Patents

Literature

58results about How to "Convenient for spraying work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

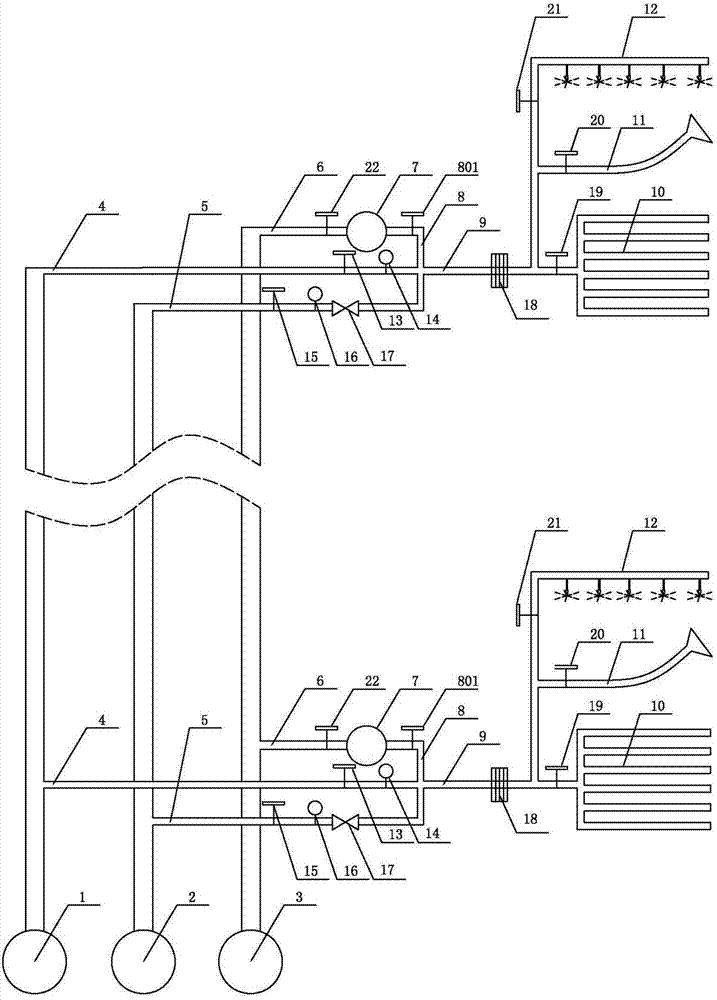

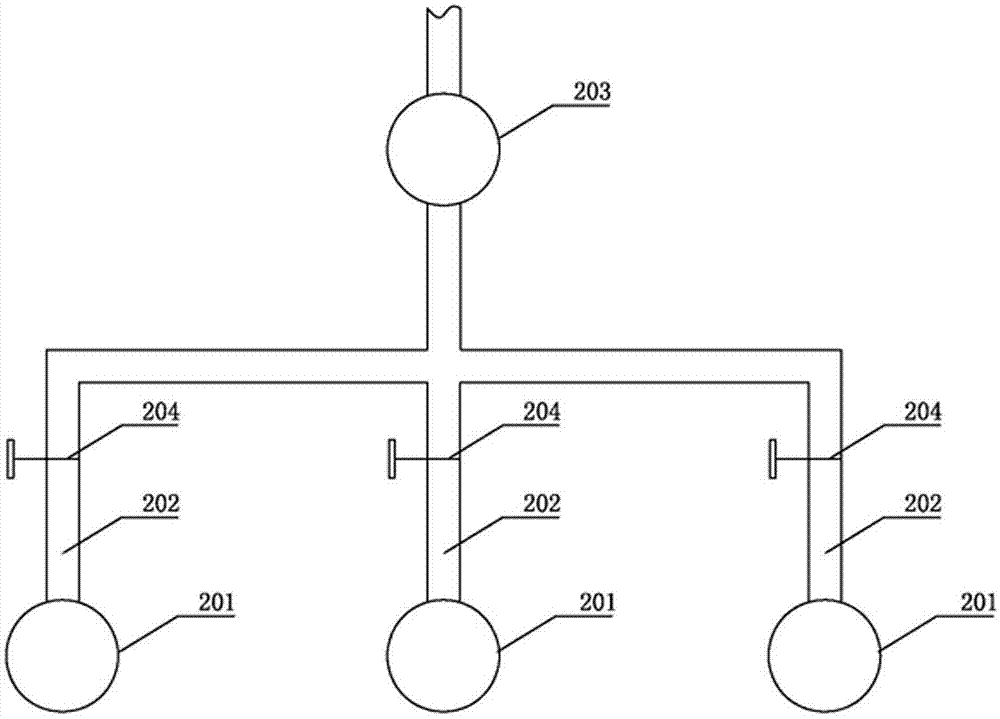

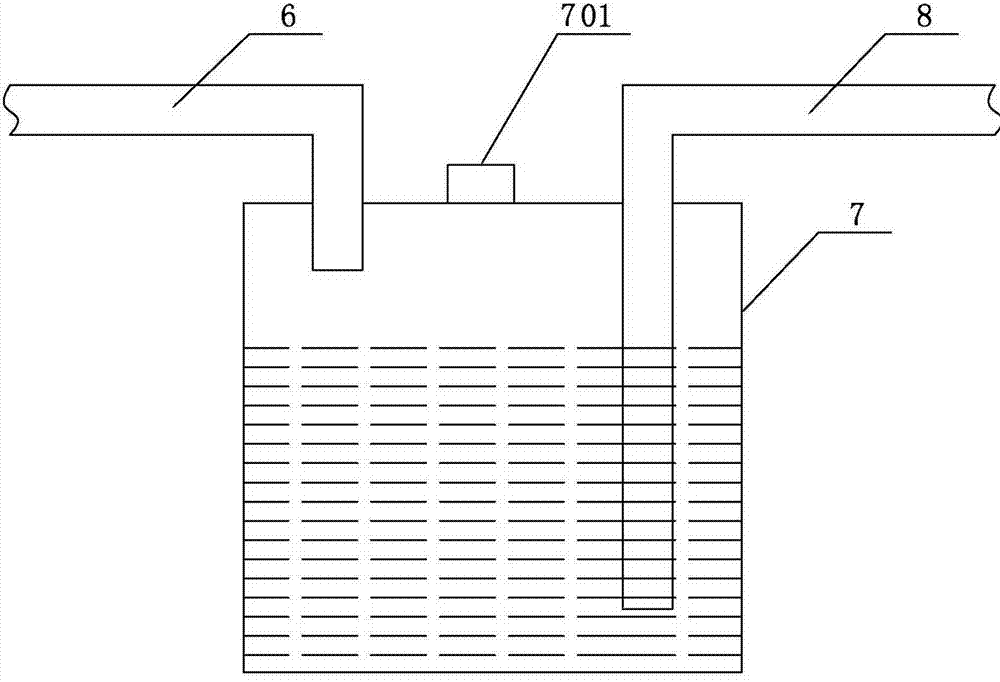

Irrigation and fertilization system with fertilizer water branching control

ActiveCN104255166AMeet the needs of unified irrigation and fertilizationMeet individual application requirementsPressurised distribution of liquid fertiliserAgriculture gas emission reductionAgricultural scienceAgricultural engineering

The invention provides an irrigation and fertilization system with fertilizer water branching control. The system comprises three sets of pipelines namely a water supply pipeline, a fertilizer supply pipeline and a gas supply pipeline, wherein the fertilizer supply pipeline comprises a fertilizer supply device, the fertilizer supply device is connected with a fertilizer supply main pipe, and a fertilizer supply branch pipe is arranged on the fertilizer supply main pipe; the gas supply pipeline comprises a gas source device, the gas source device is connected with a gas supply main pipe, a gas supply branch pipe is arranged on the gas supply main pipe, the gas supply branch pipe is connected to the top of a material batching bucket, and a material batching branch pipe is inserted into the material batching bucket; and the material batching branch pipe, the water supply branch pipe and the fertilizer supply branch pipe are combined in a field branch pipe, the field branch pipe extends to field facilities, and the field facilities comprise a drip irrigation branch pipe, a water spray and mist spray branch pipe and a micro-spray branch pipe. The irrigation and fertilization system provided by the invention can meet the unified irrigation and fertilization requirements of modern agricultural parks, and can meet the individual application requirements of the parks so as to ensure that different users can more flexibly control the periods and quantities of irrigation and fertilization according to the water and fertilizer demand characteristics of different crops and different crop growth stages, can apply different fertilizers, and can freely apply the fertilizer in farms after freely batching.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

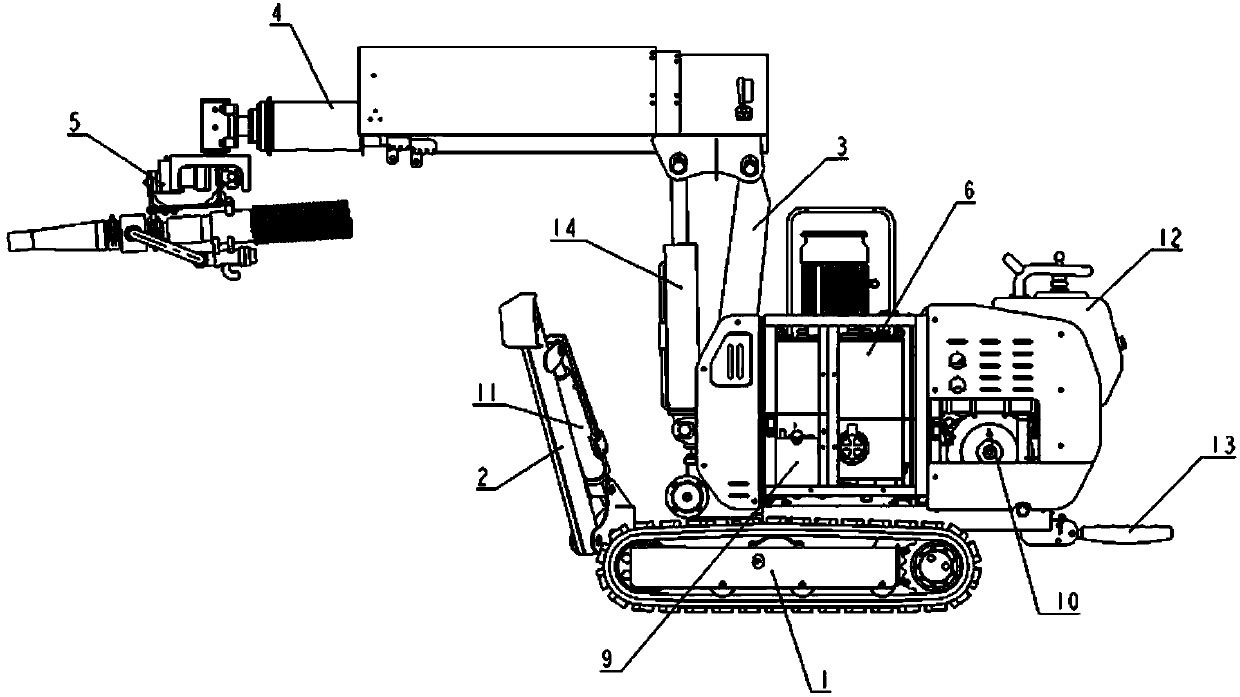

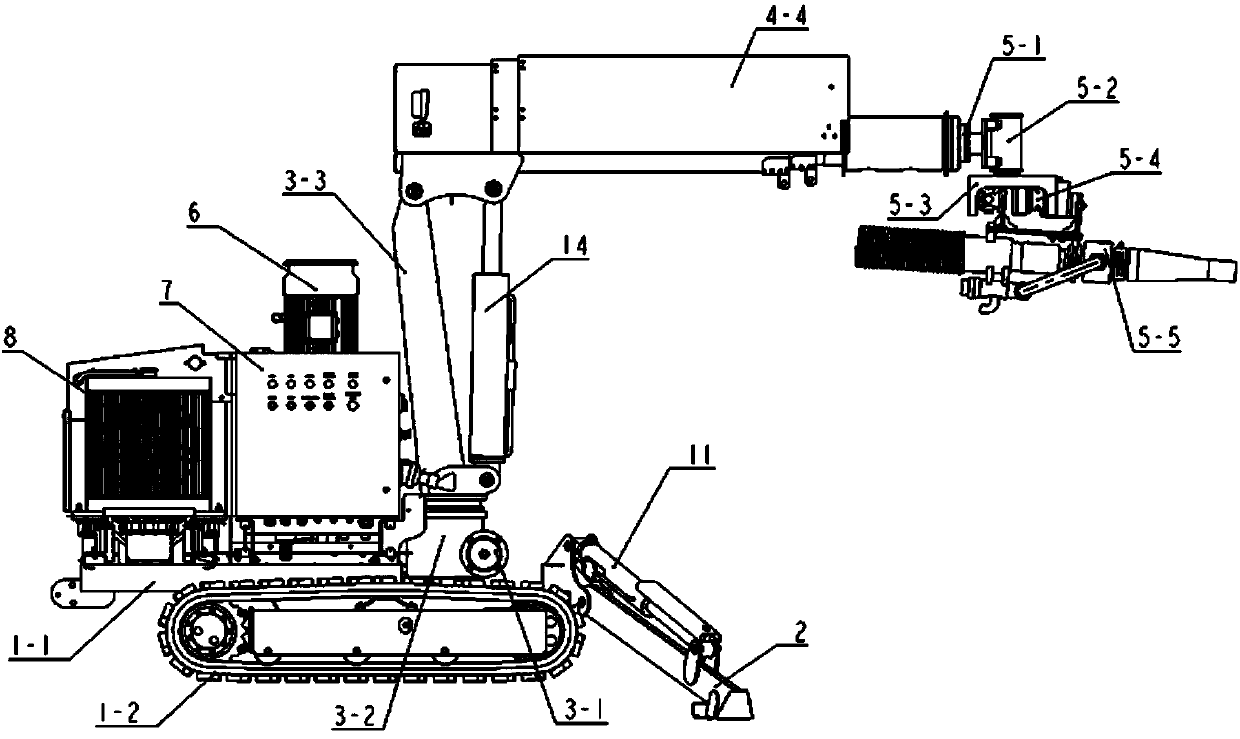

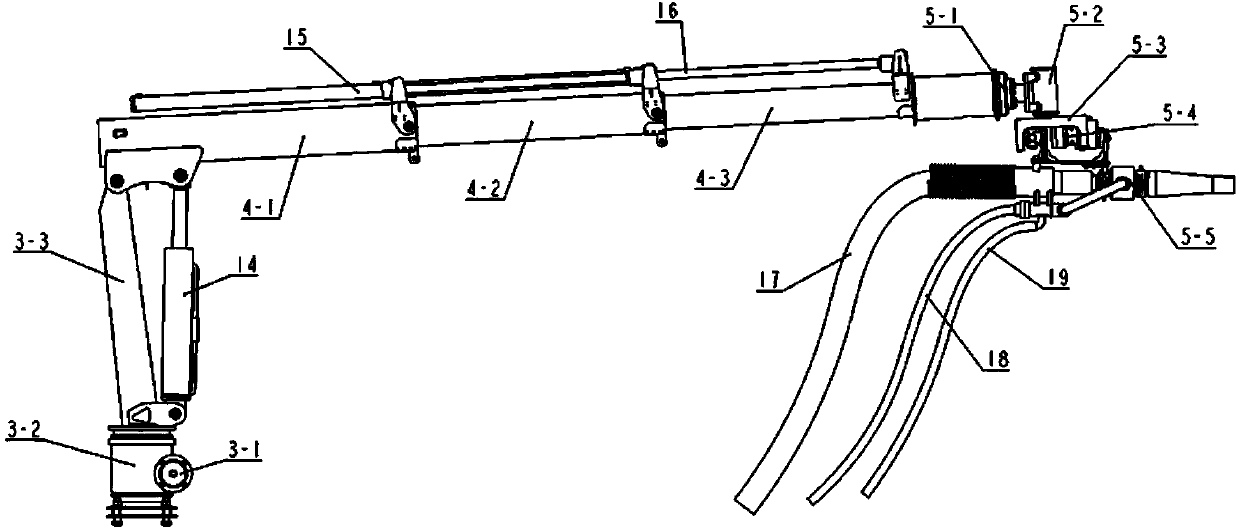

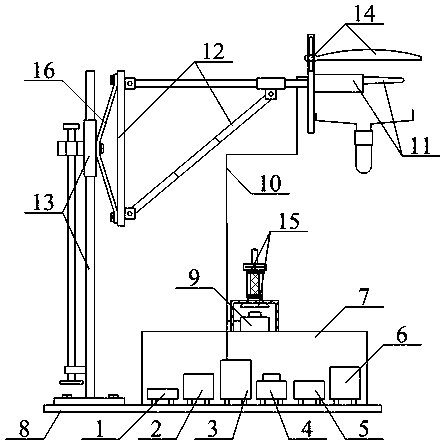

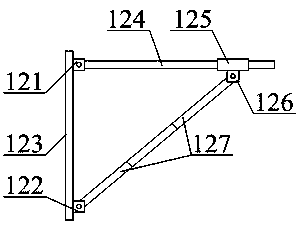

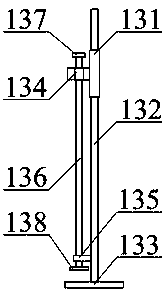

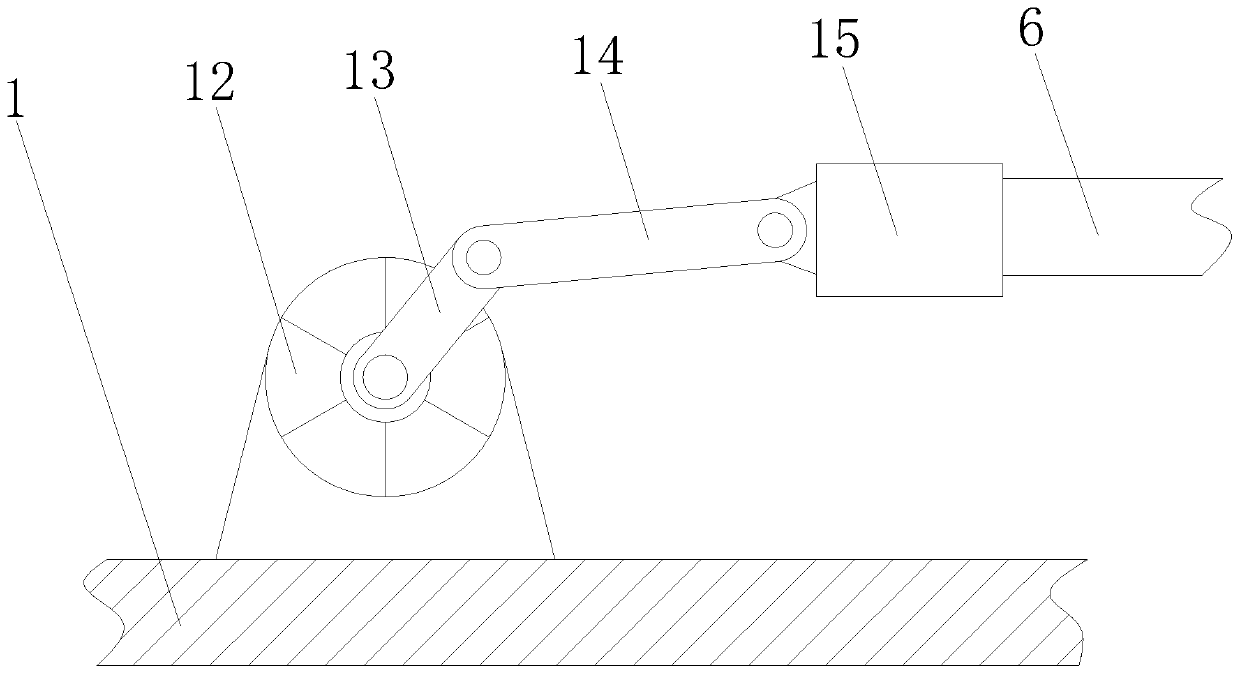

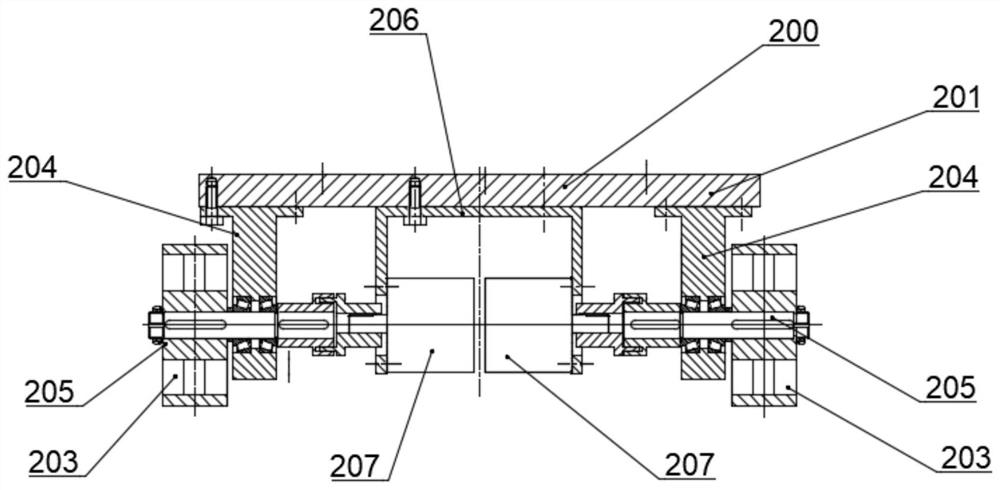

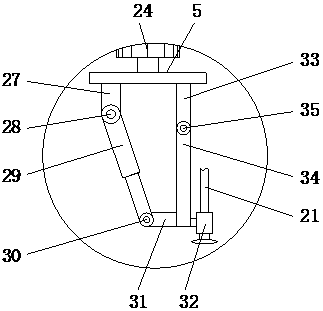

Grouting manipulator

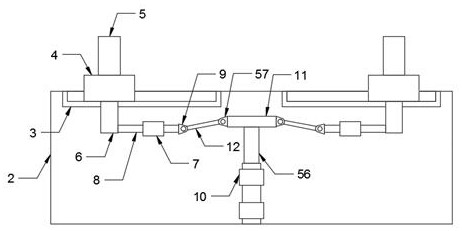

InactiveCN103775103ACooperate wellConvenient for spraying workUnderground chambersTunnel liningManipulatorCompressed air

The invention relates to a grouting manipulator. The grouting manipulator comprises a chassis, a revolving mechanism, an arm support, a spray head device, a hydraulic system and an electric system, wherein the revolving mechanism, the hydraulic system and the electric system are arranged on the chassis; the arm support is hinged to the revolving mechanism, and can be driven to rotate relative to the chassis by using the revolving mechanism; the spray head device is arranged at the front end of the arm support, and is connected with a concrete conveying pipe, a compressed air conveying pipe and a setting accelerator conveying pipe of a wet sprayer; the electric system and the hydraulic system are used for controlling the actions of the arm support and the spray head device. By adopting the grouting manipulator, efficient matching with the wet sprayer is realized, operating personnel can carry out grouting work conveniently, the spray height and position can be adjusted conveniently, heavy labor work of manual holding of a spray head is liberated, the spray range is enlarged, and the construction quality is improved. Compared with a large-sized grouting vehicle, the grouting manipulator has the advantages of simple structure, small size, lower cost, suitability for construction of certain medium and small-section tunnels, and more extensive application occasions.

