Advertising board fixing plate spraying device

A technology of spraying device and fixed plate, which is applied in the direction of spraying device, liquid spraying device, smoke and dust removal, etc. It can solve the problems of low efficiency of manual spraying, generation of harmful gas, damage to human health, etc., to improve the spraying range, avoid damage, and spray high quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

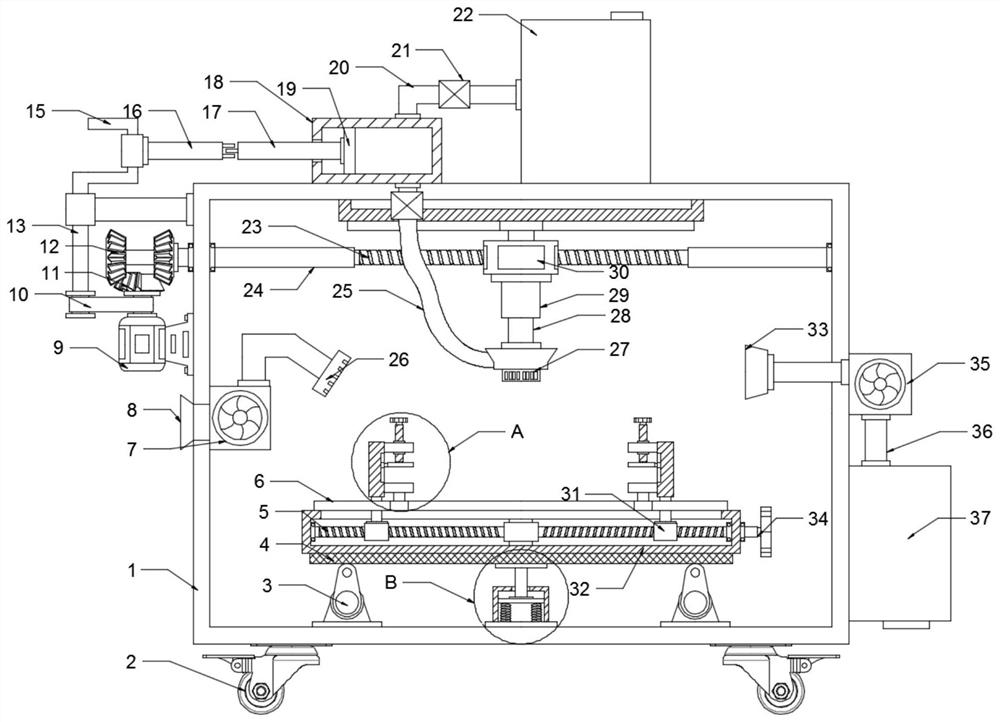

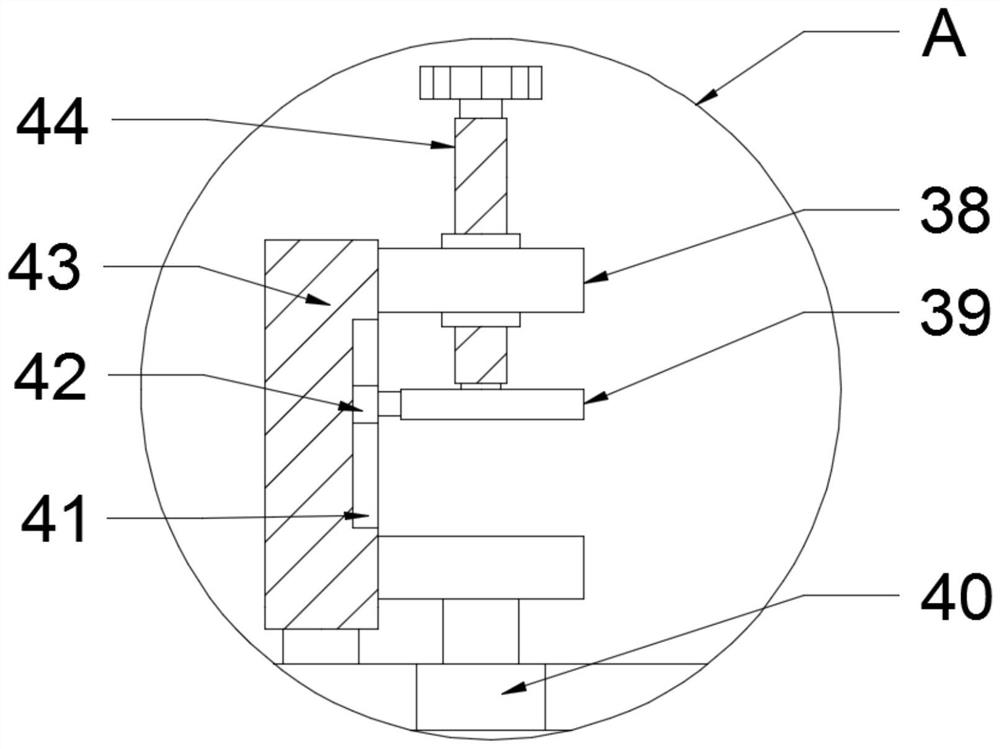

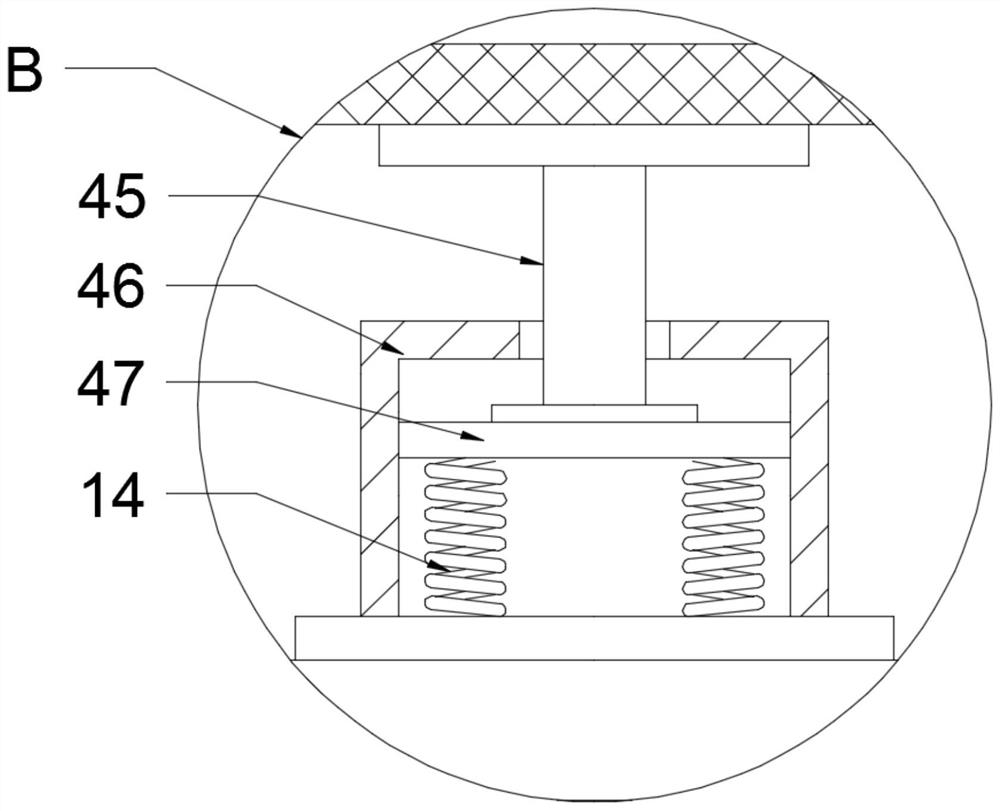

[0021] see Figure 1-4 , a billboard fixed plate spraying device, comprising a spraying box 1 and an adjusting box 32, the screw rod 5 is arranged in the adjusting box 32, the screw rod 5 is connected with the inner wall of the adjusting box 32 in rotation, and the left and right sides of the screw rod 5 The direction of the side thread is opposite, and the left and right sides of the surface of the screw mandrel 5 are symmetrically provided with nuts 31, and the nuts 31 can move left and right in the horizontal direction with the rotation of the screw mandrel 5, and the right end of the screw mandrel 5 passes through the adjustment box 32 Extend and fix the connection handle 34, and fix the support 43 above the nut 31. By turning the handle 34, the handle 34 drives the screw mandrel 5 to rotate, and the nuts 31 on the left and right sides drive the upper support 43 to move inwardly at the same time. The metal plate to be sprayed is fixed in the support 43, and the left side w...

Embodiment 2

[0028] see figure 1, on the basis of embodiment 1, in order to fully spray the surface of the metal plate, a rotating rod 24 is arranged above the inside of the spraying box 1, and the rotating rod 24 is rotationally connected with the spraying box 1, and the left side of the rotating rod 24 extends To the outside of the spraying box 1, a bevel gear 12 is arranged symmetrically at the left end of the rotating rod 24, and the output end of the drive motor 9 is fixedly connected to the incomplete bevel gear 11, and the bevel gear 12 is intermittently meshed with the incomplete bevel gear 11, Screw rods 23 are arranged between the rotating rods 24, and movable seats 30 are arranged on the surface of the screw rods 23, and the movable seats 30 can move left and right in the horizontal direction with the rotation of the screw rods 23. The driving motor 9 rotates, and the driving motor 9 drives the incomplete bevel gear 11 to rotate, and the incomplete bevel gear 11 drives the rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com