Grouting manipulator

A manipulator and spraying technology, which is applied in shaft lining, tunnel lining, underground chamber, etc., can solve the problems that the construction quality is difficult to be guaranteed, the concrete is easy to rebound and collapse, and the construction efficiency is low, so as to achieve the convenience of spraying height and Adjustment of position, convenience of spraying work and improvement of construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

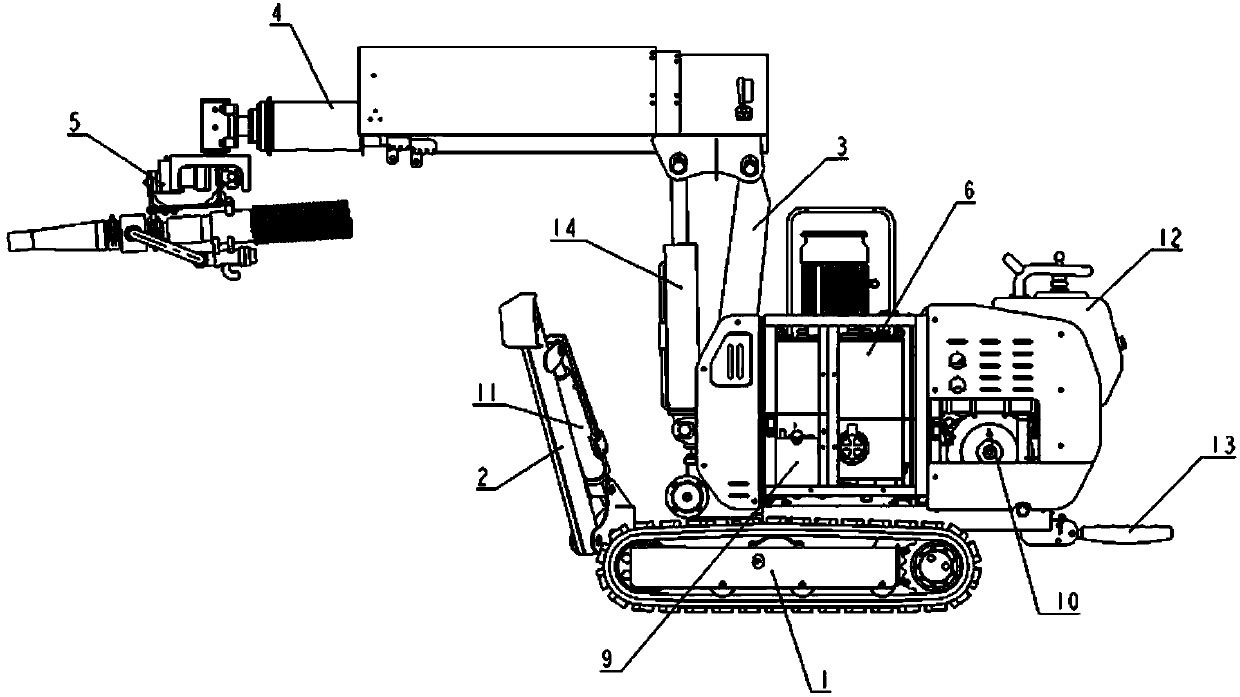

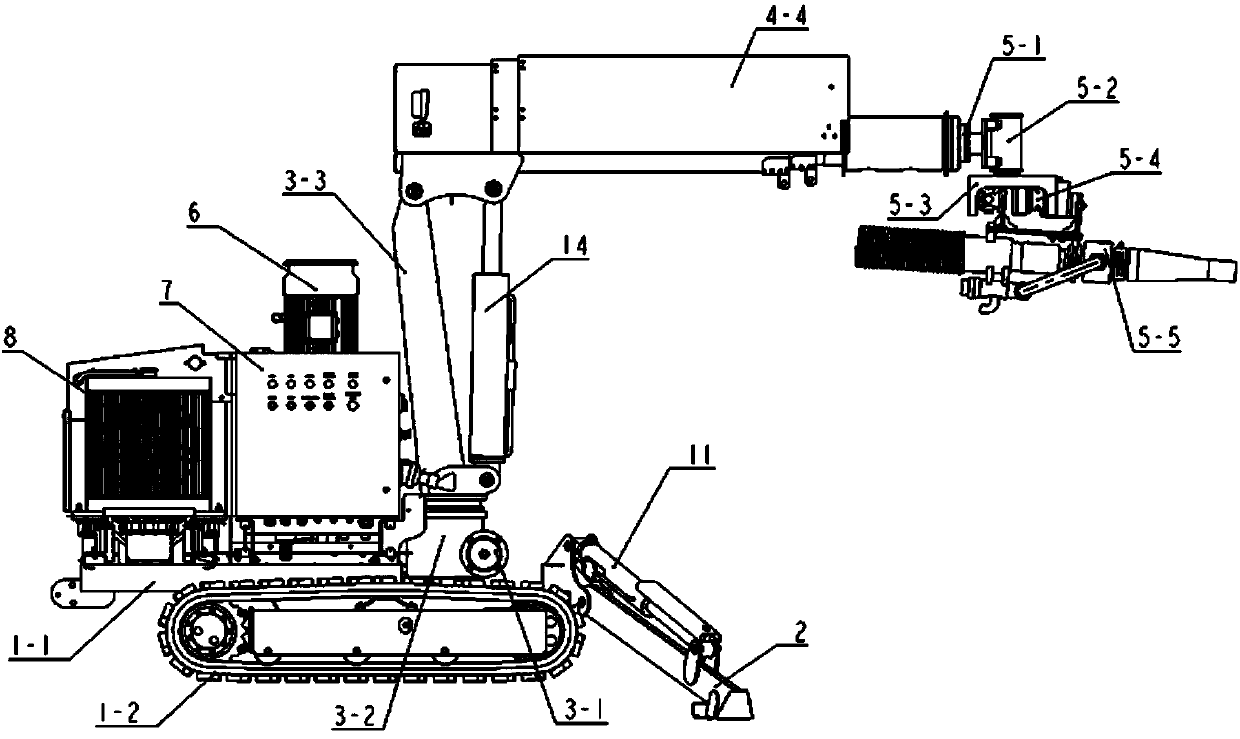

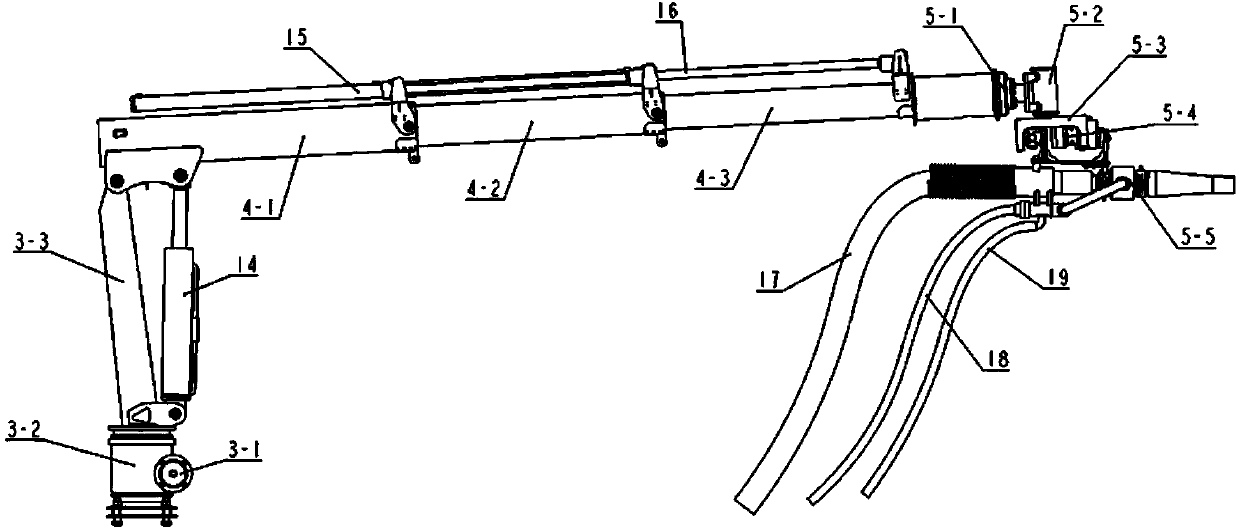

[0025] Such as figure 1 Shown is a schematic structural view of an embodiment of the spraying manipulator of the present invention. In this embodiment, the spraying robot includes a chassis 1 , a slewing mechanism 3 , a boom 4 , a spray head device 5 , a hydraulic system 6 and an electrical system 7 . The slewing mechanism 3 , the hydraulic system 6 and the electrical system 7 are all arranged on the chassis 1 . The arm frame 4 is hinged with the slewing mechanism 3 and can rotate relative to the chassis 1 driven by the slewing mechanism 3. The spray head device 5 is installed on the front end of the arm frame 4 (here, the direction pointing to the working position is forward), and is connected to the wet spraying machine. Concrete conveying pipes, compressed air conveying pipes and quick-setting agent conveying pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com