Paint spraying device capable of achieving uniform spraying and used for household appliance panel machining

A technology for processing household appliances and panels, which is applied to spray devices, liquid spray devices, etc., can solve the problems of wasting time and cumbersome methods, and achieve the effects of improving the working environment, reducing dripping on the outside, and improving the scraping effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

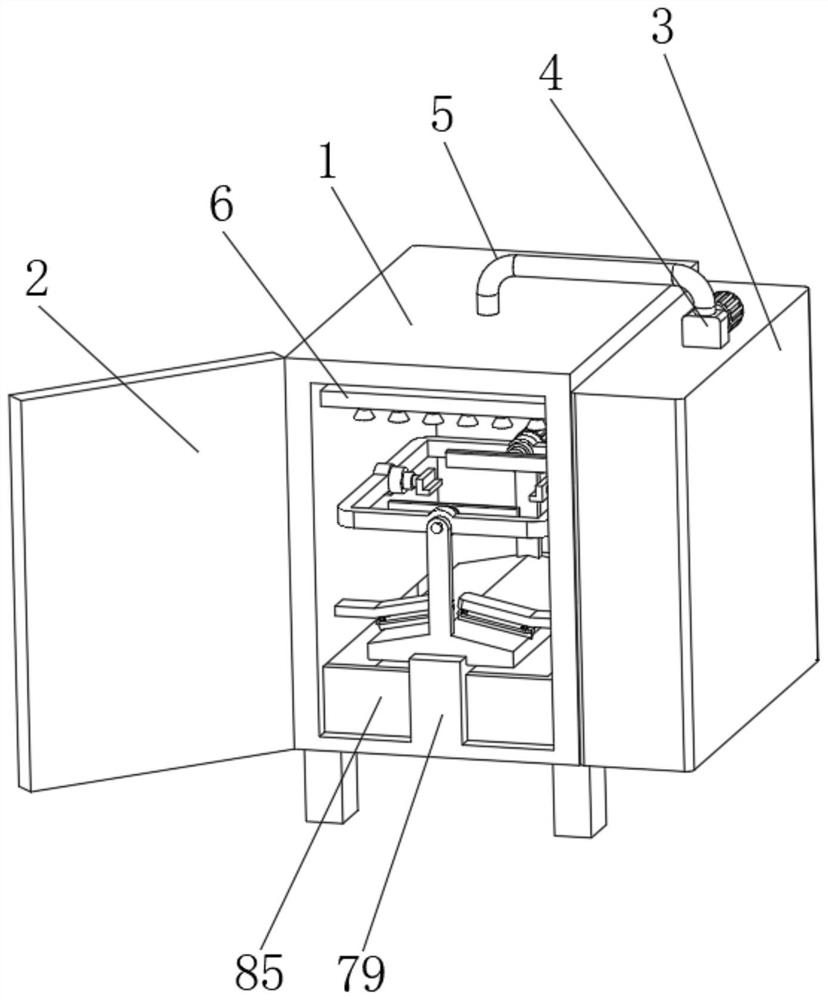

[0027] refer to Figure 1-5 , a paint spraying device for uniformly spraying household appliance panel processing, comprising a spray box 1, a box cover 2, a storage box 3, a paint pump 4, a connecting pipe 5 and a connecting plate 6, the side wall of the storage box 3 and the spray box 1 is fixedly connected, the box cover 2 and the spraying box 1 are hinged, the connecting plate 6 is fixedly installed on the inner wall of the spraying box 1, the inside of the connecting plate 6 is a hollow structure, the bottom of the connecting plate 6 is evenly equipped with spray heads, the port of the connecting pipe 5 and The connecting plate 6 communicates, the paint pump 4 is fixedly installed on the top of the storage box 3 , and the end of the connecting pipe 5 away from the connecting plate 6 communicates with the paint pump 4 .