Owner:XUZHOU XCMG CONSTR MACHINERY CO LTD BUILDING MACHINERY

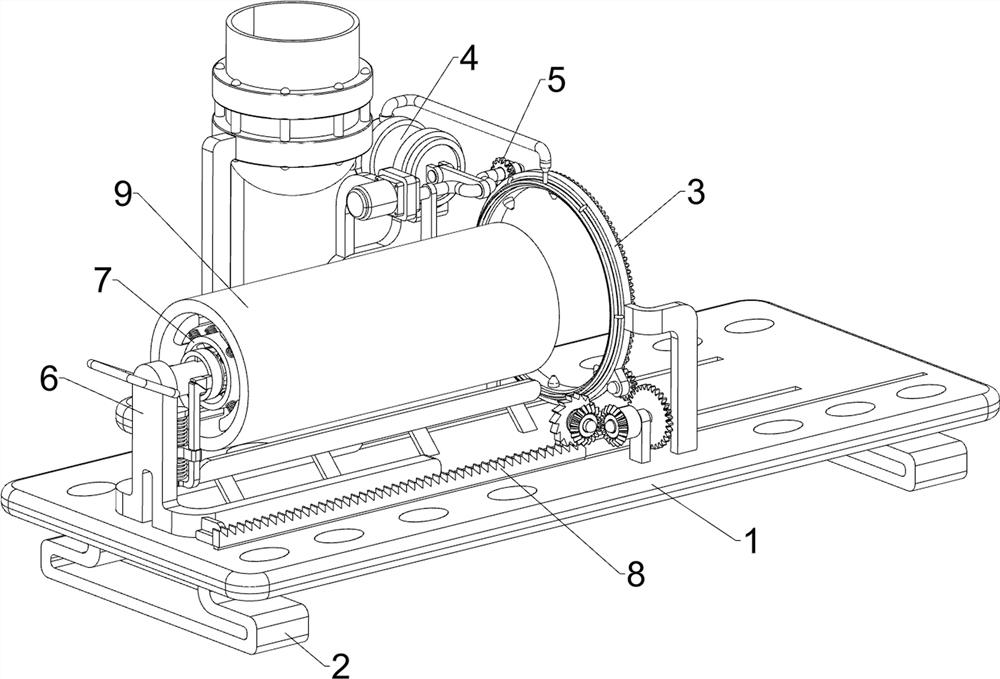

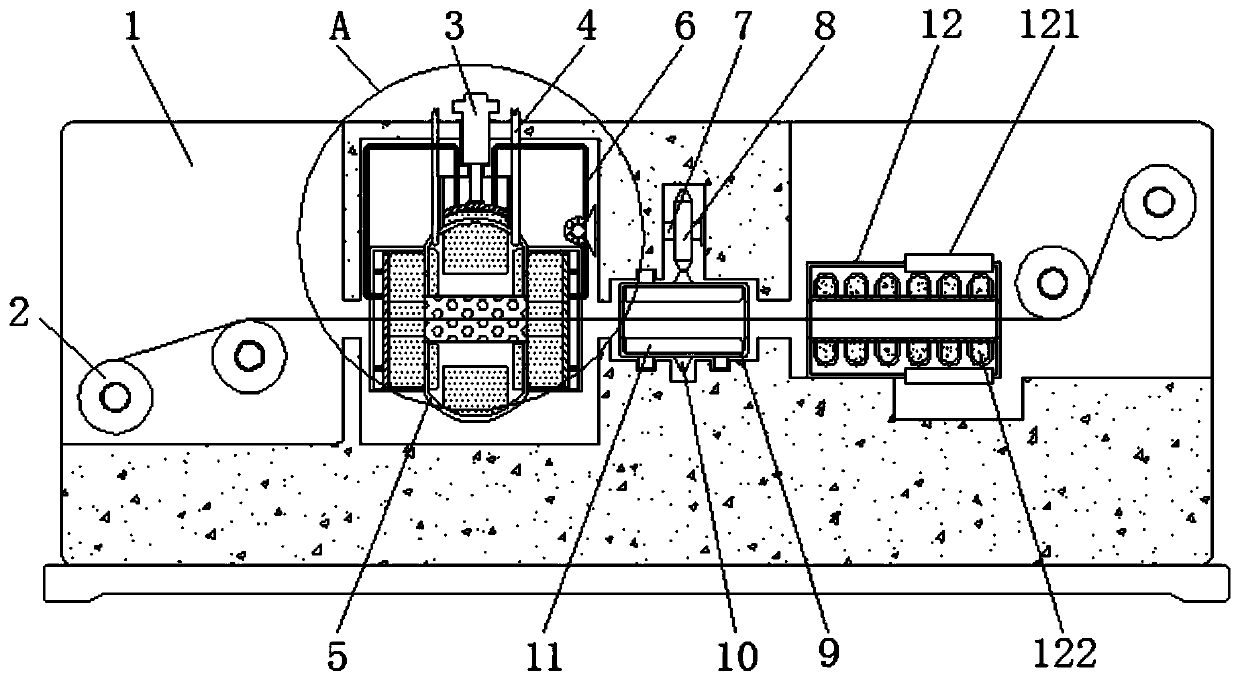

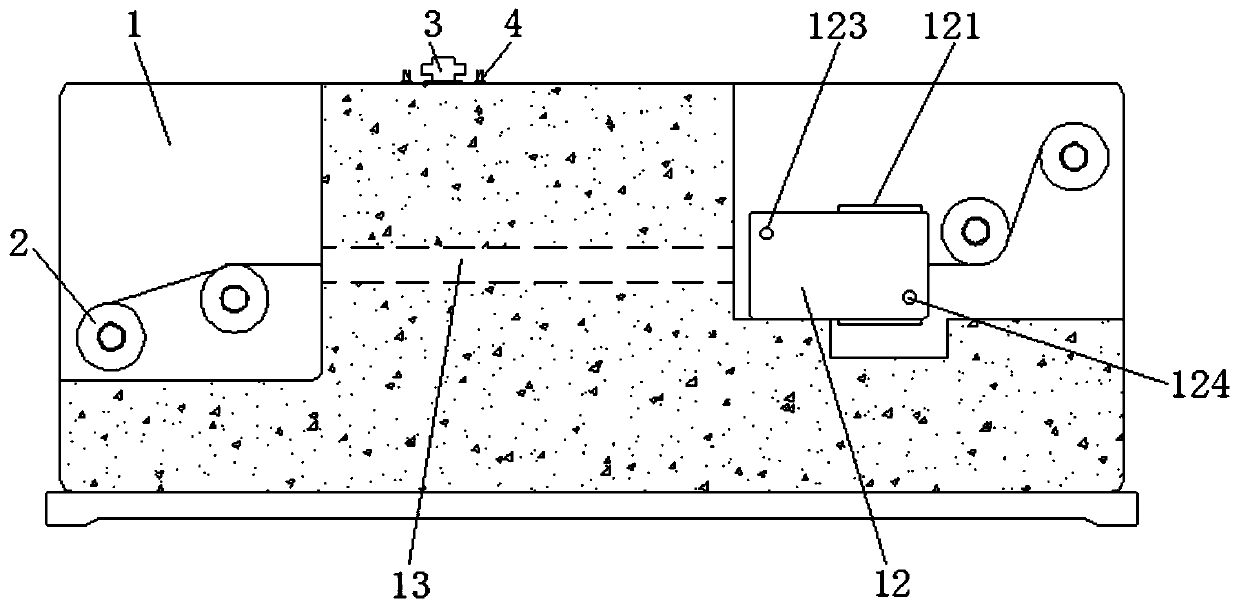

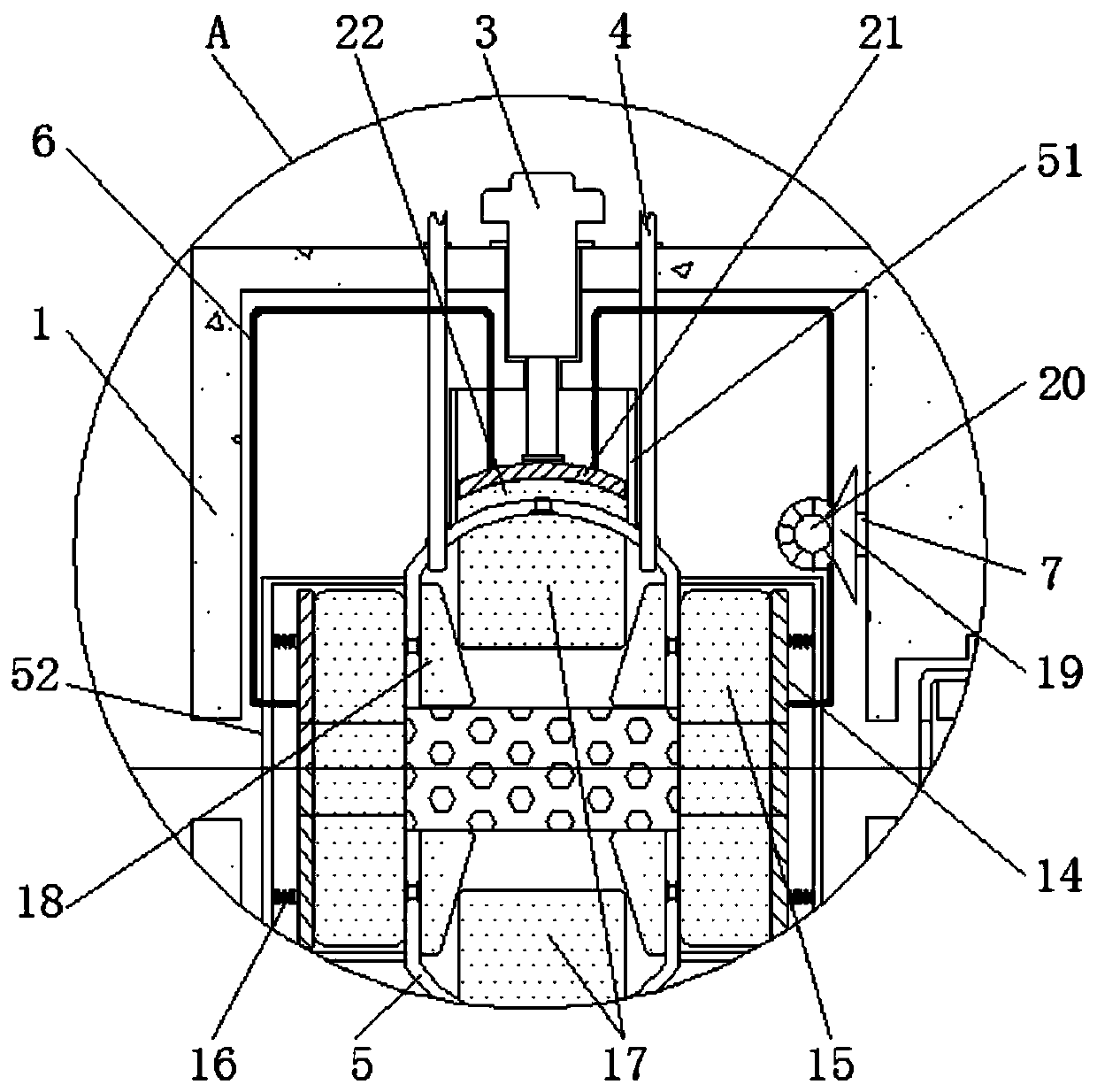

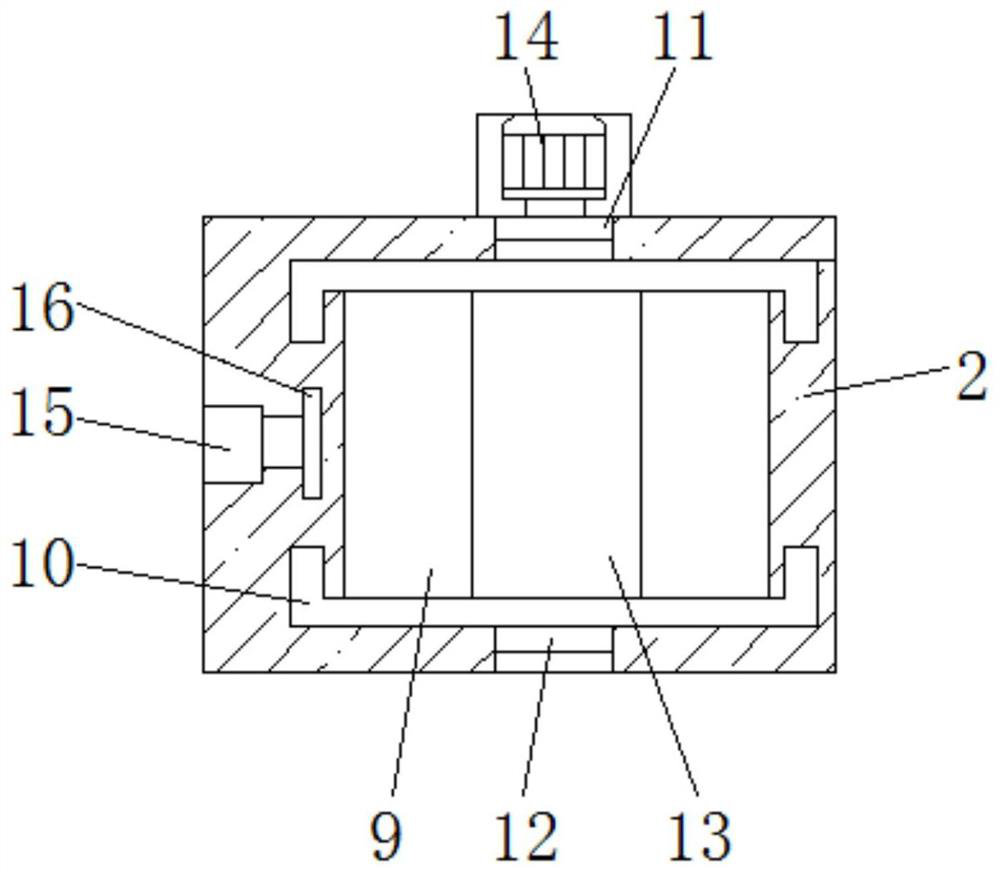

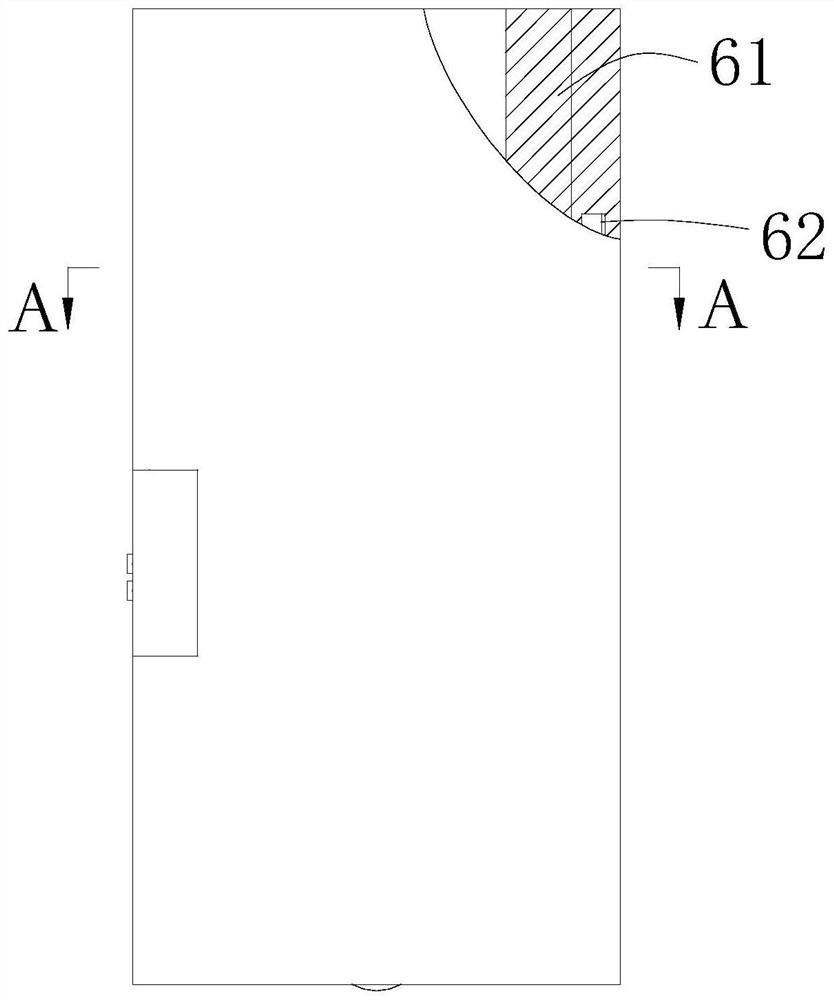

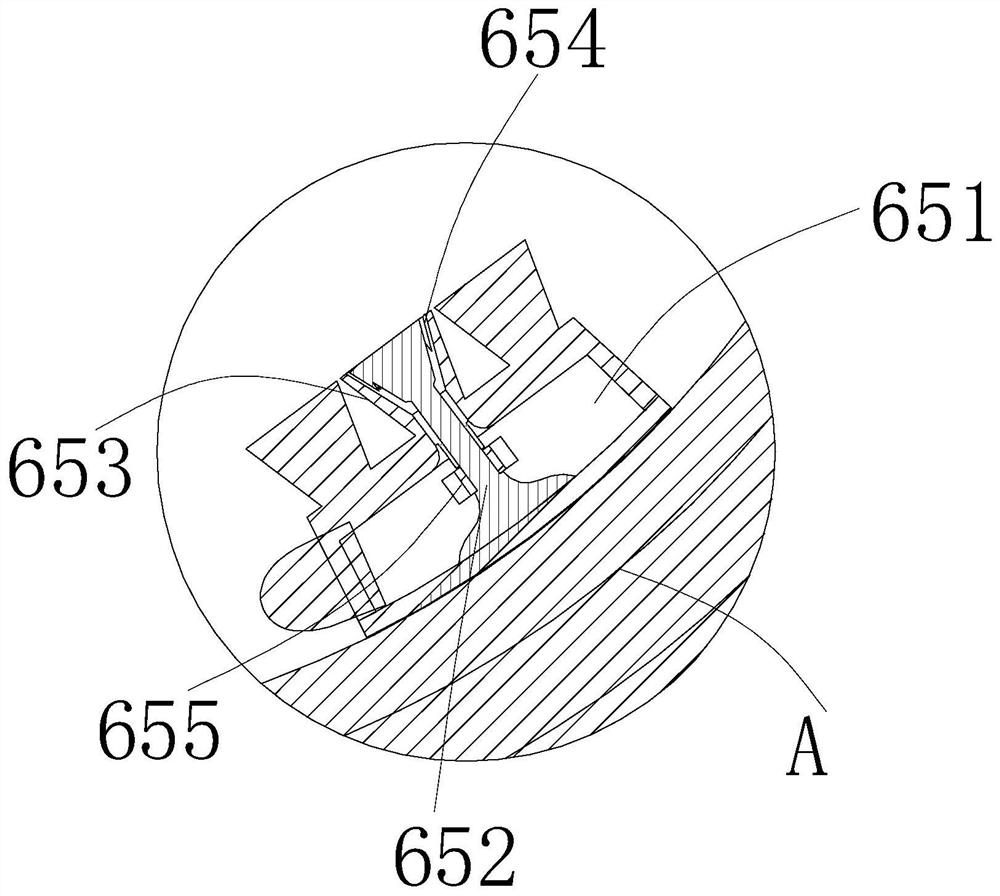

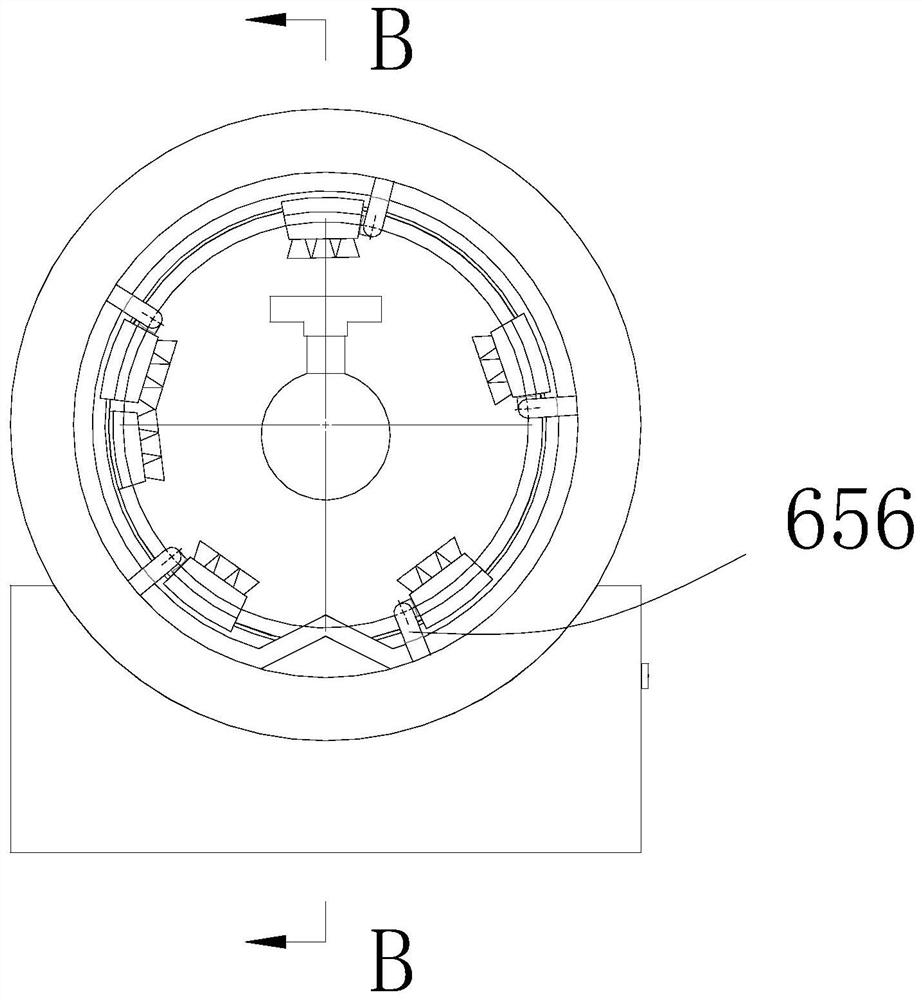

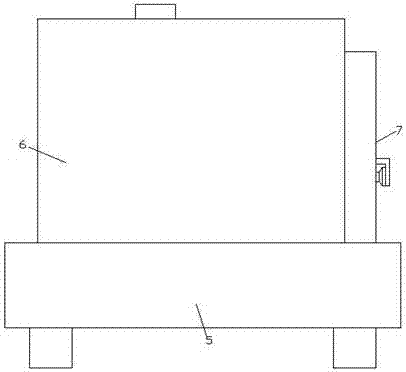

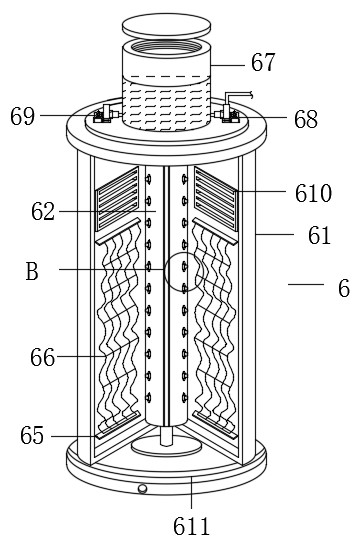

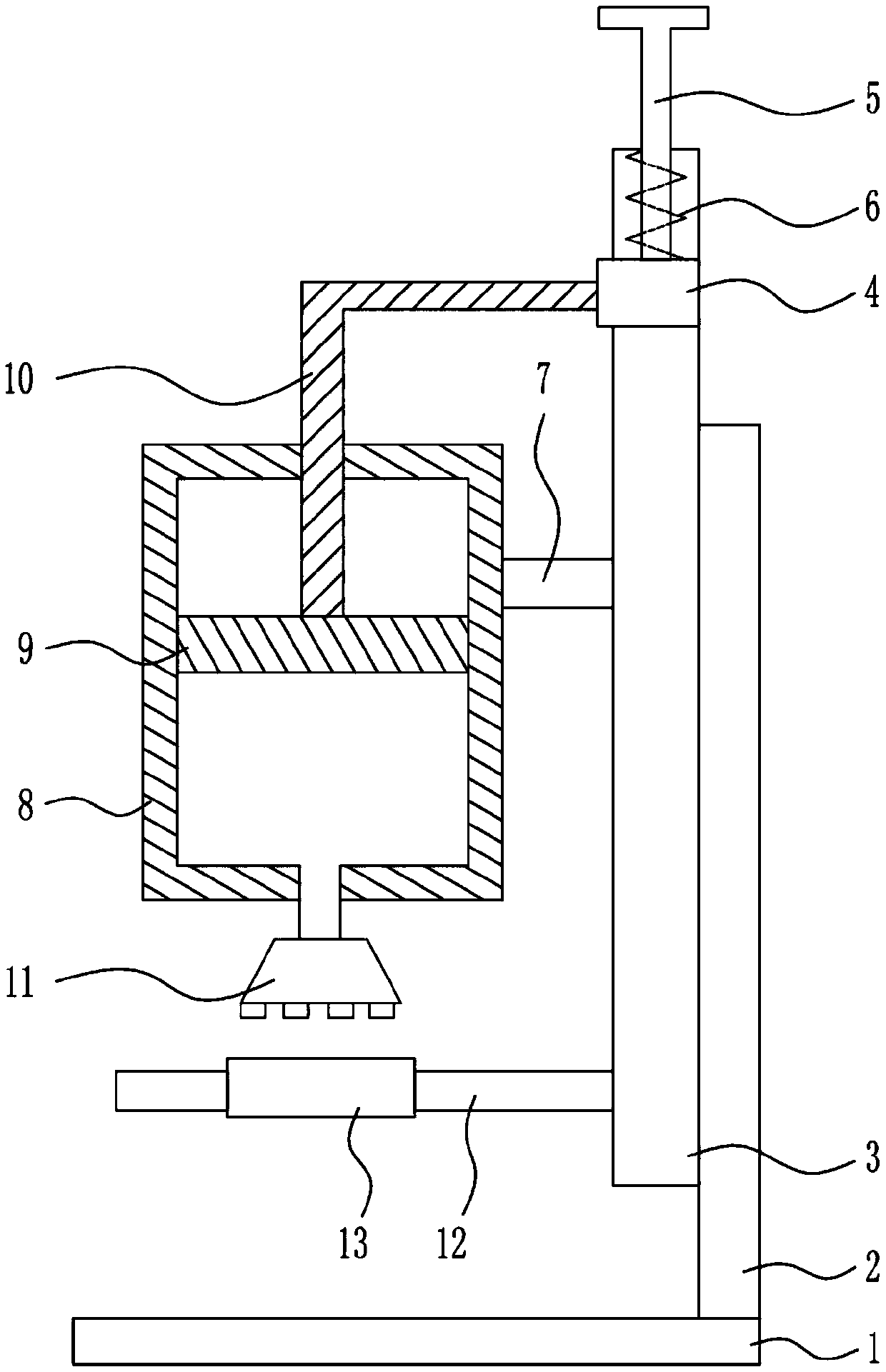

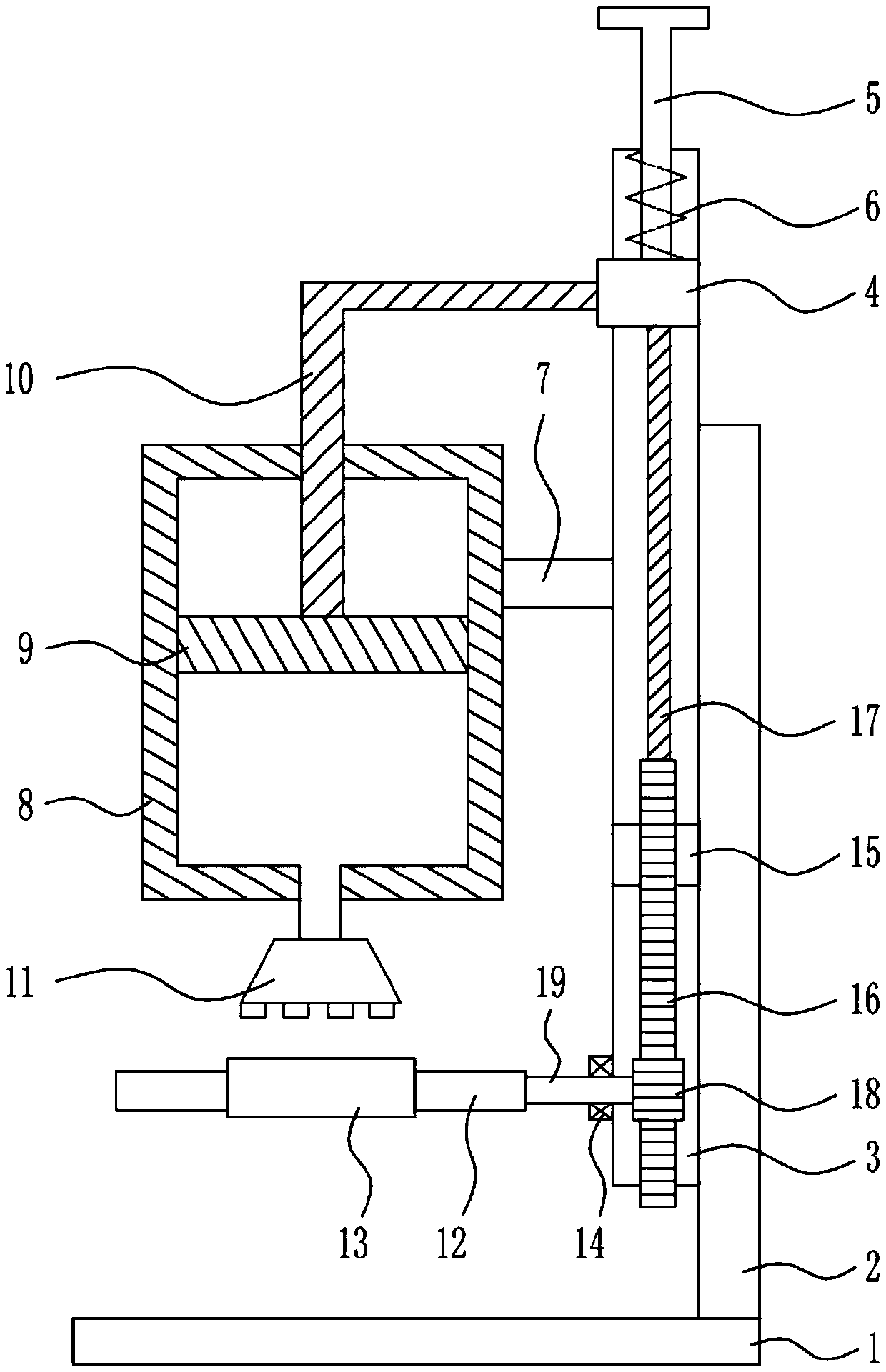

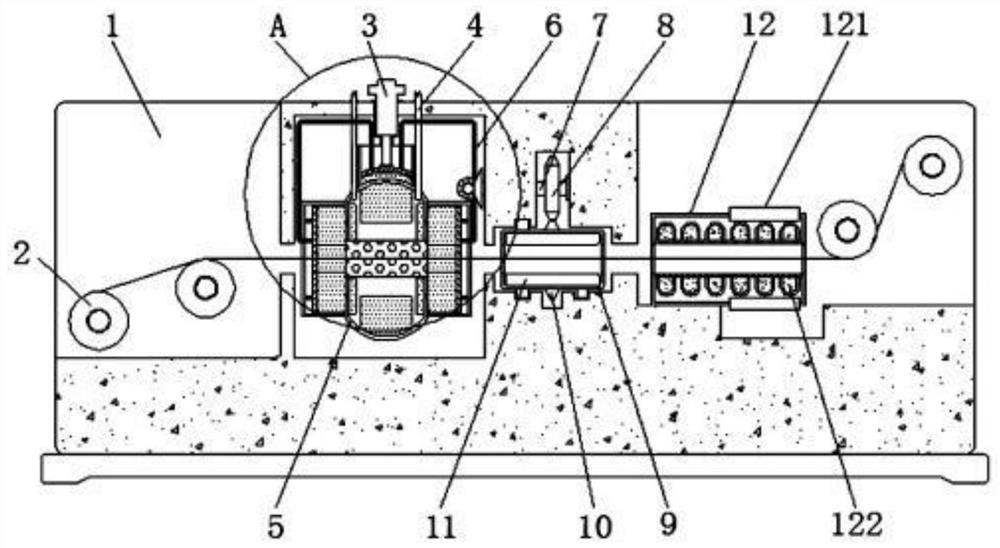

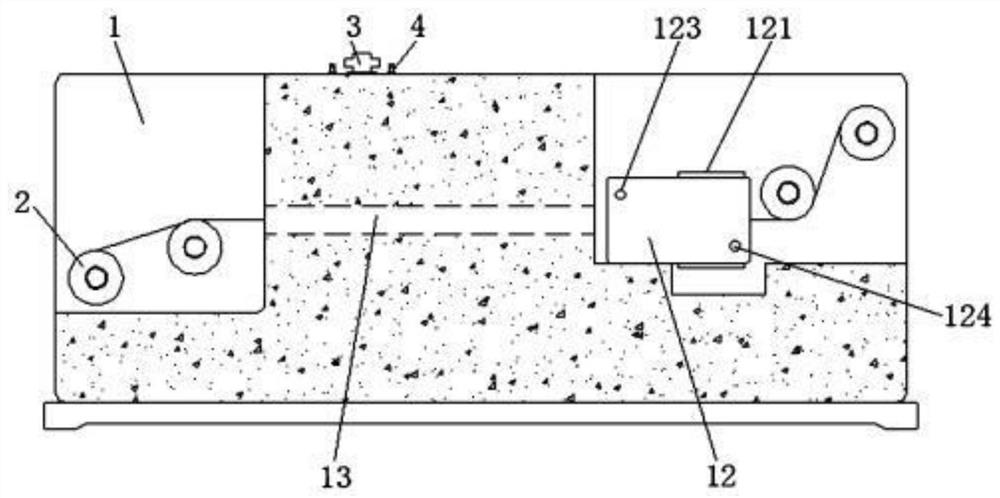

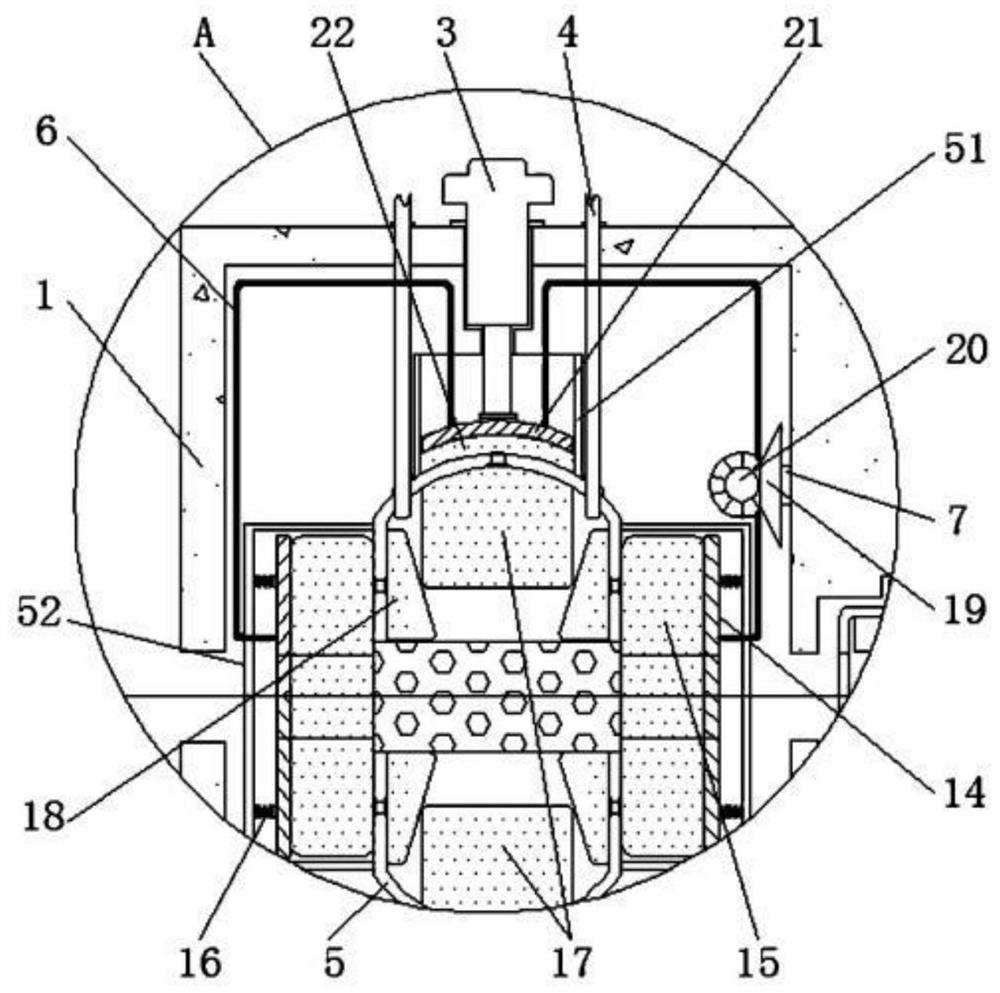

Anti-corrosion coating spraying equipment for exhaust gas emission pipeline

ActiveCN113145348AAutomatic sprayingImprove work efficiencySpraying apparatusExhaust gas emissionsExhaust fumes

The invention relates to spraying equipment, in particular to anti-corrosion coating spraying equipment for an exhaust gas emission pipeline. According to the anti-corrosion coating spraying equipment for the exhaust gas emission pipeline, anti-corrosion coating can be automatically sprayed to the outer wall of the exhaust gas emission pipeline, time and labor can be saved, and the working efficiency can be improved. The anti-corrosion coating spraying equipment for the exhaust gas emission pipeline comprises a bottom plate, a spraying mechanism, a feeding mechanism and a rotating mechanism, and supporting frames are connected to the two sides of the bottom of the bottom plate; the spraying mechanism is mounted at the top of the bottom plate; the feeding mechanism is mounted at the top of the bottom plate; and the rotating mechanism is mounted at the top of the bottom plate. Through cooperation of the spraying mechanism, the feeding mechanism and the rotating mechanism, an anti-corrosion coating can be uniformly sprayed on the outer wall of the exhaust gas emission pipeline, so that the effects that the anti-corrosion coating can be automatically sprayed on the outer wall of the exhaust gas emission pipeline, time and labor can be saved, and the working efficiency can be improved are achieved.

