Copper and steel bimetallic casting application technology

An application technology, bimetallic technology, applied in the application field of copper-steel bimetallic casting, which can solve the problems of component specific gravity segregation, inability to realize copper-steel bimetallic metallurgical combination, etc., and achieve the effect of reducing the diffusion energy barrier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

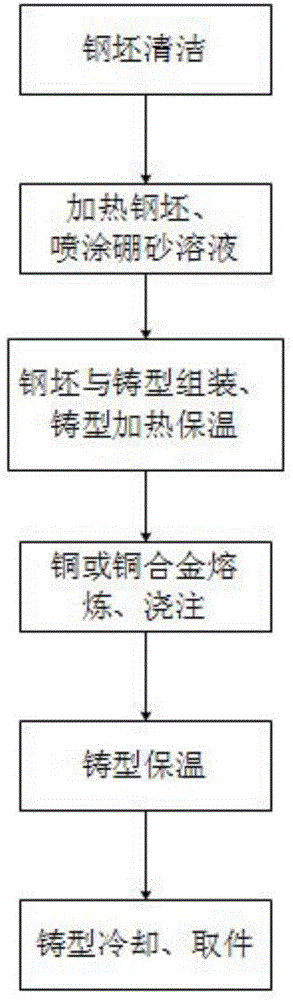

Method used

Image

Examples

Embodiment Construction

[0023] Taking Q255 carbon steel and ZCuSn3Zn11Pb4 tin bronze as examples below, the technical solution of the present invention will be described in detail.

[0024] Q255 carbon steel is often used in the manufacture of parts that do not require high strength, such as bolts, keys, rockers, shafts, tie rods and various steel structures, steel plates, etc., and its solid-liquid phase transition temperature is around 1450 °C. ZCuSn3Zn11Pb4 tin bronze is a commonly used cast copper alloy with excellent mechanical properties, good wear reduction and corrosion resistance, easy to cut, good welding performance, and small casting shrinkage coefficient. It is often used to make elastic elements and wear-resistant Components.

[0025] First, the Q255 carbon steel bar of the corresponding size is processed into a shaft sleeve with a height of 50mm, an outer diameter of 50mm and a wall thickness of 4mm by machining. Design and make the corresponding mold for use, and then refer to the at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com