first, precursor powder is prepared; second, the precursor powder is installed in a pipe to prepare a primary complex, and single-core wires are obtained through drawing machining; third, the precursor powder is installed in a pipe to prepare a secondary complex; fourth, the secondary complex processed through pre-heating seal welding is extruded, and multi-core rods are obtained; fifth, the multi-core rods are stripped and drawn to obtain multi-core wires, the multi-core wires are subjected to heat treatment, and then the multi-core MgB2 superconductive wires are obtained. According to the method, on the basis of a traditional power pipe-installing technology, a large single-pass machining deformation amount is adopted for manufacturing the multi-core MgB2 superconductive wires, in other words, the extrusion technology is adopted for manufacturing the multi-core MgB2 superconductive wires, because the secondary complex is in a very favorable three-dimensional stress state in extrusion, good metallurgical bonding will be achieved between different metal interfaces in the secondary complex along with the large extrusion deformation amount, the manufactured multi-core rods are high in composite strength, and the compactness and the yield strength of the multi-core MgB2 superconductive wires can be significantly improved.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

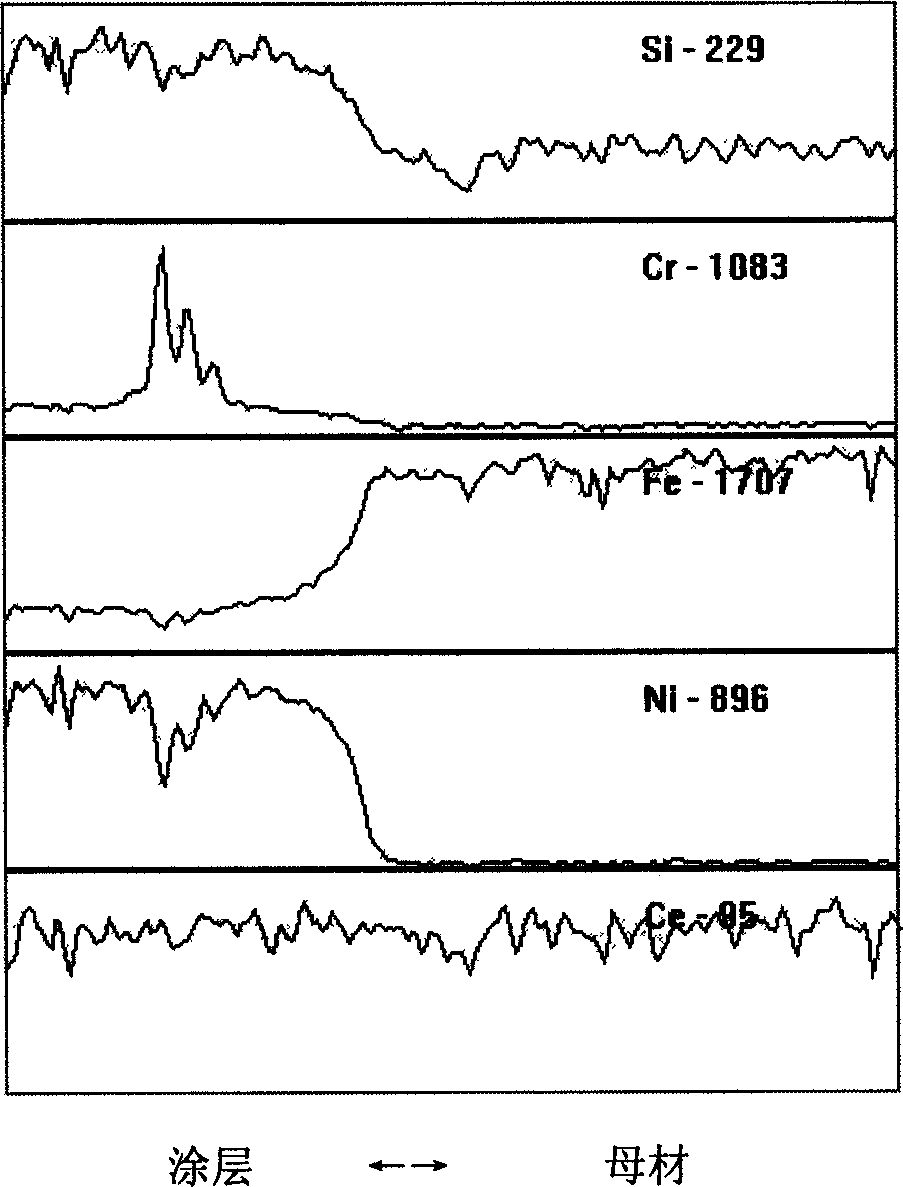

Process of laser-cladding rare earth CeO2-nickel-based alloy composite coating on surface of aluminum or aluminum alloy