Owner:河北恒泰管道科技有限公司

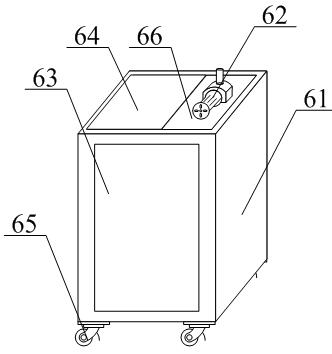

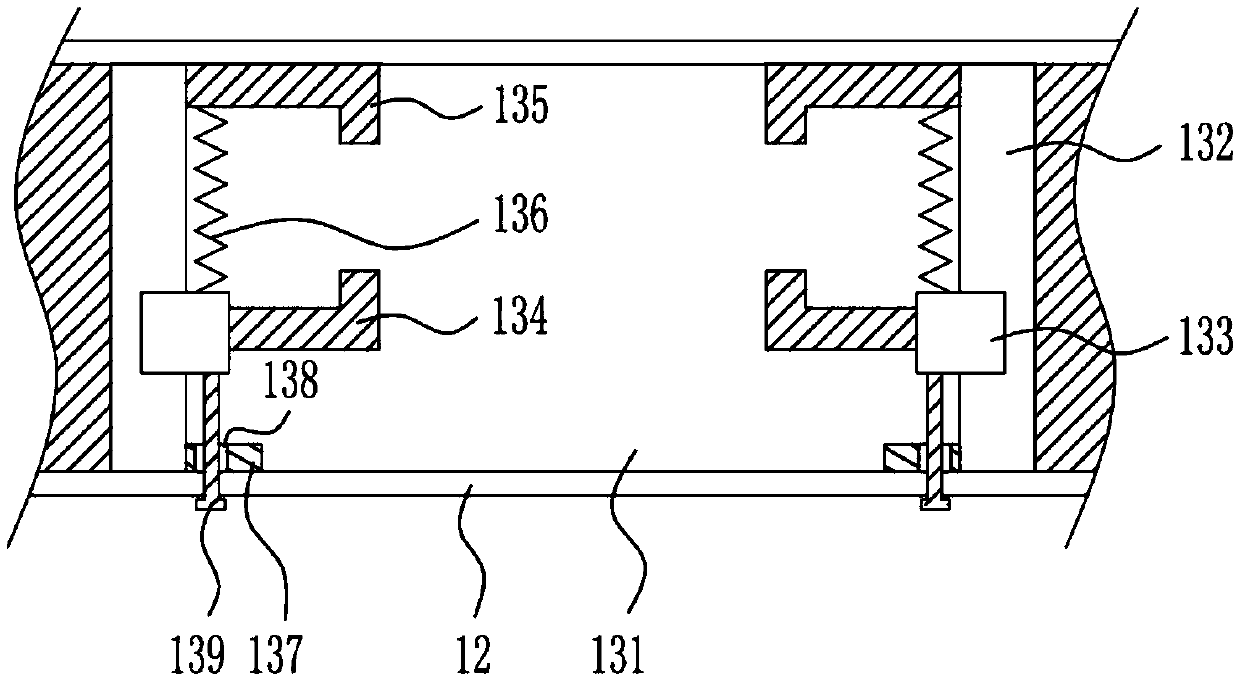

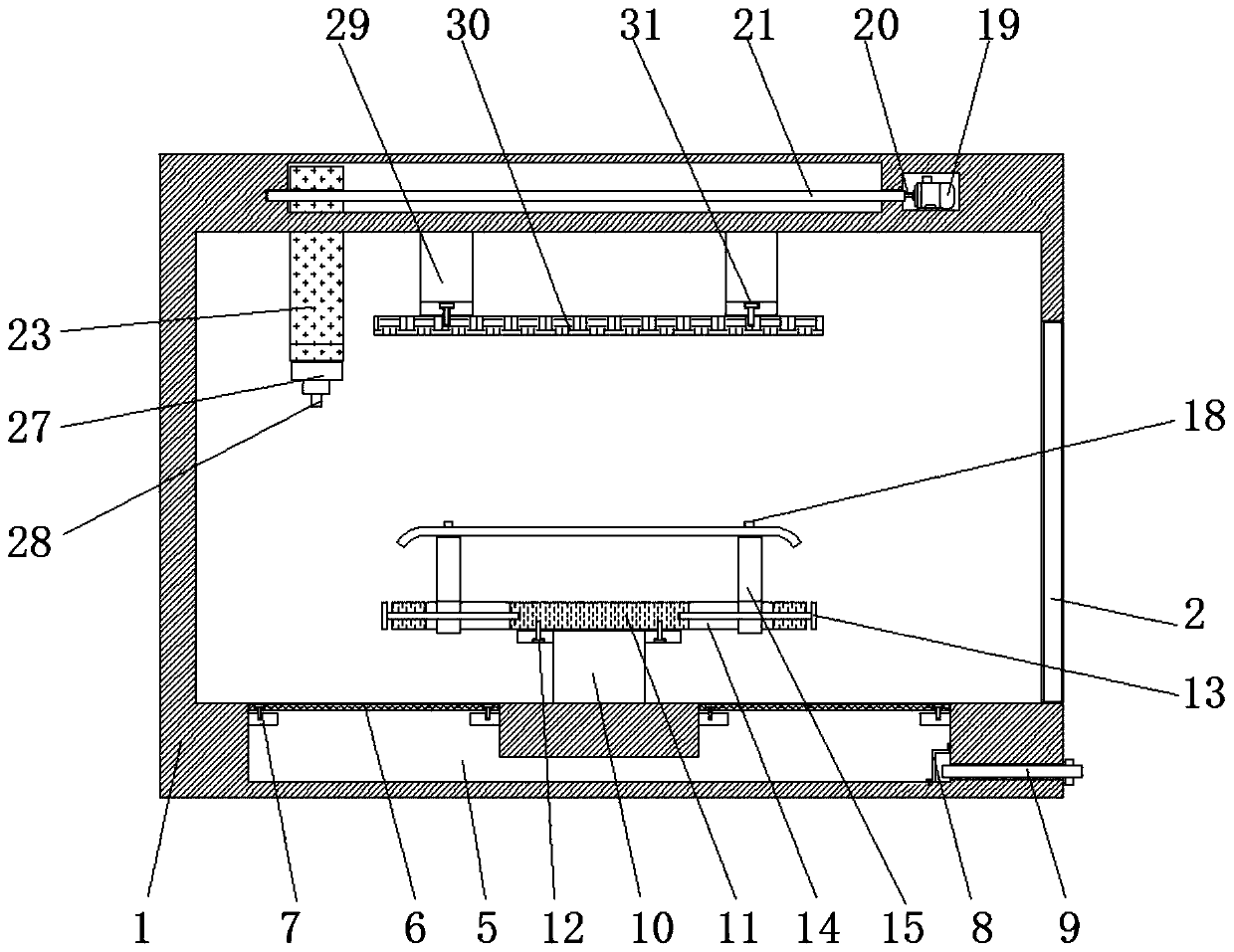

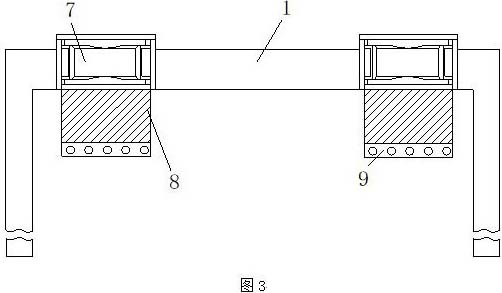

Coating equipment used for cable production and capable of rapidly reducing temperature for reducing bubbles

ActiveCN110504069ARapid coolingEasy squeezeInsulating conductors/cablesBiochemical engineeringEquipment use

The invention discloses coating equipment used for cable production and capable of rapidly reducing temperature for reducing bubbles. The coating equipment comprises a frame main body, guide rollers,an electric push rod and liquid injection pipes; the guide rollers are arranged at the left end and the right end of the frame main body; the electric push rod is fixed in the upper part of the framemain body; the liquid injection pipes are arranged on the left side and the right side of the electric push rod; a second squeezing plate is fixed at the bottom end of the electric push rod; and connecting ropes are fixed at the left end and the right end of the upper part of the second squeezing plate. The coating equipment used for cable production and capable of rapidly reducing the temperaturefor reducing the bubbles is provided with a first inner air bag and a first outer air bag; the first outer air bag is squeezed by a first squeezing plate, so that gas inside the first outer air bag enters the first inner air bag through a connecting pipe; and the inner side wall of the first inner air bag is in contact with the inner side wall of a coating sleeve ring firstly to close a discharging hole in the inner side wall of the coating sleeve ring, so that raw materials in the coating sleeve ring can be squeezed conveniently, and the bubbles in the raw materials are broken.

