Automatic spraying conveying device on annular casting production line

A technology of automatic spraying and conveying device, applied in the direction of spraying device, liquid spraying device, etc., can solve the problems of large occupation area of production line and troublesome cooperation and installation relationship, and achieve the effect of small occupation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

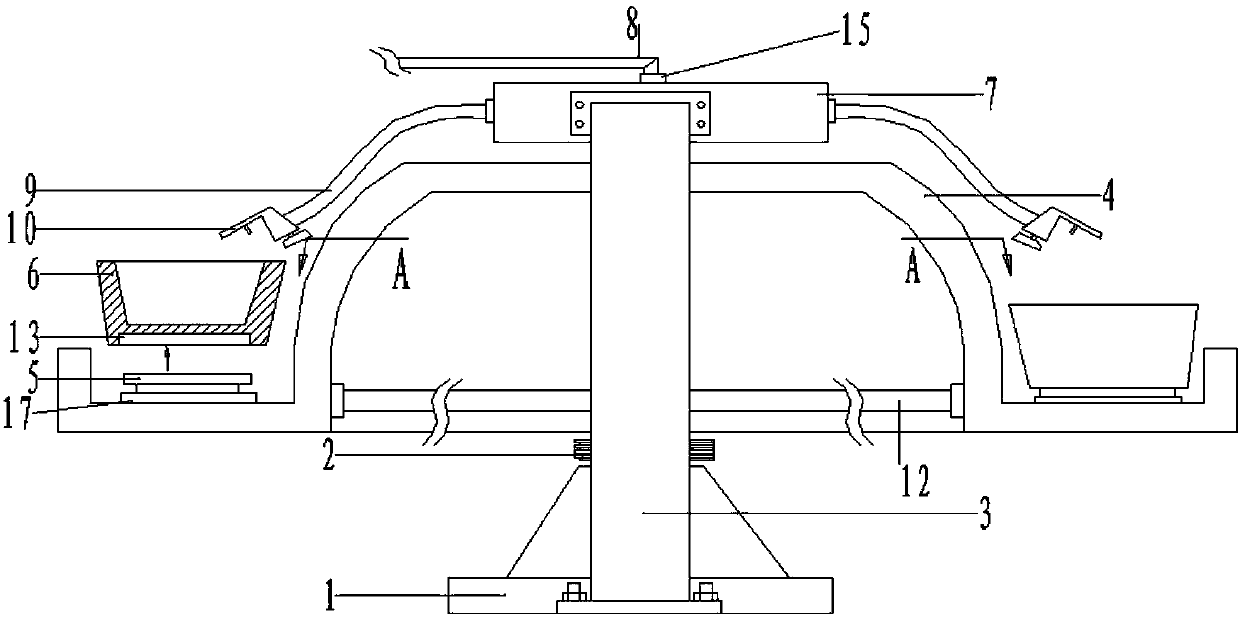

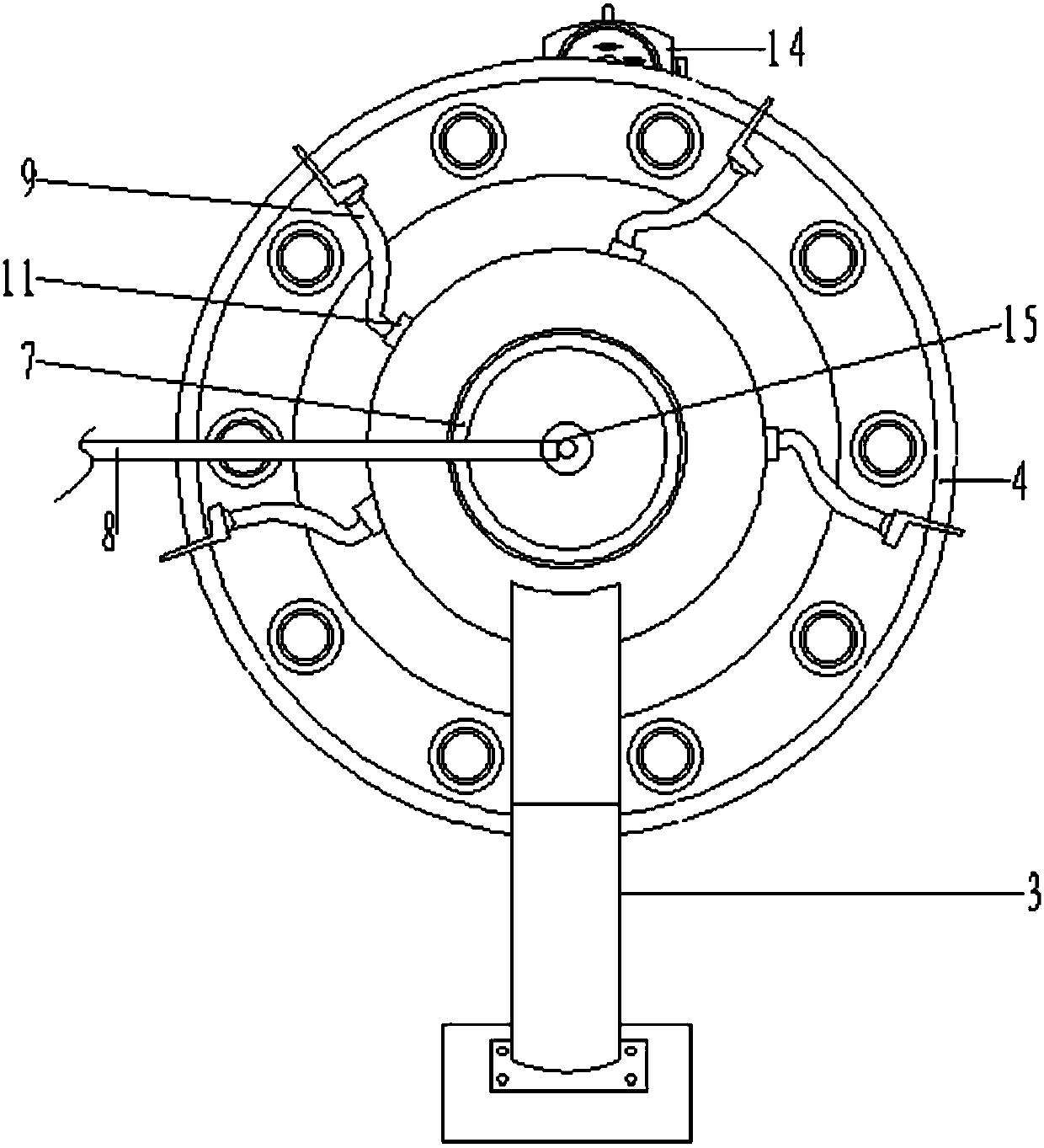