ActiveCN103628055AImprove wear resistanceImprove corrosion resistanceMetallic material coating processesRare earthAlloy composite

The invention discloses a process of laser-cladding a rare earth CeO2-nickel-based alloy composite coating on the surface of an aluminum or an aluminum alloy. The process comprises the following steps: first, coating a layer of rare earth CeO2-nickel-based self-refluxed alloy powder on the surface of the aluminum alloy by a laser surface cladding technology; then, scanning the powder layer by laser to melt and clad the powder layer on the surface of the aluminum alloy to form a rare earth CeO2-nickel-based self-refluxed aluminum alloy cladding layer. According to the process disclosed by the invention, the rare earth CeO2-nickel-based self-refluxed aluminum alloy cladding layer with high performance is prepared by taking the aluminum or the aluminum alloy as the base body material by means of the laser surface cladding technology, so that good metallurgical binding between the cladding layer and the base body material is realized, and the performances of the material such as wear resistance, corrosion resistance and resistance to oxidation are improved.

Owner:GUILIN UNIV OF ELECTRONIC TECH

High-tungsten high-abrasion-resistant high-speed steel composite roller and preparation method thereof

ActiveCN105750529AHigh hardnessImprove wear resistanceFurnace typesHeat treatment furnacesChemical compositionDuctile iron