Owner:吉林省鑫联达电缆制造有限公司

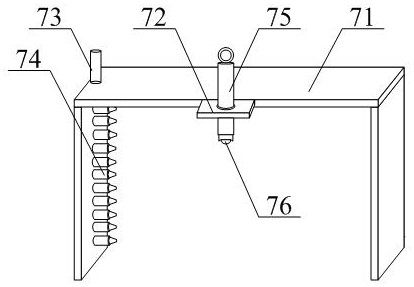

Supersonic flame spraying equipment and spraying method thereof

PendingCN109365187AEnsure safetyConvenient for spraying workSpraying apparatusSpray methodEngineering

The invention provides supersonic flame spraying equipment and a spraying method thereof. The supersonic flame spraying equipment comprises an air compressor, a heat exchanger, a main control cabinet,a pressurizing pump, an oil tank, an oxygen bus bar, a machine shell, a base, a powder feeder, an extension pipe, a supersonic fame spraying gun, an angle-adjustable supporting frame, a height position movable adjustment rod, a spattering-preventive collection cover for remaining sprayed powder, a powder pollution-preventive adsorption exporting core and a V-shaped connecting frame. According tothe supersonic flame spraying equipment, a first lining seat, a second lining seat, a joining lining seat, an angle motion bar, a sliding pipe, a third lining seat and a telescopic adjustment rod arearranged; adjustment of the telescopic adjustment rod through extension and contraction is benefited; the sliding pipe slides on the outer wall of the angle motion bar, and at this moment, the angle motion bar moves inside the first lining seat, the inclination angle of the angle motion bar is changed, and the spraying angle of the supersonic flame spraying gun is changed; and finally, extension and contraction work of the telescopic adjustment rod is stopped so that the spraying work can be guaranteed to proceed smoothly.

Owner:ZHENGZHOU LIJIA THERMAL SPRAYING MACHINERY CO LTD

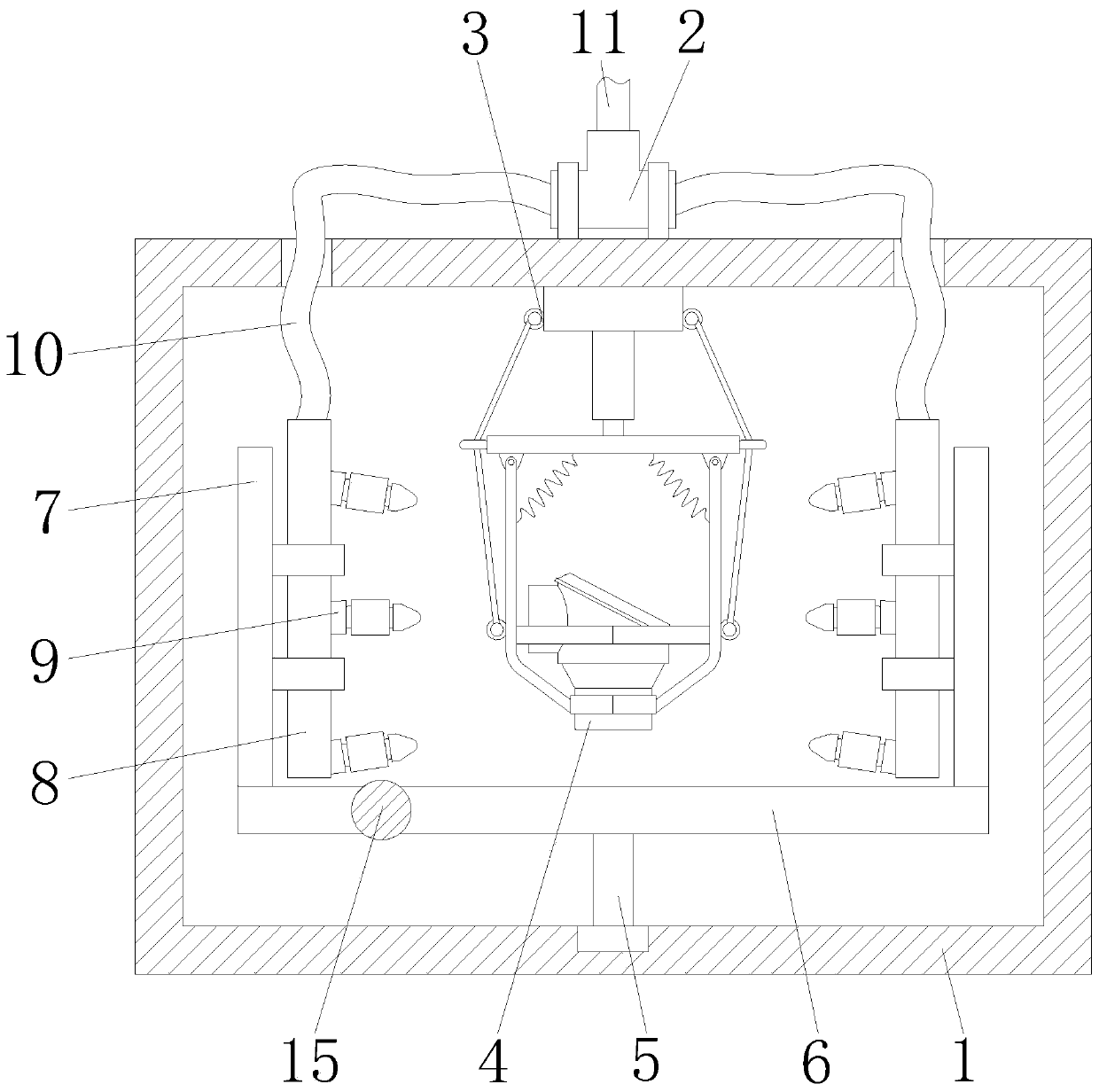

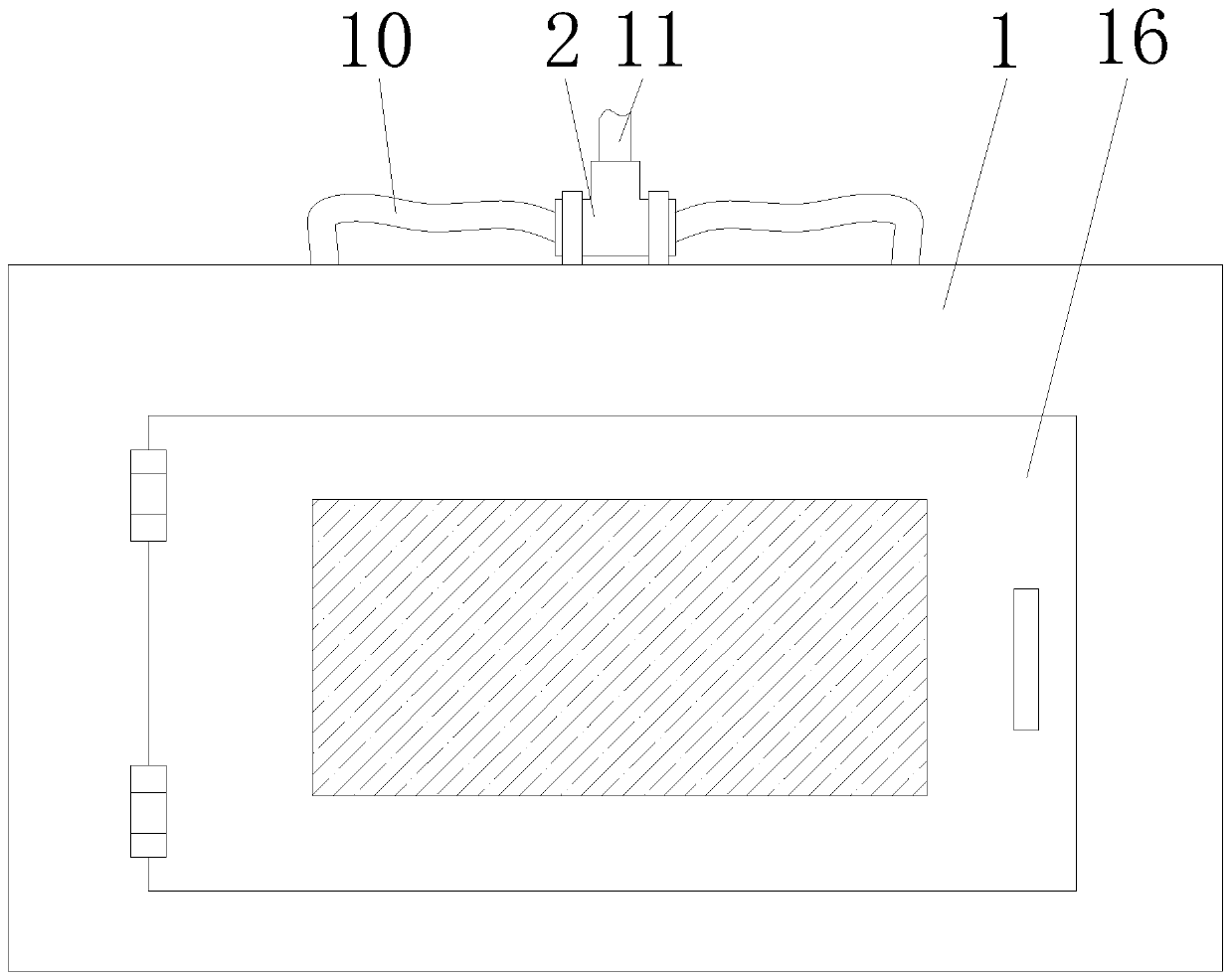

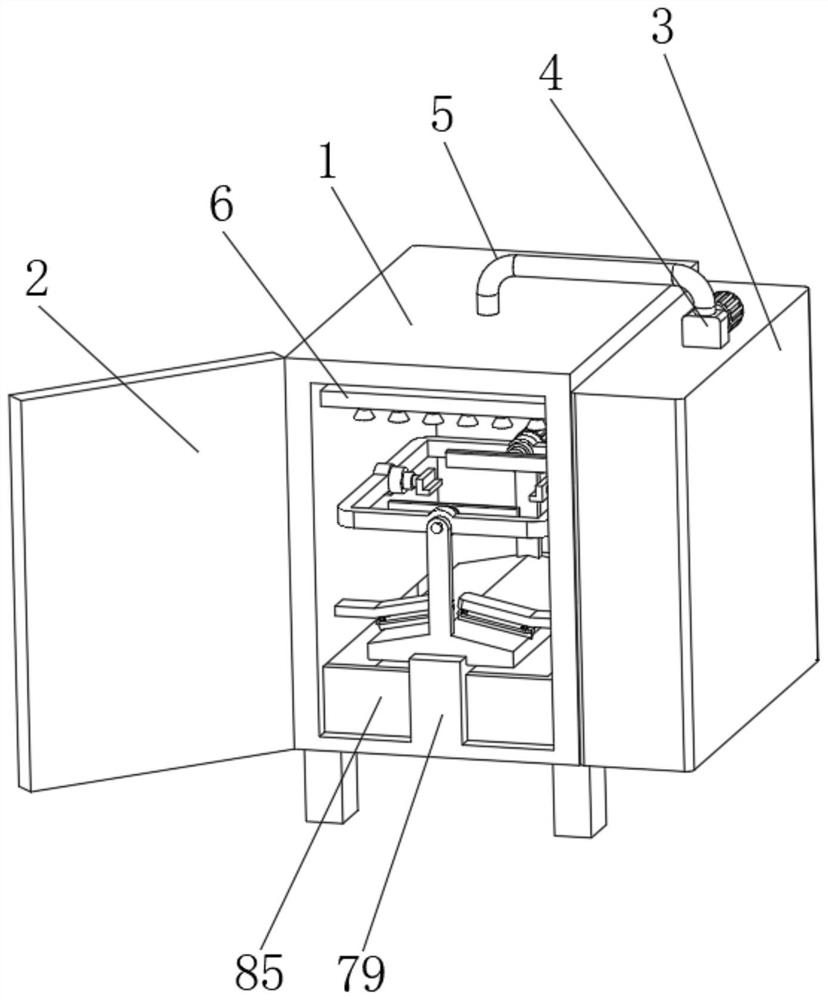

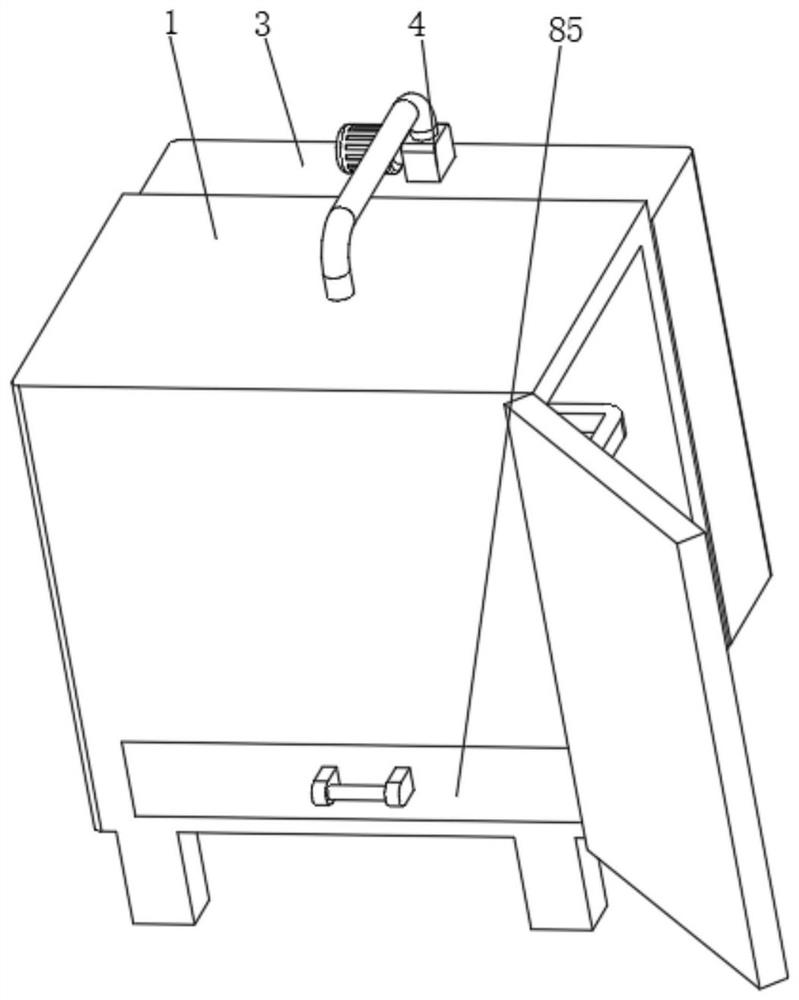

Flowmeter shell surface spraying device

ActiveCN109847976AImprove efficiencyQuality assuranceVolume meteringSpray boothsExternal connectionEngineering

The invention relates to the technical field of shell spraying devices, and discloses a flowmeter shell surface spraying device. The flowmeter shell surface spraying device comprises a device outer box and a tee-branch pipe, a hanging mechanism is arranged on the top wall in the device outer box, a shell is clamped on the hanging mechanism, a rotating shaft is rotatably connected to the middle ofthe inner bottom wall of the device outer box through a bearing, a worktable is fixedly connected with the top of the rotating shaft, two vertical plates are fixedly connected to the top of the worktable, the side faces, close to each other, of the two vertical plates are fixedly connected with material pipes through fixed rings, three atomization nozzles are fixedly mounted on the material pipes,the top ends of the material pipes communicate with hoses, the hoses penetrate through the top of the device outer box and communicate with the left end and the right end of the tee-branch pipe, andthe top end of the tee-branch pipe communicates with an external connection material box through a connecting pipe. The problems that an existing flowmeter shell spraying device is not complete in spraying, later-period spraying machining is needed, and work efficiency is low are solved.

Owner:安徽九星仪表壳体股份有限公司

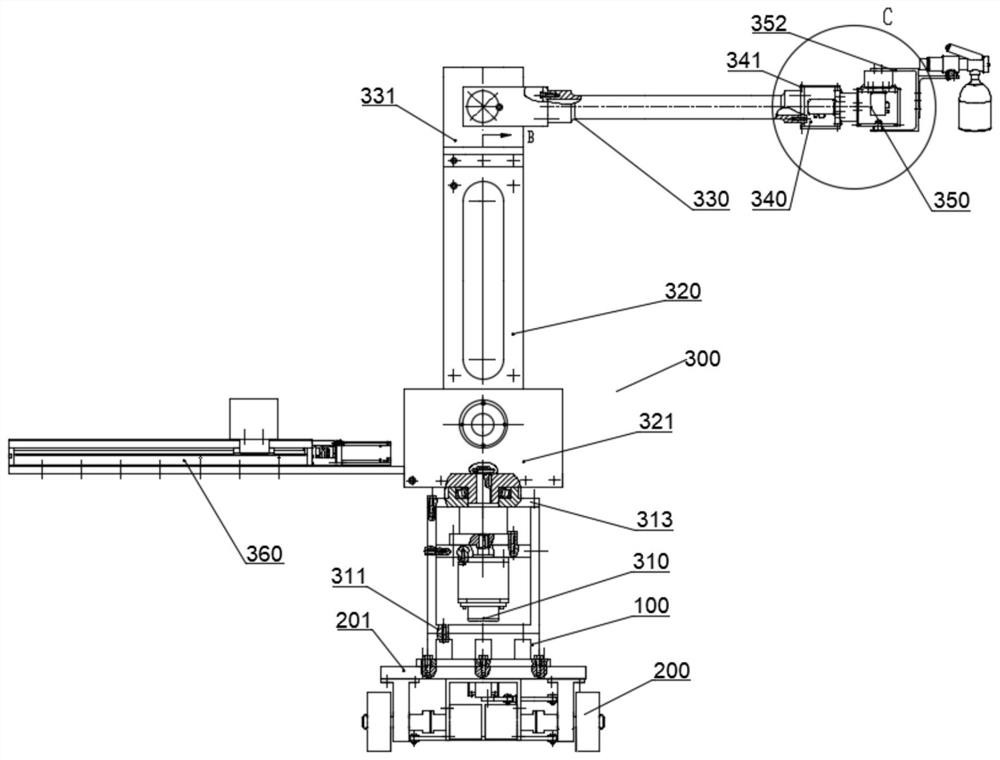

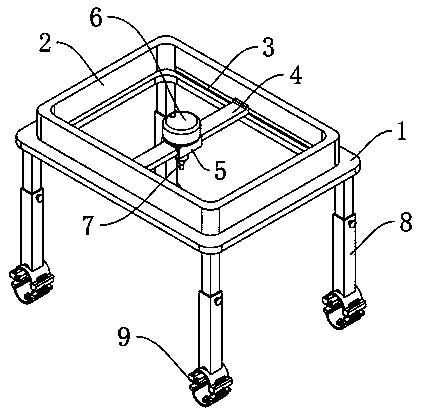

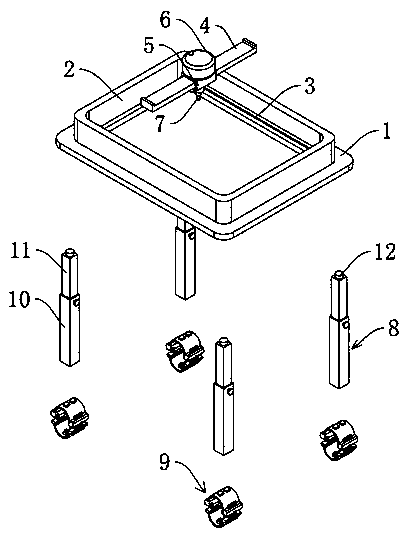

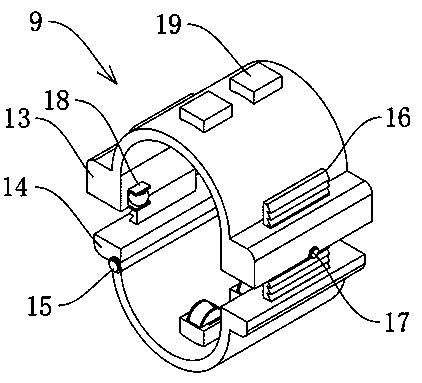

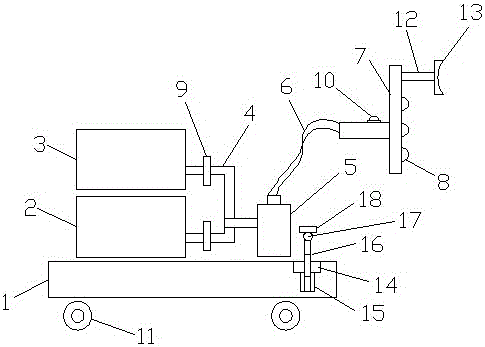

Movable paint spraying robot

InactiveCN111729790AConvenient for spraying workLarge working spaceSpraying apparatusPhysical healthPaint robot

The invention discloses a movable paint spraying robot. The movable paint spraying robot comprises a robot pedestal, a walking module and an executing module. The walking module is arranged at the bottom of the robot pedestal and used for driving the movable paint spraying robot to move forwards or backwards or turn, the executing module is arranged on the robot pedestal and used for driving the movable paint spraying robot to spray paint, and the executing module comprises a waist assembly, a big arm assembly, a small arm assembly, a wrist rotation assemble, a wrist swing assembly and a balance weight arm. The movable paint spraying robot aims to enable a paint spraying worker to conveniently spray paint to various types of vehicles in various occasions, reduce the damage of paint spraying work to the physical health of workers, lower risks and improve the spraying quality and efficiency.