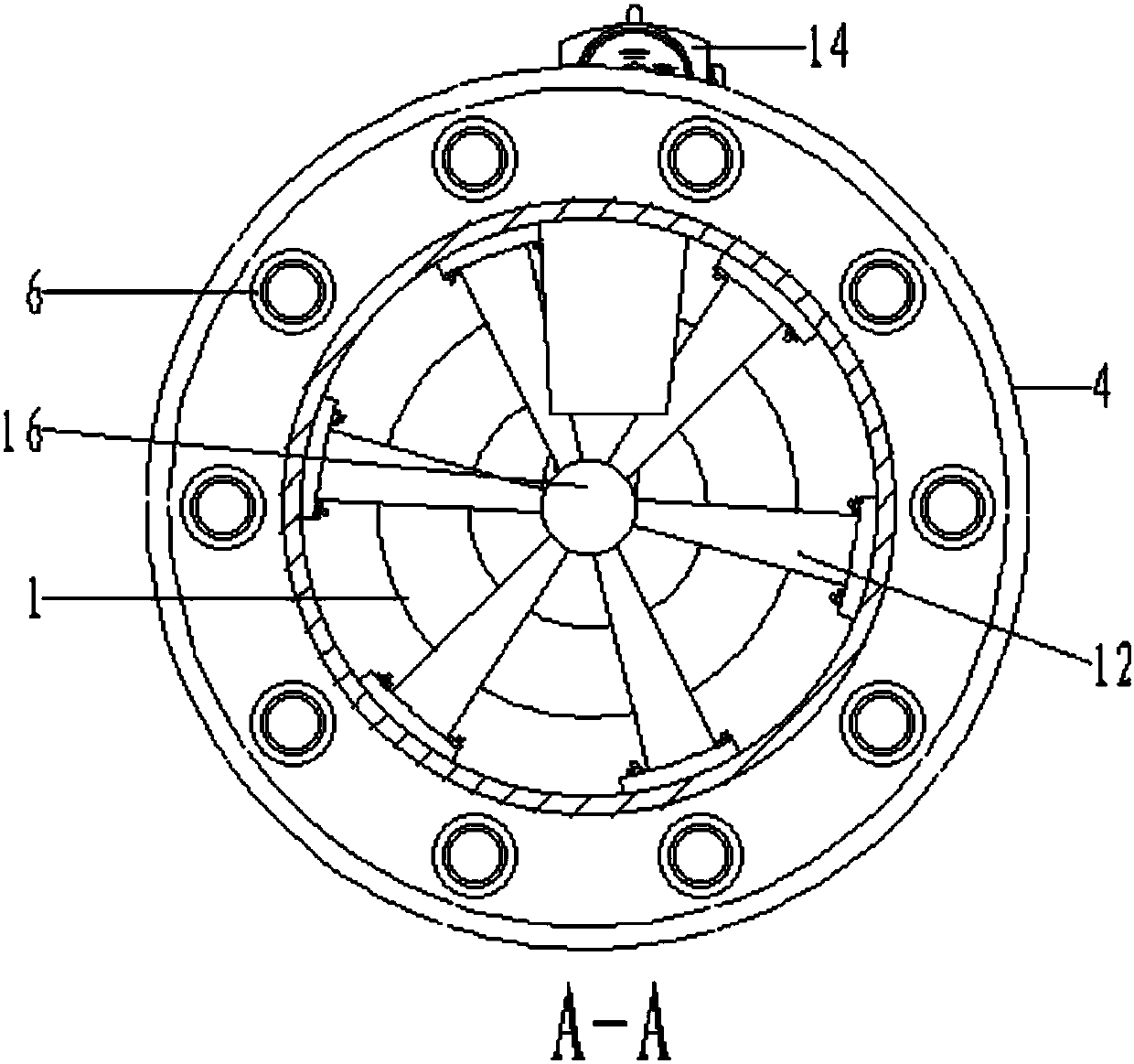

[0023] as attached figure 1 As shown in Attachment 4:

[0024] The present invention provides an automatic spraying conveying device on an annular casting production line, comprising a base 1, a pulley 2, a support arm 3, a spraying conveying seat 4, a bearing 5, a spraying cabin 6, an air collecting cabin 7, an air intake pipe 8, a spraying pipe 9, Spray gun 10, first rubber pipe inlet chuck 11, connecting rod 12, installation groove 13, slow motor 14, second rubber pipe inlet chuck 15, rotating shaft 16 and bearing support seat 17, the base 1 is a disc Shaped structure, its top surface is vertically installed with a rotating shaft 16 through the bearing seat, and the rotating shaft 16 is connected to the slow motor 14 installed on the outside through the belt through the pulley 2 installed on the shaft wall, and the slow motor 14 It is electrically connected with an external power supply; six connecting rods 12 are installed radially and uniformly on the shaft wall of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com