Owner:枣庄瑞兴机械制造有限公司

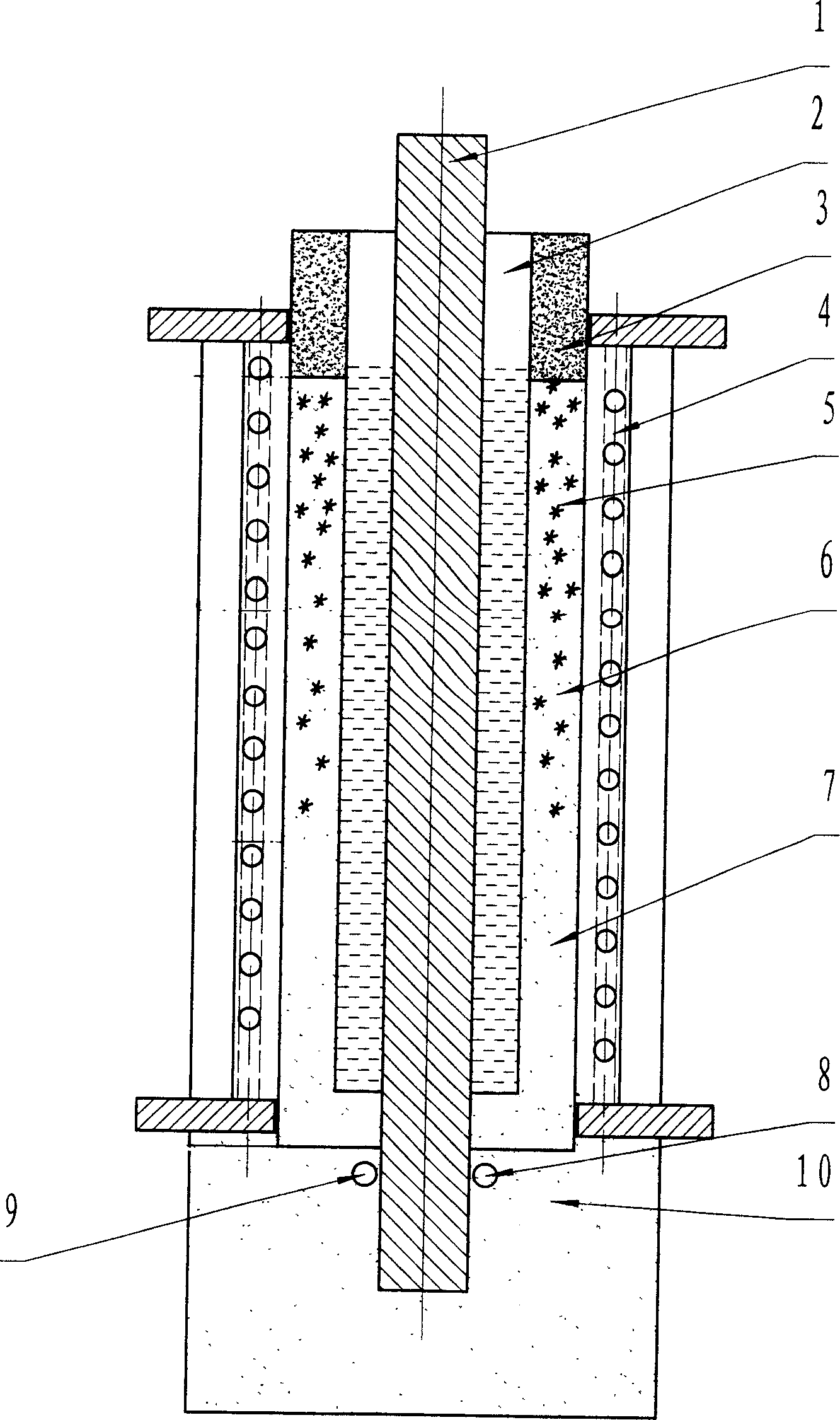

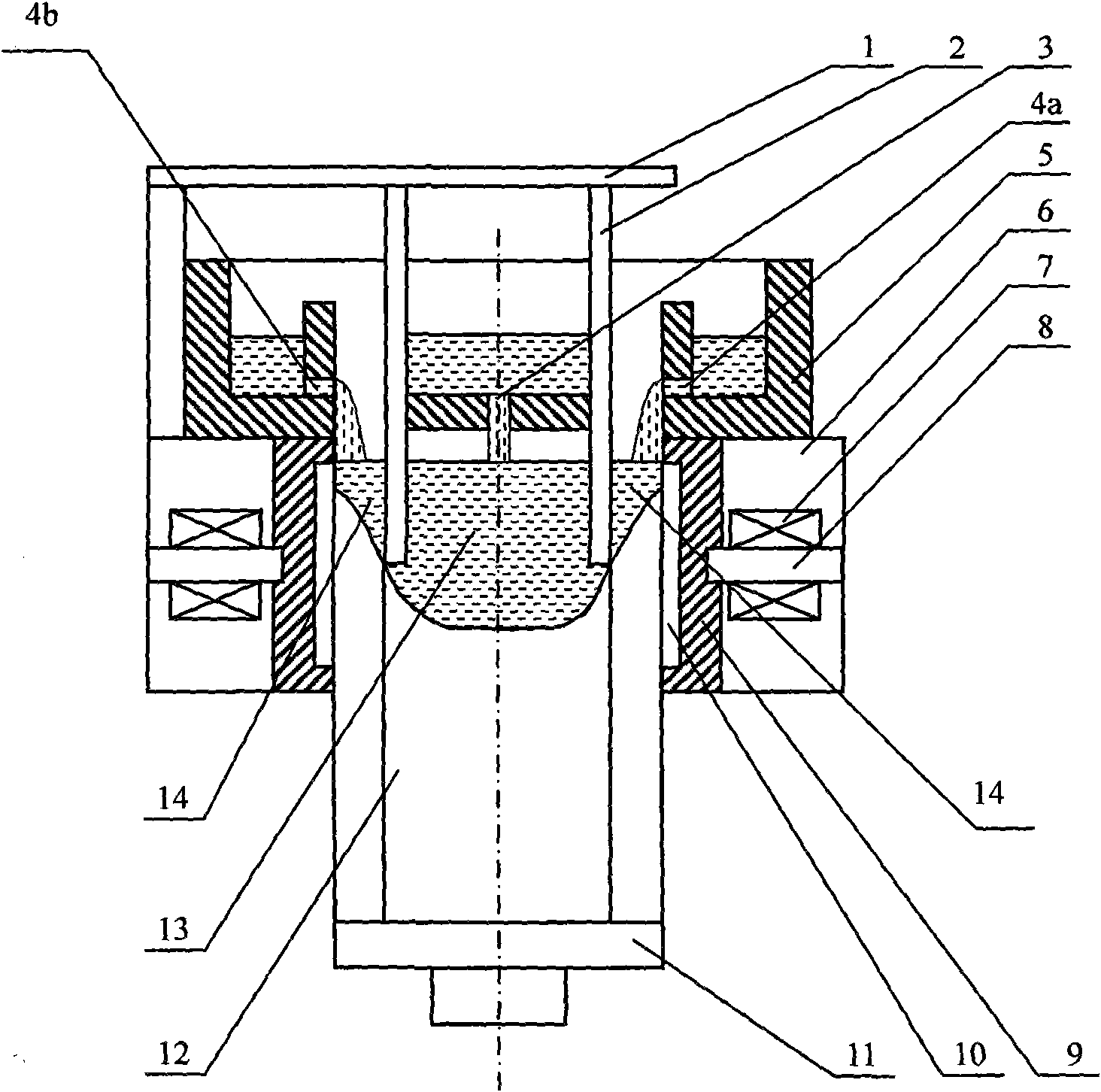

An electromagnetic continuous casting method and device of complex ingot blank

The invention discloses an electromagnetic continuous casting method and device of complex ingot blank, which inserts the graphite baffle in the continuous casting water-cooled mold, and sets up the hot top at the top of the water-cooled mold with three rain-style pouring opening on the hot top, and installs the electromagnetic brake outside the water-cooled mold and under the graphite baffle. During the casting process, the inner metal liquid pours into the water-cooled mold through the first rain-style pouring opening, the outer metal liquid pours into the water-cooled mold through the second and third rain-style pouring opening. They are divided by the graphite baffles to form the three-layer complex ingot blank. The electromagnetic force generated by iron core prevents the mixed flow of the inner and outer metal liquid under the graphite baffles. The invention uses two or more metal liquid to directly and continuously cast the complex ingot blank to ensure that the interface has a good metallurgical combination and the thickness of the ingot blank inside and outside layers are adjustable; the invention can produce large size ingot blank and significantly reduce the production cost of complex layer materials, with relatively simple process and equipment, which is easy to implement high-volume continuous production.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