Owner:HUBEI UNIV OF TECH

Grinding, drying and spraying equipment for aluminum alloy production and processing

InactiveCN112221800AImprove work efficiencyReduce workloadGrinding machinesSpray boothsElectric machineryEngineering

The invention relates to the technical field of aluminum alloy, in particular to grinding, drying and spraying equipment for aluminum alloy production and processing. The grinding, drying and sprayingequipment for aluminum alloy production and processing comprises a base, wherein a first grinding roller is rotatably connected between two first fixing blocks; an output shaft of a first motor is connected with the first grinding roller; an output shaft of a second motor penetrates through a second fixing block to be connected with a second grinding roller; a working box is arranged at the rightside of the upper end of the base; an output shaft of a third motor is connected with the lower end of a rotating shaft; a threaded rod is rotatably connected between an installing plate and the leftside of the inner wall of the working box; a spraying device is arranged at the lower end of a threaded block; and drying devices are arranged at the right side of the upper end of a separation plateand the right side of the top end of the inner cavity of the working box. The grinding, drying and spraying equipment for aluminum alloy production and processing provided by the invention has the advantages that the design is reasonable; the use is convenient; aluminum alloy can be automatically ground; the spraying effect on the aluminum alloy is good; meanwhile, drying treatment can also be performed on the aluminum alloy; the practicability is high; and the equipment is worthy of popularization.

Owner:李霞

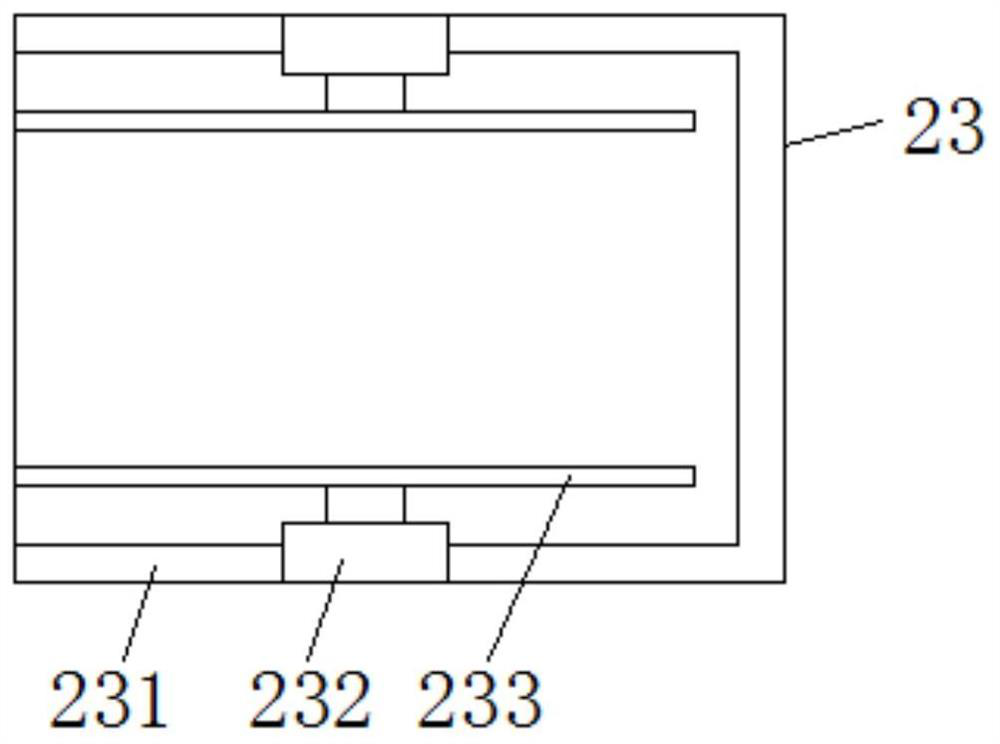

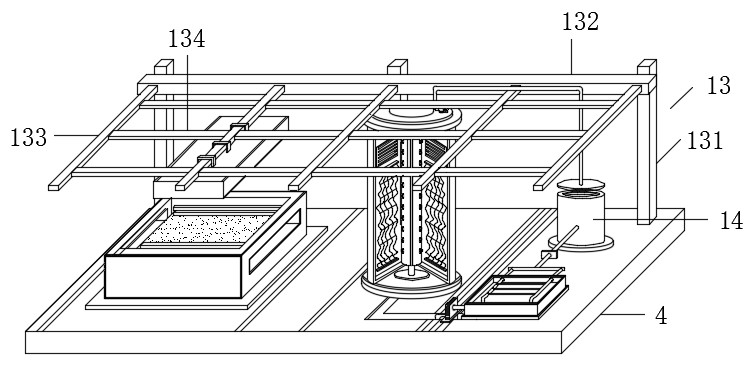

Full-automatic assembly line system for electrostatic powder coating

ActiveCN112295765AQuality improvementIncrease spray areaLiquid spraying plantsEngineeringStructural engineering

The invention discloses a full-automatic assembly line system for electrostatic powder coating. The full-automatic assembly line system comprises a fixed base, a non-contact powder bin arranged on thebase, a powder recycling system arranged on the non-contact powder bin, a barrel type coating bin fixedly connected to the fixed base, a suspension conveying mechanism arranged on the barrel type coating bin, a primary powder spraying structure arranged on the barrel type coating bin, a secondary powder spraying structure arranged on the rear side of the primary powder spraying structure and a leveling mechanism arranged on the secondary powder spraying structure. The two spraying structures are arranged, the spraying area between of a flowing water chamber is enlarged, the conveying speed ofthe suspension conveying structure can be further increased, and therefore the working efficiency is improved. And the powder recycling system is arranged and matched with the barrel type coating binso that powder can be recovered and utilized in time, powder waste is reduced, and the cost is also reduced.

Owner:明德新材料科技(浙江)股份有限公司

Spraying mechanism in spraying equipment for fabric

ActiveCN108411514APrevent precipitationQuality assuranceTextile treatment machine arrangementsTextile treatment by spraying/projectingPrecipitationNozzle

The invention provides a spraying mechanism in spraying equipment for fabric. The spraying mechanism in the spraying equipment for fabric solves the technical problems that the structure of an existing spraying device is too simple, a feed liquid is prone to precipitation which can influence fabric spraying, and the spraying quality is poor. The spraying equipment for fabric comprises a bottom plate, and a storage box is fixed to the bottom plate; the spraying mechanism comprises an input pipe, an output pipe and a liquid pump, wherein the input pipe is slidingly arranged on the storage box, the lower end of the input pipe is located in the storage box, the upper end of the input pipe is communicated with a feed port of the liquid pump, the liquid pump is connected with a first fixing plate, a discharge port of the liquid pump is communicated with one side face of the output pipe through a connecting pipe, the other side face of the output pipe is provided with a plurality of nozzles,and the lower surface of the output pipe is fixedly connected with the upper surface of the first fixing plate. The spraying mechanism has the advantage of good spraying effect.

Owner:泰州增荣特种装备科技有限公司

Intelligent container spraying device

PendingCN111760695AAvoid pollutionConvenient collection workGas treatmentDispersed particle separationElectric machineryEngineering

The invention provides an intelligent container spraying device. The device comprises a spraying base, supporting rods, conical rods, a fixed hole, a supporting roller, a movable observing dustproof spraying box structure, an adjustable detection spraying frame structure, a movable container collecting and absorbing structure, a rotatable absorbing odor removing frame structure, a connecting hose,a conveying motor, a control box, a PLC, a power switch, a rotation cover, an arc guide conveying plate and a protection roller, the upper ends of the supporting rods are in bolt connection to the four corners of the lower end of the spraying base, the upper ends of the conical rods are welded to the lower ends of the supporting rods, a laser sensor, the PLC, the conveying motor and a spraying pump are arranged, during spraying, through the laser sensor, a signal is transmitted to the PLC, the PLC controls the spraying pump to begin to work, and coating in a coating box is sprayed to the surface of a container through a spraying pipe and a nozzle connected with the spraying pipe to finish intelligent spraying work.

Owner:山东华海新材料有限公司

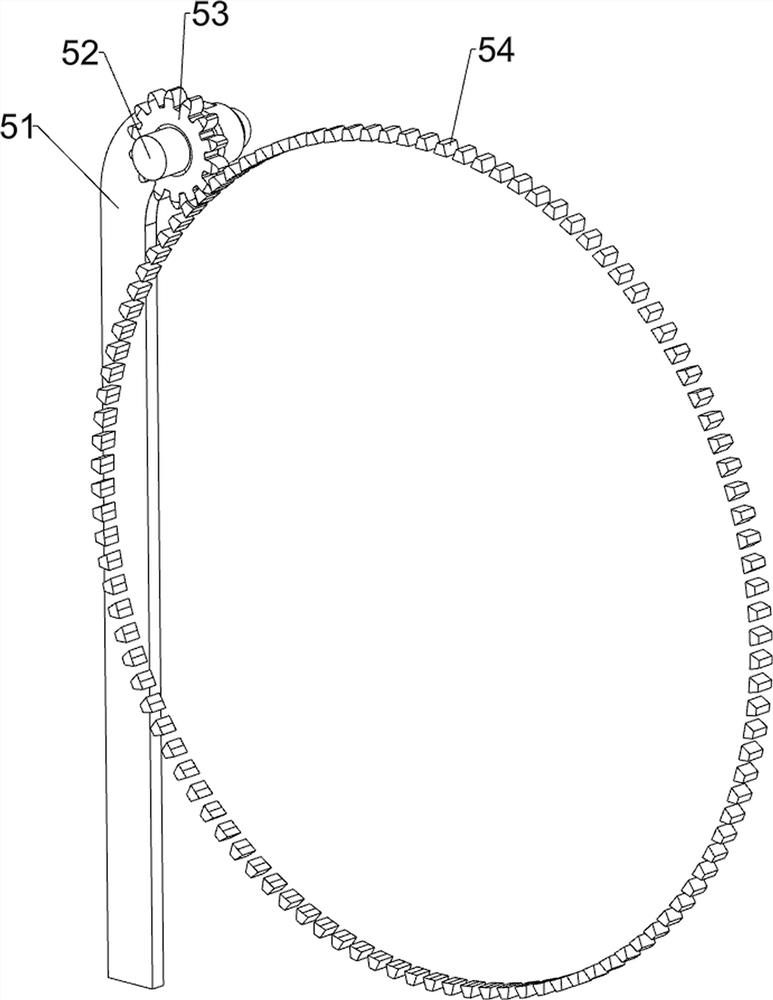

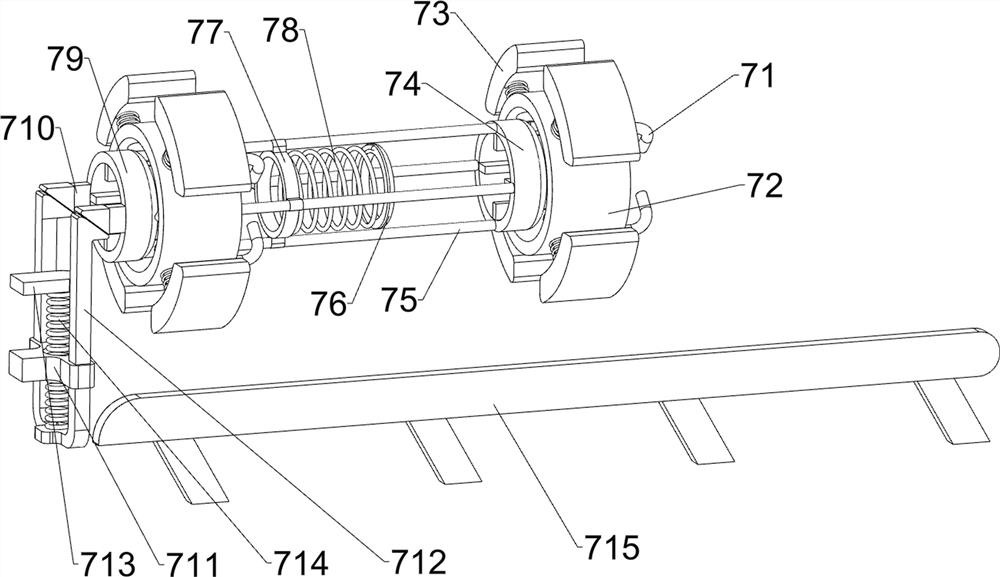

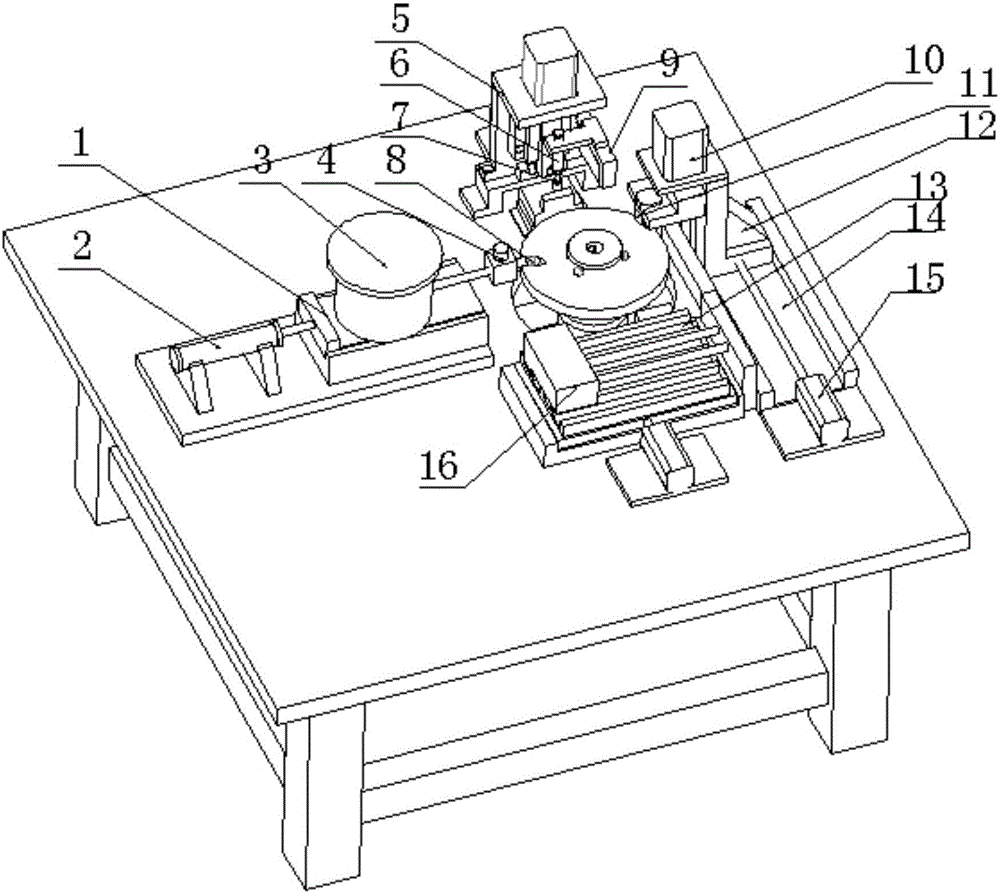

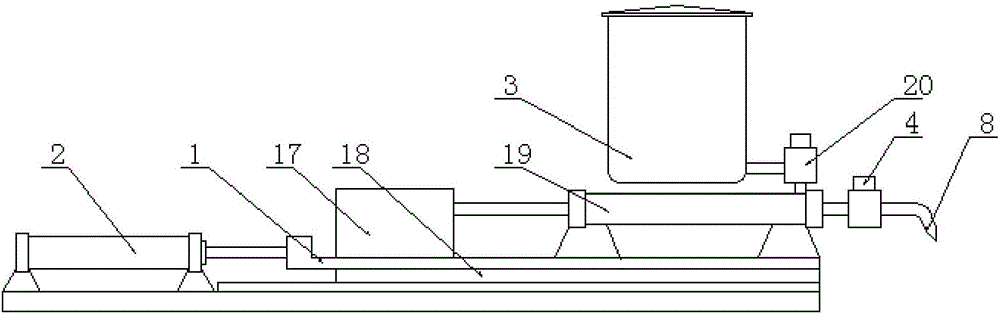

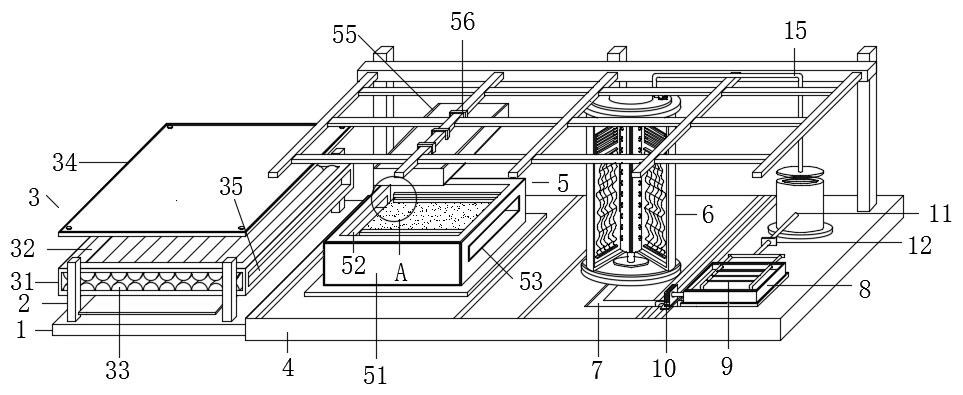

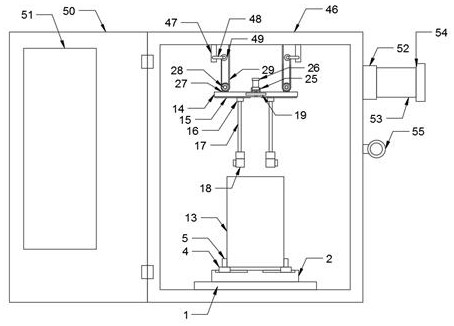

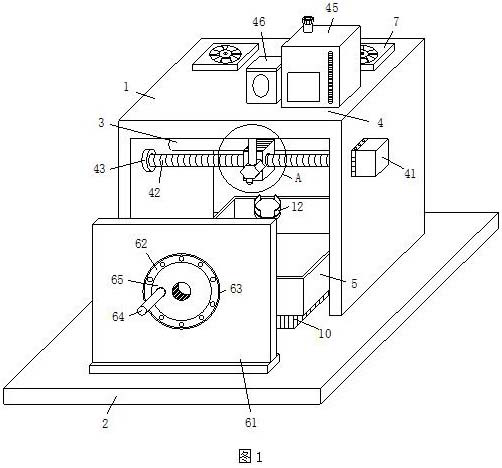

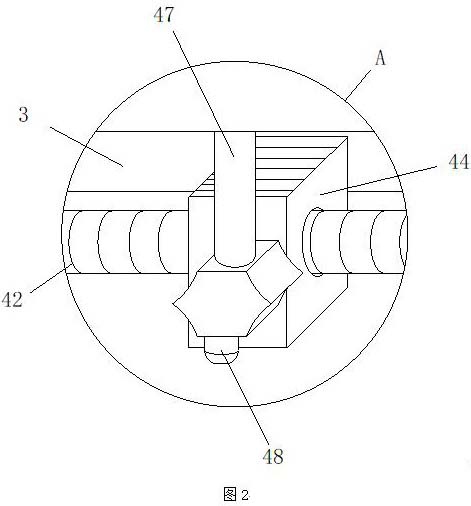

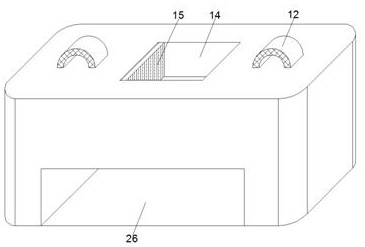

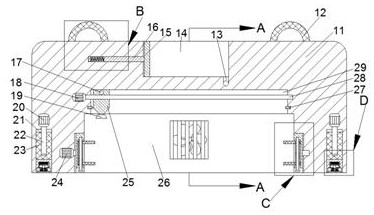

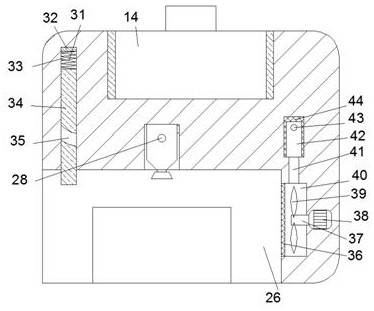

Before-welding assembly automation device for edge grinding wheel

ActiveCN106181154AFast assemblyImprove assembly efficiencyWelding/cutting auxillary devicesAuxillary welding devicesDislocationSoldering

The invention discloses a before-welding assembly automation device for an edge grinding wheel. The before-welding assembly automation device comprises a machine frame body. An assembly station hole is formed in an operation platform of the machine frame body. A rotation device is arranged below the assembly station hole. A base plate can be fixed to the rotation device, and the rotation device can drive the base plate to rotate. A tool bit feed system, a welding rod feed system and a soldering flux spray and feed system are arranged outside the assembly station hole. The soldering flux spray and feed system, the welding rod feed system and the tool bit feed system can all feed materials to the edge of the base plate by moving towards the base plate. The before-welding assembly automation device overcomes the defects of manual assembling and is high in assembly speed, high in assembly efficiency, good in assembly effect and free of tool bit dislocation.