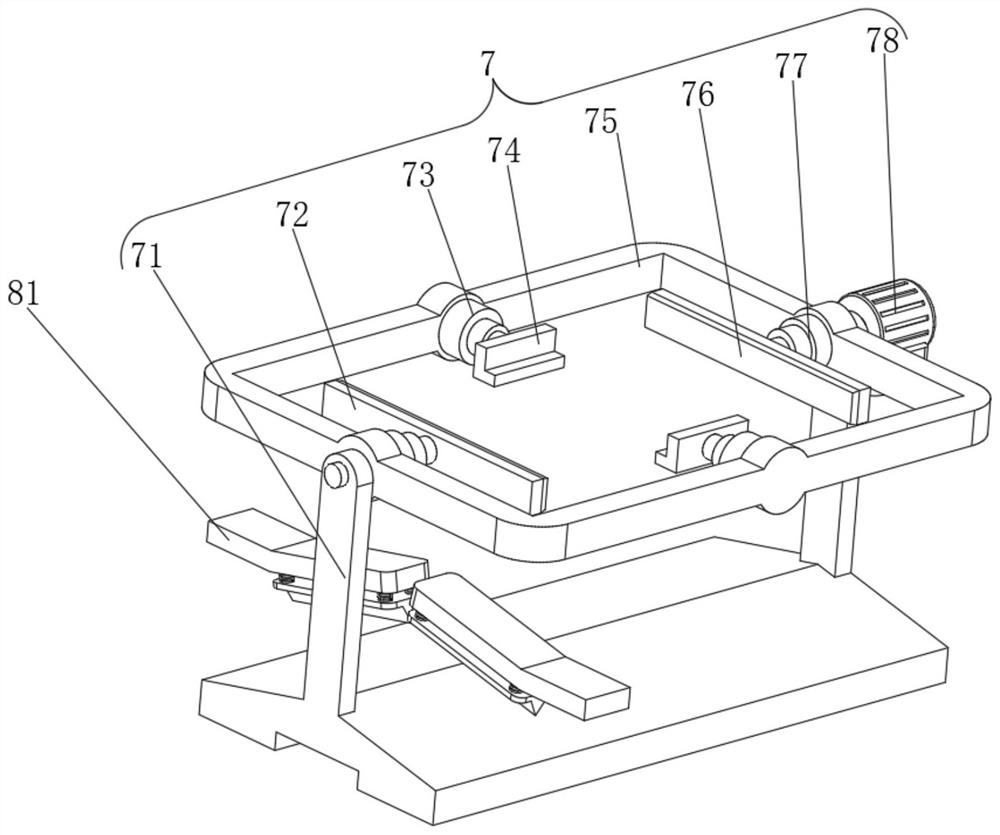

[0028] The interior of spraying box 1 is provided with fixing device 7, and fixing device 7 comprises fixing frame 79, and fixing frame 79 is fixedly ins...

Embodiment 2

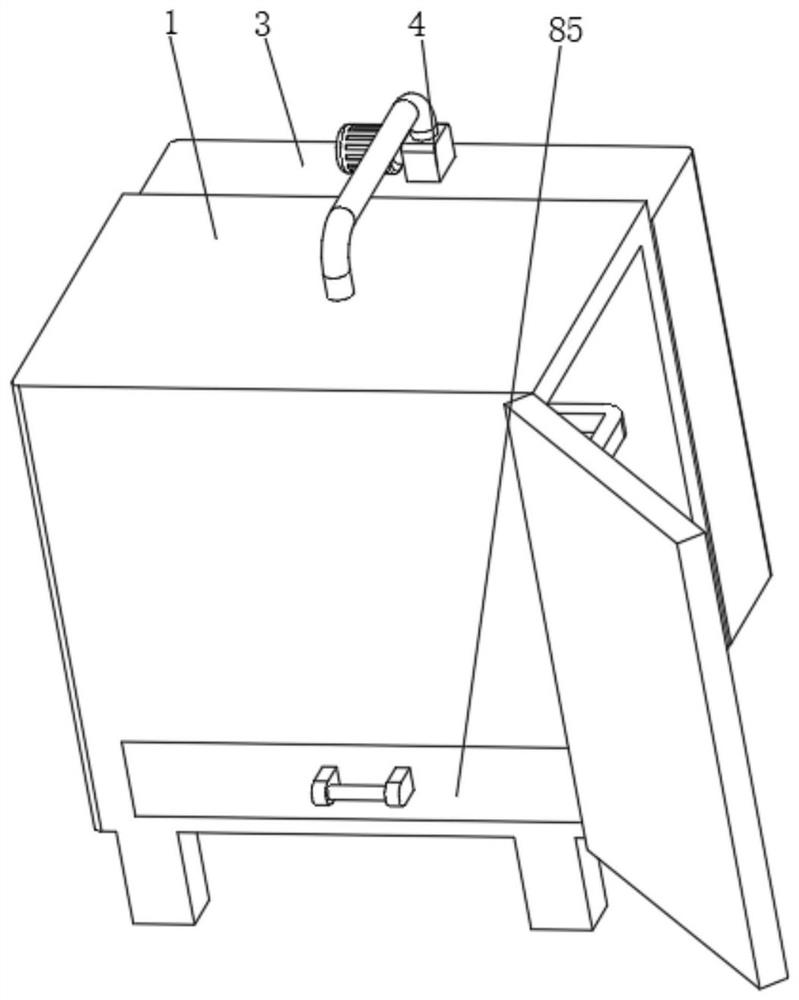

[0038] refer to Figure 1-5 , a paint spraying device for uniformly spraying household appliance panel processing, comprising a spray box 1, a box cover 2, a storage box 3, a paint pump 4, a connecting pipe 5 and a connecting plate 6, the side wall of the storage box 3 and the spray box 1 is fixedly connected, the box cover 2 and the spraying box 1 are hinged, the connecting plate 6 is fixedly installed on the inner wall of the spraying box 1, the inside of the connecting plate 6 is a hollow structure, the bottom of the connecting plate 6 is evenly equipped with spray heads, the port of the connecting pipe 5 and The connection plate 6 is connected, the paint pump 4 is fixedly installed on the top of the storage box 3, and the end of the connection pipe 5 away from the connection plate 6 is connected with the paint pump 4,

[0039] The inner wall of the spray box 1 is provided with an auxiliary device 8, the auxiliary device 8 includes two fixed rods 81, the ports of the two fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com