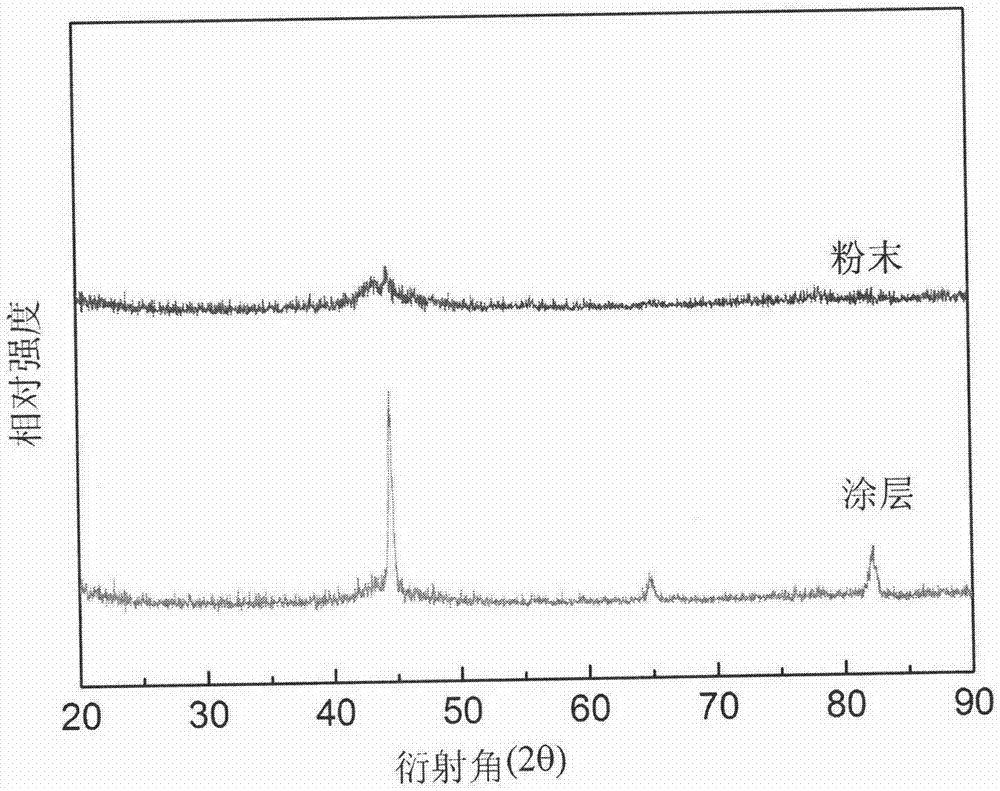

Method for preparing anticorrosion wear-resisting iron-based amorphous coating through laser cladding technology

InactiveCN106868496AUniform tissueNo crackMetallic material coating processesChemical compositionCoupling

The invention relates to a method for preparing an anticorrosion wear-resisting iron-based amorphous coating through a laser cladding technology. Chemical components of Fe-based amorphous alloy powder comprise, by mass percent, 17.3% to 19.4% of Cr, 1.8% to 2.2% of Mn, 12.9% to 15.8% of Mo, 5.0% to 6.2% of W, 2.8% to 4.1% of B, 0.7% to 1.1% of C, 1.0% to 1.5% of Si and the balance Fe, wherein the total mass is 100%. The industrial pure raw materials and the tight coupling gas atomization technology are adopted for preparing the iron-based amorphous alloy with the components into powder stock, and the single-pass diode laser cladding technology is used for preparing the amorphous alloy coating. The preparing technology of the iron-based amorphous coating approaches to the actual industrial level, the technology condition is controllable, the cost is low, the beneficial effects of being compact in structure, uniform in structure, free of crack and hole defects, high in hardness, anti-corrosion, resistant to wear and the like are achieved, and the great utilization potentiality is achieved in the national defense industry.