Owner:广东奔朗新材料科技有限公司

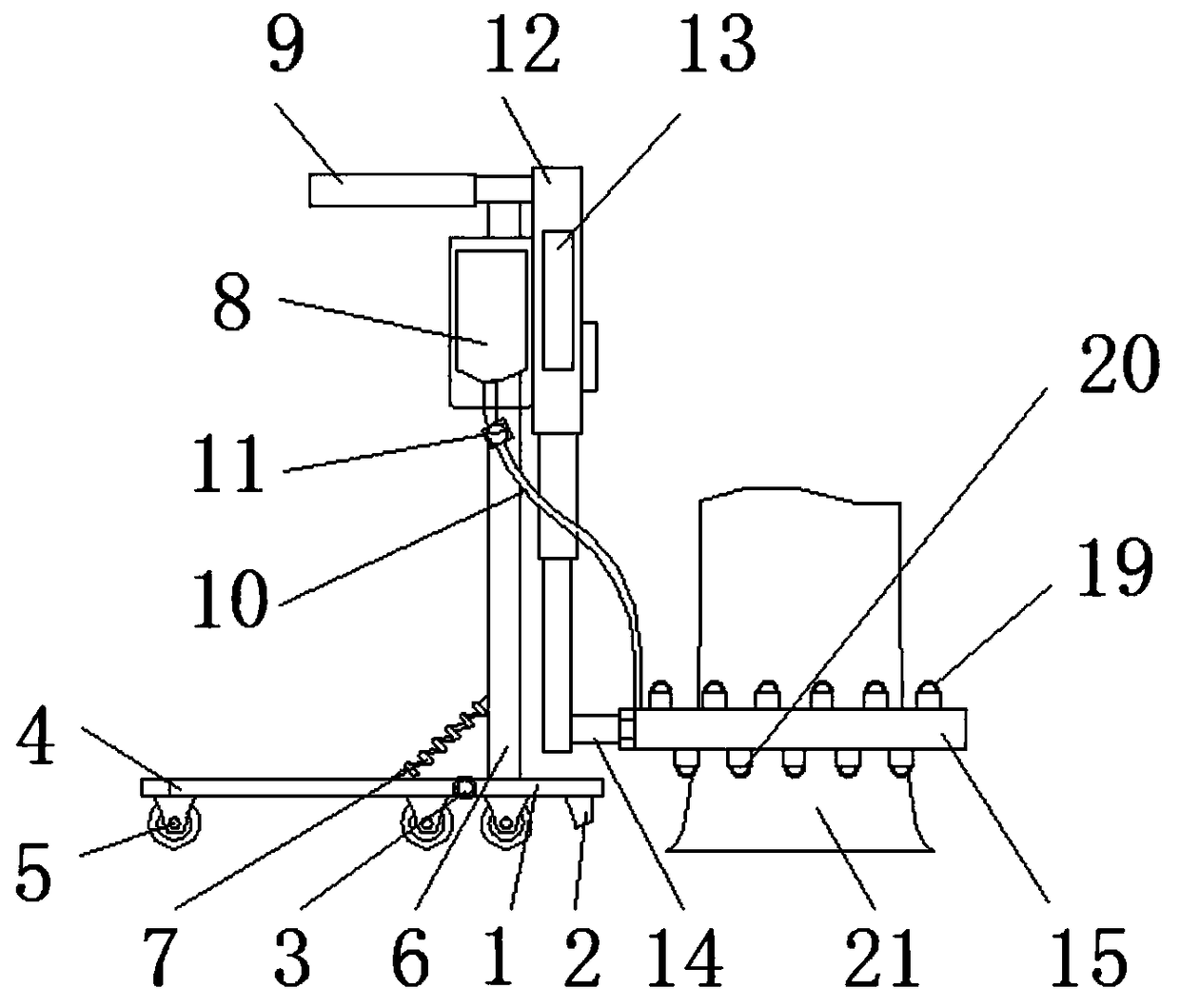

Tree trunk spraying device for garden tree maintenance

The invention discloses a tree trunk spraying device for garden tree maintenance. The tree trunk spraying device comprises a first stable plate, an electric lifting rod and a spraying part, wherein the right side of the lower end of a first stabilizing plate is welded with an abutting part, rolling wheels are installed at the lower ends of the first stabilizing plate and a second stabilizing plate, a liquid medicine storage box is fixed on the side surface of a supporting rod, a pressurizing pump is arranged on the surface of a pipeline, an electric lifting rod is welded to the right side of the upper end of the supporting rod, the spraying part is welded on the right side surface of a cross rod, second atomizing nozzles are fixed on the surfaces of the inner sides of a first rotating rodand the lower end of the inner side of a second rotating rod respectively, a tree trunk is arranged in the center of the spraying part, and a preformed hole is formed in the upper end surface of the second stabilizing plate. According to the tree trunk spraying device for garden tree maintenance, the inner diameter value of the cross section of the spraying part is larger than that of the cross section of the tree trunk, so that the spraying piece can be coated on the tree trunk, the device can conveniently carry out subsequent spraying work, and the device is more labor-saving, fine in spraying and large in coverage area.

Owner:ANHUI ORIGINAL POWER PRODUCTIVITY PROMOTION CENT CO LTD

Steel component spraying device easy to fix on site

PendingCN110433995AEasy to adjustEasy to completeSpraying apparatusAgricultural engineeringStorage tank

The invention discloses a steel component spraying device easy to fix on site, and belongs to the technical field of steel component processing devices. The steel component spraying device easy to fixon site comprises a connecting plate and a mounting plate, wherein the mounting plate is fixedly connected to the connecting plate, a sliding groove is formed in the inner wall of the mounting plate,a mounting frame is slidably connected to the sliding groove, a connecting sleeve is slidably mounted on the mounting frame, a coating storage tank is fixedly connected to the upper surface of the connecting sleeve, a spraying mechanism is fixedly installed on the lower surface of the connecting sleeve, and the spraying mechanism is matched with the coating storage tank; and a supporting mechanism is connected with the lower surface of the connecting plate, and comprises a supporting rod and a telescopic rod, the telescopic rod is in telescopic connection with the supporting rod, and a connecting bearing is fixedly installed at the top end of the telescopic rod. According to the device, the problems that existing design is large in size, fixed in structure, inconvenient in steel componentspray, troublesome to fix and mount and inconvenient to use on the construction site are effectively solved.

Owner:JIANGXI FUHUANG STEEL STRUCTURE CO LTD

Chemical spraying device

InactiveCN108380412AReduce pollutionMeet mixing needsLiquid spraying apparatusPolypropyleneCompound (substance)

The invention discloses a chemical spraying device which comprises a support seat. A filter tank is fixedly connected to the left end of the bottom part of the support seat; a polypropylene filter screen layer, a particle filter screen layer and a sponge filter layer are sequentially and fixedly connected into an inner cavity of the filter tank from top to bottom; and a reflowing hole is formed between the left end of the top part of the filter tank and the left end of the bottom part of a reflowing tank. According to the chemical spraying device provided by the invention, a first slider is slidably connected to the outer surface of a first sliding seat, a second slider is slidably connected to the outer surface of a second sliding seat, a first electric telescopic rod is fixedly connectedto the bottom part of the second slider, a second support rod and a fifth support rod are sequentially and fixedly connected to the bottom part of a first support rod from left to right, and throughthe action of a first movable joint, a second electric telescopic rod, a second movable joint, a third support rod, a third movable joint, a fourth support rod and a steering motor, the demand on all-dimensionally spraying a chemical product without a dead corner can be met, and great convenience is brought for the use by people.

Owner:李丽倩

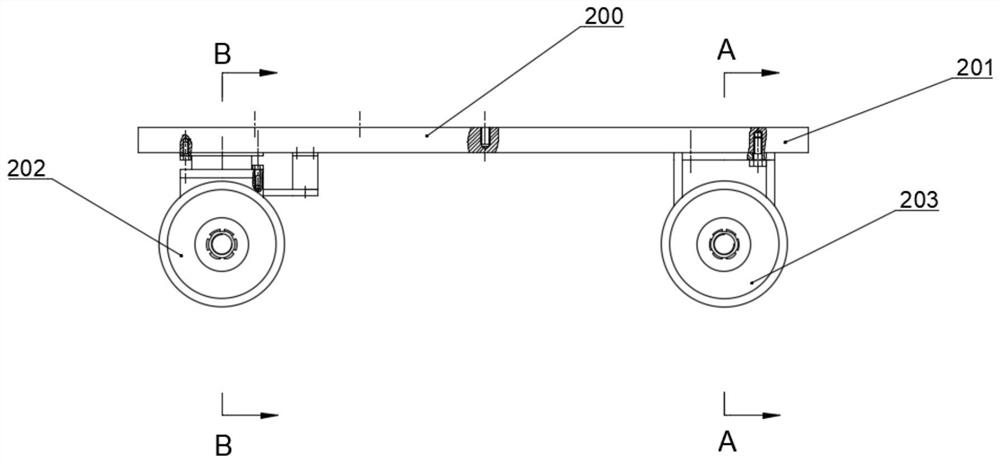

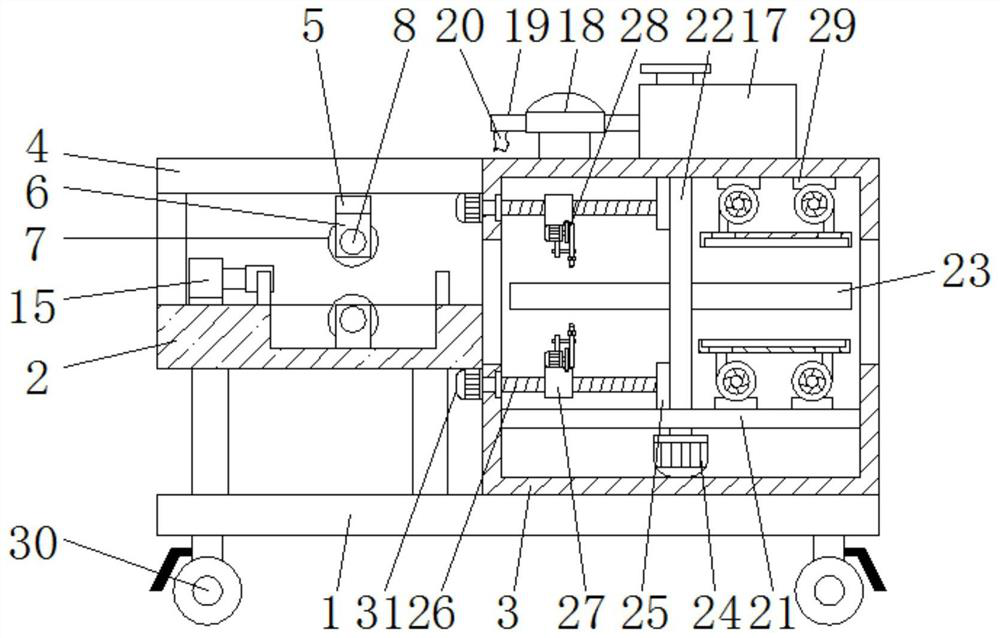

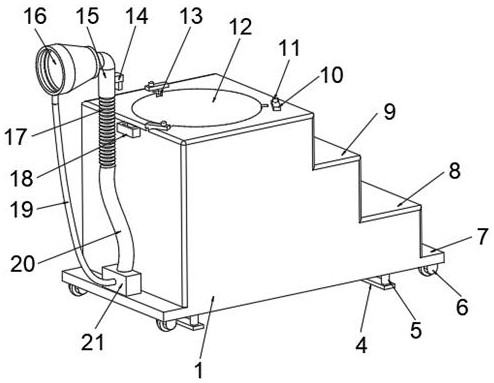

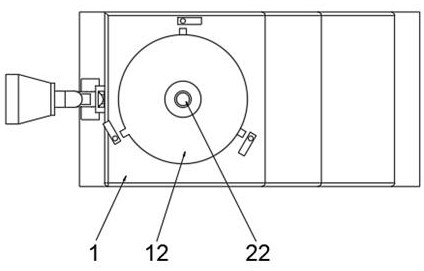

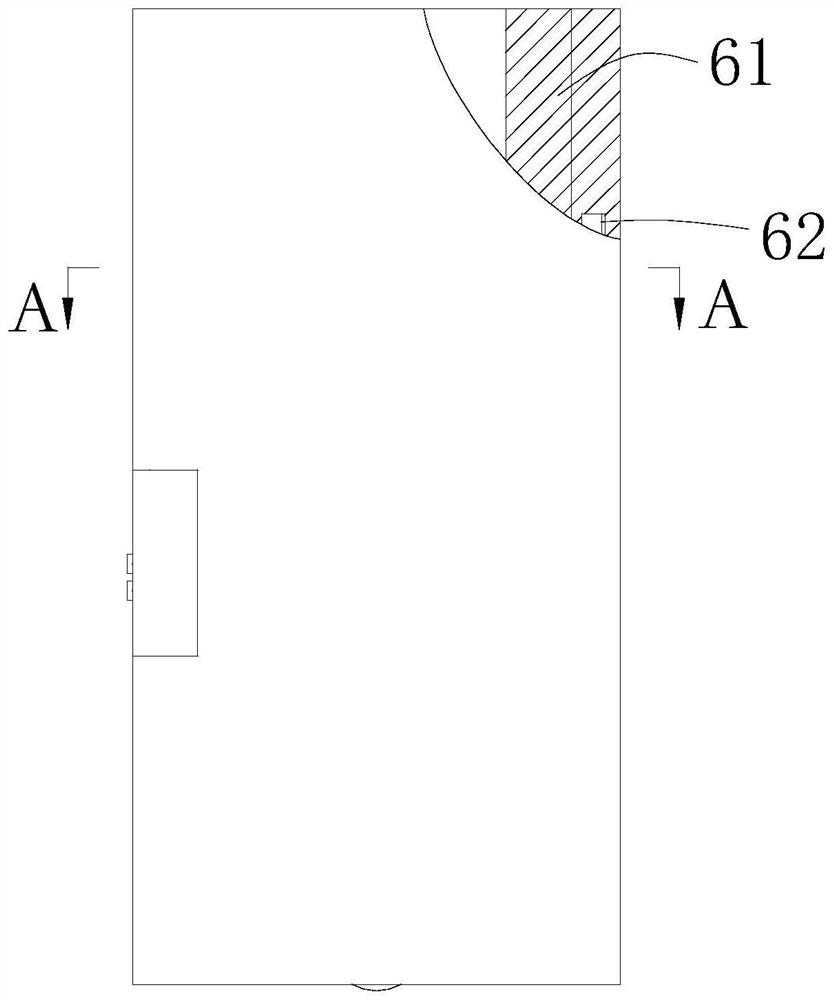

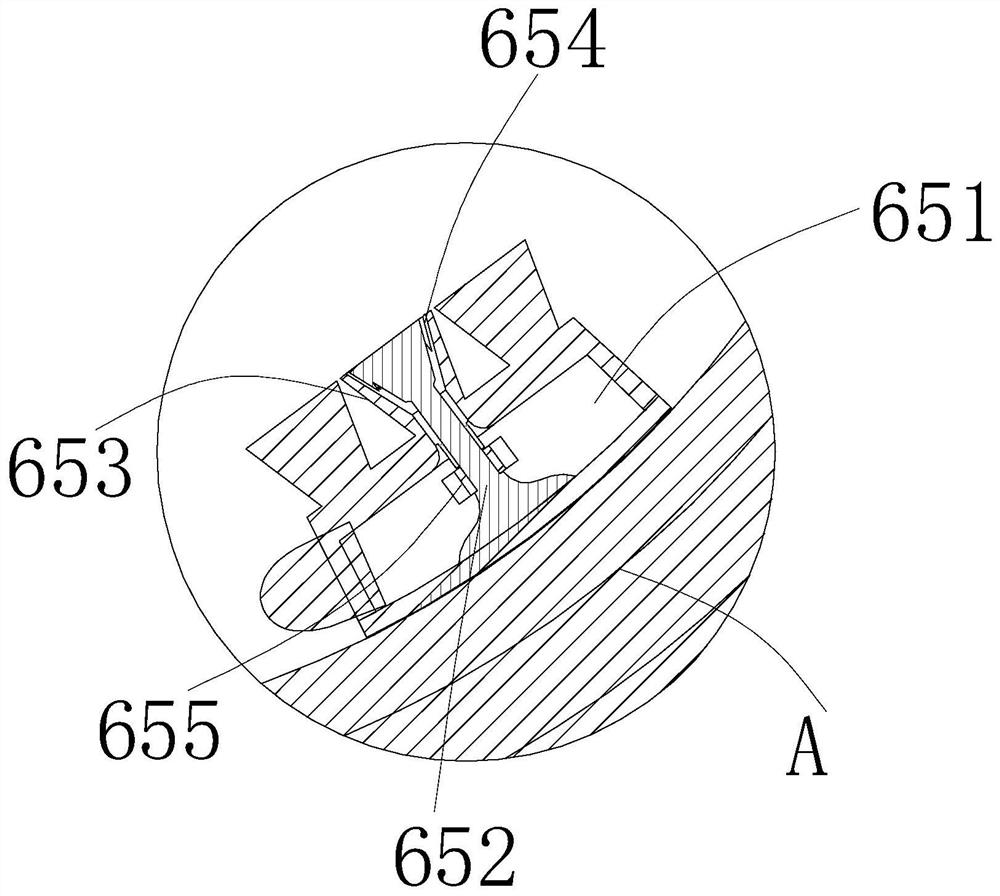

Agricultural pesticide spraying machine device convenient to use

InactiveCN107258752AImprove mixing efficiencyReduce damageInsect catchers and killersAutomatic controlEngineering

The invention discloses a portable agricultural pesticide spraying machine device, which comprises a mobile vehicle body, a medicine storage box arranged on the top of the mobile vehicle body, and a spraying mechanism for cooperating with the medicine storage box to control spraying. The spraying mechanism is fixedly installed. On the top of the mobile car body on the right side of the medicine storage box, a medicine storage chamber is arranged in the medicine storage box, and a first cavity is arranged in the medicine storage box above the top of the medicine storage chamber, and the top end surface of the medicine storage box above the first cavity There is a drug supply groove inside, and an isolation plate is arranged between the first cavity and the drug storage chamber. The isolation plate is rotated and connected with a rotating sleeve extending up and down, and the rotating sleeve is connected with a drug supply extending up and down. The extension section at the top of the drug supply tube passes through the first cavity and runs through the inner wall of the drug storage box between the first cavity and the drug supply groove and is fixedly connected, and the extended end of the bottom of the drug supply tube extends into the drug storage cavity; The invention has the advantages of simple structure, convenient operation, automatic control to realize rapid spraying work, uniform spraying, and improved service life at the same time.

Owner:崔盛科

Spray cleaning machine used for garden greening

InactiveCN105880068AAvoid wastingSolve the problem of not being able to spray onto tree trunksLiquid spraying apparatusPlant protectionWater storage tankGreening

A spray cleaning machine used for garden greening comprises a base. A water storage tank and a mortar box are arranged on the base. The water storage tank and the mortar box are each connected with the input end of an injection pump through a guide pipe. The output end of the ejection pump is connected with a T-shaped handle through a hose. The T-shaped handle is of a hollow structure. Three injection heads are arranged on the side wall of the T-shaped handle. Flow control valves are arranged on the guide pipes. The design of the water storage tank and the mortar box is adopted, the problem that because a trunk is too dirty, mortar cannot be sprayed to the trunk is effectively solved, the structure is simple, and the labor intensity of workers is relieved. Due to the design of an arc-shaped clamping body, the injection heads are effectively and accurately aligned with the trunk, and it is avoided that because of shaking generated when the handle is held by hand, the mortar cannot be completely sprayed to the trunk and the mortar is wasted. By means of a lamp pole and a damping rotating shaft, the height and irradiation angle of a reflector lamp can be regulated, the reflector lamp can irradiate an assigned area due to brightness, and the spray work is facilitated.

Owner:HARBIN GONGYANG SCI & TECH CONSULTATION CO LTD

Ultrasonic atomization pyrolysis spraying device and spraying method

PendingCN112495671AEasy compression managementEasy to completePretreated surfacesLiquid spraying apparatusEngineeringUltrasonic atomization

The invention discloses an ultrasonic atomization pyrolysis spraying device and a spraying method. The ultrasonic atomization pyrolysis spraying device comprises a first bottom plate, a conveying mechanism, a second bottom plate, a spraying mechanism, a cleaning mechanism, a pipeline box and a support mechanism, supporting columns are fixedly installed at the four corners of the upper surface of the first bottom plate through fixing bolts, and the conveying mechanism is fixedly installed among the four supporting columns. The second bottom plate is fixedly installed on the outer wall of one side of the first bottom plate, the spraying mechanism is fixedly installed on one side of the upper surface of the second bottom plate, and the cleaning mechanism is fixedly installed on the other sideof the upper surface of the second bottom plate. The ultrasonic atomization pyrolysis spraying device and the spraying method have the beneficial effects that according to the ultrasonic atomizationpyrolysis spraying device, through the cooperation use of each structure, the conveying, spraying and cleaning work can be conveniently completed, the device can integrate automatic conveying, automatic spraying, automatic cleaning and automatic drying, has good functionality, multiple functions, a simple structure and a high spraying effect, can complete water recycling of the whole device, improves the resource utilization rate, and is suitable for popularization and application.

Owner:绍兴权电科技有限公司

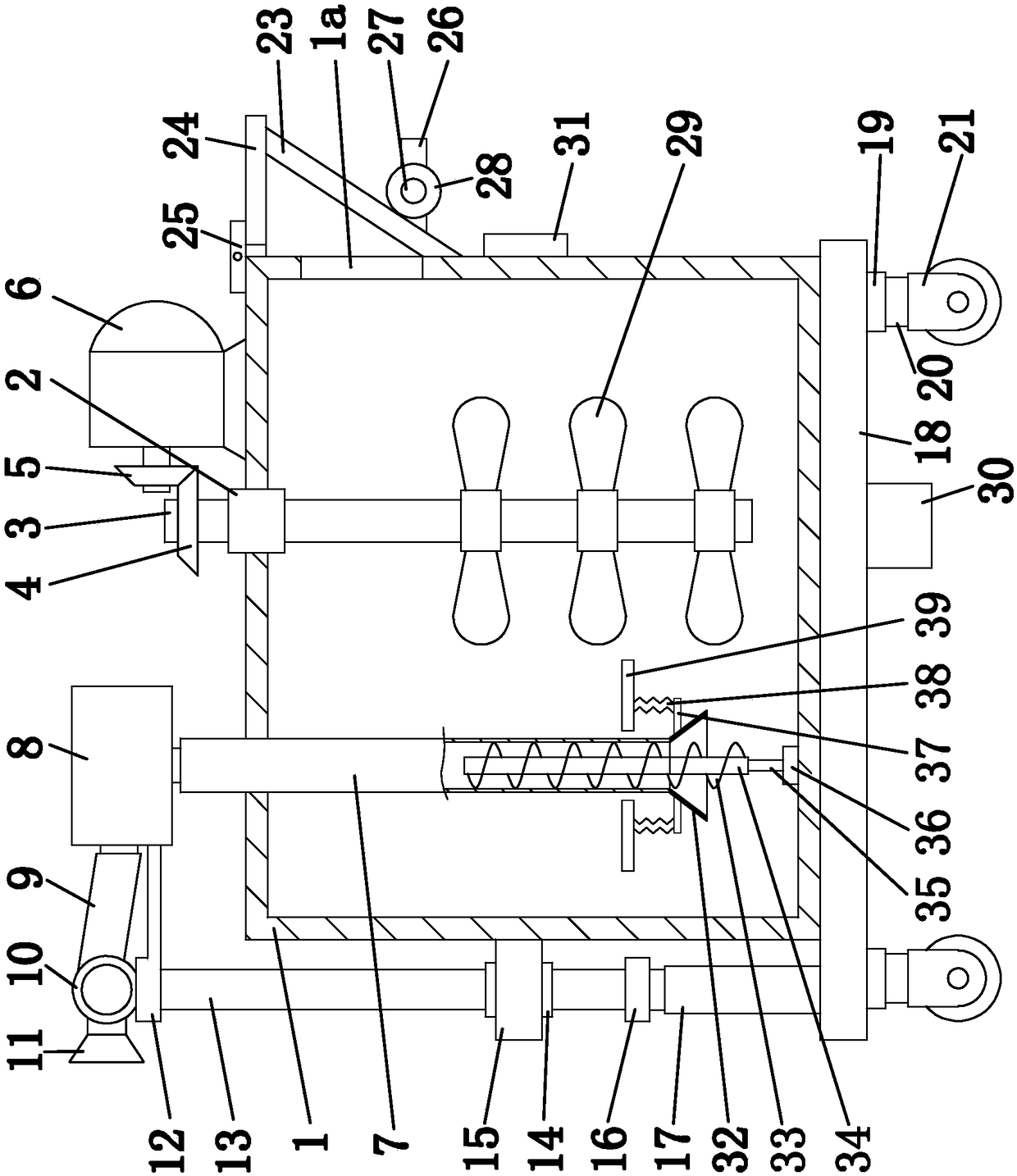

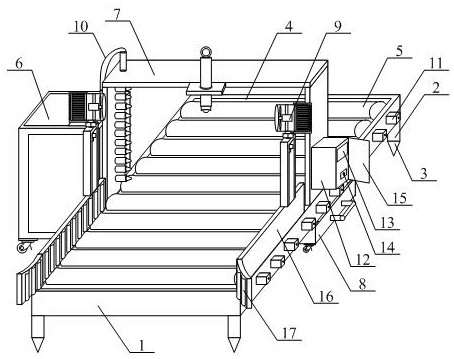

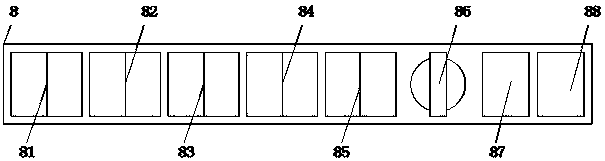

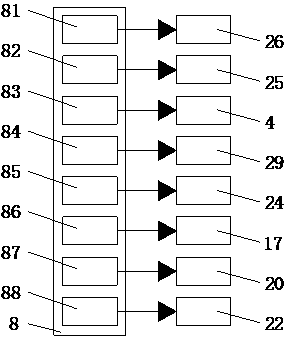

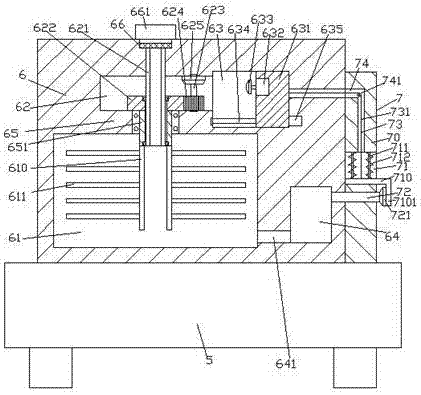

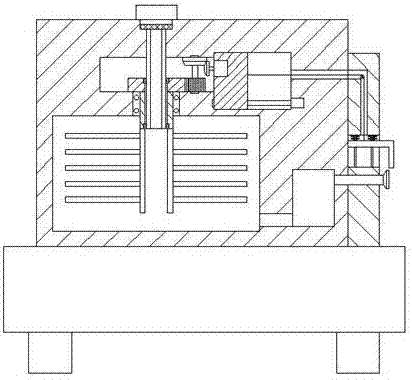

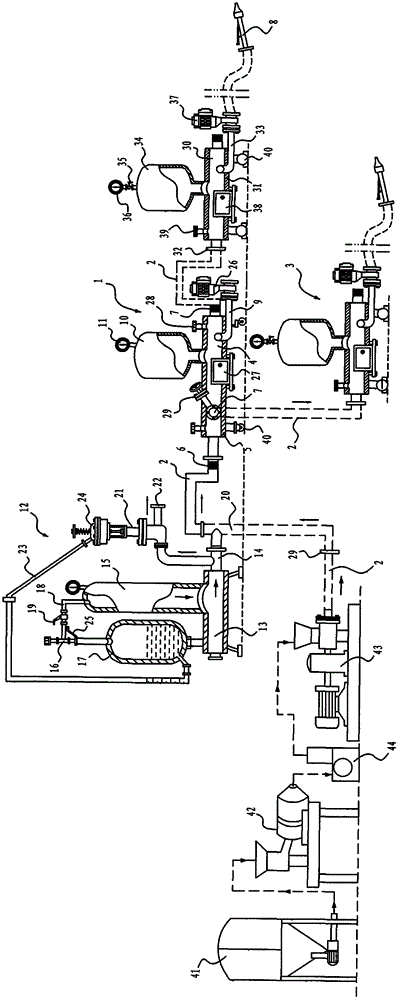

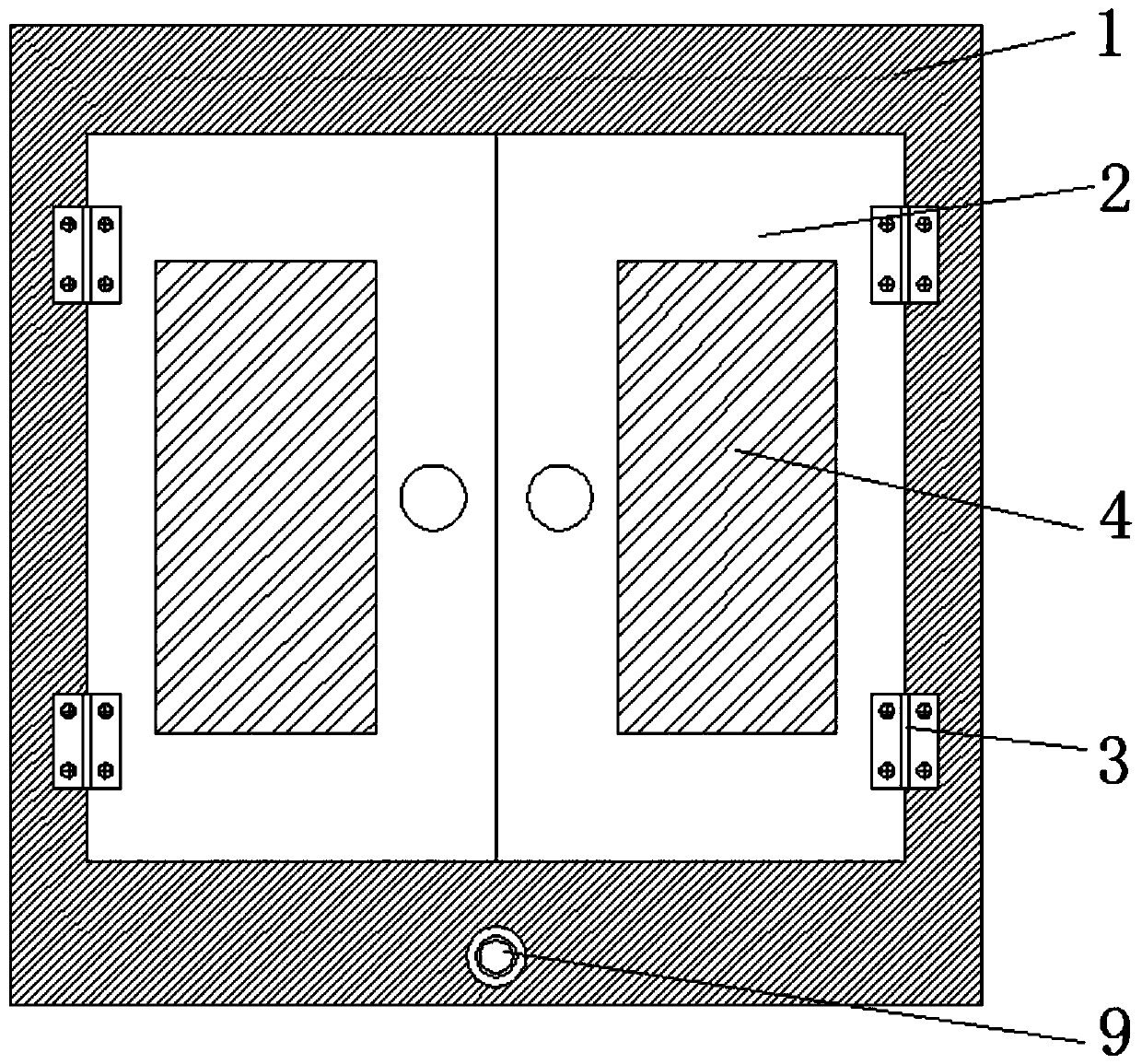

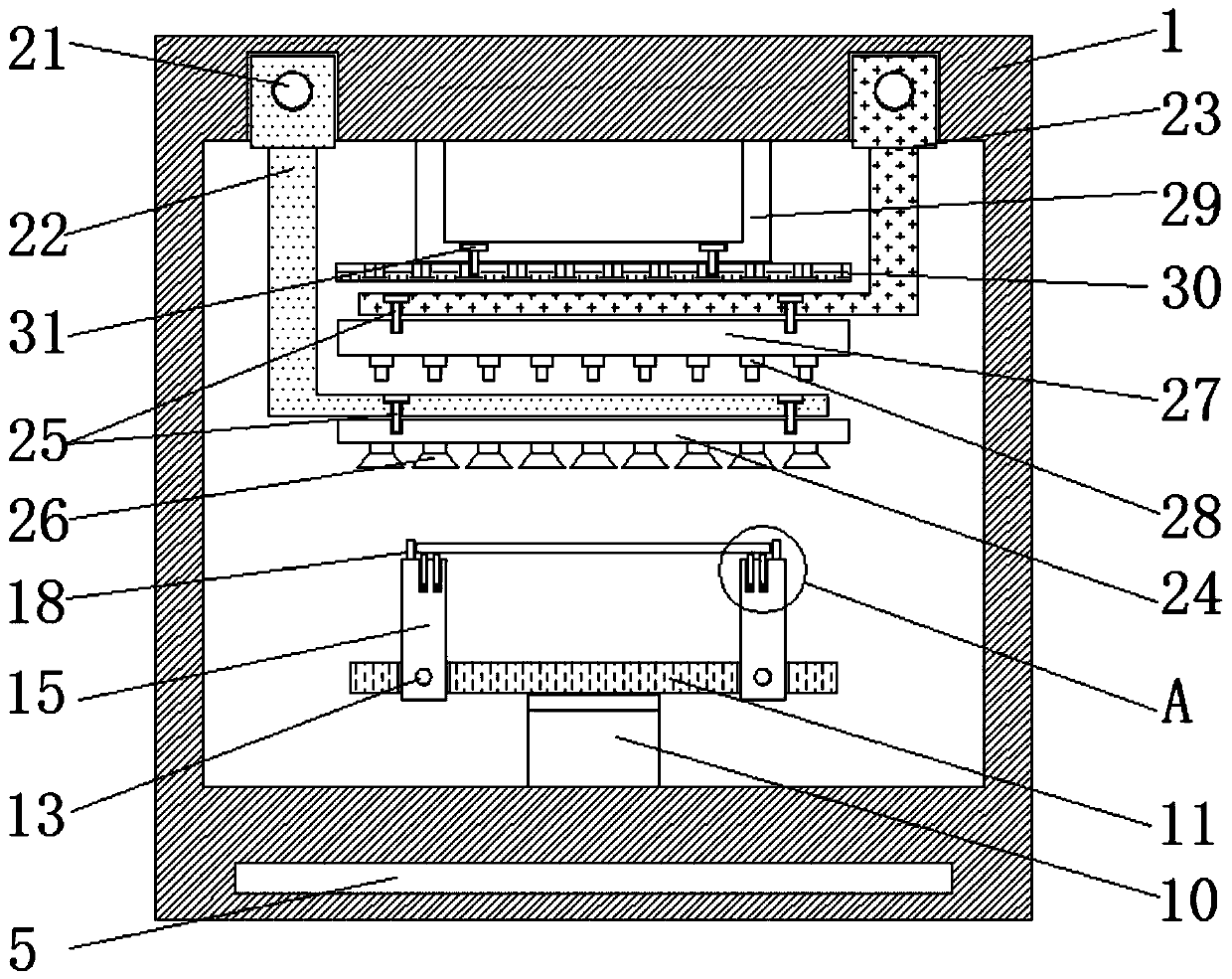

Intelligent and comprehensive dry-mixed mortar wall coating system

InactiveCN104088447AReduce wasteReduce disseminationBuilding constructionsCoating systemAir compressor

The invention discloses an intelligent and comprehensive dry-mixed mortar wall coating system. The intelligent and comprehensive dry-mixed mortar wall coating system comprises a mortar storing tank, a continuous type cement mortar mixer, a secondary stirring storage tank and a mortar conveying pump, all of which are connected through a material conveying pipeline in sequence. The intelligent and comprehensive dry-mixed mortar wall coating system further comprises a full-automatic mortar spraying distributing system directly connected with the mortar conveying pump through the material conveying pipeline. The full-automatic mortar spraying distributing system comprises a main spraying distributing machine and a plurality of auxiliary spraying distributing machines connected with the main spraying distributing machine through the material conveying pipeline. An air storage tank can balance uneven feeding pressure for a mortar conveying pump piston to push mortar to reverse and guarantee balance of mortar spraying discharging pressure, the modes that the mortar conveying pump is directly connected with the main spraying distributing machine and the mortar conveying pump directly provides power for the main spraying distributing machine are adopted, the mode that in a traditional spraying machine, an electromotor and an air compressor need electric energy to carry out spraying is abandoned, energy sources are greatly saved, the equipment fault rate is reduced, and the service life of equipment is prolonged.

Owner:胡维毅

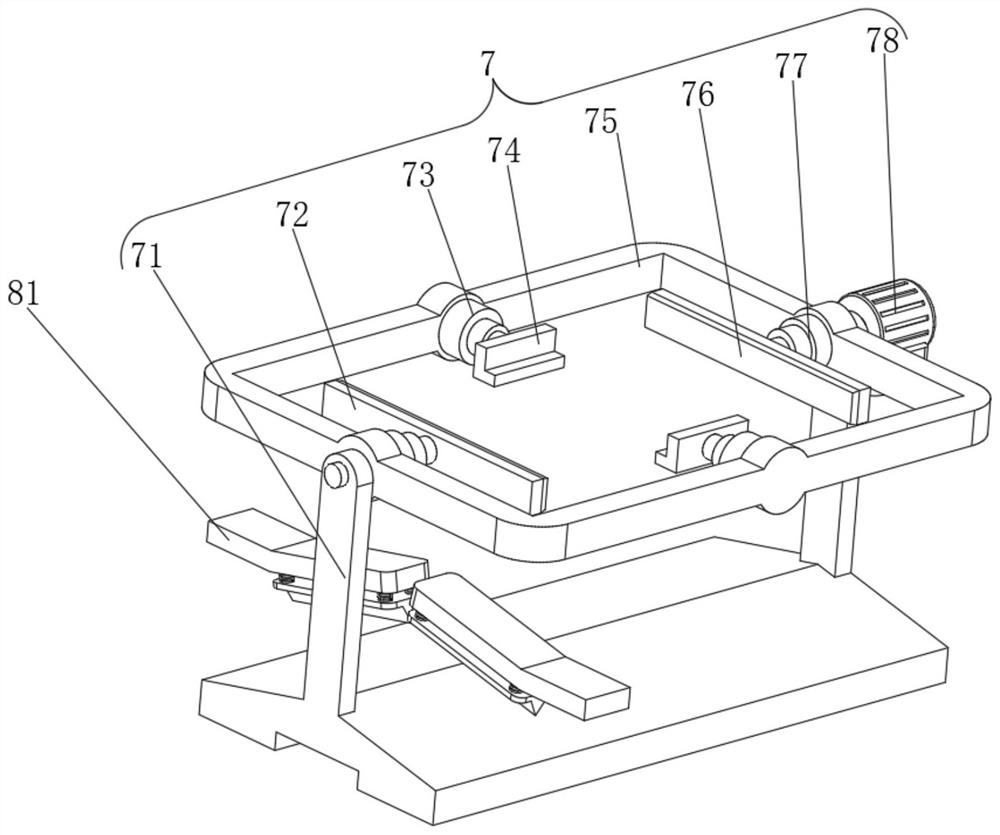

Negative ion coating spraying system and spraying method thereof

PendingCN114086104AFine adjustment of spraying directionImprove spray qualityMolten spray coatingEngineeringWorkbench

The invention discloses a negative ion coating spraying system and a spraying method thereof. The spraying system comprises a bottom plate, a workbench is fixedly arranged in the middle of the upper end of the bottom plate, a clamping mechanism is arranged in the workbench, and the clamping mechanism comprises a first sliding groove, a first sliding block, a tensioning block and a connecting block; a plurality of first sliding grooves are evenly formed in the periphery of the surface of the upper end of the workbench, first sliding blocks are movably arranged in the first sliding grooves in a clamped mode, tensioning blocks are fixedly arranged at the upper ends of the first sliding blocks, connecting blocks are fixedly arranged at the lower ends of the first sliding blocks, a first transmission mechanism is arranged in the workbench, the first transmission mechanism comprises a fixed block, a movable rod, a first transmission block, a first mounting seat, an electric push rod, a movable plate, a second transmission block and a first transmission rod. The spraying system is good in using effect, a deflection electric field is arranged on the outer side of the ion spraying mechanism, the spraying direction can be finely adjusted during ion spraying, and therefore the spraying quality of the device can be improved.

Owner:罗海蓉

Guitar surface electrostatic spraying technology

InactiveCN111482343APromote wettingImprove bindingPretreated surfacesCoatingsActive agentElectron flow

The invention relates to the technical field of guitar production, in particular to a guitar surface electrostatic spraying technology. Before guitar surface paint spraying, scrubbing treatment, microwave treatment, surface active agent wiping and corona treatment are sequentially conducted on the guitar surface, and some novel hydroxide radical, carbonyl, amidogen and other polar functional groups and surface free radicals are generated on the guitar surface, guitar surface wetting and interface bonding are facilitated through the groups, and accordingly, the guitar surface gluing quality iseffectively improved. During finishing coat spraying, the electrostatic spraying technology is adopted, it can be guaranteed that powder in the finishing coat can be evenly and firmly sprayed to the guitar surface, and the electrostatic spraying quality is ensured; and in addition, through setting of the electrostatic spraying voltage, the phenomenon of stream of electrons can be effectively reduced, and it is guaranteed that the appearance of a coating formed on the guitar surface is good.