Owner:TIANJIN POLYTECHNIC UNIV

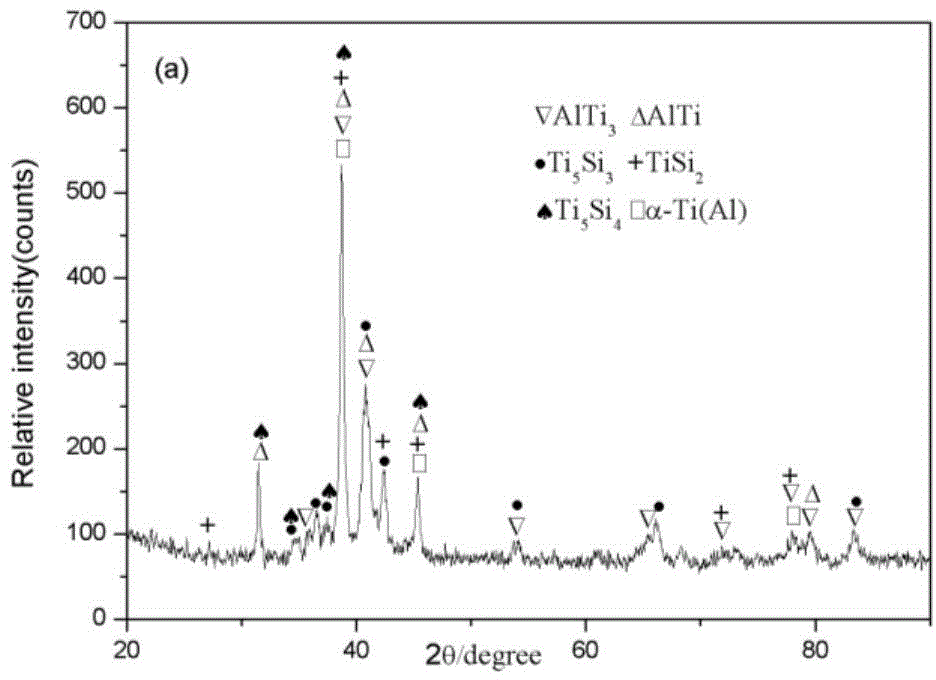

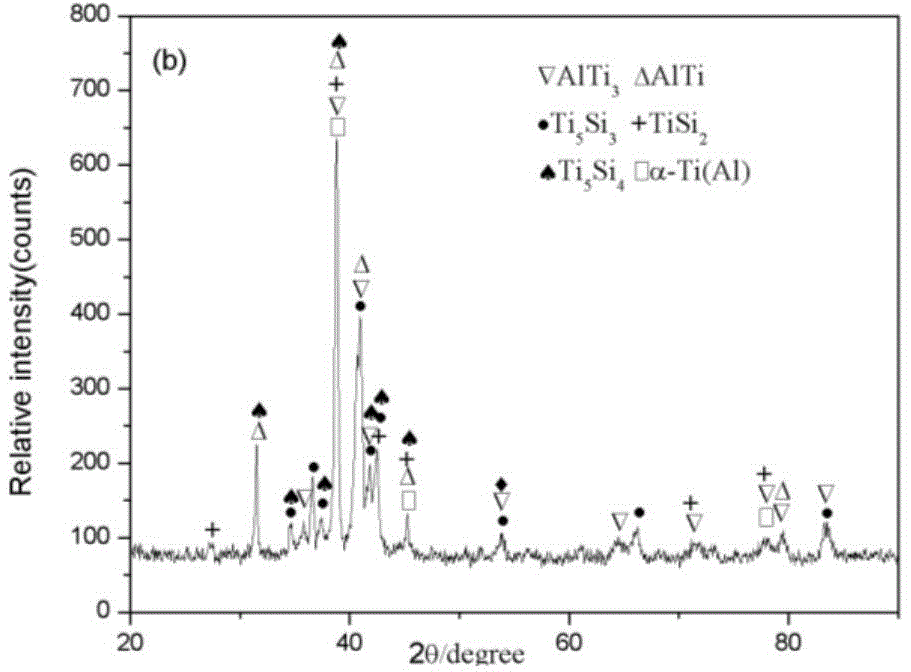

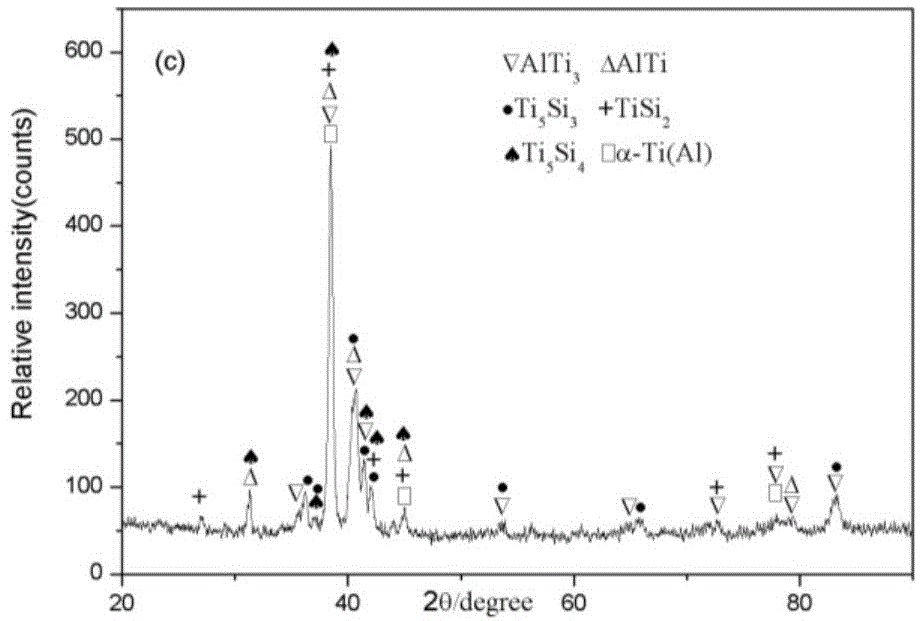

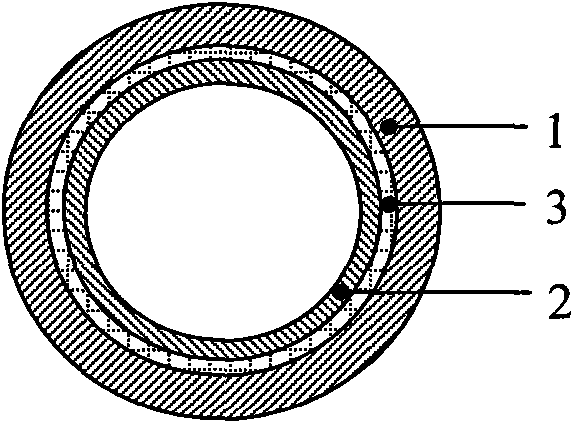

Preparation technology of intermetallic compound based ceramic composite coating on surface of titanium alloy