Owner:雅歌乐器(漳州)有限公司

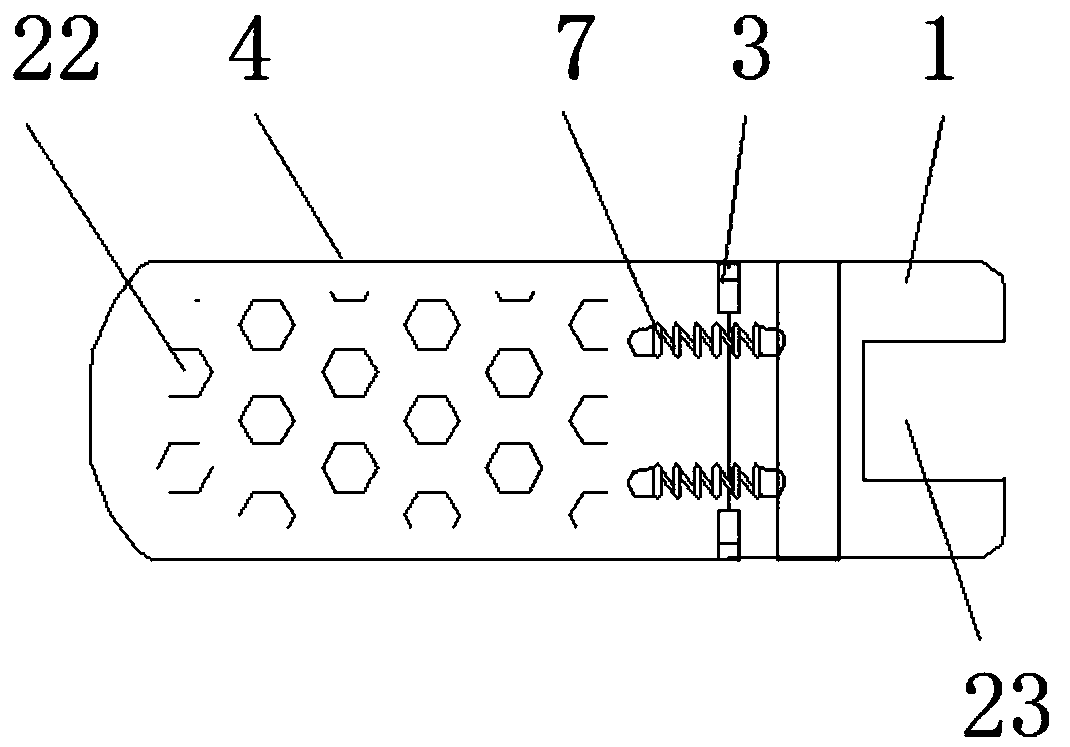

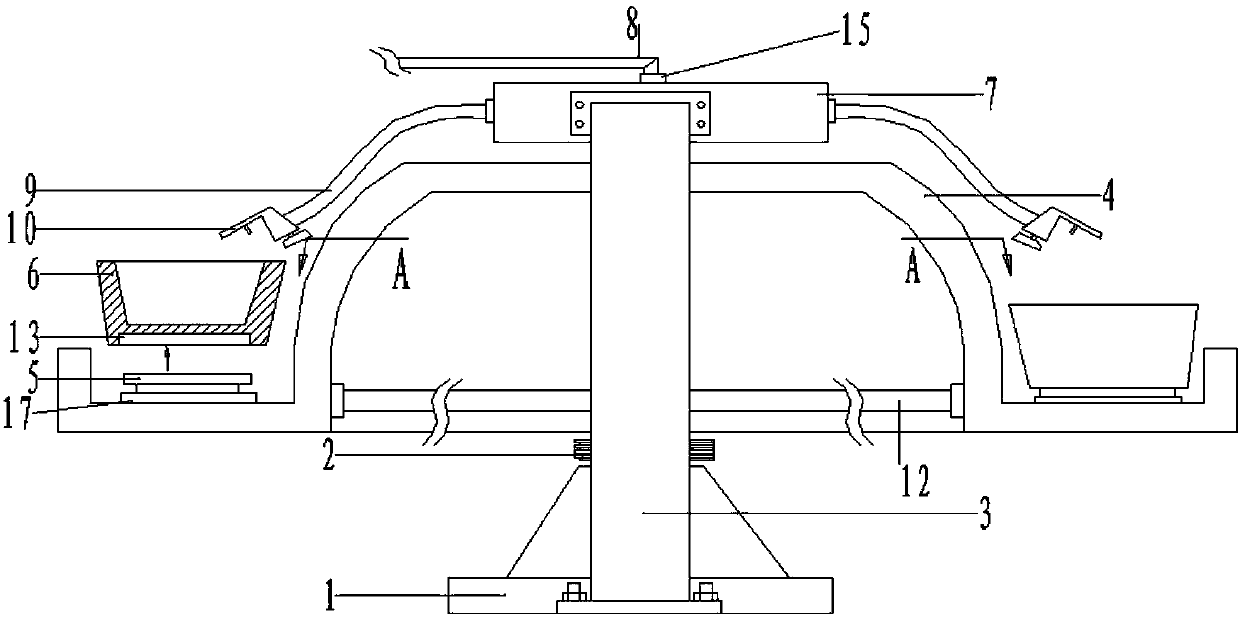

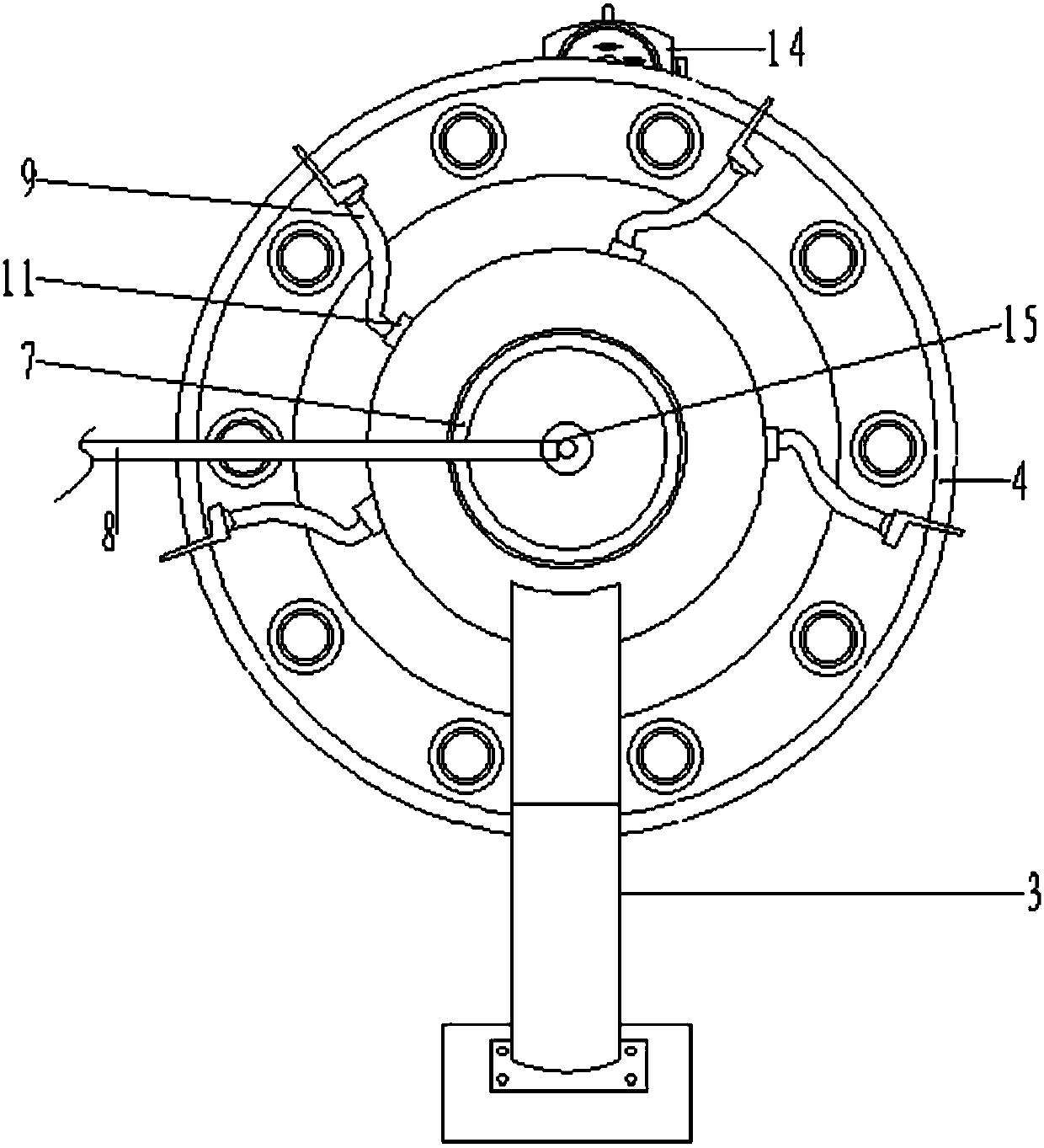

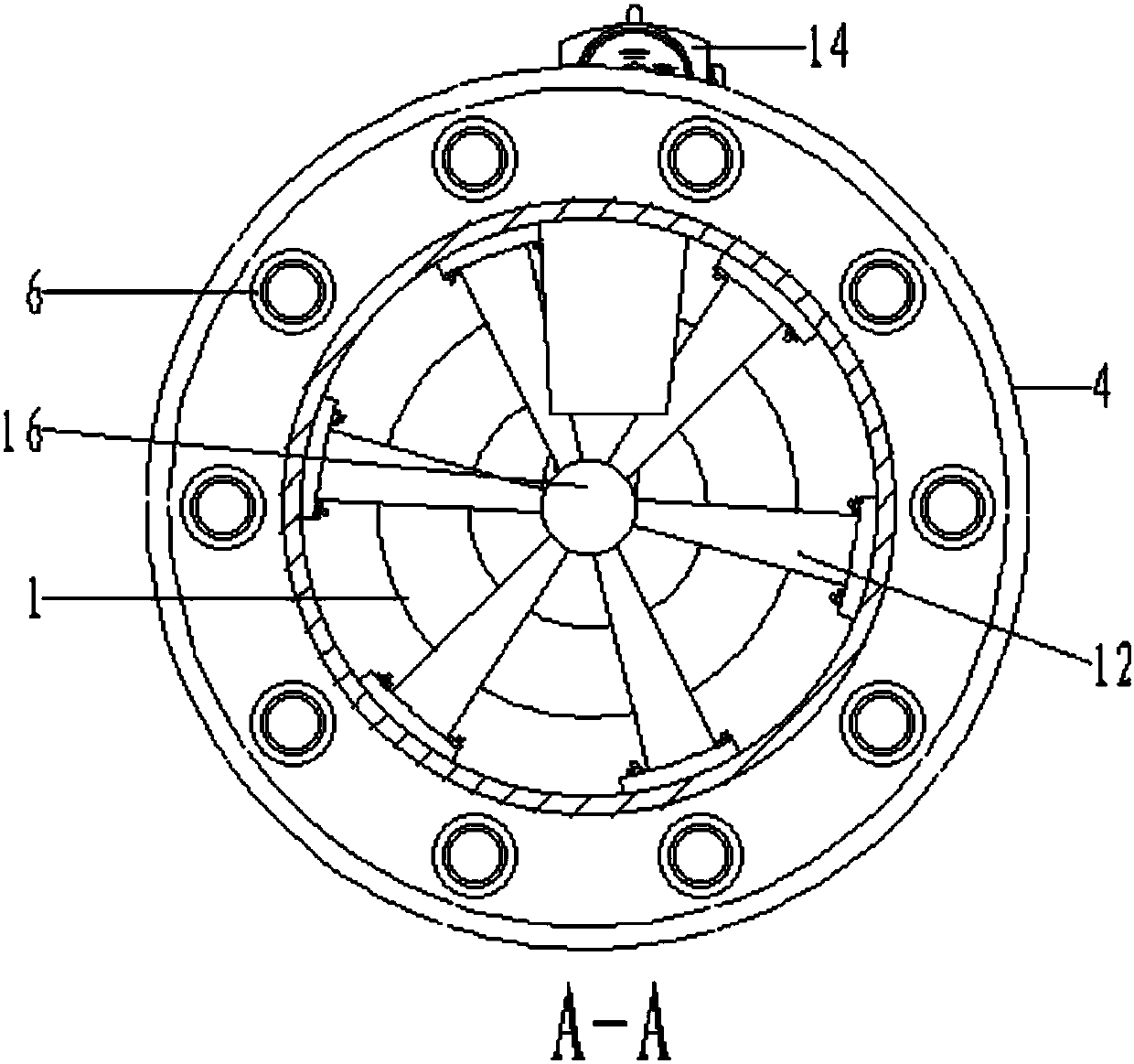

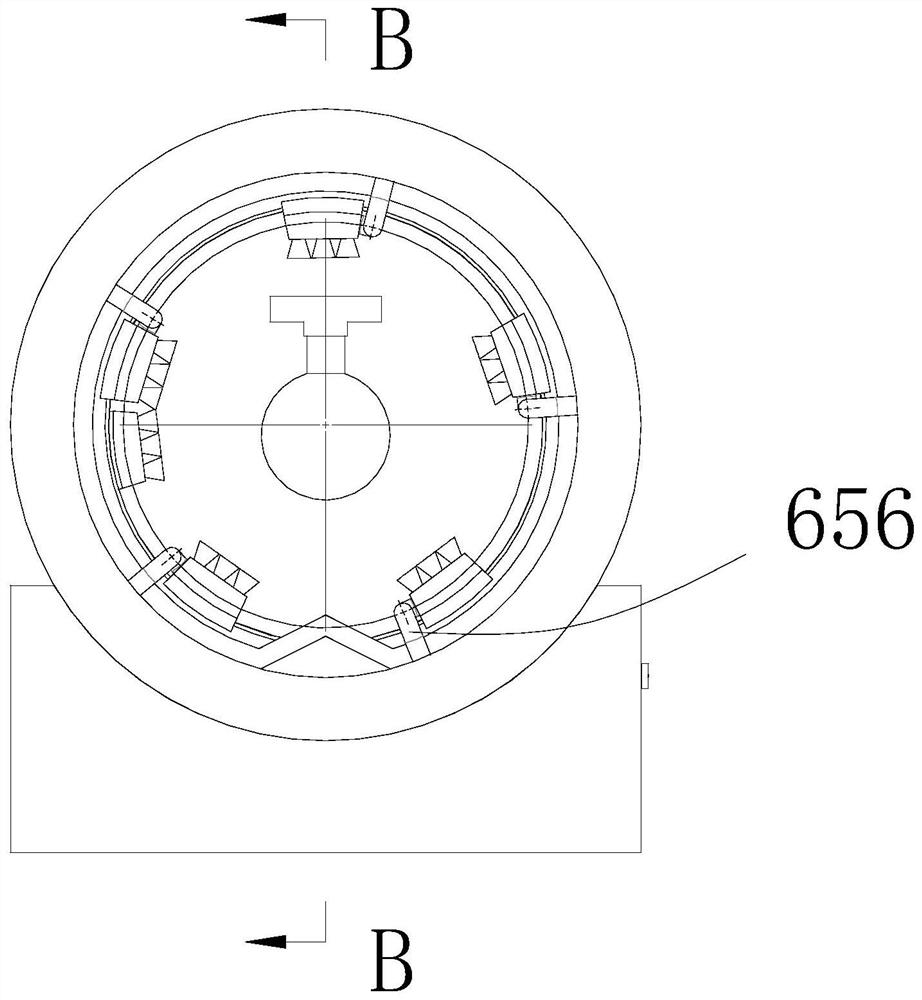

A rotary main valve plate coating equipment

ActiveCN106824602BEffectively fixedConvenient for spraying workLiquid spraying apparatusSpray coatingEngineering

The invention relates to coating equipment, in particular to rotary coating equipment for main valve plates. The technical problem to be solved is to provide rotary double-side-spraying coating equipment for main valve plates. In order to solve the technical problem, the invention provides such rotary coating equipment for main valve plates, comprising a base, a right rack, a first slide rail, a first slider, a push rod, a first spring, a support and the like; the right rack is arranged on the right side of the top of the base, the left side of the right rack is connected with the first slide rail, the first slider is connected to the first slide rail, the first slider fits the first slider rail, the first spring is connected between the top of the first slider and the top of the first slide rail, the push rod is arranged at the top of the first slider, and a moving rod is arranged on the left side of the first slider. A fixture in the rotary coating equipment for main valve plates designed herein allows a main valve plate body to be effectively fixed for better spraying, and the fixture may also be rotated during spraying.

Owner:JIANGSU CHENLONG VALVE MFG CO LTD

Paint spraying device capable of achieving uniform spraying and used for household appliance panel machining

The invention relates to the technical field of panel paint spraying, in particular to a paint spraying device for processing a household appliance panel, which is uniform in spraying, and solves the problems that in the prior art, only one surface can be sprayed during paint spraying of the panel, and if the other surface needs to be sprayed, the panel needs to be taken out and manually turned over, so that the paint spraying efficiency is high. And then the paint spraying treatment is carried out, the mode is tedious, and time is wasted. A paint spraying device capable of achieving uniform spraying and used for household appliance panel machining comprises a spraying box, a box cover, a storage box, a paint pump, a connecting pipe and a connecting plate, a fixing device is arranged in the spraying box and comprises a fixing frame, and the fixing frame is fixedly installed at the bottom of the spraying box. By arranging the fixing device, a panel can be fixed, the panel can be turned over in the spraying box, the two sides of the panel can be uniformly sprayed conveniently at the same time, and operation is convenient.

Owner:湖南容大之光通信设备有限责任公司

Coating control method for cable production

ActiveCN112002487AEasy squeezeConvenient for spraying workInsulating conductors/cablesStructural engineeringElectric cables

The invention discloses a coating control method for cable production. The control method is realized on the basis of coating equipment. The coating equipment comprises a frame body, guide rollers, electric push rods and liquid injection pipes, wherein the guide rollers are arranged at the left end and the right end of the frame body correspondingly, the electric push rods are fixed in the upper portion of the frame body, the liquid injection pipes are arranged on the left sides and the right sides of the electric push rods correspondingly, and second extrusion plates are fixed to the bottom ends of the electric push rods. The coating equipment capable of quickly cooling and reducing bubbles for cable production is provided with the first inner air bag and the first outer air bag; the first outer air bag is extruded through the first extrusion plate; the first outer air bag is arranged, so that air in the first outer air bag enters the first inner air bag through the connecting pipe, the inner side wall of the first inner air bag is in contact with the inner side wall of the coating lantern ring firstly, a discharging hole in the inner side wall of the coating lantern ring is closed, raw materials in the coating lantern ring can be extruded conveniently, and bubbles in the raw materials are broken.

Owner:JIANGSU XINCHANGFENG CABLE

Coating equipment for machining carbon fiber automobile engine hood

The invention discloses coating equipment for machining a carbon fiber automobile engine hood. The coating equipment comprises a coating box and a first threaded rod, wherein a filter frame is fixed on the right side of the bottom of a groove through first bolts; a support is fixed on the inner bottom of the coating box; the first threaded rod penetrates through the bottom of a moving frame to beconnected with a bearing plate, and the top of the moving frame is connected with supporting columns through compression springs; motors are arranged on the front side and the rear side in the top ofthe coating box; a storage plate is fixed at the bottom of a first sliding frame through third bolts; a water storage plate is fixed at the bottom of a second sliding frame through third bolts; and ahanging bracket is fixed at the inner top of the coating box. According to the coating equipment for machining the carbon fiber automobile engine hood, in the process of placing the carbon fiber automobile engine hood, the supporting columns can move up and down to different heights under the action of the compression springs and are tightly attached to the lower end face of the carbon fiber automobile engine hood, and unstable placement of the carbon fiber automobile engine hood caused by an uneven lower end face is prevented.

Owner:江苏东科复合材料有限公司

High-performance sheet metal part spraying system

PendingCN113522577AEasy to cleanPrevent paint corrosionSpraying apparatusElectric machineryEngineering

The invention discloses a high-performance sheet metal part spraying system, and relates to the technical field of sheet metal part spraying. The high-performance sheet metal part spraying system comprises a rack, a base, a limiting rod, a spraying device, a collecting box and a clamping device, the base is fixedly arranged at the bottom of the rack, the limiting rod is fixedly arranged on the inner wall of the rack, and the spraying device is movably arranged on the outer wall of the limiting rod; and the spraying device comprises a forward and reverse motor, a ball screw, a nut seat, a sliding block, a coating box, a hydraulic pump, a conveying pipe and a spraying head. By arranging the spraying device, efficient spraying can be conducted on sheet metal parts, uniform spraying can be conducted on the circular sheet metal parts in a left-right transmission mode, spraying work on the sheet metal parts is facilitated, key spraying can be conducted on spraying areas when the sheet metal parts rotate, and the spraying device is simple and effective; and assembling and disassembling of the collecting box is facilitated by forming a movable groove, when the sheet metal parts are sprayed, the collecting box can collect waste materials and liquid generated during spraying, and energy conservation and environment protection are achieved.

Owner:山东吉宇建材有限公司

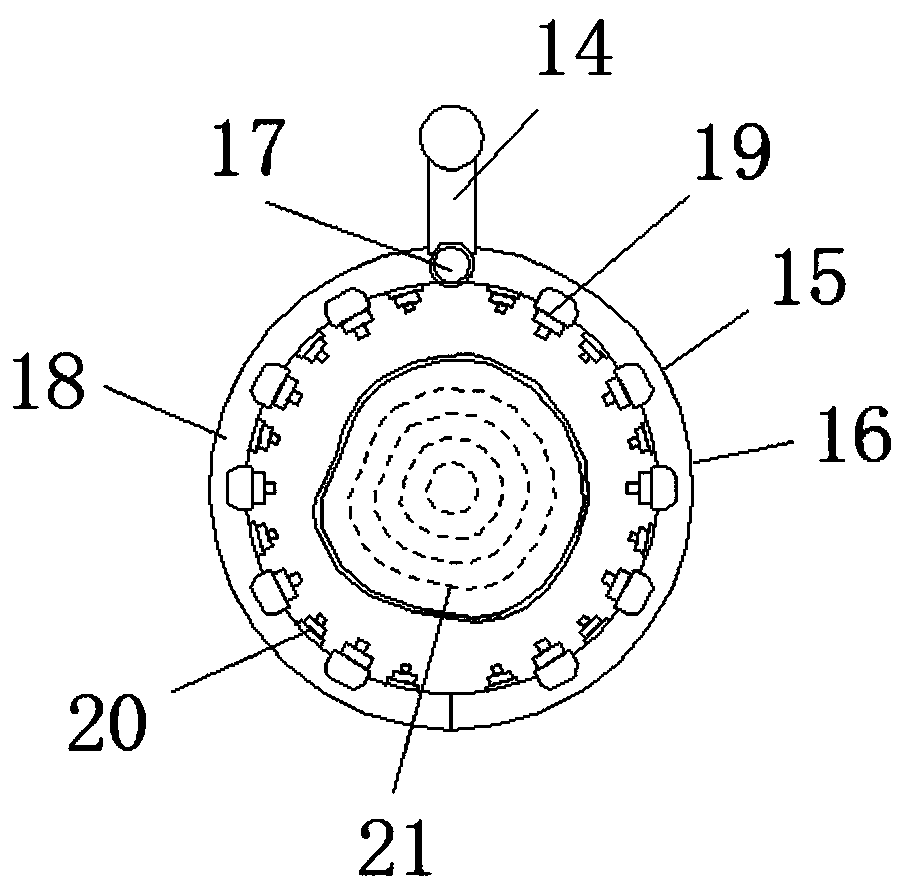

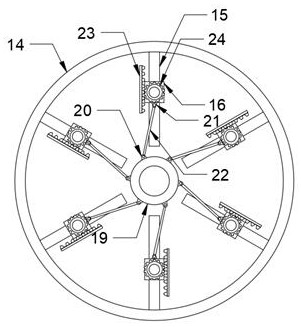

Automatic spraying conveying device on annular casting production line

InactiveCN107626495ASmall footprintConvenient for spraying workLiquid spraying apparatusRotational axisLow speed

The invention provides an automatic spraying conveying device on an annular casting production line. The automatic spraying conveying device comprises a low-speed motor, a second rubber inlet pipe clamping head, a rotating shaft and bearing supporting seats; a base is of a disc-shaped structure, the rotating shaft is perpendicularly mounted on the top face of the base through the bearing seats, and the rotating shaft and the low-speed motor mounted on the outer side of the rotating shaft are in transmission connection through a belt wheel mounted on the shaft wall of the rotating shaft and a belt; six connecting rods are radially mounted on the shaft wall of the rotating shaft in a uniformly distributed mode; a gas inlet pipe and four spraying pipes are mounted in the top face and the annular periphery of a gas collection compartment through the penetrating second rubber inlet pipe clamping head and four penetrating first rubber inlet pipe clamping heads in a penetrating mode correspondingly, wherein spraying guns are mounted at the pipe heads of the spraying pipes correspondingly; a spraying compartment is of an inverted-cone-shaped cavity type structure and supported and connected by bearings and accordingly can rotate by 360 degrees, thus, a worker can conduct spraying work on a workpiece in multiple directions conveniently, and using is more flexible.

Owner:十堰市宏昌达工贸股份有限公司

Closed surface spraying equipment

InactiveCN113680551ASpeed up the flowImprove stabilityPretreated surfacesLiquid spraying apparatusSurface cleaningEngineering

The invention discloses closed surface spraying equipment. The closed surface spraying equipment comprises a main machine body, wherein a storage cavity with an upward opening is formed in the main machine body, spraying raw materials for spraying are stored in the storage cavity, and an adjusting plate capable of moving left and right is arranged in the storage cavity. According to the closed surface spraying equipment, a rotating fan rotates, air in a fan cavity is discharged forwards into a working plate, air in a heating cavity is sucked in through an air inlet pipeline, at the moment, air in the working plate is promoted to flow through rotation of the rotating fan, at the moment, air in the working plate is discharged outwards through an exhaust port, in the process, the surface of a to-be-sprayed plate is cleaned again, subsequent spraying work is facilitated, meanwhile, the hydraulic strength of the spraying raw materials stored in a storage cavity is kept through a movable adjusting plate, and then the spraying raw materials entering the communicating pipeline and output are kept at the same speed all the time, and therefore, the stability of spraying work and the spraying uniformity are improved.

Owner:厦门蝉令贸易有限公司

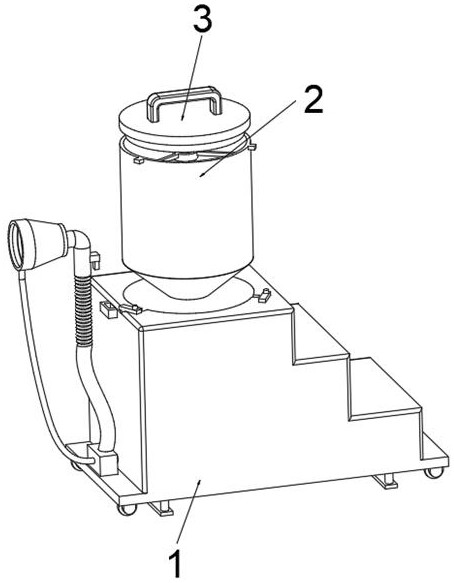

Mortar spraying equipment for decoration engineering and using method thereof

InactiveCN112459418AEasy to cleanReduce the difficulty of cleaningSpraying apparatusBuilding constructionsStructural engineeringMechanical engineering

The invention discloses mortar spraying equipment for decoration engineering and a using method thereof, and relates to decoration equipment. The mortar spraying equipment specifically comprises a base, a mixing tank mounted on the base and used for stirring mortar, and a tank cover mounted at the top of the mixing tank; a mounting groove used for mounting the mixing tank is formed in the base; awater pump is fixedly installed on a protruding block at one side of the base through a bolt; the input end of the water pump is communicated with a material receiving opening; the output end of the water pump is fixedly connected with one end of a rubber hose; the other end of the rubber hose is fixedly connected with one end of an elastic telescopic pipe; the other end of the elastic telescopicpipe is fixed to one end of a curved pipe; and a spray head for spraying is fixed at the other end of the curved pipe in a threaded connection mode. A return pipe communicated with the water pump is arranged on a protective cover, so that the situation that the mortar drips onto the ground and is difficult to clean is effectively avoided, and the waste of the mortar is avoided.

Owner:楼路洁

A fully automatic assembly line system for electrostatic powder coating

ActiveCN112295765BIncrease spray areaIncrease delivery speedLiquid spraying plantsStructural engineeringProcess engineering

The invention discloses a fully automatic assembly line system for electrostatic powder coating, which comprises a fixed base, a non-contact powder bin arranged on the base, a powder material recovery system arranged on the non-contact powder bin, and a device fixedly connected to the fixed base. Cylindrical coating silo, suspension conveying mechanism located in the cylindrical coating silo, primary powder spraying structure located in the cylindrical coating silo, secondary powder spraying structure located in the rear side of the primary powder spraying structure The powder spraying structure and the leveling mechanism located in the secondary powder spraying structure; two spraying structures are set to expand the spraying area between the flowing water, and the conveying speed of the suspended conveying structure can be further accelerated, thereby improving the working efficiency; setting A powder recovery system is installed, which can realize the timely recovery and utilization of powder in conjunction with the drum-type coating silo, reducing the waste of powder and saving costs.

Owner:明德新材料科技(浙江)股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com