ActiveCN104152895AHigh hardnessGood metallurgical bondMetallic material coating processesCeramic compositeShielding gas

The invention discloses a preparation technology of an intermetallic compound based ceramic composite coating on the surface of a titanium alloy. The preparation technology comprises the following steps of: (1) uniformly mixing cladding material powder, preparing mixed powder into paste with a water glass solution, uniformly coating the surface of the titanium alloy with the paste with the coating thickness of 0.5-1.0mm, carrying out airing, and (2) carrying out laser cladding on the coating on the surface of the titanium alloy with the laser power of 800-1200W and the laser scanning speed of 2.5-7.5mm / s, and blowing argon for shielding with the shielding gas pressure of 0.2-0.4MPa, wherein a laser spot diameter is fixed at 4mm.The mixed cladding material powder comprises the following ingredients by mass percentage: 25-65% of Ti, 20-60% of Al, 5-30% of Si and 0-3% of Y2O3, or 25-65% of Ti, 20-60% of Al, 5-30% of Si, 2-40% of B4C and 0-3% of Y2O3, or 25-65% of Ti, 20-60% of Al, 5-30% of Si, 5-40% of TiC, and 0-3% of Y2O3. The composite coating prepared by the technology can significantly increase microhardness of the titanium alloy, improve wear resistance of titanium alloy components, and extend an application scope of titanium alloy spare parts.

Owner:SHANDONG UNIV

Stainless steel composite steel pipe and manufacturing method thereof

InactiveCN101566256AImprove corrosion resistanceCombined with good qualityRigid pipesSolution stateHeating temperature

The invention discloses a stainless steel composite steel tube and a manufacturing method thereof. The method overcomes the technical prejudices in the prior manufacture of brazing stainless steel composite steel tube, adopts a brass foil with lower price as a brazing material, and avoids the problems of environmental pollution, high cost, large energy consumption and the like in the prior art which uses a nickel-based brazing material coated layer; and a method for performing diffusion brazing by air-cooling a composite tube blank from bottom to top according to a temperature reducing gradient of between 100 and 200 DEG C per minute so as to solidify a brazing solder in sequence from bottom to top not only sufficiently fills the brazing material in the inner and outer tube gaps but also forms diffusion with a distance of a few microns with inner and outer layer materials, wherein an inner layer stainless steel tube and an outer layer carbon steel tube form good metallurgical bonding through a diffusion brazing layer; and simultaneously, the heating temperature, the soaking time and the cooling speed can make carbon steel in a normalized condition to obtain fine textures, and the strength matches well with the plasticity and the stainless steel which is in a solution state and has optimal corrosion resistance at the same time.

Owner:大连合生科技开发有限公司

Method for preparing wear-resistance toughening coating layer on surface of high-manganese steel

ActiveCN107815682AReduce pollutionImprove wear resistanceMetallic material coating processesSolution treatmentCoated surface

The invention discloses a method for preparing a wear-resistance toughening coating layer on a surface of high-manganese steel. The method is characterized by comprising the steps of: (S1) pretreatment of a basal body before cladding, (S2) pretreatment of powder before cladding, (S3) cladding, and (S4) heat treatment after cladding. A plasma cladding technology, solid solution treatment and a coating layer surface aging process are adopted to prepare the Fe-Ni base alloy coating layer with high hardness, high wear resistance and high impact toughness; the surface hardness and the wear resistance of the basal body material are improved; the problem of easy cracking of a traditional hard particle reinforcing metal base wear-resistance coating layer under such conditions as medium and high stress is solved; and the prepared coating layer is excellent in metallurgical bonding with the basal body material, so that the comprehensive performance of the coating layer is greatly improved, the basal body material is protected more sufficiently, the service life of the basal body material is prolonged, and the application prospect is broad.

Owner:梧州啟润机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com